Self-adaptive vibration accumulation and energy supply high-efficiency vertical roller mill

A vertical roller mill, self-adaptive technology, applied in the direction of grain processing, etc., can solve the problems of stability and vibration sensitivity of the equipment itself, difficult safety control, non-linearity, etc., to improve the stability and service life of the equipment, and avoid collisions risk and the effect of reducing vibration intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

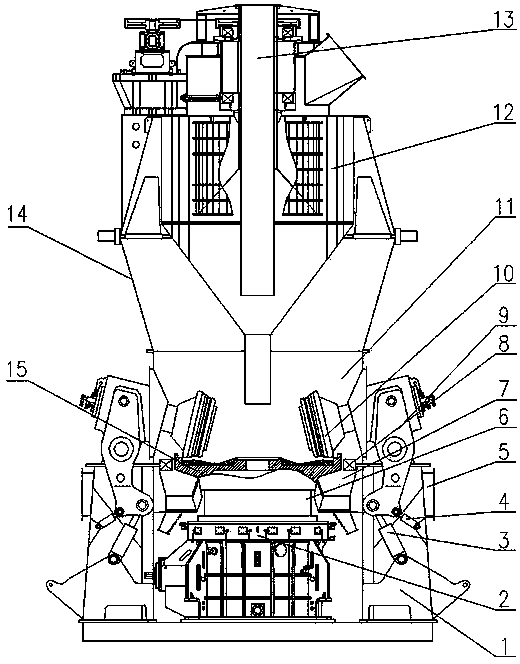

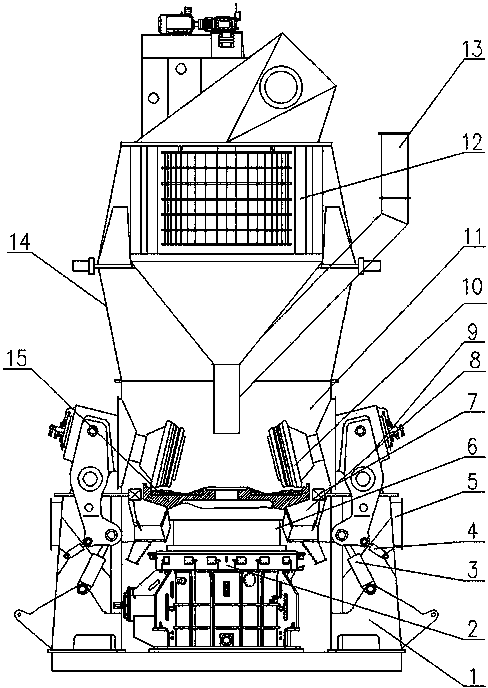

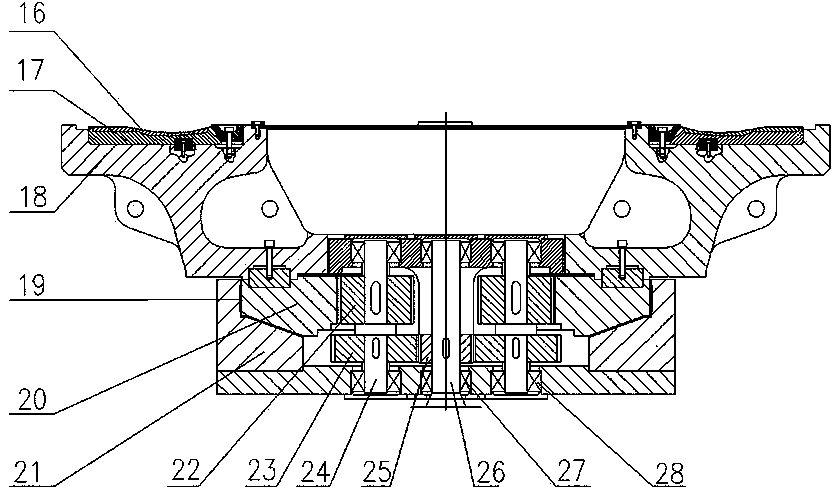

[0021] Figures 1~7 It is the best embodiment of the self-adaptive energy-gathering and energy-supplying high-efficiency vertical roller mill of the present invention. Figures 1~7 The present invention will be further described.

[0022] refer to figure 1 : Self-adaptive energy-gathering and high-efficiency vertical roller mill includes a hydraulic transmission system, an intelligent control system, a frame 1, a transmission device 2 installed on the frame 1, and a reduction mechanism 6, and the output end of the reduction mechanism 6 is installed with a grinding disc device 15. The lower casing 11 is installed on the top of the frame 1, the air ring 8 is installed on the outer circle of the grinding disc device 15 and the upper opening of the air inlet duct 7 communicating with the air inlet pipe 5, and a plurality of grinding roller devices 10 pass through the lower casing The grinding door on the body 11 is installed above the grinding disc device 15, the rocker arm 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com