Large-format high-speed high-precision automatic optical detector

An automatic optical detection, high-precision technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of moving small field of view lenses, etc., to optimize the structure, improve the imaging speed, and overcome technical limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

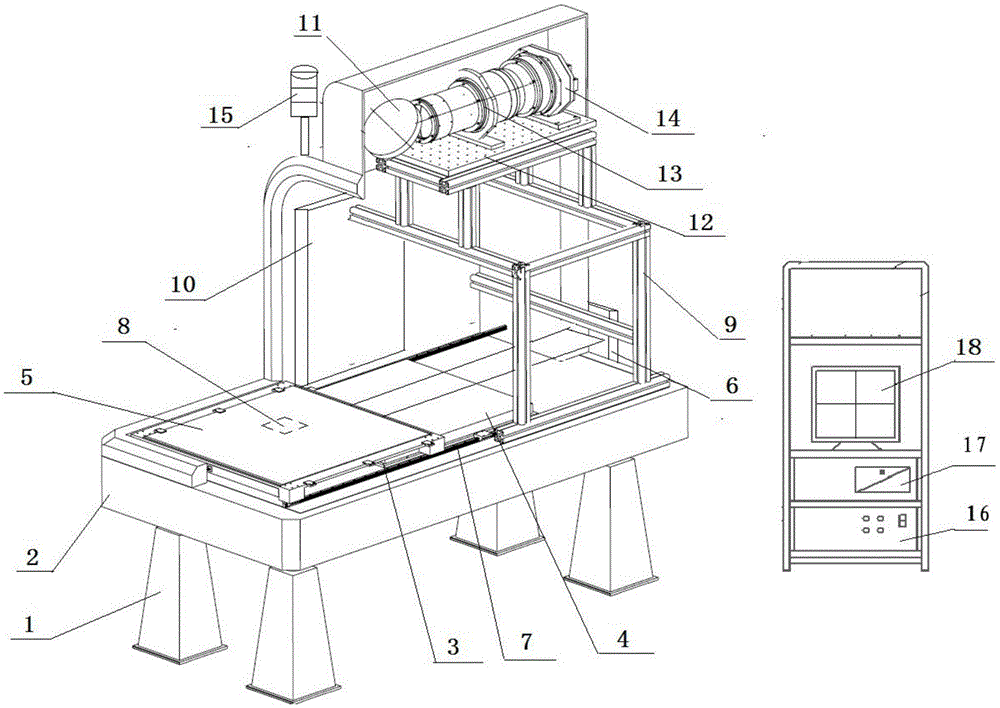

[0048] Such as figure 1 As shown, a large-format, high-speed, high-precision automatic optical inspection device of the present invention mainly includes: a plurality of shock absorbing supports 1, a support platform 2, two translation guide rail pairs 3, a transmission lighting source 4, a workpiece table 5, a precision drive Device 6, grating ruler 7, workpiece indicator 8, lens bracket 9, reflected lighting source 10, reflector 11, precision focusing platform 12, large field of view high-precision lens 13, splicing detector focal plane assembly 14, equipment status light 15. Controller 16, computer 17, display 18. Wherein the lens bracket 9, reflected illumination light source 10, reflector 11, precision focusing platform 12, large field of view high-precision lens 13 and splicing detector focal plane assembly 14 are located in the shell, and the shell is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com