Work vehicle

一种作业车辆、废气处理装置的技术,应用在作业车辆领域,能够解决降低散热器冷却效率、空气通风阻力增大、发动机室空间狭窄等问题,达到抑制冷却效率降低、降低热影响、提高视野性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

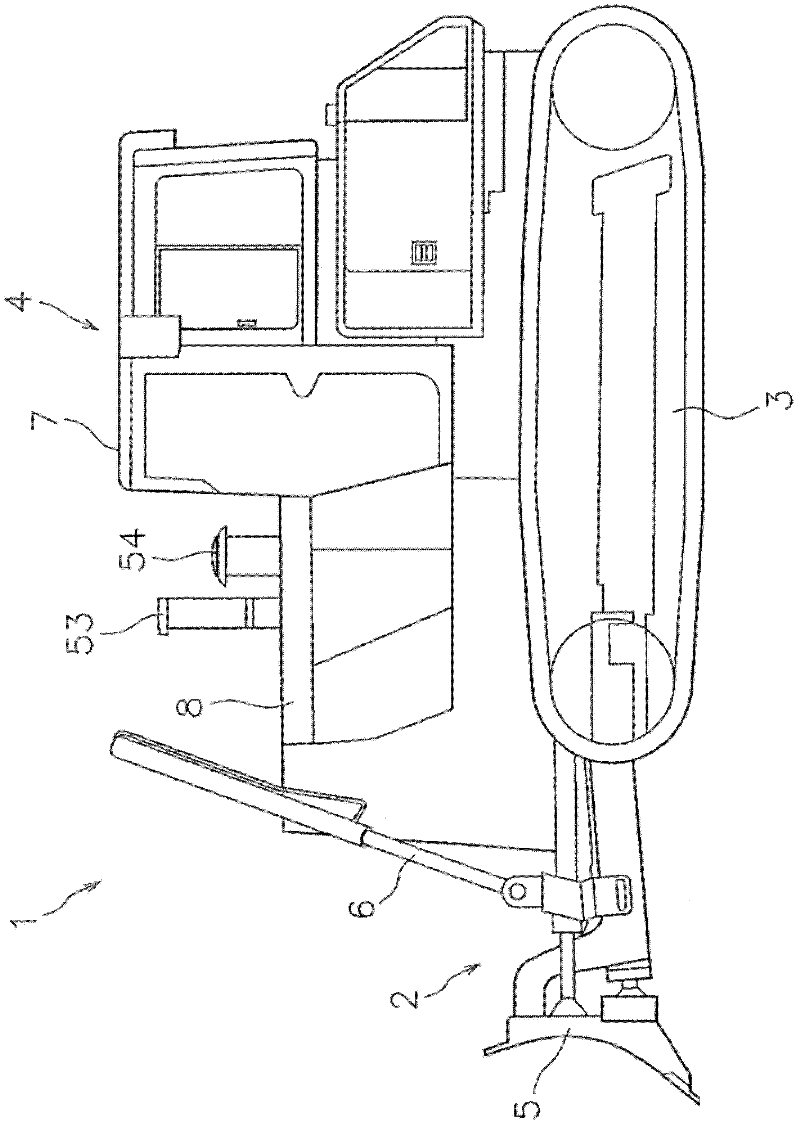

[0045] figure 1 A work vehicle 1 according to one embodiment of the present invention is shown. The work vehicle 1 is a bulldozer, figure 1 It is a left side view of the work vehicle 1 . In addition, in the following description, left-right means the left-right direction in the state which looked ahead from inside the cab 7. As shown in FIG. The work vehicle 1 includes a work implement 2 , a traveling device 3 , and a vehicle main body 4 . The working device 2 has a scraper 5 and a hydraulic cylinder 6 . The scraper 5 is arranged on the front side of the vehicle body 4 . The hydraulic cylinder 6 is driven by hydraulic pressure generated by a hydraulic pump not shown, and moves the scraper 5 up and down. The traveling device 3 is a crawler-type traveling device, and is attached to the vehicle body 4 . The vehicle body 4 has a cab 7 and an engine room 8 .

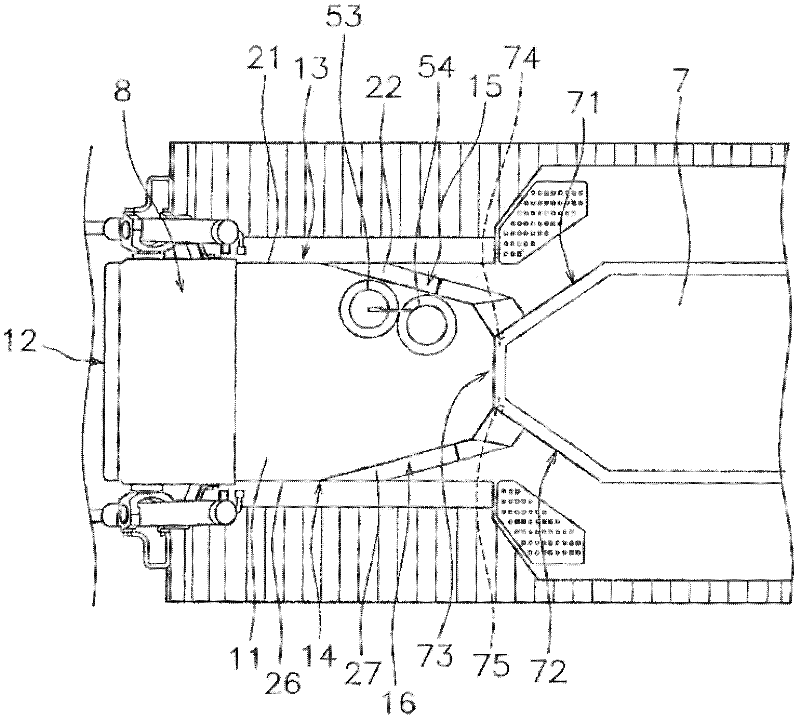

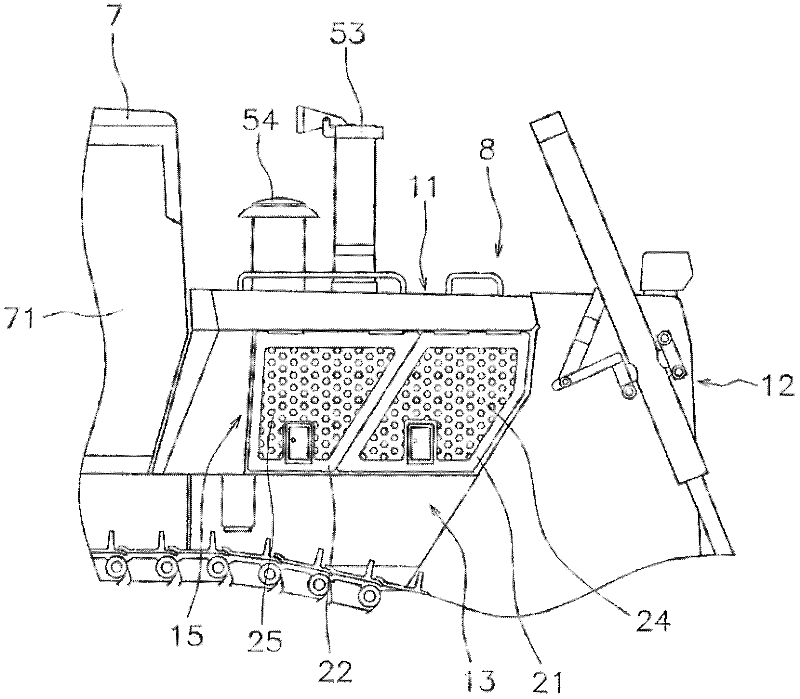

[0046] A vehicle seat and an operating device (not shown) are installed in the cab 7 . figure 2 It is a plan view ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com