Substrate inspecting device and transmission illumination device for substrate inspecting device

A substrate inspection and substrate technology, which is applied in the direction of optical testing flaws/defects, etc., can solve the problems of high infrared light intensity, difficulty in identification, and inability to accurately identify microcracks or pores in solar cells, so as to improve uniformity and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods of the substrate inspection device and the transmissive illumination device for the substrate inspection device proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , structure, feature and effect thereof, detailed description is as follows.

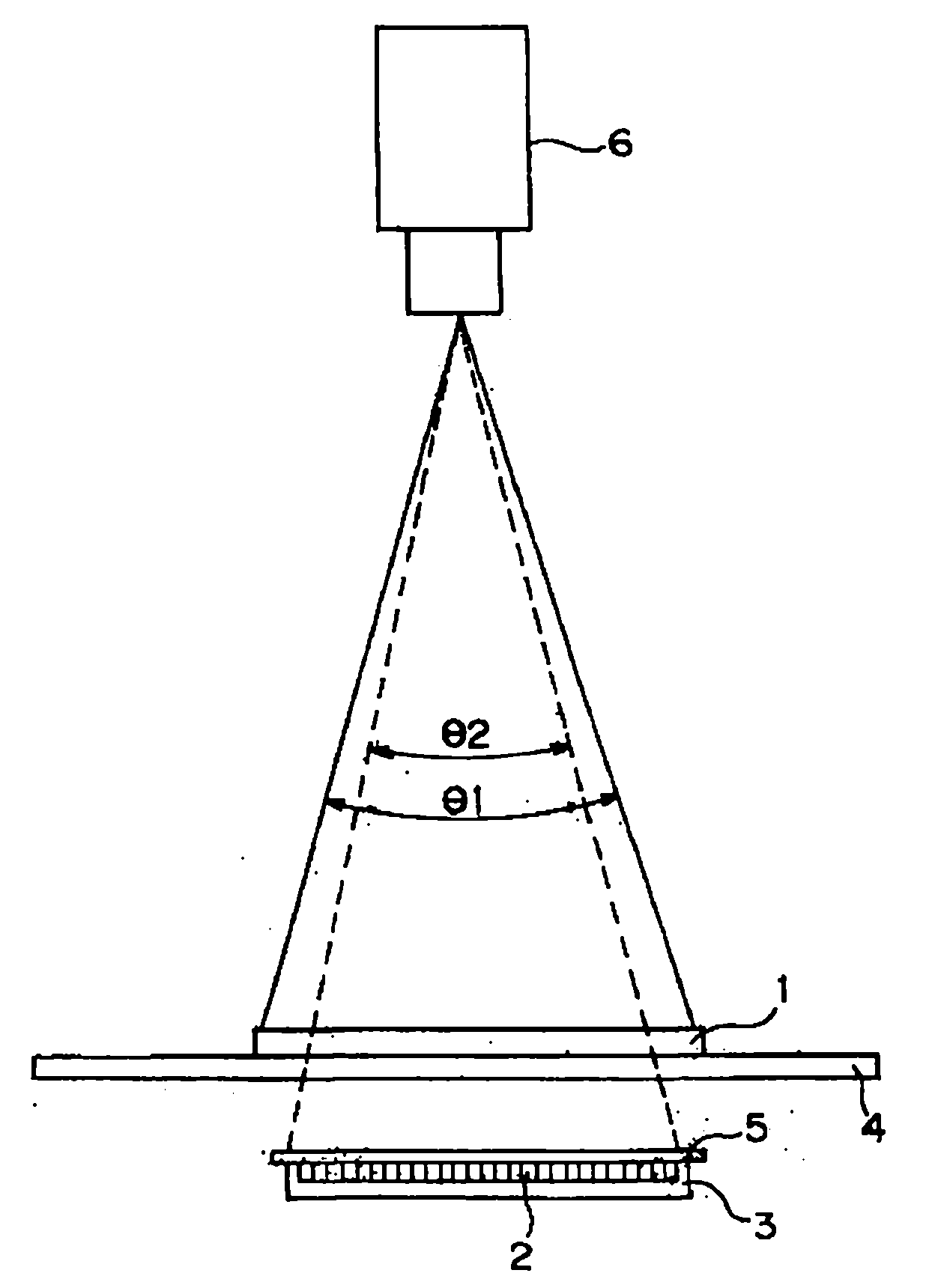

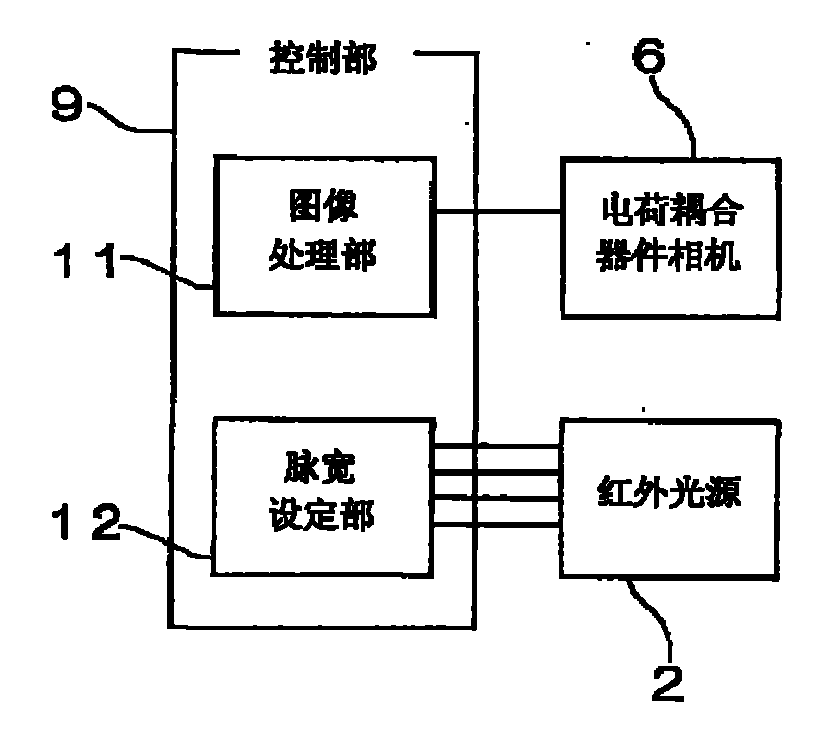

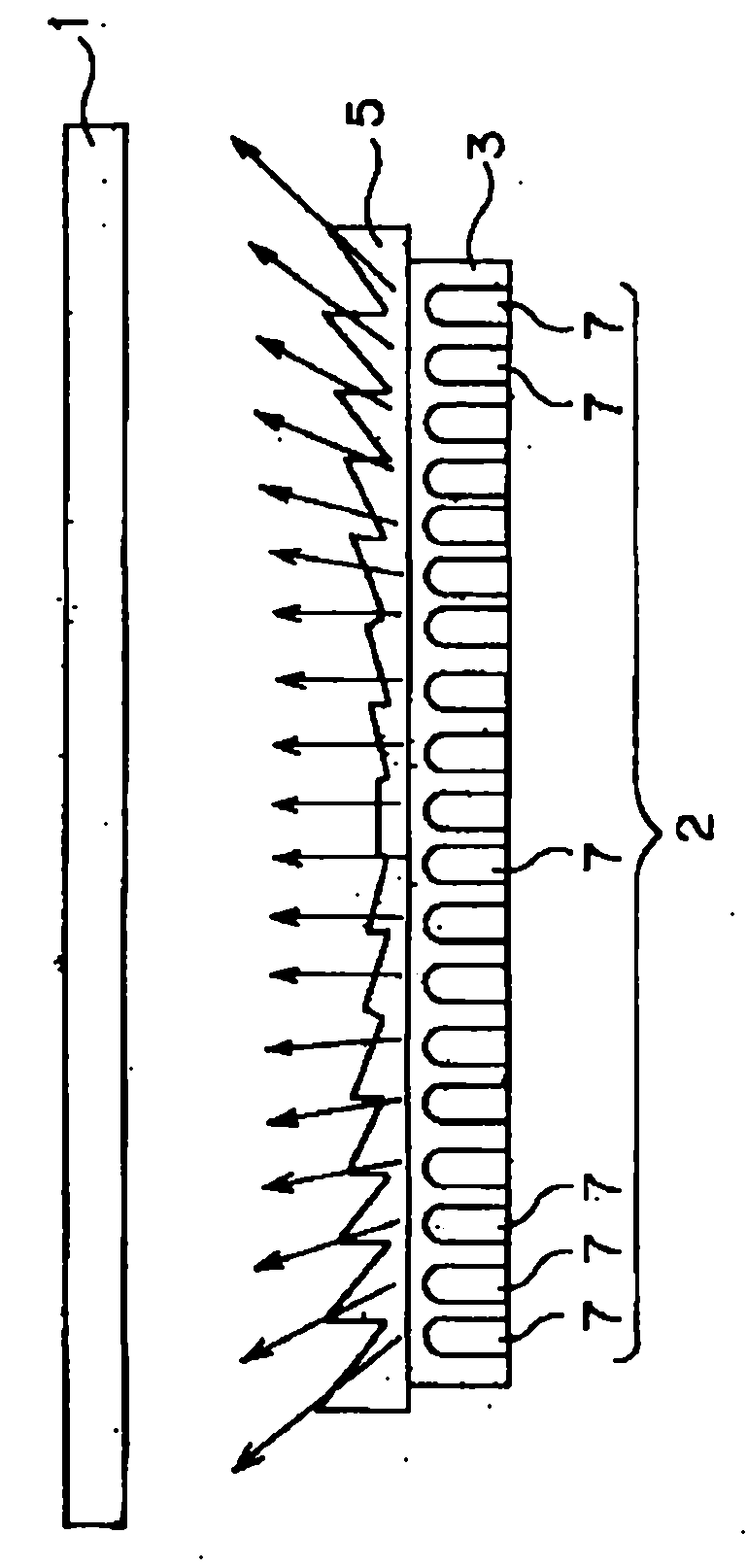

[0070] Hereinafter, a first embodiment of the present invention will be described based on the drawings. figure 1 It is a schematic diagram which shows the structure of the board|substrate inspection apparatus of this invention. also, figure 2 It is a block diagram (block diagram) showing the main control system of the board|substrate inspection apparatus of this invention. also, Figure 7 It is a schematic diagram showing the configuration of a conventional substrate insp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com