Brake controller

A brake control and control panel technology, applied in the direction of brakes, brake components, control valves and air release valves, etc., can solve the problems of control panel solenoid valve heat dissipation, complex piping connections, large installation space, etc. The effect of reducing, securing distance, and reducing the influence of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

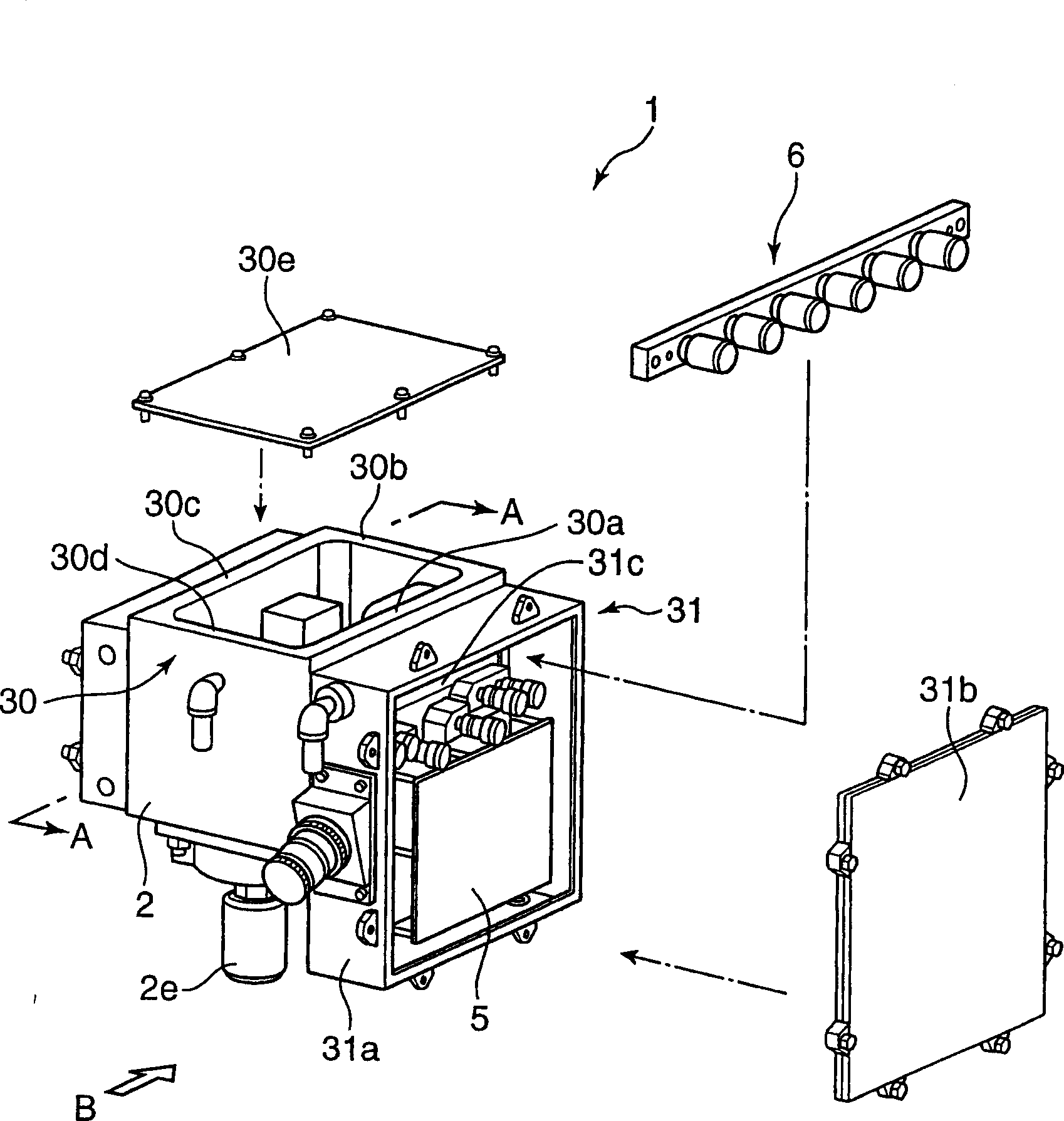

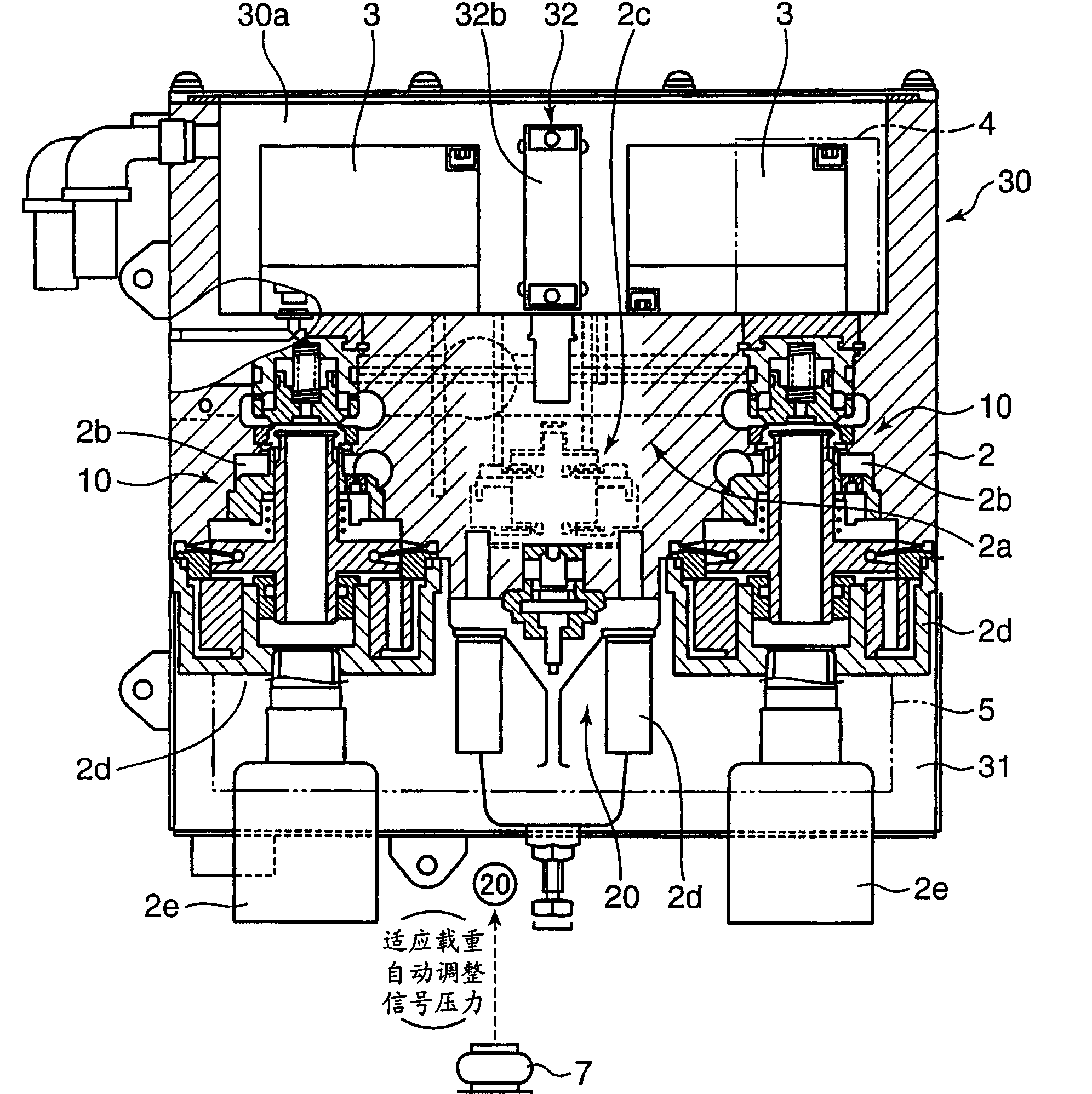

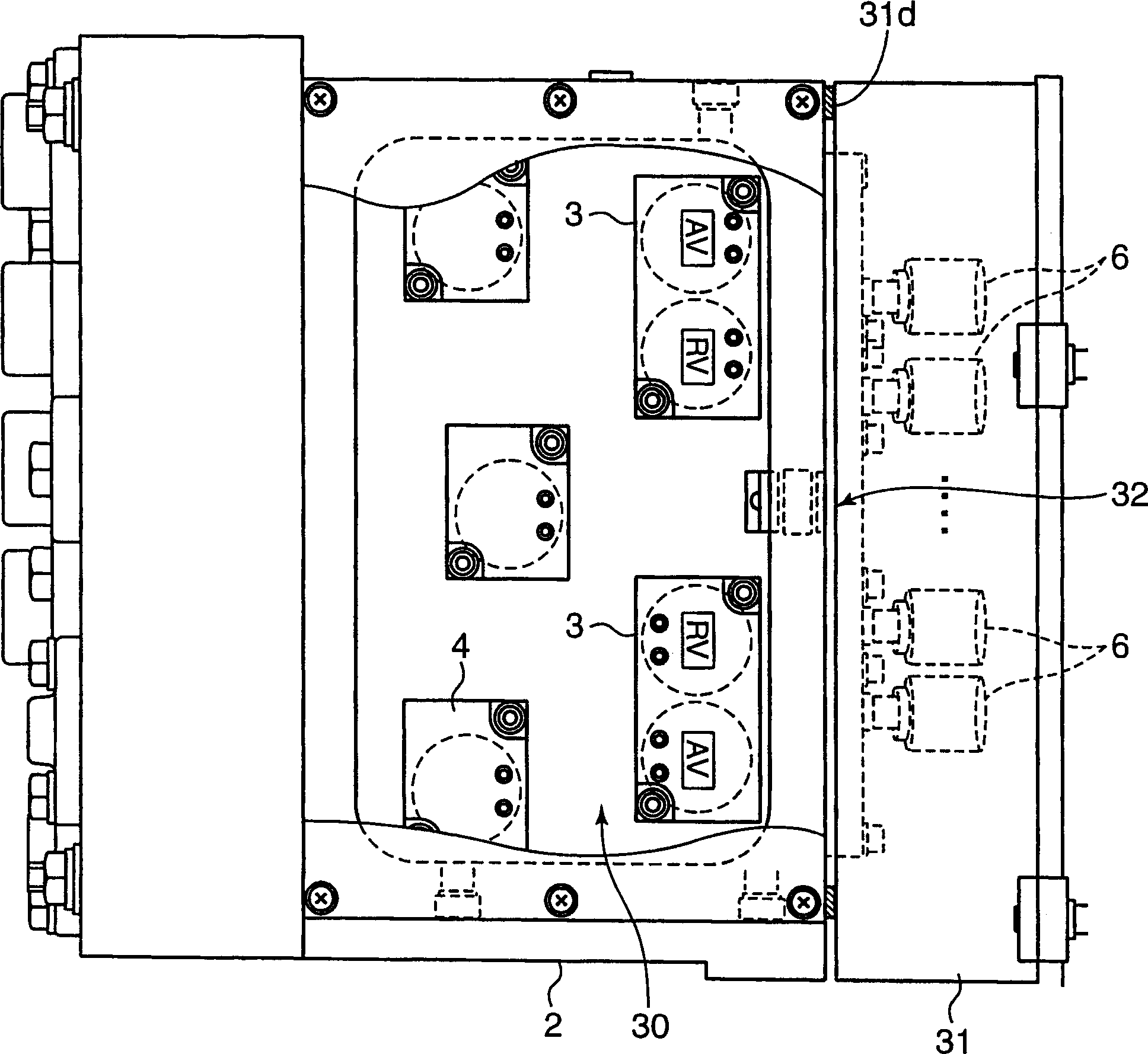

[0030] figure 1 is an exploded perspective view showing the brake control device according to the first embodiment of the present invention, figure 2 It is a longitudinal section view of the brake control device ( figure 1 The profile of the A-A line), image 3 is the brake control device with figure 1 The plan view (partial section) when the B direction is the front, Figure 4 is a schematic diagram showing a control object of the brake control device.

[0031] In a vehicle 100 provided with this brake control device 1, a total of four wheel axles 103, 103 are provided at the front and rear of two bogies 101, 101 provided at the front and rear of the vehicle. A total of 12 ( Figure 4Indicates 4) brake cylinders 110. In the first embodiment, the control device 1 is structured such that it is provided at the rear with respect to three brake cylinders 110 as a set provided on the front wheel axle and the left and right wheels of one bogie. Three sets of brake cylinder...

no. 2 example

[0041] Figure 6 is an exploded perspective view showing a brake control device according to a second embodiment of the present invention, Figure 7 is a front view showing the brake control device, Figure 8 It is a plan view of the same brake control device. In addition, in this second embodiment, it is possible to choose between using different relay valves to actuate a group of brake cylinders on the front side of the bogie and a group of brake cylinders on the rear side of the bogie and using a common relay valve. The valve activates the brake cylinder. Additionally, with Figure 1 to Figure 5 The same symbols are used for the same parts.

[0042] In this brake control device 1A, the valve main body unit 40 includes a substantially rectangular parallelepiped block 40 a having an automatic load-adaptive adjustment valve and a relay valve and their input and output lines inside, and a relay valve and its input pipes inside. A substantially rectangular parallelepiped-sh...

no. 3 example

[0048] Figure 9 is an exploded perspective view showing a brake control device according to a third embodiment of the present invention, Figure 10 It is a plan view showing the state where the two storage parts are turned relative to the valve body unit. Additionally, with Figure 1 to Figure 5 The same symbols are used for the same parts.

[0049] This brake control device 1B has a structure in which a rotating shaft 43 is provided in the vertical direction on a valve body unit 40B and an accommodating portion 41 arranged on the upper surface thereof, and the accommodating portion integrated like the second embodiment can be integrated. 41 and 42 rotate around the rotation shaft 43 with respect to the valve body unit 40B, and the storage portion 42 can be formed into a state of covering the side surface of the valve body unit 40B and a state of exposing the side surface of the valve body unit 40B by rotation.

[0050]This valve body unit 40B is different from the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com