Platform seal strip, turbine blade assembly and method for assembling it

a technology for turbine blades and seals, which is applied in the direction of valve construction, marine propulsion, forging/pressing/hammering apparatus, etc., can solve the problems of affecting engine efficiency, difficult assembly, and easy leakage, so as to improve the cooling of the blade, improve the sealing of the turbine hot blade components, and improve the cooling effect of the blad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

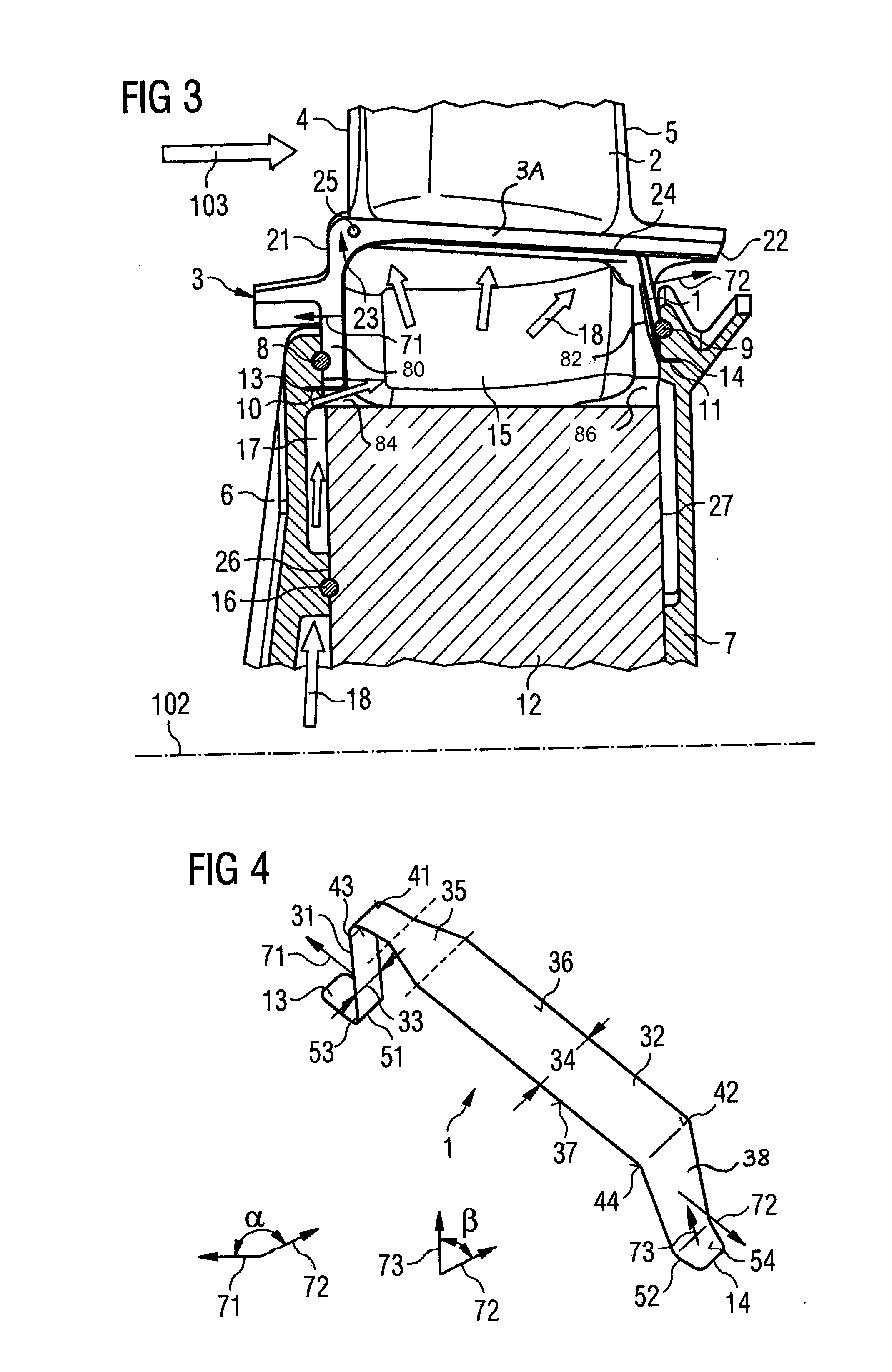

Embodiment Construction

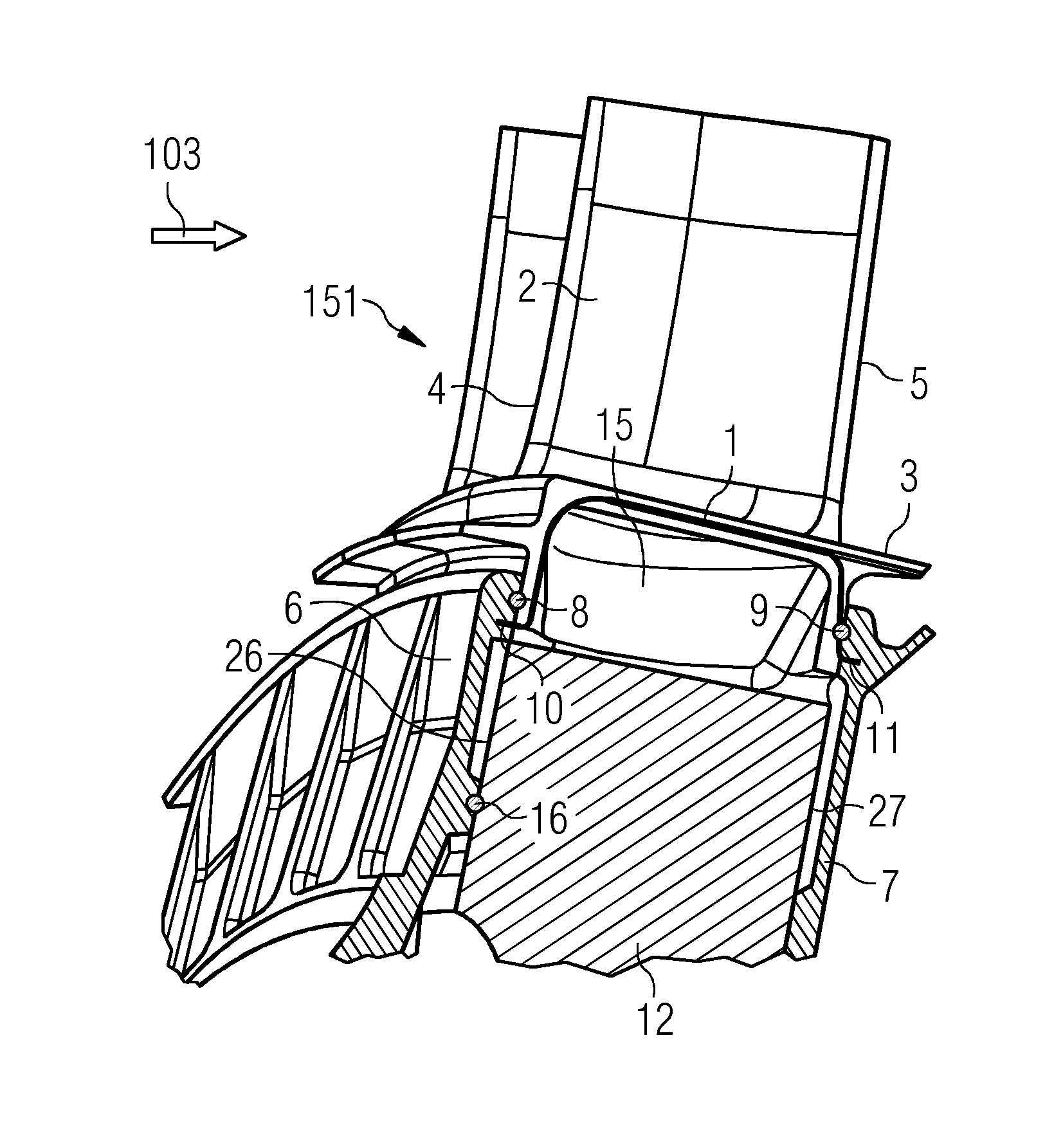

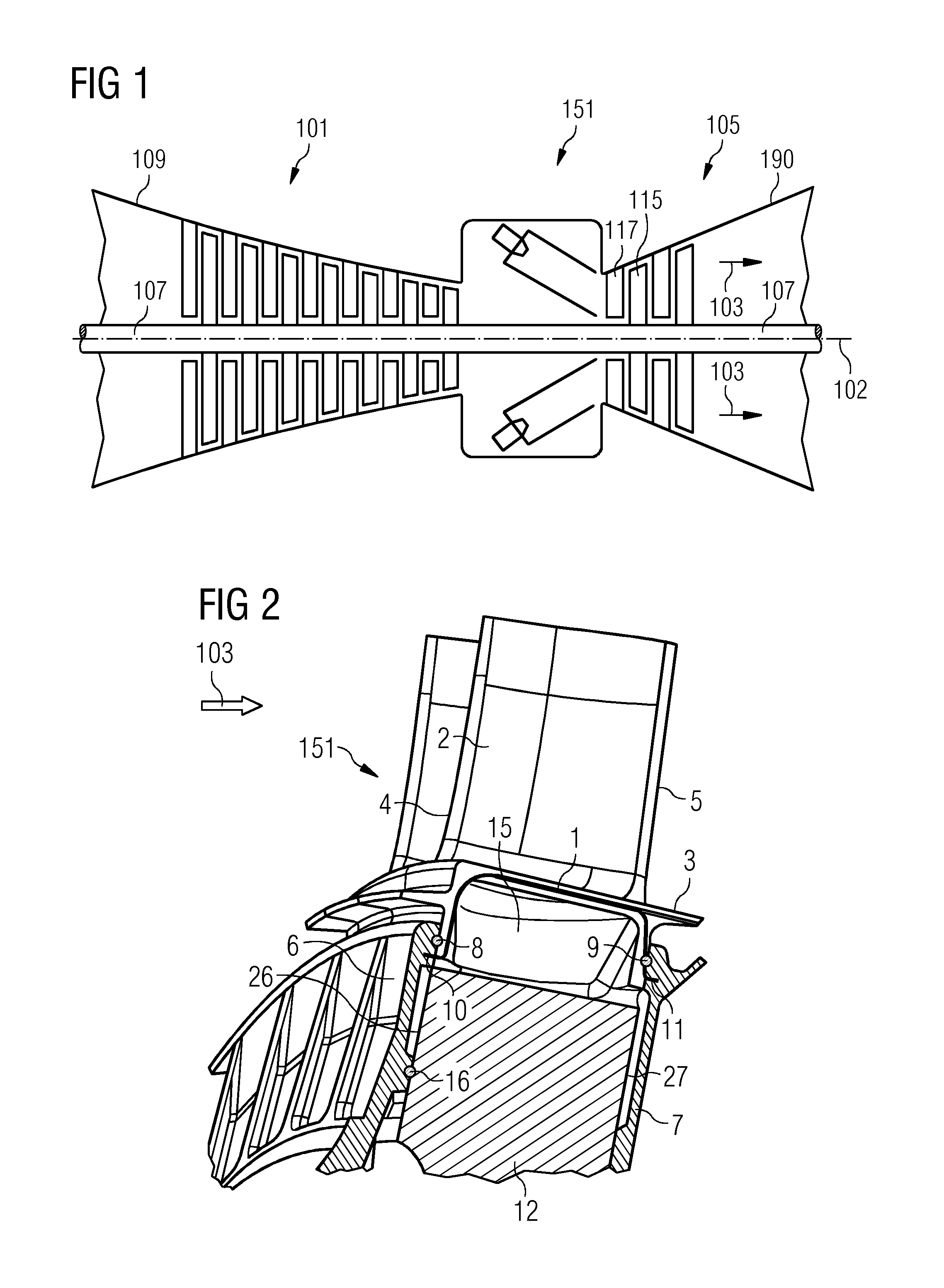

[0045]FIG. 1 schematically shows a gas turbine. A gas turbine comprises a rotation axis with a rotor. The rotor comprises a shaft 107. Along the rotor a suction portion with a casing 109, a compressor 101, a combustion portion 151, a turbine 105 and an exhaust portion with a casing 190 are located.

[0046]The combustion portion 151 communicates with a hot gas flow channel which may have a circular cross section, for example. The turbine 105 comprises a number of turbine stages. Each turbine stage comprises rings of turbine blades. In flow direction 103 of the hot gas in the hot gas flow channel a ring of turbine guide vanes 117 is followed by a ring of turbine rotor blades 115. The turbine guide vanes 117 are connected to an inner casing of a stator. The turbine rotor blades 115 are connected to the rotor. The rotor is connected to a generator, for example.

[0047]During operation of the gas turbine air is sucked and compressed by means of the compressor 101. The compressed air is led t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com