Wiring pattern check up apparatus

A wiring pattern and inspection device technology, applied in the direction of measuring devices, optical devices, underwater structures, etc., can solve the problems of difficult wiring pattern inspection, unclear, false detection of attached dust, etc., to shorten the inspection the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

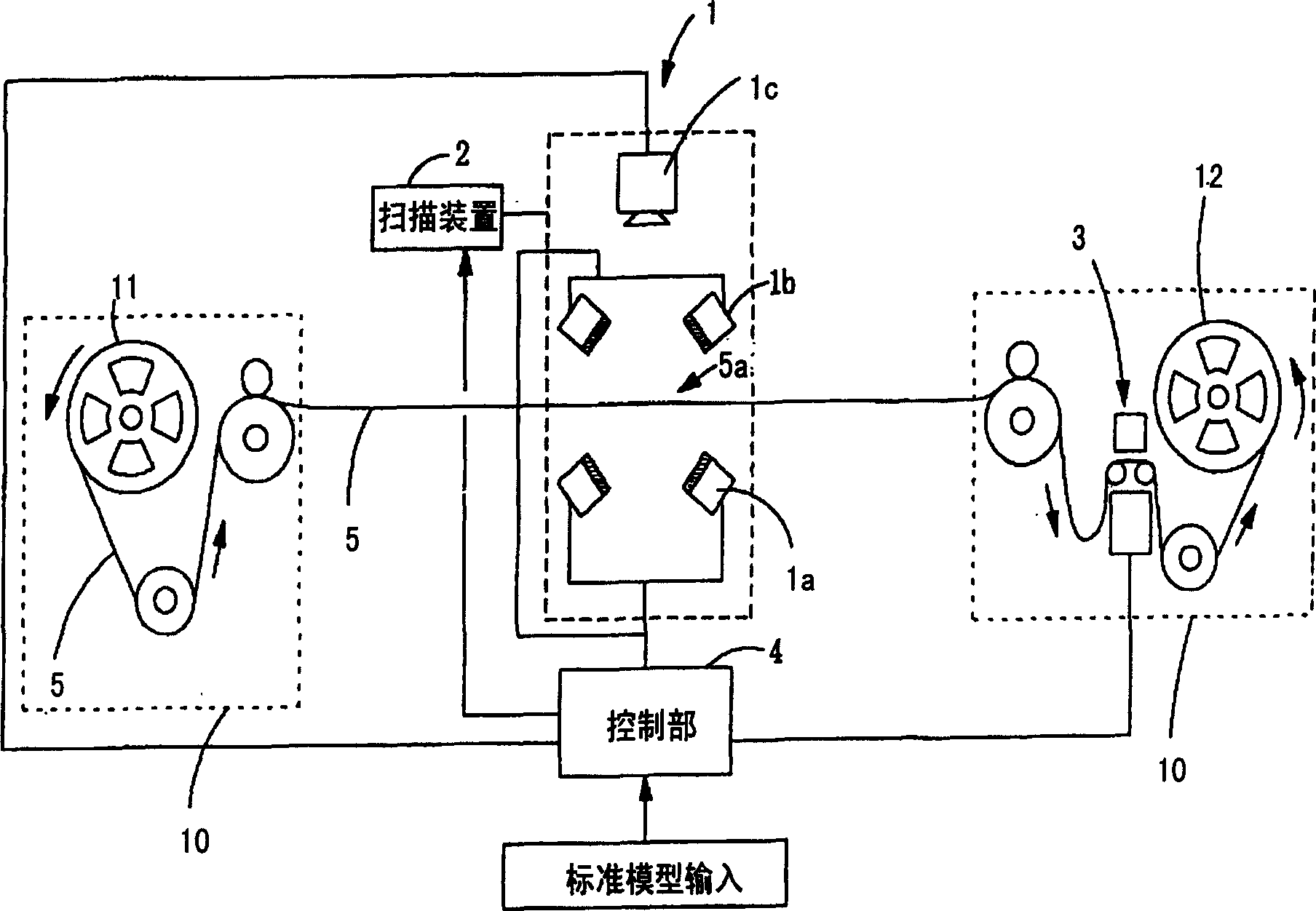

[0057] figure 1 is a block diagram showing a wiring pattern inspection device according to an embodiment of the present invention.

[0058] In addition, in the following examples, the case where the substrate is a TAB tape will be described, but the present invention can also be applied to inspection of various substrates using transmitted illumination light other than the TAB tape.

[0059] The graphic inspection device of the present embodiment, as shown in this figure, has: the tape conveying mechanism 10 that is constituted by the output reel 11 of conveying TAB tape 5 or take-up reel 12 etc.; The belt 5 irradiates transmitted illumination light and reflected illumination light, and captures the pattern 5a; the scanning device 2 scans the inspection part 1 on the upper part of the inspection pattern 5a of the TAB tape; the marking part 3 attaches a mark to the unqualified pattern.

[0060] In the marking part 3, the pattern judged as defective may be punched with a punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com