Dedicated automatic rolling riveting fixed machine tool for oscillating bearing

A joint bearing and rolling riveting technology, which is applied in the field of machine tools, can solve the problems of non-adjustable rolling speed, difficult alignment, and inability to measure parameters online, so as to facilitate disassembly and assembly of test pieces, improve work efficiency, and improve the quality of rolling riveting fixation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

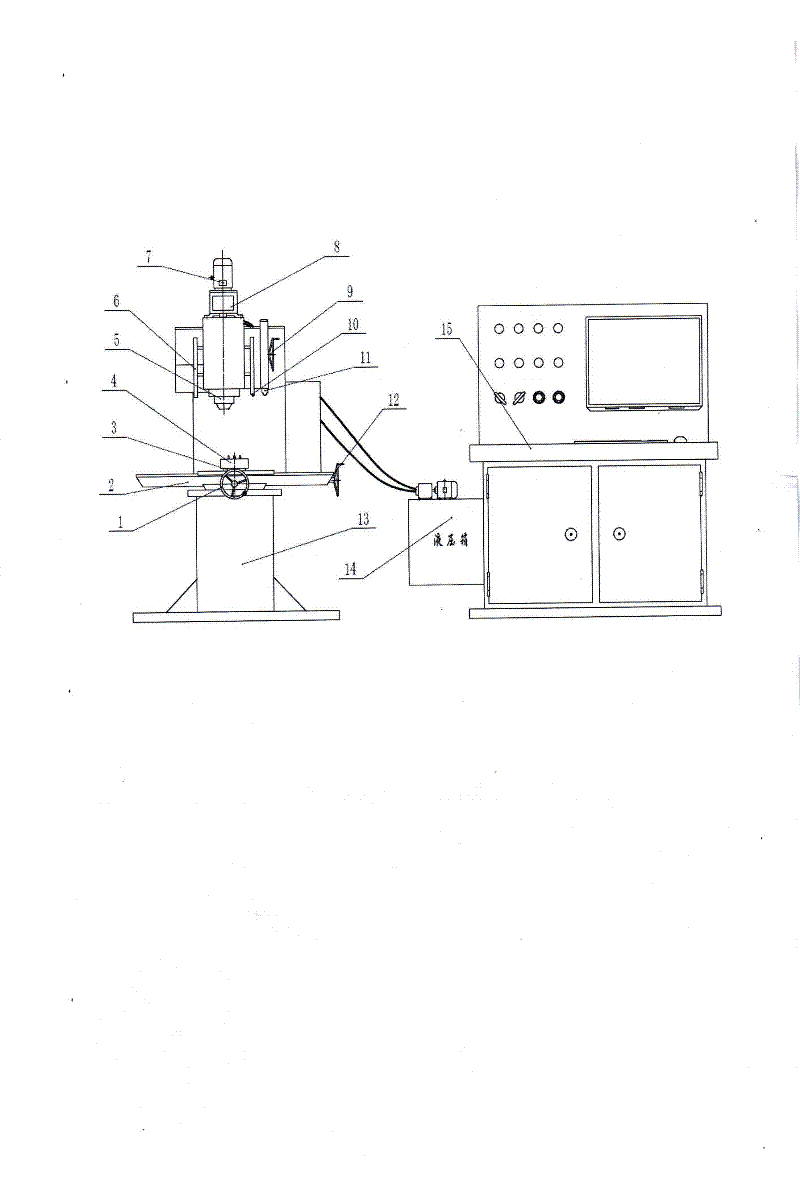

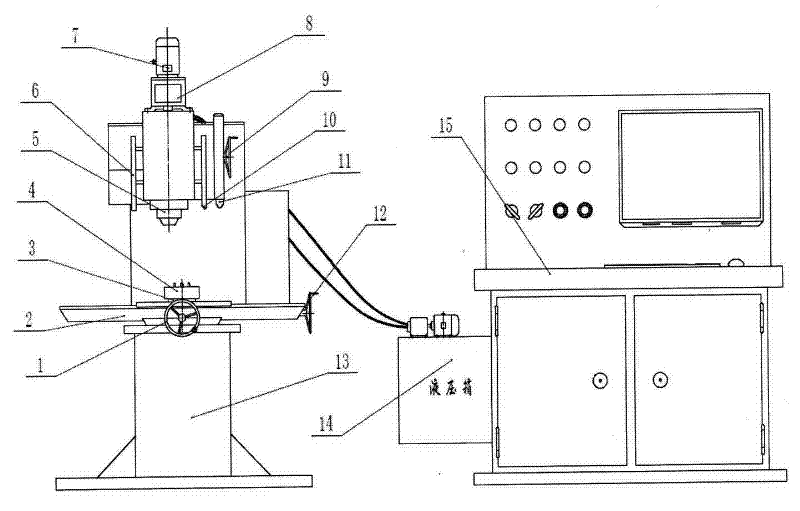

[0013] exist figure 1 In the schematic diagram of the front view of a special automatic rolling riveting fixed machine tool for joint bearings shown, the rough adjustment handwheel 1 in the X direction is connected to the working slide 2 located on the bed 13 through a screw in the X direction, and the Y The handwheel 12 for rough adjustment of the direction and position is connected to the working slide table through a screw in the Y direction, the joint bearing clamping device 4 is connected to the working slide table through the pressure-torque sensor 3, and the connecting device 5 of the rolling riveting fixing device is installed on the The top of the clamping device corresponds to it, the connecting device is connected to the servo 8 and is on the same axis as the motor 7 installed on the servo; the optical projection display screen 6 is installed on the connecting device shell of the above-mentioned rolling riveting fixing device On one side, the transmission and refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com