Parts mounting system, image-recognition data creating apparatus, and image-recognition data creating method

A technology for parts installation and image recognition, which is applied in image data processing, image data processing, computer parts, etc., can solve the problems of large workload and time, achieve the effect of reducing workload and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

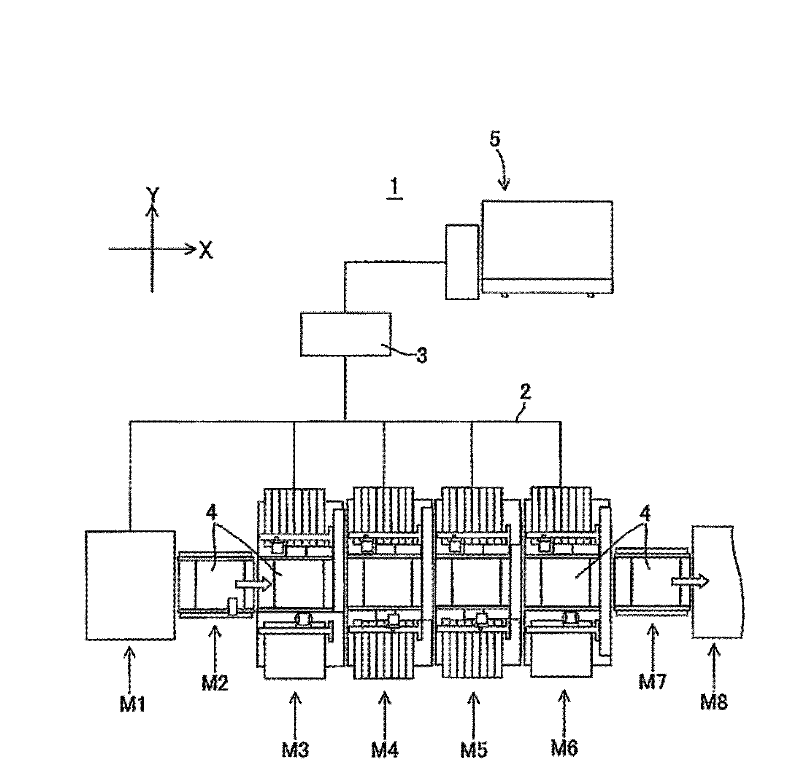

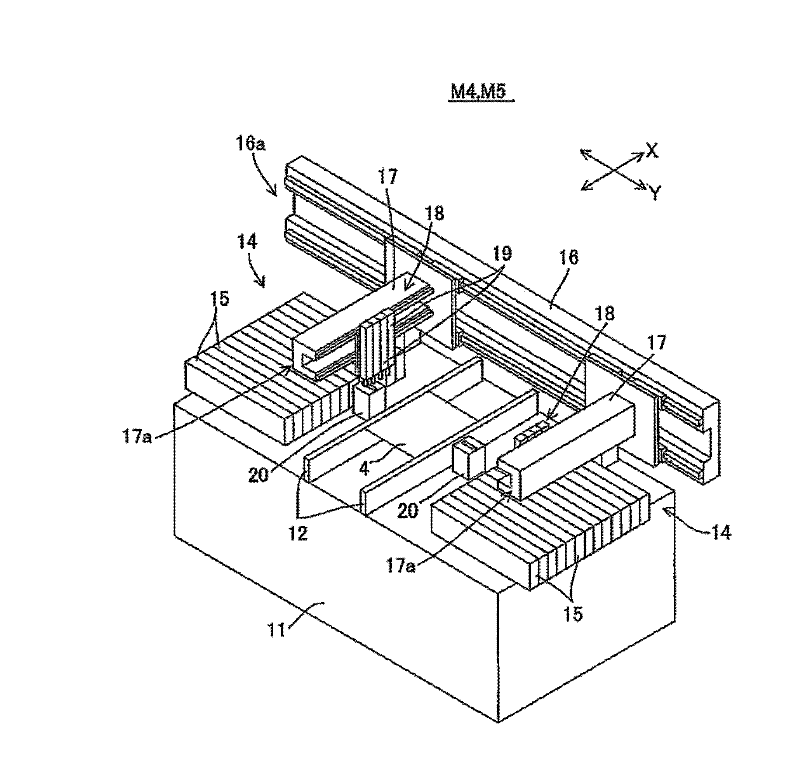

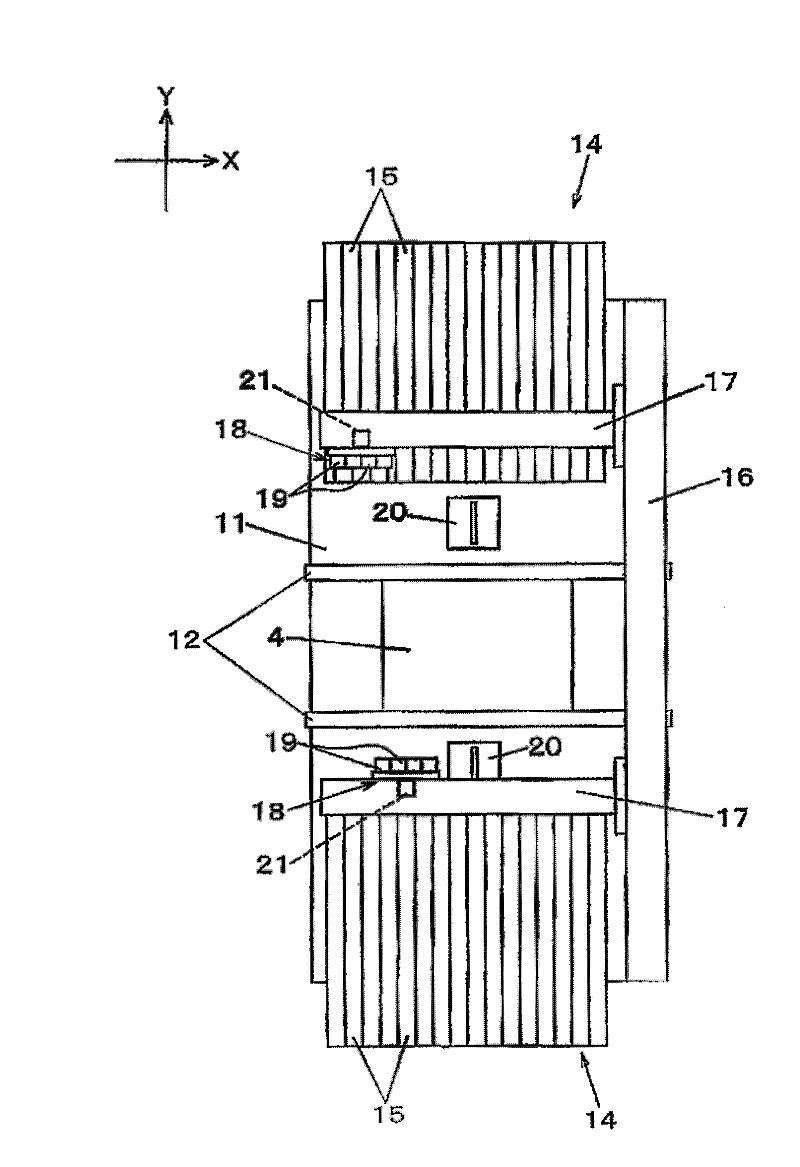

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 , the component mounting system 1 for mounting components on a substrate to manufacture a mounted substrate will be described. figure 1 Among them, the component mounting system 1 connects the printing device M1, the substrate delivery device M2, the inspection / mounting device M3, the component mounting devices M4, M5, and the inspection / mounting device M6 in the substrate conveyance direction (X direction) of the substrate 4 to be conveyed. The component mounting line mainly consists of each device (device for component mounting) of the board transfer device M7 and the return device M8.

[0034] Each device constituting the component mounting line is connected through a communication network 2 (LAN), and is controlled by a host device 3 having a management computer function. A data generation device 5 for image recognition is attached to the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com