Self-propelled leaf vegetable harvester

A self-propelled technology for leafy vegetables, applied to harvesters, agricultural machinery and implements, applications, etc., can solve problems such as poor adaptability, poor harvest quality, soil mixing, etc., achieve reasonable harvest height, ensure service life, and avoid The effect of soil mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

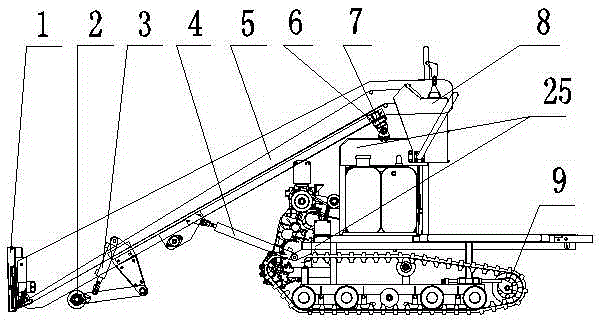

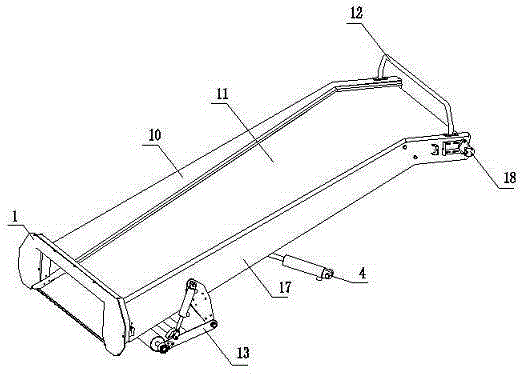

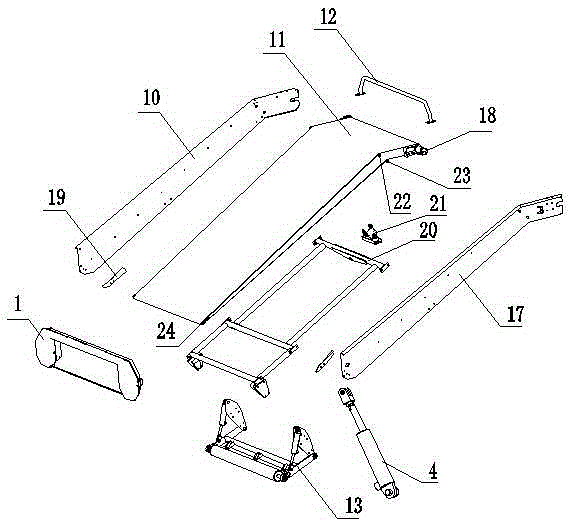

[0022] Referring to the accompanying drawings, the self-propelled leafy vegetable harvester shown in the embodiment of the present invention is composed of a frame 25, a power system, a band saw cutting device 1, a conveying device 5, and a driving console that a chassis traveling mechanism 9 is installed. 8 is composed of several major parts, wherein the rear end of the conveying device 5 is installed on the frame 25 through the rear biaxial support mechanism 21 composed of the horizontal pin shaft 6, the longitudinal pin shaft 7 and the biaxial hinge 21-1, respectively. Simultaneously realize the horizontal and vertical hinges with the frame 25.

[0023] The rear biaxial support mechanism 21 is composed of a biaxial hinge 21-1 and a hinge support base plate 21-2. The hinge support base plate is fixedly installed on the frame 25, and the biaxial hinge passes through the horizontal pin shaft 6 and the vertical pin shaft 7 Connect, biaxial hinge is connected with mainframe 20 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com