High-low cutting edge double-wall steel cofferdam reinforced concrete once bottom sealing construction method

A double-wall steel cofferdam and reinforced concrete technology, which is applied in the direction of foundation structure engineering, caisson, and foundation structure tests, can solve the problems of large amount of concrete, difficult construction, and short construction period, and achieve short construction period and fast construction time. The difficulty is low and the effect of ensuring the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

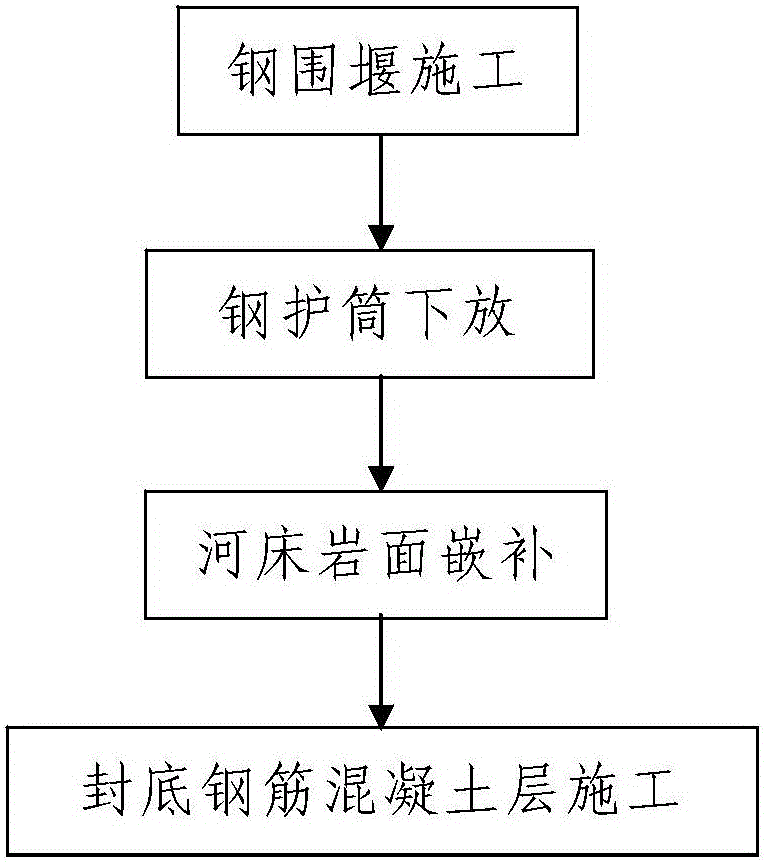

[0044] Such as figure 1 A reinforced concrete one-time back-sealing construction method for double-walled steel cofferdams with high and low blade feet is shown, including the following steps:

[0045] Step 1, steel cofferdam construction: use hoisting equipment to sink the double-wall steel cofferdam 1 to the pre-designed construction position; A number of bored piles are arranged at the bottom of the platform;

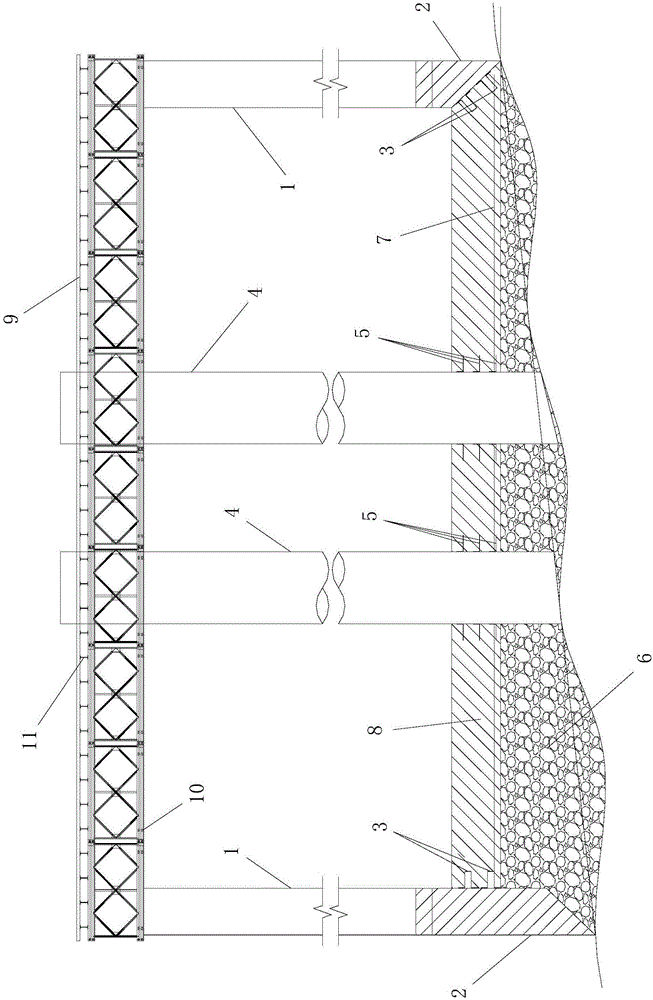

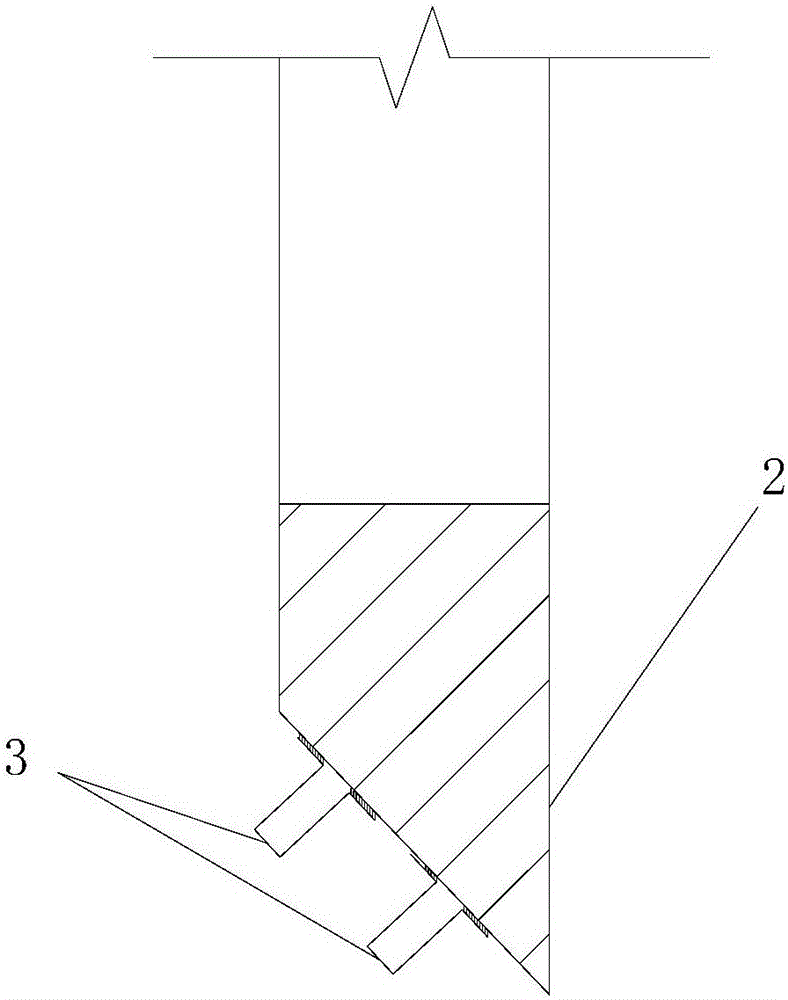

[0046] Such as figure 2 As shown, the bottom of the double-wall steel cofferdam 1 is provided with a blade foot 2, and the blade foot 2 is a high and low blade foot; the bottom surface of the blade foot 2 is an inclined surface and it is supported on the rock surface of the river bed, and the river bed The rock face is an inclined bare rock face; there are multiple sets of first anchoring reinforcement bars 3 arranged on the same horizontal plane inside the blade foot 2, and the first anchoring reinforcement bars 3 are arranged on the blade foot 2 or double-walled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com