Patents

Literature

210results about How to "Low ventilation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

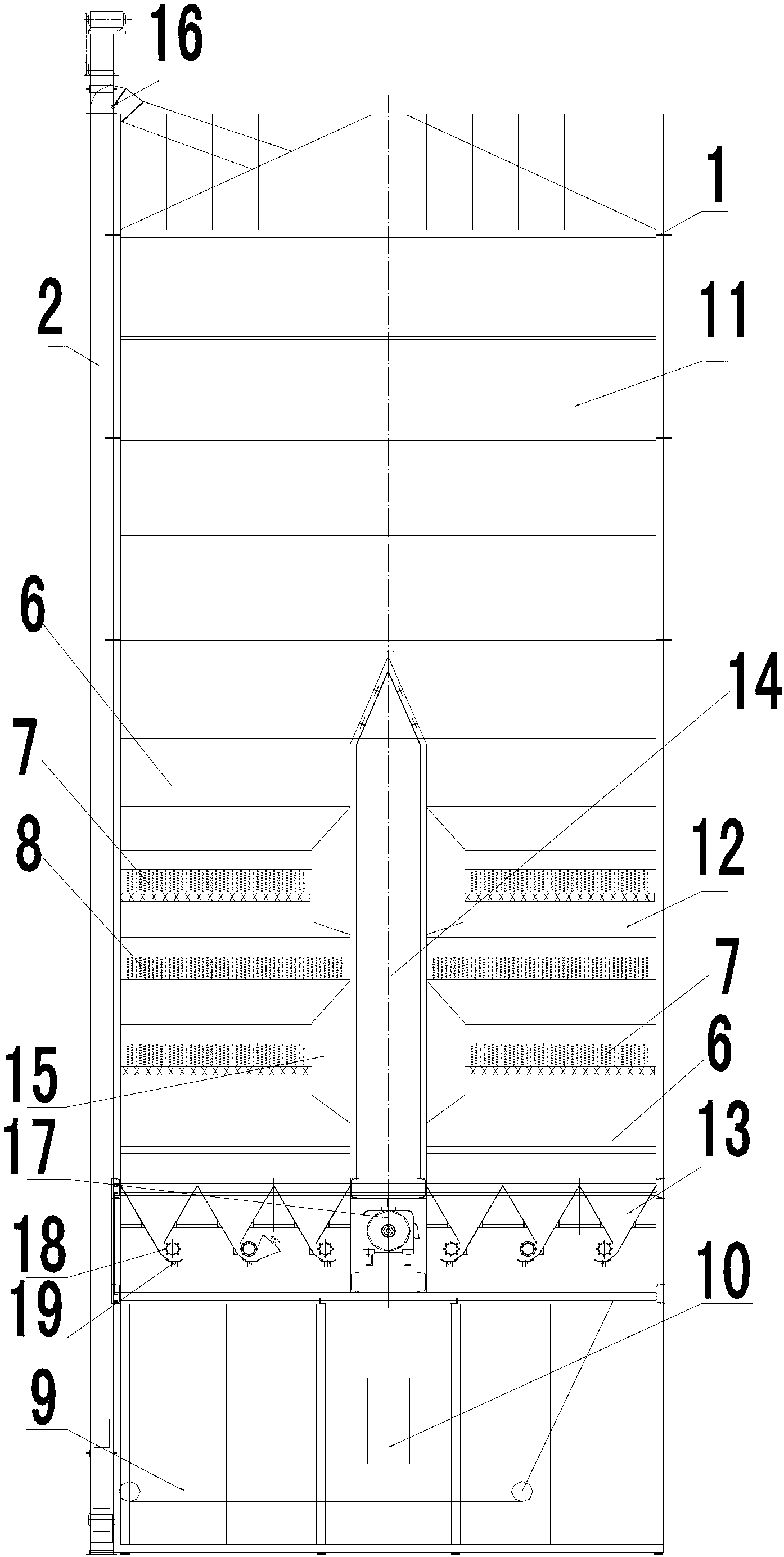

Circulating sludge biological fermentation tank, processing system and processing method

ActiveCN102153388AReduce wind pressureReduce air volumeBio-organic fraction processingSludge treatment by de-watering/drying/thickeningSludgeControl room

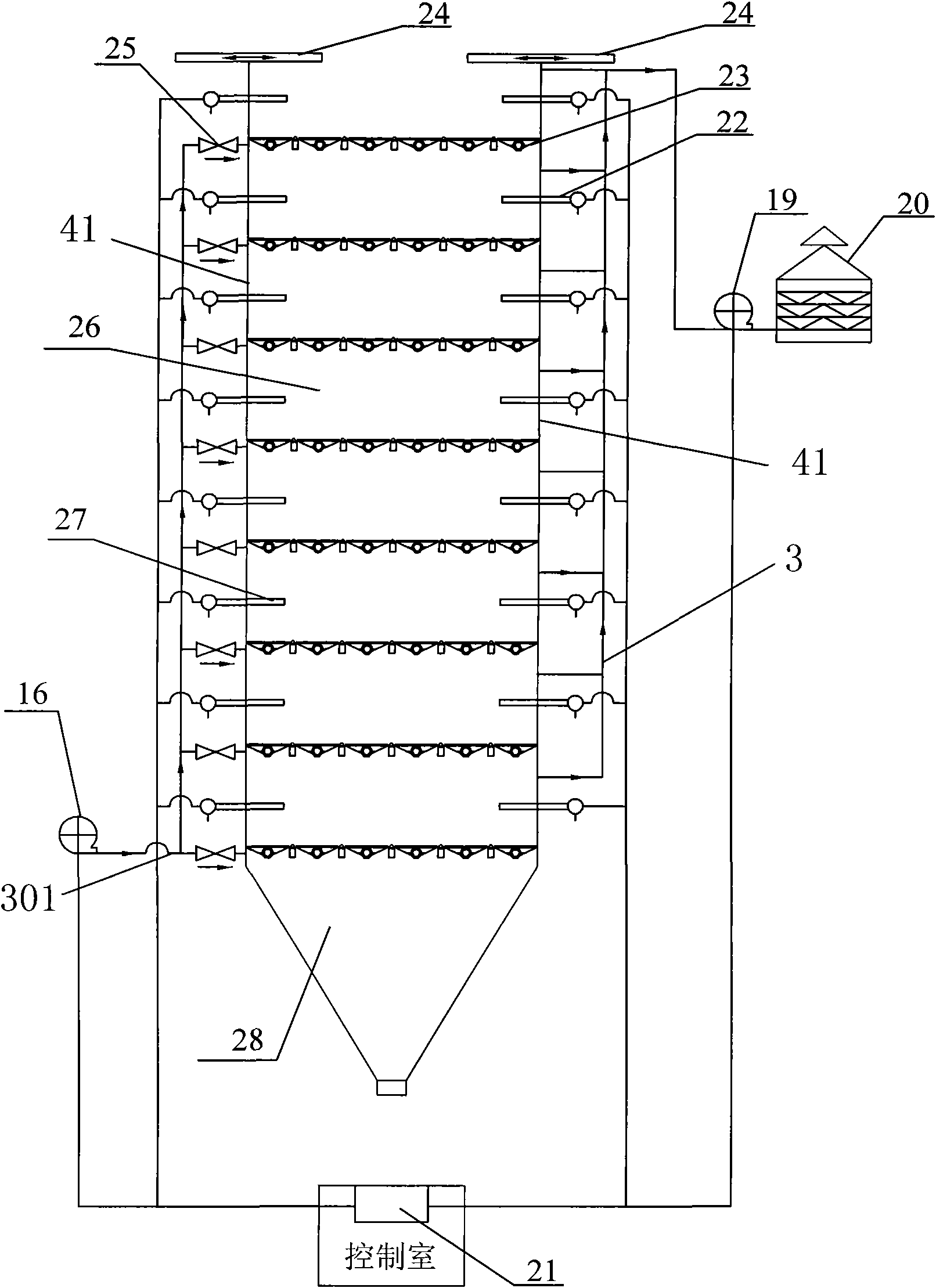

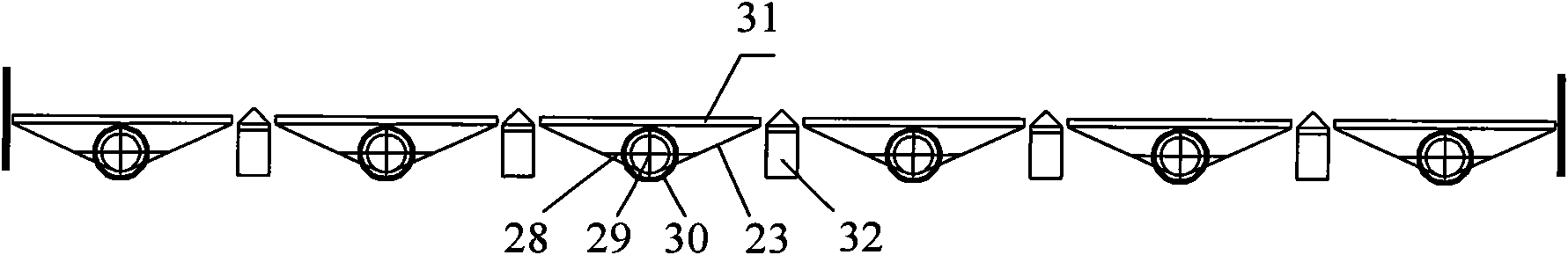

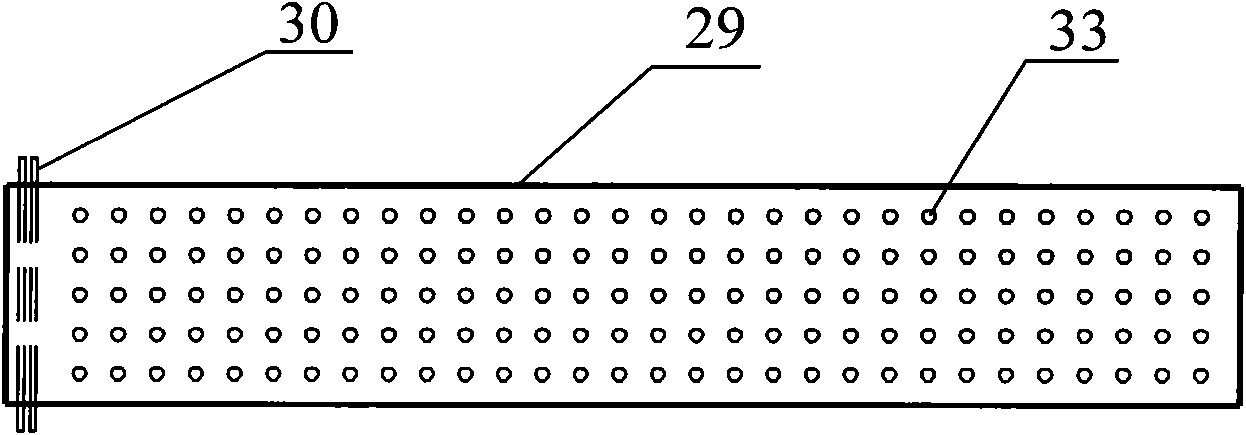

The invention discloses a circulating sludge biological fermentation tower which comprises a tower body, an openable tower cover, a storage tank and a plurality of rotatable fermentation devices, wherein the openable tower cover is arranged on the top of the tower body; the storage tank is arranged at the bottom of the tower body; the rotatable fermentation devices are arranged in the tower body in parallel; the fermentation devices divide an inner cavity of the tower body into a plurality of layers of fermentation bins along the axial direction; the lower part of each layer of fermentation device is provided with a ventilating oxygen supply pipeline communicated with a blower; the upper part of each layer of fermentation device is provided with an air outlet pipeline communicated with aninduced draft fan and a monitoring device; the monitoring device is controlled by a control room; and a mechanism for driving the fermentation devices and the tower cover to move, the blower and the induced draft fan are all controlled by the control room. The invention also discloses a circulating sludge biological processing system and a processing method. By the circulating sludge biological fermentation tower, the circulating sludge biological processing system and the processing method, industrial biological fermentation desiccation treatment can be continuously and stably carried out onsludge under the conditions of high efficiency and low energy consumption.

Owner:深圳市如茵生态环境建设有限公司

Production process of environmental-protection plant energy particle fuel

InactiveCN101892108AReduce pollutionMeet the requirements of energy saving and emission reductionBiofuelsSolid fuelsEnergy particleSolid fuel

The invention relates to a production process of an environmental-protection plant energy particle fuel, which is characterized by collecting combustible plant materials as raw materials and then sequentially processing the raw materials by the following steps of: (1) pulverizing: the raw materials are pulverized into powdery particle materials with the particle size less than 2 mm; (2) drying: the pulverized materials are dried so that the water content of the materials is 12%-20% by drying; and (3) extrusion molding: extrusion molding is carried out to the dried materials so that the materials form a solid particle fuel with the density of 1.0-1.4 g / cm<3> through extrusion molding. The invention can be used for processing various combustible plant materials comprising agricultural or forestall wastes and the like into high-efficiency combustible solid fuel particles, thereby solving the problem of considerably increased agricultural (forestall) wastes at present, also relieving the current situation of increasing energy shortage at present and being beneficial to environmental protection and energy saving.

Owner:福建泰和生物质能源科技有限公司 +2

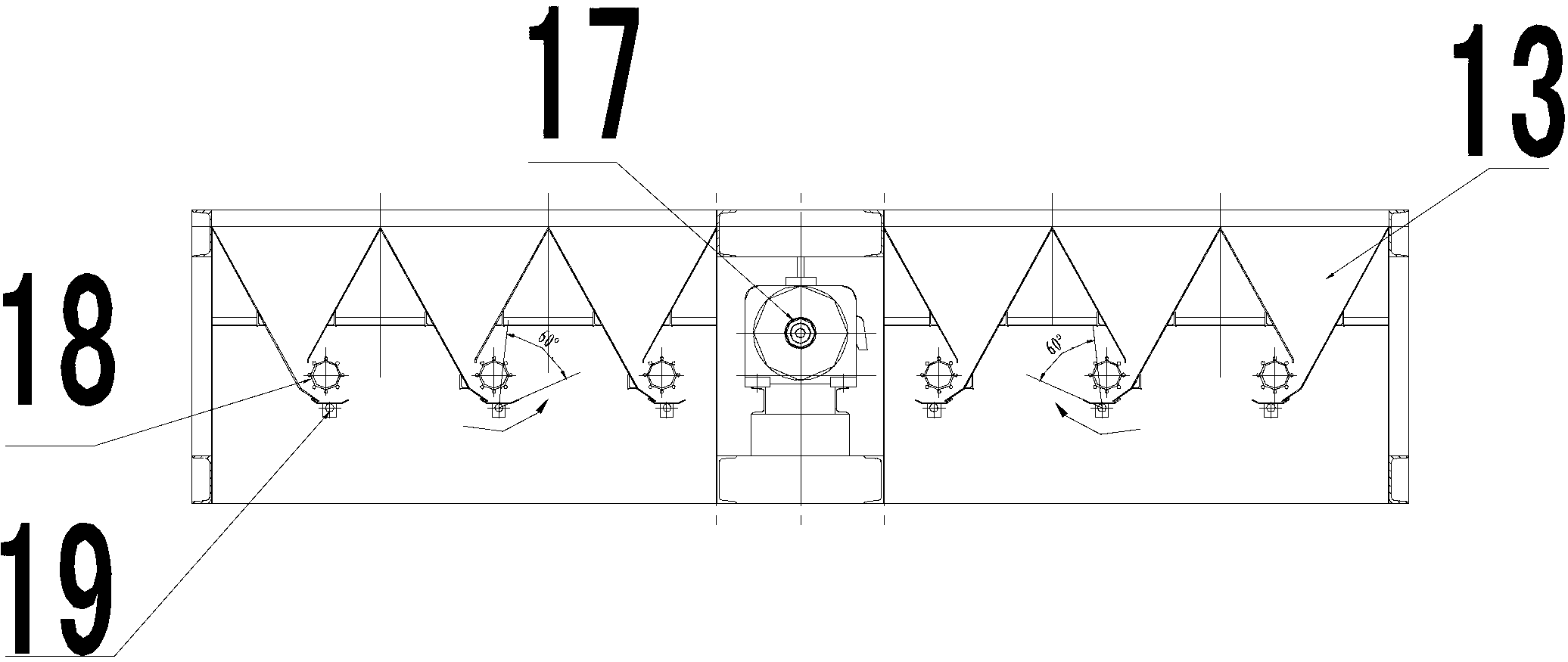

Low-temperature circulation dryer for crop seeds

InactiveCN103070232ARealize cycleImprove uniformityDrying gas arrangementsSeed preservation by dryingHigh energyEngineering

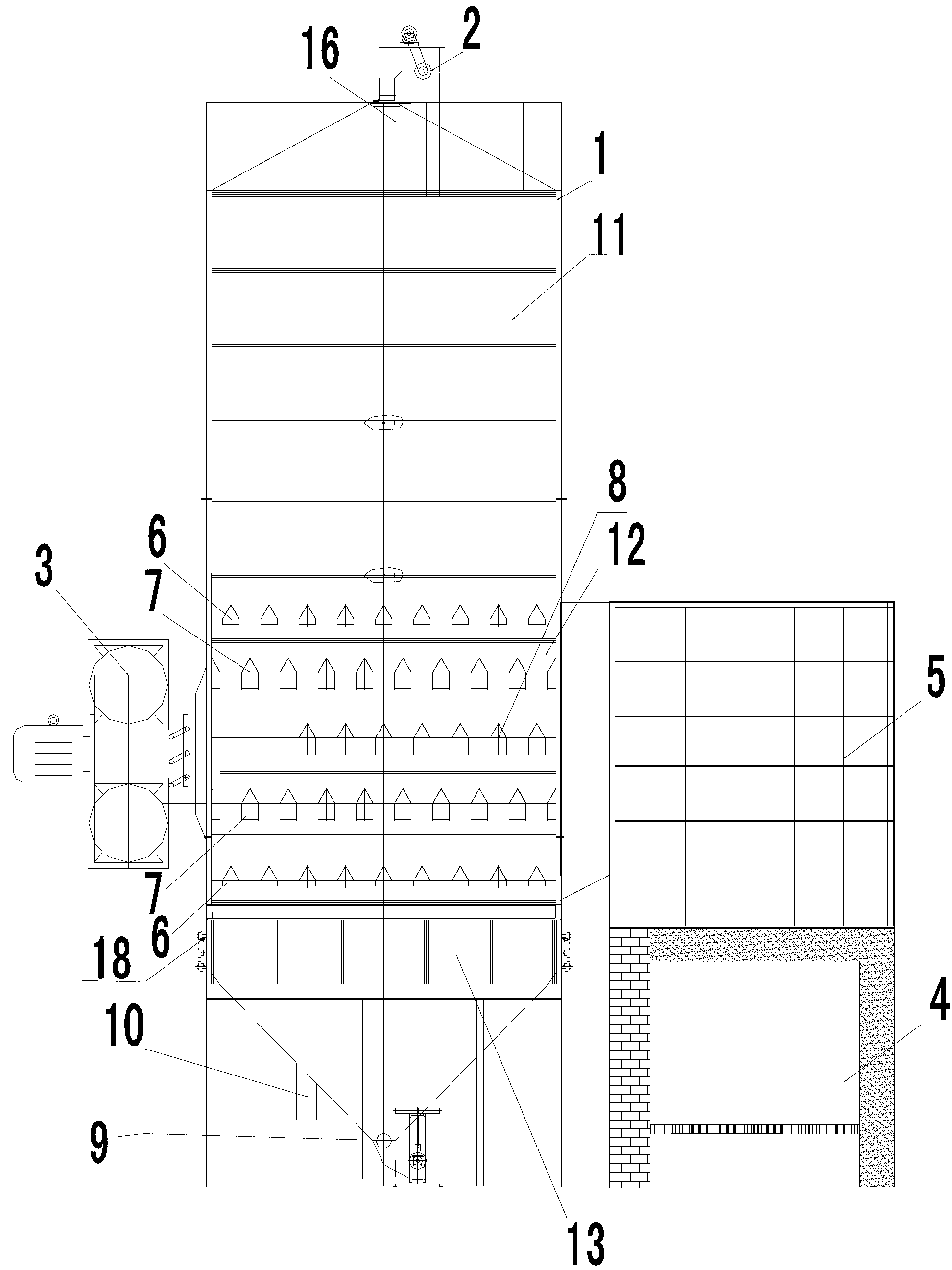

The invention discloses a low-temperature circulation dryer for crop seeds, which comprises a dryer body, a hoister, a draught fan, a hot-blast furnace, a heat exchanger, small air inflow angle boxes, air exhaust angle boxes, air inflow angle boxes, a grain discharge device, a delivery machine under the dryer and a grain-moisture and drying-temperature on-line detector. The low-temperature circulation dryer solves the problems of uneven material drying, higher energy consumption, a low annual utilization rate and the like in the prior art effectively, and has the characteristics of simple structure, simplicity in operation, high applicability, high-quality, efficient, safe and energy-saving low-temperature quick drying and the like.

Owner:SOUTH CHINA AGRI UNIV

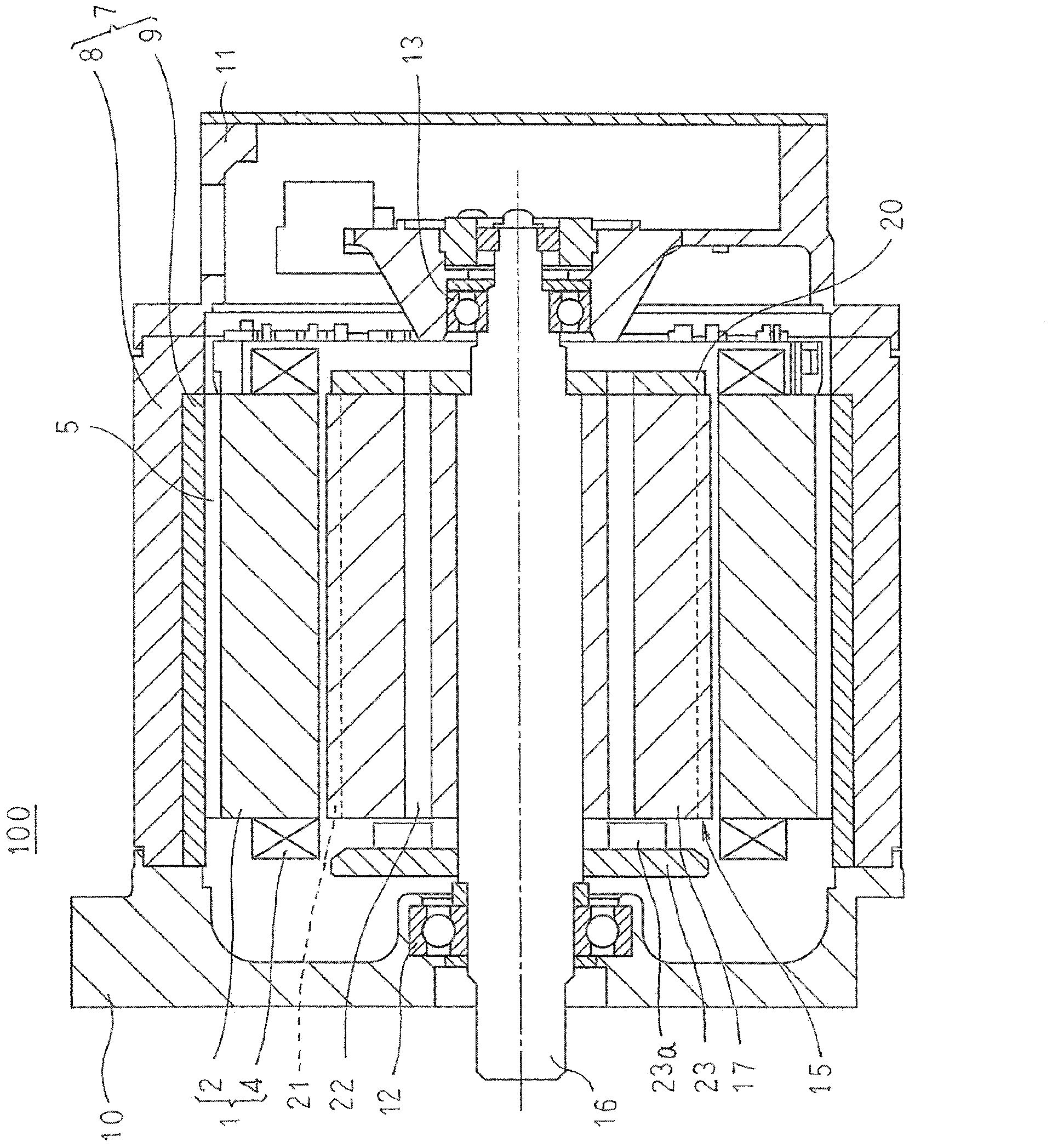

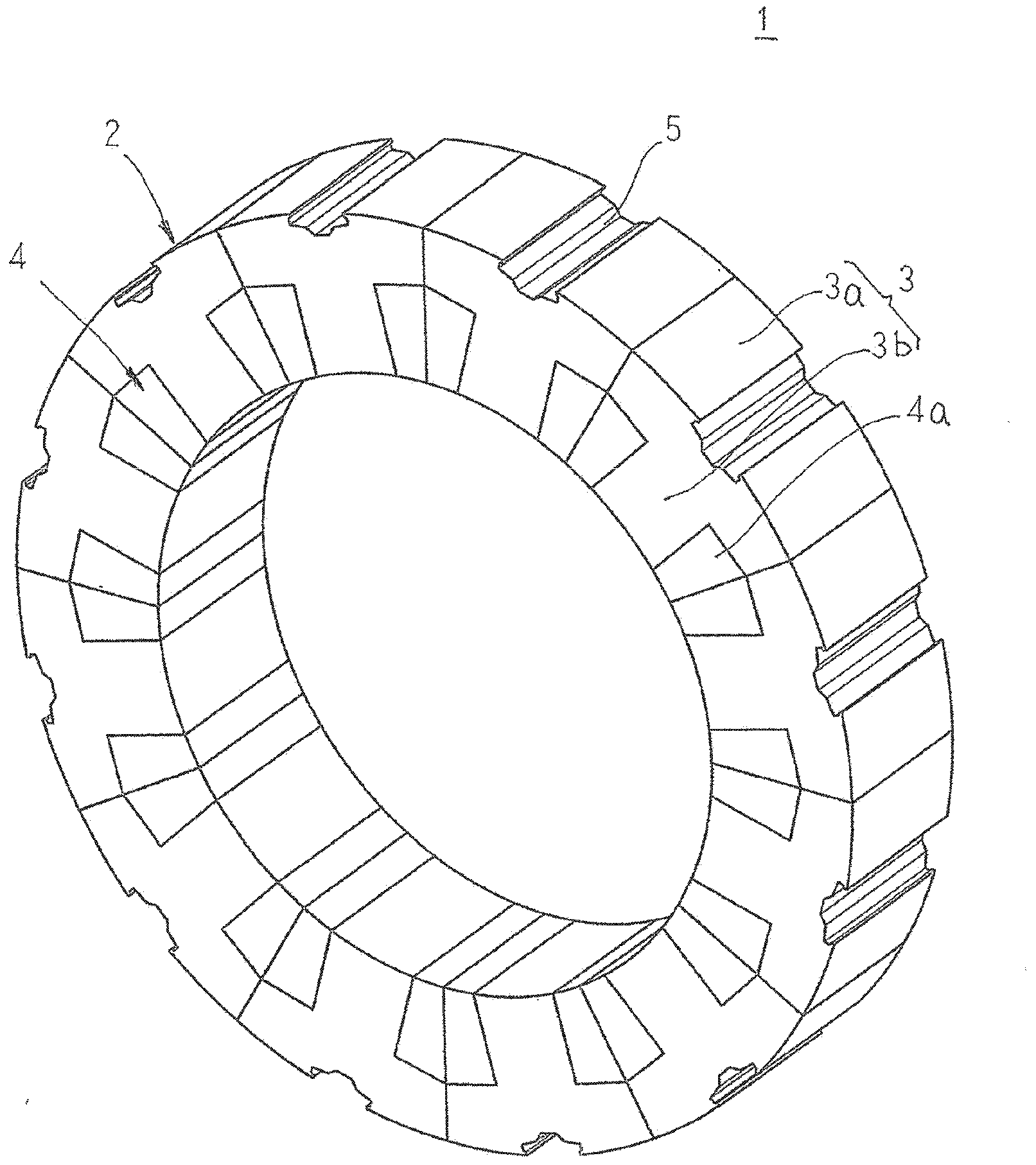

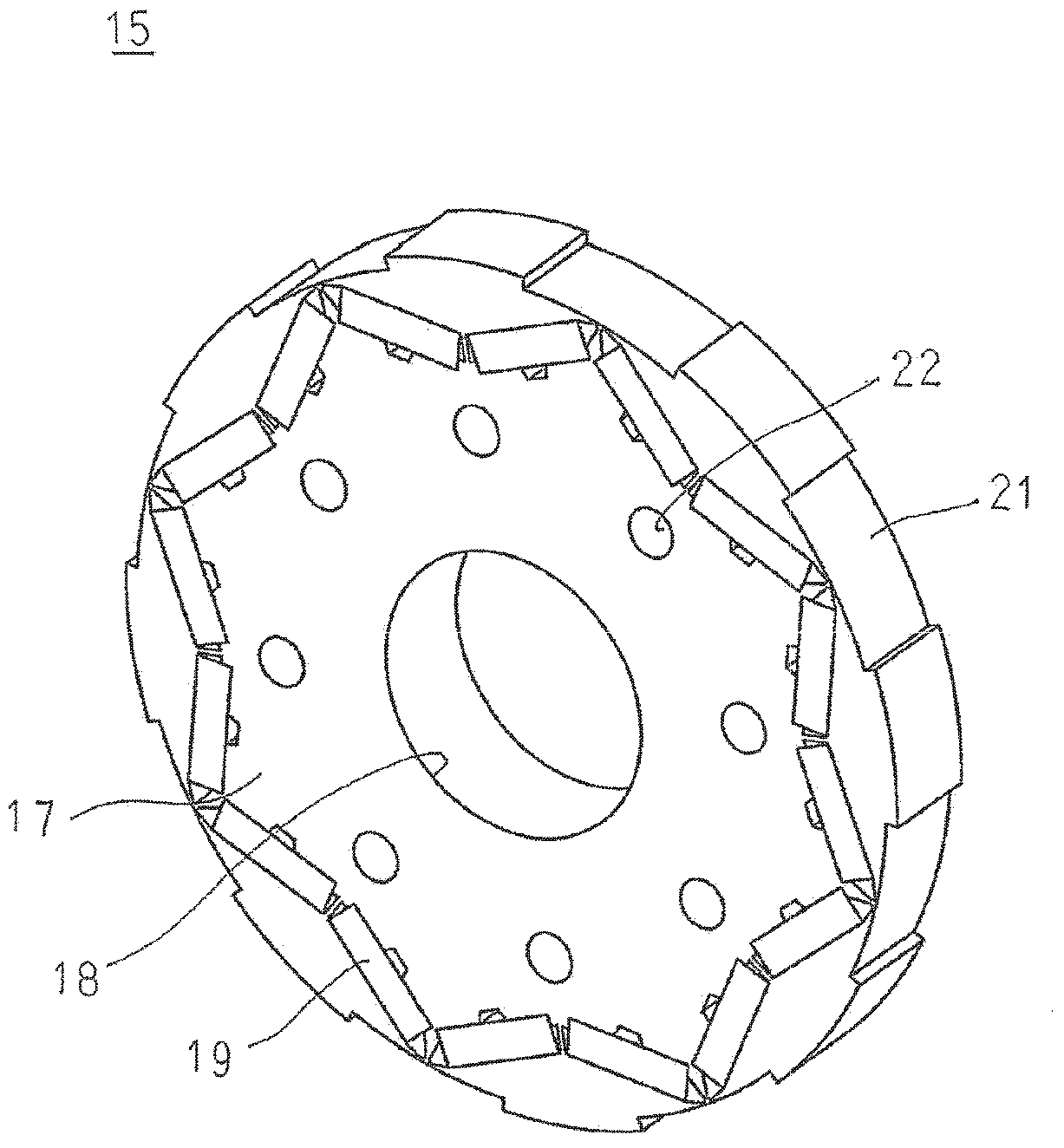

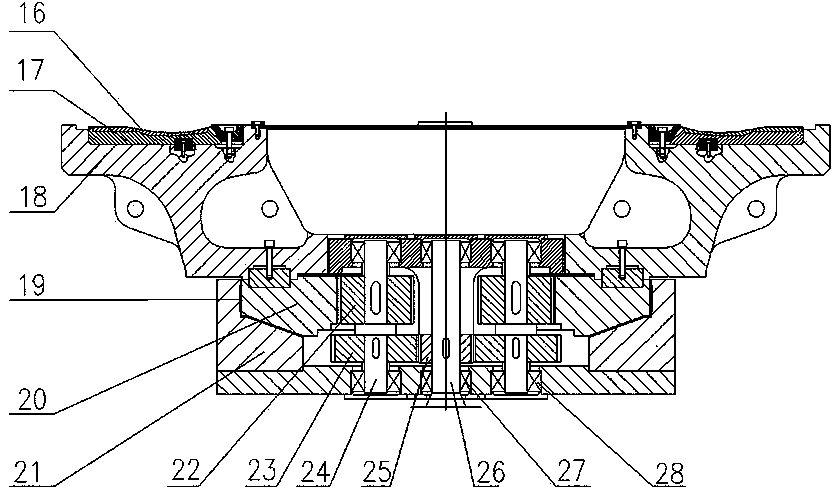

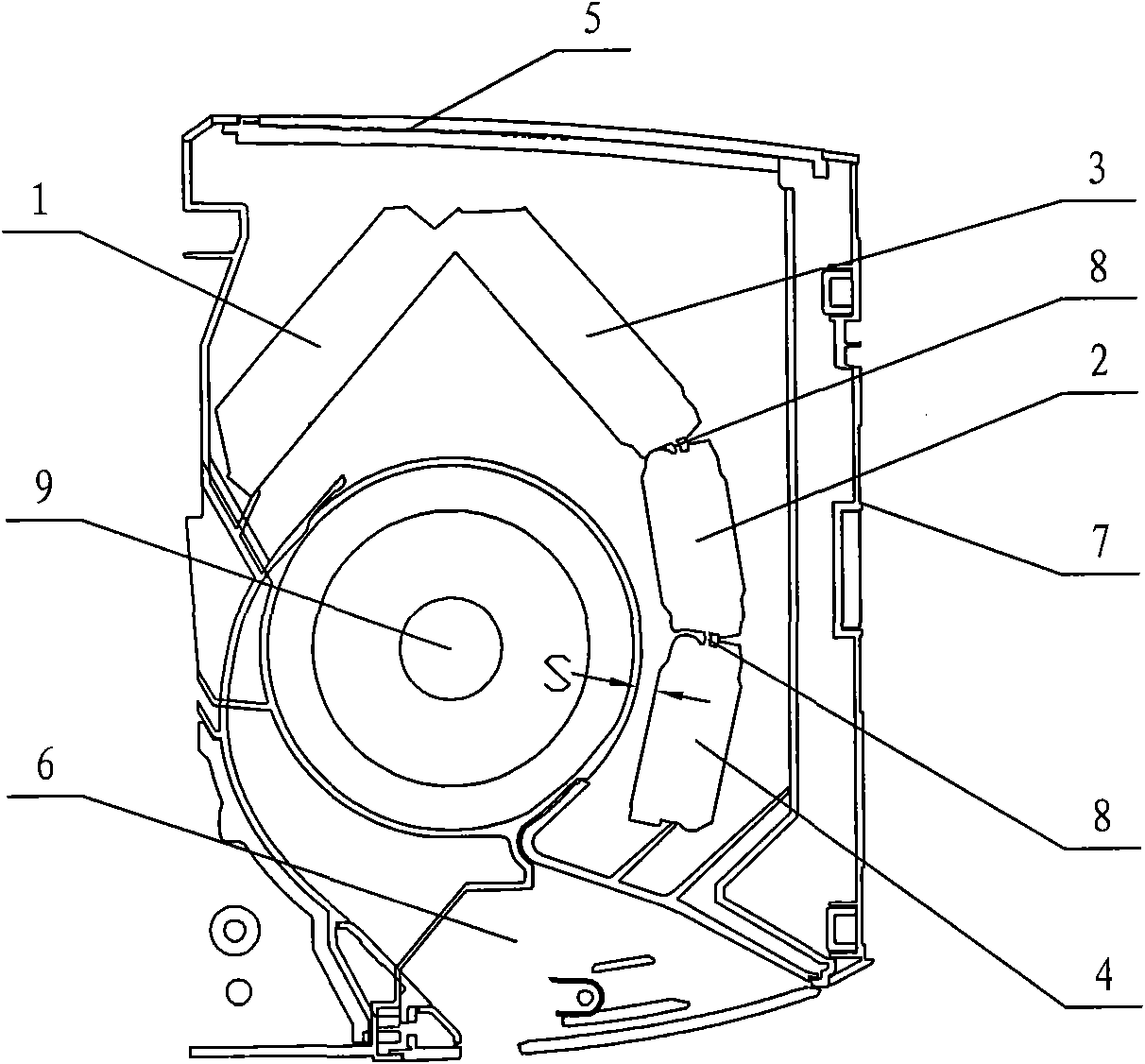

Embedded permanent magnet rotary electric machine

ActiveCN104143892ALow ventilation resistanceImprove performanceMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetEngineering

Ventilation apertures are respectively formed circumferentially so as to pass axially through an inner circumferential side of a rotor core, rotor grooves are respectively formed circumferentially on an outer circumferential surface of the rotor core so as to have groove directions in an axial direction, and a centrifugal fan is fixed to the shaft at an end of the rotor core near the front frame, and a cyclic path is formed in which, during operation of the centrifugal fan, cooling air flows into the ventilation apertures from near a rear frame, passes through the ventilation apertures and flows out near the front frame, flows radially outward near the front frame and flows into the rotor grooves, passes through the rotor grooves and flows out near the rear frame, and flows radially inward near the rear frame and flows into the ventilation apertures.

Owner:MITSUBISHI ELECTRIC CORP

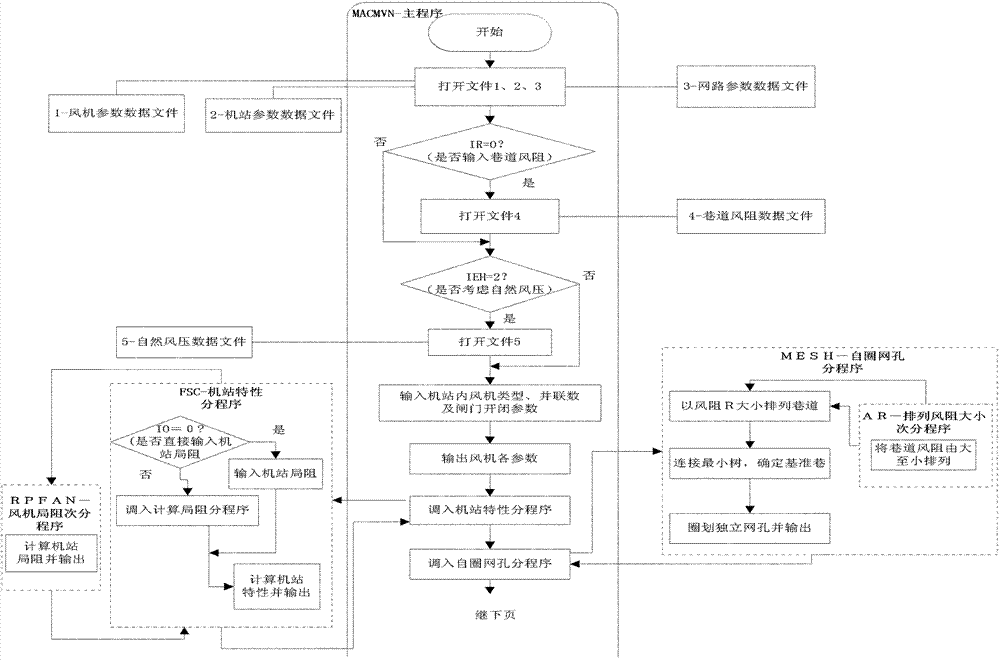

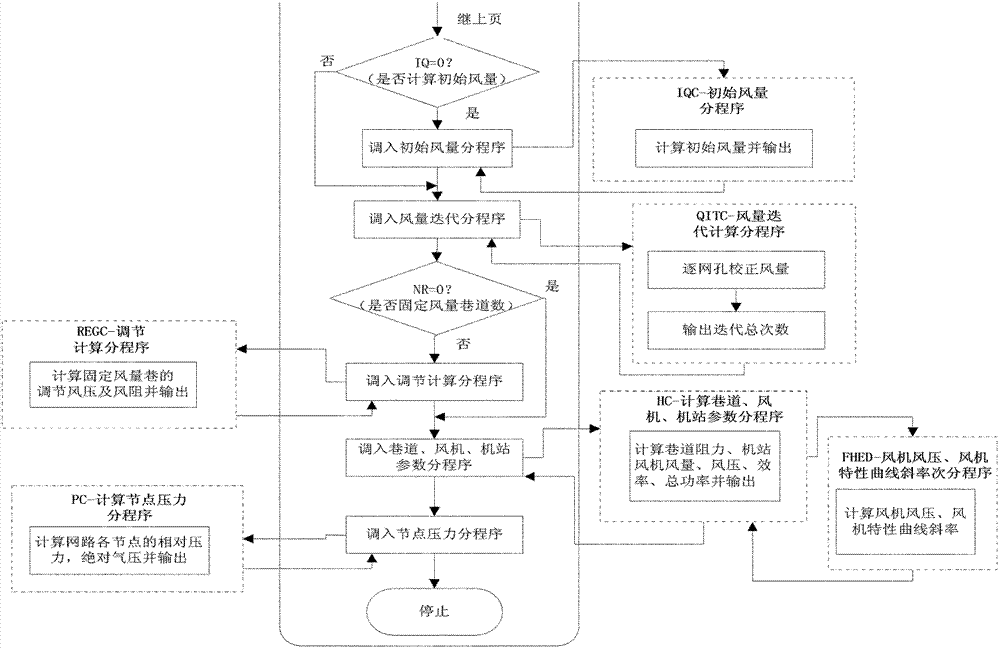

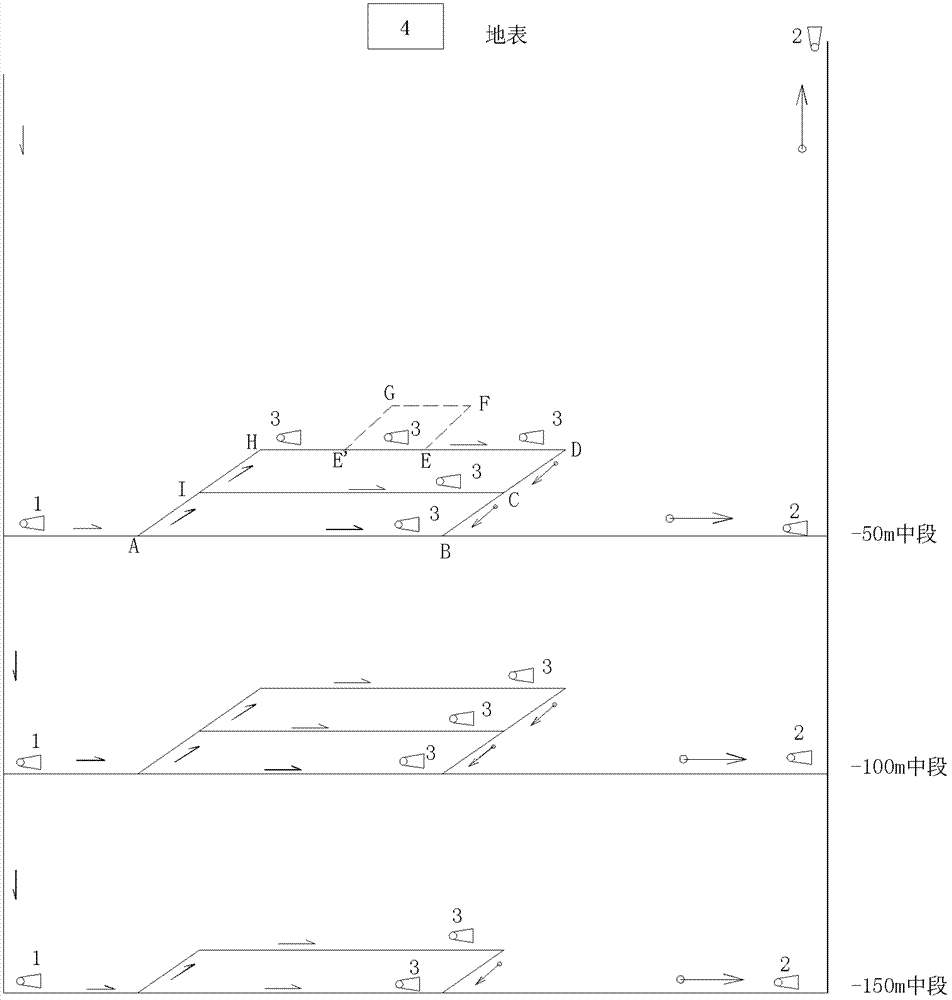

High-efficiency energy-saving mine multi-stage fan station ventilation monitoring technology system

ActiveCN102953745ASimple structureEasy to adjustTunnel/mines ventillationPump controlPower factorMonitoring system

The invention discloses a high-efficiency energy-saving mine multi-stage fan station ventilation monitoring technology system. Intake fan stations (1) are arranged in the intake sections of a mine, return fan stations (2) are arranged in the return air sections, air consumption fan stations (3) are arranged in the air consumption sections, and a ground main mine monitoring room (4) is arranged on the ground surface of the mine. A multi-stage fan station ventilation network calculation program is developed to carry out numerical calculation on the ventilation parameters of the ventilation system, such as ventilation resistance, the blowing rates of fans of the fan stations, wind pressure, efficiency and total power; the number of fan station stages and the locations of the fan stations are determined; fan models are chosen, and the blowing rates are regulated; and a remote centralized multi-stage fan station monitoring system and an underground on-line atmospheric environment monitoring system are constructed. The pressure-equalizing ventilation of each mine ventilation network section can be realized, air leakage is reduced, the starting and stopping of the fans of the intake fan stations, the return fan stations and the air consumption fan stations in the mine can be remotely controlled, the variable-frequency speed regulation of the fans is realized, the system can perform inverted ventilation, parameters, such as the operating states of the fans, the blowing rates and wind pressure of the fans, motor bearing temperatures and power factors, can be monitored in real time, and the underground ventilation environment can be monitored in real time and on line.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

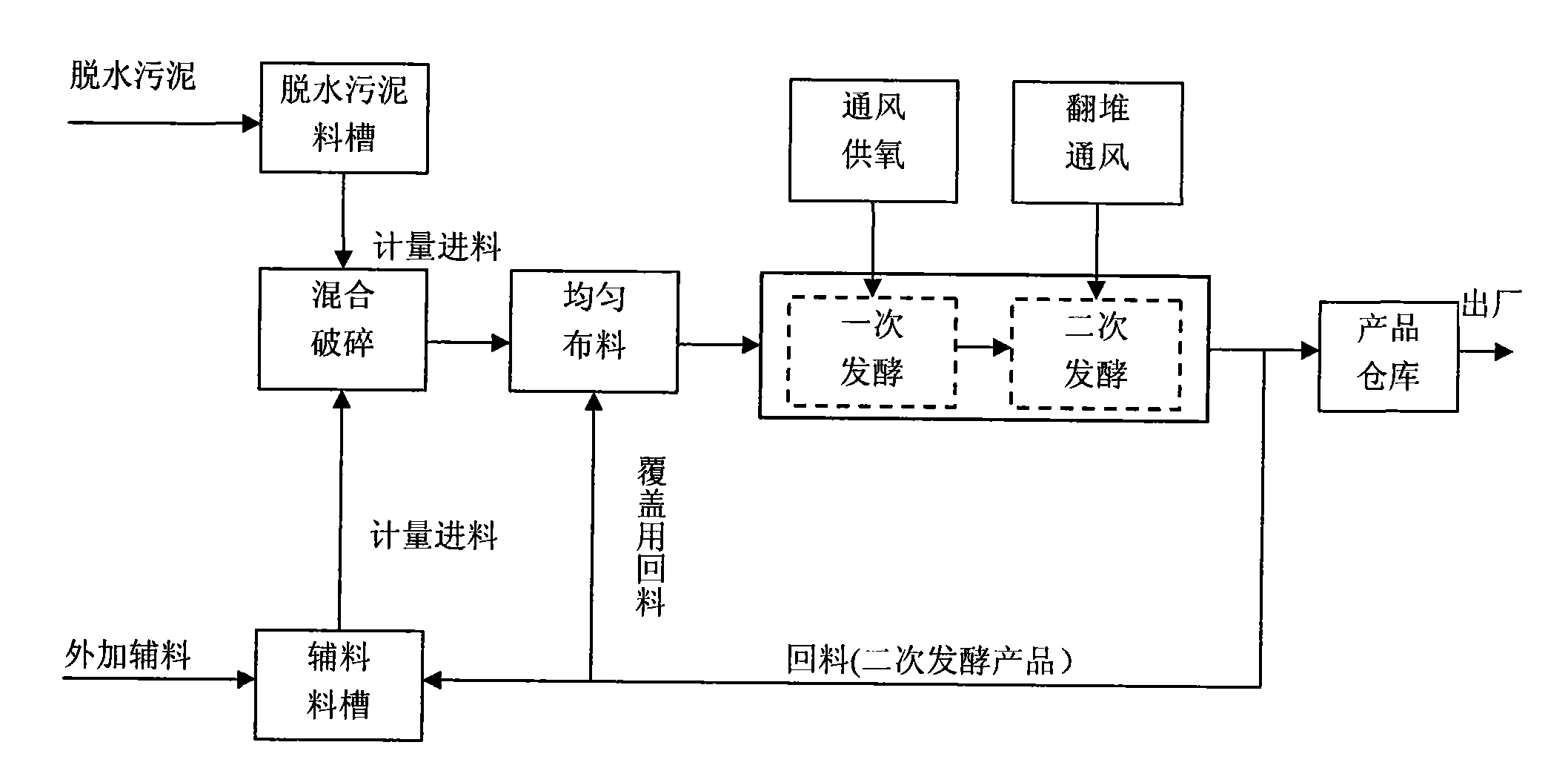

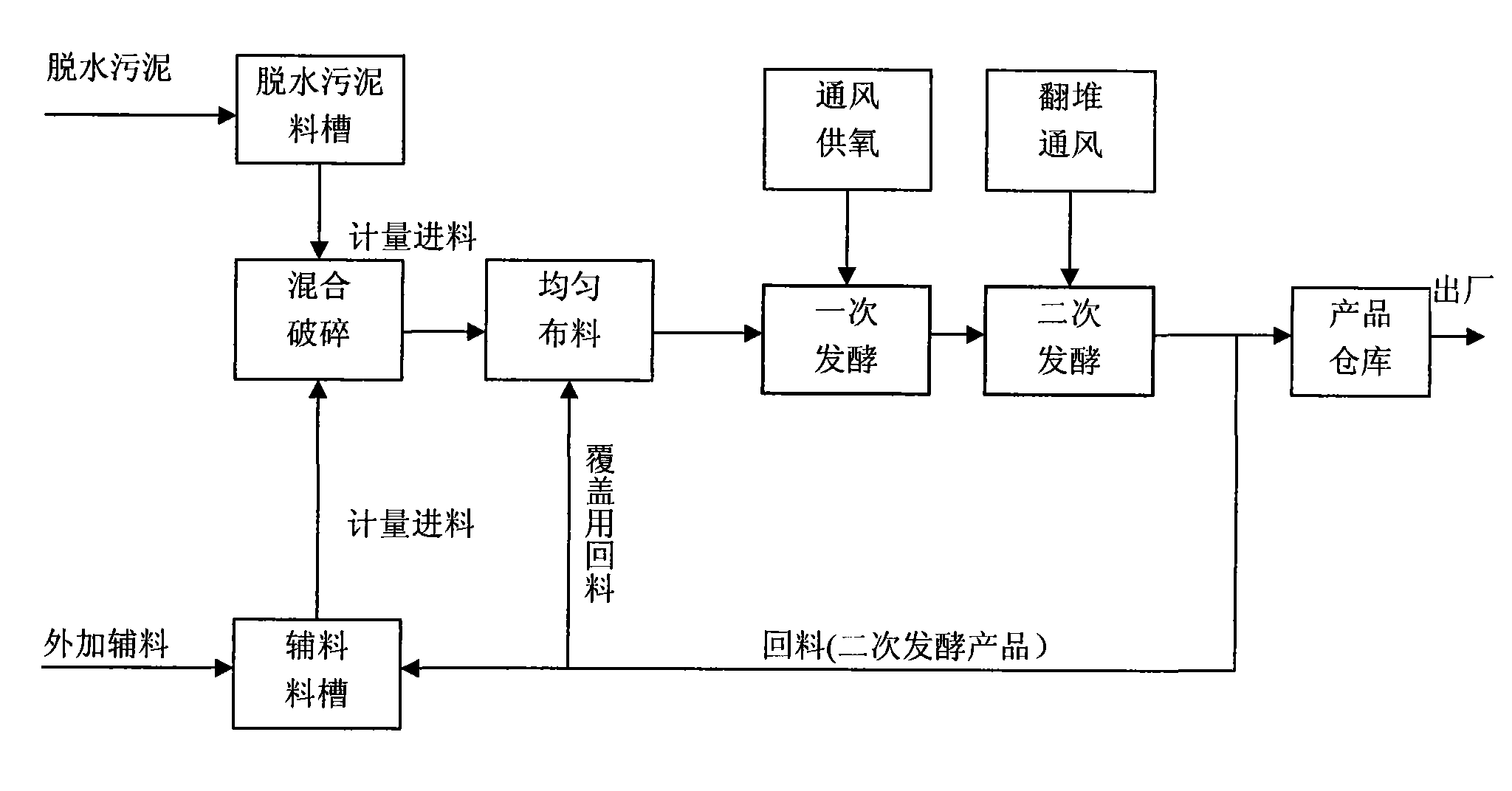

High-temperature aerobic fermentation process for sludge with low energy consumption and no pollution

InactiveCN101618977AAvoid pollutionPromote fermentationBio-organic fraction processingClimate change adaptationReduction treatmentIndustrial waste water

The invention discloses a high-temperature aerobic fermentation process for sludge with low energy consumption and no pollution, and relates to the technology for aerobic fermentation treatment on dewatered sludge. The process is used for decontamination, stabilization and reduction treatment of town sewage sludge, sewage sludge, organic industrial wastewater sludge and organic sludge. In the process, the dewatered sludge and auxiliary materials are mixed, the mixture is crushed into composting particles with the diameter less than or equal to 20mm, the composting particles are evenly distributed into a pile with the height of 2m by a spreader, and the pile is covered by fermented decaying products to effectively reduce the odor emitted by the composting. A fermentation bin with two combined or separated bins is provided with a ventilation and oxygen supply system which is detachable, is easy to clear, prevents blockage and has even gas distribution, and a pile turning device inside; and the oxygen concentration, fermentation temperature, water ratio of the pile in the fermentation bin are controlled, so that sludge fermented products meet national standard. The process facilitates air supply and aerobic fermentation of the pile due to small diameter of the composting particles and the loose pile, has thorough fermentation of the particles of the sludge mixture, improves the quality of the sludge fermented products, makes the sludge fermented products meet the decontamination, stabilization and reduction index requirements specified by the national standard, and greatly saves electric energy consumption and reduces operating cost.

Owner:城市污染控制国家工程研究中心 +2

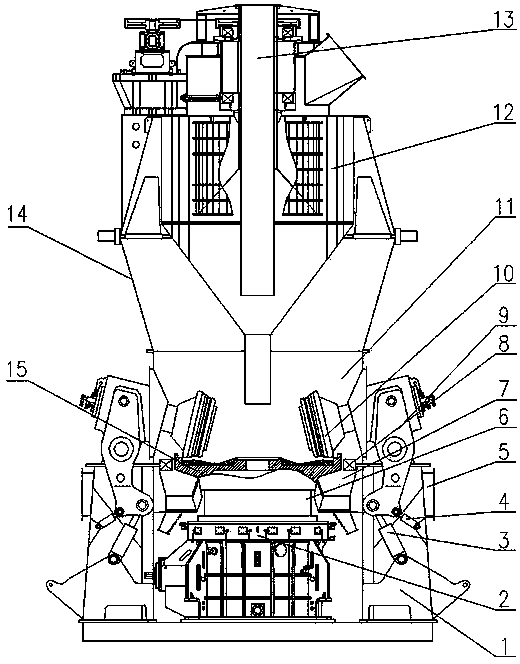

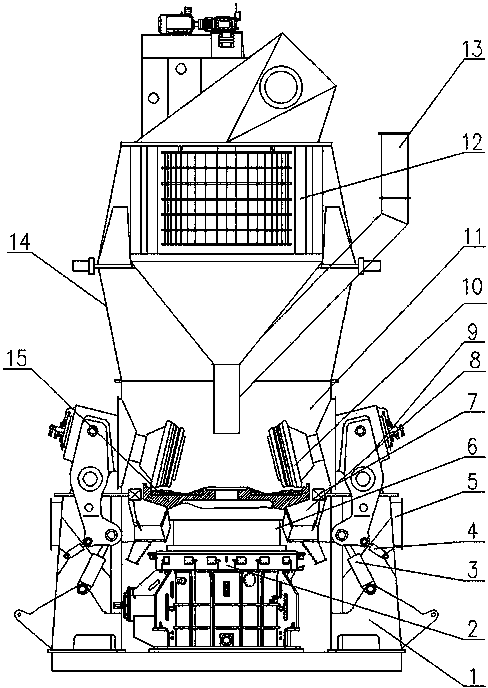

Self-adaptive vibration accumulation and energy supply high-efficiency vertical roller mill

ActiveCN103639018AAvoid collision riskReduce vibration intensityGrain treatmentsEngineeringRocker arm

The invention relates to a self-adaptive vibration accumulation and energy supply high-efficiency vertical roller mill which comprises a hydraulic transmission system, an intelligent control system, a stand (1), a transmission device (2) and a speed reducing mechanism (6), wherein the transmission device (2) and the speed reducing mechanism (6) are arranged on the stand (1); an output end of the speed reducing mechanism (6) is provided with a grinding table device (15); an air ring (8) is arranged at the excircle of the grinding table device (15) and at an upper opening of an air inlet duct (7) communicated with an air inlet pipe (5); a plurality of grinding roller devices (10) are arranged above the grinding table device (15) by a mill door arranged on a lower shell (11); a rocker arm (9) is arranged at the outer ends of the grinding roller devices (10); one ends of a pressurizing oil cylinder (3) and a magnetic fluid damping adjustment device (4) are respectively connected with the rocker arm (9), and the other ends of the pressurizing oil cylinder (3) and the magnetic liquid damping adjustment device (4) are respectively connected with the stand (1); the upper end of a middle shell (14) is provided with a powder concentrator (12). The self-adaptive vibration accumulation and energy supply high-efficiency vertical roller mill has the advantages that the extrusion energy and the impact energy are efficiently utilized, the vibration intensity of a grinding host machine can be reduced, the grinding efficiency is improved, the grinding energy consumption is reduced, the stability of equipment is improved, the service life of the equipment is prolonged, and the running cost is lowered.

Owner:临沂市博信机械有限公司

Environment protection coal-saving agent for cement vertical kiln

The invention provides an environmental-friendly coal-saving agent for a cement shaft kiln, comprising the following raw materials by weight portion: 3-7 portions of a coal combusting low-temperature modifying agent, 2-6 portions of a compound sulphur-fixing agent, 0.5-0.96 portion of a combusting inductive agent, 3-7 portions of a raising agent, 56-96 portions of a combusting poising agent, and 5-15 portions of a highly-efficient sulphur-fixing agent. The coal combusting low-temperature modifying agent can be potassium permanganate, potassium chlorate, potassium perchlorate, sodium chlorate, sodium nitrate and the like; the compound sulphur-fixing agent can be sodium carbonate, calcium oxide and the like; the raising agent can be waste liquor of paper mill containing Na or / and Ca sulphonate and the like; and the combusting poising agent can be a chemical waste reducing substance containing sodium chloride and the like. The method solves the problems of environmental pollution and resource waste in the prior art, uses compatibility of multiple chemical raw material of 6-10 percent and chemical waste to prepare the coal-saving agent with small dosage and fast effect to be added to the production of the cement shaft kiln in trace quantity, and has the advantages of resource conservation by using waste, coal conservation and consumption reduction, and reduction of dust and SO2 discharge and environmental pollution.

Owner:陶小勇

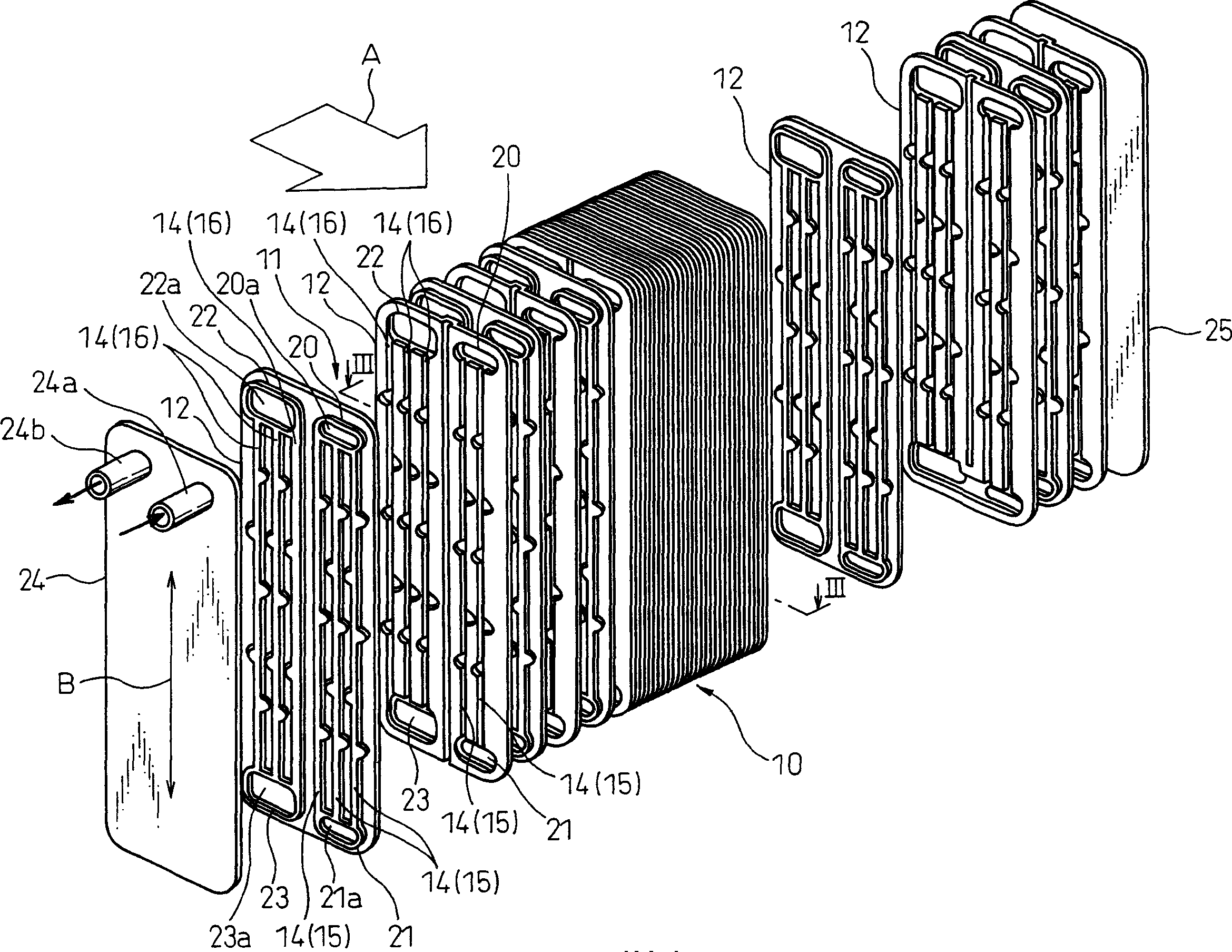

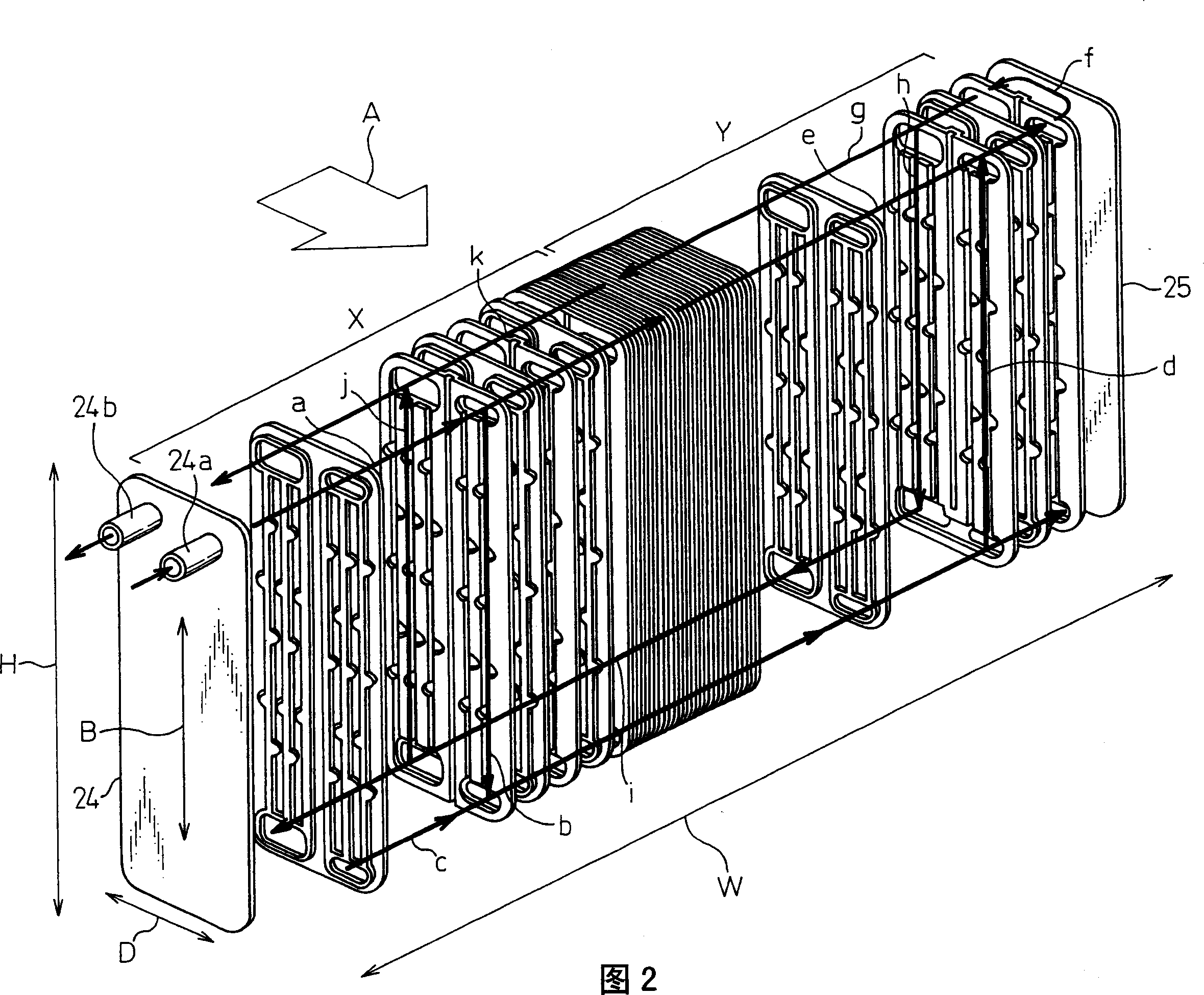

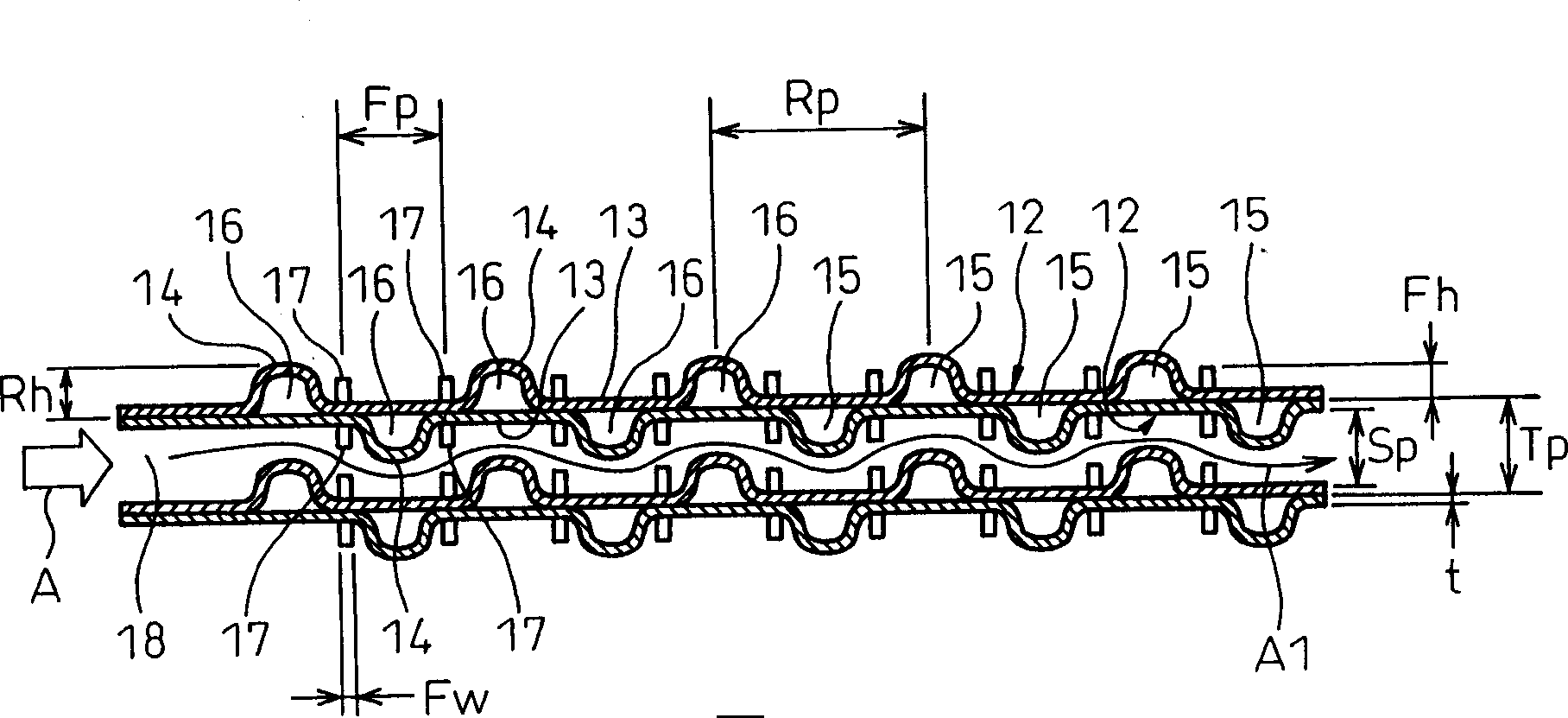

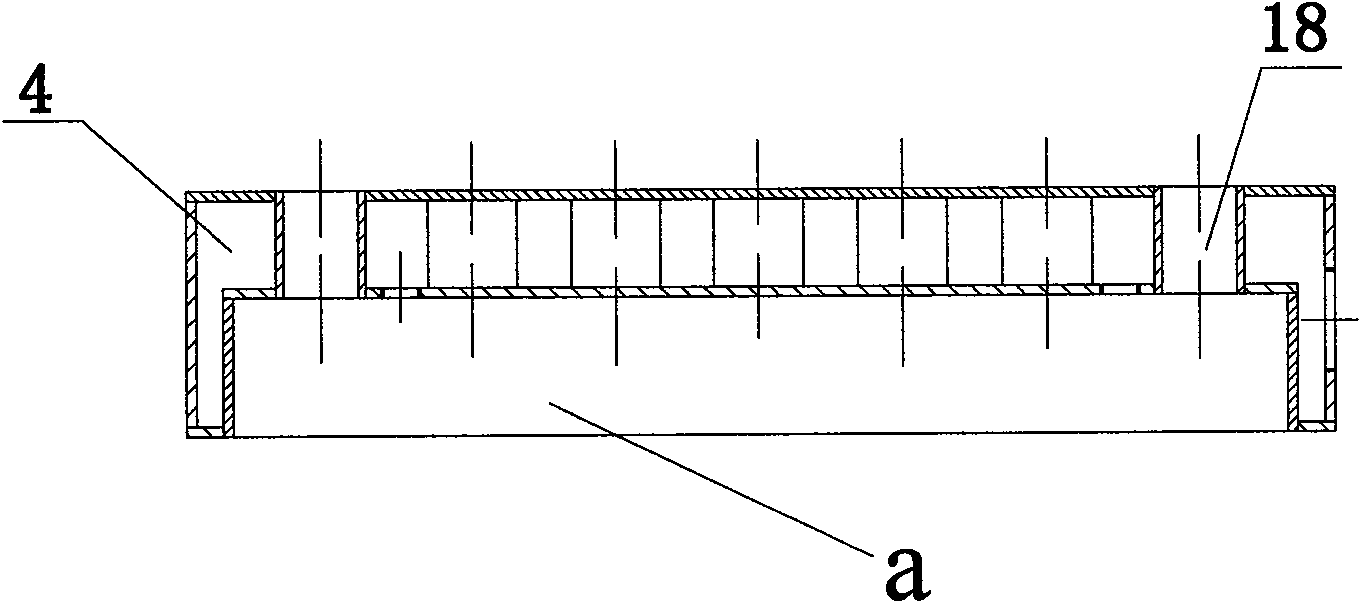

Heat exchanger

InactiveCN1851372ASmall pressure lossReduce in quantityStationary conduit assembliesHeat sinkCoolant

Air passages 18 are formed between surfaces of a plurality of heat transfer plates 12 laid together. A plurality of rib sections 14 extending orthogonal to the air flowing direction A are formed on a surface of the heat transfer plate 12 and projected into the air passage 18. By shifting the positions of the rib sections 14 to each other in the air flow direction, coolant passages 15, 16 are formed inside the plurality of rib sections 14. Between the plurality of rib sections 14, fin sections 17 are formed integral with the heat transfer plate 12 and projected from the plate surface. The fin section 17 has a protruded shape formed by pressing and having a cut portion partially cut a plate thickness of the heat transfer plate 2.

Owner:DENSO CORP

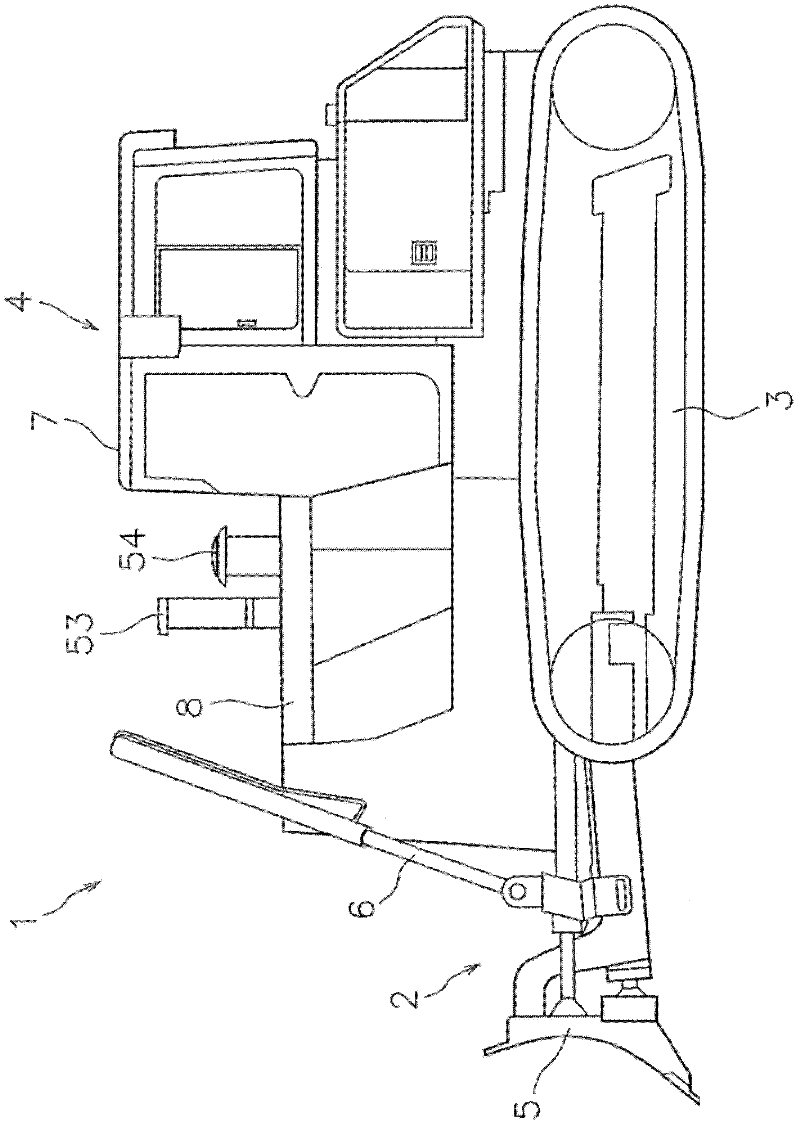

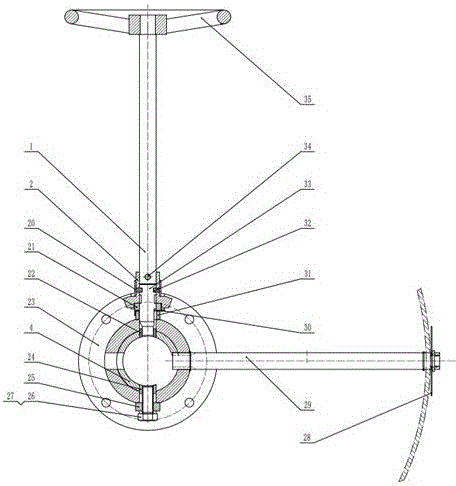

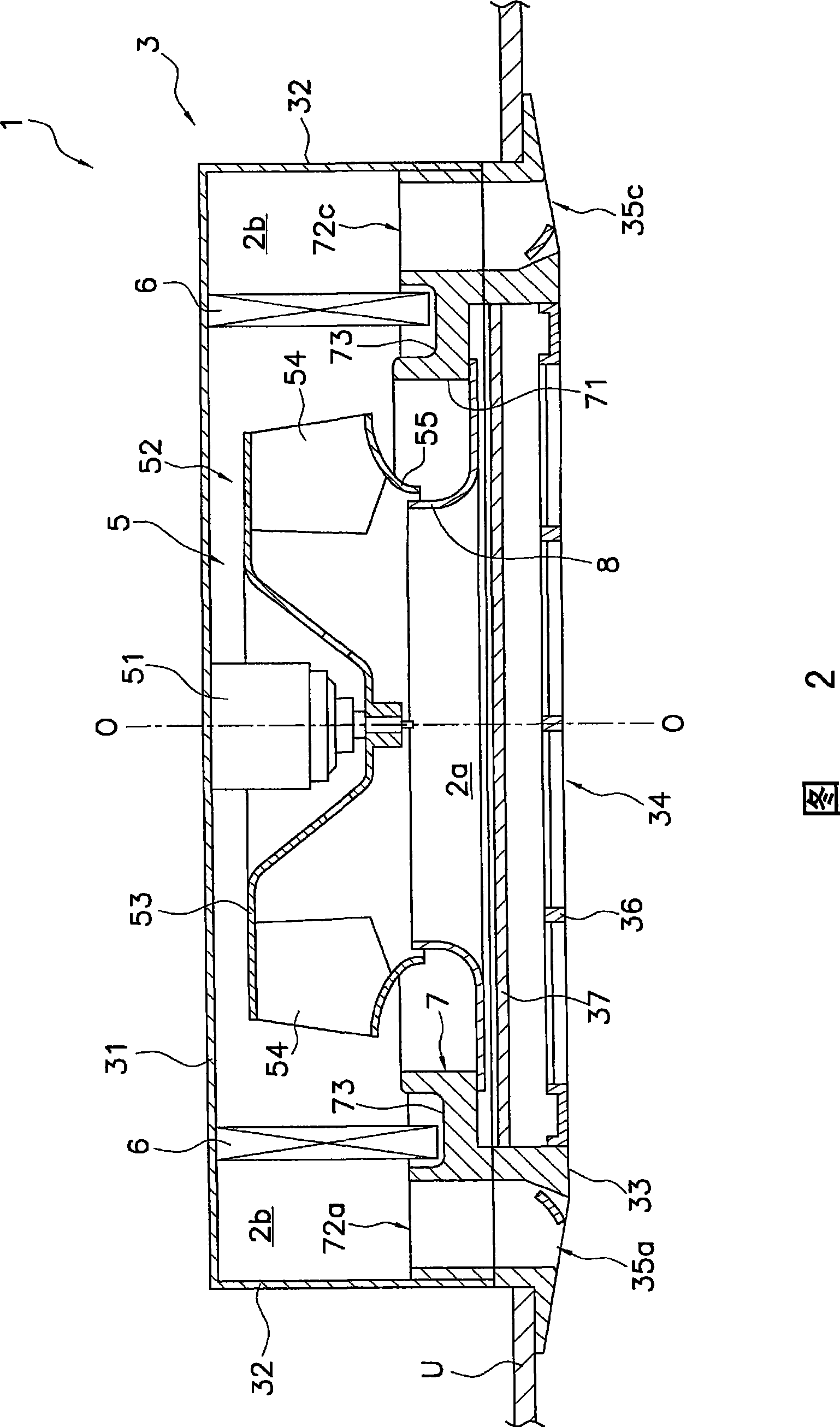

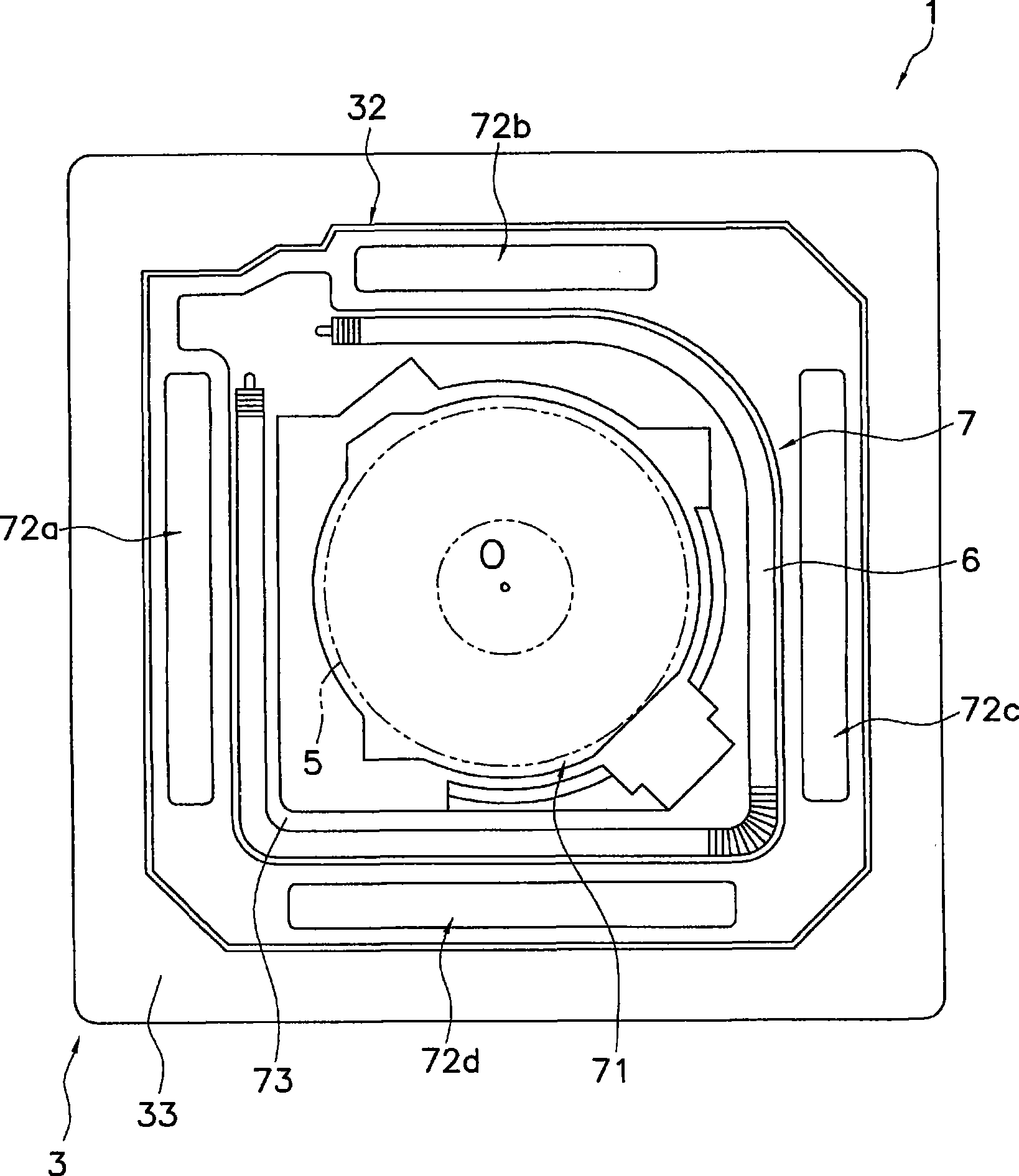

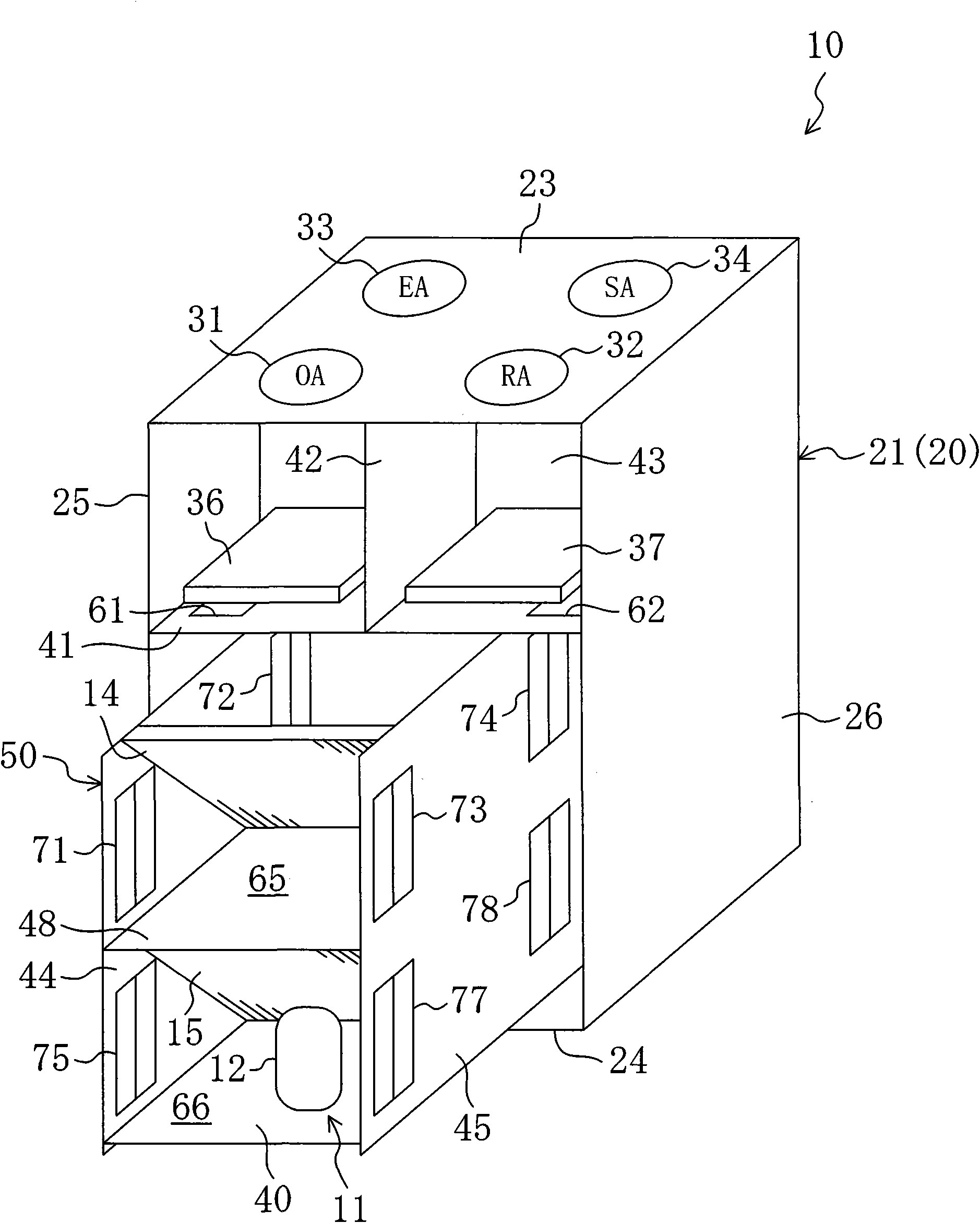

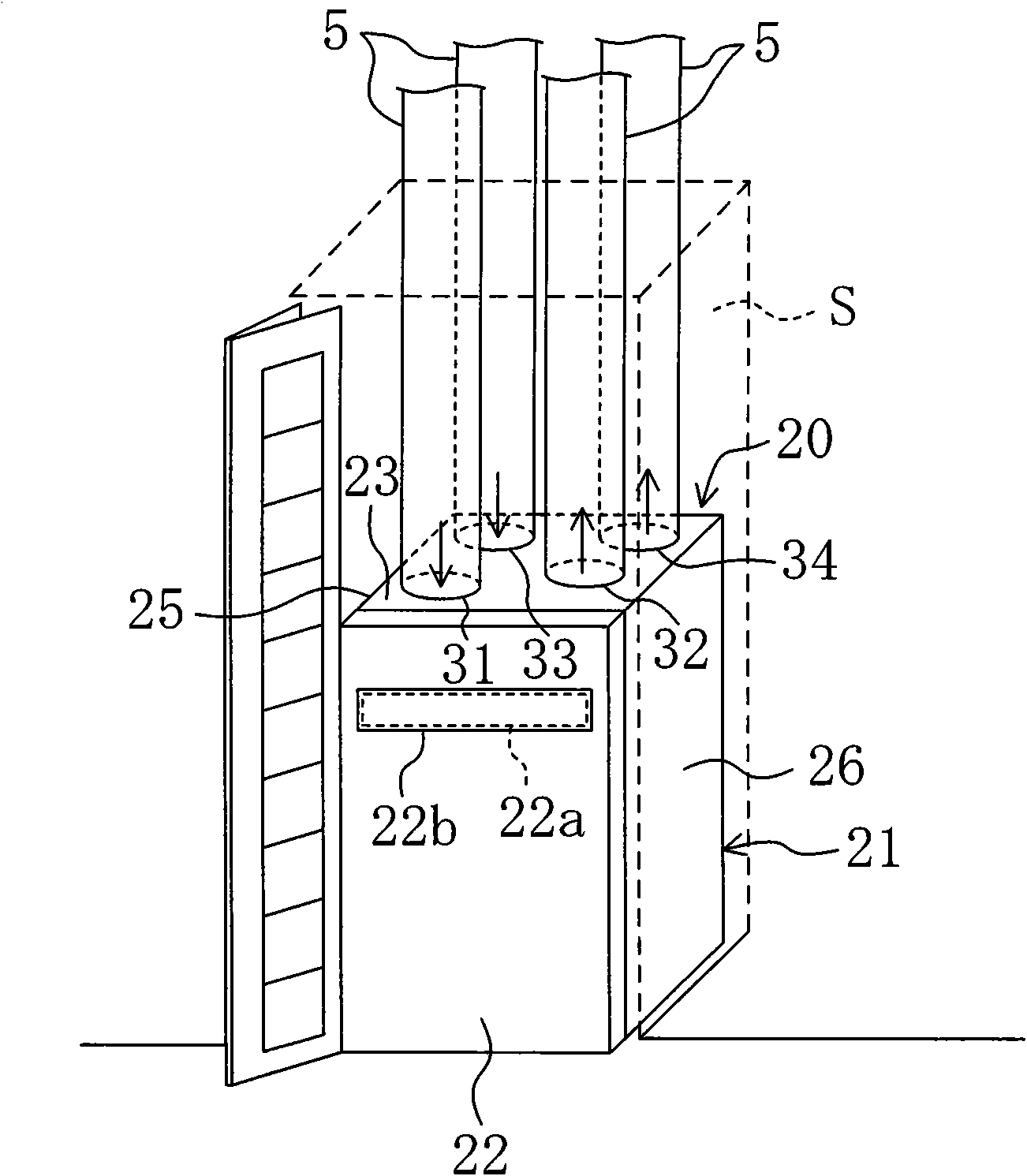

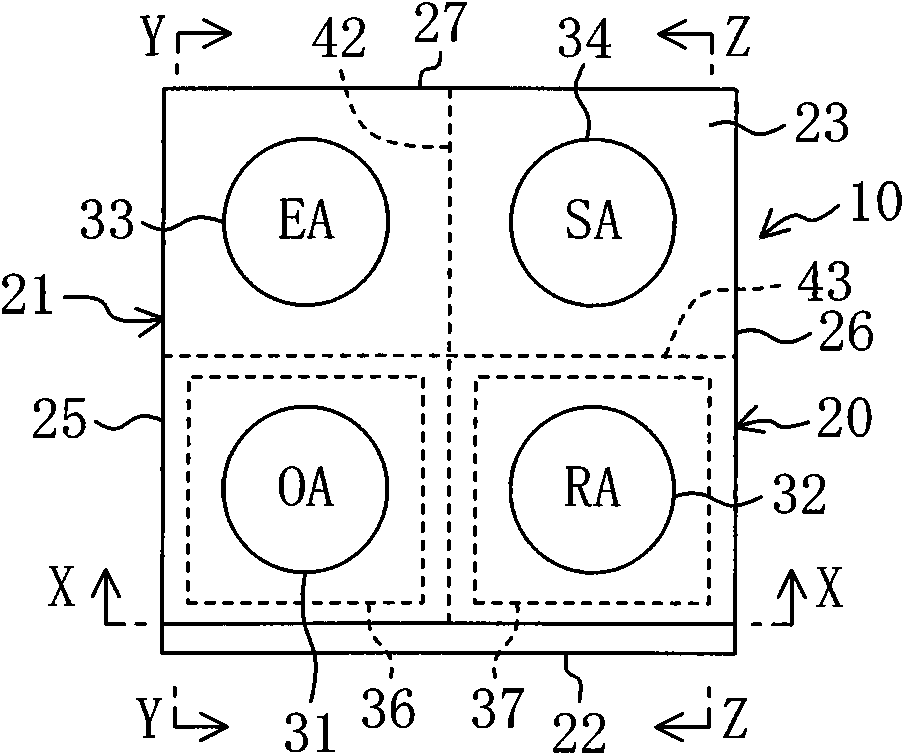

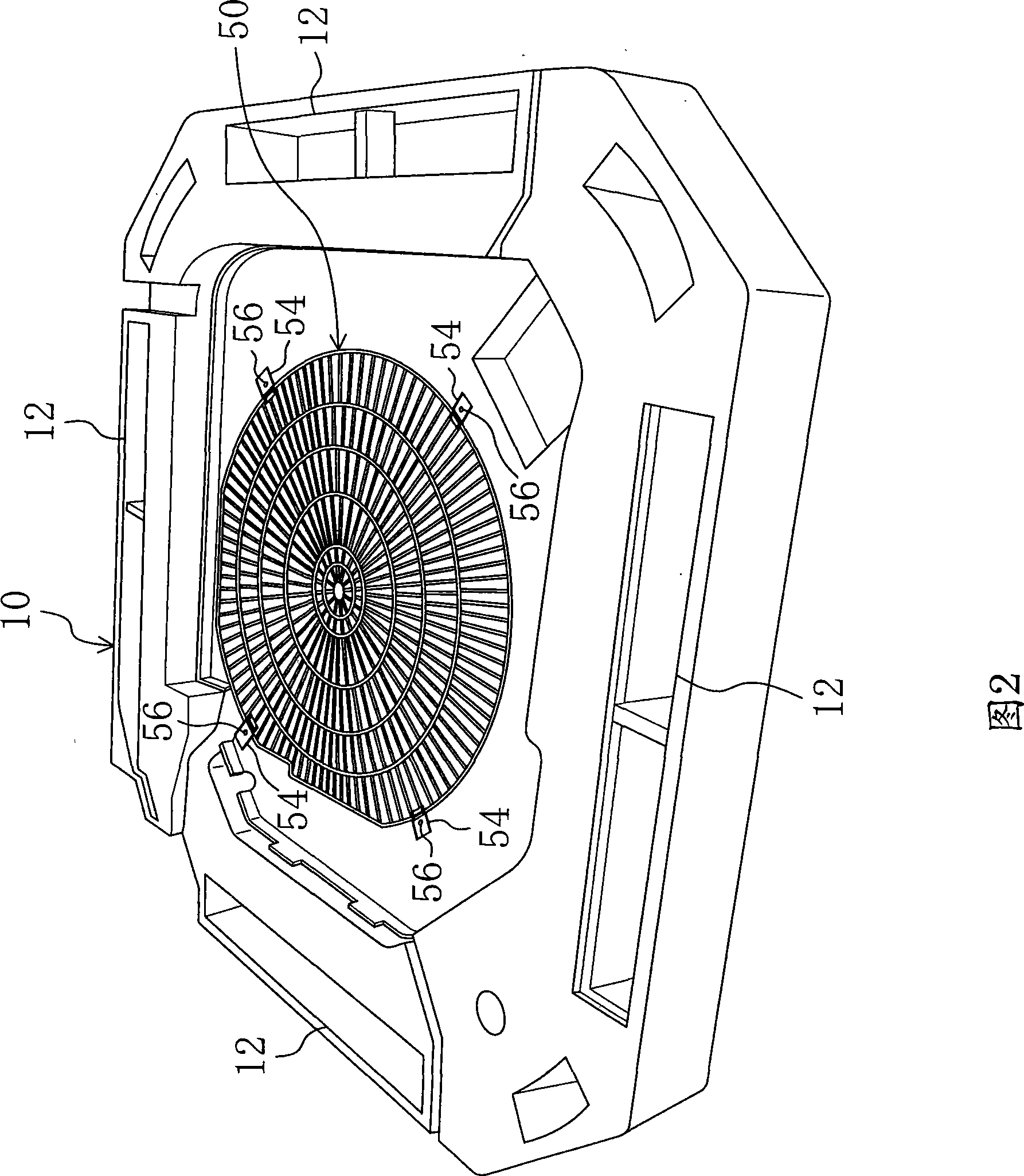

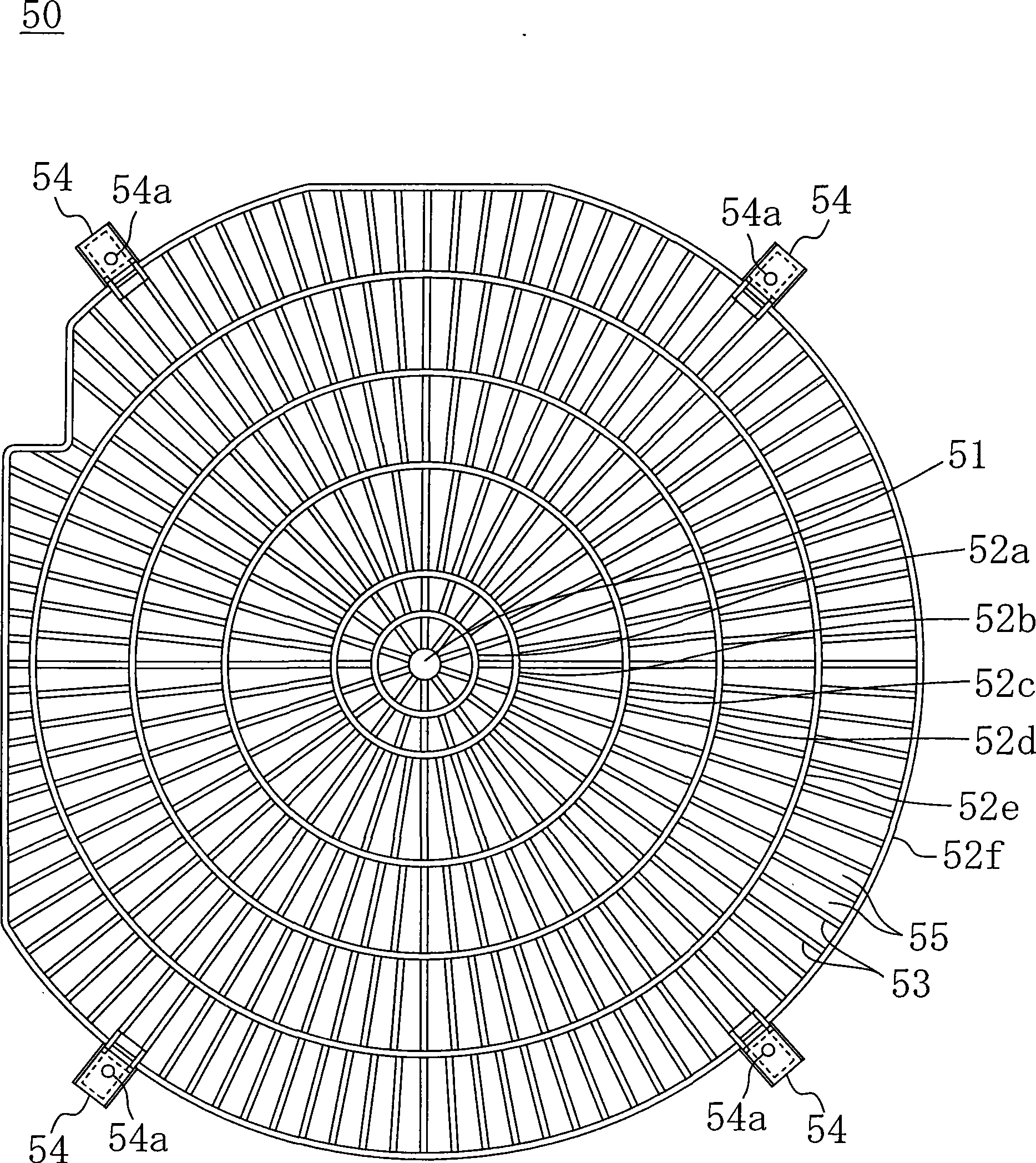

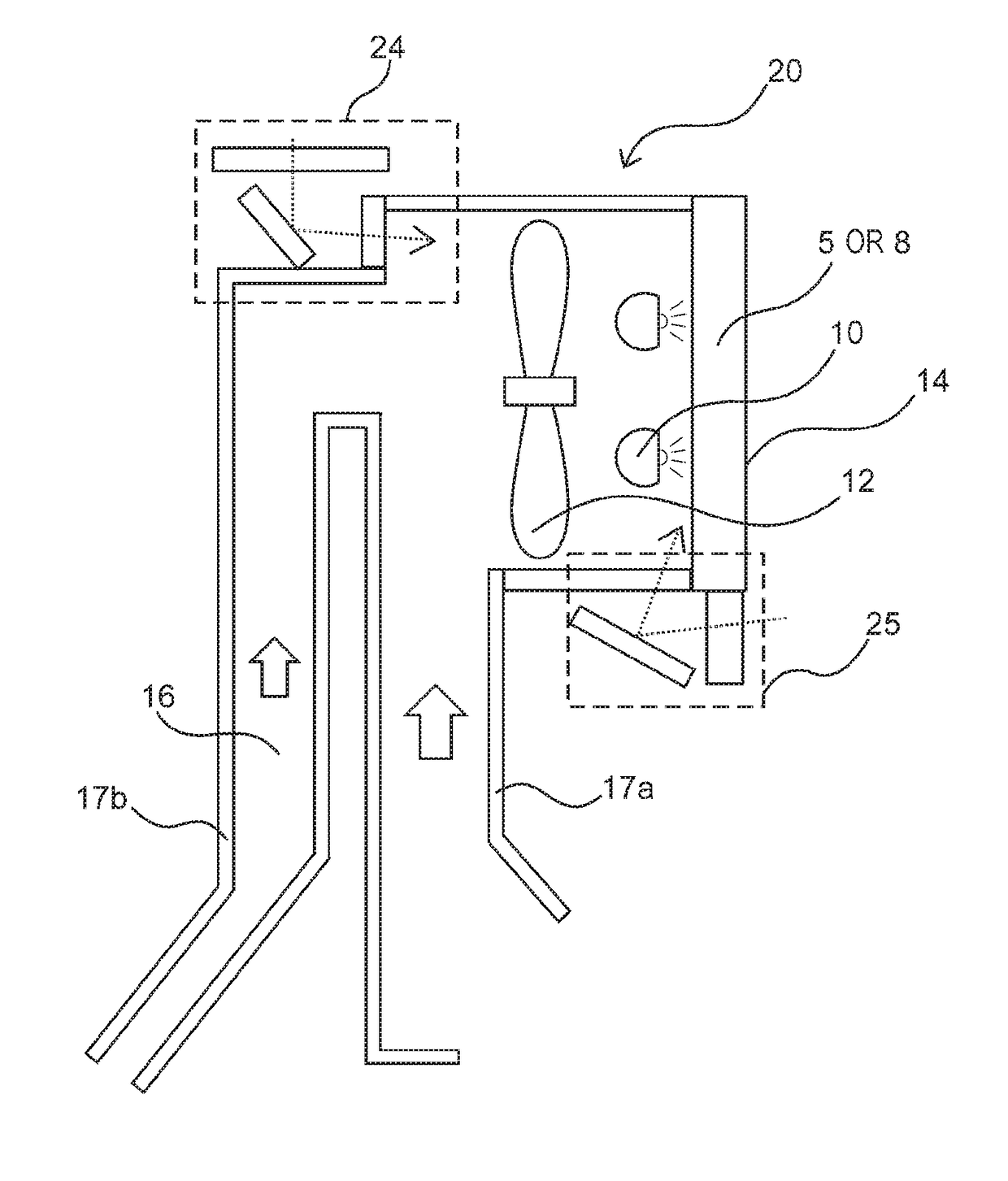

Air supply device and air conditioner using same

InactiveCN1752622ASimple structureImprove reliabilityLighting and heating apparatusHeating and ventilation casings/coversEngineeringIndoor air

To provide a small blowing device of high reliability, simple in constitution and capable of switching to air supply and exhaust. The blowing device 20 is provided with a blower section 50 and an air course switching device 40 for switching to an air course for supplying outdoor air into a room, and to an air course for exhausting indoor air to the outdoors. The blower section 50 is provided with a centrifugal blower 33 for sucking air from an axial direction and blowing off air in a circumferential direction, a suction chamber 31 formed larger than a suction port of the blower 33, and a blowoff chamber 32 formed on the blowoff side of the blower 33. The air course switching device 40 is provided with an outer shell 46 having a plurality of openings, an air course switching body 41 turnably arranged in the outer shell 46 and having a partition wall for dividing the inside into a plurality of air courses, and a driving device 47 for turning the air course switching body 41 to switch communication between the plurality of air courses of the air course switching body 41 and the plurality of openings of the outer shell 46. The air course switching device 47 is juxtaposed to overlap the suction chamber 31 of the blower section 50.

Owner:HITACHI APPLIANCES INC

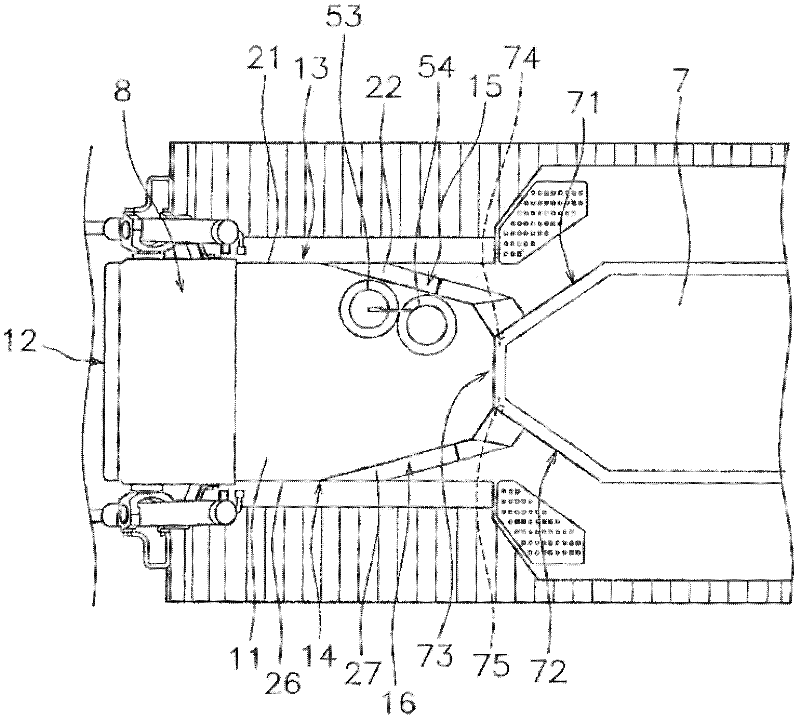

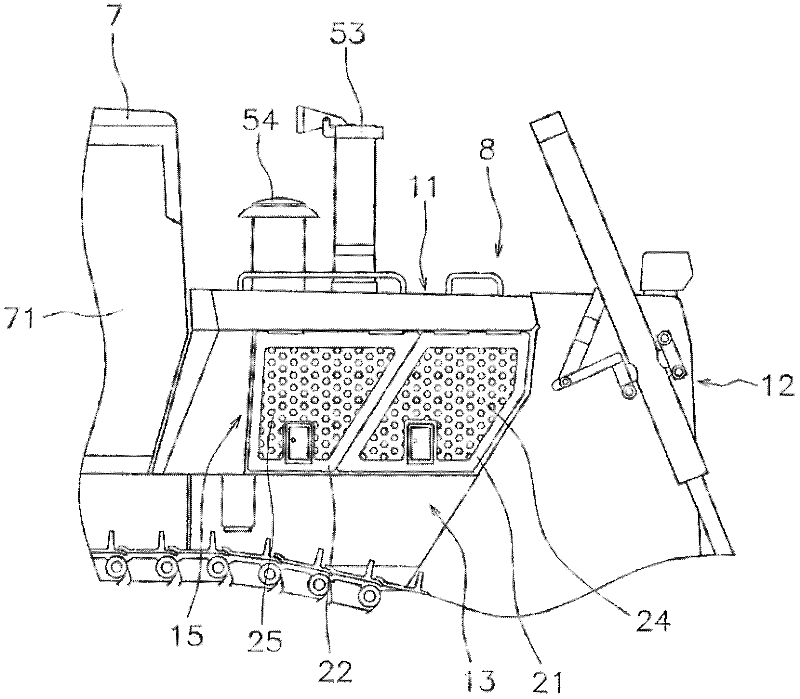

Work vehicle

ActiveCN102666174AReduce cooling efficiencyGreat accessExhaust apparatusSilencing apparatusEngineeringHeat spreader

In a work vehicle, an engine compartment is disposed forwards of a cab. An exhaust gas treatment device is disposed over an engine in the engine compartment. A radiator is disposed forwards of the exhaust gas treatment device (33) in the engine compartment. A blower is configured to generate an airflow passing through the radiator from back to front of the radiator. The exhaust gas treatment device is slanted with respect to a vehicle width direction for increasing a distance between the exhaust gas treatment device and the radiator towards a first lateral face portion. Further, the first lateral face portion includes air inlets facing a space between the exhaust gas treatment device and the radiator.

Owner:KOMATSU LTD

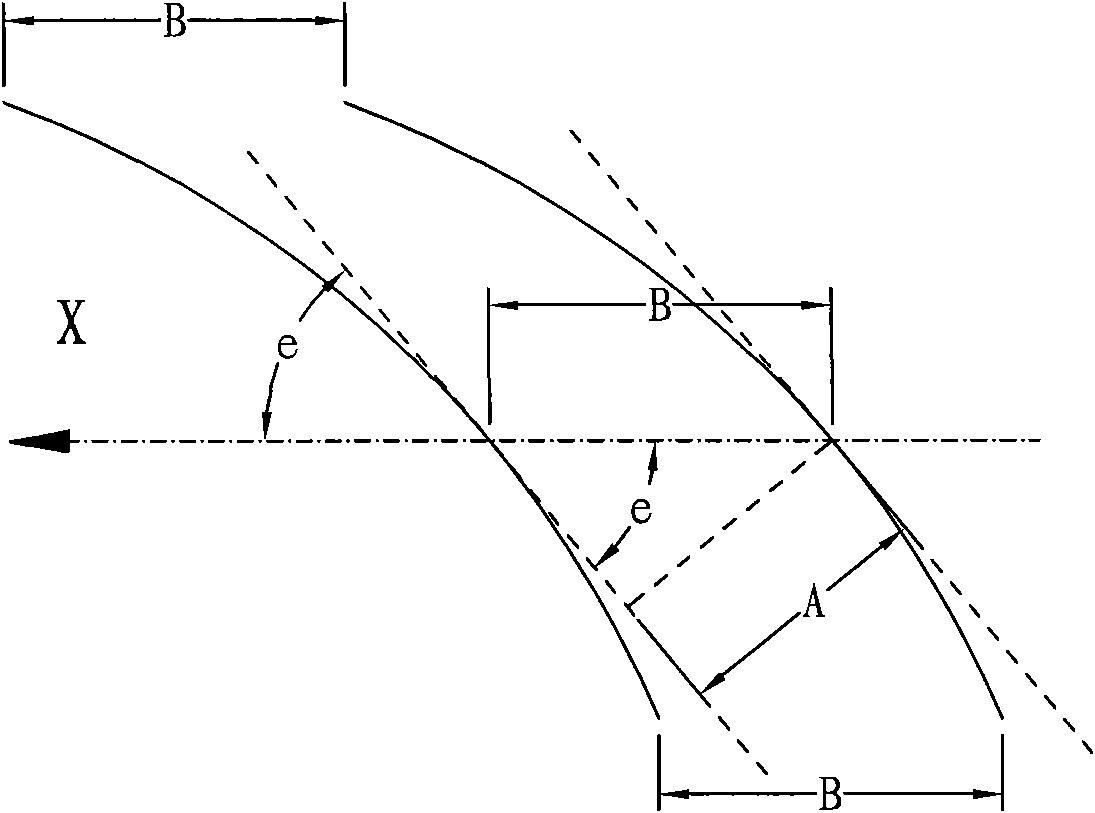

Finned tube type heat exchanger and manufacture method thereof

ActiveCN101907374AImprove the uniformity of heat transfer performanceImprove uniformityEvaporators/condensersNoise suppressionAir volumeEngineering

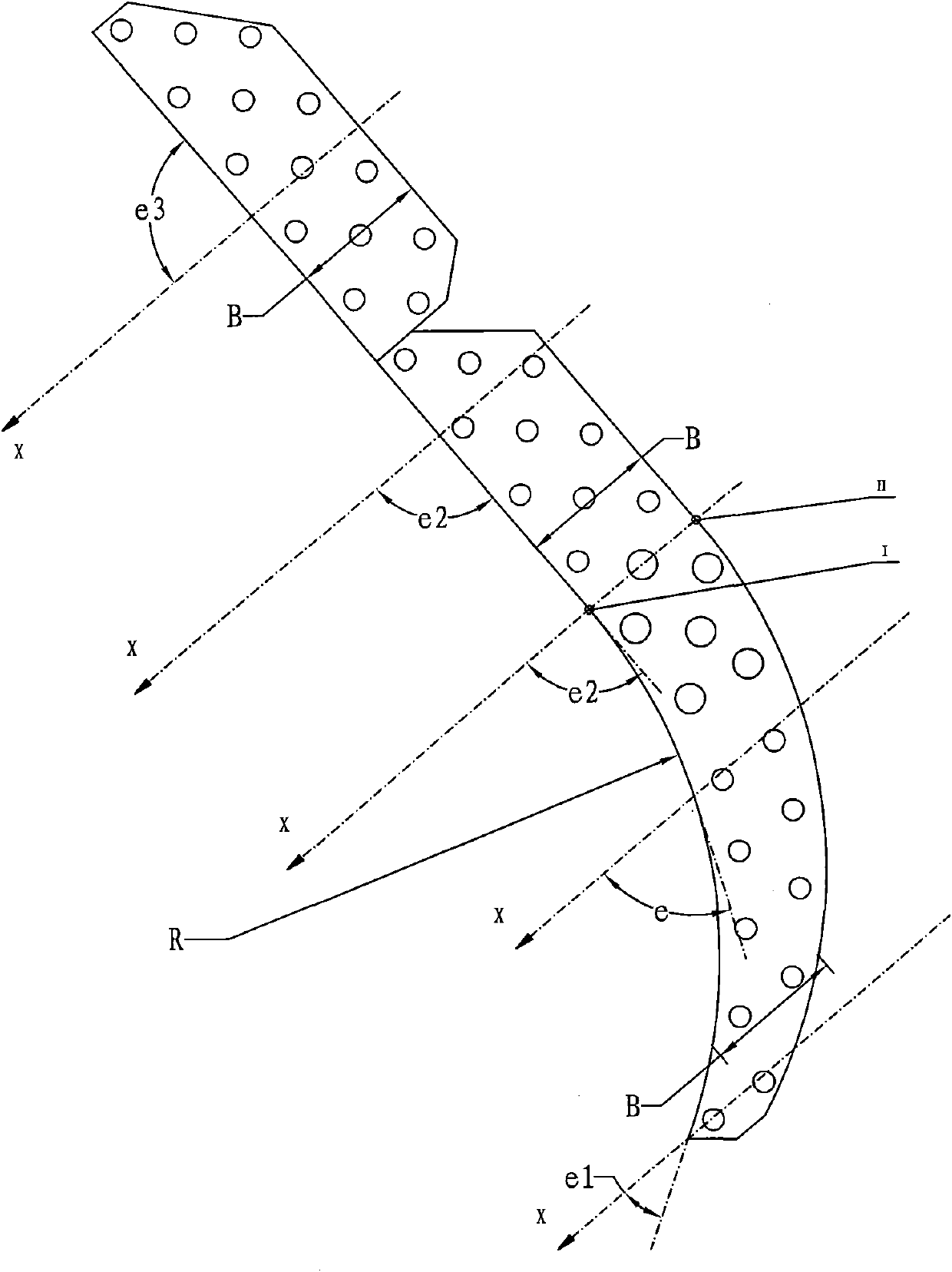

The invention relates to a finned tube type heat exchanger and a manufacture method thereof. The finned tube type heat exchanger is arranged in an indoor unit frame with an air inlet and an air outlet. A flow-through fan is also arranged in the indoor unit frame, and the finned tube type heat exchanger is arranged around the flow-through fan. The finned tube type heat exchanger comprises a first heat exchanger fin and a second heat exchanger fin. The second heat exchanger fin comprises an upper fin and a middle and lower fin; and the edge of the middle and lower fin is an arc. The average airflow direction flowing through the whole second exchanger fin is set as an X direction. The distances between the air-feeding edges and the air-exhausting edges at all positions of the second exchanger fin along the average airflow direction are same, wherein the air-exhausting edge of the middle and lower fin is tangent to the air-exhausting edge of the upper fin at a first tangency point; and the air-feeding edge of the middle and lower fin is tangent to the air-feeding edge of the upper fin at a second tangency point. The invention has the characteristics of increasing the heat exchanging capacity, enlarging the air quantity, reducing the noise, and promoting the exhaustion of condensate water.

Owner:MIDEA GRP CO LTD

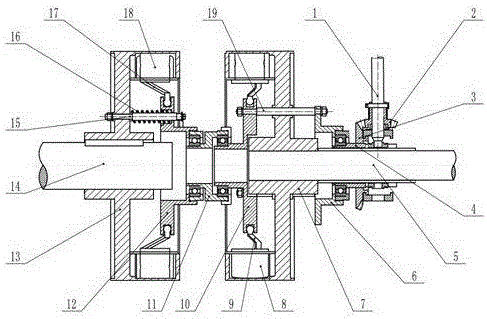

Two-stage blade adjusting mechanism for opposite-rotating axial flow fan

InactiveCN105673560ASolve the problem of high manufacturing and maintenance costsReduce consumptionPump componentsAxial flow pumpsImpellerTransmitted power

The invention discloses a two-stage blade adjusting mechanism for an opposite-rotating axial flow fan. A blade adjusting operation shaft is adjusted to drive a pair of bevel gears to transmit power to a threaded pair coaxial with a transmission shaft; then the threaded pair is used for converting rotation movement of the bevel gears into linear movement to push a thrust disc in a hub, and therefore the blade installation angle of a first impeller is adjusted; and power is transmitted through a spacer bush, and the blade installation angle of a second impeller is adjusted. Thus, synchronization adjustment and arbitrary angle adjustment of the two-stage blade installation angles is achieved. The mechanism is simple and compact in structure, low in manufacturing and maintaining cost and capable of being widely applied to large, medium and small size opposite-rotating axial flow fans.

Owner:TAIYUAN UNIV OF TECH

Noise reducing and anti-freezing device outside power plant cooling tower

InactiveCN101377387AStrong sound absorption and noise reduction abilityImprove noise reductionSound producing devicesTrickle coolersCooling towerAnti freezing

The invention provides a noise reducing and antifreezing device used outside a power plant. One of two adjacent noise absorbing plates is fixed with and has an included angle with a horizontal beam, while the other one is arranged in a rotatable way; the cross-sections of the two noise absorbing plates are in a bullet-shape, the effective size of noise absorption is larger, and the gap between the two noise absorbing plates is adjustable, therefore, sound waves produced by a noise source are attenuated repeatedly when passing between the two noise absorbing plates arranged in a slanted way, and the attenuating path is increased; under the conditions of the same distribution density, the effect of noise reduction is more ideal; compared with the prior vertical arrangement proposal, under the same noise reduction conditions, the number of noise absorbing plates adopted by the slanted arrangement proposal of the invention can be reduced by 20 to 40 percent, therefore, the proposal is an ideal proposal to reduce production cost; as the included angle between the two noise absorbing plates is adjustable, the effect of noise reduction can be improved, the cooling tower has antifreezing effect, and the safe and normal operation of the cooling tower in winter is ensured.

Owner:常州金坛塑料厂

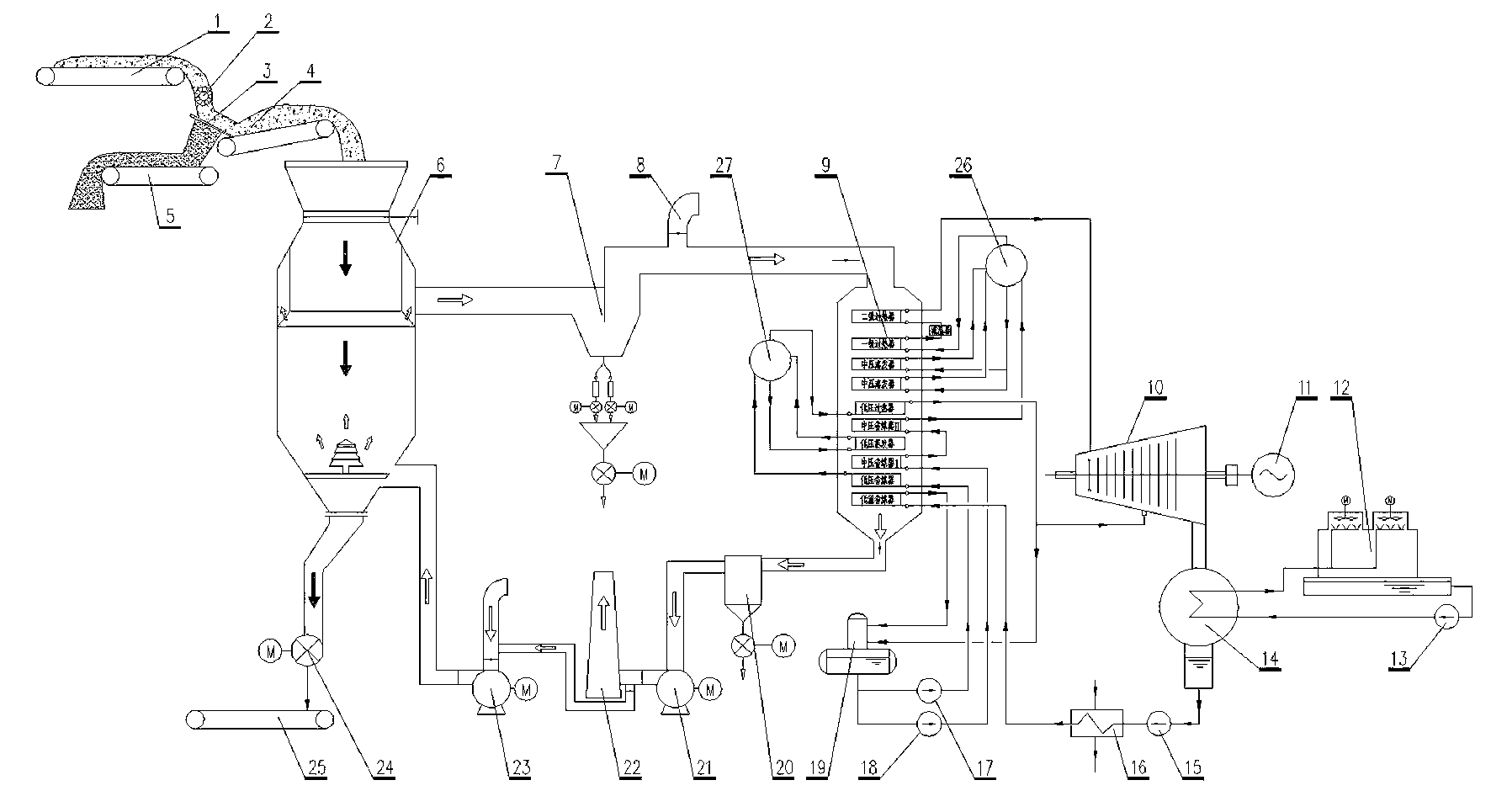

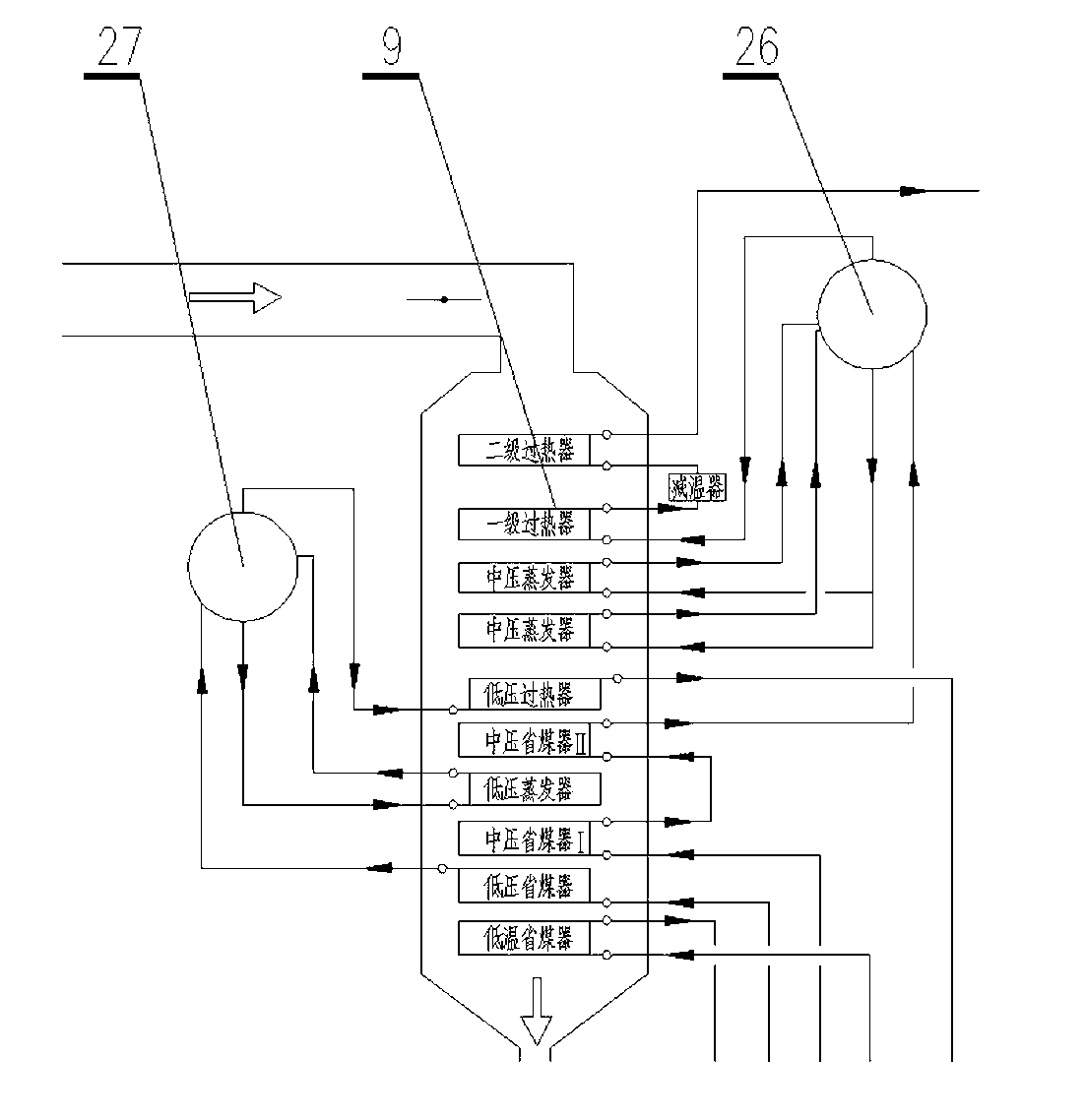

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

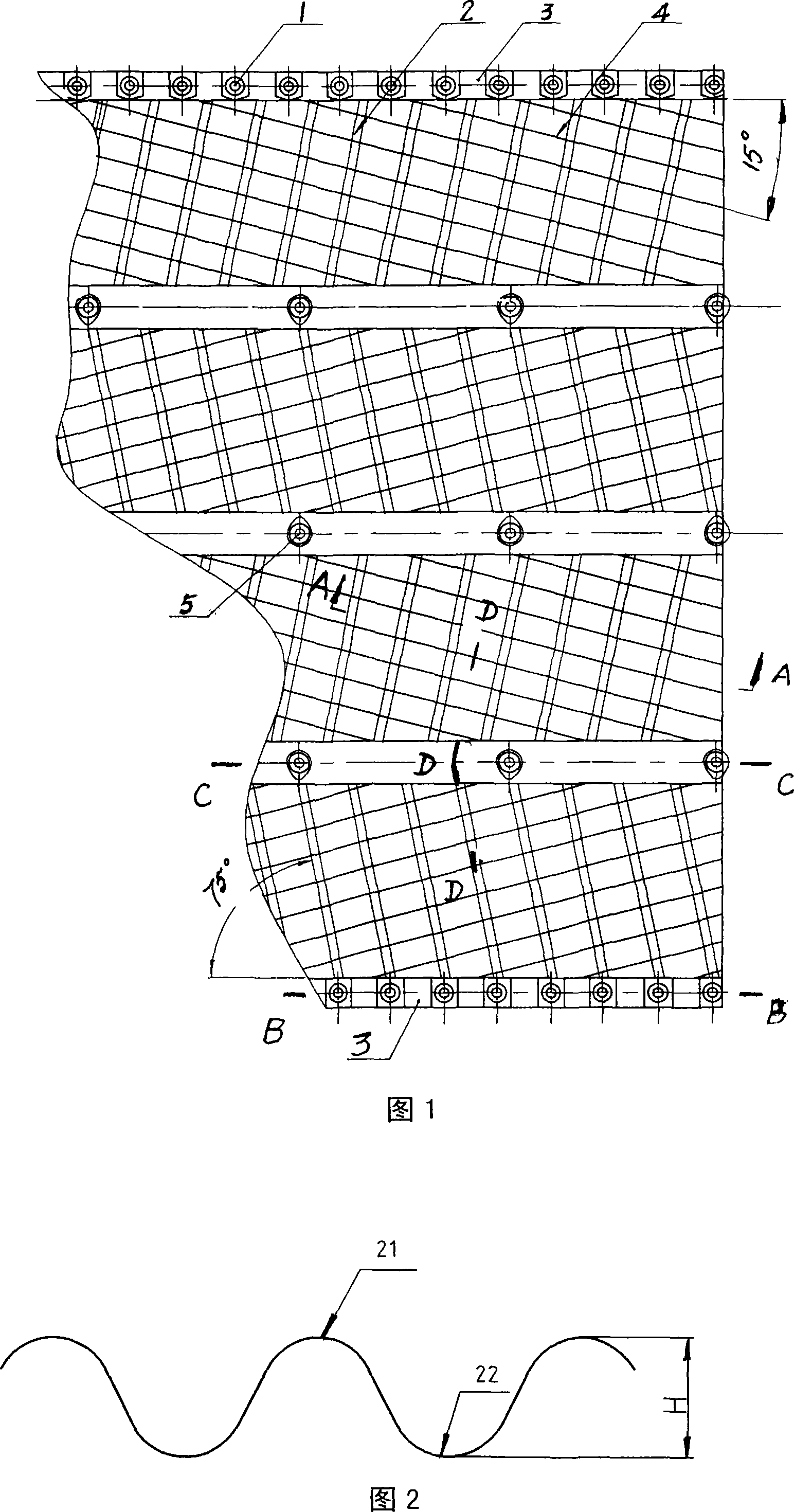

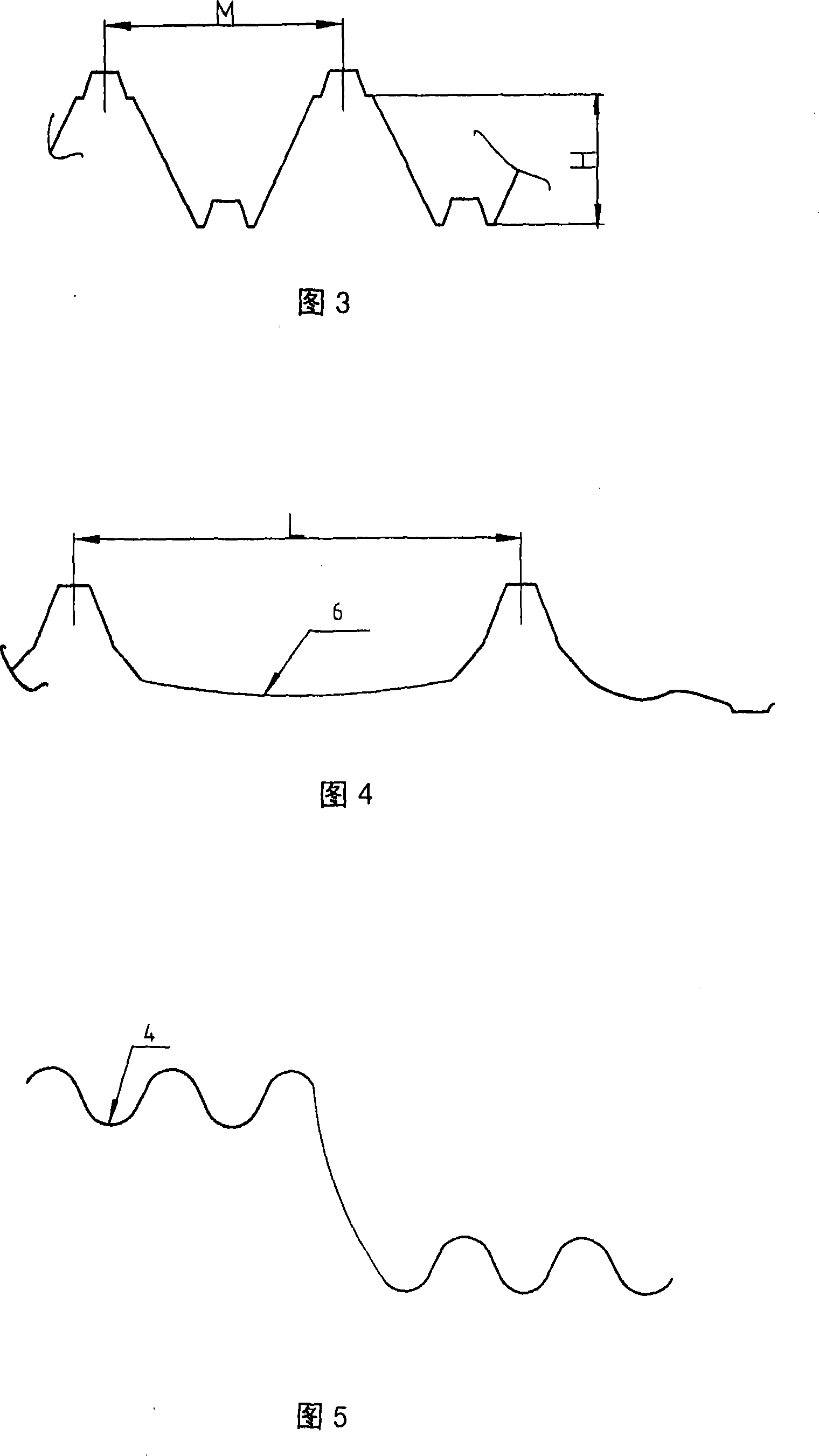

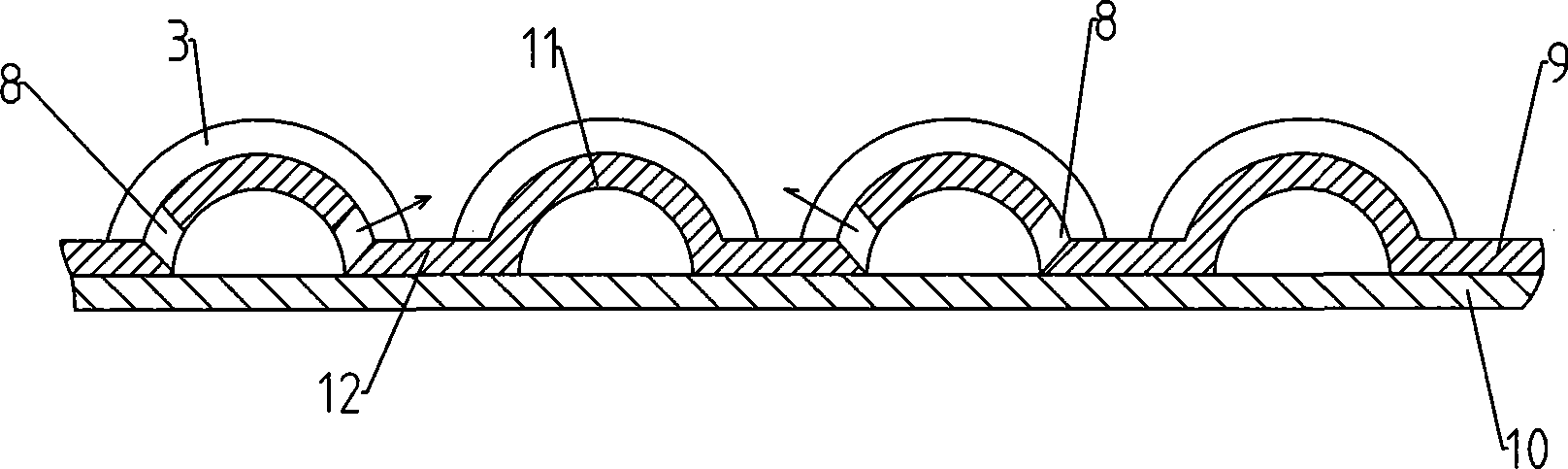

New type dual oblique wave spraywater stuffing for cooling tower

This invention relates to new double-slope wave trickle fillings of a cooling tower, in which two adjacent sets of main cooling wave bands are arranged reversely in stagger with a pitch of waves in between, the distance of the internal binding points is 2-3 times that of the exterior one, a secondary stagnant wave groove is set on the wave band and the cross section is a sine wave, the angle between the stagnant wave groove and the length edge is 15deg, a shunt bank is set between the peak of a main wave band and the valley of the adjacent main wave band to transit smoothly and the highest point of the shunt bank is 4 / 1-2 / 1 of the peak.

Owner:常州金坛塑料厂

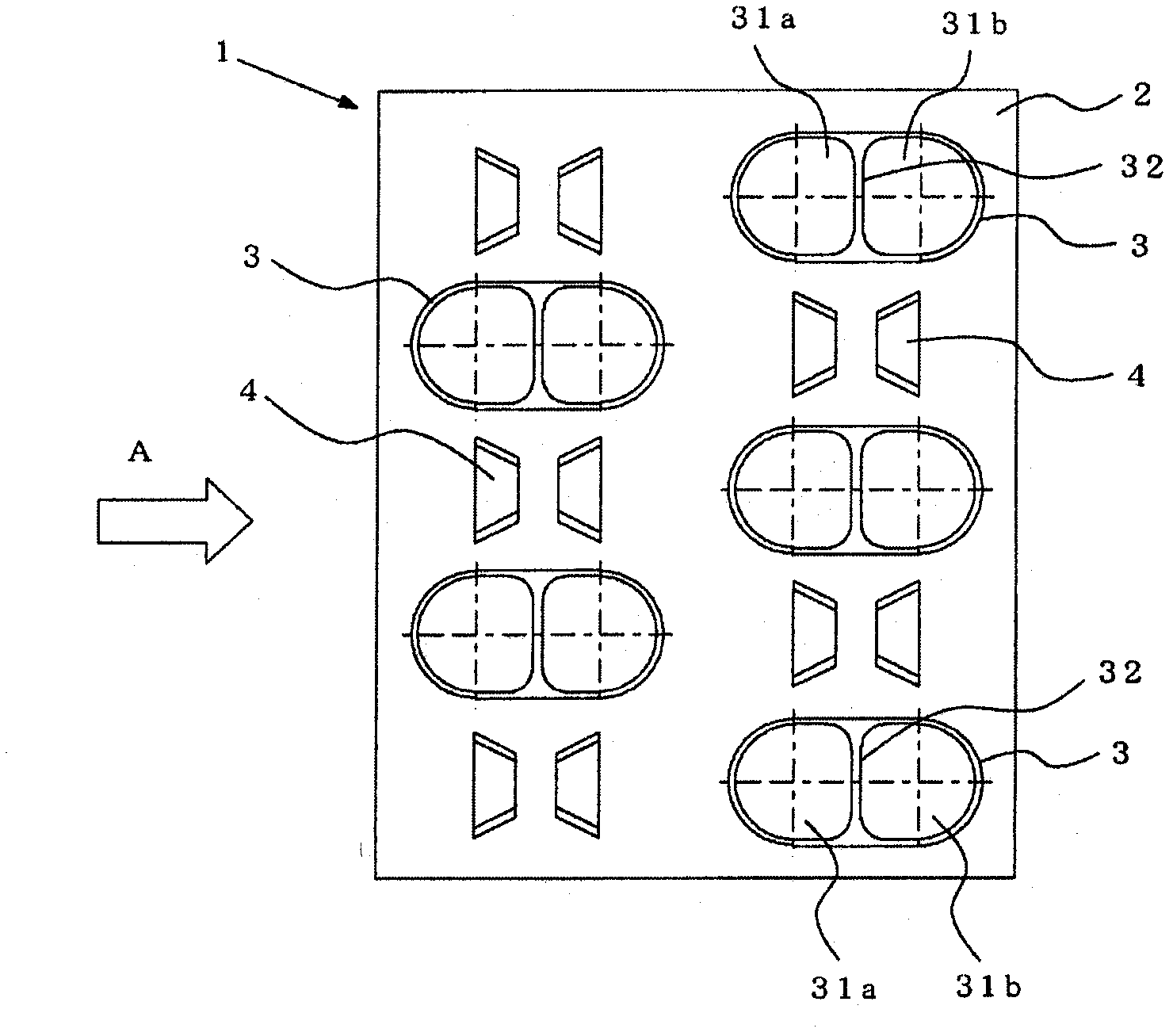

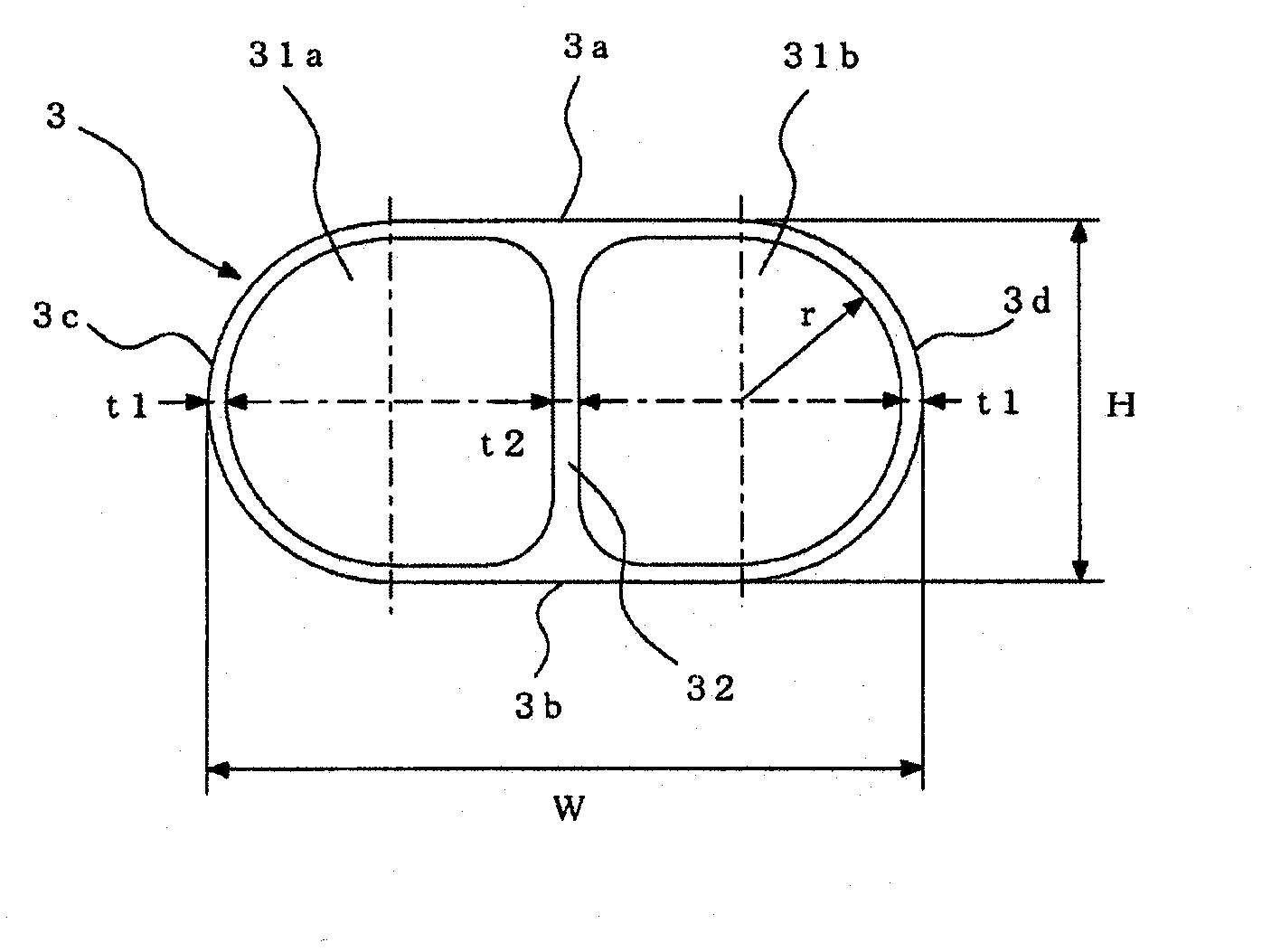

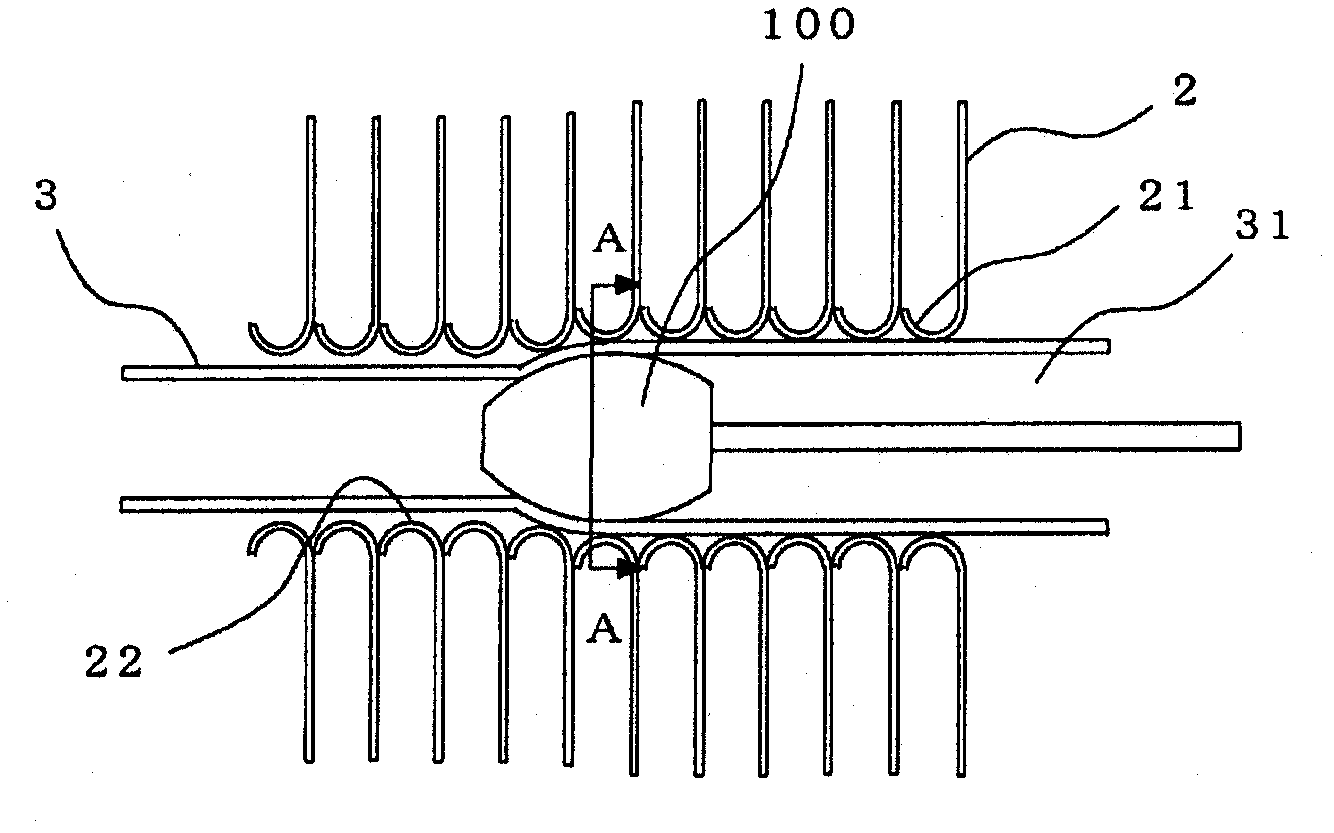

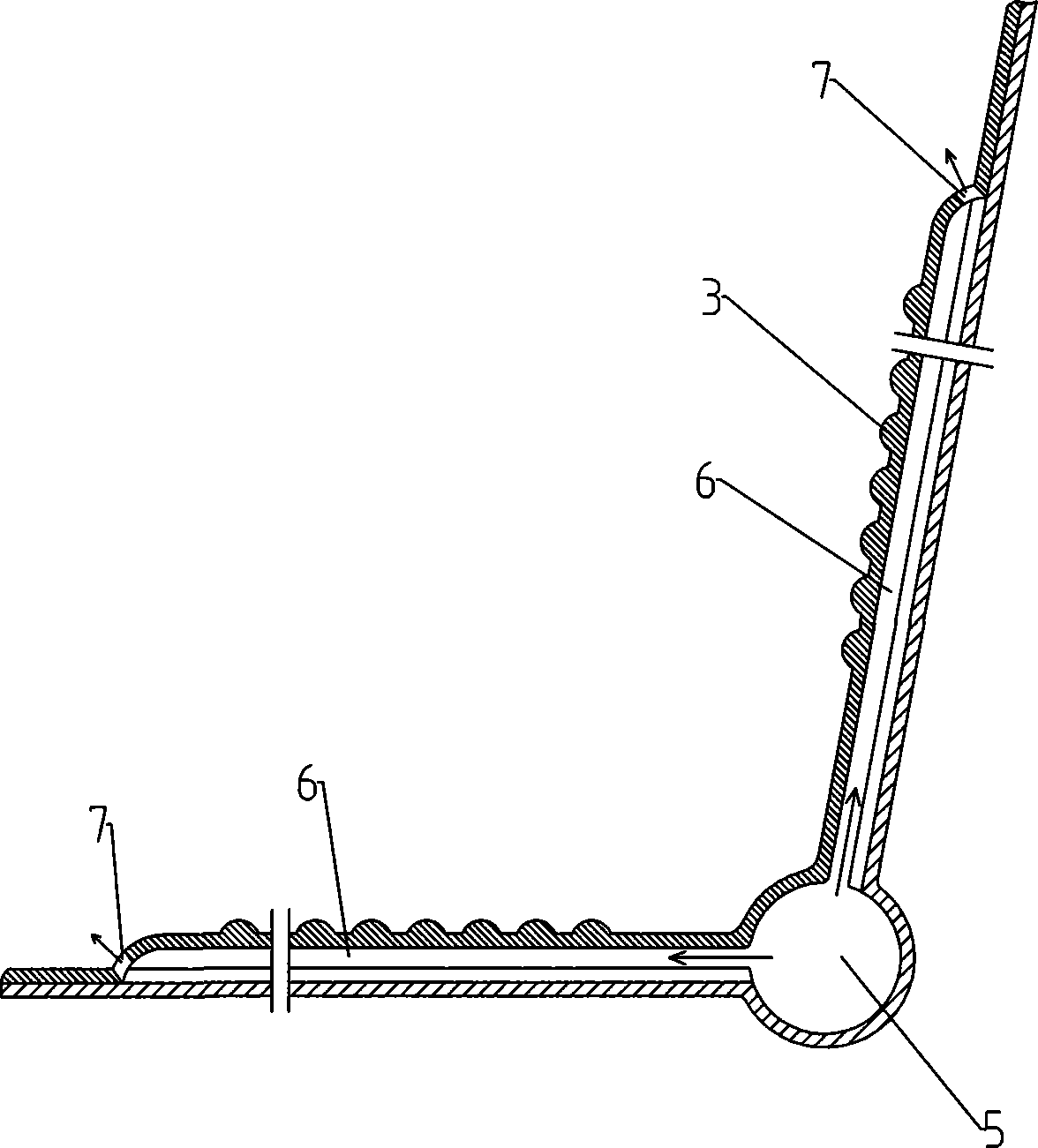

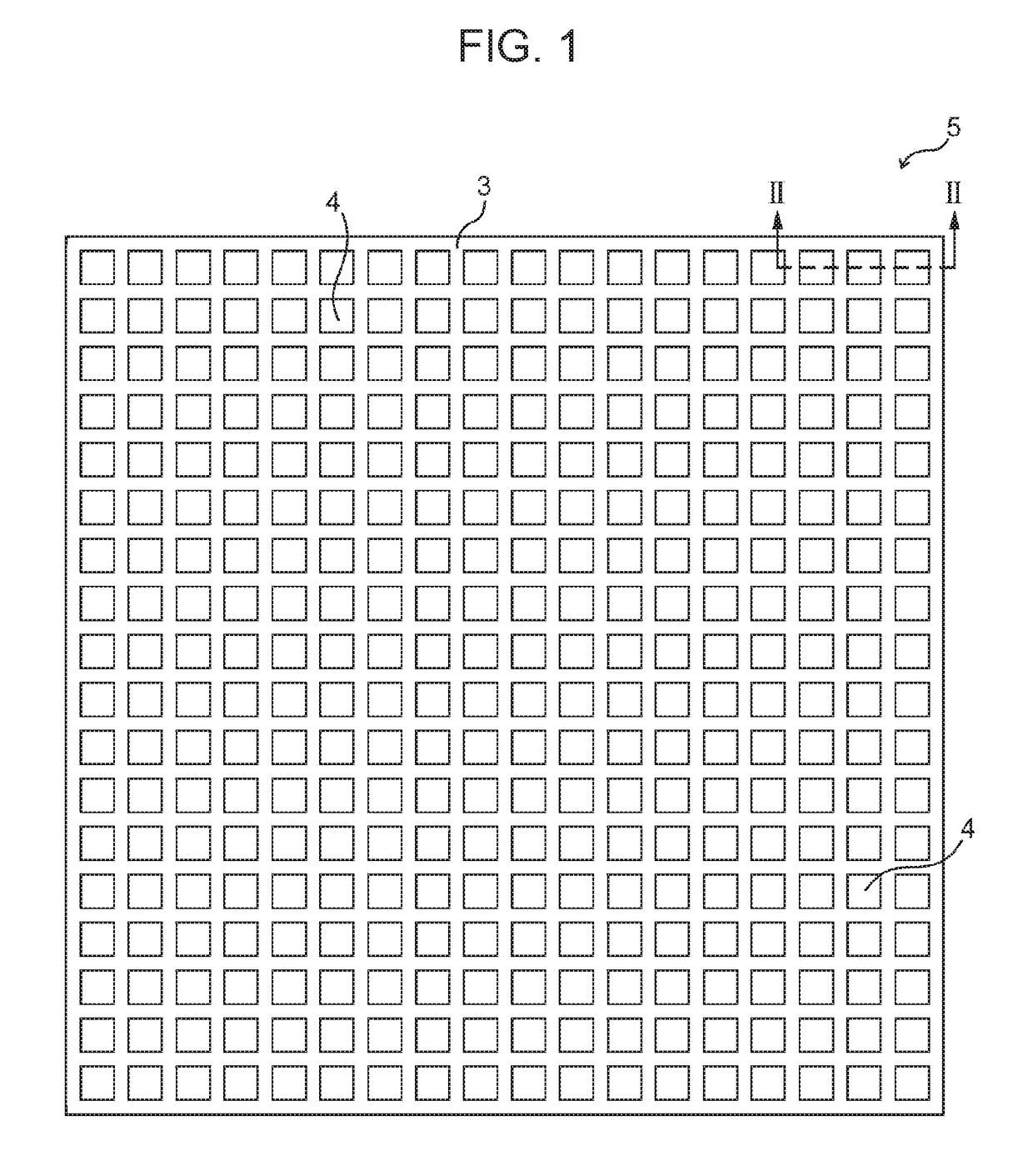

Heat exchanger and air conditioner having the heat exchanger

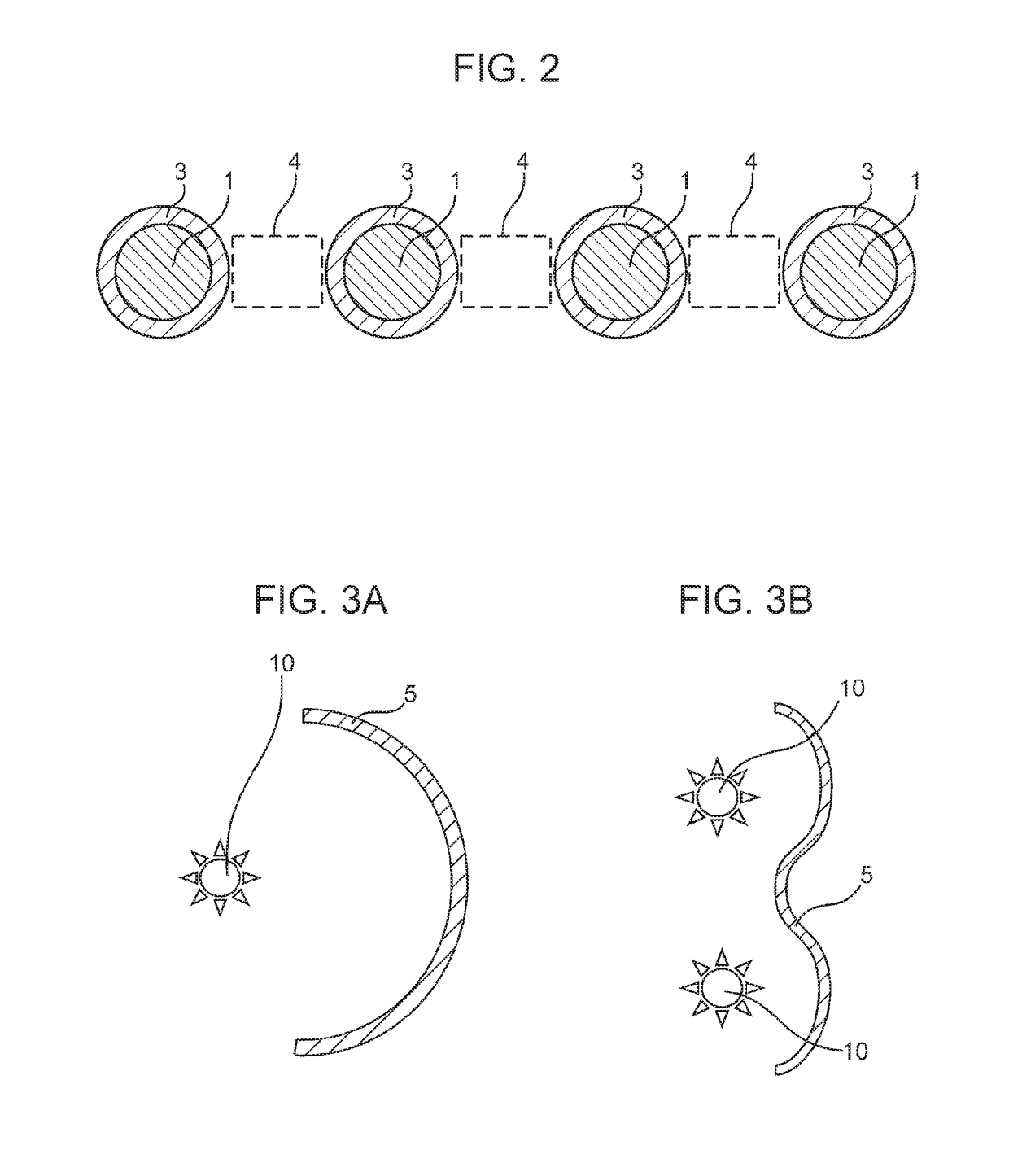

ActiveCN102066866AImprove heat transfer performanceLow ventilation resistanceCompression machines with non-reversible cycleEvaporators/condensersEngineeringAir conditioning

Provided are a heat exchanger and an air conditioner equipped with the heat exchanger. The heat exchanger has enhanced heat exchange ability and reduced airflow resistance. These are achieved by using heat transfer tubes which are not deformed by the pressure therein despite the heat transfer tubes having a flat shape, which make very close contact with plate-like fins, and which are mounted easily. The heat exchanger is provided with plate-like fins (2) arranged at predetermined intervals, and also with flat heat transfer tubes (3) passed through the plate-like fins (2) in the direction perpendicular to the plate-like fins (2) and allowing a refrigerant to flow in the heat transfer tubes (3). Each heat transfer tube (3) has an outer shape having flat outer surfaces arranged along the direction of airflow and having a substantially oval cross-sectional shape. Inside each heat transfer tube (3) are formed first and second refrigerant flow paths (31a, 31b) which are two symmetrical substantially D-shaped through-holes arranged with a partition wall (32) provided between the first and second refrigerant flow paths (31a, 31b). The first and second refrigerant flow paths (31a, 31b) areexpanded in diameter by means of a pipe expanding billet ball to join each heat transfer tube (3) to the plate-like fins (2).

Owner:MITSUBISHI ELECTRIC CORP

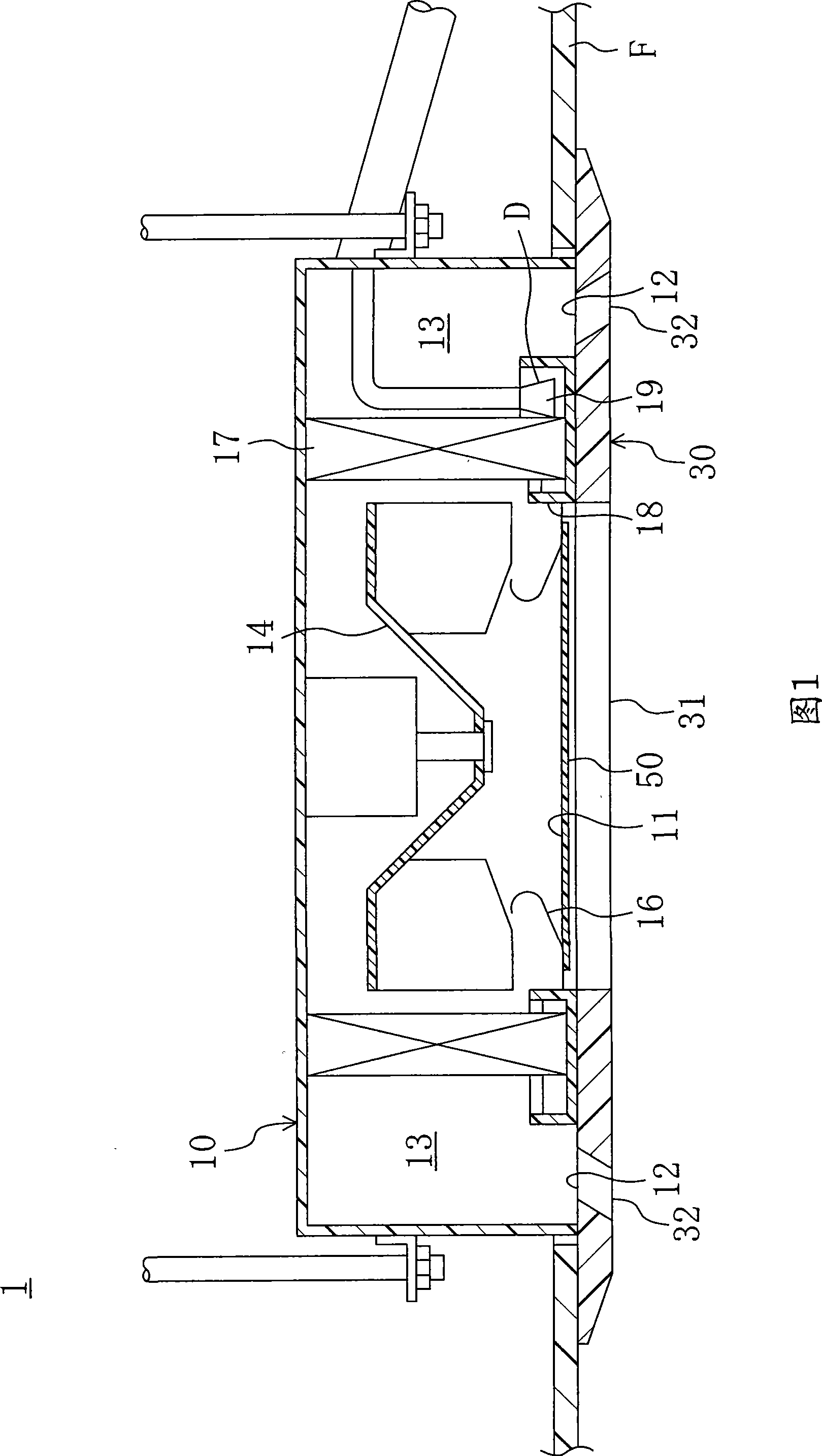

Tridimensional distributed type material stream circulating method and ventilated synthetic energy-saving method

InactiveCN101280948ALow investment costLow running costAgriculture tools and machinesInternal combustion piston enginesSteam condensationChemical reaction

The present invention provides a tridimensional distributed materials throughflow method and ventilated synthetic energy-saving method, applied to physical or chemical reaction field of biomass fermentation, thermal decomposition, drying, fluid and materials thermal transmission transfer of mass beween fluid and materials. Fluid inlet duct and outlet duct having throughflow holes bestrewed are arranged in materials, fluid passes through the materials layer through the throughflow in short distance to implement low resistance ventilation of materials, and uncontrolled ventilation without draught fan is implemented. Wind column can be added to use rotation stream inside the column and an optothermal increase system ventilation ability, and superabundance dynamic force can be used for power generation, and circumferential wind of the wind column can be used for power generation. the invention comprises methods of using warm air produced by discharged turbine tail steam condensation heat of thermal power generating plant to generate power or to be as uncontrolled ventilation smoke discharging dynamic force for boiler, and methods of uncontrolled ventilation fermentation type ecological urinal and polyporous material tridimensional arrangement throughflow thermal transmission transfer of mass employing polyporous material such as foam copper or the like.

Owner:张玉良

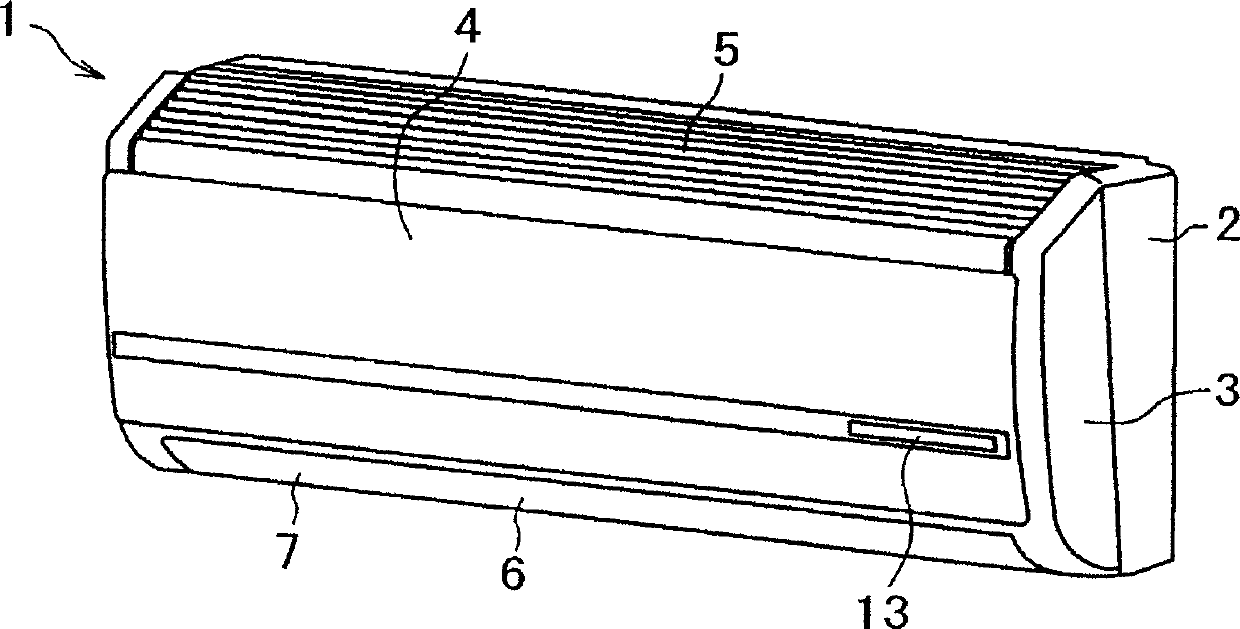

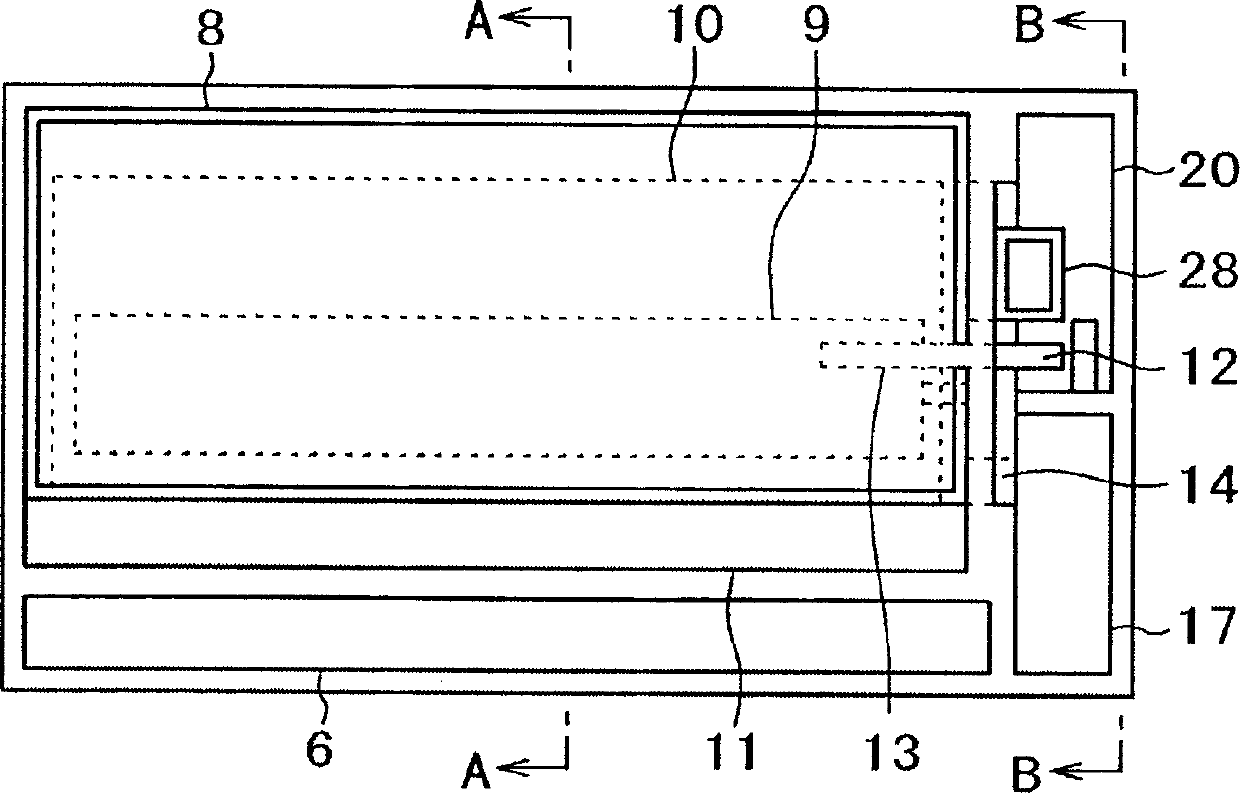

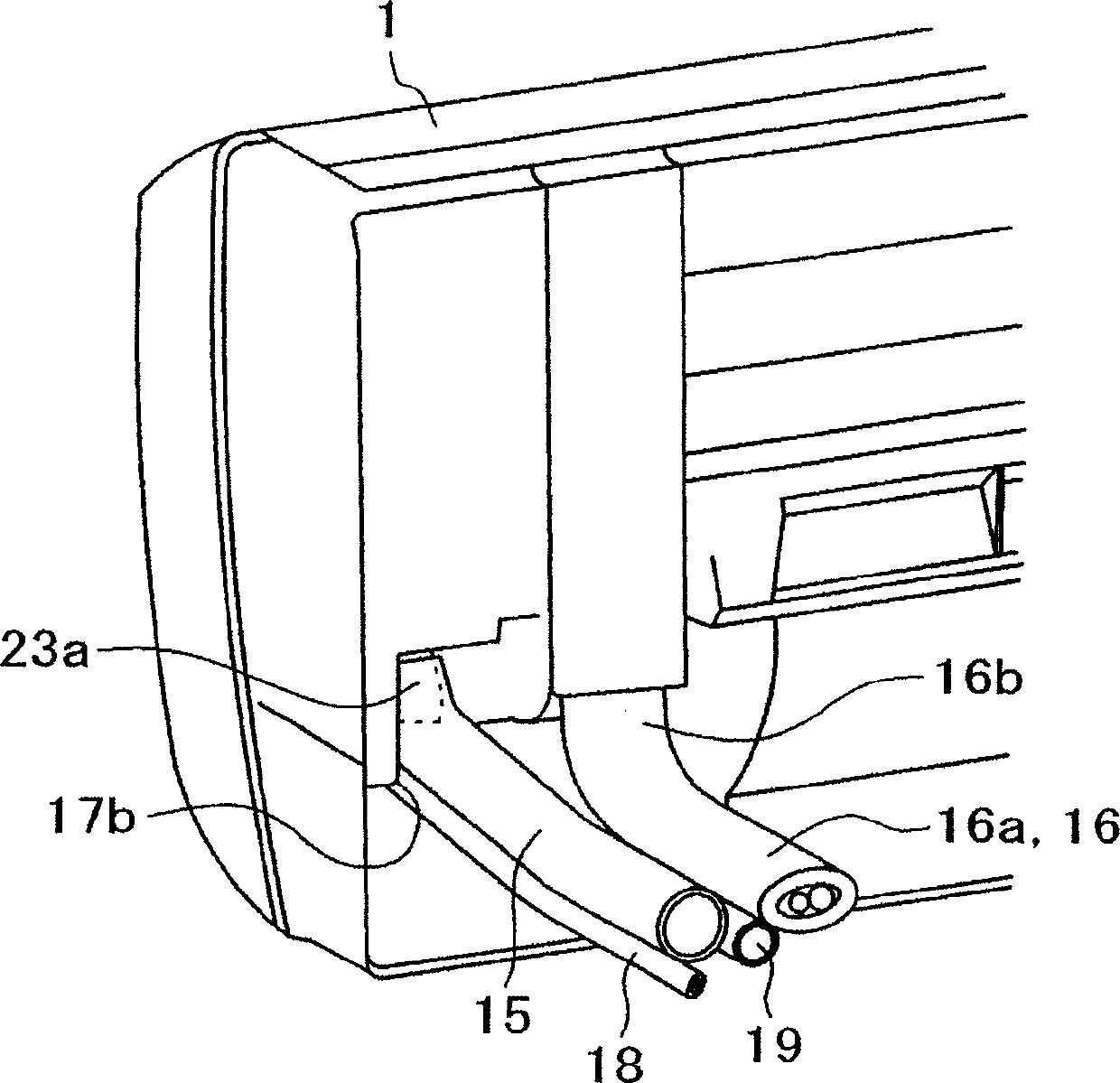

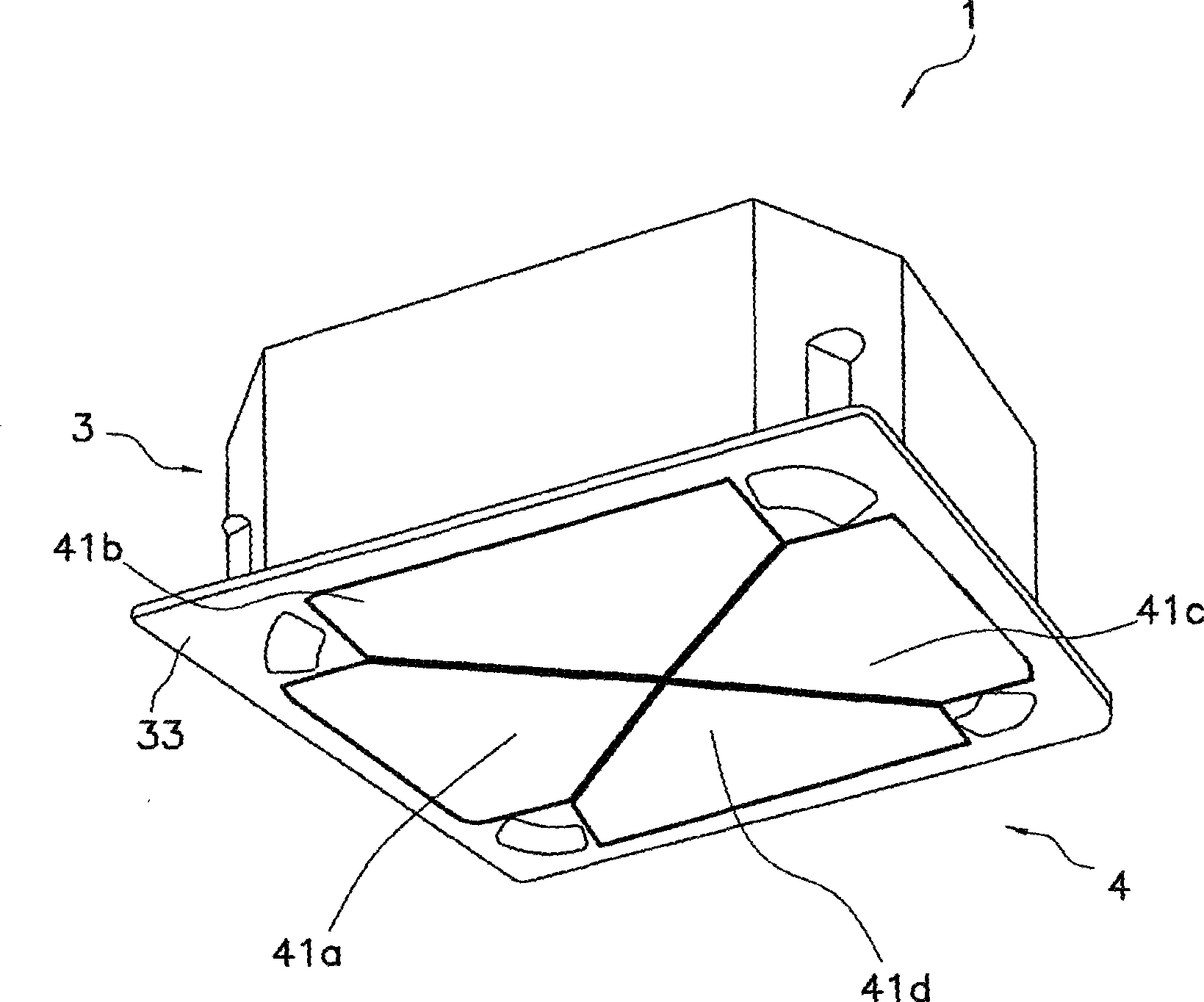

Air conditioning apparatus

InactiveCN101421563ABeautiful appearanceGuaranteed ventilationLighting and heating apparatusHeating and ventilation casings/coversEngineeringAir conditioning

An air conditioning apparatus includes a casing and a dividing cosmetic panel. The casing has a suction port and a discharge port. The dividing cosmetic panel has a plurality of dividing panels and an opening / closing moveable mechanism for varying the positions of the dividing panels relative to the suction port. The opening / closing moveable mechanism switches between a state in which the dividing panels are disposed in proximity to each other, thereby blocking air flow through the suction port, and a state in which the dividing panels are separated from each other to allow ventilation through the suction port.

Owner:DAIKIN IND LTD

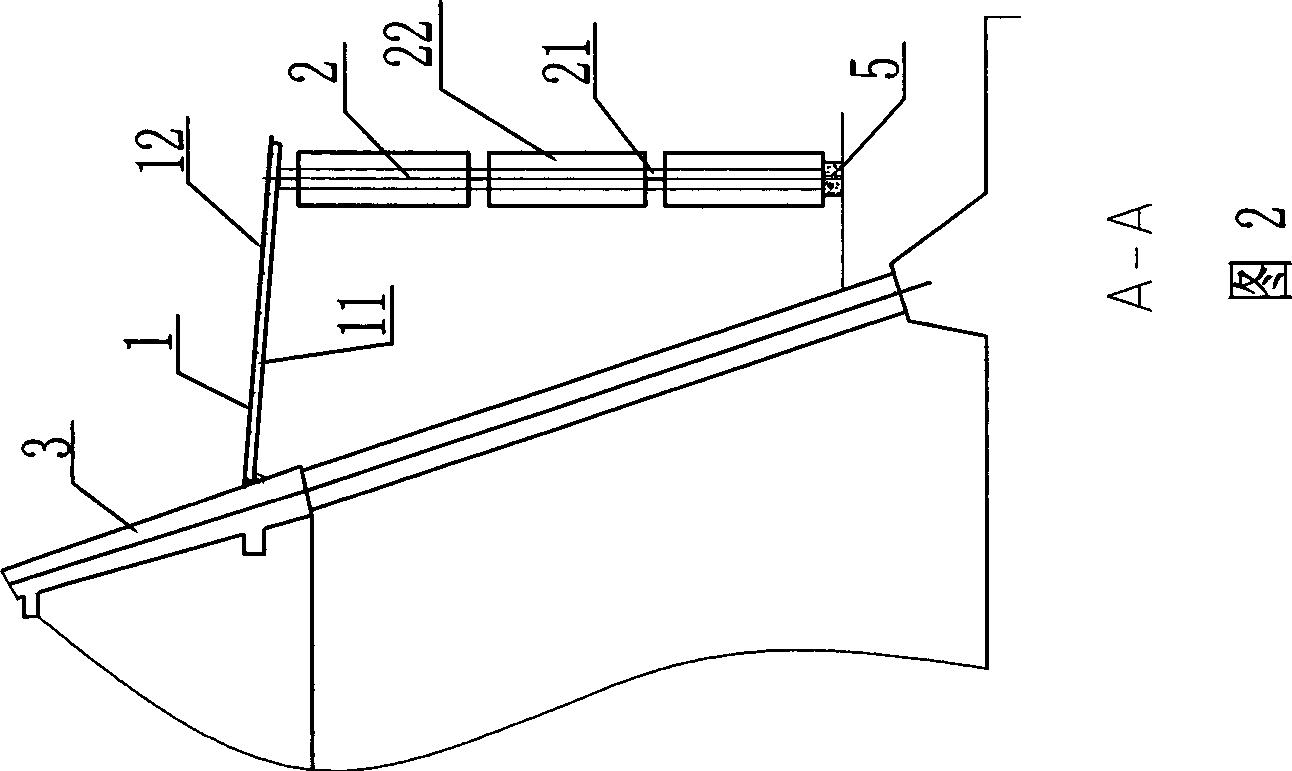

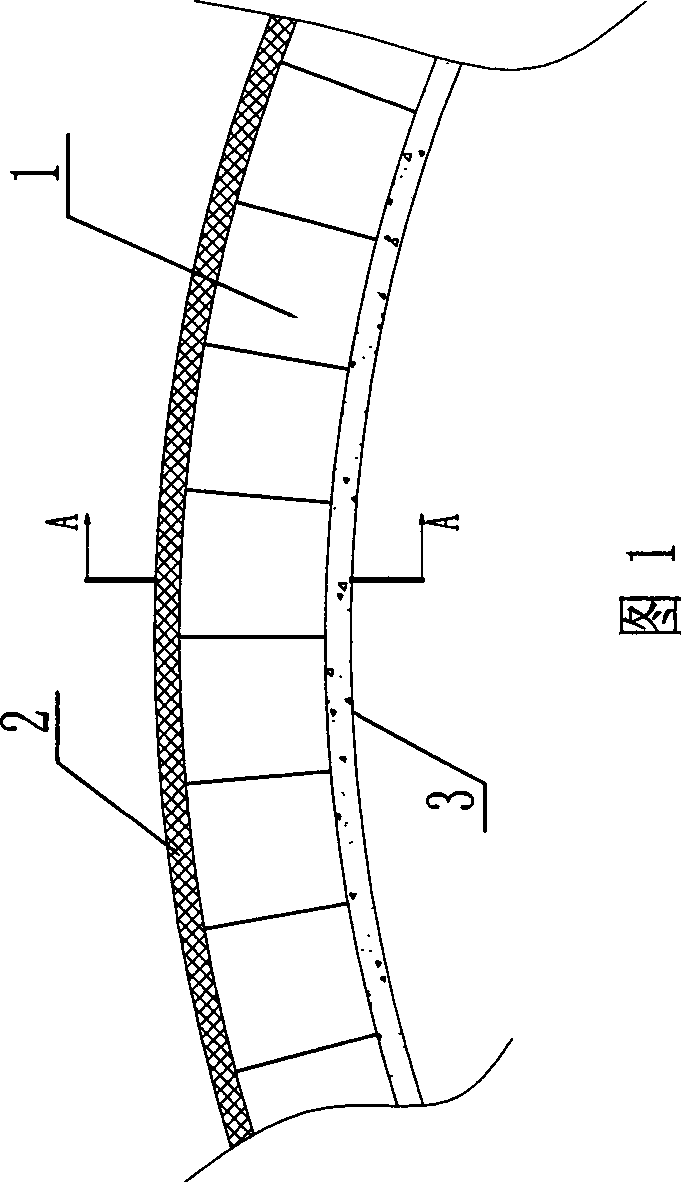

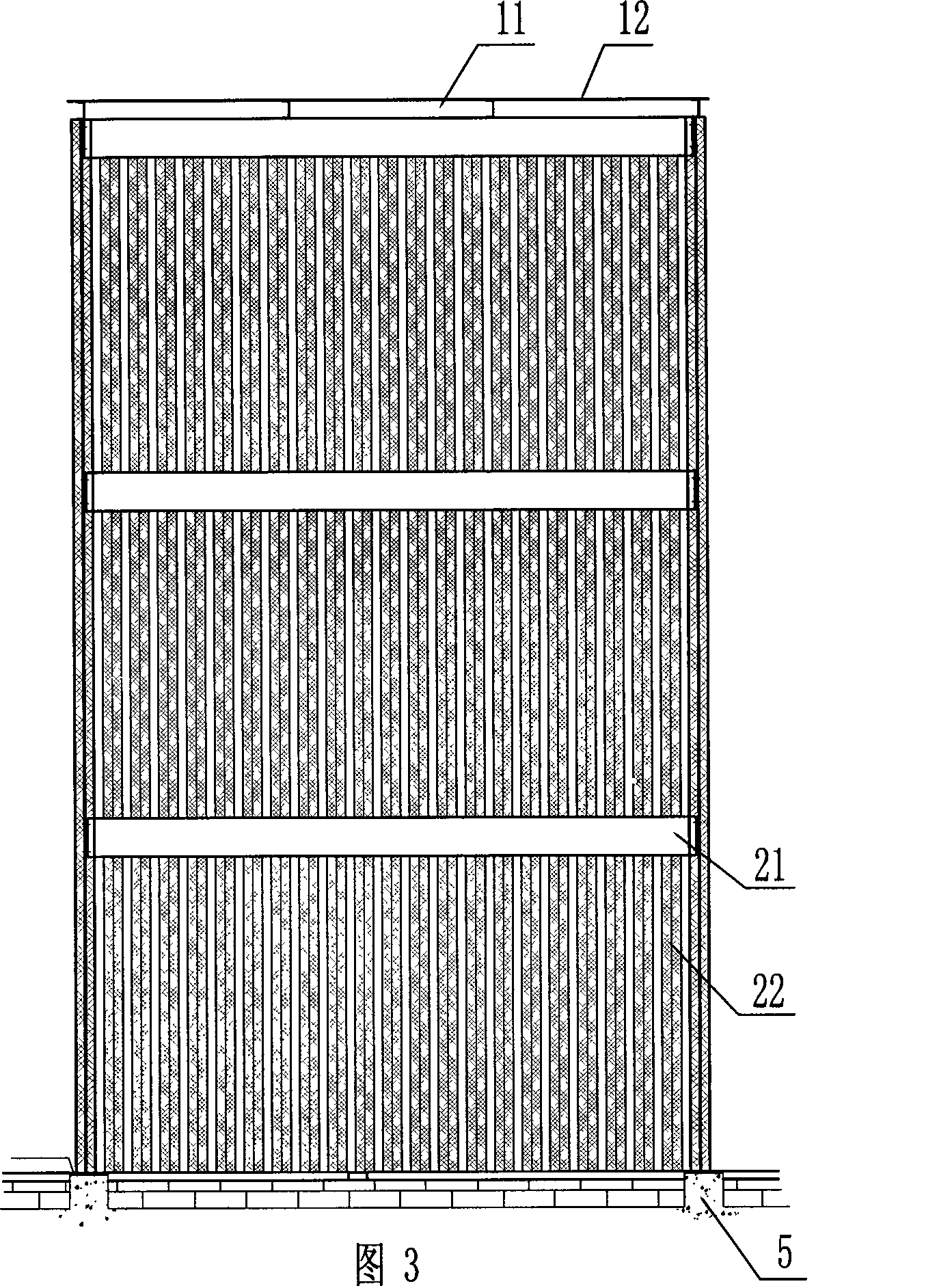

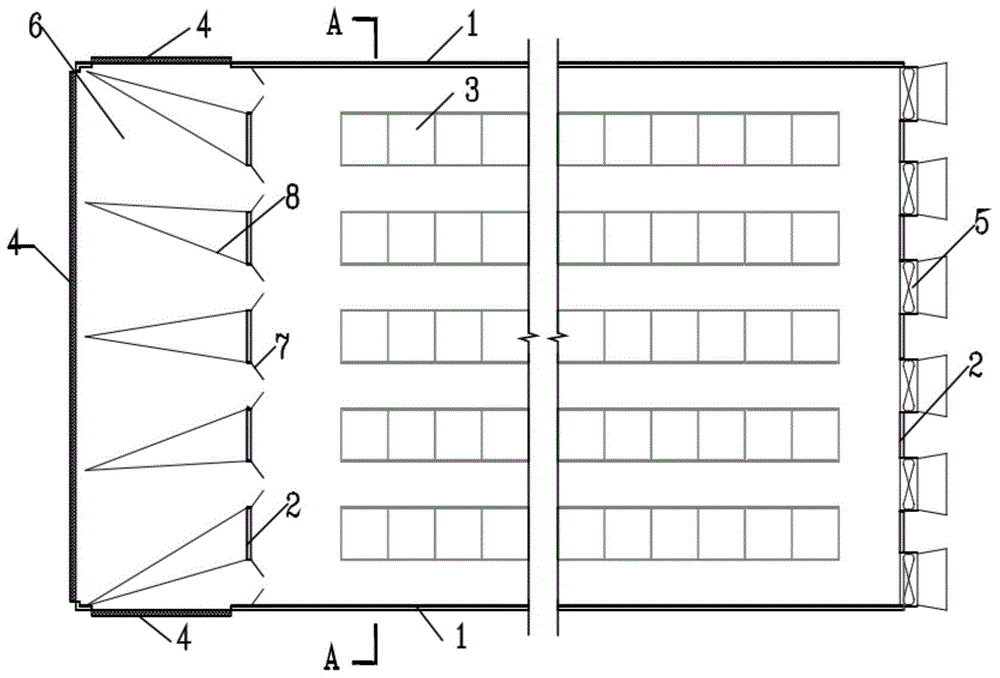

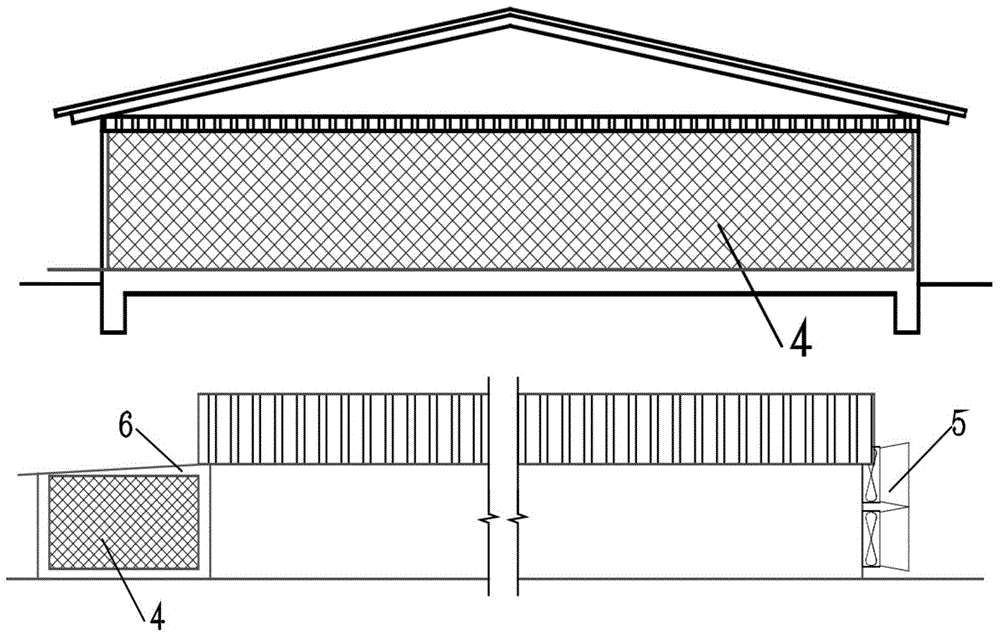

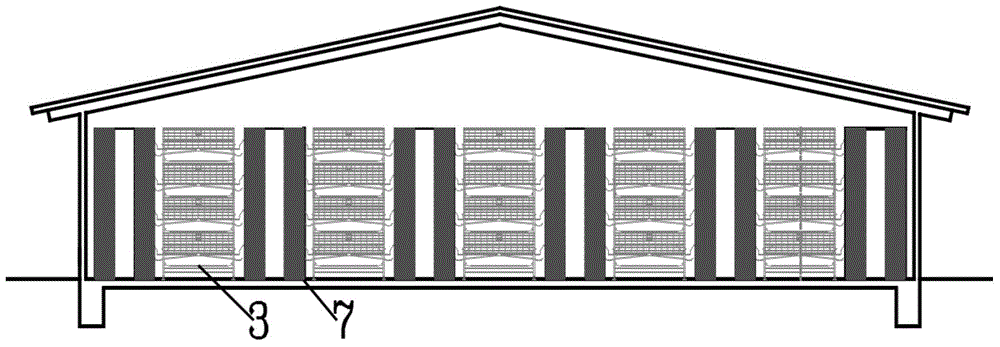

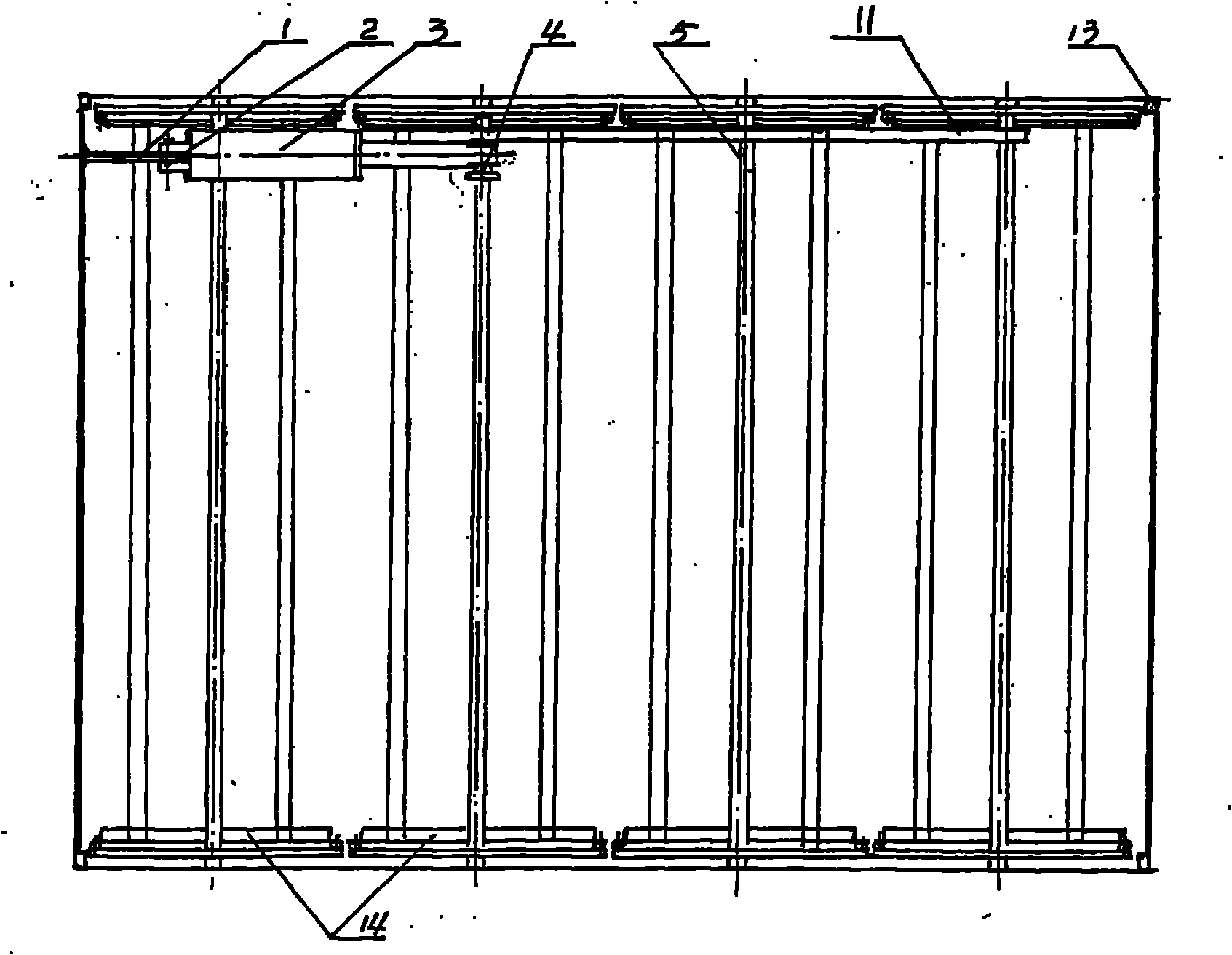

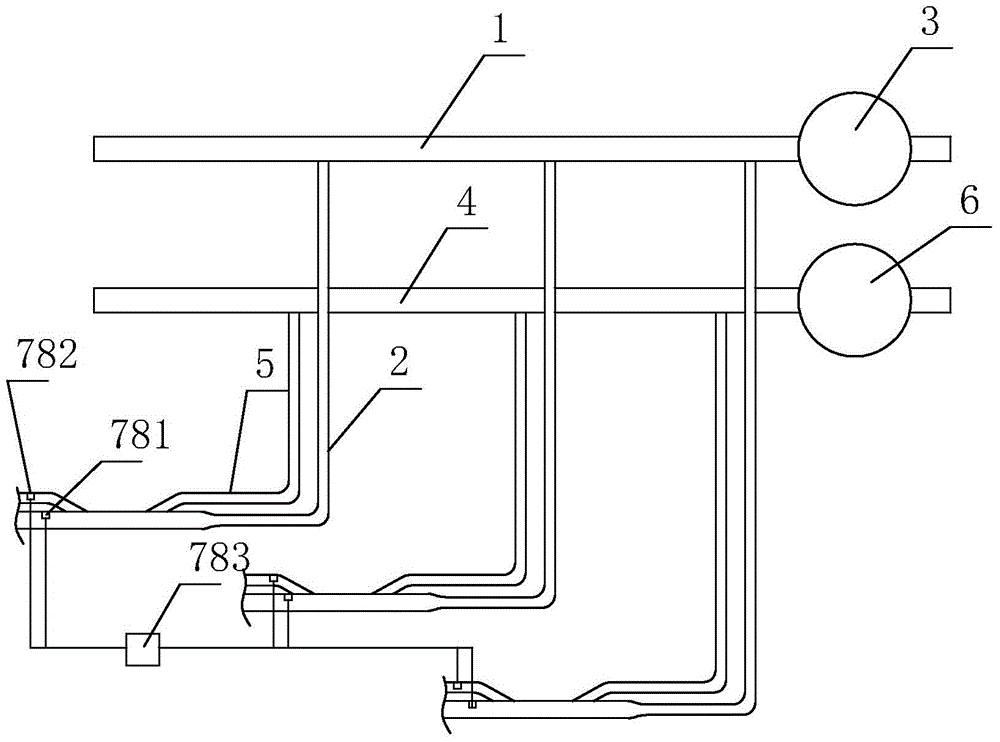

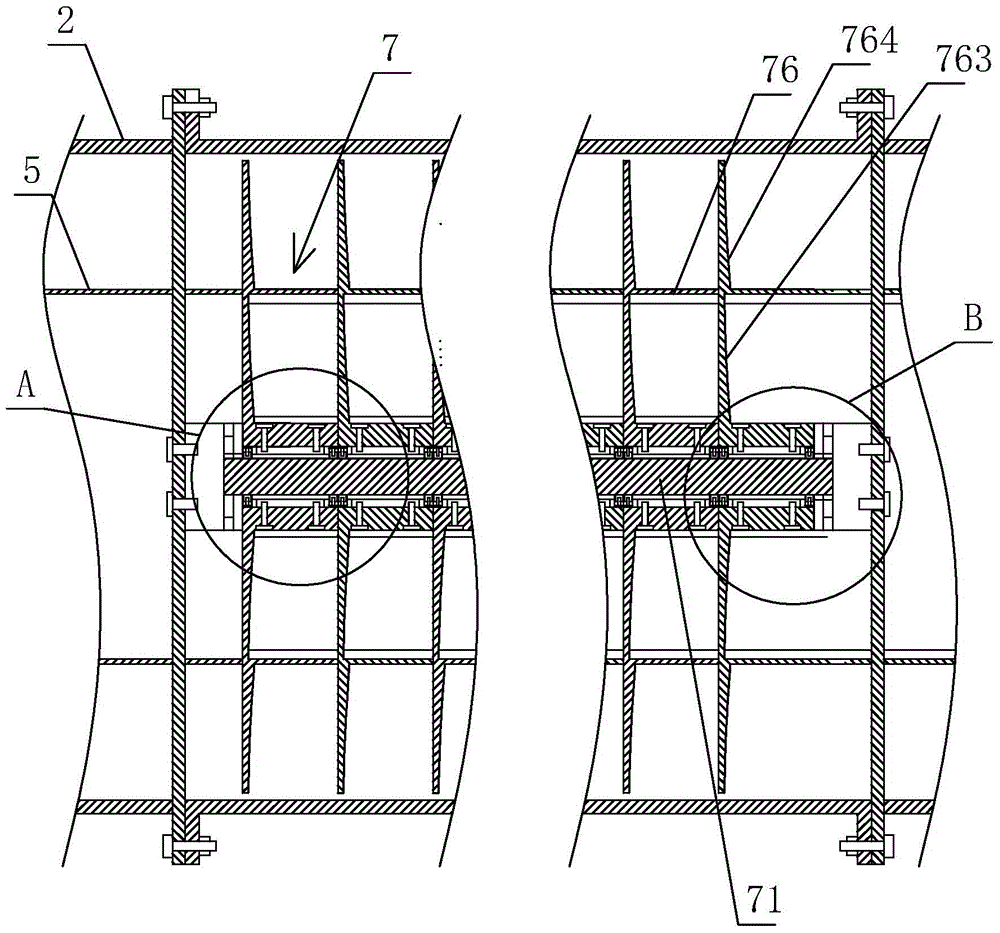

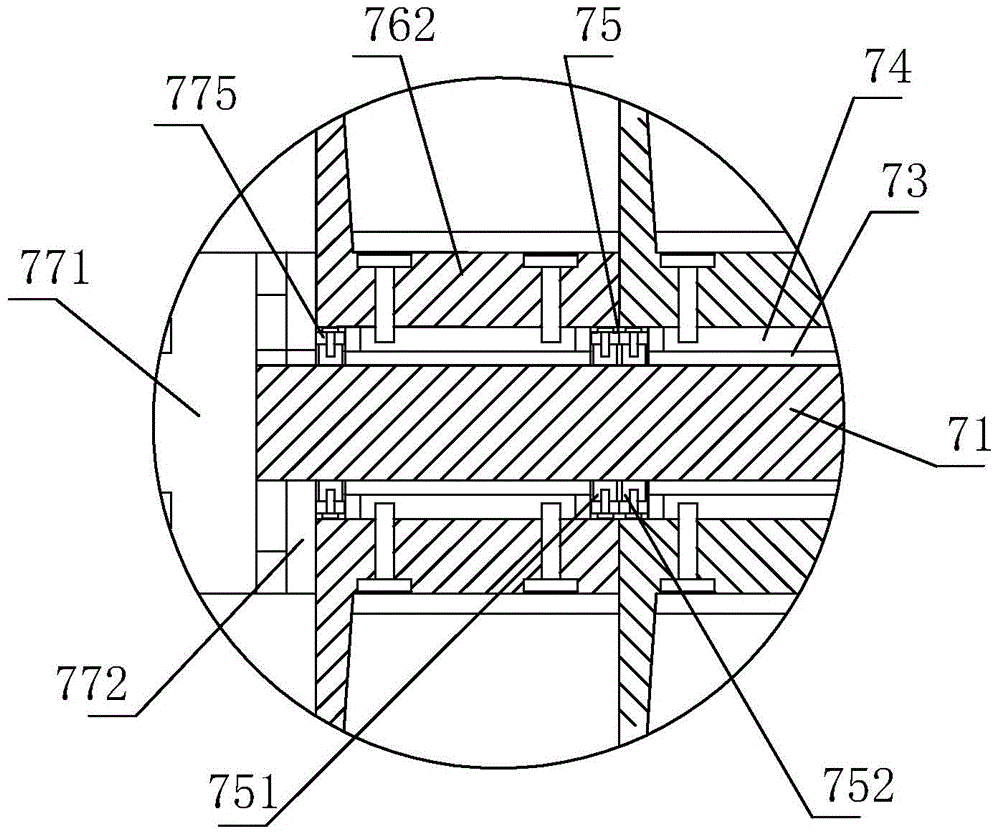

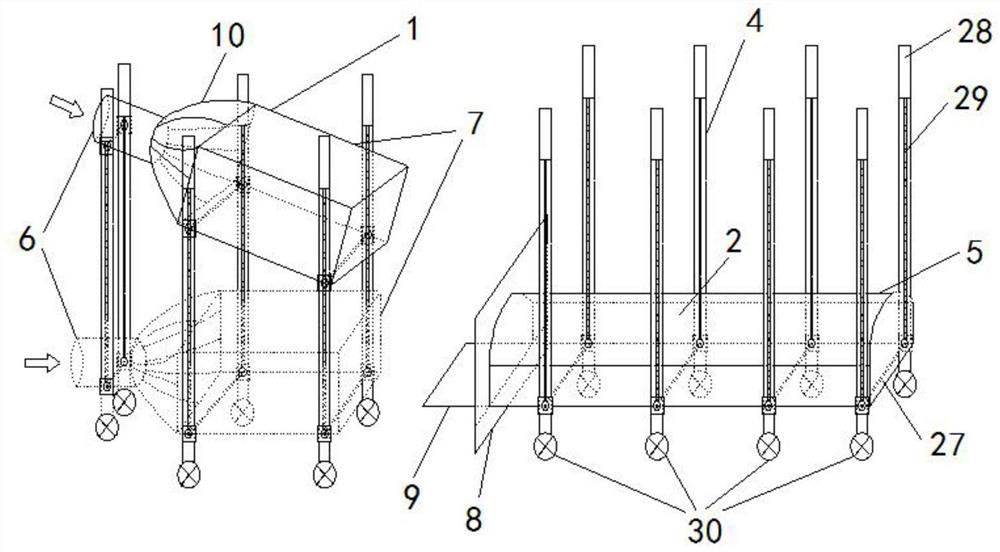

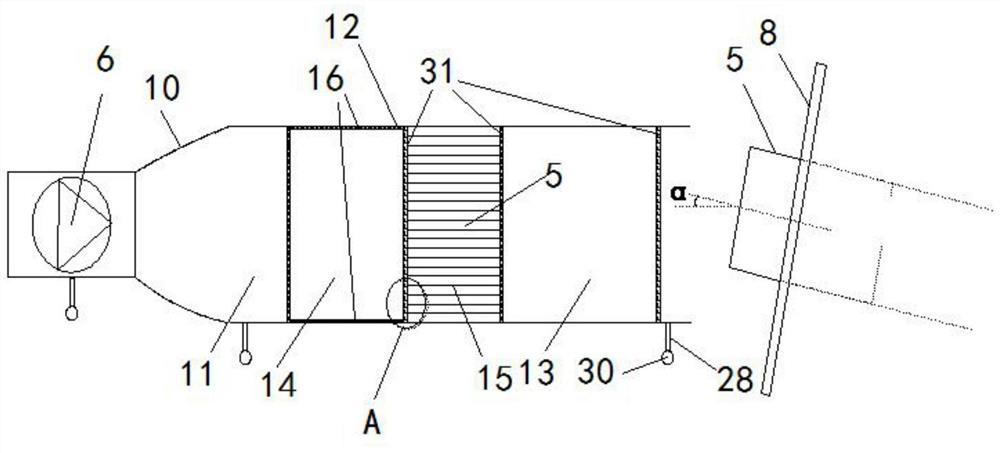

Closed henhouse ventilating system and air flow organization method

The invention belongs to the field of agriculture facilities, and relates to a closed henhouse ventilating system and an air flow organization method. The system includes a longitudinal wall (1), a mountain wall (2), hen cages (3), a wet curtain cooling device (4) and a blower (5); the hen cages (3) are in parallel to the longitudinal wall (1), and channels are formed between different lines of hen cages (3) or between the hen cage (3) at the outermost side and the longitudinal wall (1); the blower (5) is installed on the mountain wall (2) at one end, and an air inlet dual-leaf guide flow plate (7) and a compartment (6) are respectively arranged on the mountain wall (2) at the other end and the outside; the wet curtain cooling device (4) is installed on the wall body of the compartment (6) except for the mountain wall (2); two blades of the air inlet dual-leaf guide flow plate (7) are opened towards the hen cages, and vertically arranged and aligned to every channel, and its height is equal to that of the hen cages (3). The closed henhouse ventilating system can reduce the resistance to air flow by the hen cages, effectively reduce the temperature difference between the air inlet and the exhaust opening; moreover, the air flow organization is orderly and evenly distributed, and the venting and cooling efficiency is high.

Owner:CHINA AGRI UNIV

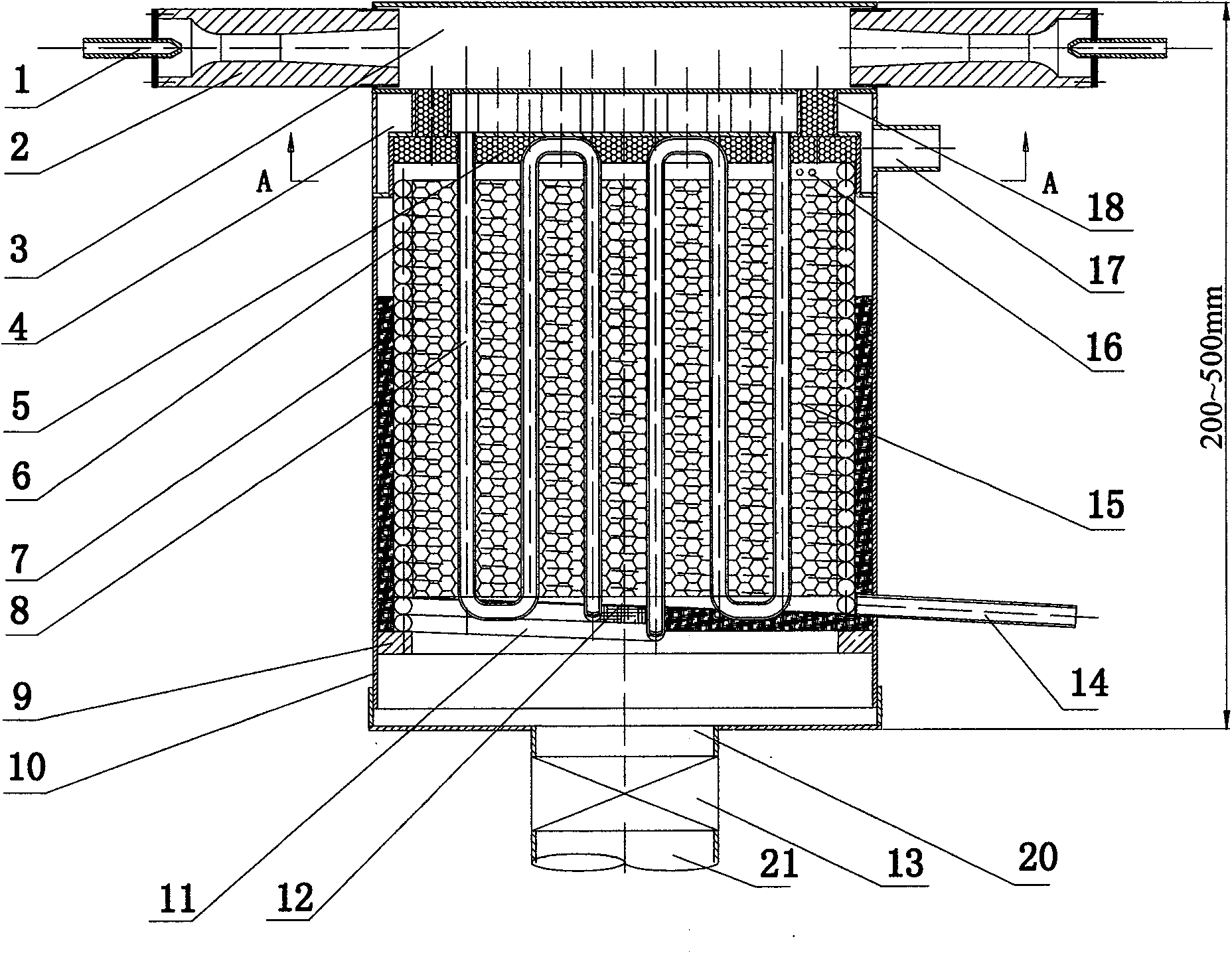

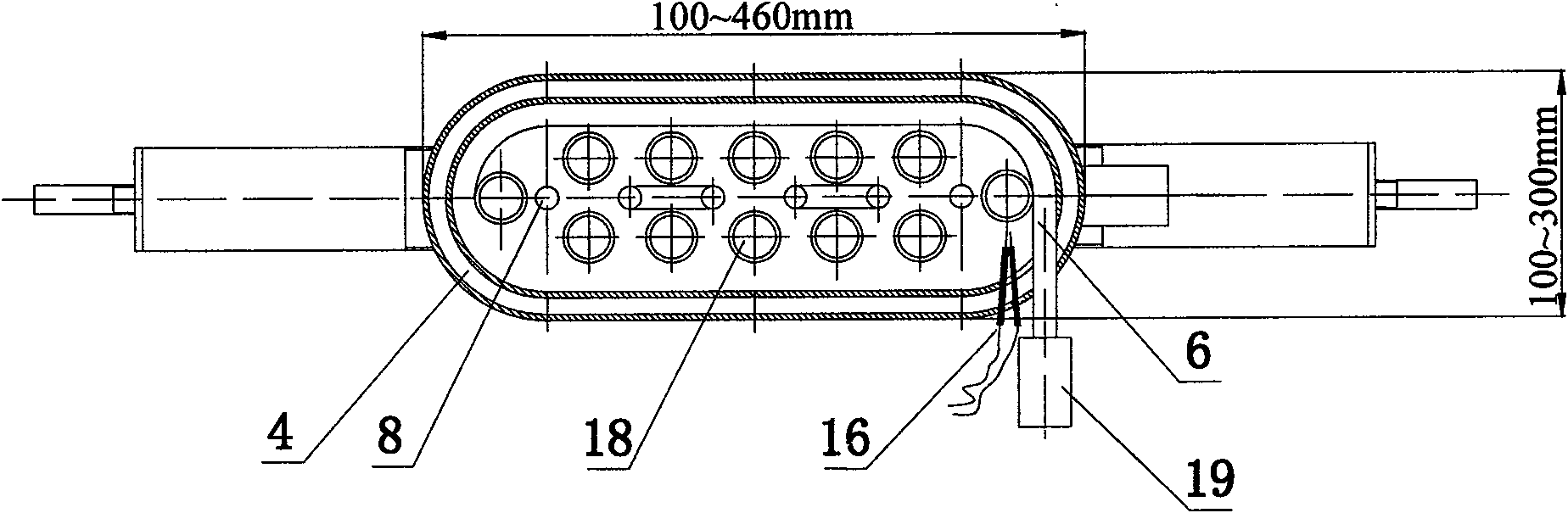

Porous-medium gas hot water heater

ActiveCN101566386AFast and efficient deliveryLower exhaust gas temperatureWater heatersCombustion chamberPorous medium

The invention discloses a porous-medium gas hot water heater, relating to a heater in which a pipe is wound into a spiral form to separate the continuous flows of water and a heating medium; the heater is structurally characterized in that: fine-pore porous medium materials are filled in an anti-backfire channel and a groove of a water cooling sleeve; macropore porous medium materials, which are metal fibers or foamed ceramics, are filled in a combustion chamber; heat exchanging tubes exchange heat directly with the macropore porous medium materials in the combustion chamber to conduct radiation or or heat exchange with the form of heat conduction, and high temperature fume realizes strong heat exchange between the peripheral dense heat exchanging tubes and the macropore porous-medium materials and leads the fume to be cooled rapidly and steam to condense directly on the tube walls; therefore, the heat conduction of the combustion chamber is strengthened and the heat released by the combustion can be rapidly and effectively transferred to water so that the steam in the fume condenses to recycle the condensation heat of water, thus realizing the goal of ultimately absorbing the heat released by the combustion. The hot water heater has simple structure and heat efficiency of over 96 percent, meeting the Grade-I energy efficiency standard for household rapid water heaters.

Owner:河北泓碳能源技术有限公司

Humidity control device and ventilation device

InactiveCN101815906AImprove maintainabilityEasy to take outEnergy recovery in ventilation and heatingGas treatmentMoistureElectrical and Electronics engineering

Owner:DAIKIN IND LTD

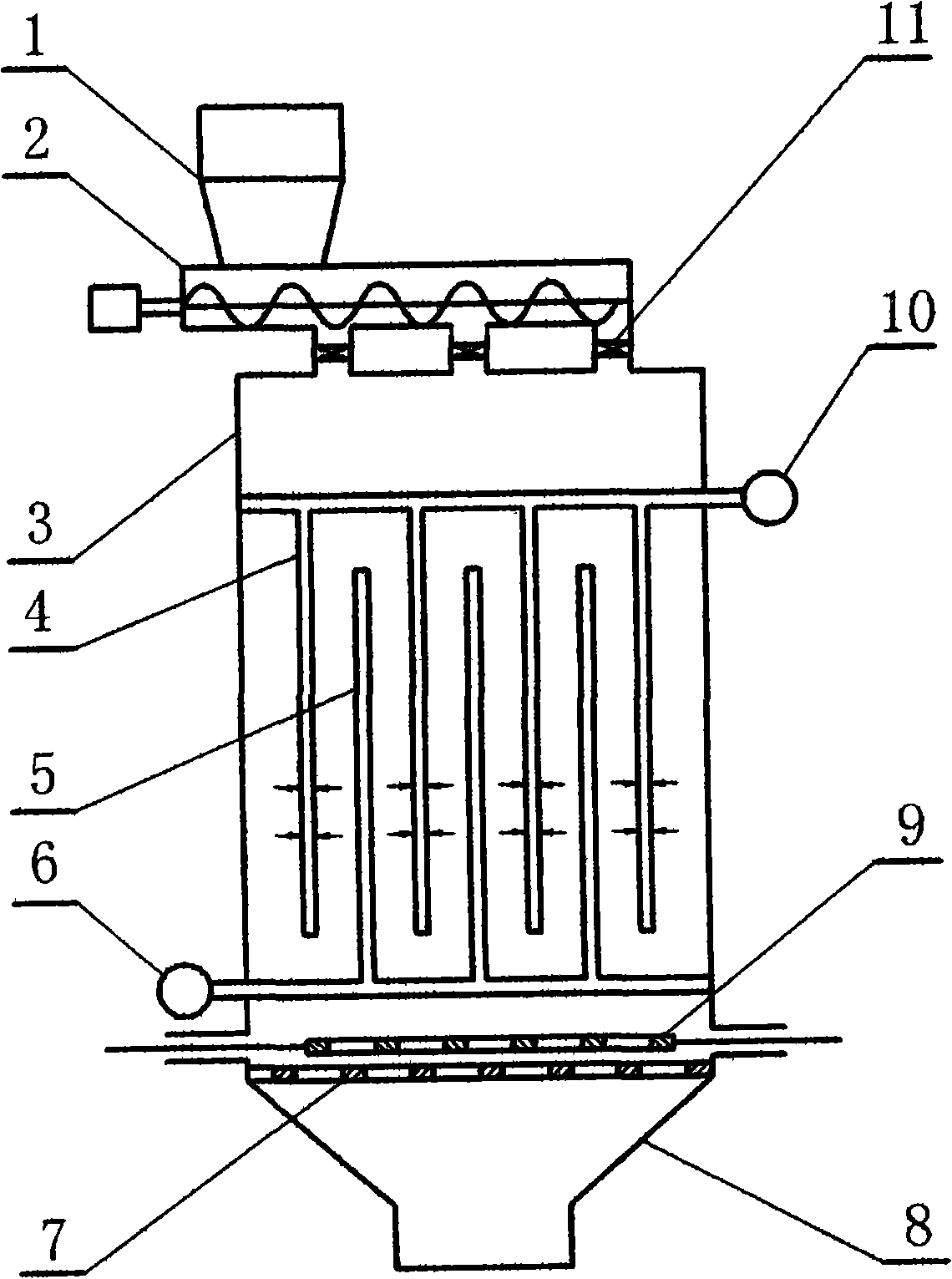

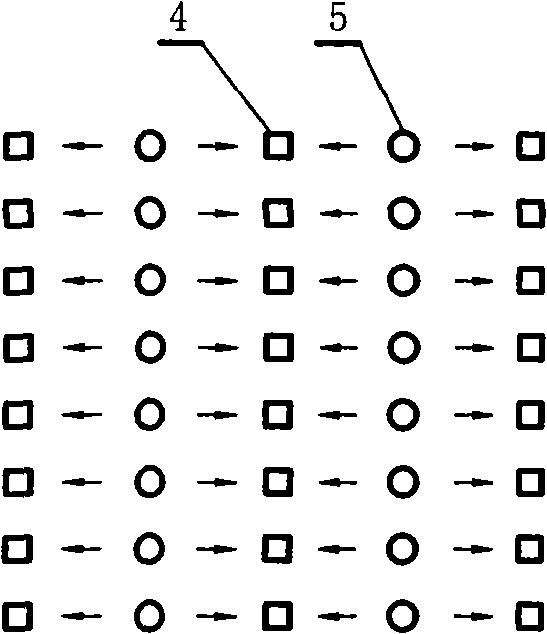

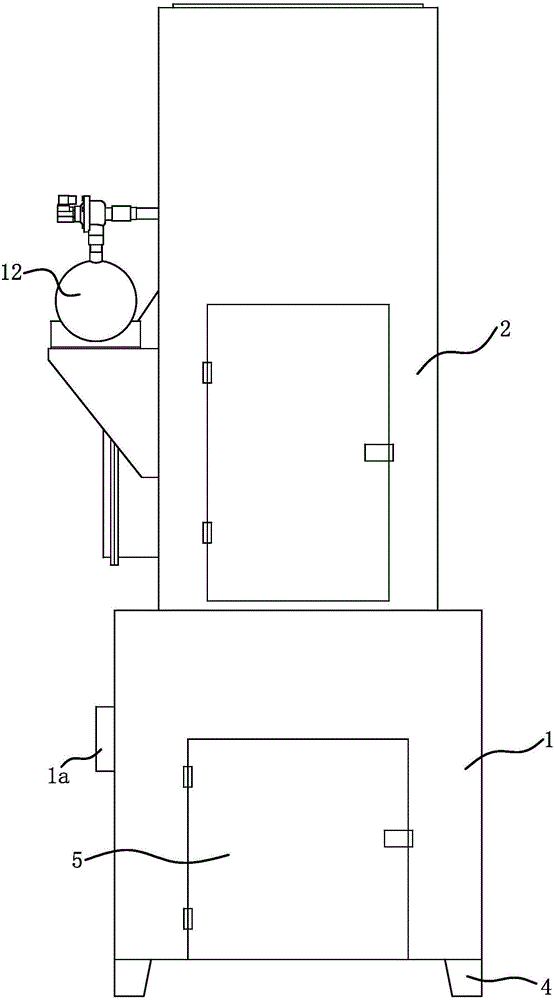

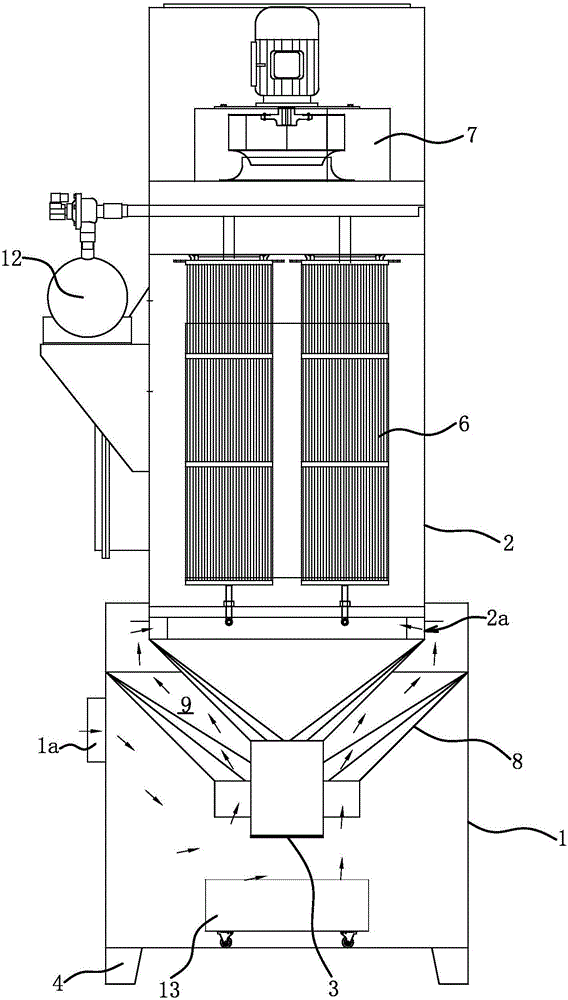

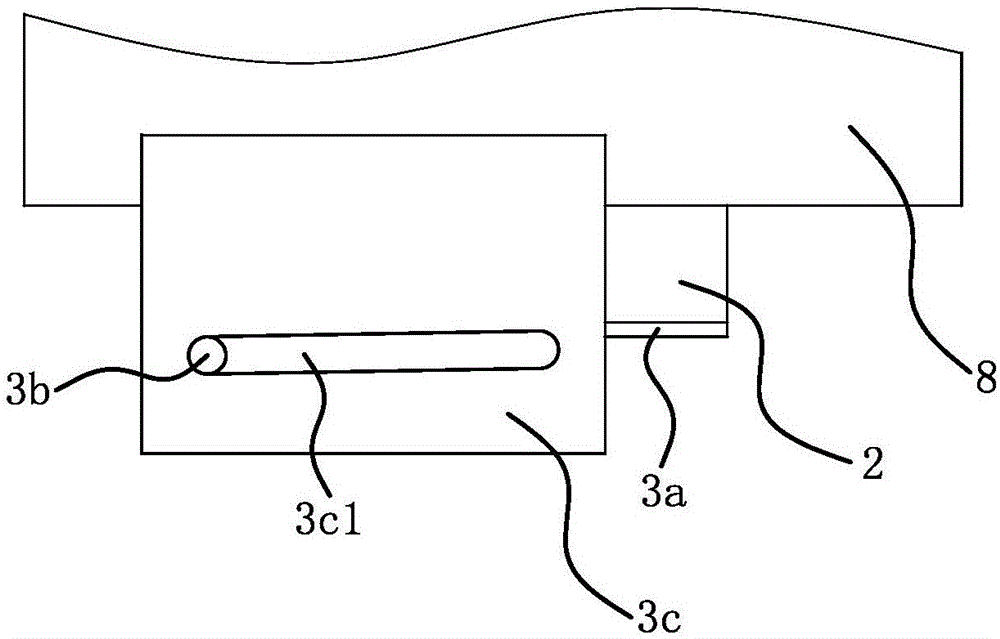

Dust remover

The invention provides a dust remover, belongs to the technical field of work, and solves the problems of short service life of a filter element and high unit energy consumption of the existing dust remover. The dust remover comprises a dust pre-removal box and a fine dust removal box; the bottom of the fine dust removal box is located in the dust pre-removal box; an ash discharging opening is formed in the bottom of the fine dust removal box; the dust remover further comprises an ash discharging control valve for controlling the ash discharging opening to be communicated with an inner cavity of the dust pre-removal box; a fan is arranged at the top of the fine dust removal box; the filter element is arranged in the fine dust removal box; a ventilating pipe sleeves the outer side of the bottom of the fine dust removal box; the upper end of the ventilating pipe communicates with a cavity on the outer side of the filter element in the fine dust removal box. The dust remover guarantees the spark eliminating rate, reduces the dust content of air flow entering the fine dust removal box and improves the distribution uniformity of dust in the fine dust removal box so as to guarantee the use safety of the filter element, reduce the dust removal amount of the filter element and improve the consistency of dust treatment amounts of all the filter elements; therefore, the ventilating smoothness of the filter element is improved, and the back-blowing interval of the air flow is prolonged.

Owner:玉环太平洋机械有限公司

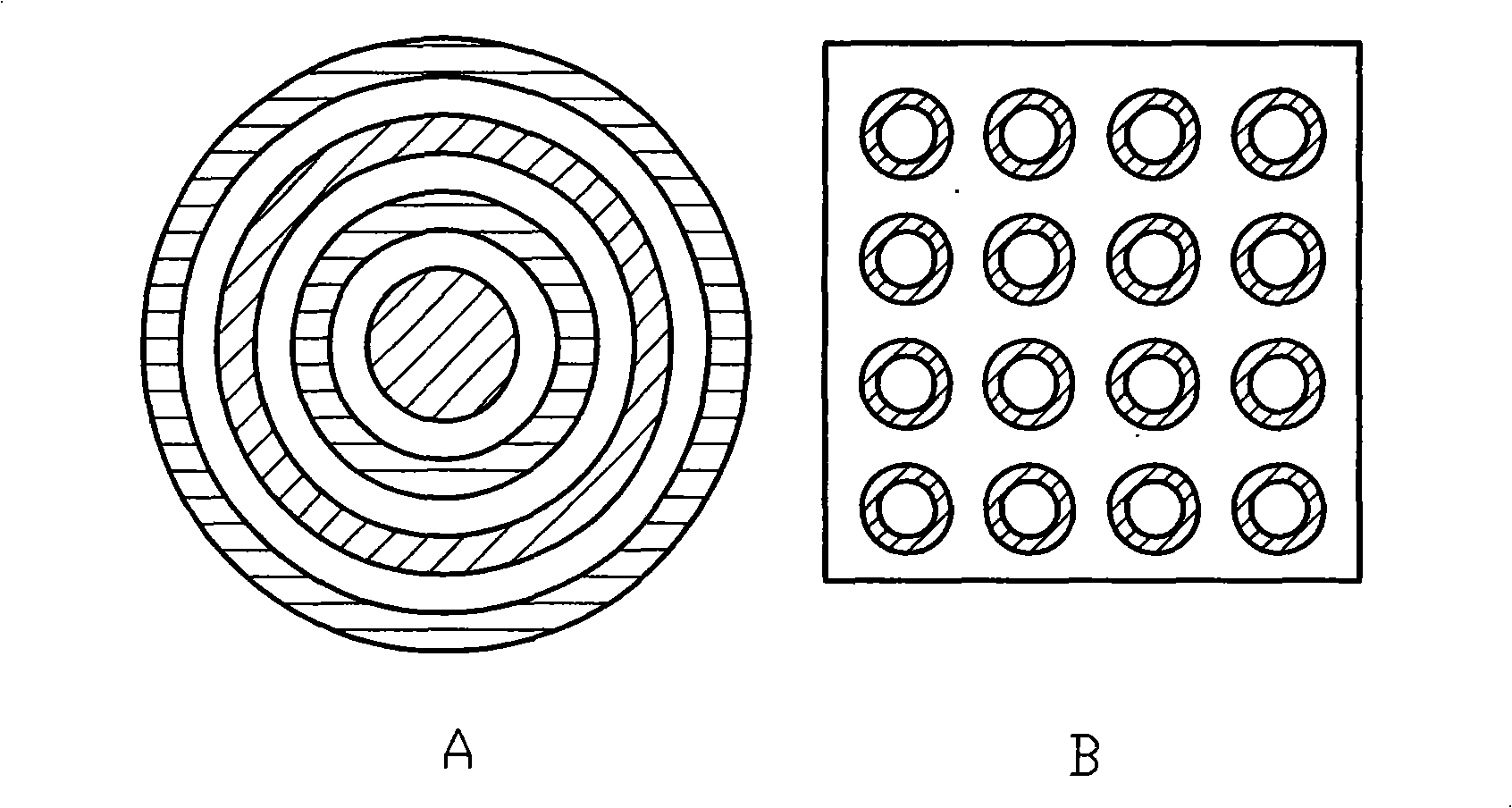

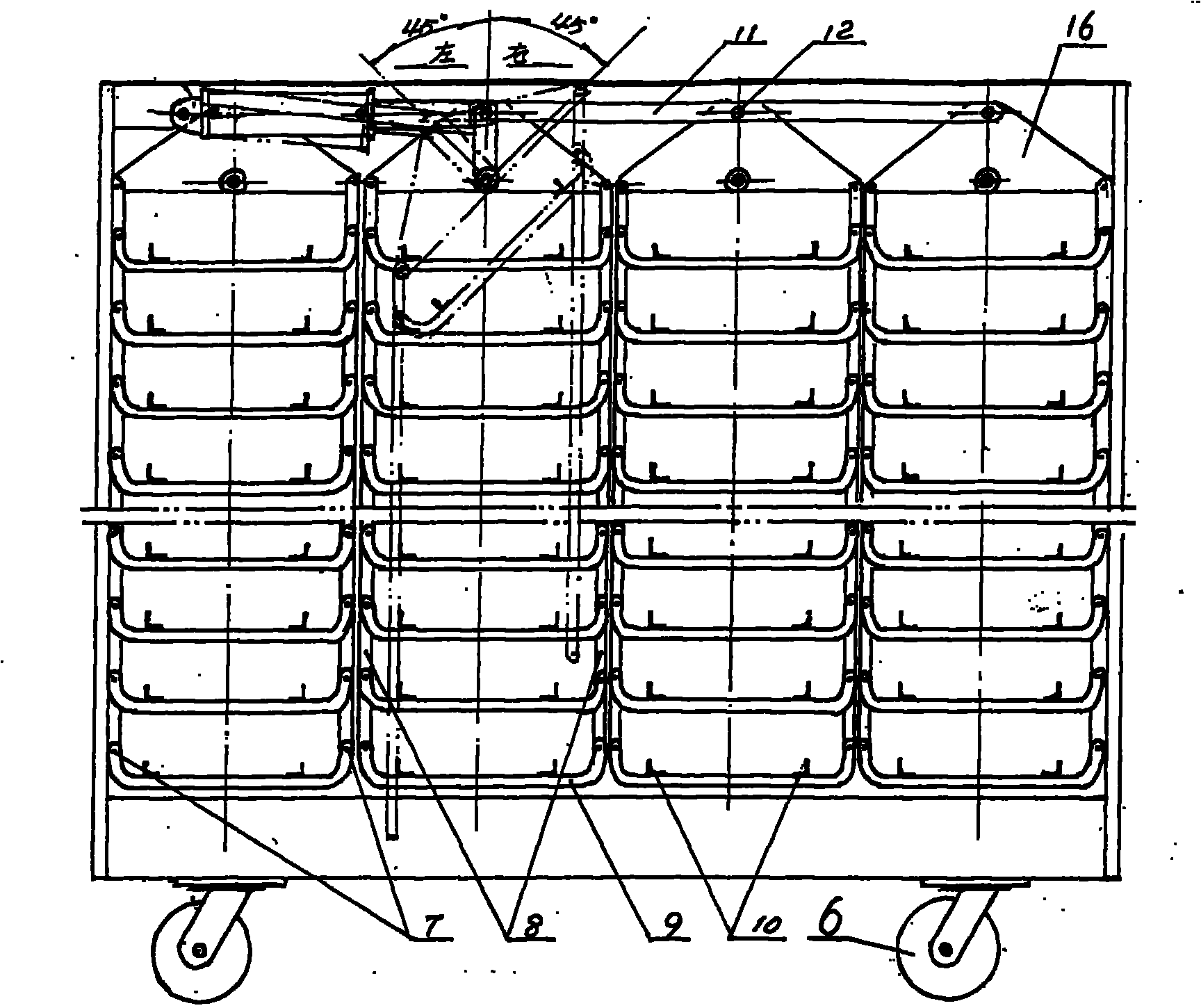

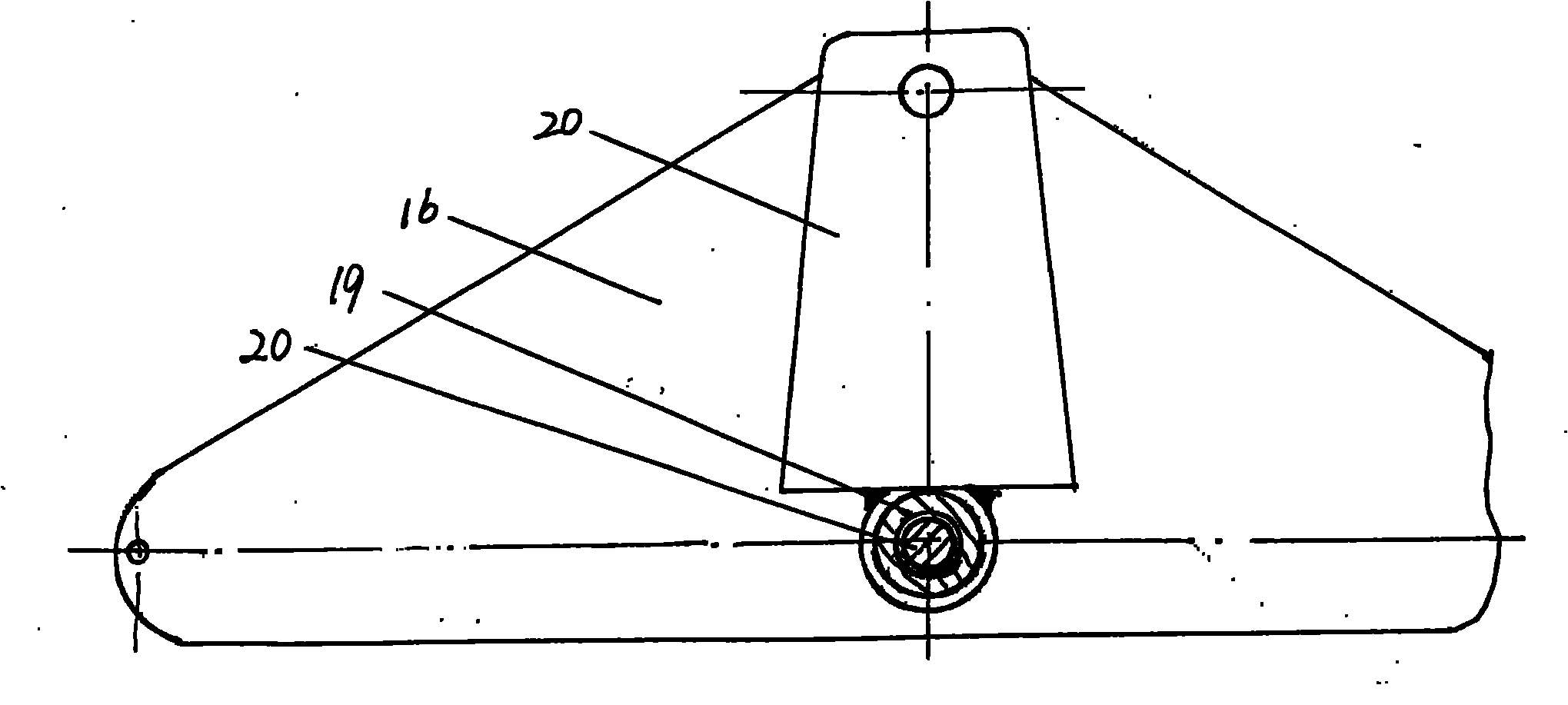

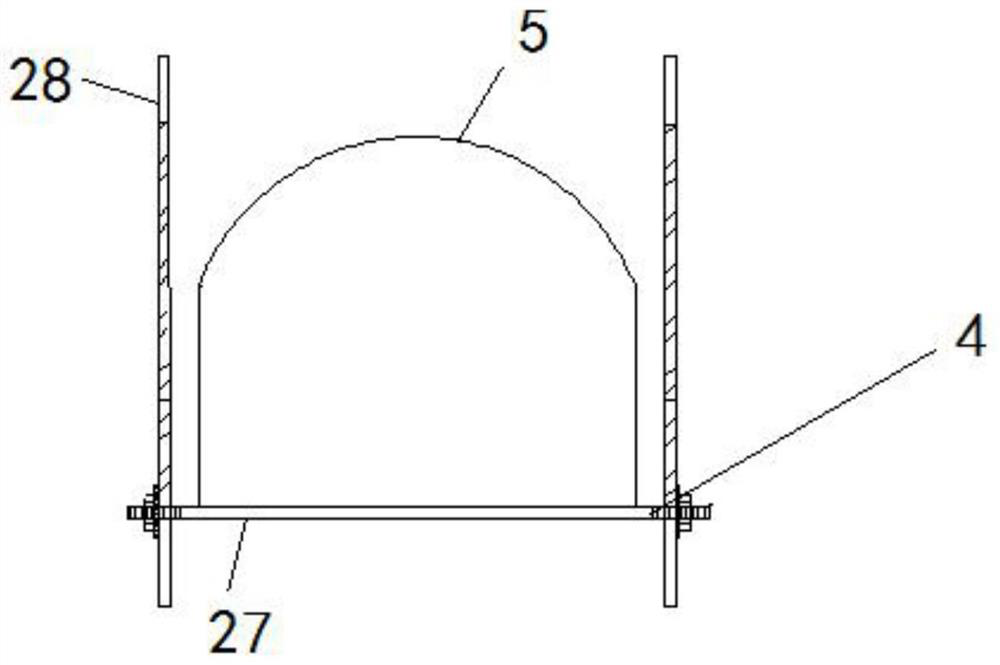

Egg trolley for roadway incubation machine

InactiveCN101766126ALow ventilation resistanceSmooth ventilationPoultry incubationAirflowEngineering

The invention relates to an egg trolley for a roadway incubation machine, belonging to the poultry cultivating technology; the egg trolley comprises a frame with caster wheels, a turning driving device arranged on the frame, a plurality of groups of egg brackets, a connecting rod, a rotary arm and a rotary arm shaft; each group of the egg brackets are connected on each group of the rotary arms, and the arms are arranged on the connecting rod connected with the turning driving device, each rotary arm is arranged on the rotary arm shaft and swings around the rotary arm shaft, the rotary arm shaft is arranged on the frame and is parallel to the air flowing direction of the incubation machine, when an egg tray on the egg bracket is turned, the egg tray plane is parallel to the air flowing direction of the incubation machine. By changing the egg turning structure of the egg trolley and leading the back and forth egg turning of the egg tray of the existing egg trolley to be changed into left and right egg turning thereof with the same direction with the air supplying, the ventilating resistance is reduced, the ventilation is smooth, the phenomenon that local high temperature and low temperature caused by non-uniform humidity and high temperature difference is eliminated, so as to lead the hatching egg embryonic development time to be consistent, improve the survival rate and increase the hatching rate and healthy chick rate.

Owner:于文天

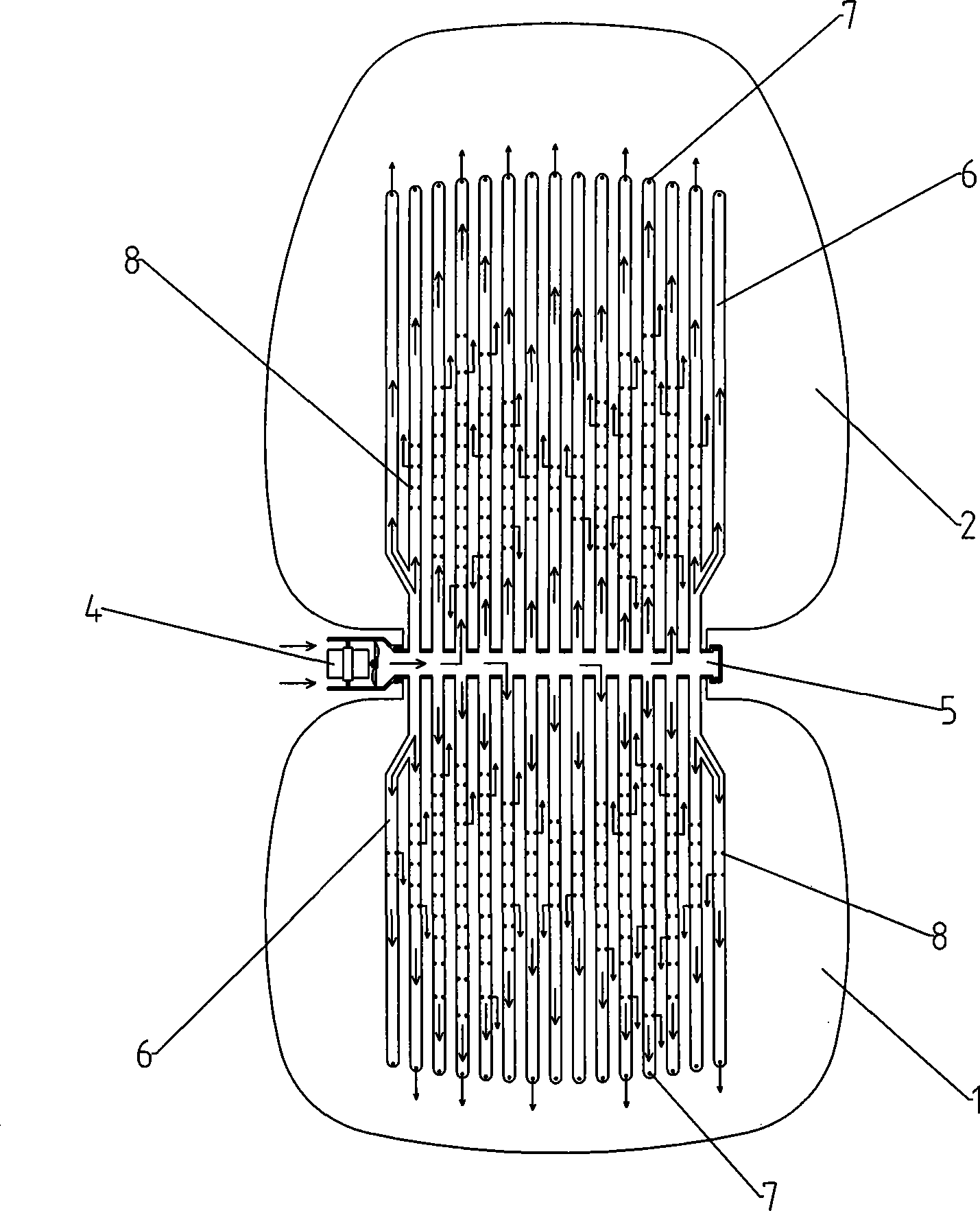

Ventilation mattress

The invention relates to a ventilating cushion, comprising a cushion and a back cushion; wherein, a laterally extended main air duct is connected between the cushion and the back cushion, one end of the air duct is closed and the other end of the air duct is connected with the outer gas source, the cushion and the back cushion are respectively provided with a vertically extended air distributing duct communicated with the main air duct, the air distributing duct are arrayed laterally and transversely, the tail end of the air distributing duct is communicate with air, the two lateral faces of the pipeline of the air distributing duct are provided with a plurality of air holes and the grooves between the two adjacent air distributing duct forms the air holes for the passing channel of air. The ventilating cushion has the advantages that: the cushion has favorable unblocked performance of the ventilation circuit for the air outlet is difficult to be blocked and good ventilation and cooling effect.

Owner:符巨章

Ventilation control system for laboratory

InactiveCN105115095AReduce temperature differenceRealize heat exchangeSpace heating and ventilation safety systemsLighting and heating apparatusControl systemTorque motor

The invention discloses a ventilation control system for a laboratory. The system comprises a main air inflow pipe, an air inflow pipe branch, an air inflow device, a main exhaust pipe, an exhaust pipe branch and an exhaust device and is characterized in that an air adjusting heat exchange segment used for adjusting the air flow and heat exchange is arranged on the exhaust pipe branch and located in the air inflow pipe branch; the air adjusting heat exchange segment comprises a connecting shaft, a first torque motor, a rotating bearing, a gear sleeve, a transmission gear set and connecting cylinders, and the connecting cylinders are sequentially arranged from left to right. In the rotating process of a plurality of inner air adjusting heat exchange fins, a spiral channel can be formed, the size of the channel and the size of an opening of the channel change regularly, and therefore the air flow of the exhaust pipe branch can be adjusted, and in a similar way, the air inflow of the air inflow pipe branch can be adjusted; in the rotating process of the inner air adjusting heat exchange fins, the contact area of air in the channel and the inner air adjusting heat exchange fins is unceasingly increased, and therefore heat exchange between the exhaust pipe branch and the air inflow pipe branch can be achieved through the inner air adjusting heat exchange fins and outer air adjusting heat exchange fins, and the temperature difference of air in the exhaust pipe branch and air in the air inflow pipe branch is reduced.

Owner:LANZHOU UNIVERSITY

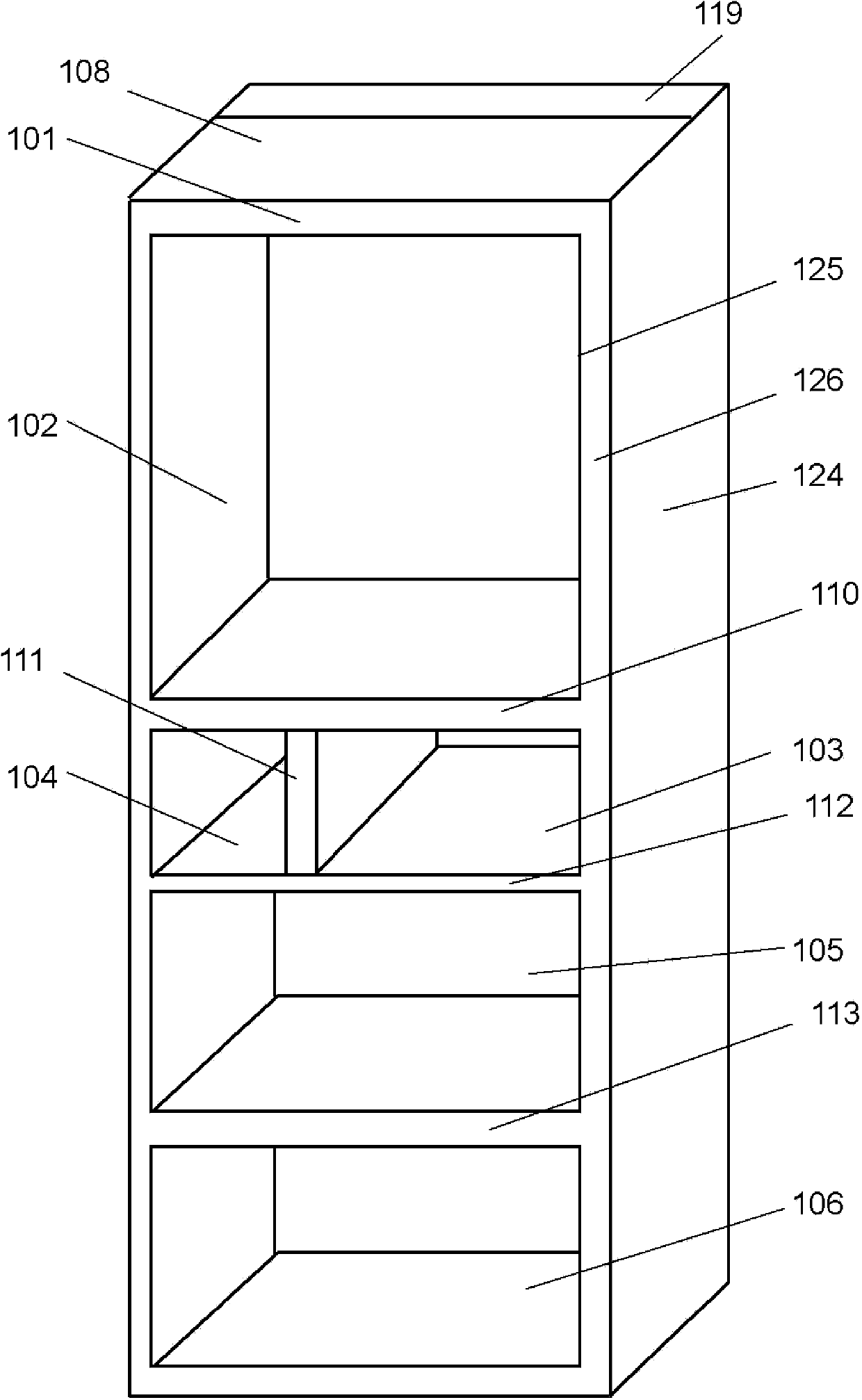

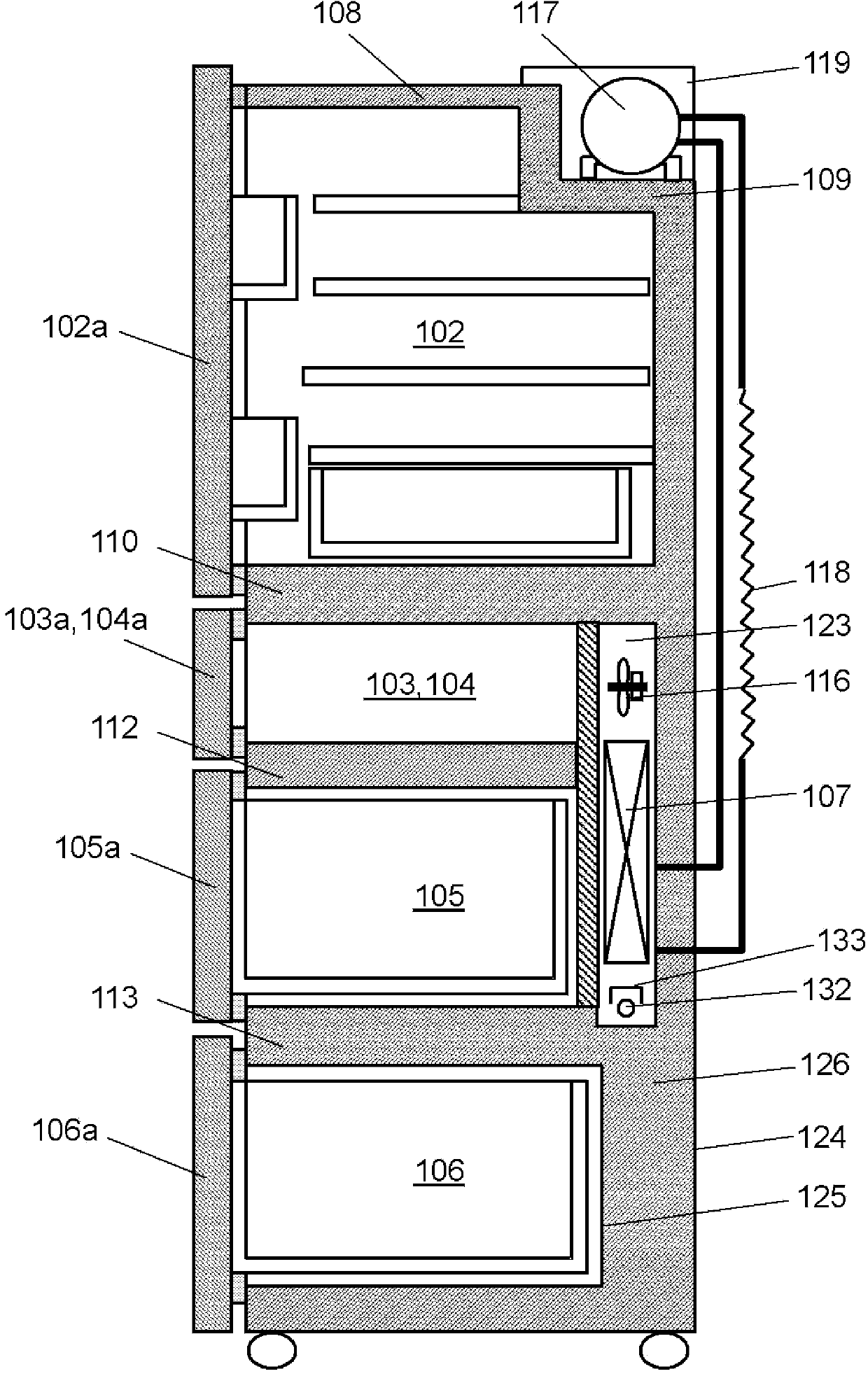

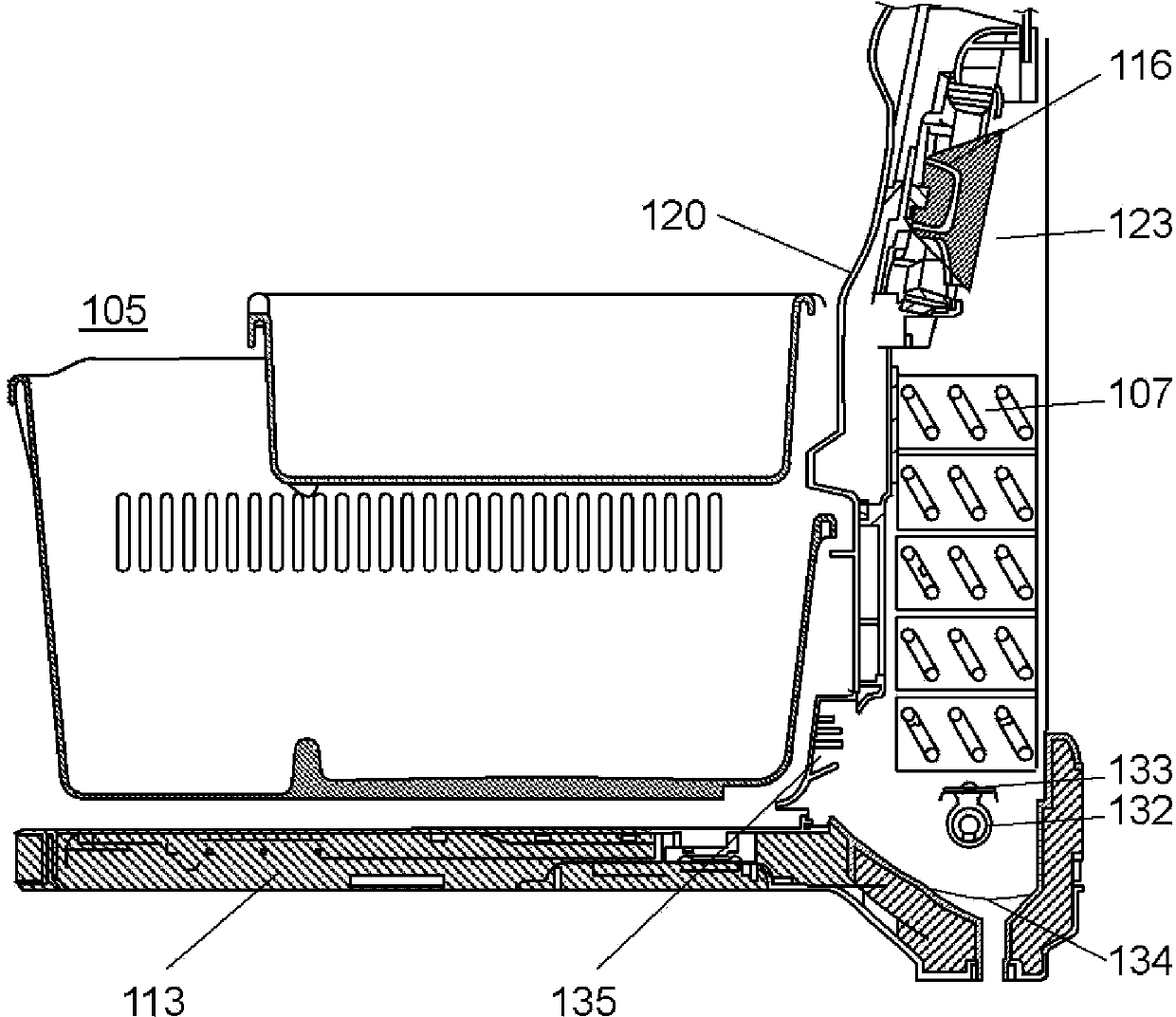

Refrigerator

InactiveCN103975207AShorten the timeLess typingLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

Cooler (107) provided on the back surface side of a refrigerator, the cooler for generating cool air, defrosting heater (132) provided below cooler (107), and cooler cover (120) having cool air return port (135) are provided. Center of defrosting heater (132) is set on the upper side of a lower surface of a freezing compartment, projection member (136) protruding into the interior side is arranged on the lower surface of the freezing compartment, and a lower end of cool air return port (135) and an upper end of projection member (136) are overlapped with each other in the height direction.

Owner:PANASONIC CORP

Protective cover and air conditioner with the same

InactiveCN101371081AAvoid contactLow ventilation resistanceLighting and heating apparatusHeating and ventilation casings/coversEngineeringMechanical engineering

Owner:DAIKIN IND LTD

Photocatalyst filter, photocatalyst filter laminate, exhaust unit, and image forming apparatus

ActiveUS20180001312A1Efficient decompositionEliminate effectiveGas treatmentDispersed particle separationLength waveAperture ratio

The present disclosure provides a photocatalyst filter that can efficiently decompose and eliminate ozone gas or VOC and has a low ventilation resistance. The photocatalyst filter includes a sheet-like filter substrate and a photocatalyst layer supported by the filter substrate. The photocatalyst layer exhibits a photocatalytic action by receiving light having a wavelength of 400 nm or more. The photocatalyst filter has an aperture ratio of 35% or more and 80% or less.

Owner:SHARP KK

Tunnel fire simulation experiment device under action of multi-angle canyon wind

InactiveCN111968479ASimple structureLow costAerodynamic testingEducational modelsFire safetyEnvironmental geology

The invention relates to a tunnel fire simulation experiment device under the action of multi-angle canyon wind, which belongs to the technical field of fire safety and comprises an experiment table main body, a canyon wind system and a matched measurement and control system, wherein the experiment table main body comprises a tunnel model movably connected to a bracket; the canyon wind system comprises a draught fan and a rectification box which are movably connected to the bracket, and an air outlet of the draught fan is communicated with the rectification box through a soft connection section. The rectification box comprises a butt joint section, a rectification section and a current stabilization section which are connected in sequence. The device is simple in structure, the device is simple in structure and low in manufacturing cost, makes up the defects that a full-size experiment is high in cost and a numerical simulation tool is not accurate enough, guarantees the repeatabilityof the experiment, and has great application value and important guiding significance for developing laboratory scientific research and the influence of actual canyon wind on bridge tunnel ventilationand tunnel fire in a high-altitude area.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com