Patents

Literature

59results about How to "Fast and efficient delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

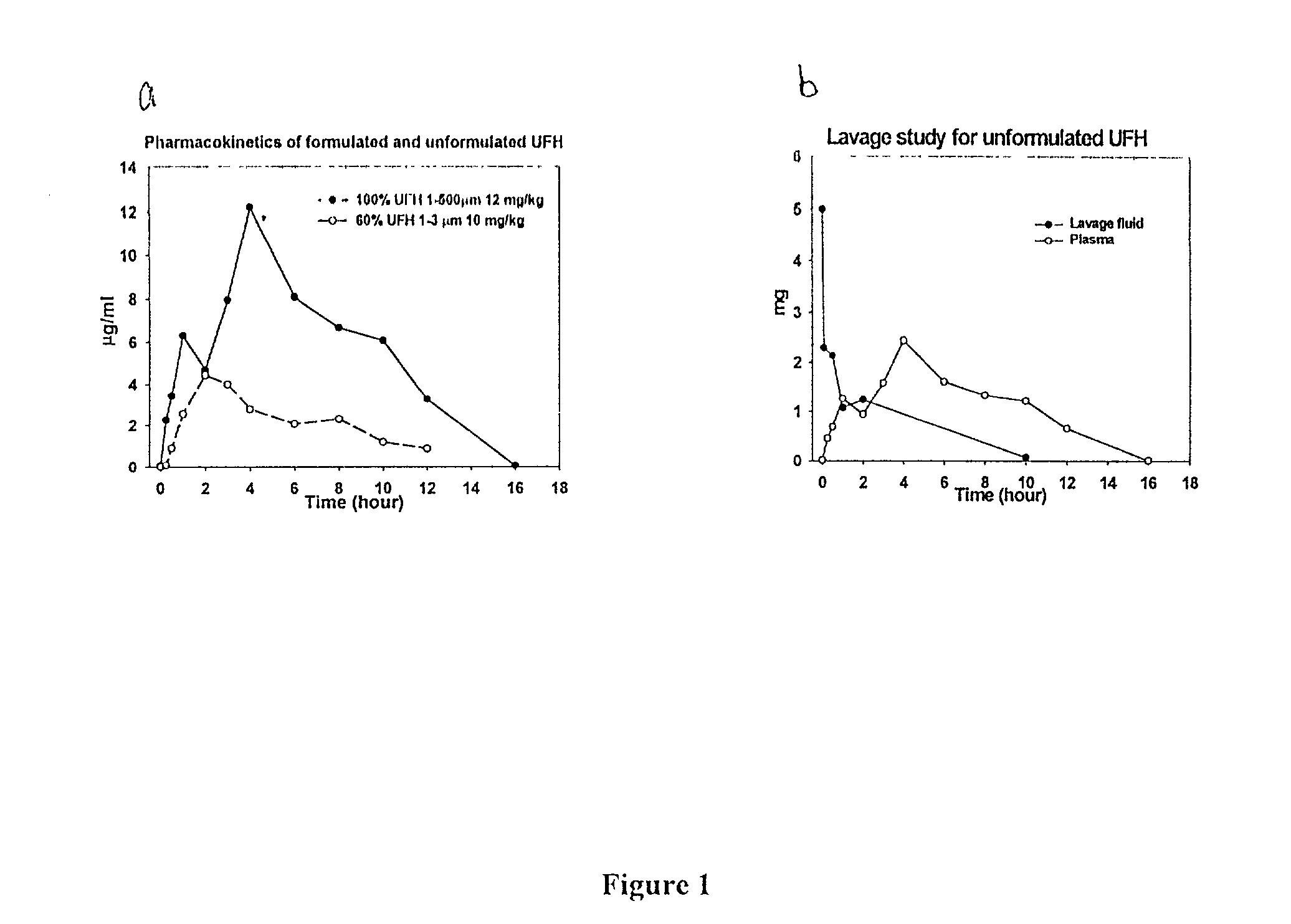

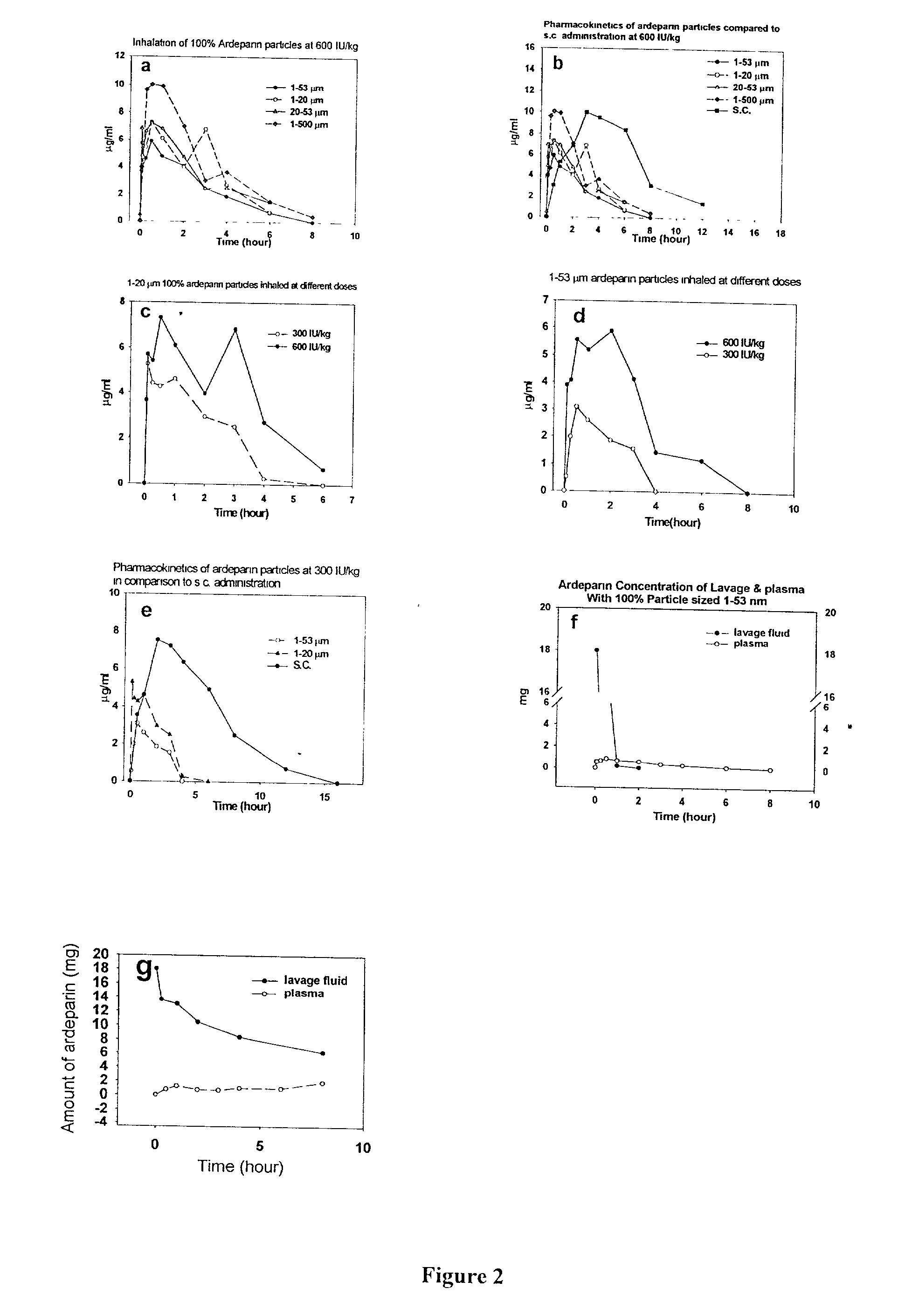

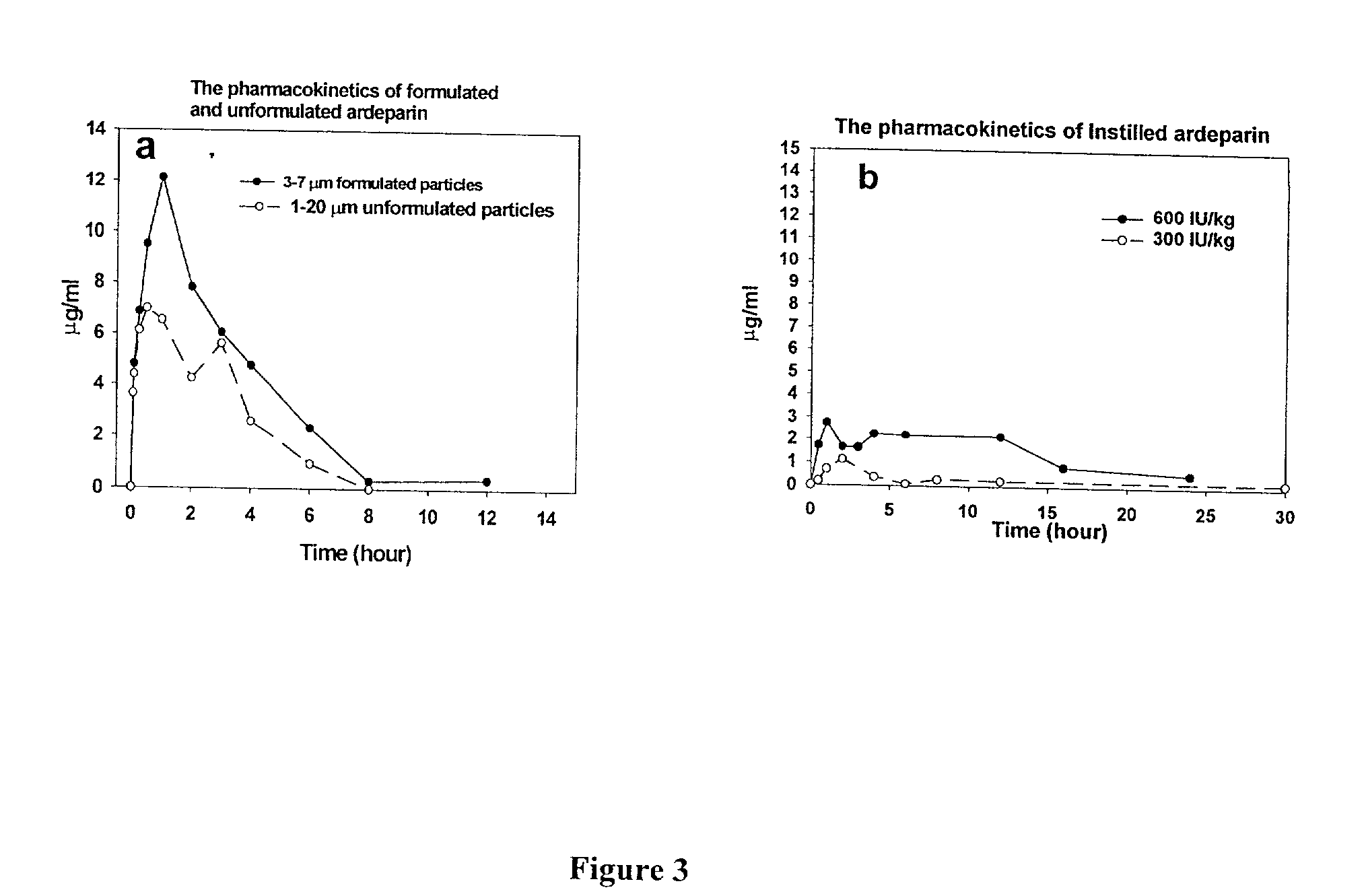

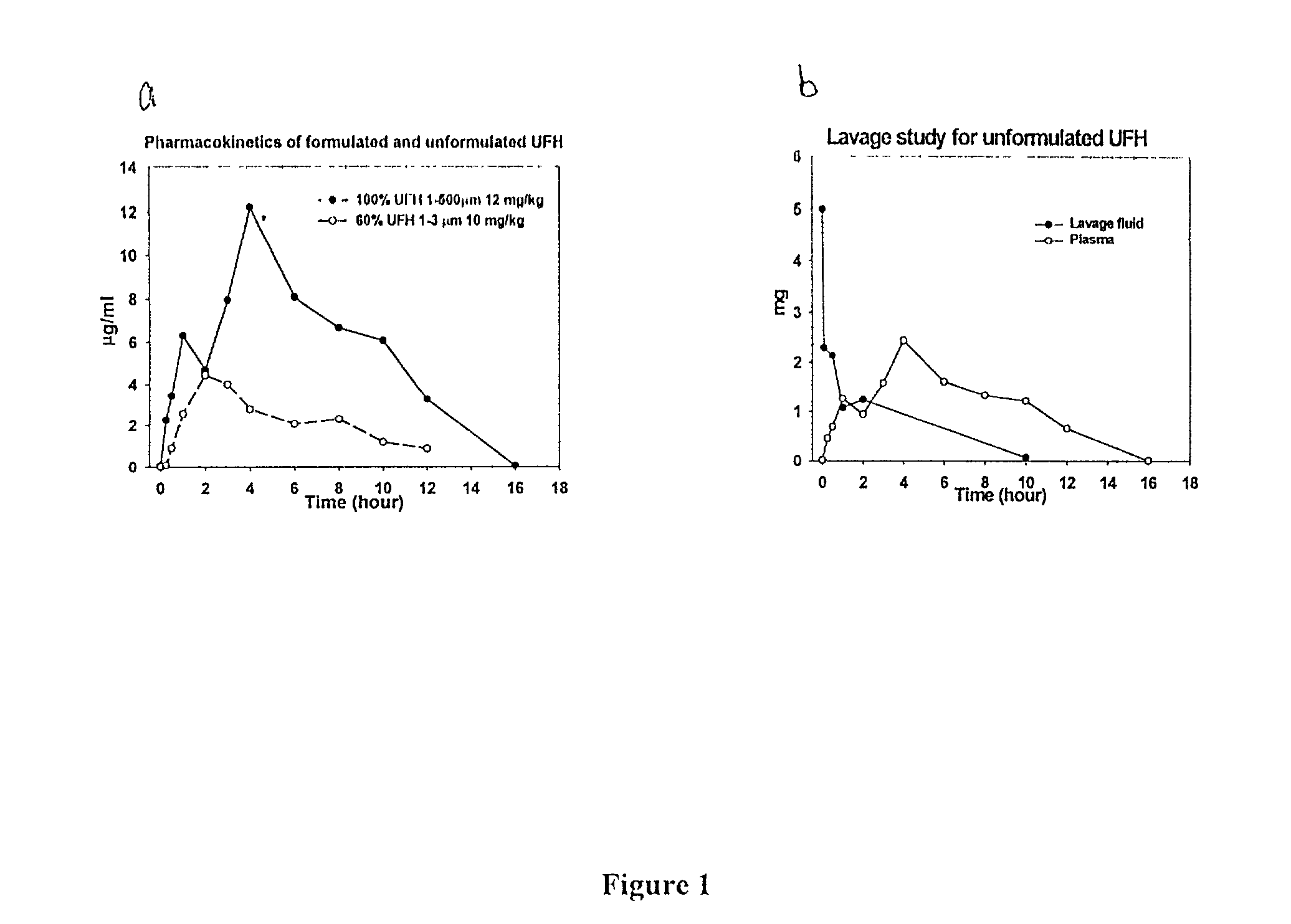

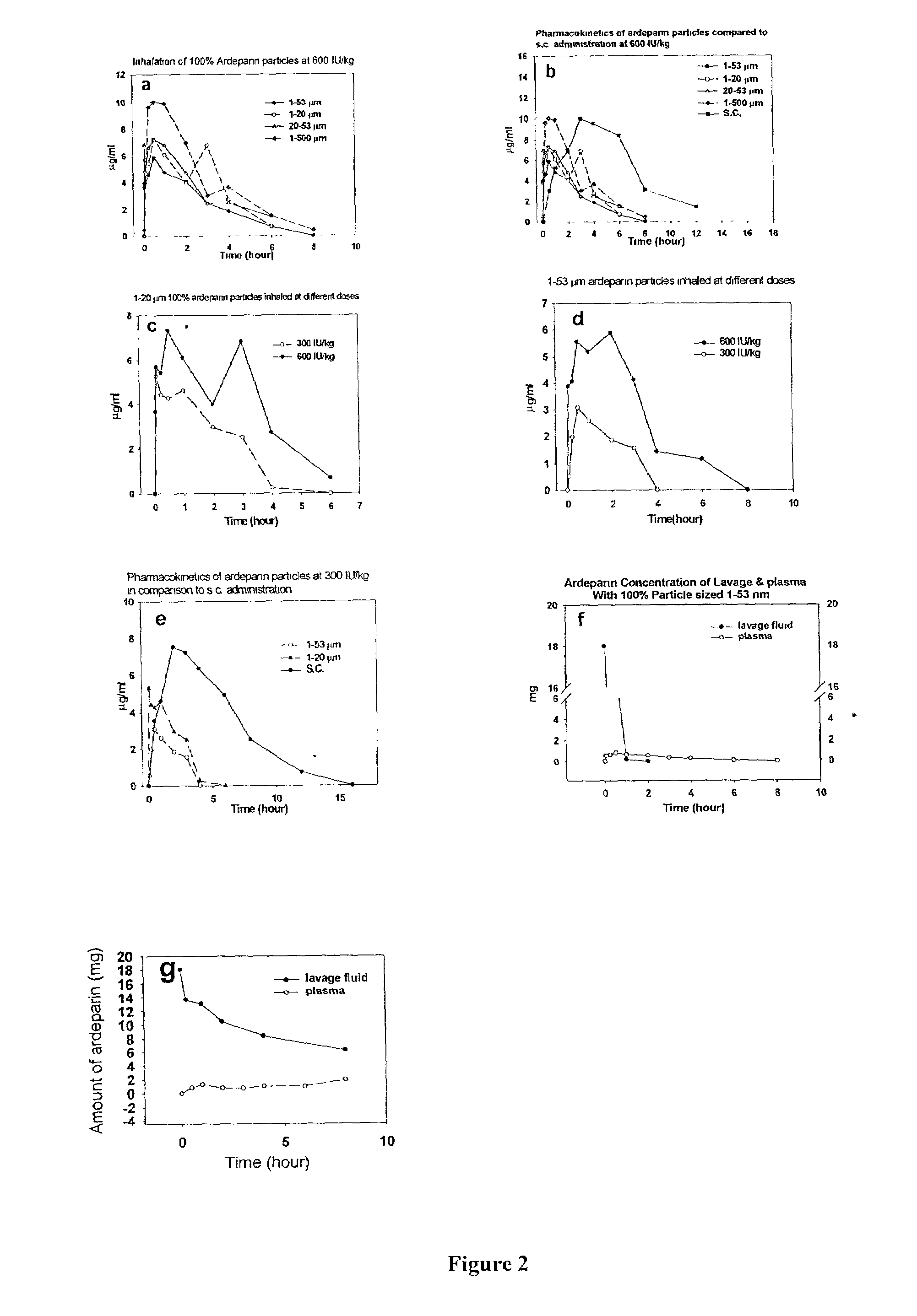

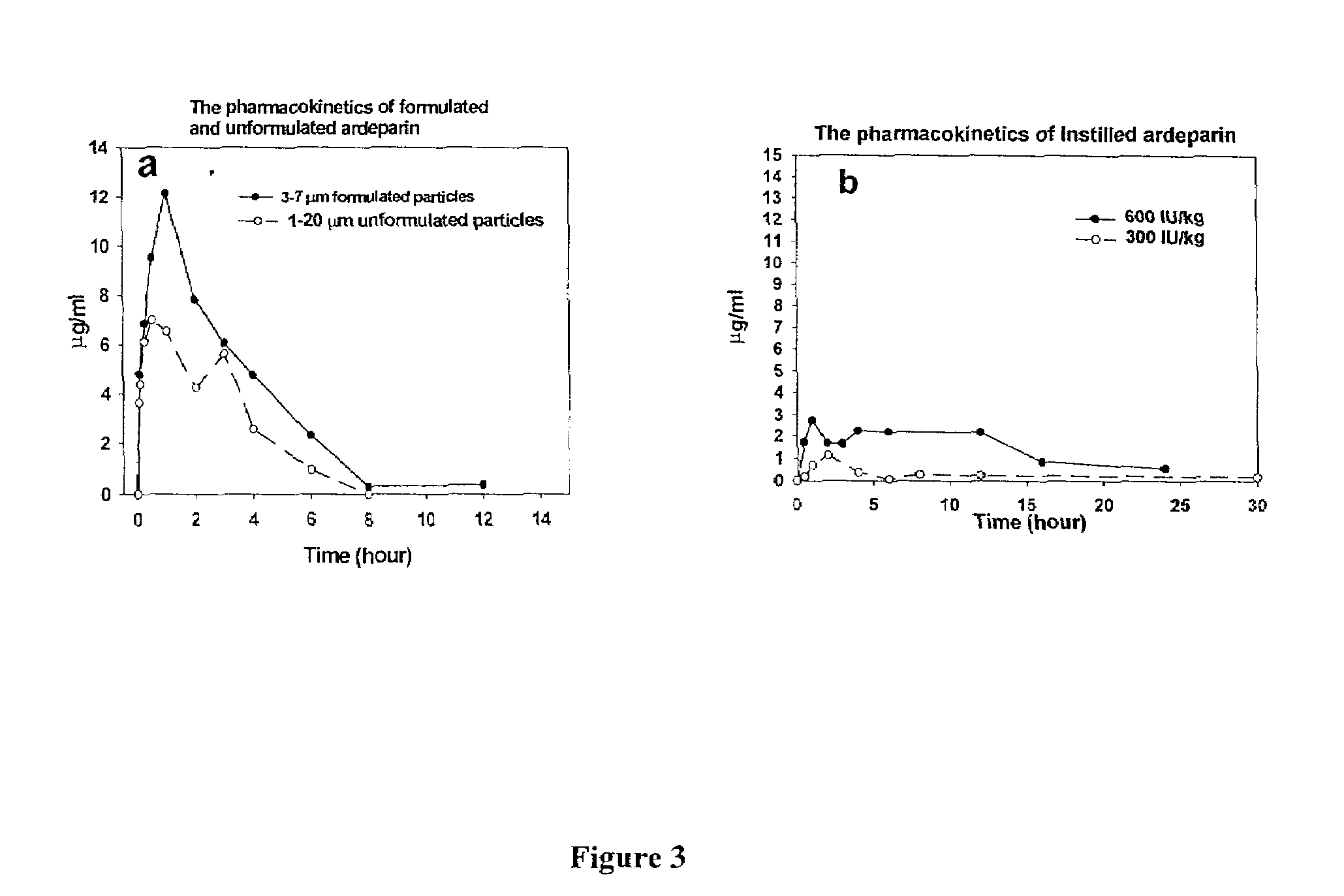

Methods and products related to pulmonary delivery of polysaccharides

InactiveUS20020128225A1Fast and efficient deliveryGood resultPowder deliveryOrganic active ingredientsAbsorption rateUnexpected therapeutic effect

The invention relates to methods for delivering polysaccharides by a pulmonary route to achieve local and systemic therapeutic effects. The polysaccharides may be formulated or unformulated and in some instances have an extremely fast absorption rate.

Owner:MASSACHUSETTS INST OF TECH

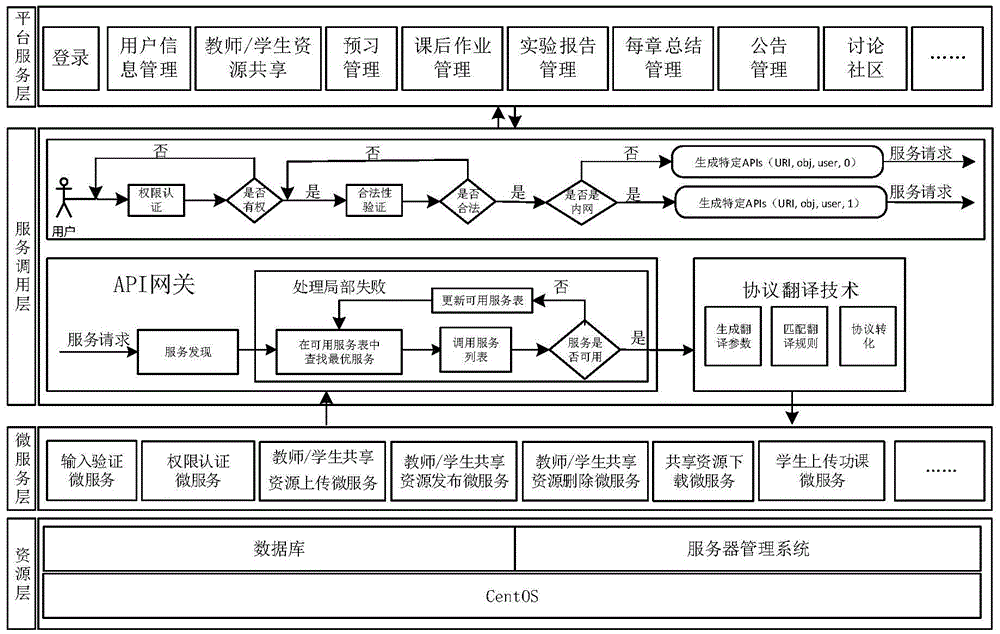

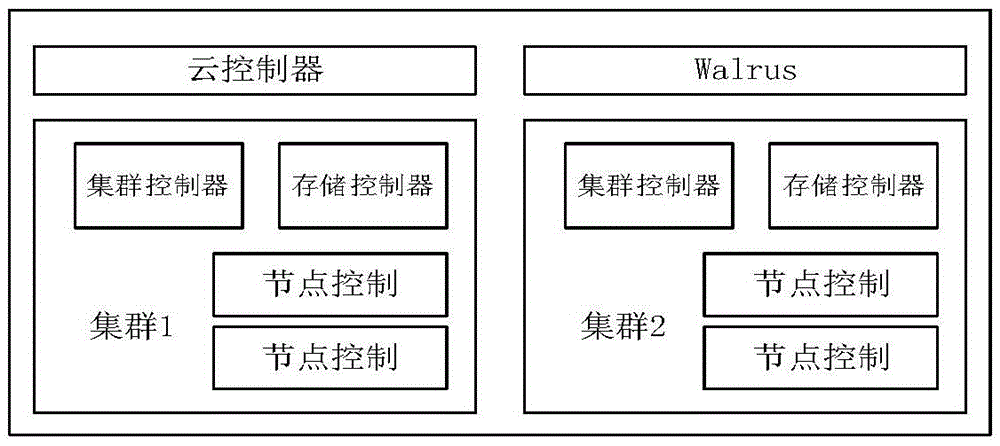

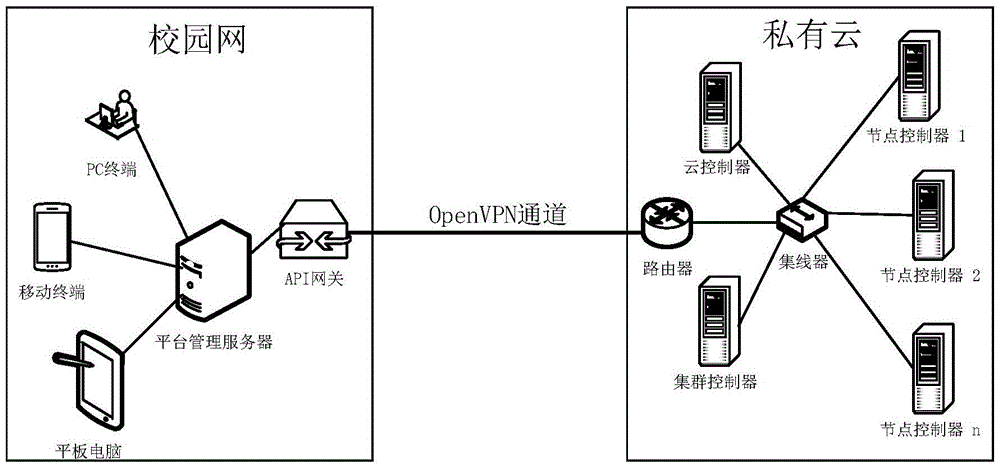

College teaching cloud platform based on micro services

InactiveCN105577780AFast and efficient deliveryImprove efficiencyTransmissionPrivate networkOpen source

The invention discloses a college teaching cloud platform based on micro services. A campus network and private cloud are combined through a virtual private network to build a cloud platform, and a micro service architecture is utilized to build services of the cloud platform; using an open source project Eucalyptus developed by the Department of Computer Science of the University of California to set up private cloud; and all requests of a client first pass through an API gateway, then the API gateway routes the requests to appropriate micro services, and generally the APT gateway calls a plurality of micro services and merges a result to process a request. According to the invention, the micro service architecture is used for the college teaching cloud platform, application of the teaching cloud platform is decoupled into micro services of different functions, thereby enabling each link of teaching to be called in a micro service mode, the response is quick, and the efficiency is high; and the private cloud and the campus network are connected through the virtual private network to form the college teaching cloud platform, thereby providing better resource sharing for teachers and students, and the college teaching cloud platform has good elasticity and expansibility.

Owner:WUHAN UNIV OF TECH

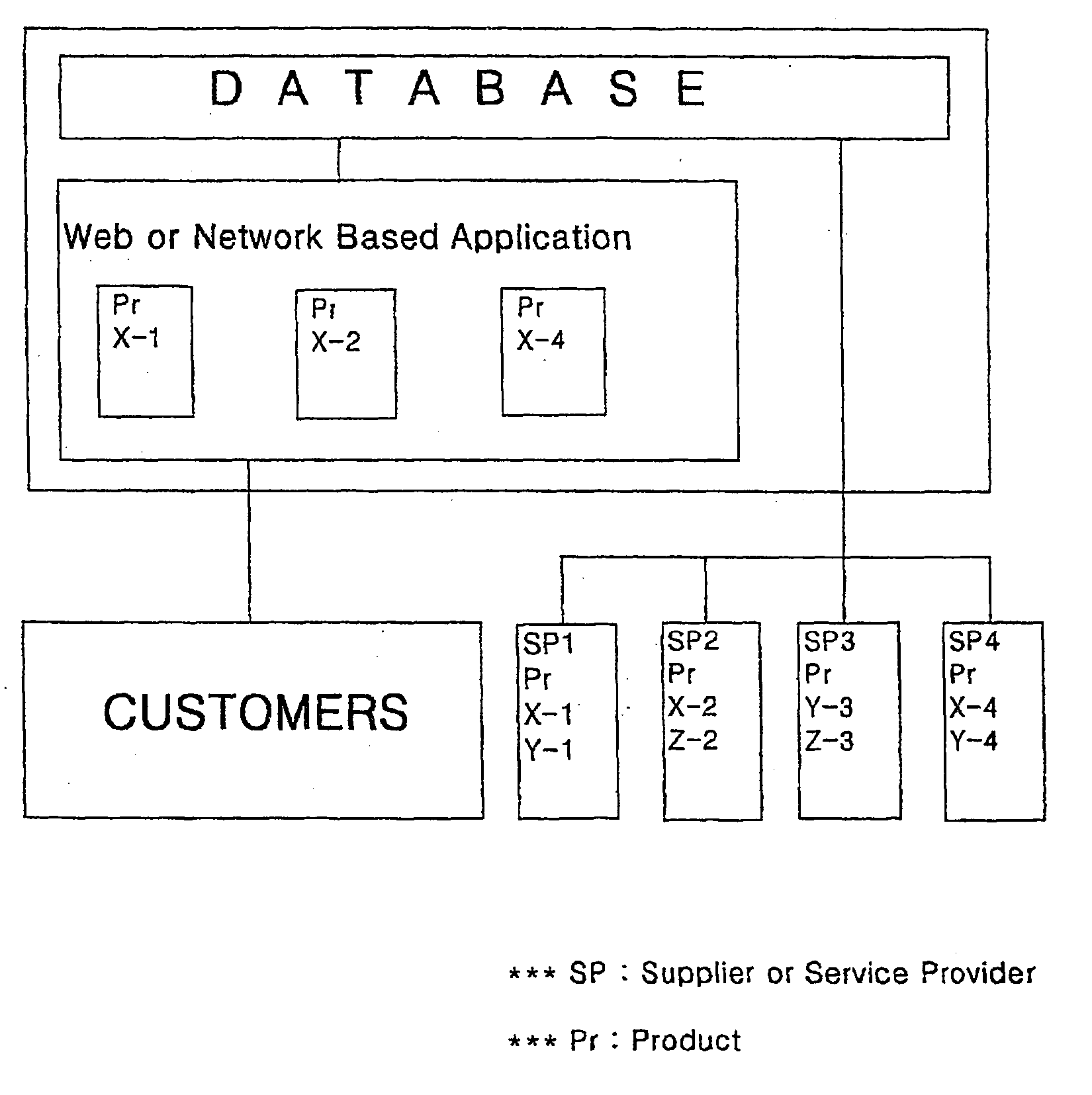

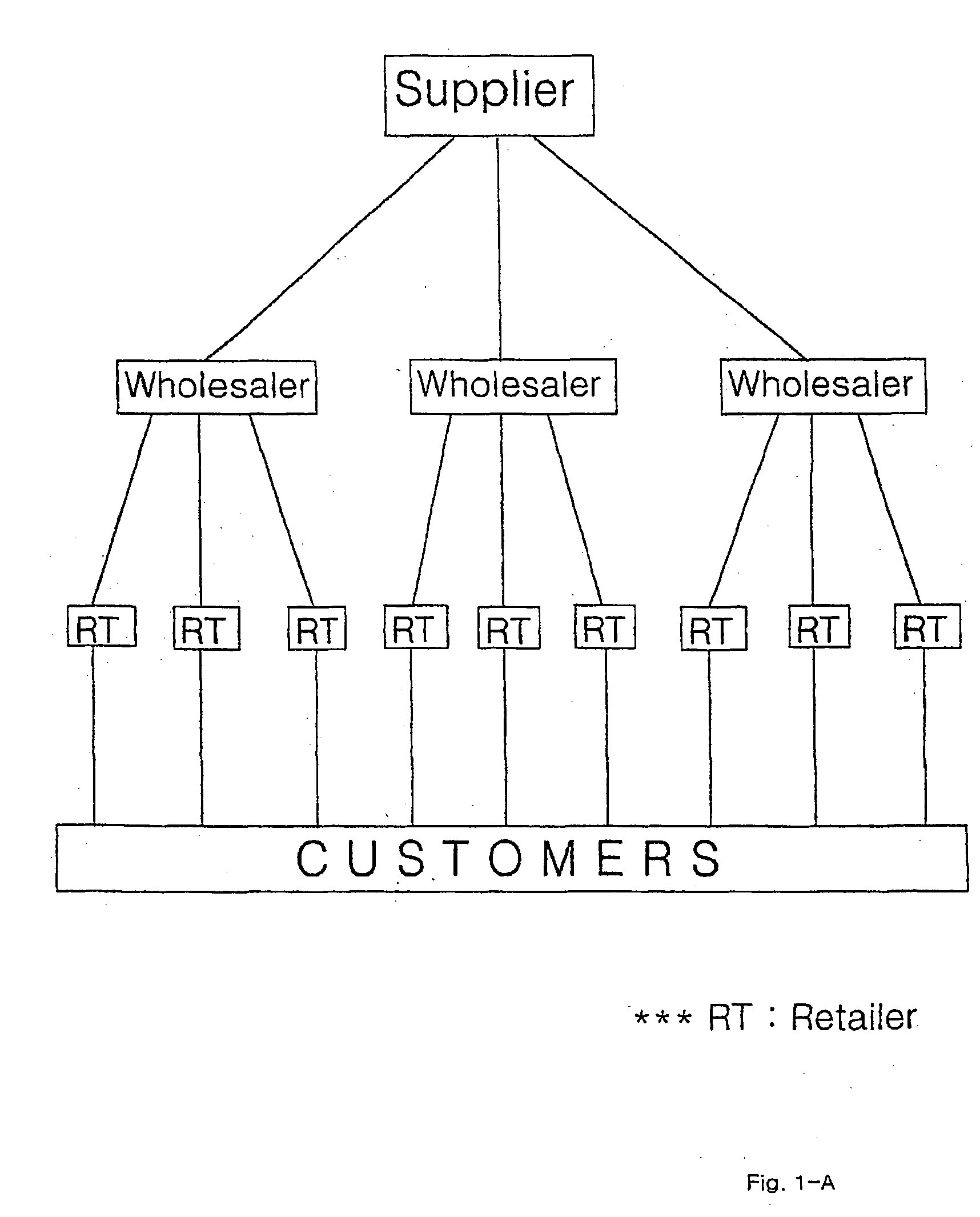

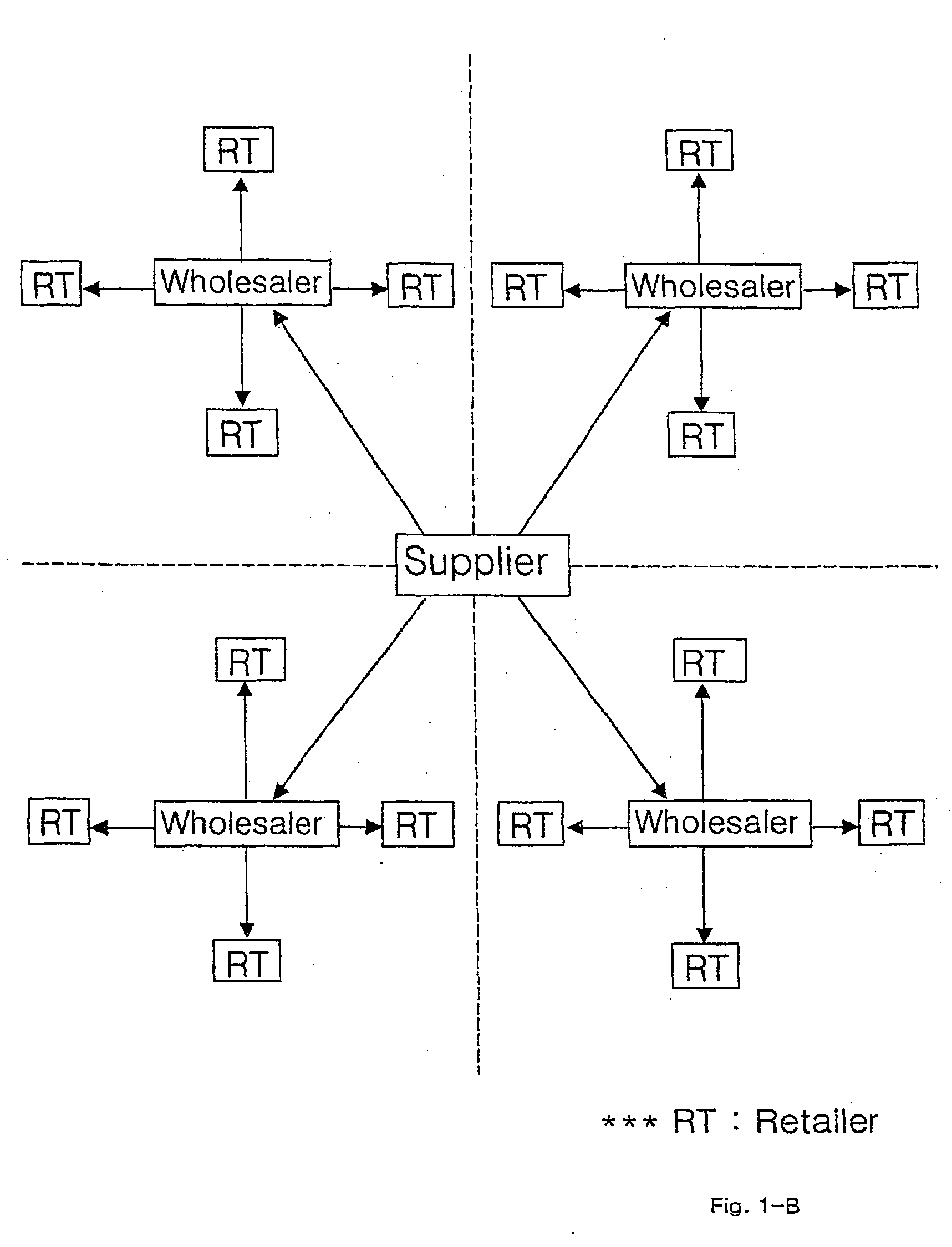

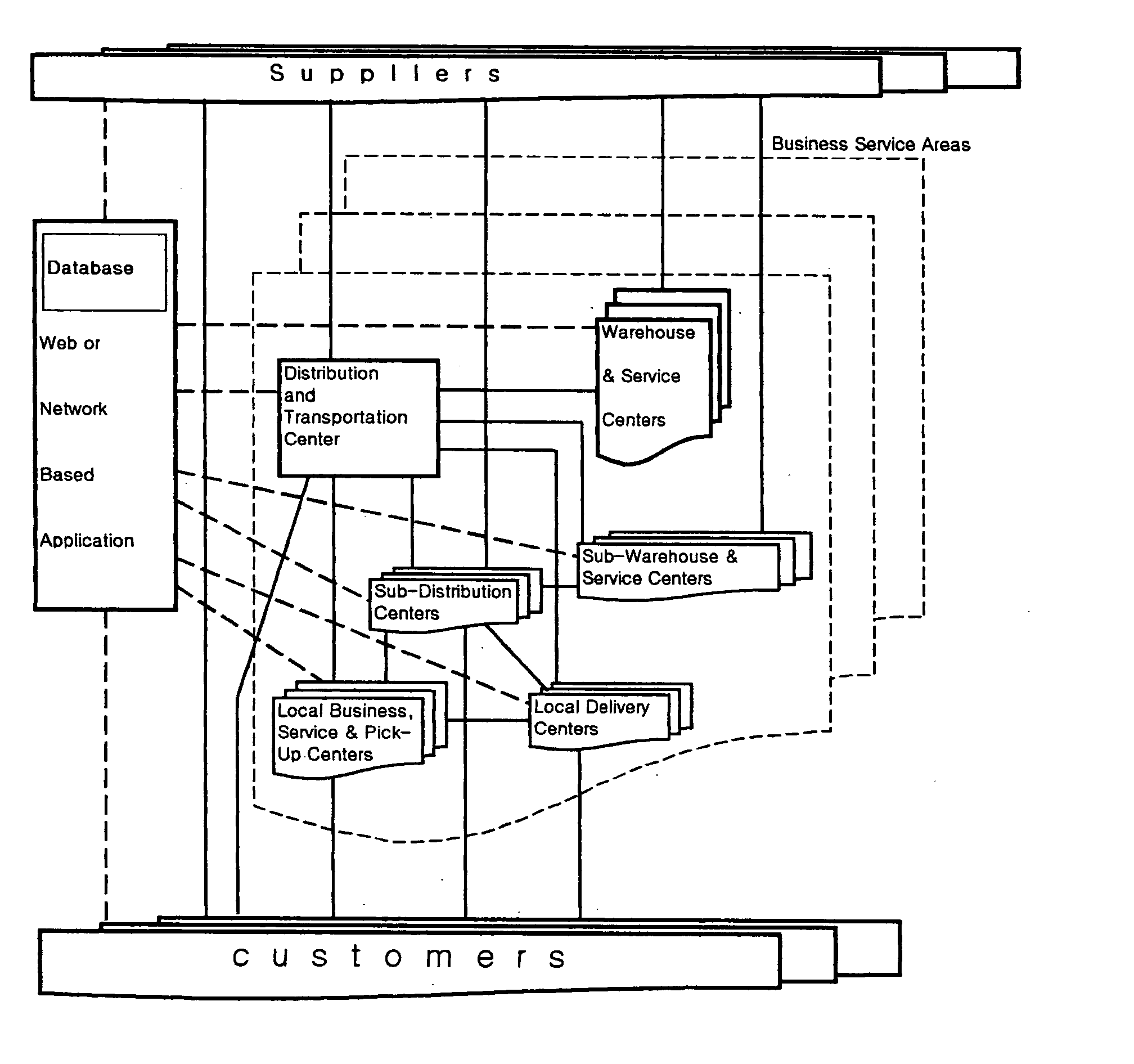

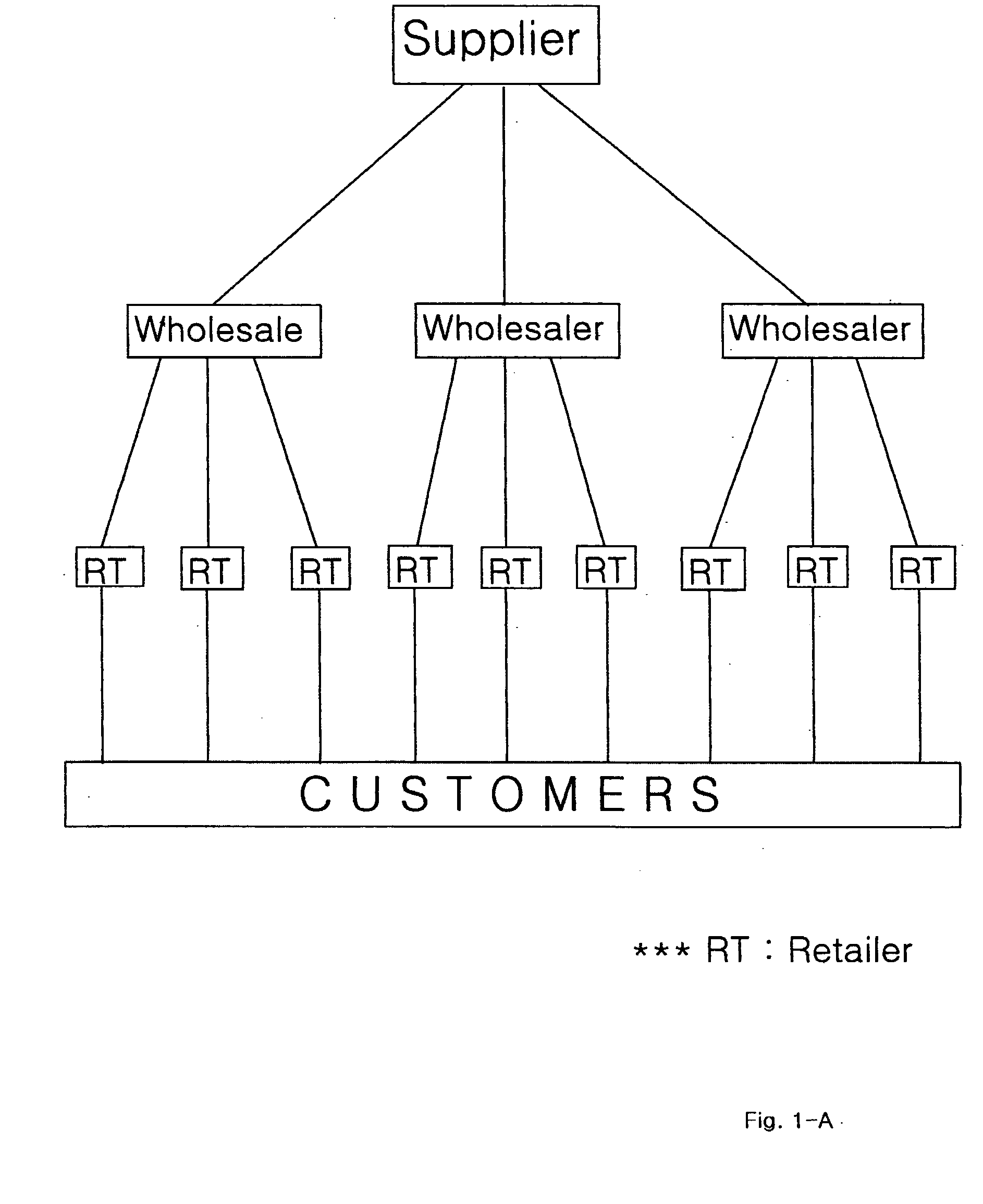

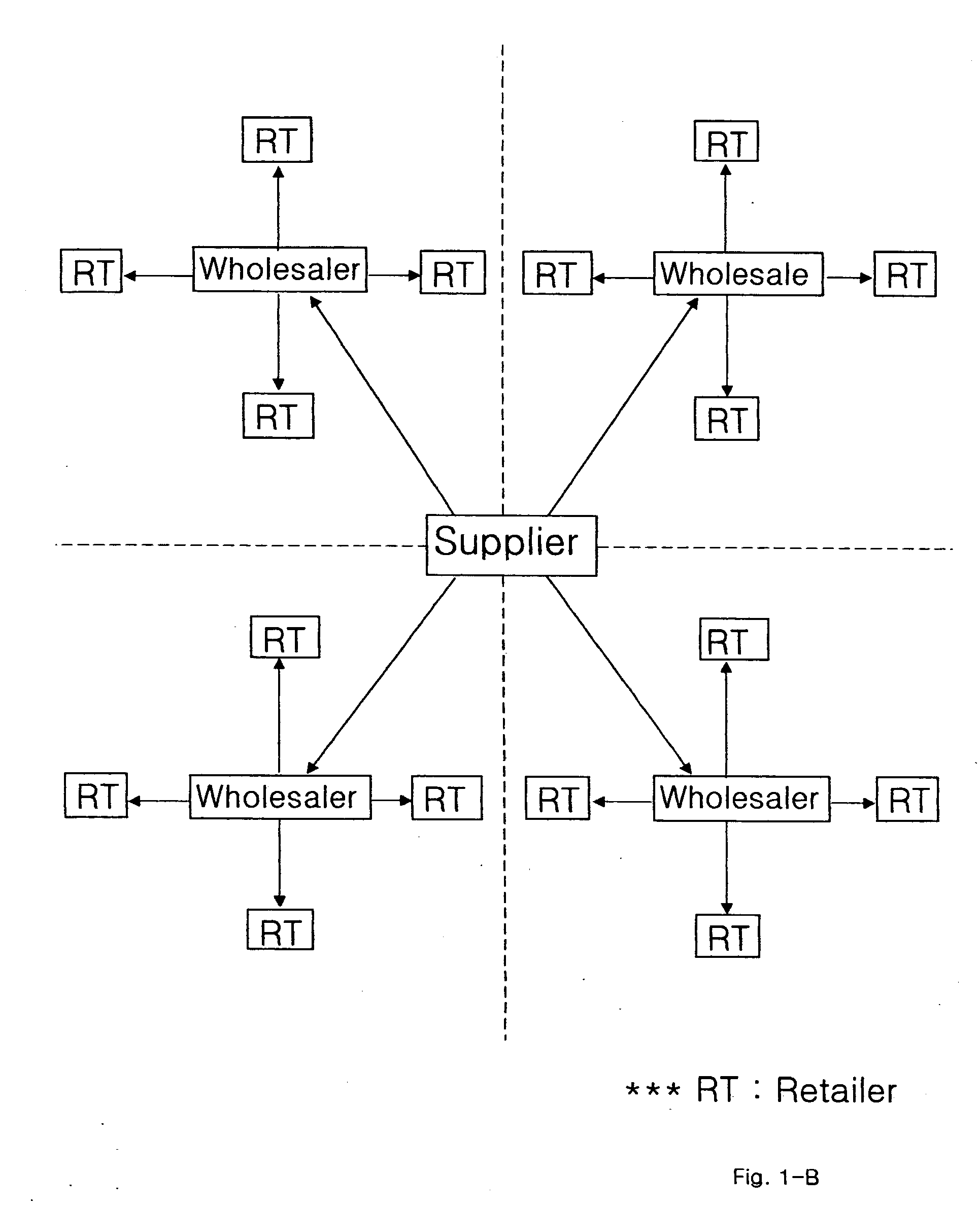

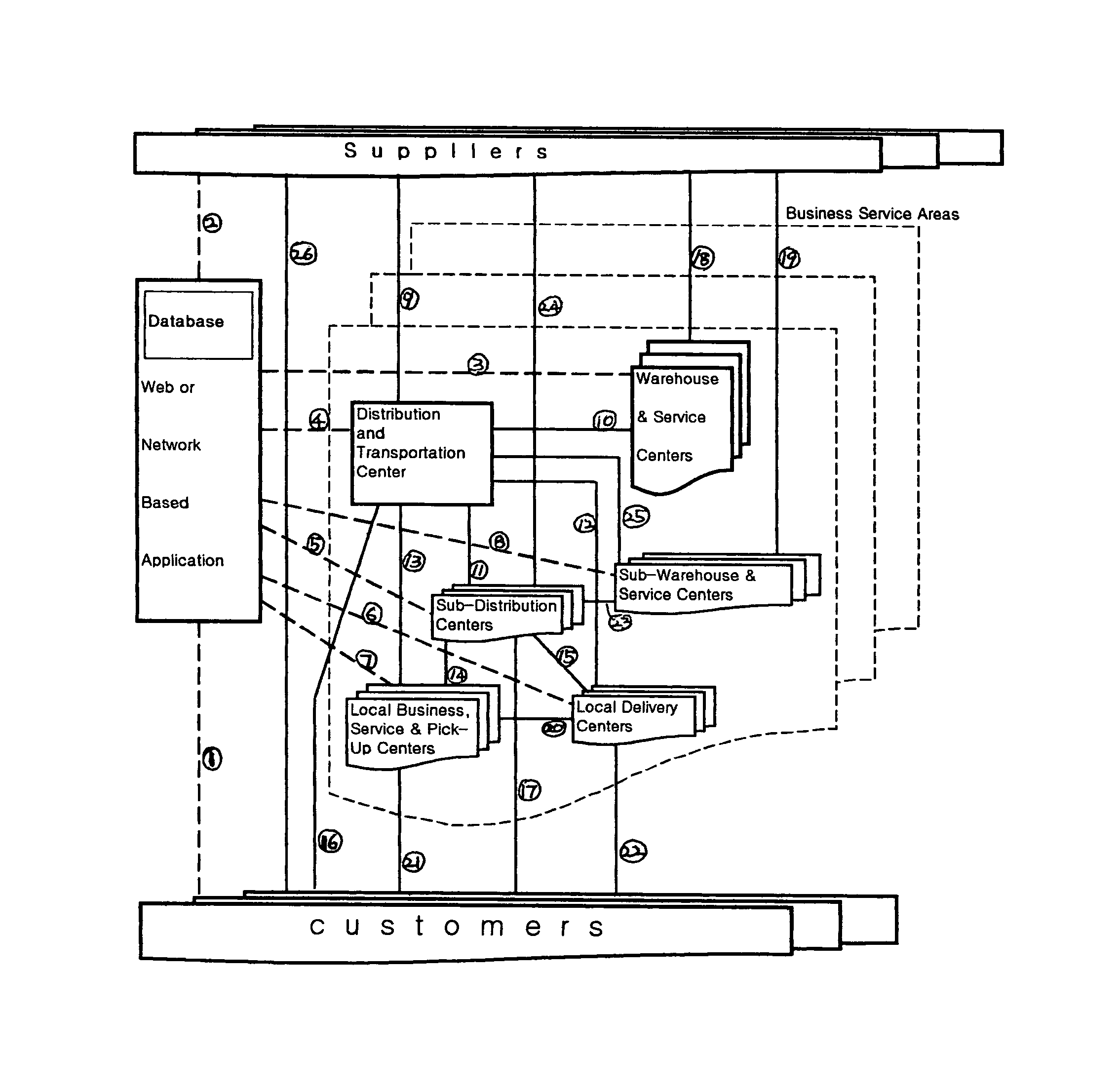

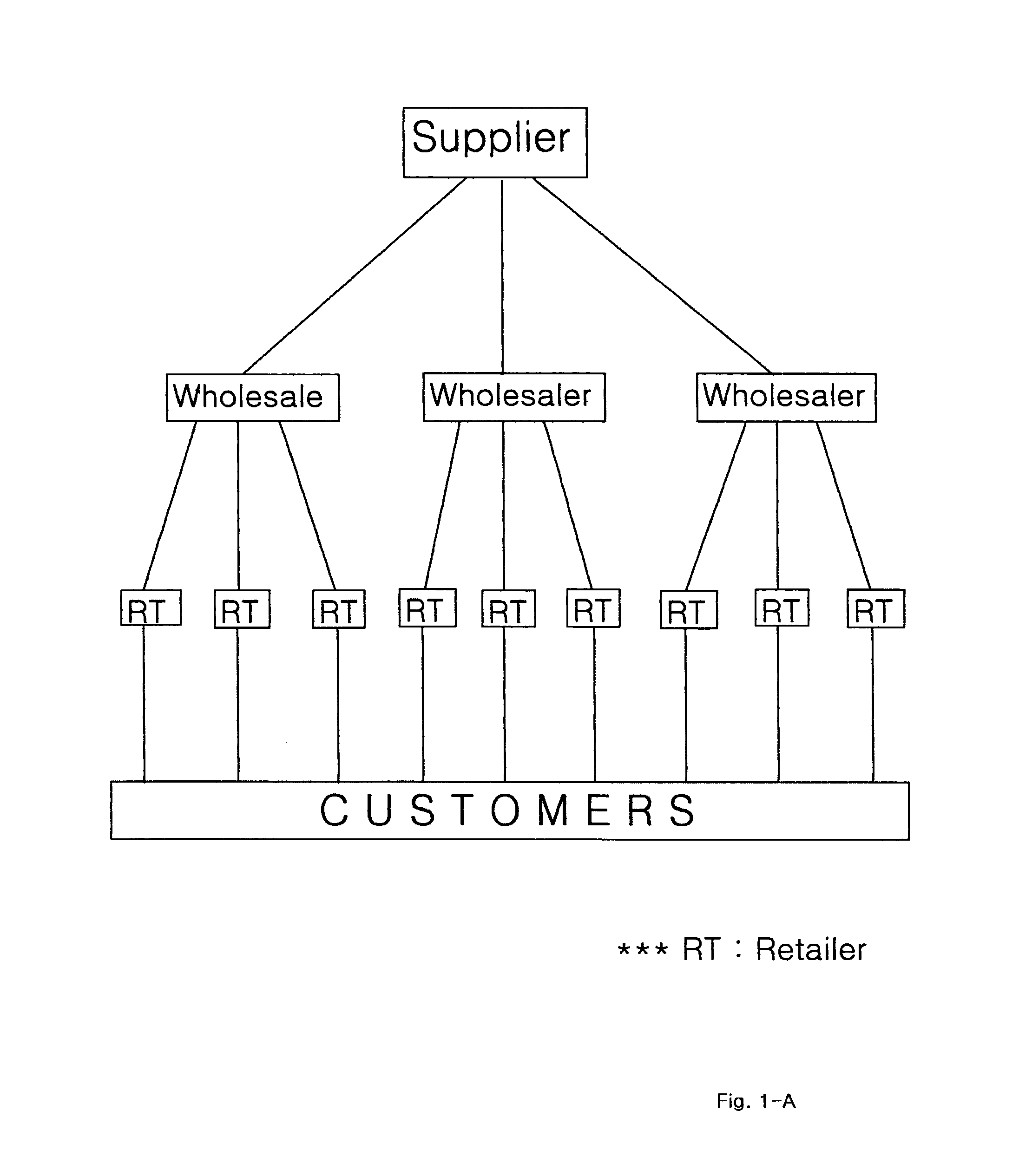

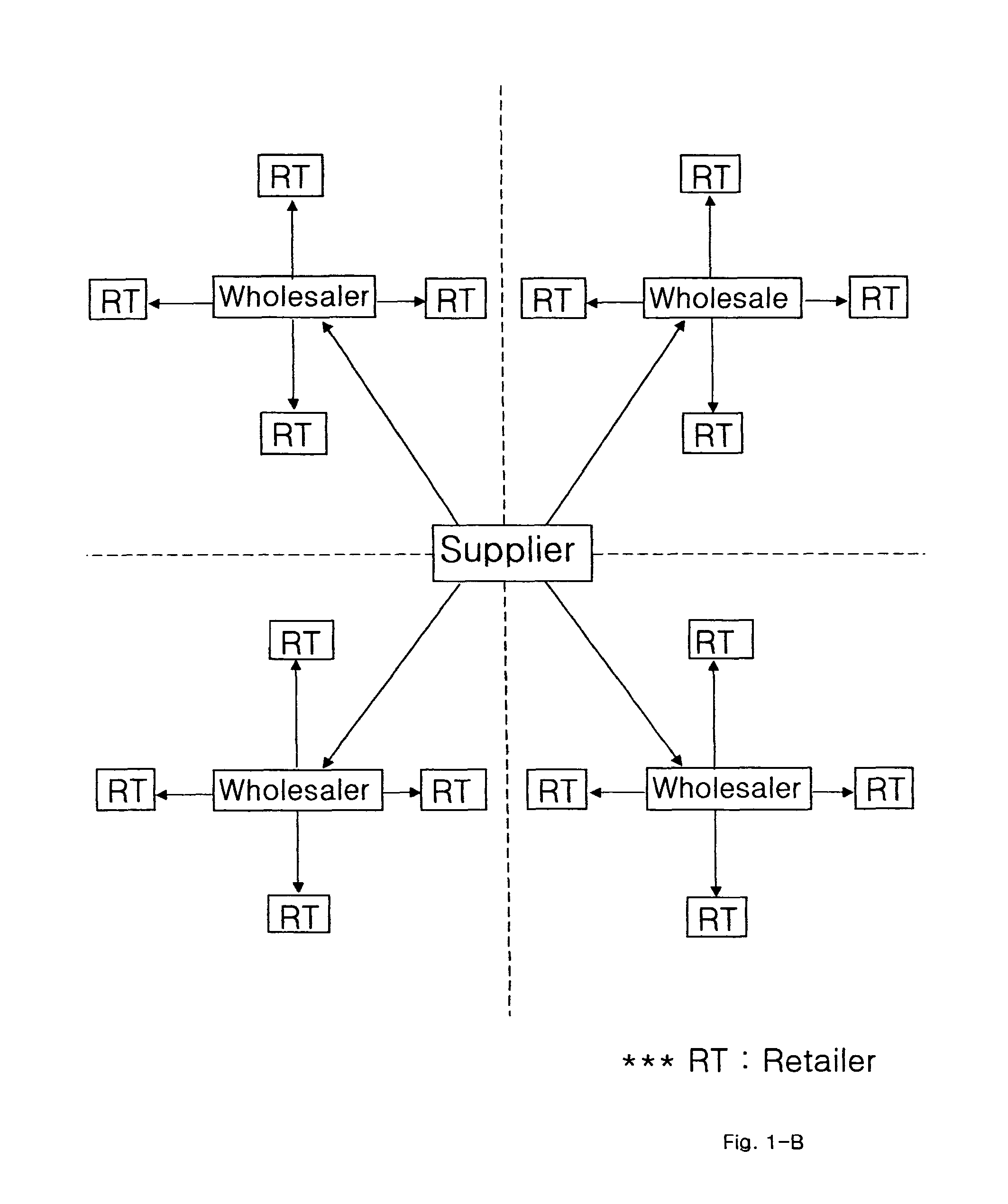

Direct distribution system for consumer goods and services

InactiveUS20050080635A1Improve convenienceIncrease volumeBuying/selling/leasing transactionsLogisticsDelivery costDistribution system

A system and method for enabling direct transactions between a customer and a provider of goods and / or services. A plurality of suppliers or service providers provide data regarding offerings and services, and a database of selected information is collected and integrated for review and comparison by potential customers. An efficient distribution system delivers products and services to local service and pick-up centers where the customer retrieves them, or delivers the products and services directly to the customer, depending on customer preference. The cost of delivery is dependent on the customer preference and is based on proximity of delivery to customer.

Owner:GROFF BRADLEY K +1

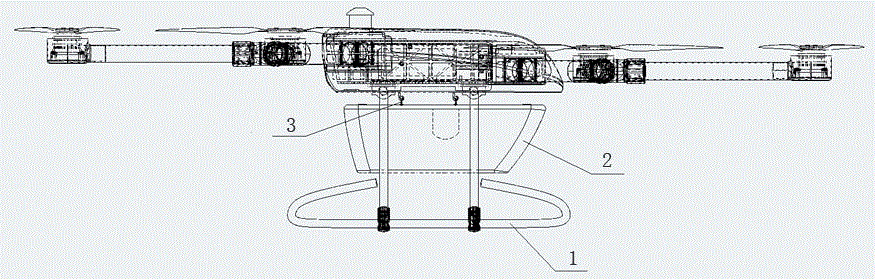

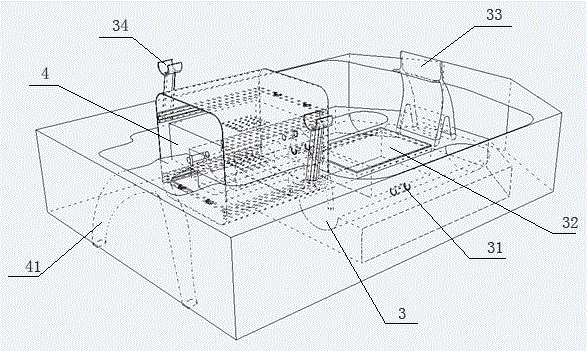

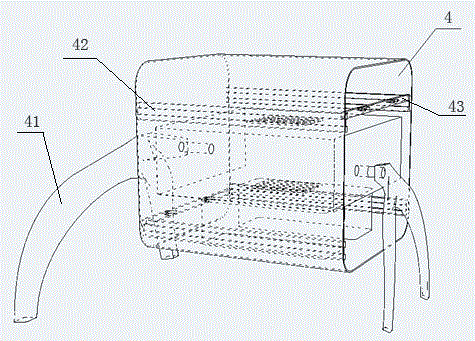

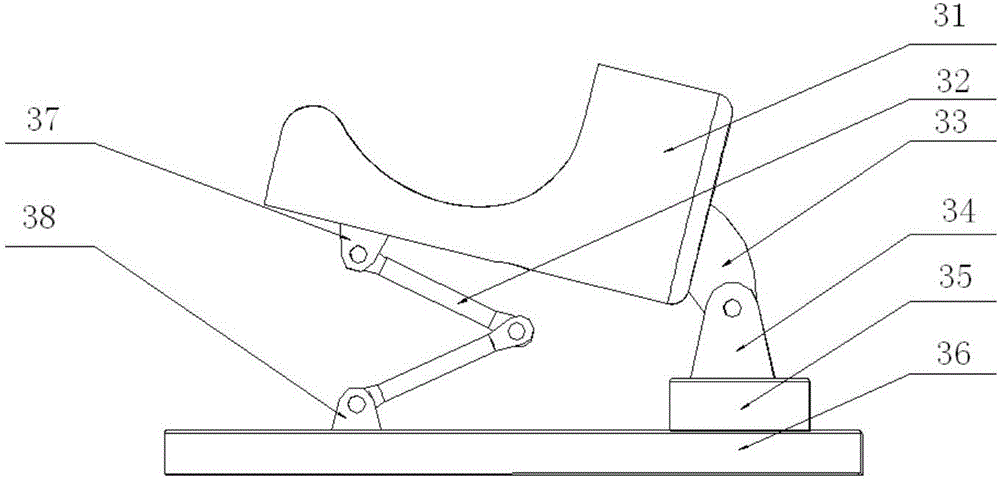

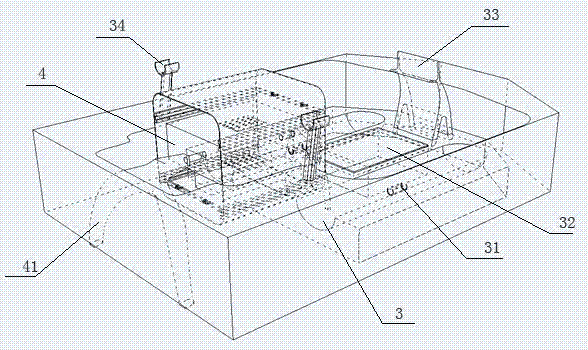

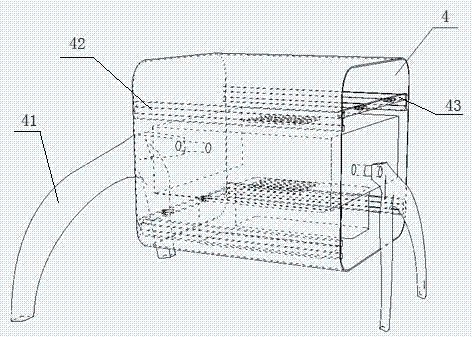

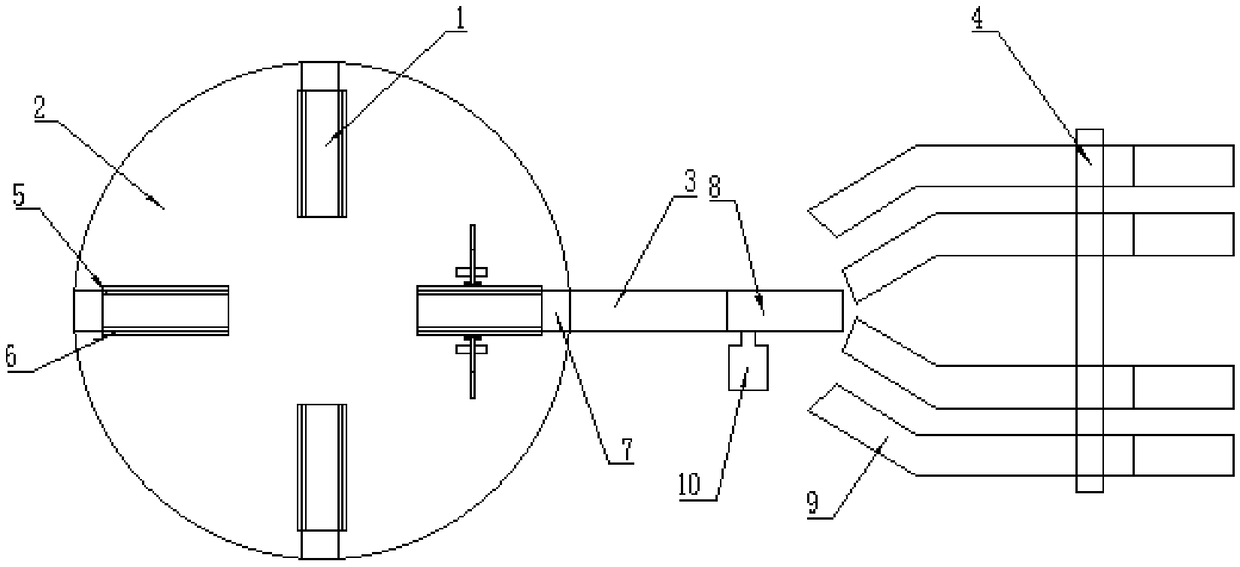

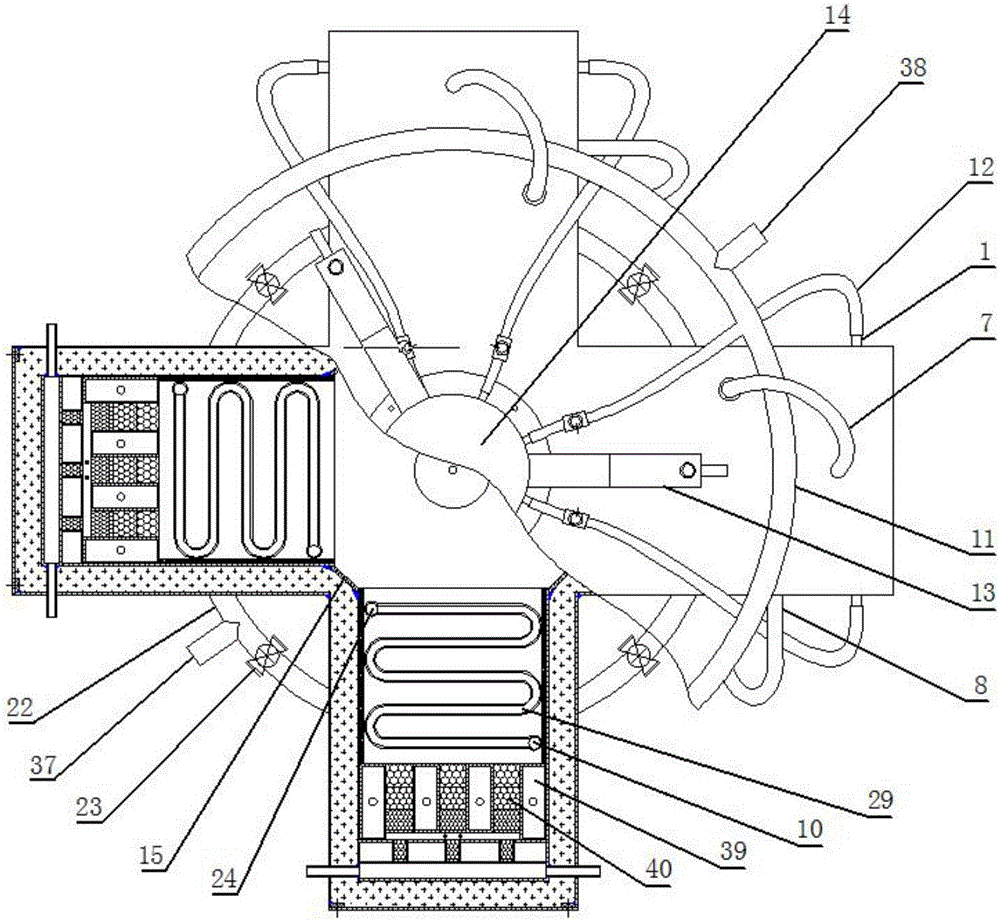

Unmanned aerial vehicle express system

The invention relates to the technical field of unmanned aerial vehicles, in particular to an unmanned aerial vehicle express system. The unmanned aerial vehicle express system comprises an unmanned aerial vehicle and express cabinets distributed on different networks. A battery pack of the unmanned aerial vehicle is horizontally and slidably arranged at the tail of the unmanned aerial vehicle, and a vertical lifting type express box is arranged below the unmanned aerial vehicle. A fixing device for fixing an undercarriage of the unmanned aerial vehicle is arranged at the top of each express cabinet. Limiting devices for fixing an unmanned aerial vehicle body are arranged on the front side and the rear side of each fixing device. A battery replacement device for replacing the battery pack is arranged on the rear side of each fixing device. An opening corresponding to the express box is formed in the position, located in the middle of the corresponding fixing device, of each express cabinet. A sorting device is arranged in each express cabinet. By the adoption of the unmanned aerial vehicle express system, delivery can be conducted quickly and effectively, the problems that the express delivery efficiency is low, and the coverage range is narrow are solved, and accurate delivery is achieved; and batteries of the unmanned aerial vehicle can be replaced automatically, the defects that the voyage is short and the load is low are overcome, meanwhile express receiving and delivery are integrated, and stable delivery of objects is guaranteed.

Owner:LINYI HI TECH ZONE XIANGHONG ELECTRONICS SCI & TECH CO LTD +2

Direct distribution system for consumer goods and services

ActiveUS20050137935A1Increase volumeReduce operating costsCommerceSpecial data processing applications

A system and method for enabling direct transactions between a customer and a provider of goods and / or services. A plurality of suppliers or service providers provide data regarding offerings and services, and a database of selected information is collected and integrated for review and comparison by potential customers. An efficient distribution system delivers products and services to local service and pick-up centers where the customer retrieves them, or delivers the products and services directly to the customer, depending on customer preference. The cost of delivery is dependent on the customer preference and is based on proximity of delivery to customer.

Owner:LEE HOHYUNG

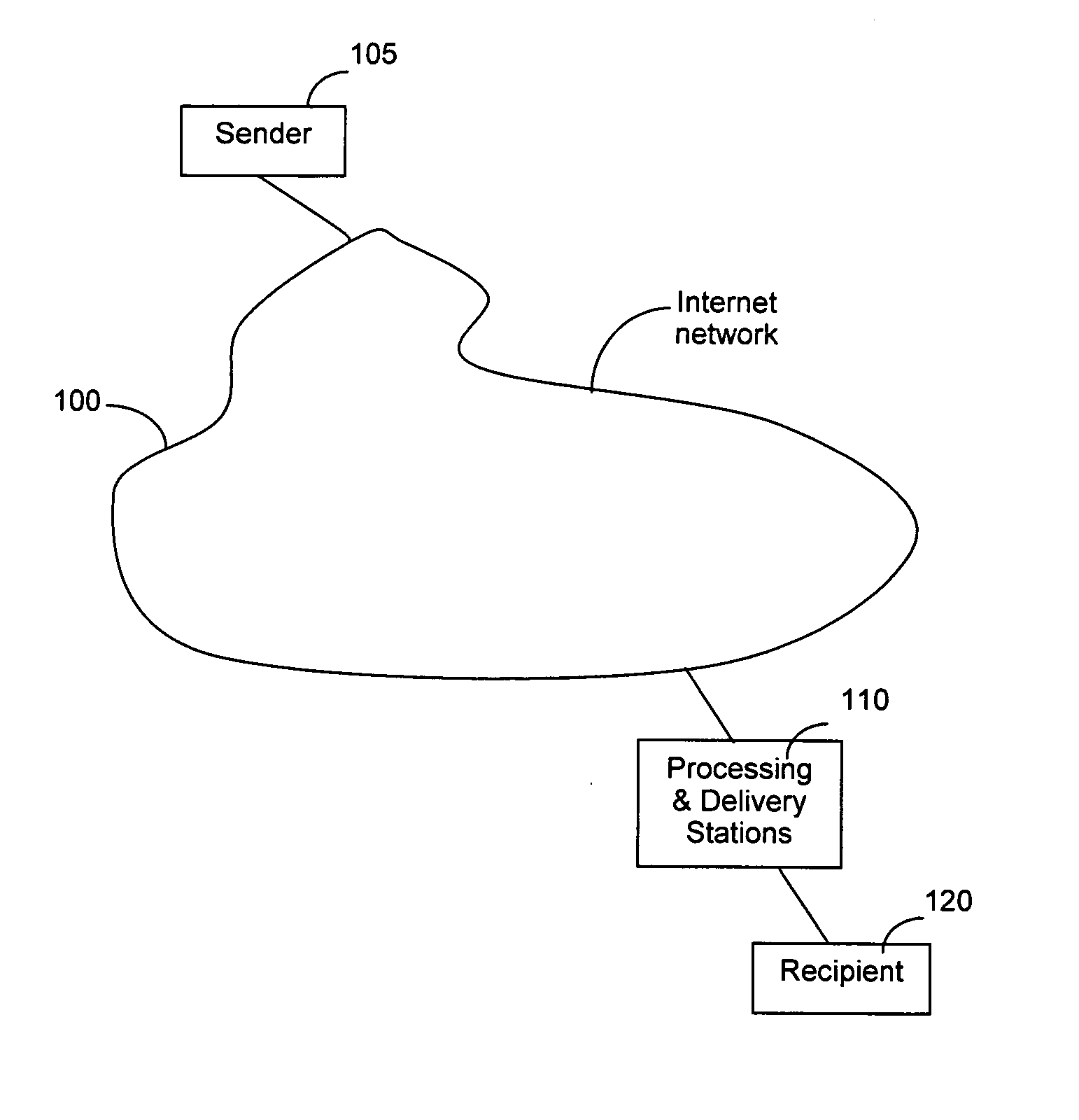

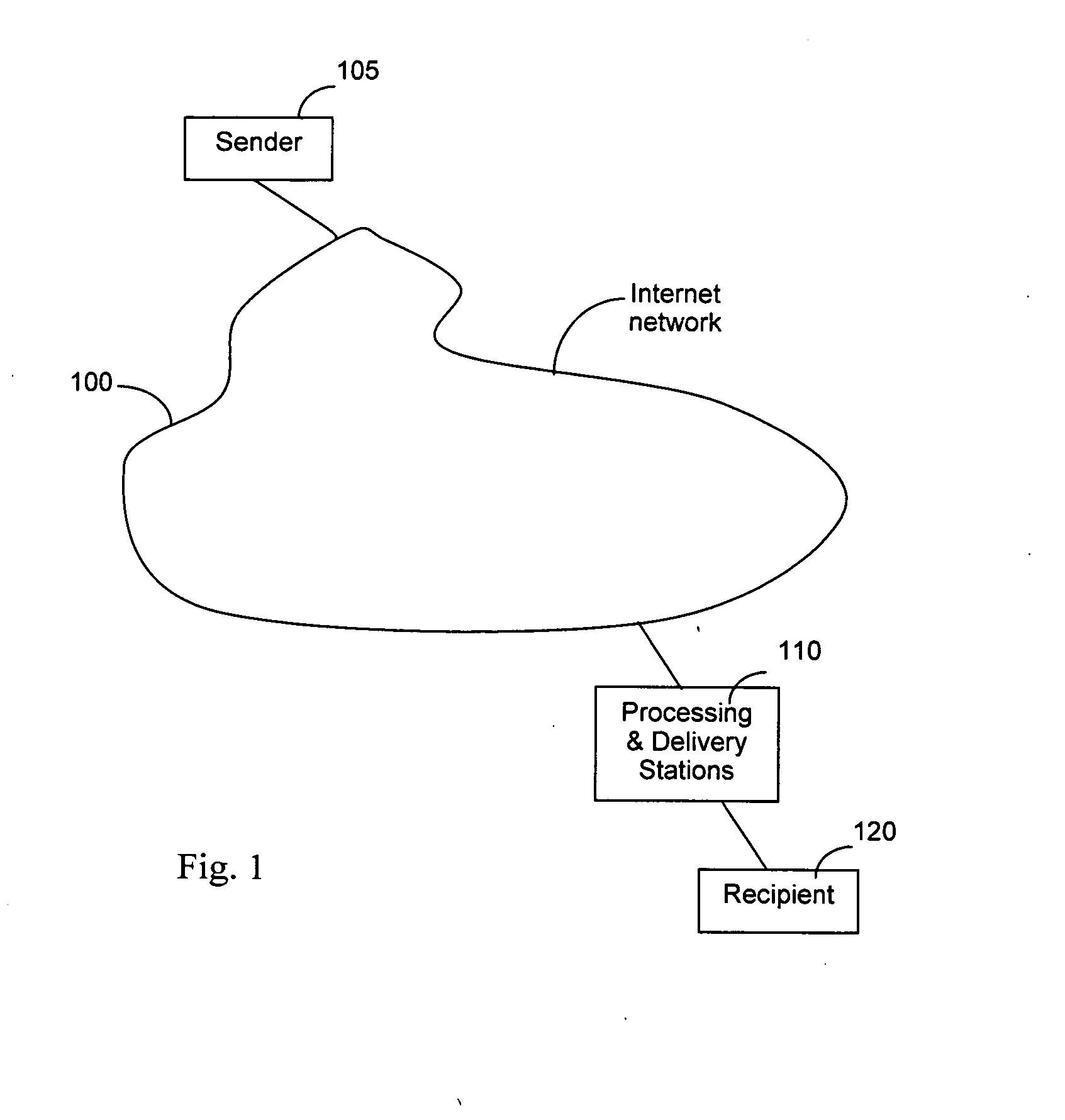

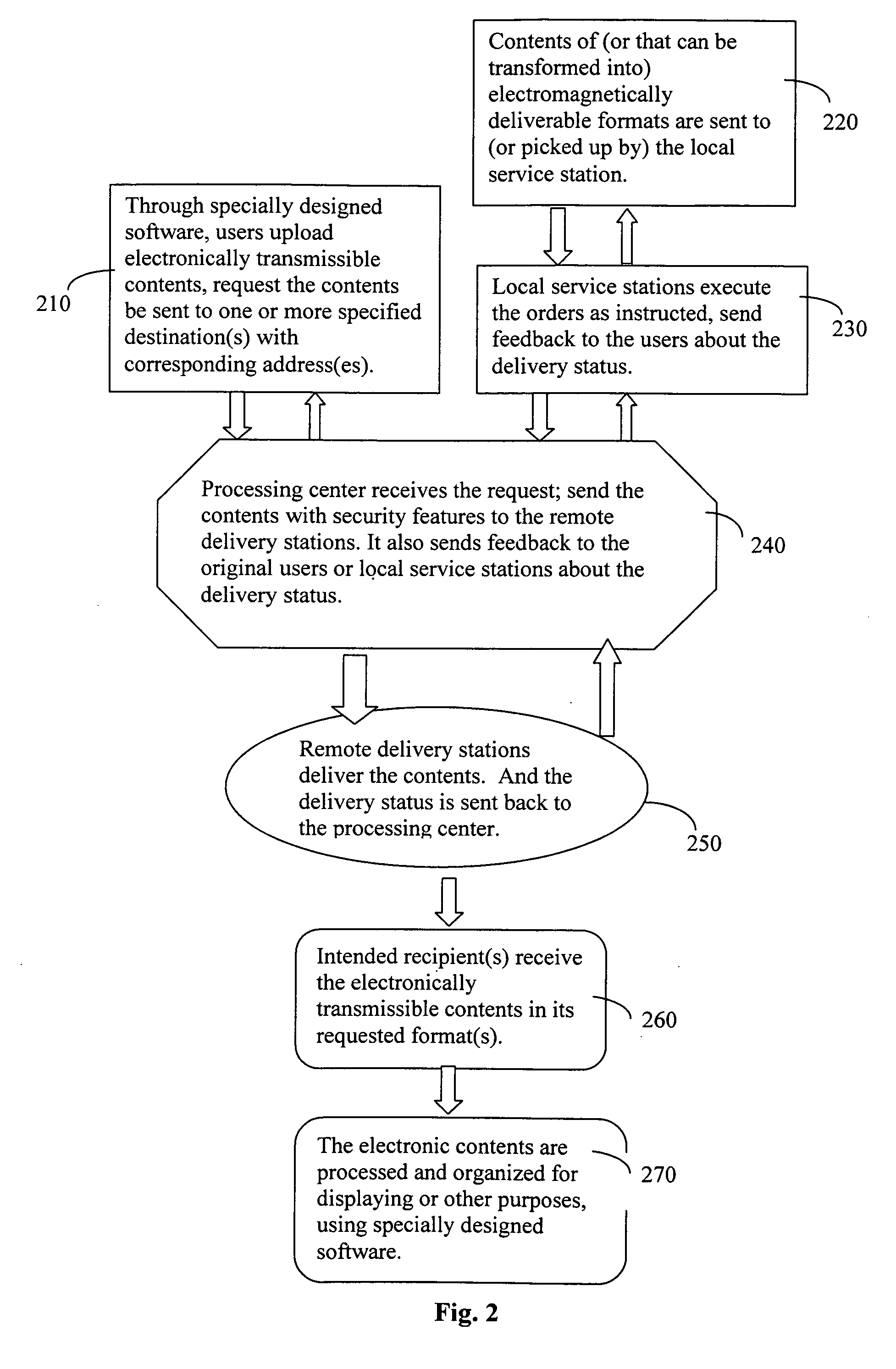

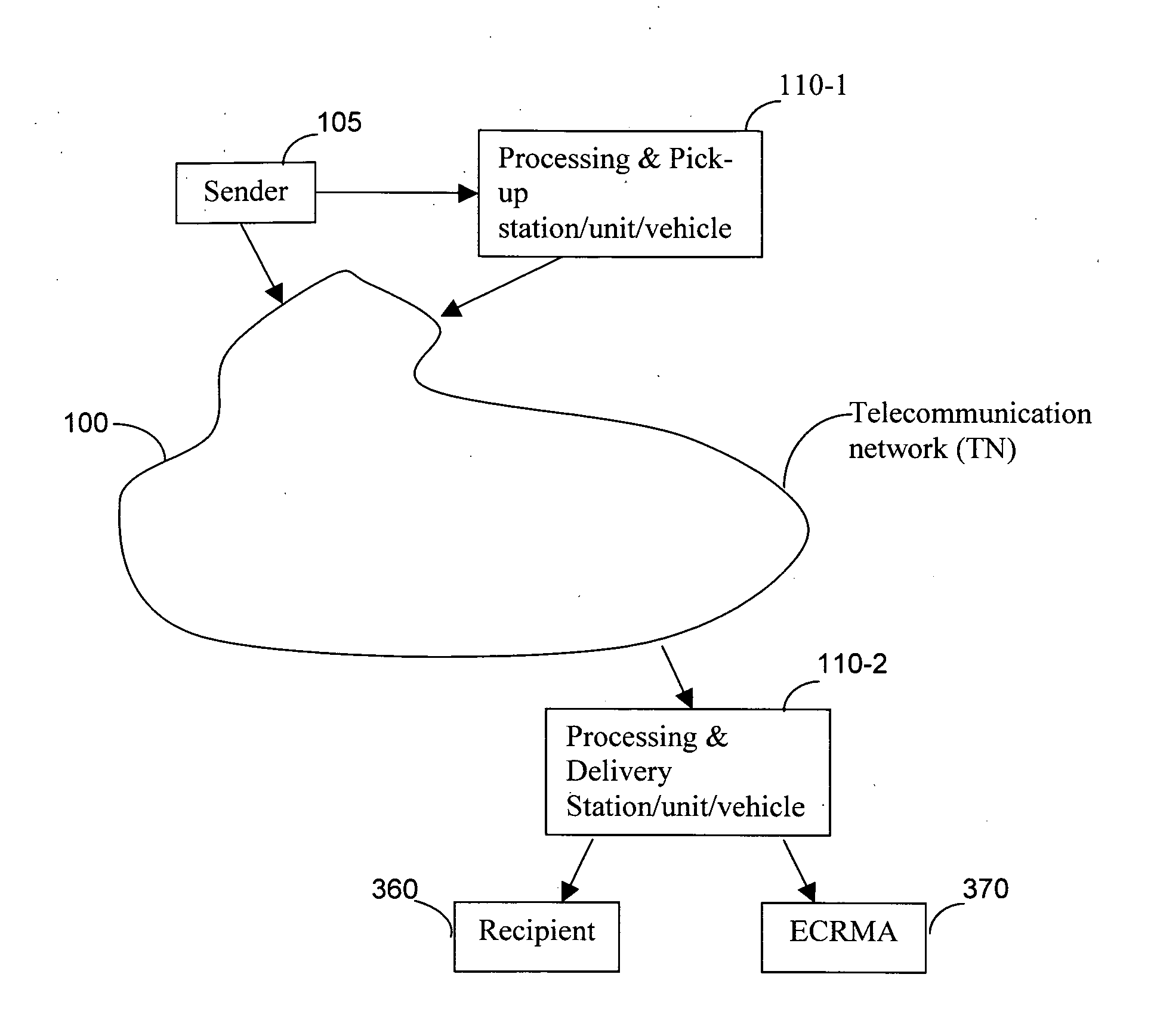

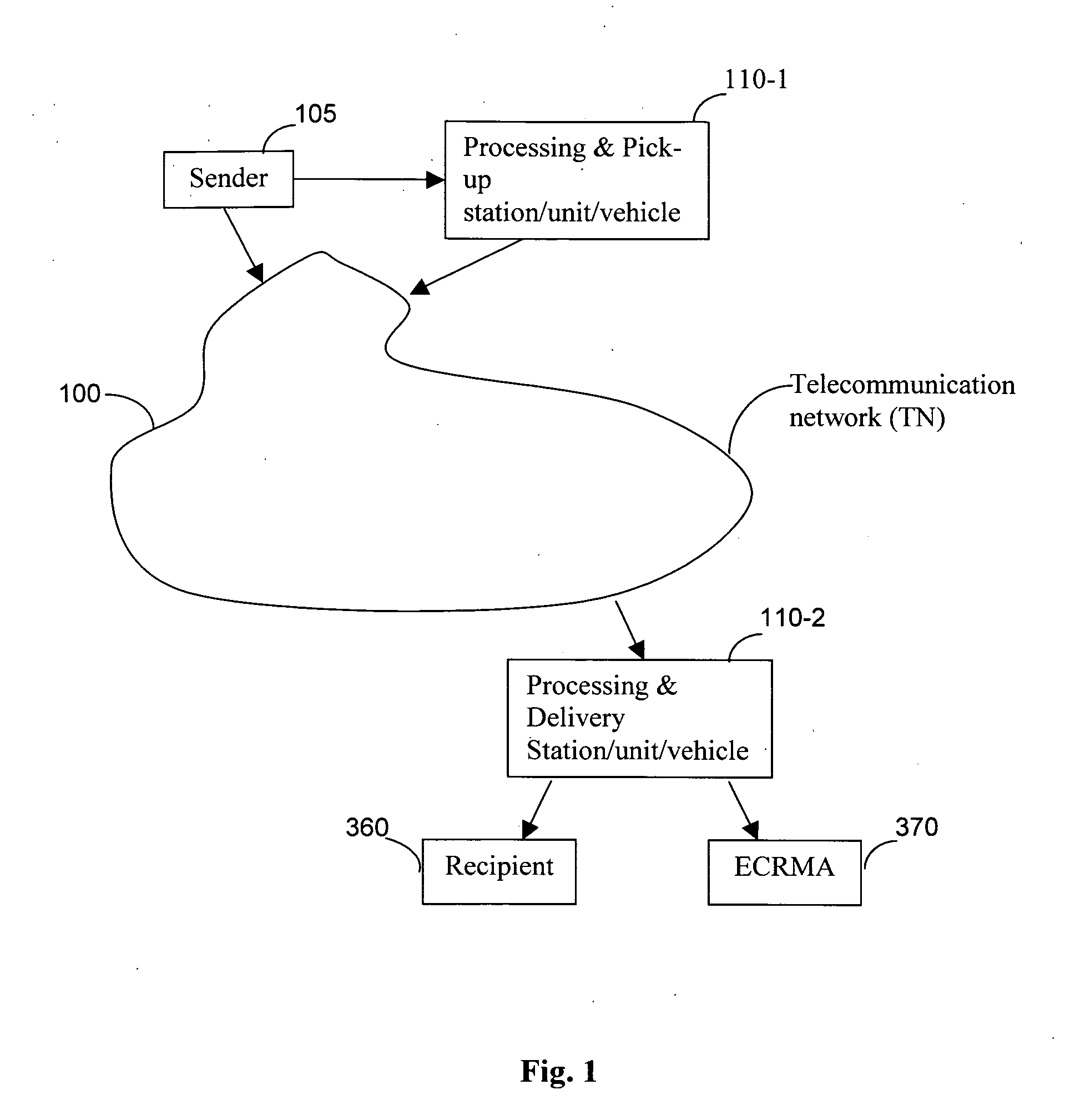

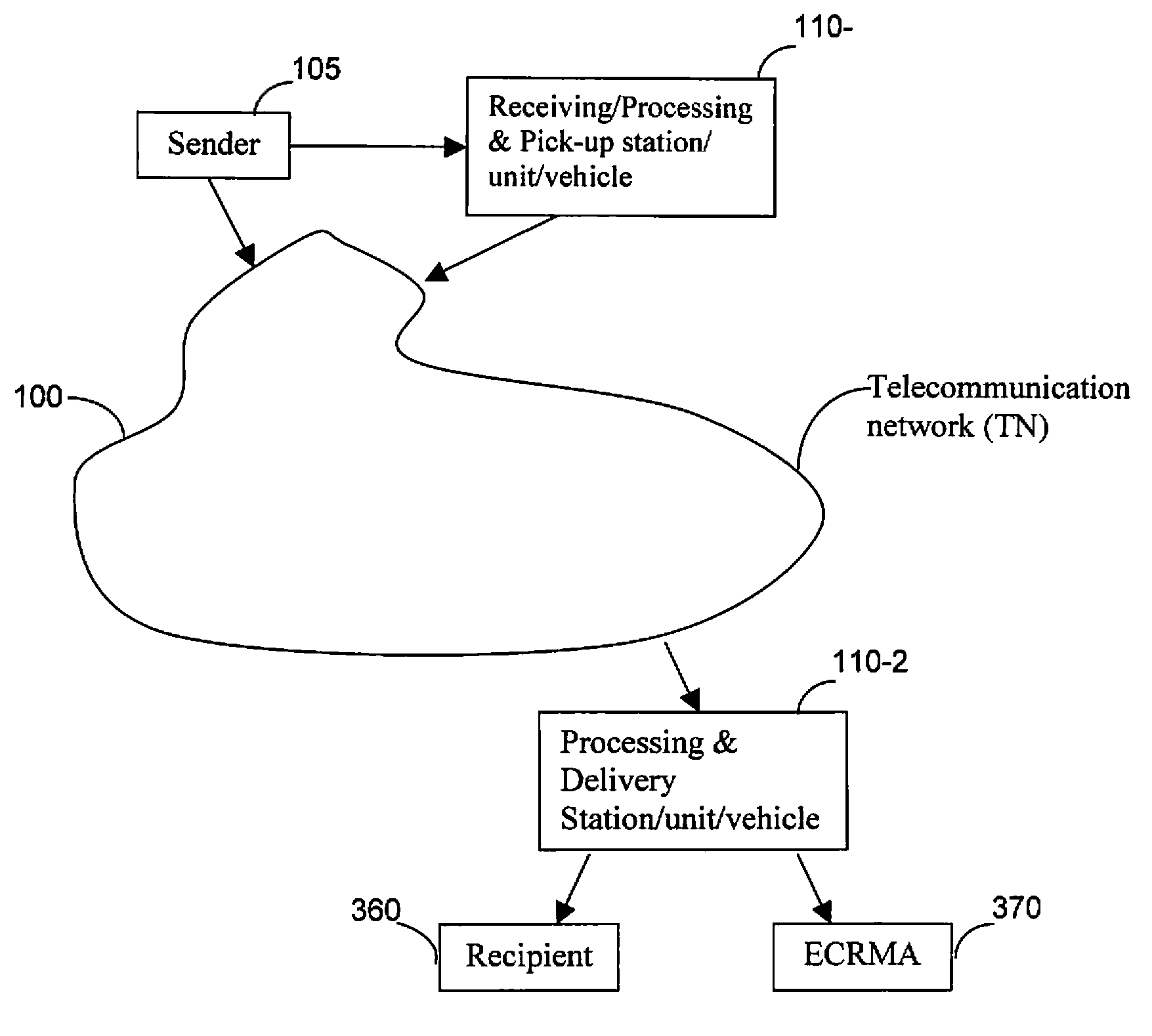

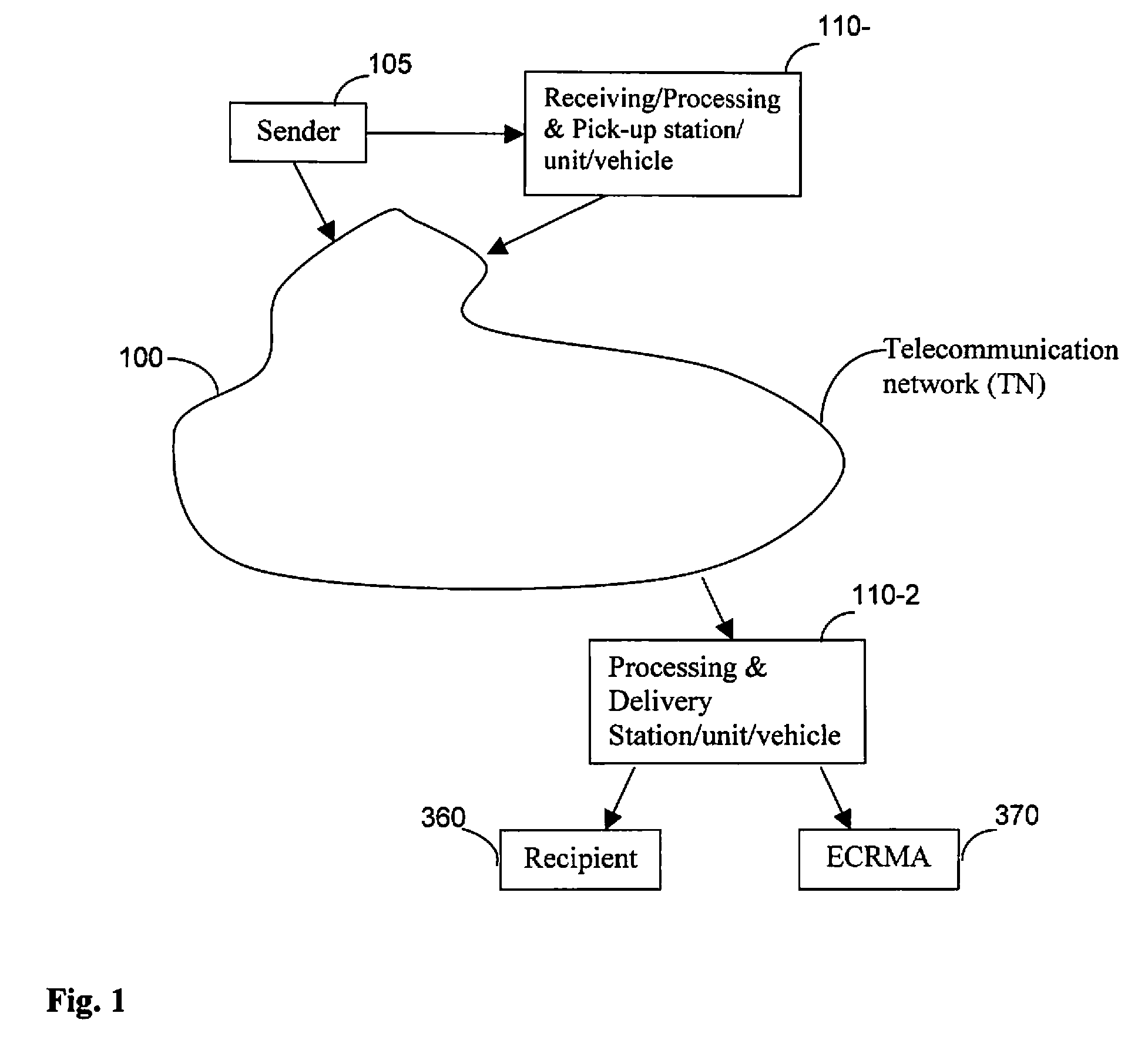

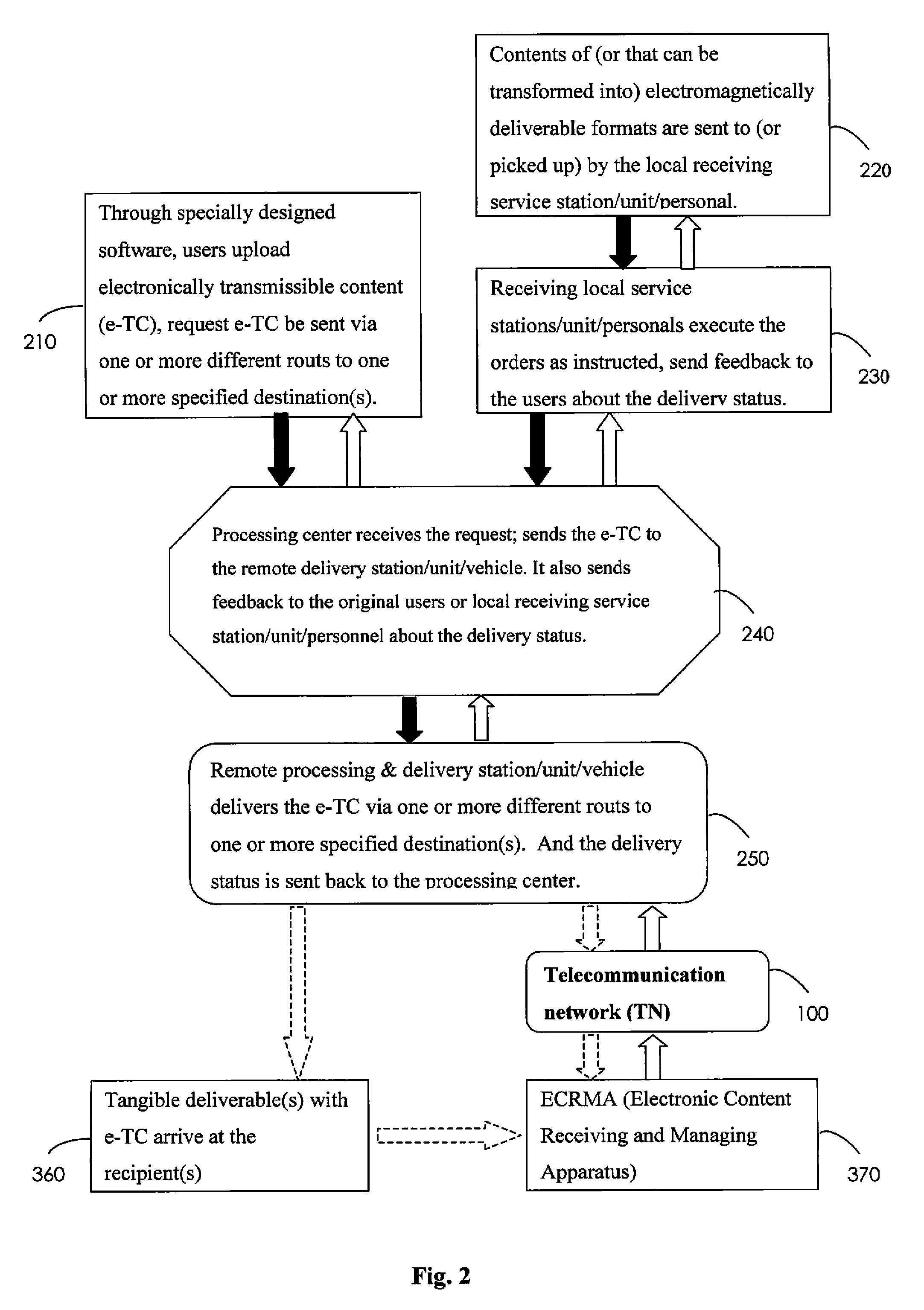

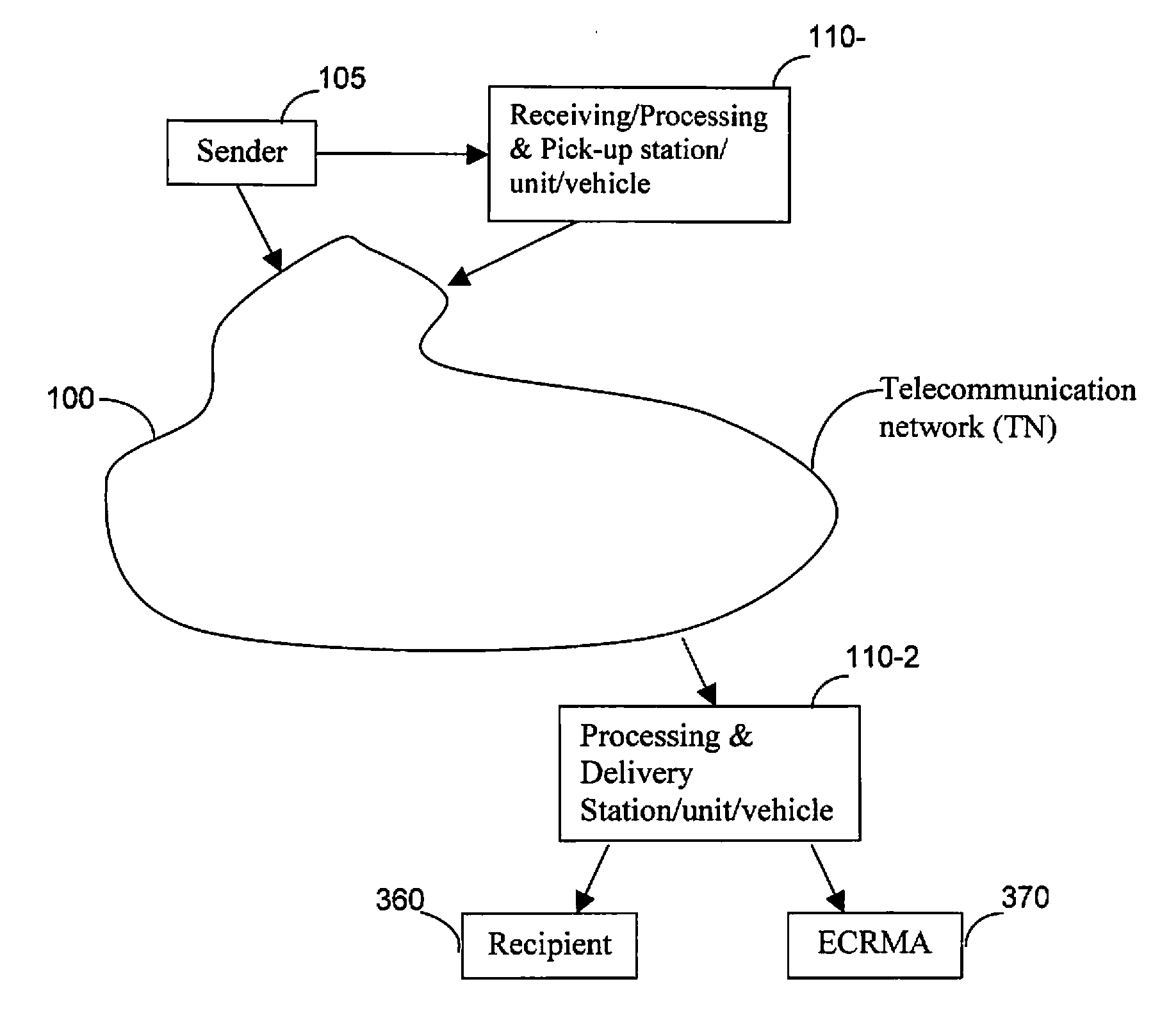

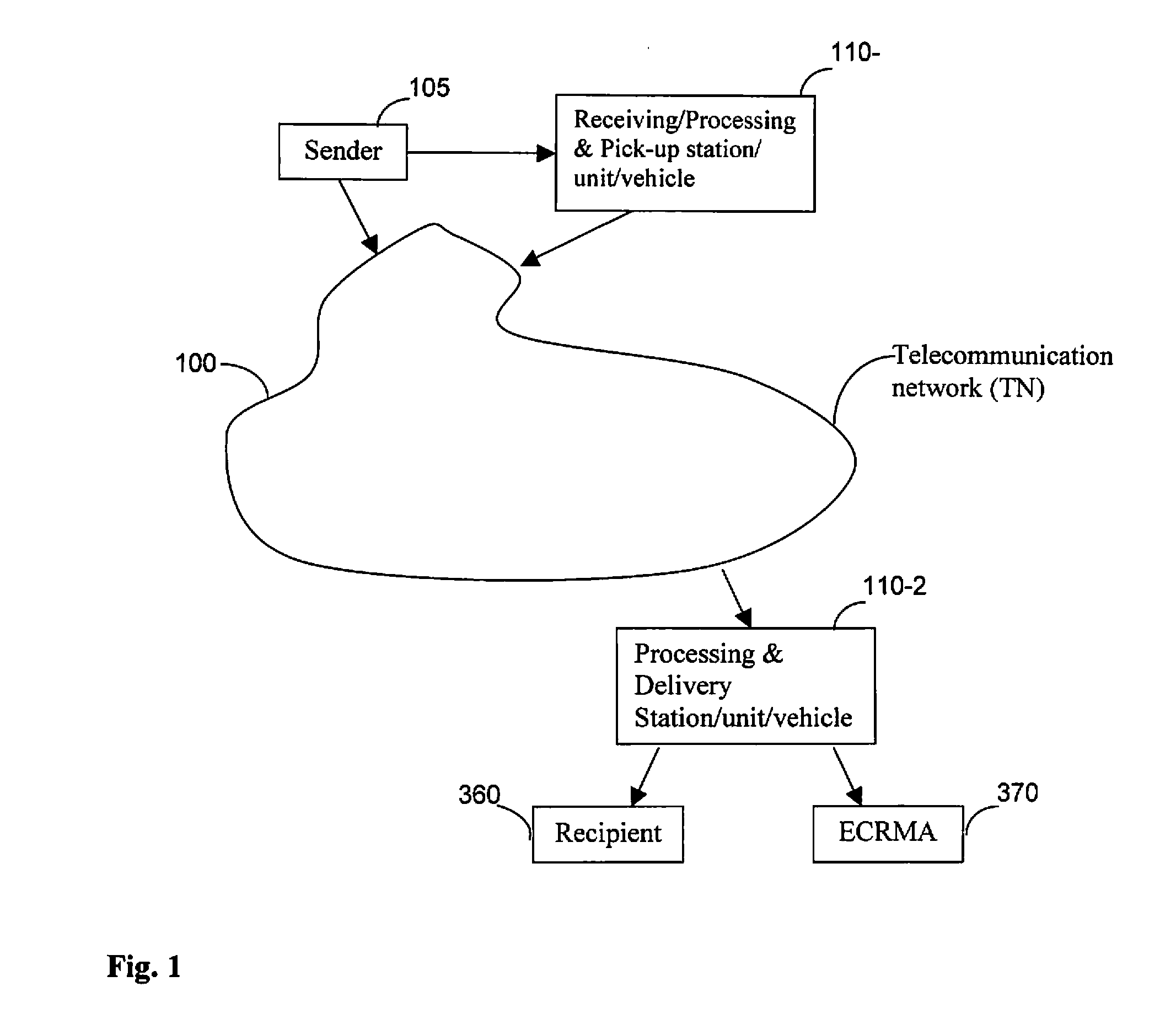

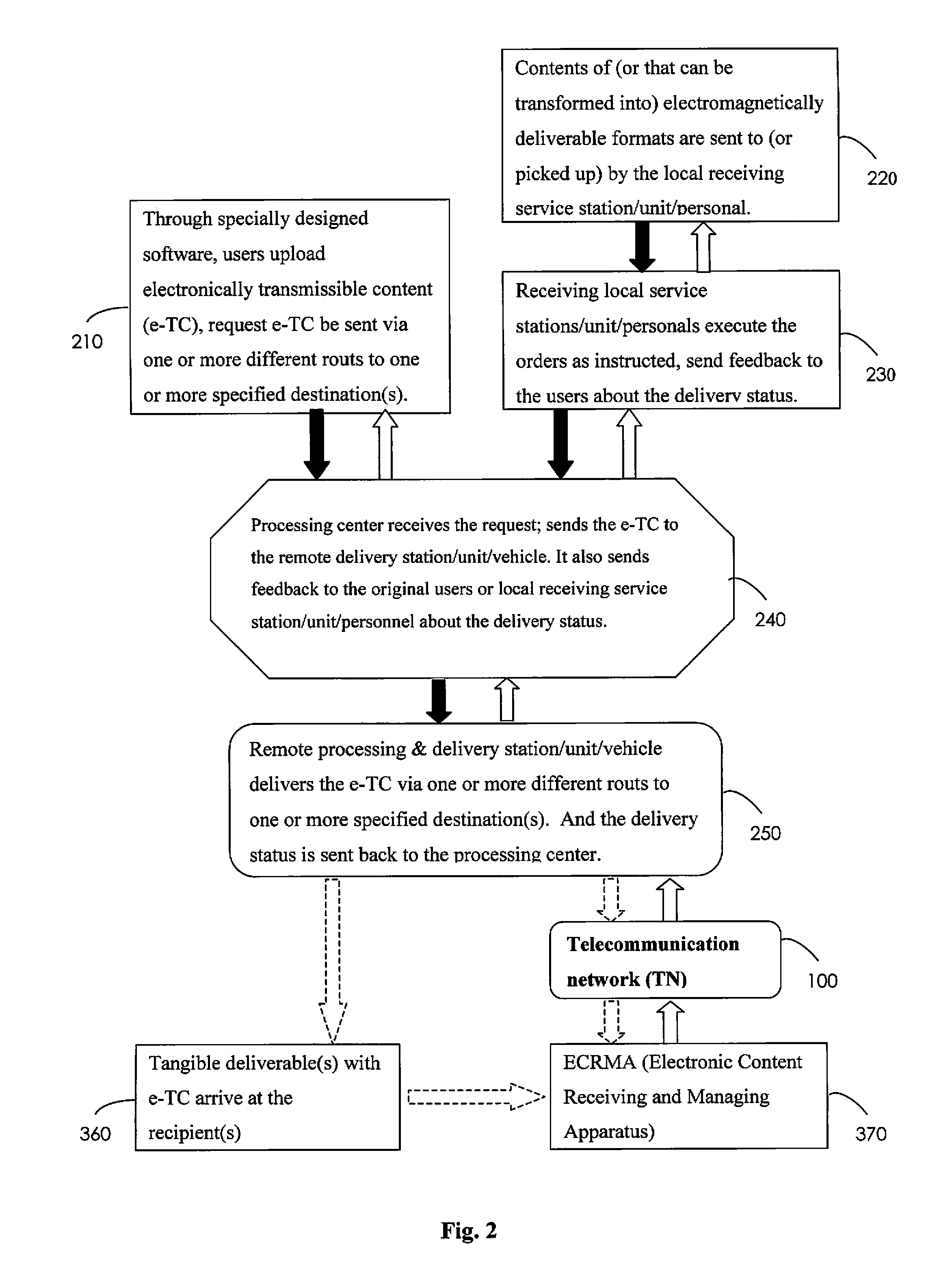

User initiated and controlled electromagnetic transmissions for remotely rendering a tangible delivarable to recipients

InactiveUS20090089385A1Fast and efficient deliveryImprove efficiencyMultiple digital computer combinationsData switching networksCommunications systemNetwork communication

The present invention discloses a network communication system that includes a network processing center for receiving and converting an electro-magnetically transmissible data / content into a physically deliverable object for physically delivering to a recipient.

Owner:DU LEE

Methods and products related to pulmonary delivery of polysaccharides

InactiveUS7709461B2Fast and efficient deliveryReduce the amount requiredPowder deliveryOrganic active ingredientsWhole bodyTherapeutic effect

Owner:MASSACHUSETTS INST OF TECH

Direct distribution system for consumer goods and services

ActiveUS8793194B2Improve convenienceIncrease volumeLogisticsCommerceDistribution systemWorld Wide Web

A system and method for enabling direct transactions between a customer and a provider of goods and / or services. A plurality of suppliers or service providers provide data regarding offerings and services, and a database of selected information is collected and integrated for review and comparison by potential customers. An efficient distribution system delivers products and services to local service and pick-up centers where the customer retrieves them, or delivers the products and services directly to the customer, depending on customer preference. The cost of delivery is dependent on the customer preference and is based on proximity of delivery to customer.

Owner:LEE HOHYUNG

Plaster for treating bony spur and osteoproliferation and preparation method thereof

InactiveCN101085181AQuick resultsGood curative effectHydroxy compound active ingredientsAerosol deliveryMyrrhOsteoproliferation

The invention provides a medicinal paste for treating Chinese honeylocust spine and hyperosteogeny and its preparing process, wherein the raw material herbs include the following constituents (by weight ratio): Chinese angelica root, Chinese ephedra, rhubarb horsetails, radix paeoniae rubrathe, dried rehmannia root, goldthread root, licorice root, thunberg fritillary bulb, honeysuckle flower, safflower, stem pith of the ricepapr plant, dahurian angelica root, radix aconiti. and the preparing process steps of cooling down the plaster and charging the following fine materials: pangolin scales, camphor, musk, boneol, frankincense, myrrh, and dragon's blood resin.

Owner:韩世昌

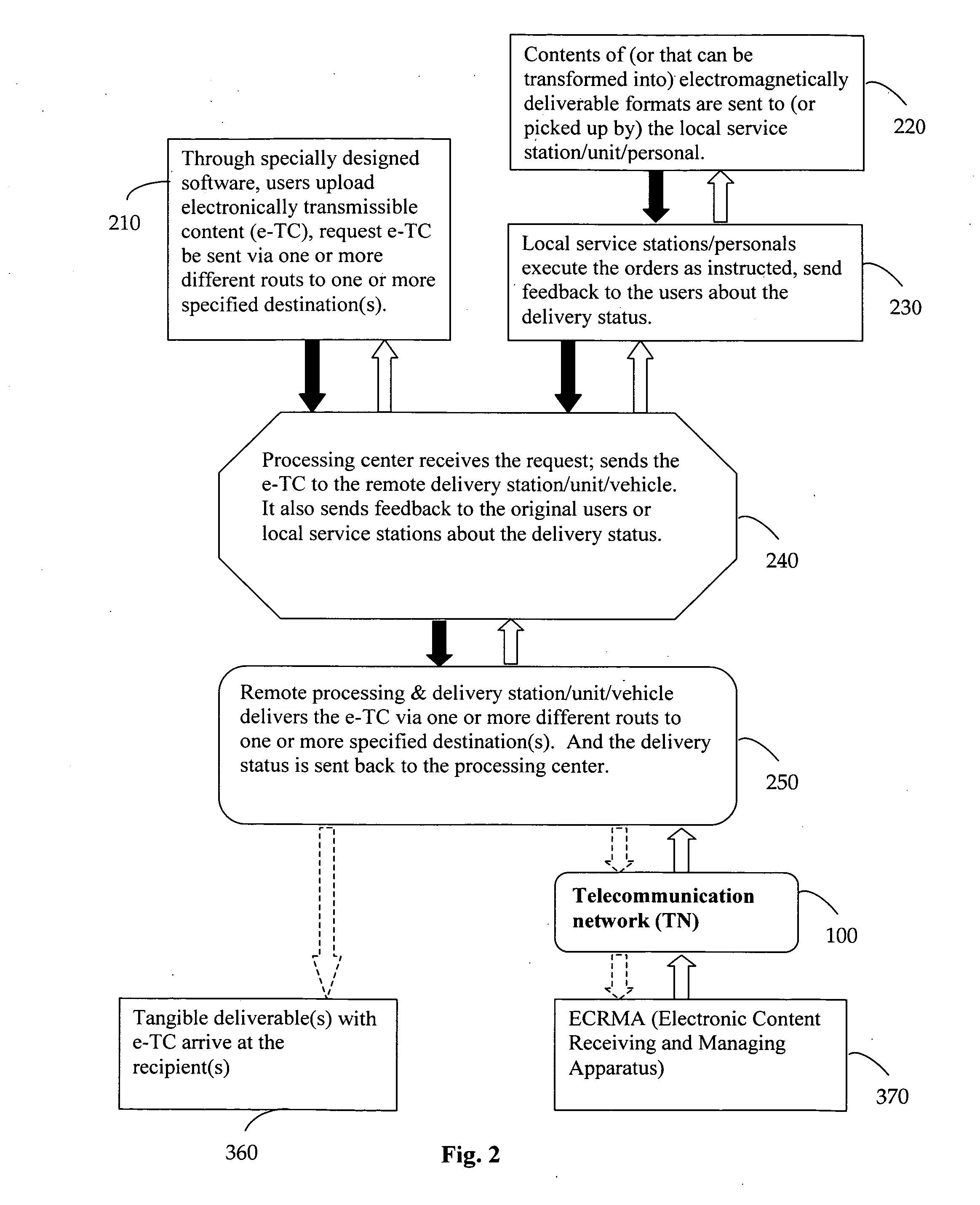

User initiated and controlled delivery in hybrid mode of electromagnetically transmissible contents to recipients in designated delivery locations or apparatus

ActiveUS20110099238A1Fast and efficient deliveryImprove delivery efficiencyMultiple digital computer combinationsSpeech recognitionData fileNetwork communication

The present invention discloses a network communication system that includes a network processing center for receiving and converting an electronic or electro-magnetically transmissible data / content into a physically deliverable object and / or network transmissible content data files for carrying out a hybrid delivery of the data / content by a physical delivery process and / or a network electro-magnetic delivery process to a recipient or an ECRMA.

Owner:DU LEE

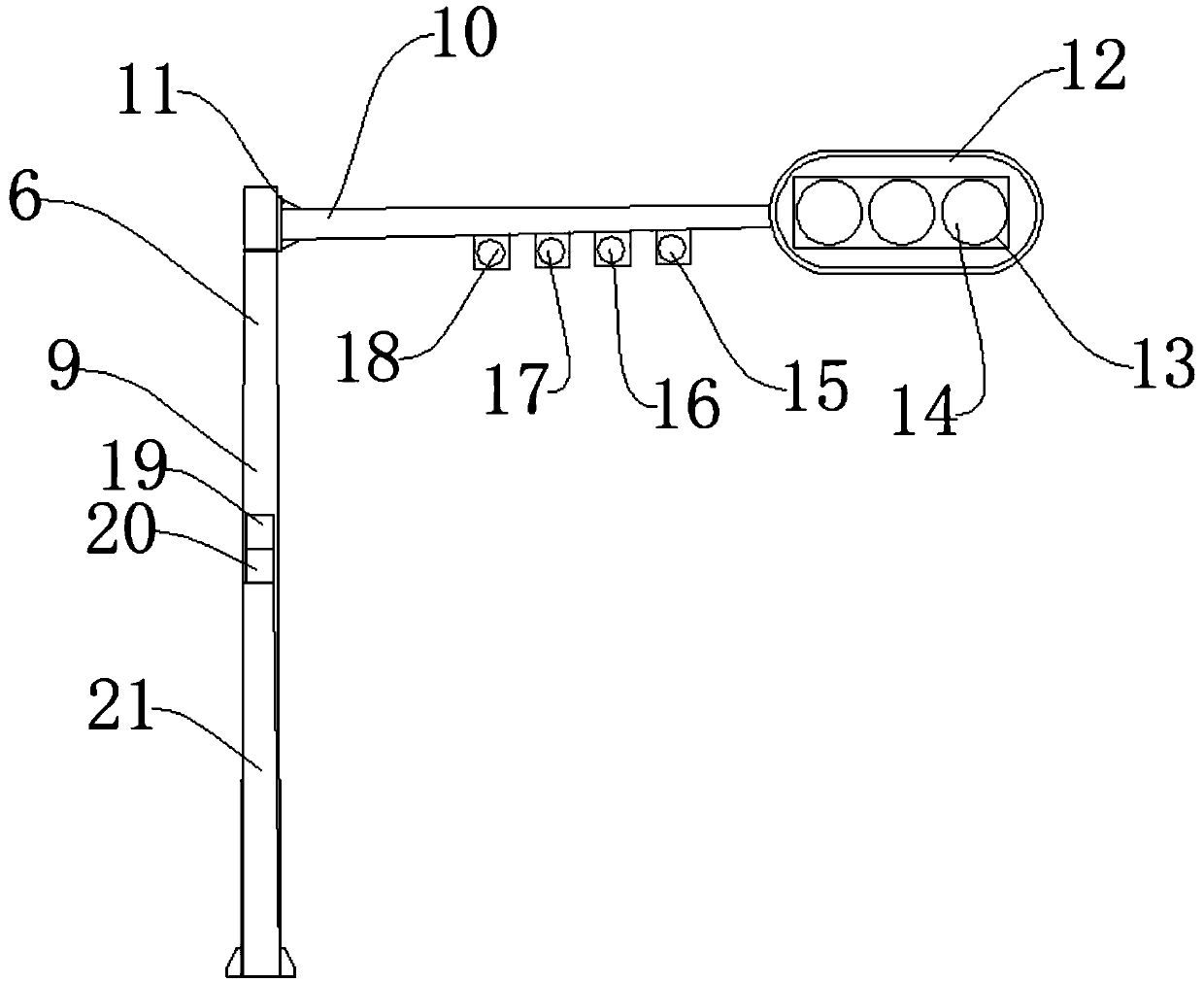

Intelligent traffic monitoring system

InactiveCN109559520AReasonable structureEasy to operateRoad vehicles traffic controlTraffic signalsMonitoring systemUnexpected events

The invention discloses an intelligent traffic monitoring system. The intelligent traffic monitoring system comprises a central road segment, split road segments, a centerline mechanism, and a centralprocessing room. Four split road segments are disposed outside of the central road segment. The central road segment is provided with four zebra crossing mechanisms. Each zebra crossing mechanism comprises a zebra crossing paint layer and a pedestrian warning LED light bar. One side of the zebra crossing paint layer is provided with a positive LED light panel. The intelligent traffic monitoring system has reasonable structure, simple operation, strong intelligence, and convenient use. The system can quickly and efficiently classify processed data and send instructions, can quickly handle emergencies, and use a signal light as a quick reminder device to guide traffic easily and clearly. The system uses a two-way LED light panel to guide traffic easily and clearly, and can quickly and effectively handle emergencies to improve the efficiency of traffic handling emergencies and safety.

Owner:广西数创智能科技有限公司

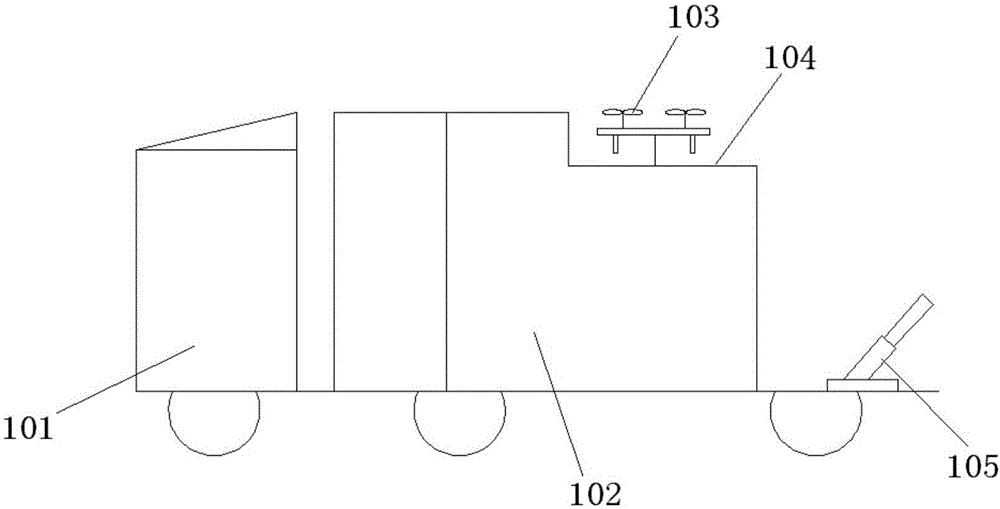

Multifunctional logistical support vehicle

InactiveCN106585469ADelivery is fast and effectiveConvenient and effective rescue functionLoading/unloading vehicle arrangmentWorkshop/display transportationDisaster areaEngineering

A multifunctional logistical support vehicle comprises a vehicle body and a carriage, wherein a cooking utensils and a medical device are arranged in the carriage; a throwing device is arranged at the rear part of the carriage; and the throwing device can realize throwing of emergency relief supplies within a distance of 200-1000 m. The logistical support vehicle can realize normal supply of logistical supports such as daily meals, medicals and so on; and moreover, when roads in disaster areas having earthquakes, flood disasters, wars and so on are cut off and vehicles and rescue workers cannot reach the scene of the disaster, the throwing device can be used for throwing the emergency relief supplies, such as foods, drinking water, drugs and so on, within the distance of 200-1000 m. Practice has proved that the logistical support vehicle can play an extremely convenient and effective rescue effect in similar environments with bridge collapses in flood disasters and materials in urgent need, such as vaccines, drinking water and the like, in disaster environments are rapidly and effectively thrown.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

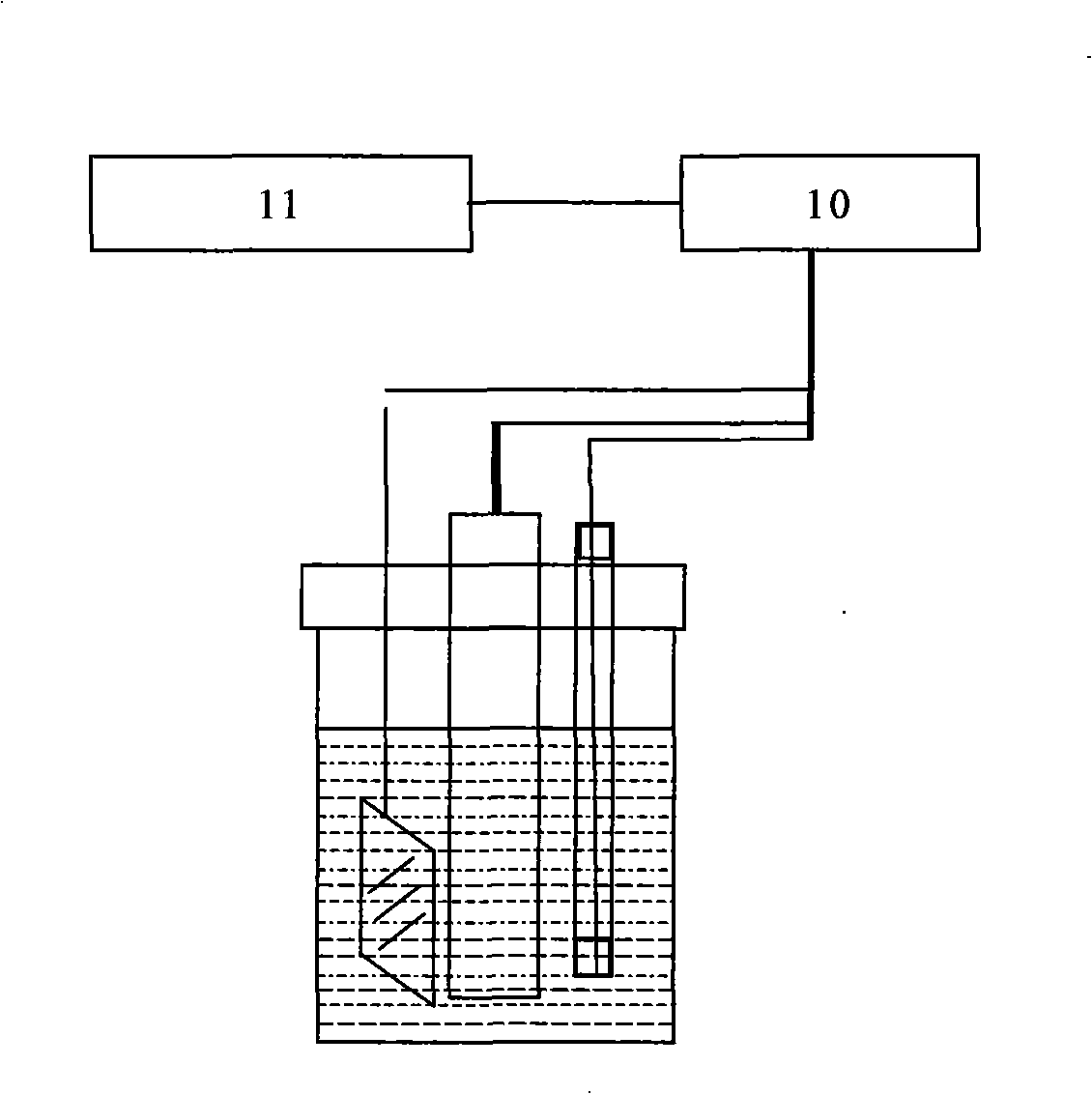

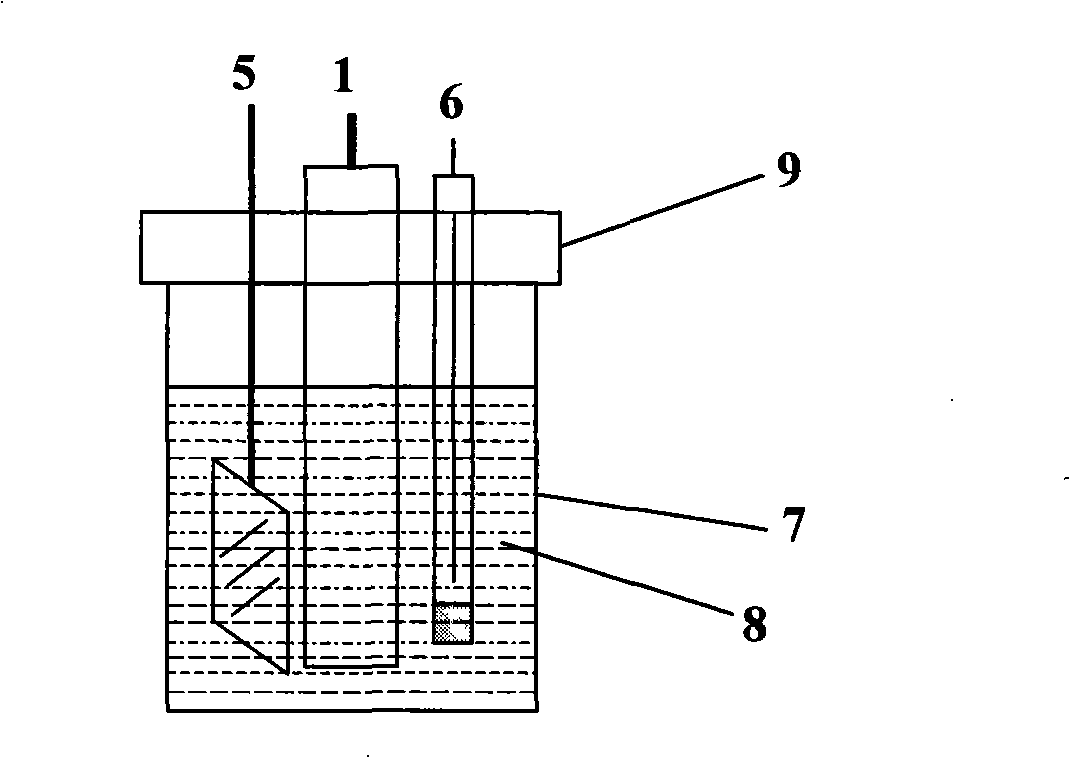

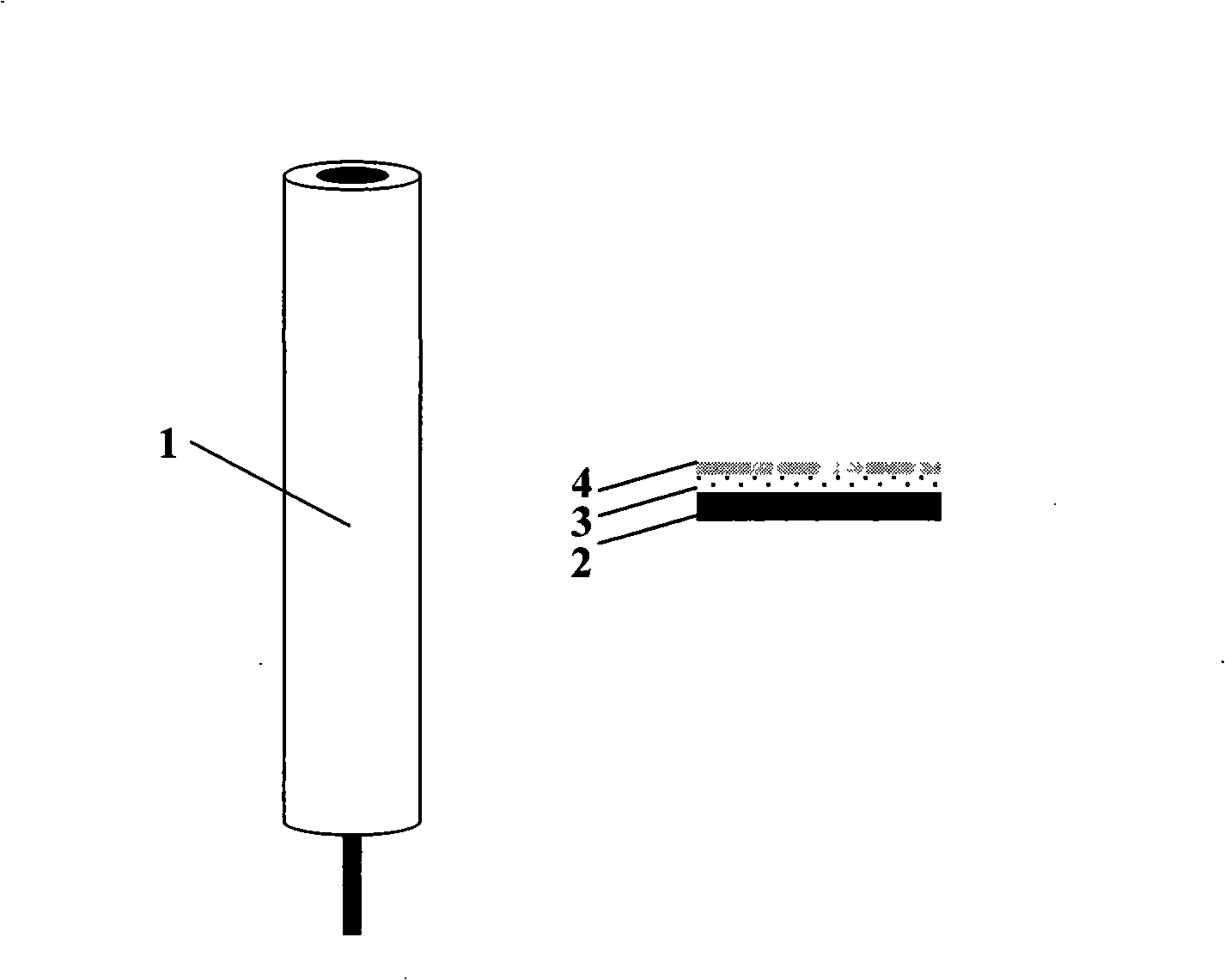

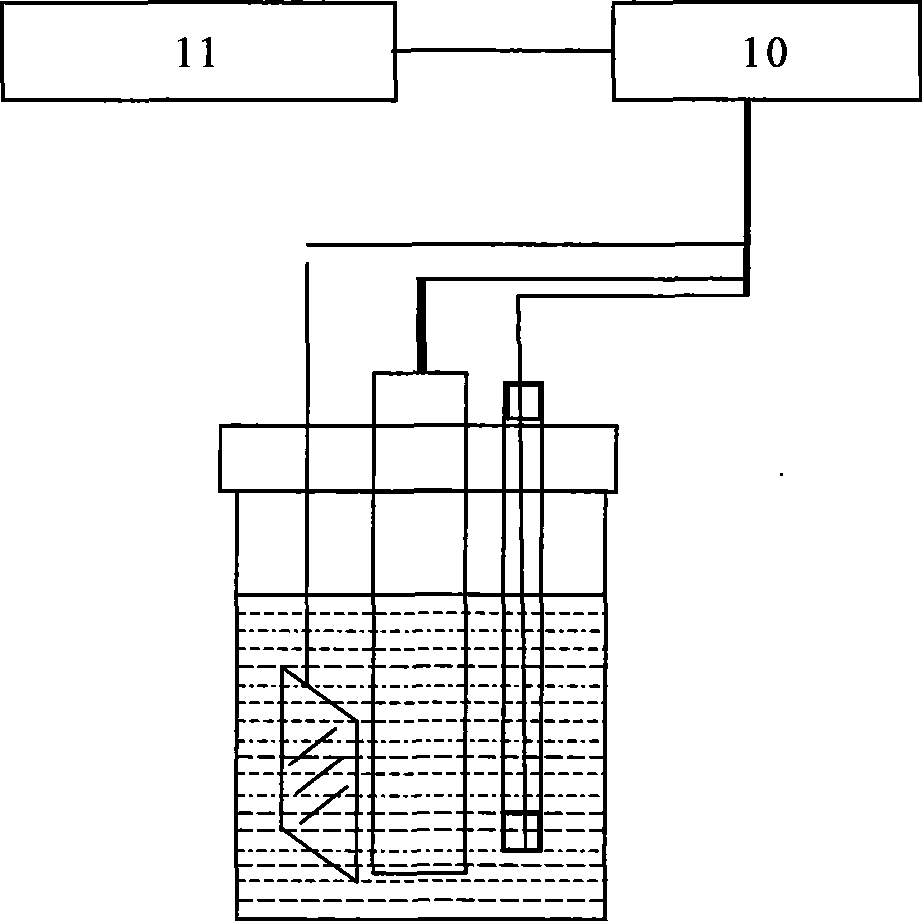

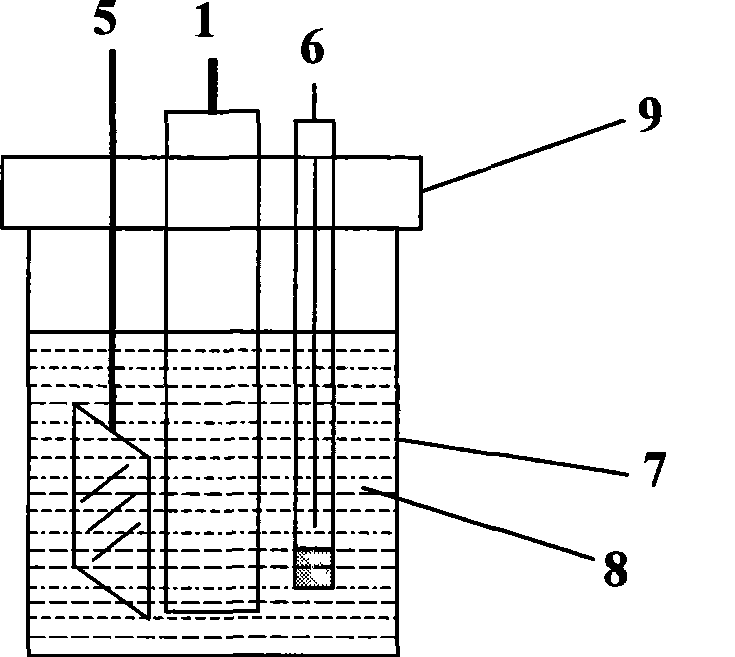

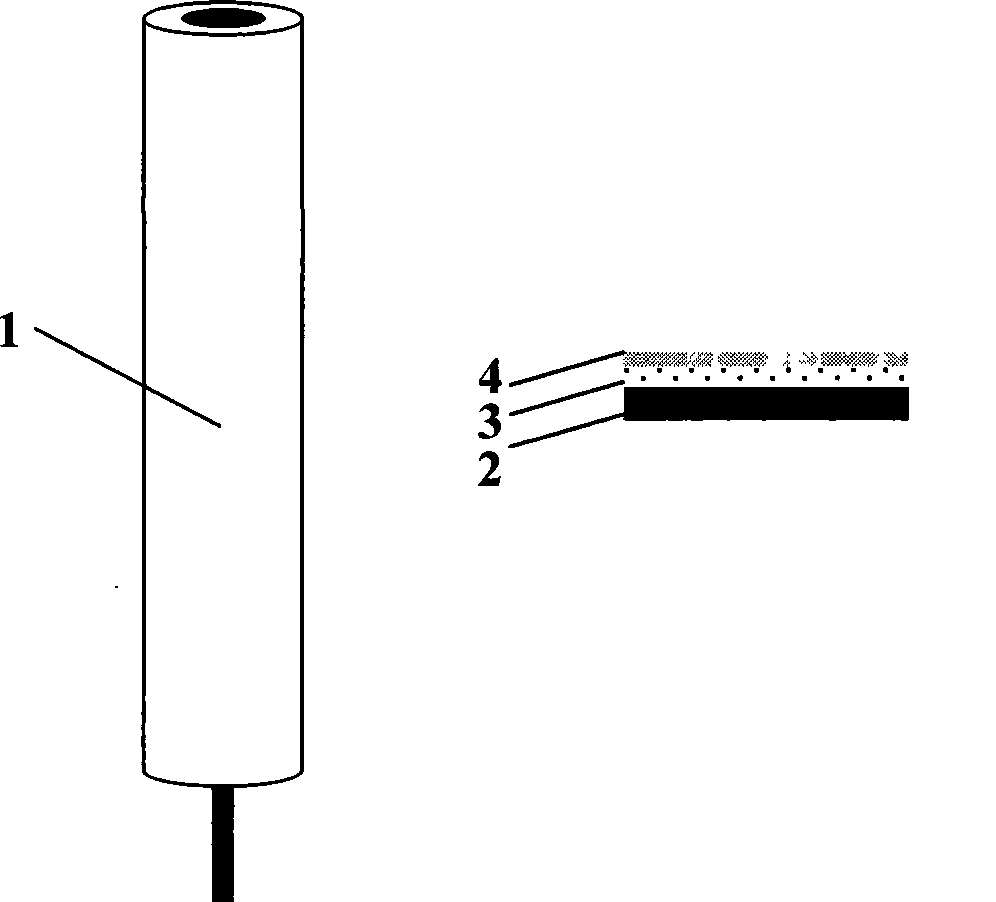

Preparation method for biologic sensor and modified electrode based on attapulgite clay soil as substrate

InactiveCN101344522AEasy to prepareFast and efficient deliveryBiological testingMaterial electrochemical variablesNano structuringDisplay device

The invention discloses a preparation method of a biosensor and a modified electrode that take attapulgite clay as substrate, the sensor takes the attapulgite clay with natural nano structure as the substrate, and utilizes the unique pore canal structure and the excellent adsorptive capability of the attapulgite clay to fix glucose oxidase (GOD) on the surface of the attapulgite clay, coats the attapulgite clay with adsorbed oxidase on the surface of a glassy carbon electrode, and drops and coats a layer of Nafion methanol solution on the surface, thus forming the Nafion-GOD / ATP / GC modified electrode. The modified electrode, a platinum sheet electrode, a saturated calomel electrode form an electrolytic cell which is further connected with a converter and a display screen to form the biosensor. The biosensor has quick response time, high sensitivity, simple and convenient production method, good repeatability and stability, and convenient mechanization, integration and commercialization.

Owner:HUAIYIN TEACHERS COLLEGE

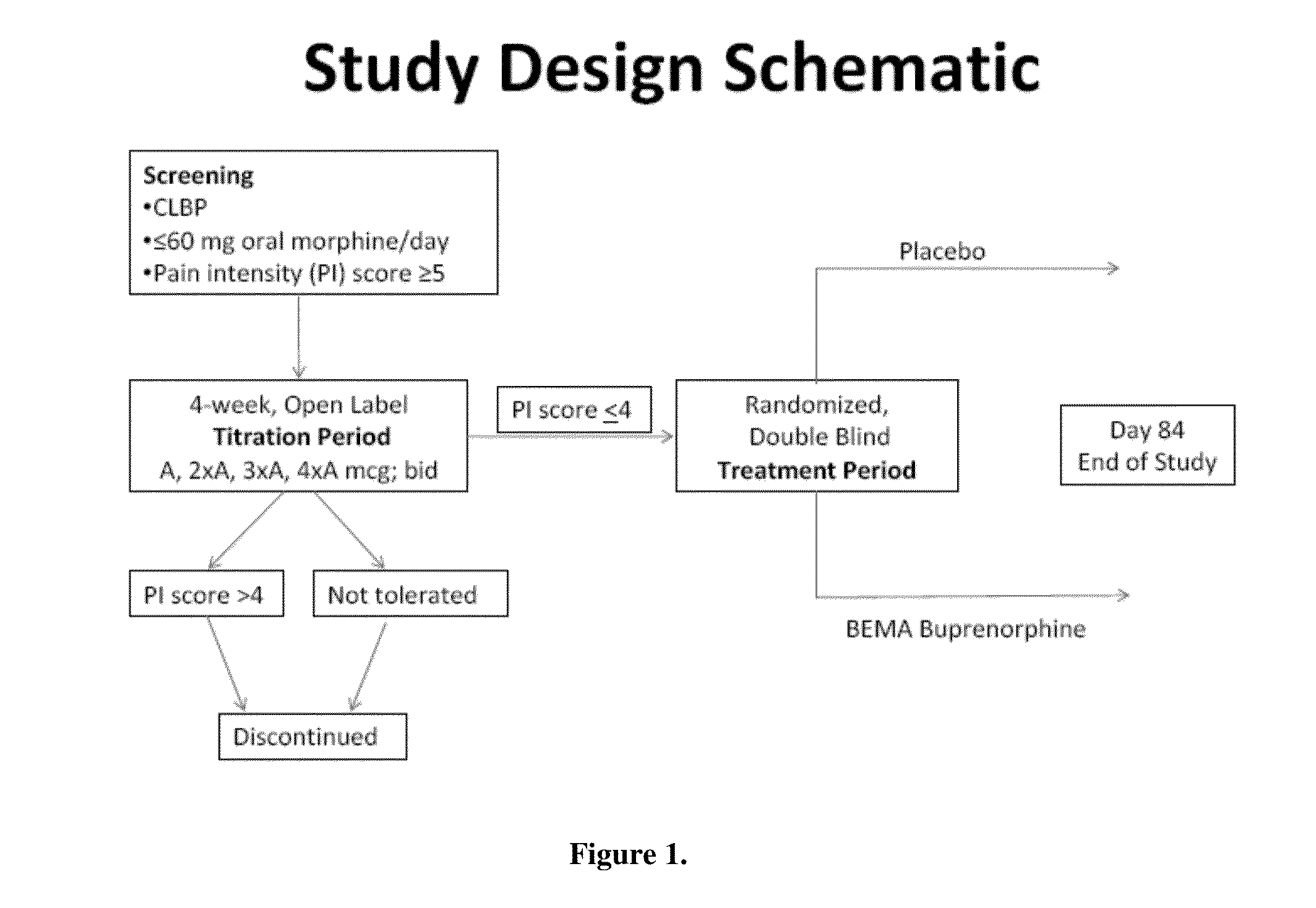

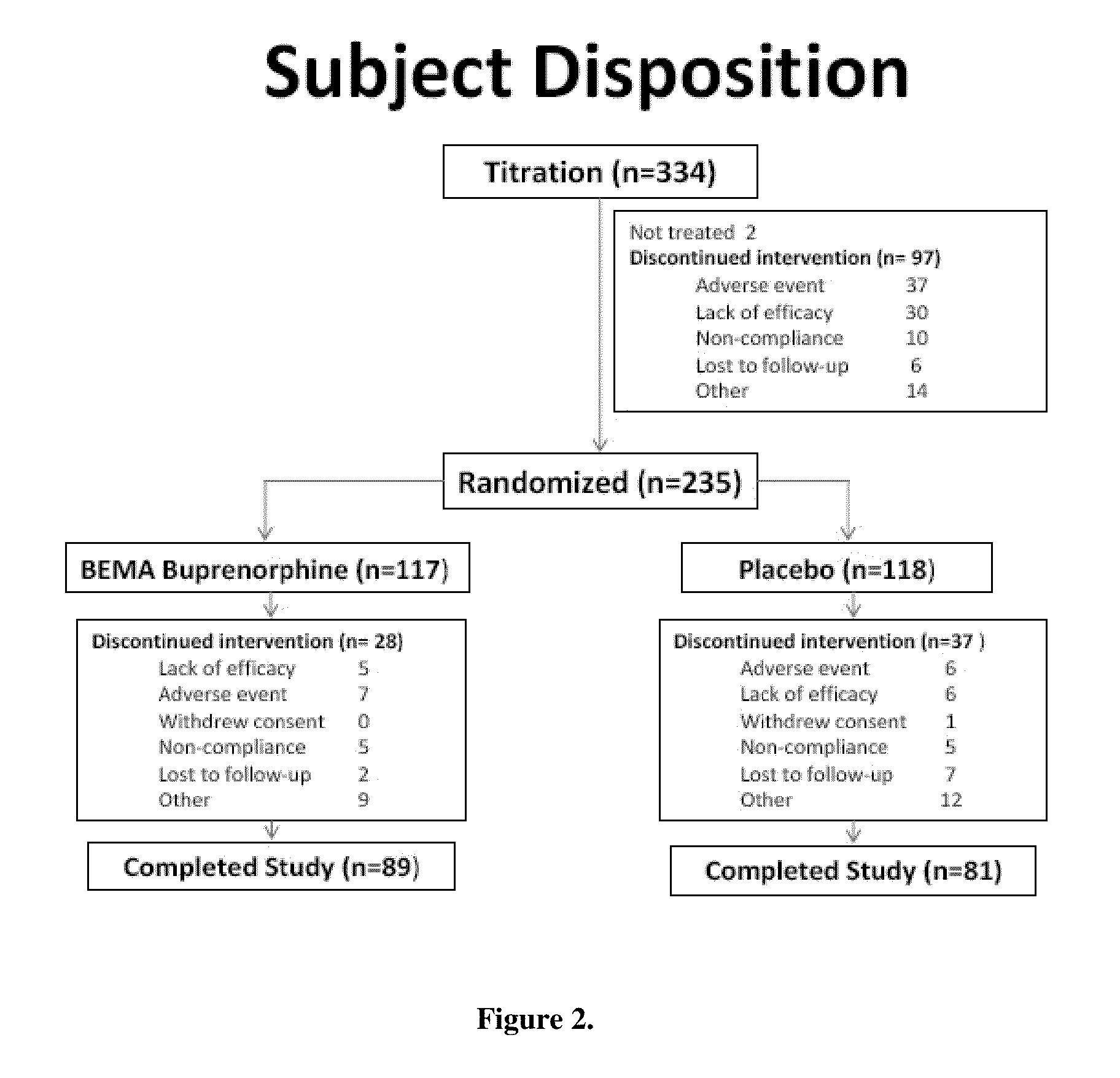

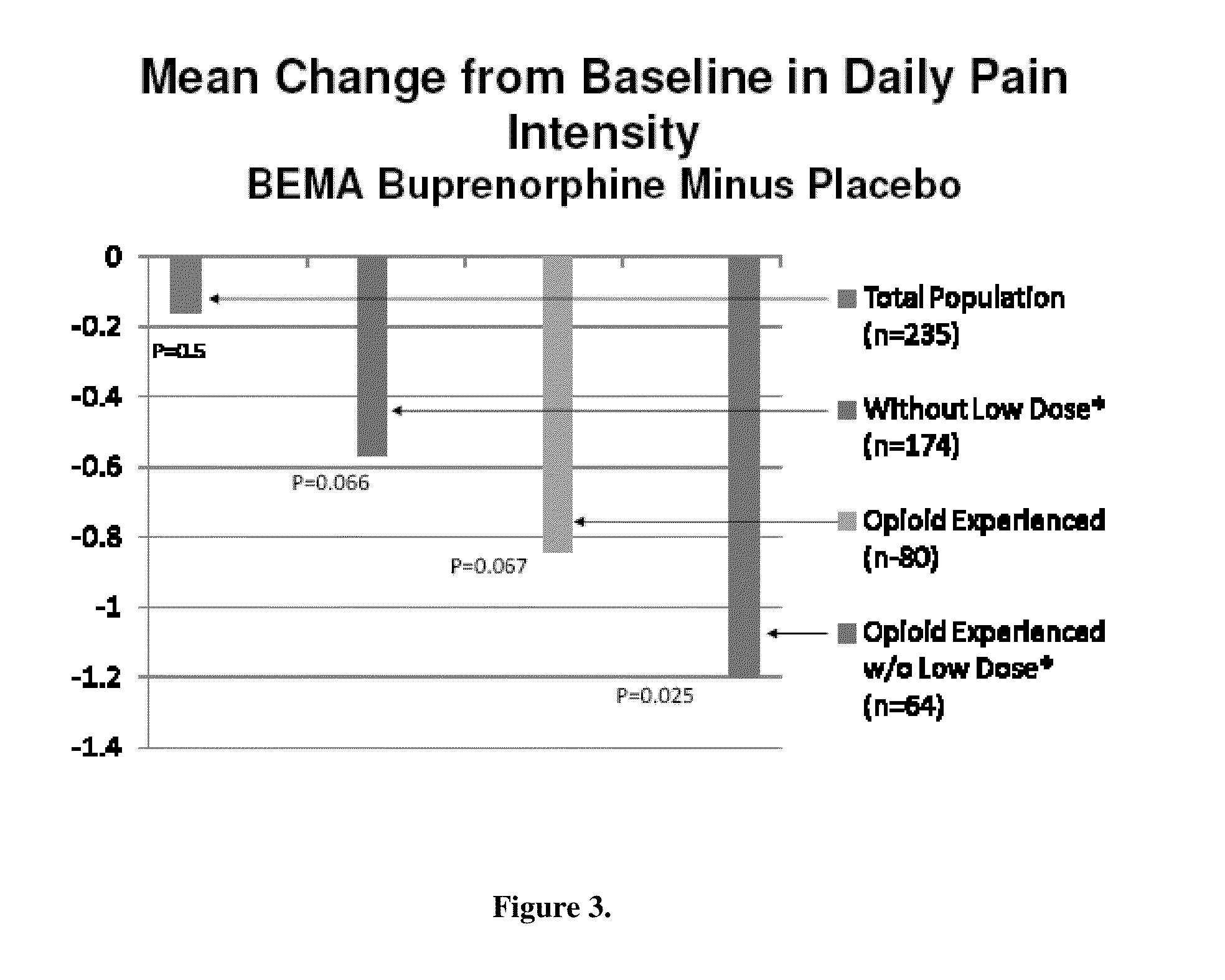

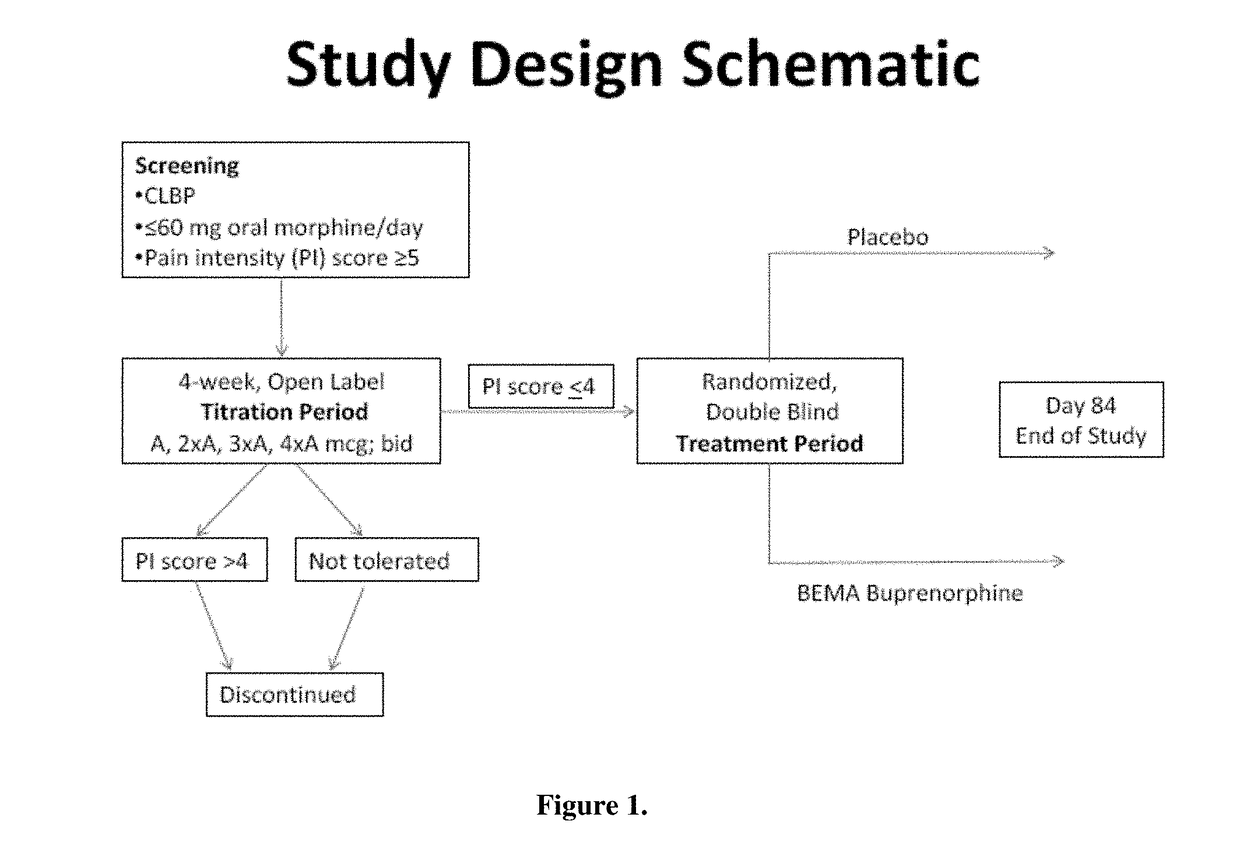

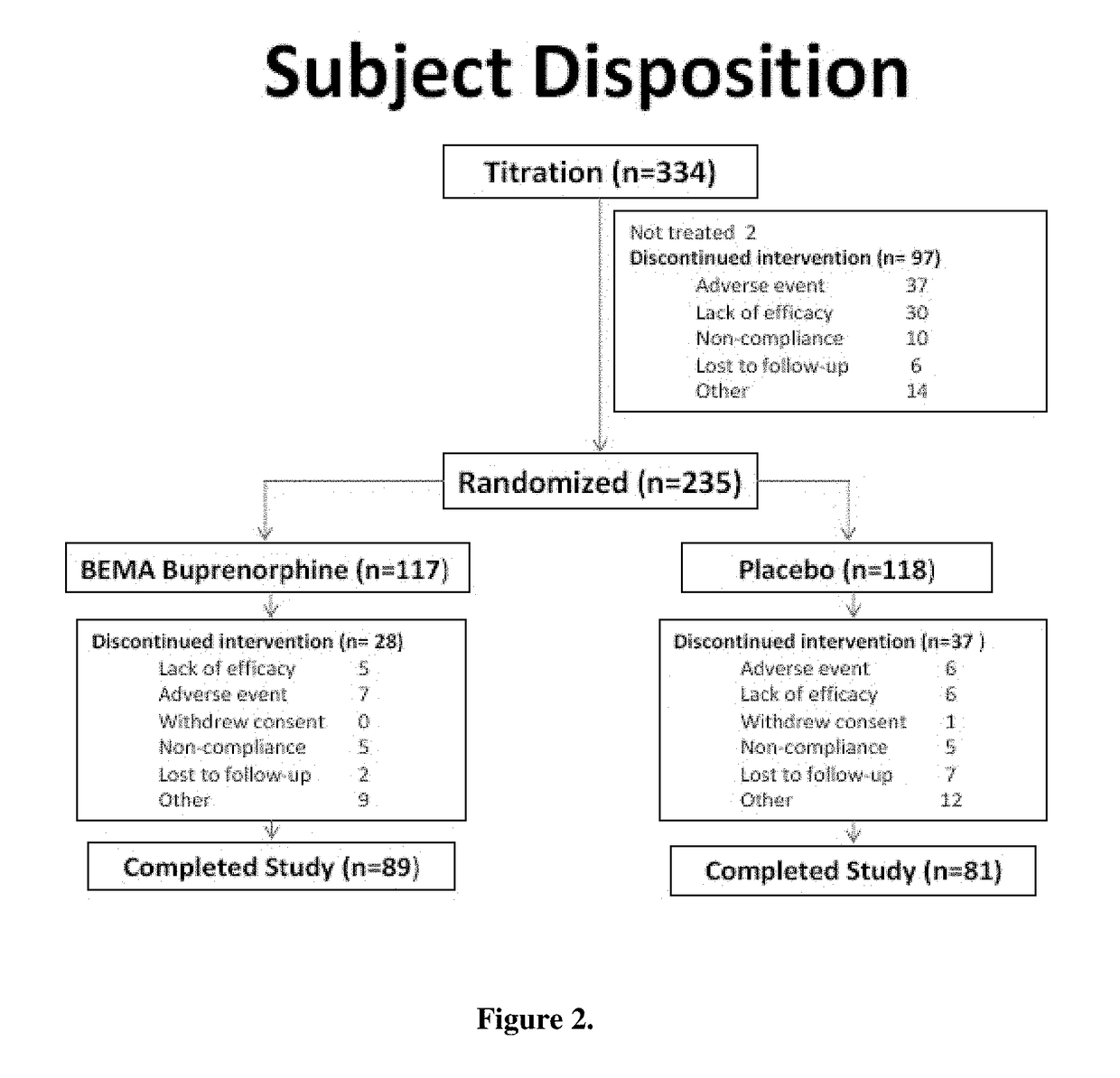

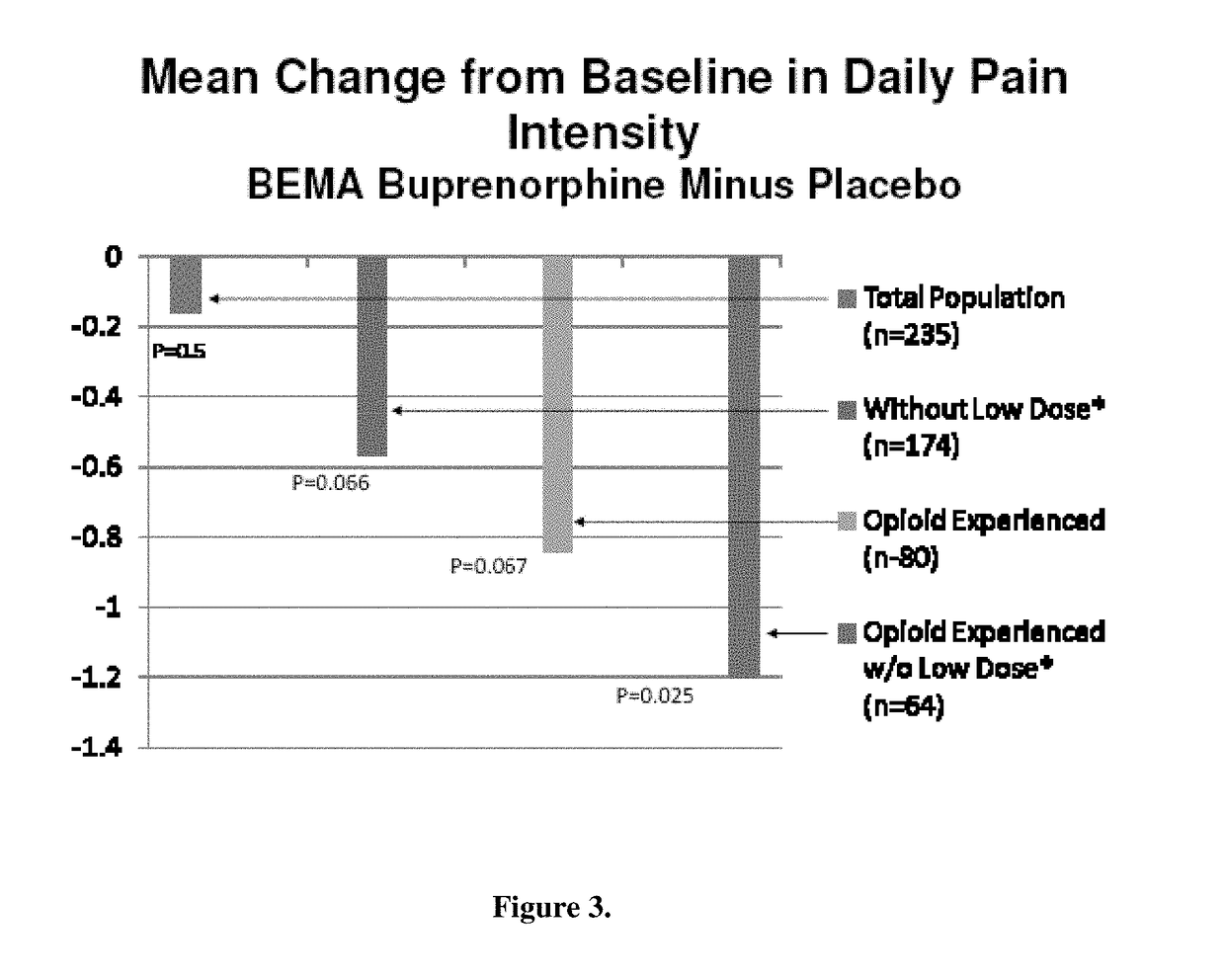

Transmucosal drug delivery devices for use in chronic pain relief

ActiveUS20140178440A1Efficiently treat chronic painFast and efficient deliveryBiocidePharmaceutical delivery mechanismSide effectChronic pain

Provided herein are methods for treating chronic pain by administering low doses of buprenorphine twice daily (or once daily) via a transmucosal drug delivery device. The methods and devices efficiently treat chronic pain without significant side effects.

Owner:BIODELIVERY SCI

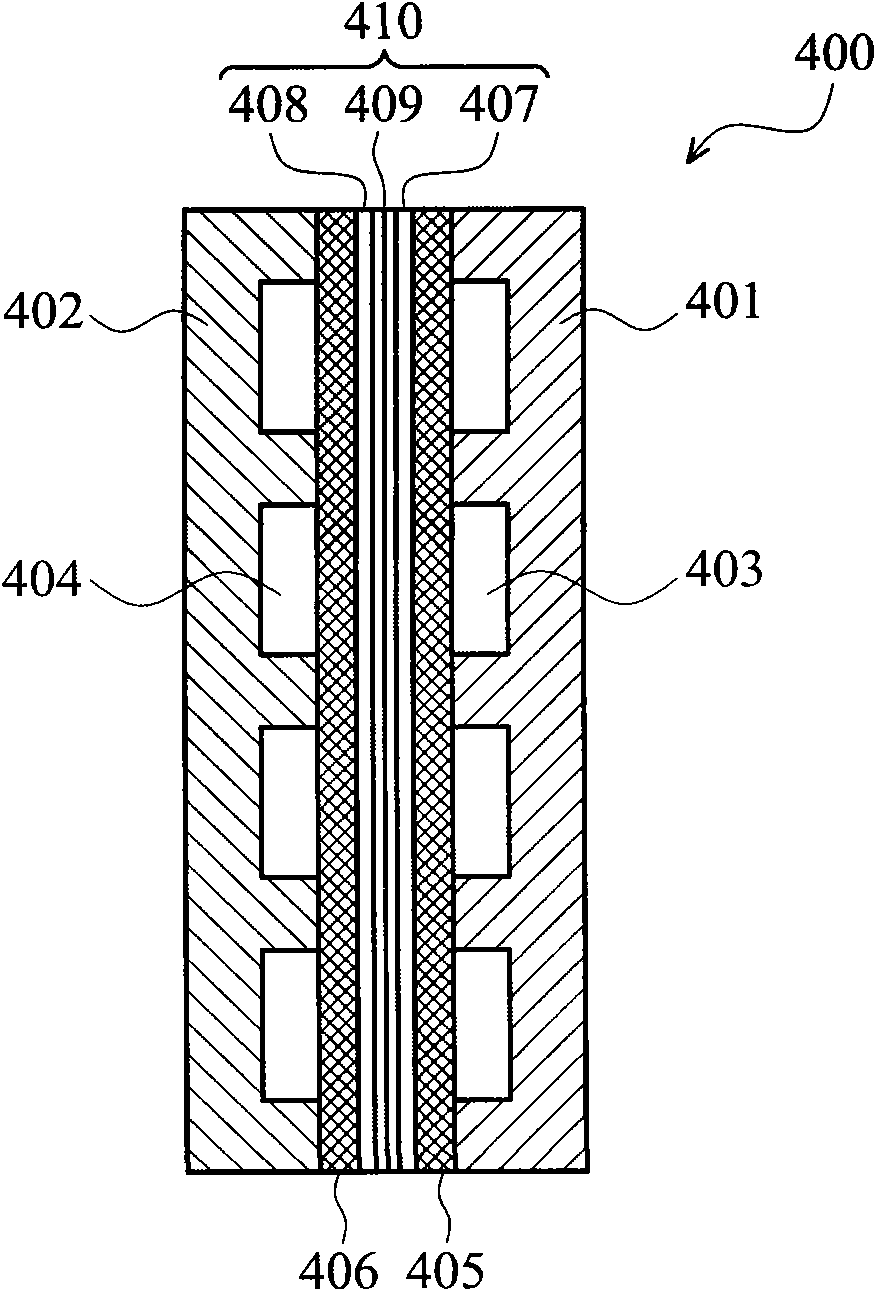

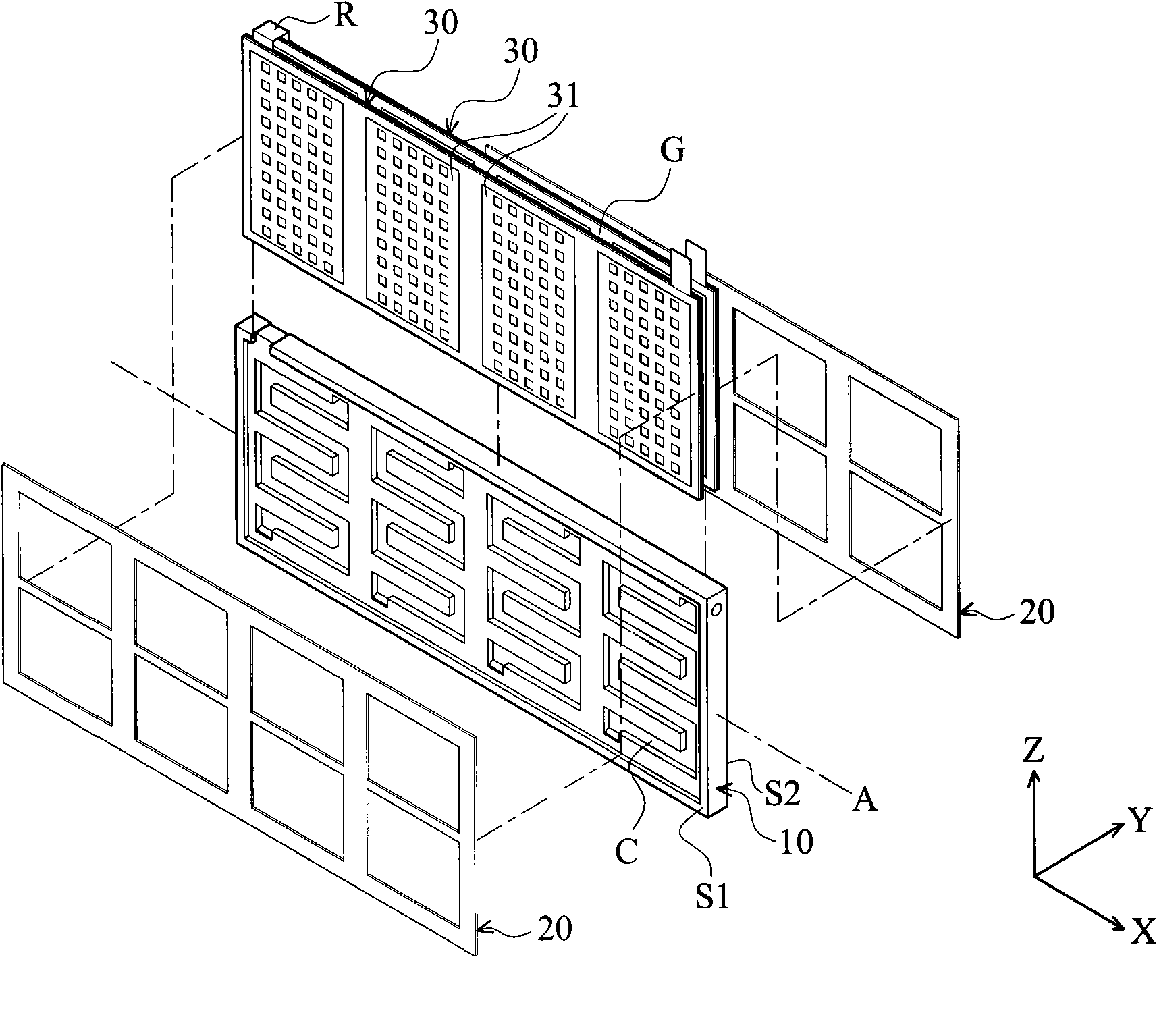

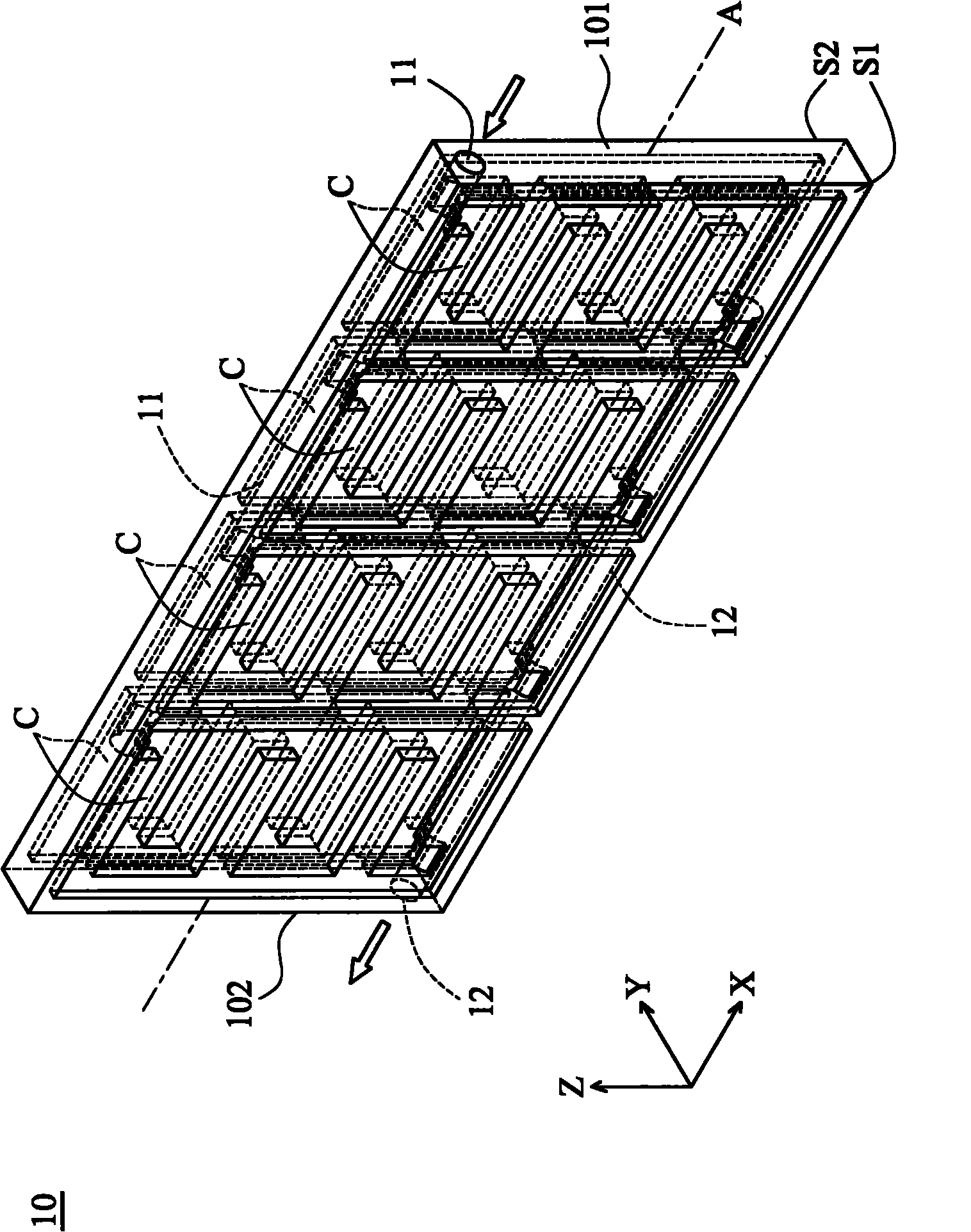

Flat type fuel cell module and flow field plate thereof

InactiveCN102117922AImprove performanceFast and efficient deliveryElectrolyte stream managementSolid electrolyte fuel cellsFuel cellsEngineering

The invention provides a flat type fuel cell module and a flow field plate thereof.The flow field plate arranged inside a fuel cell module comprises at least two flow channels, a first manifold and a second manifold.The two flow channels are respectively formed on opposite sides of the flow field plate.The first manifold and the second manifold are formed inside the flow field plate.The first manifold and the second manifold communicate with the at least two flow channels.The reaction fluid flows from the first manifold into the flow field plate.Then the reaction fluid flows into the second manifold after passing through the two flow channels.Finally, the reaction fluid is discharged out of the flow field plate via the second manifold.

Owner:IND TECH RES INST

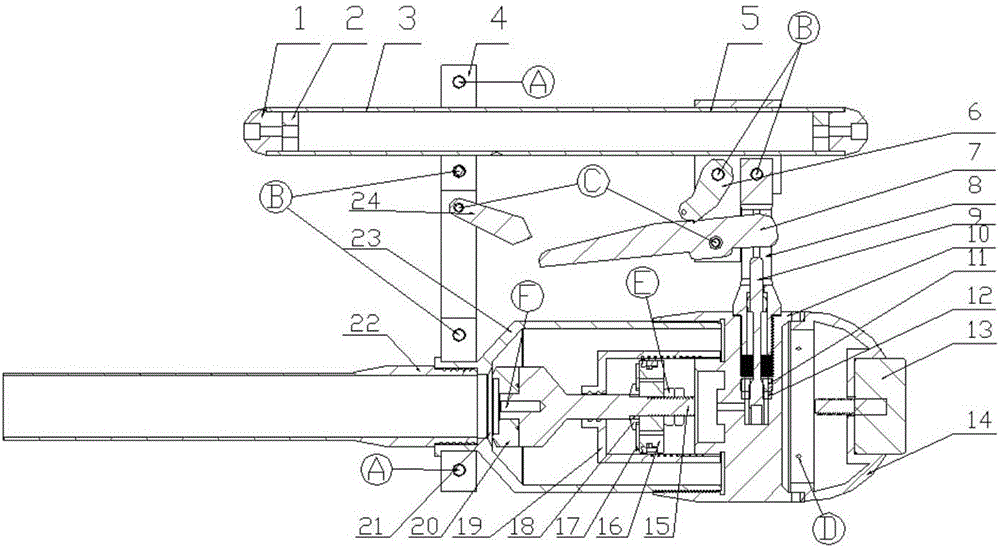

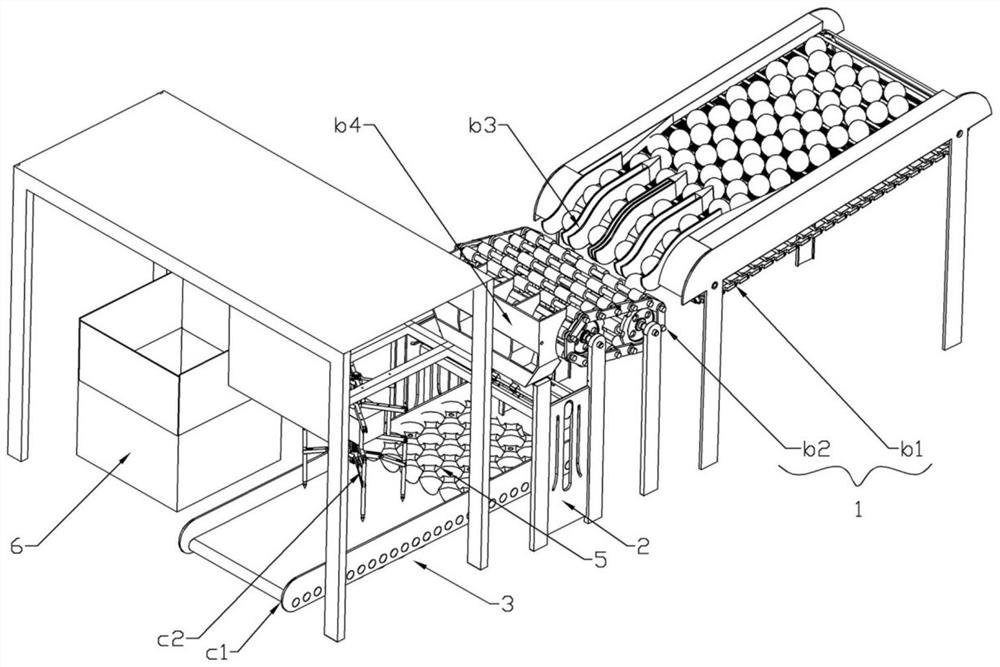

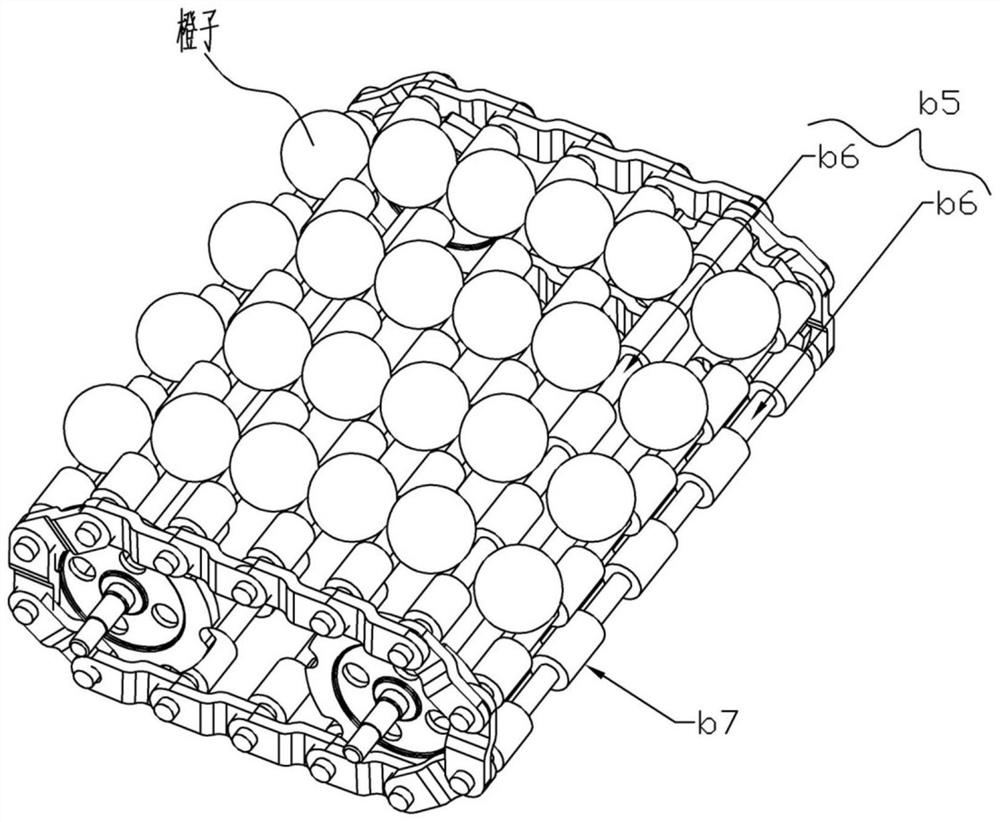

Efficient automatic sealing structure

ActiveCN111645912ASimple structureReduce labor costsWrapper twisting/gatheringPackaging fruits/vegetablesProcess engineeringManufacturing engineering

The invention discloses an efficient automatic sealing structure. The invention aims to provide the efficient automatic sealing structure, which has the advantages that the structure is simple, fruitssuch as oranges and the like can be orderly filled on a tray, the labor cost is effectively reduced, collision and extrusion during packing of the oranges are reduced, and quick and efficient delivery can be realized. The efficient automatic sealing structure comprises a conveying mechanism, a filling mechanism, a packing mechanism and a sealing mechanism, wherein the oranges are conveyed to thefilling mechanism by the conveying mechanism, the oranges are filled on the tray of the packing mechanism by the filling mechanism, the tray filled with the oranges is put in a box of the sealing mechanism by the packing mechanism, and the box is sealed by the sealing mechanism. The efficient automatic sealing structure is applied to the technical field of the efficient automatic sealing structure.

Owner:BEIJING INST OF TECH ZHUHAI CAMPUS

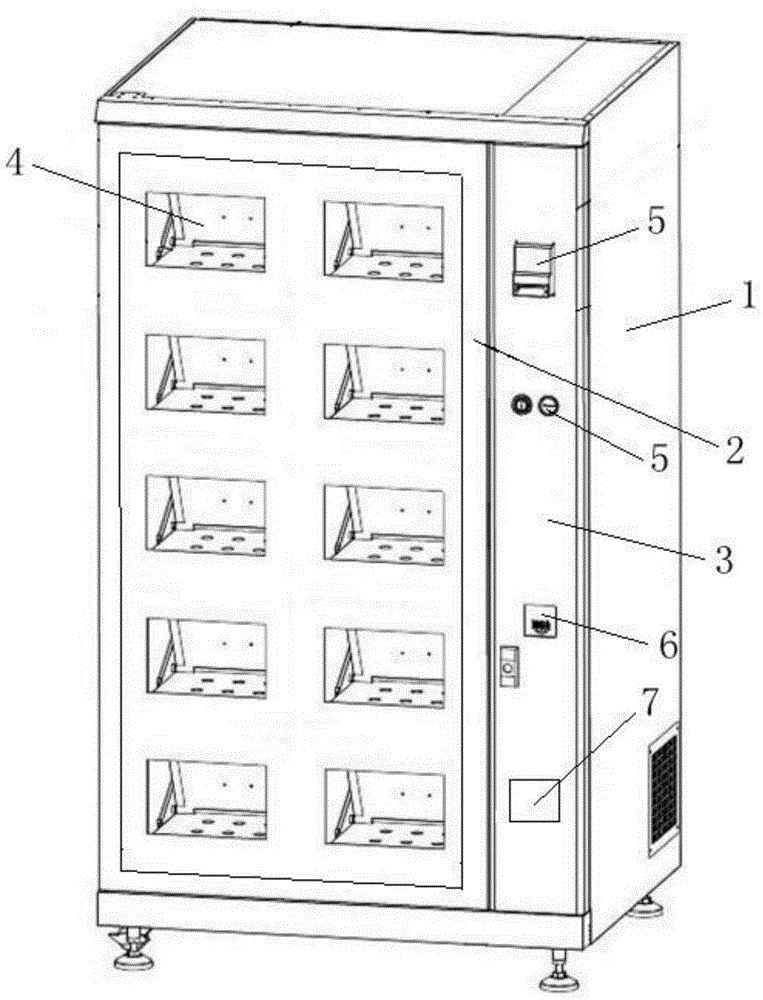

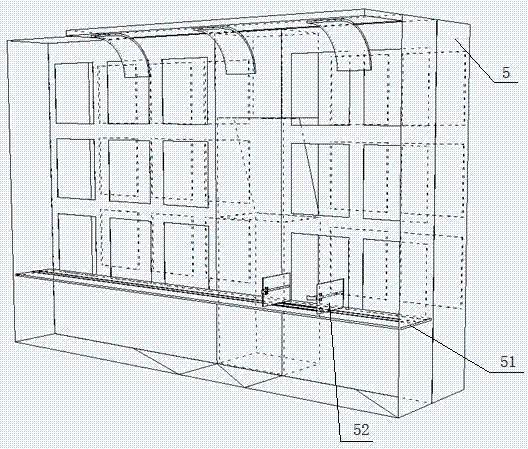

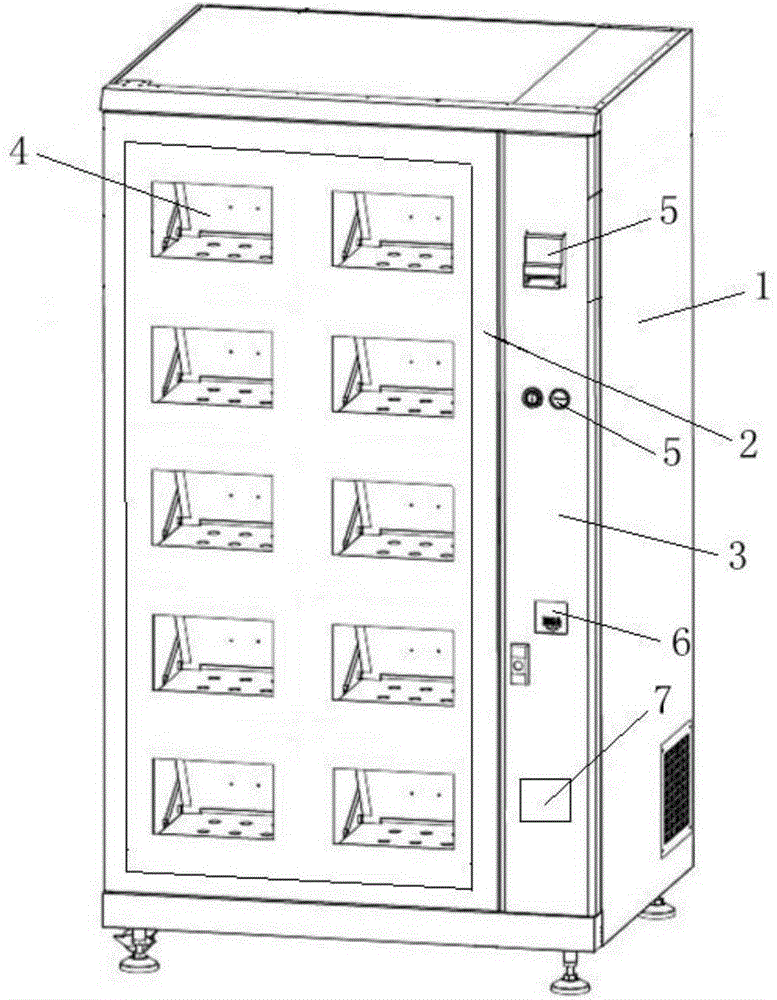

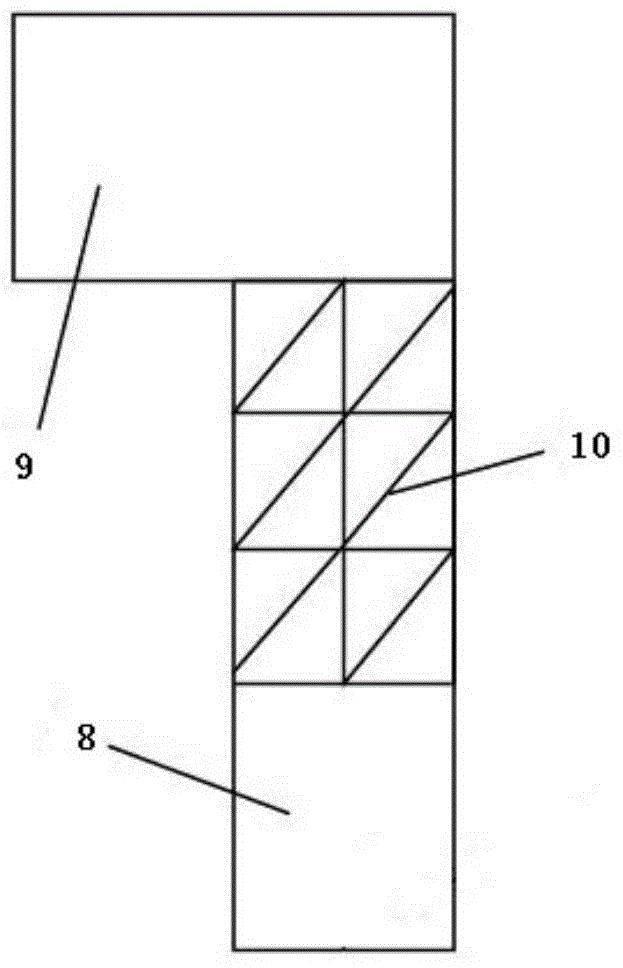

Vending machine capable of automatically replenishing goods repeatedly

InactiveCN106297005AFast and efficient deliveryAvoid cargo damageCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineering

The invention provides a vending machine capable of automatically replenishing goods repeatedly. The vending machine comprises a cabinet body, wherein a vending cabinet and an electric appliance cabinet are arranged inside the cabinet body; the vending cabinet and the electric appliance cabinet comprise a vending cabinet door and an electric appliance cabinet door respectively; automatic goods replenishing devices are arranged inside the vending cabinet; each automatic goods replenishing device comprises a rail, a telescopic turnover plate, an induction control device, a transmission device and a cylinder; one end of the rail is fixedly connected with the top of the vending cabinet; the telescopic turnover plate is arranged on the rail; a telescopic turnover plate rail movably connected with the rail is arranged on the telescopic turnover plate; the induction control device is arranged on the telescopic turnover plate; the bottom of the telescopic turnover plate is connected with the cylinder through the transmission device; a goods discharging device is arranged between the vending cabinet and the vending cabinet door. The vending machine has the beneficial effects of simple structure, convenience in maintenance, low cost and human labor saving.

Owner:TIANJIN ZHIDING CHUANGLIAN INFORMATION SCI & TECH

UAV delivery system

The invention relates to the technical field of unmanned aerial vehicles, and relates to an unmanned aerial vehicle delivery system, including unmanned aerial vehicles and express cabinets distributed in various outlets. Lifting express box; the top of the express cabinet is equipped with a fixing device for fixing the landing gear of the drone, and the front and rear sides of the fixing device are equipped with limiting devices for fixing the drone body, and the rear side of the fixing device is equipped with a replacement battery pack The battery replacement device; the express cabinet is provided with an opening suitable for the express box in the middle of the fixing device, and the inside of the express cabinet is provided with a sorting device. The invention can deliver quickly and effectively, solve the problems of low express delivery efficiency and narrow coverage, and realize accurate delivery; it can automatically replace the battery of the drone, overcome the defects of short flight range and low load, and realize the sending and receiving of express delivery at the same time Integrate to ensure the smooth delivery of items.

Owner:LINYI HI TECH ZONE XIANGHONG ELECTRONICS SCI & TECH CO LTD +2

Transmucosal drug delivery devices for use in chronic pain relief

ActiveUS9901539B2Efficiently treat chronic painFast and efficient deliveryOrganic active ingredientsPharmaceutical delivery mechanismSide effectChronic pain

Provided herein are methods for treating chronic pain by administering low doses of buprenorphine twice daily (or once daily) via a transmucosal drug delivery device. The methods and devices efficiently treat chronic pain without significant side effects.

Owner:BIODELIVERY SCI

Systems and methods of tracking the delivery and post-delivery status for electromagnetically transmissible contents delivered via user initiated and controlled hybrid delivery modes

ActiveUS9425991B2Fast and efficient deliveryInformativeMultiple digital computer combinationsRecord carriers used with machinesData fileNetwork communication

Owner:DU LEE

Systems and methods of tracking the delivery and post-delivery status for electromagnetically transmissible contents delivered via user initiated and controlled hybrid delivery modes

ActiveUS20120136713A1Fast and efficient deliveryImprove delivery efficiencyMultiple digital computer combinationsRecord carriers used with machinesData fileNetwork communication

The present invention discloses a network communication system that includes a network processing center for receiving and converting an electronic or electro-magnetically transmissible data / content into a physically deliverable object and / or network transmissible content data files for carrying out a hybrid delivery of the data / content by a physical delivery process and / or a network electro-magnetic delivery process to a recipient or an ECRMA. The delivery status of the electronic content and the post-delivery activities are tracked by a variety of mechanisms and the information obtained from the tracking is send back to the content-sender.

Owner:DU LEE

Preparation method for biologic sensor and modified electrode based on attapulgite clay soil as substrate

InactiveCN101344522BEasy to prepareFast and efficient deliveryBiological testingMaterial electrochemical variablesNano structuringDisplay device

The invention discloses a preparation method of a biosensor and a modified electrode that take the substrate of attapulgite clay, the sensor takes the substrate of the attapulgite clay with a natural nano structure, utilizes the unique pore canal structure and the excellent adsorptive power of the attapulgite clay, fixes glucose oxidase (GOD) on the surface of the attapulgite clay, coats the attapulgite clay with adsorbed oxidase on the surface of a glassy carbon electrode, and drops and coats a layer of Nafion methanol solution on the surface, thus forming the Nafion-GOD / ATP / GC modified electrode. The modified electrode, a platinum sheet electrode, a saturated calomel electrode form an electrolytic cell, which is further connected with a converter and a display screen into the biosensor. The biosensor has quick response time, high sensitivity, simple and convenient production method, good repeatability and stability, and convenient mechanization, integration and commercialization.

Owner:HUAIYIN TEACHERS COLLEGE

Material receiving device for multi-mold-cavity injection molding products

PendingCN108995140AFast and efficient deliveryEasy to operatePlastic recyclingRotating discOpen treatment

The invention relates to a material receiving device for multi-mold-cavity injection molding products. The material receiving device for the multi-mold-cavity injection molding products comprises a material bag, a rotating disc, a conveying track and a material receiving device body. The rotating disc is provided with a material bag placing disc. The material bag is placed on the material bag placing disc. The material bag placing disc is rotatably arranged by the center line of the rotating disc, and the rotating angle is 90 degrees. A transition channel for conveying the material bag to theconveying track is arranged at front end of the material bag placing disc. The end of the convey track is connected with the transition channel. A connecting channel for controlling the track direction of material bag conveying is arranged at the tail end of the conveying track. At least four independent tracks are arranged under the connecting channel. The material receiving device body is arranged at the tail end of the independent tracks and is used for receiving material bags. According to the material receiving device for the multi-mold-cavity injection molding products, through the rotating disc and a pneumatic suction disc, the material bags can be quickly and effectively transferred and the material bags are subjected to opening treatment, and the material collecting device body can rapidly receive materials, so that the operation is simple, and the working efficiency is high.

Owner:江苏旭虹精密零组件有限公司

Dustproof vending machine

InactiveCN106297003AFast and efficient deliveryAvoid cargo damageCoin-freed apparatus detailsApparatus for dispensing discrete articlesAnti theftAisle

The invention provides a dustproof vending machine, which comprises a box body. A selling bin and an electrical bin are arranged in the box body, and are respectively provided with a selling bin door and an electrical bin door; an automatic replenishment device and a dust collection device are arranged in the selling bin; the automatic replenishment device comprises a rail, a telescopic reverse turning bed, an inductive control device, a transmission device and an air cylinder; one end of the rail is fixedly connected with the top part of the selling bin; a discharge device is arranged between the selling bin and the selling bin door; an anti-theft plate is arranged on the bottom end of a goods aisle; a money storage warning device is arranged in the electrical bin; the electric bin door is sequentially provided with an automatic coin slot, a slot card inducting zone and a discharge hole from top to bottom; the dust collection device comprises a filter rack; a filter channel is arranged in the filter rack; a dust screen is arranged in the filter channel and is distributed in the filter channel in a Z shape. The dustproof vending machine provided by the invention has the beneficial effects of simple structure, convenience in maintenance, low cost, and manual labor saving.

Owner:TIANJIN ZHIDING CHUANGLIAN INFORMATION SCI & TECH

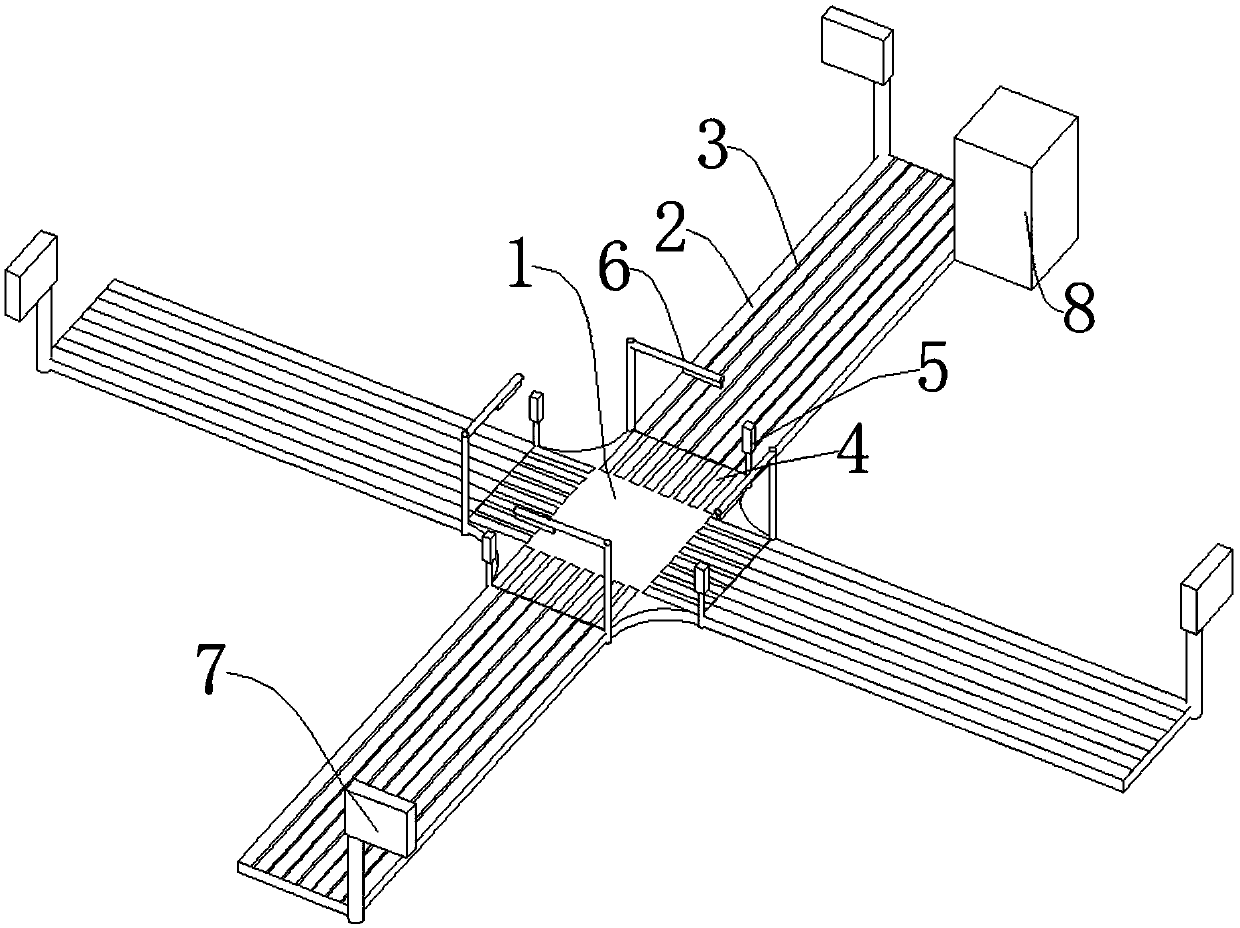

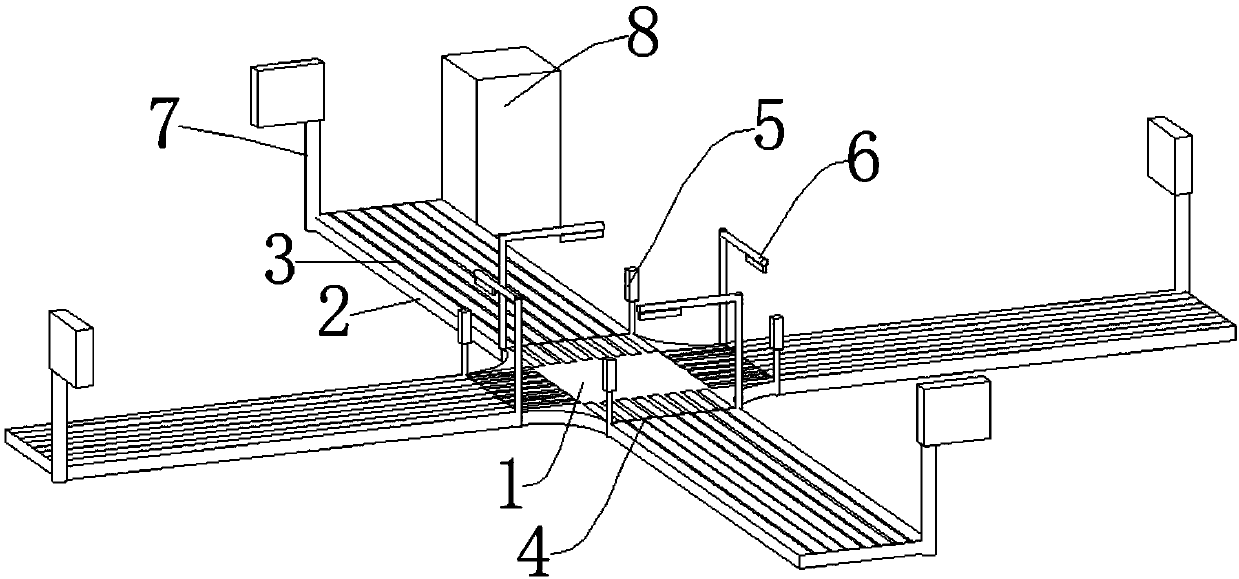

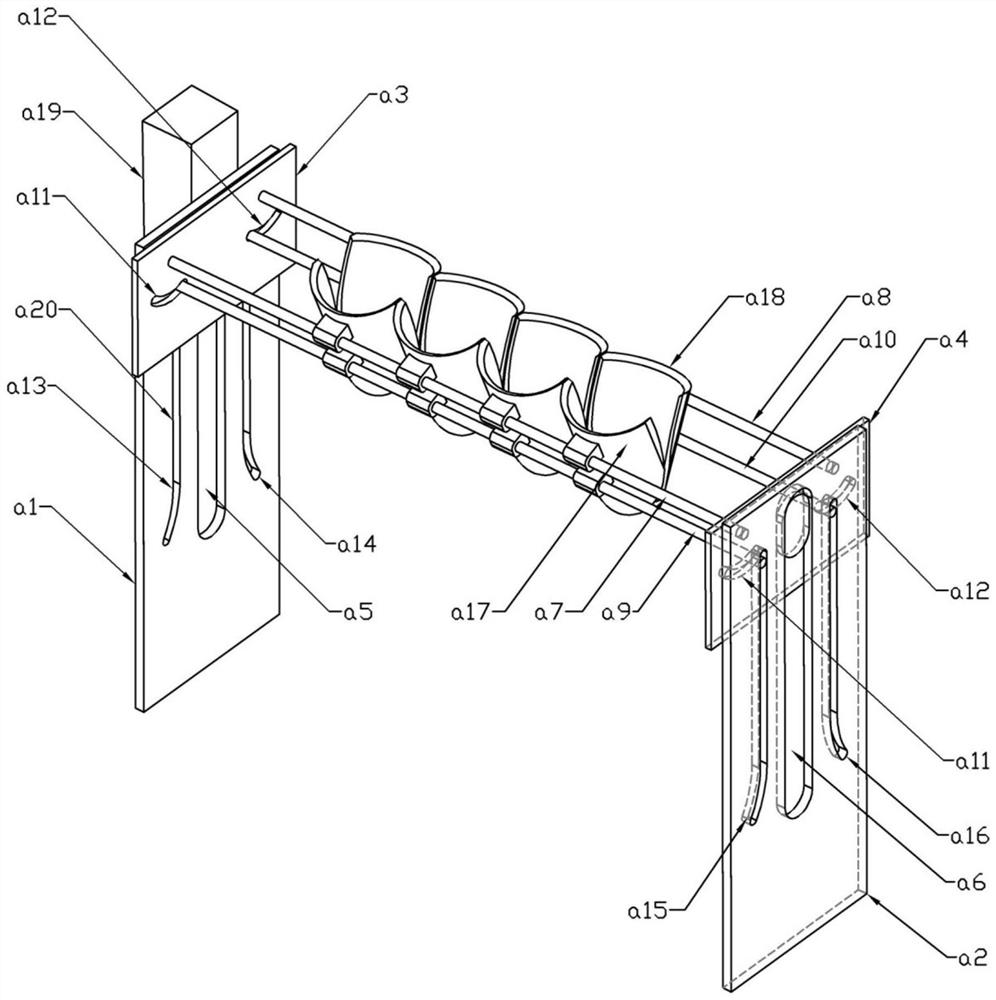

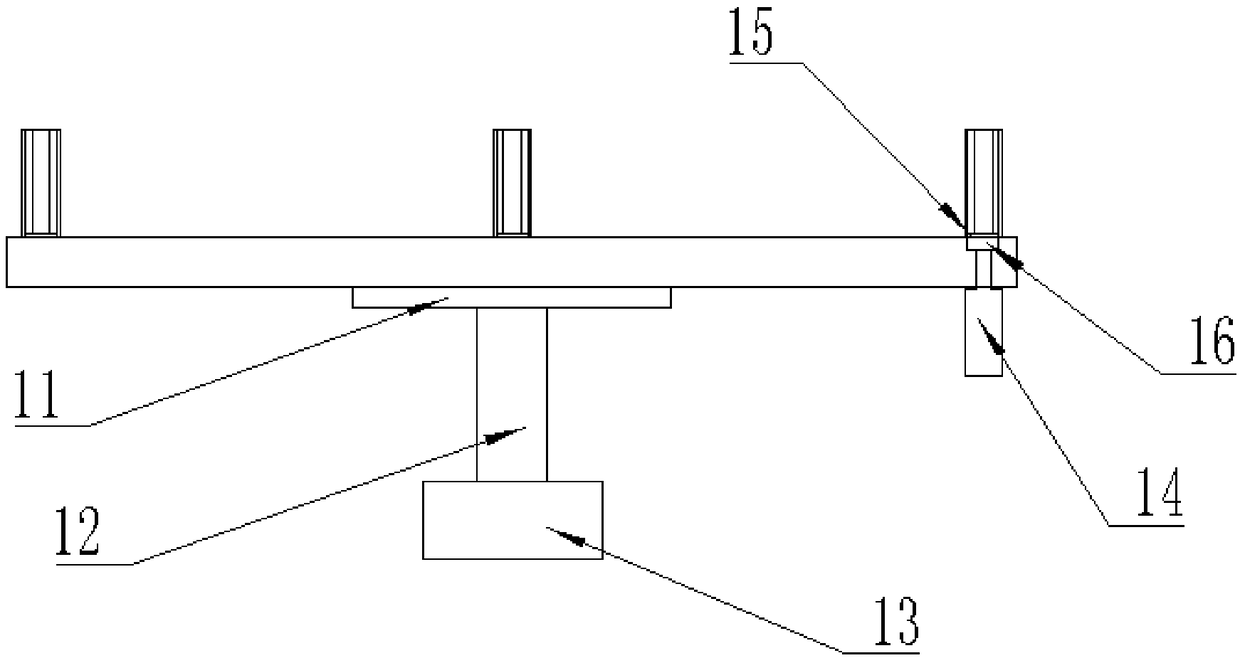

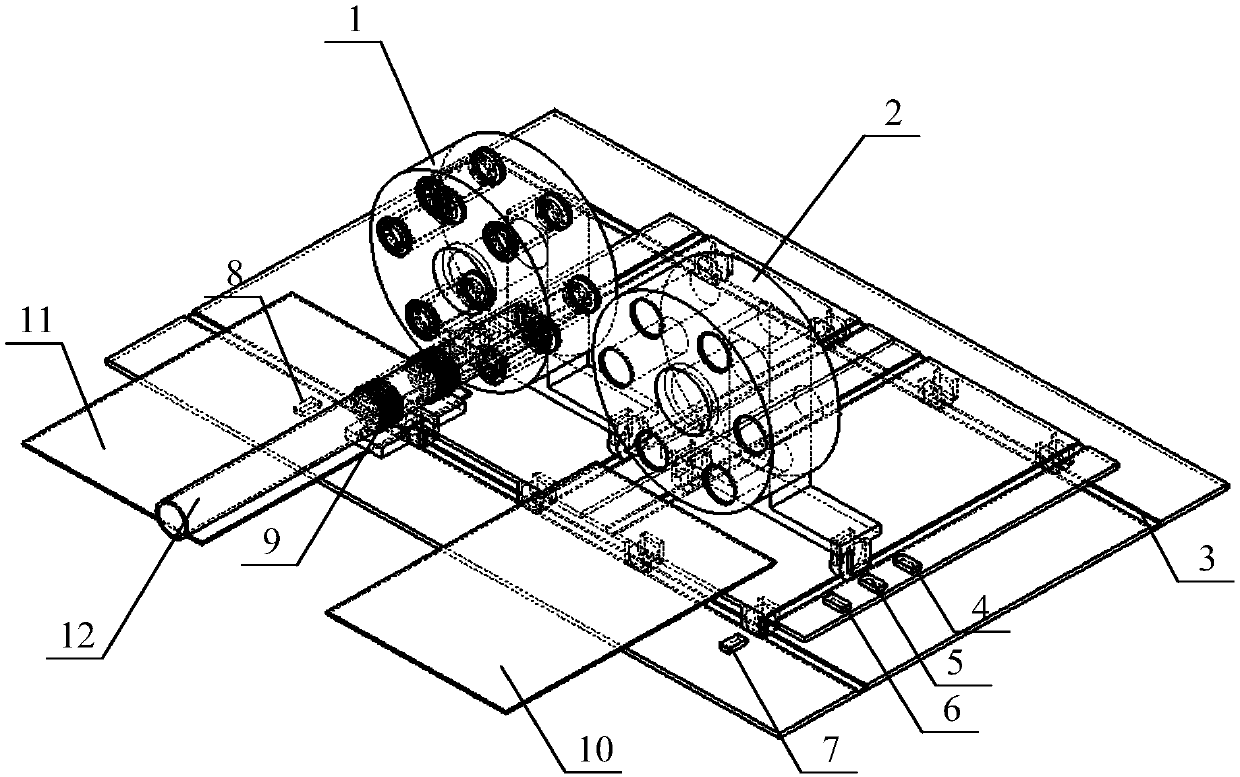

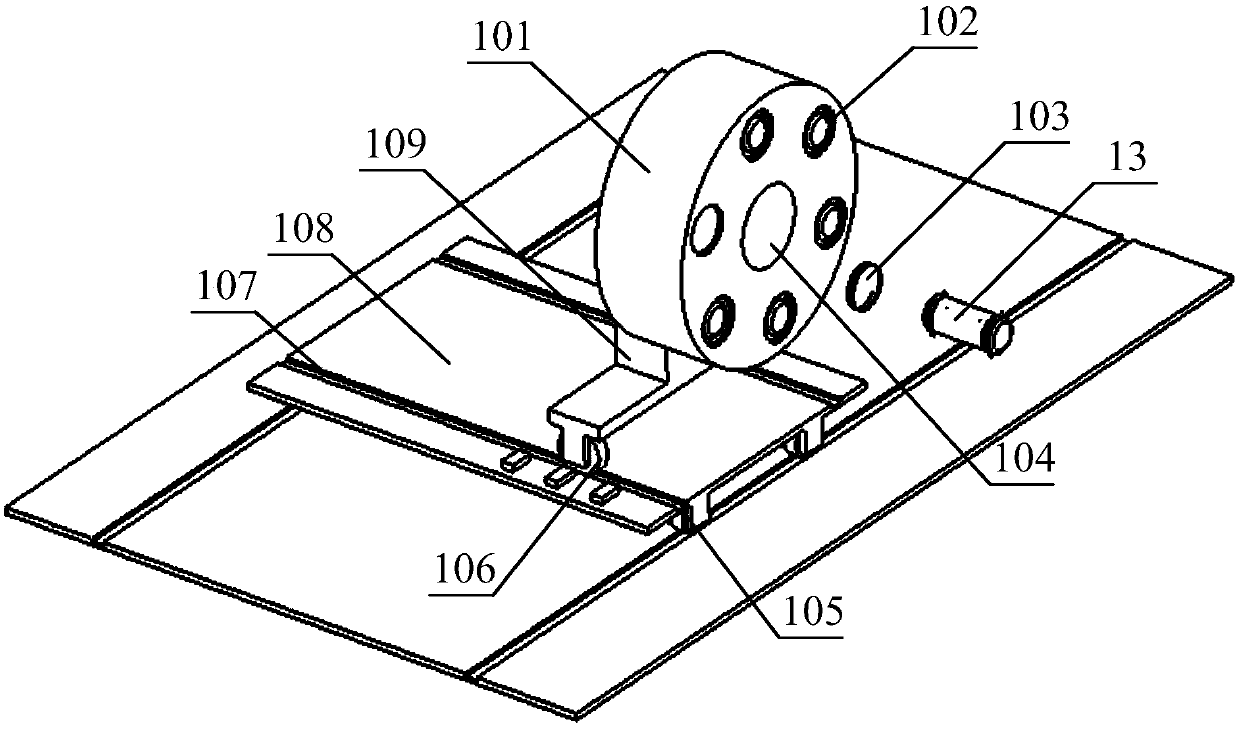

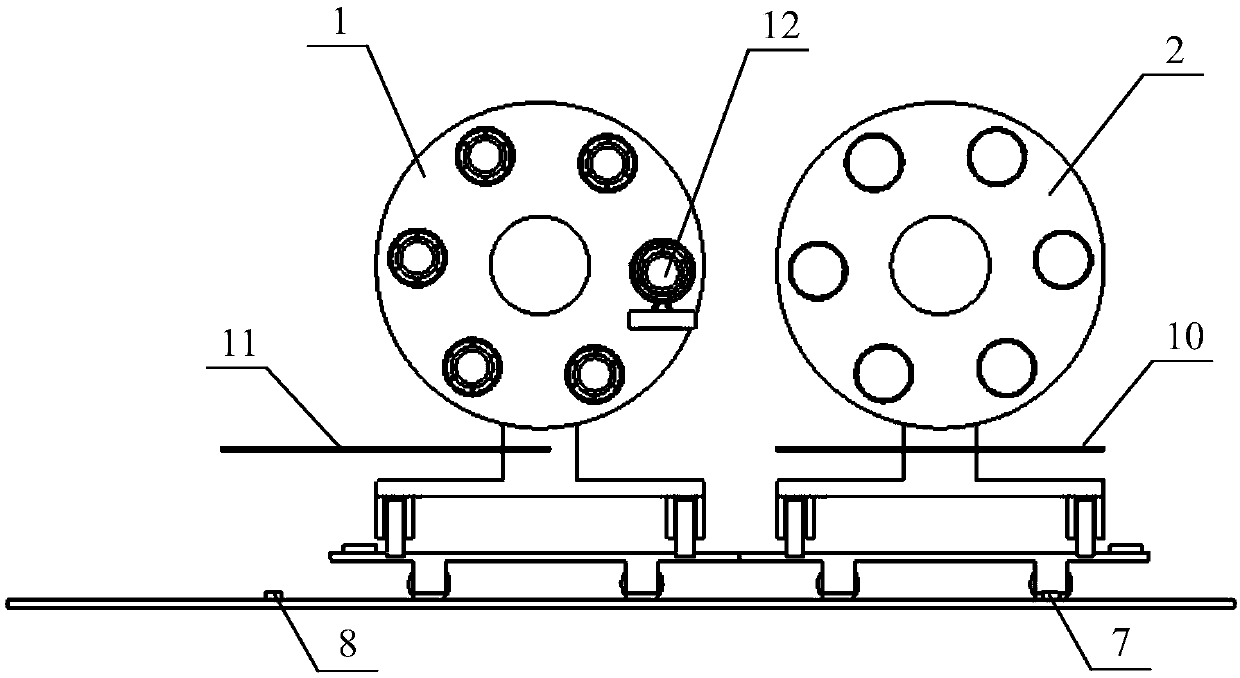

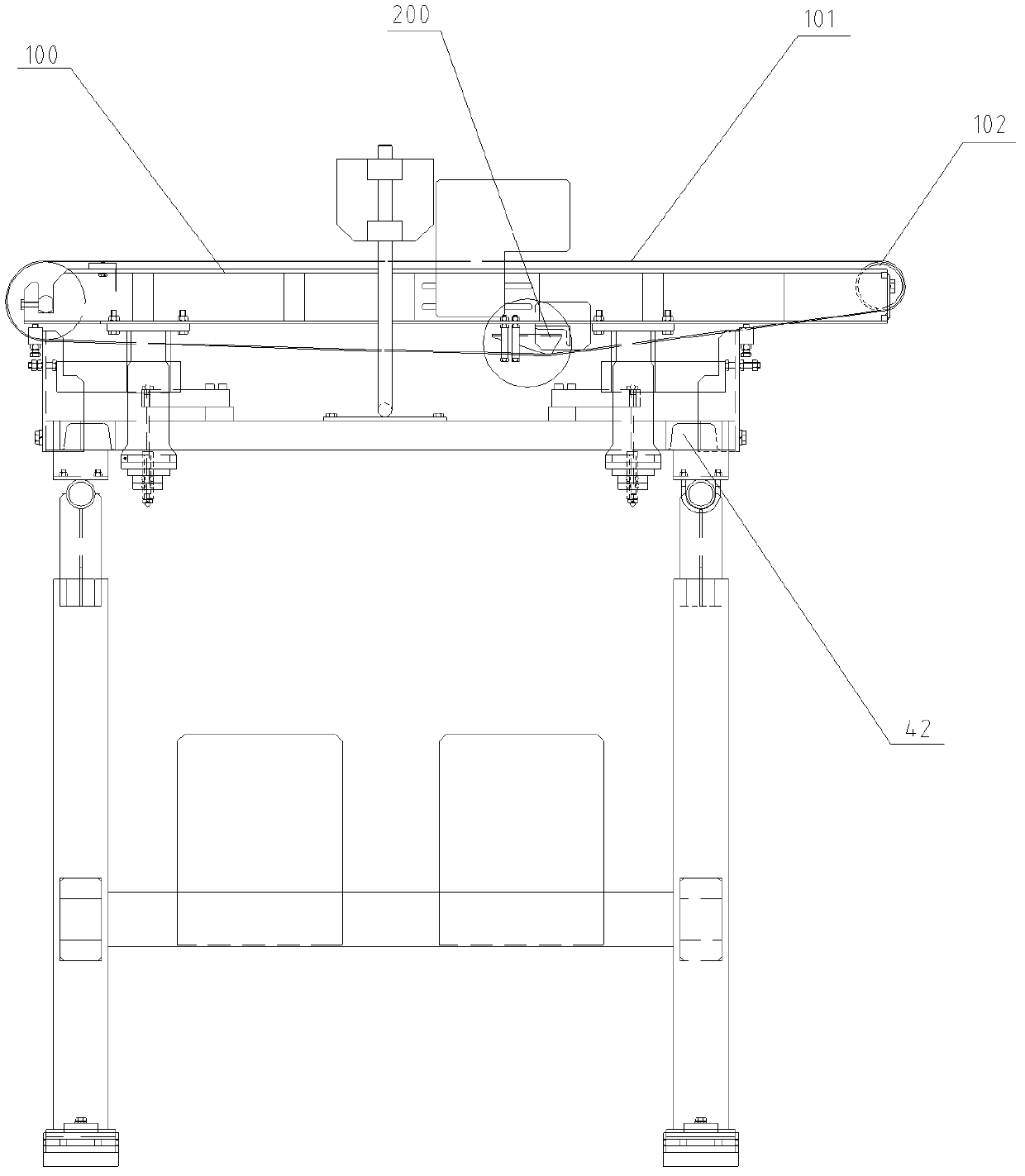

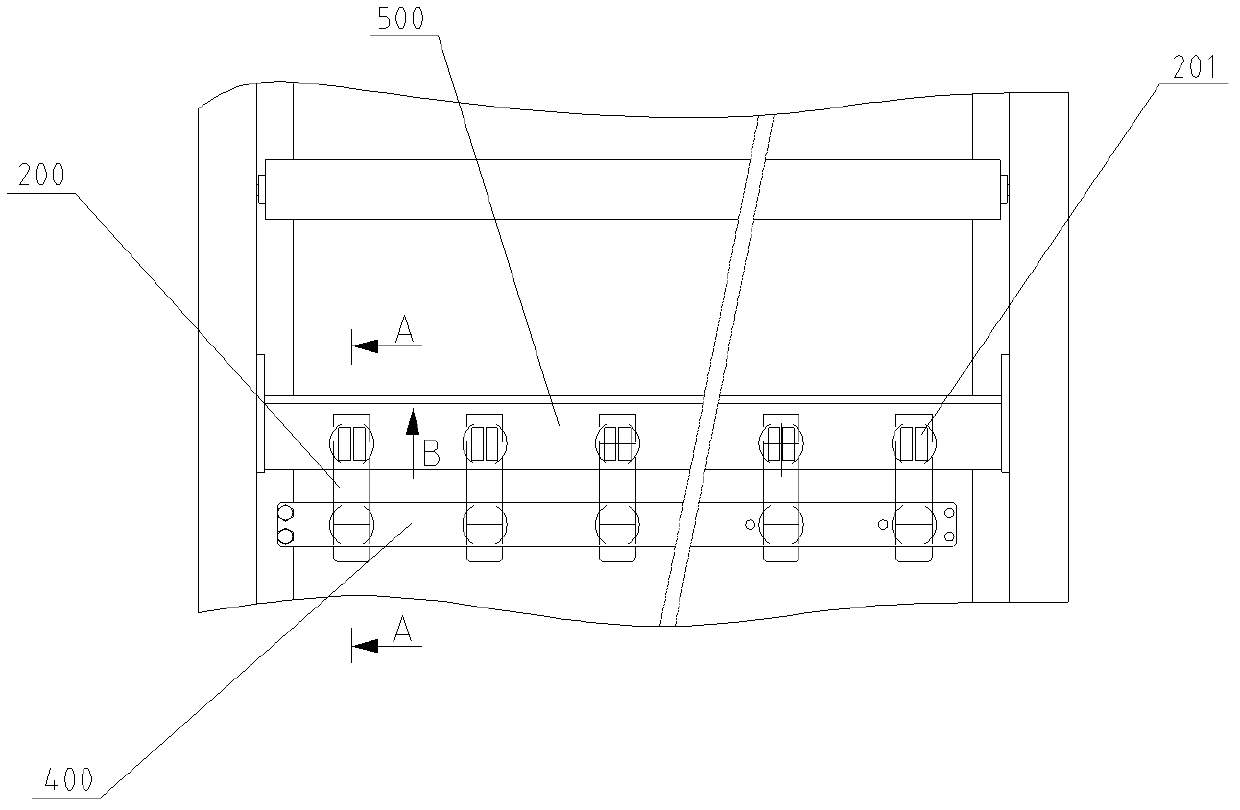

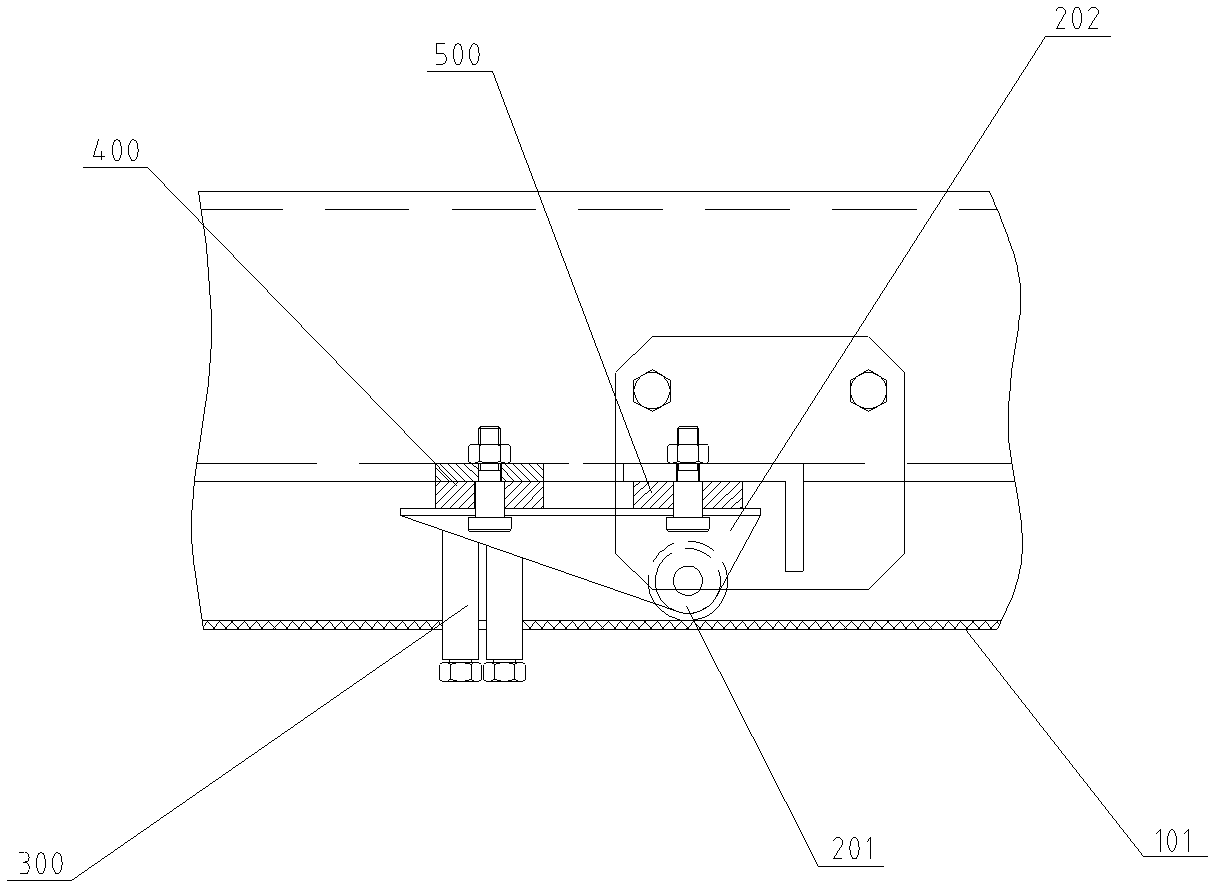

Rotary continuous receiving and sending system and method for cold chain logistics pipeline system

ActiveCN109552887AImplement pipeliningFast and efficient deliveryNon-mechanical conveyorsCold chainLogistics management

The invention discloses a rotary continuous receiving and sending system for a cold chain logistics pipeline system, characterized by comprising: a first rotary receiving and sending device (1), a second rotary receiving and sending device (2), a lateral movement device, and longitudinal movement devices; the first rotary receiving and sending device (1) and the second rotary receiving and sendingdevice (2) are each configured with a plurality of receiving and sending places (102) for housing cold chain collectors (13); the first rotary receiving and sending device (1) and the second rotary receiving and sending device (2) are fixedly connected in a lateral direction of a cold chain transmission conduit (12), and laterally and synchronously driven by the lateral movement device; longitudinal movements of the first rotary receiving and sending device (1) and the second rotary receiving and sending device (2) in a longitudinal direction of the cold chain transmission conduit (12) are independent of each other, and the first rotary receiving and sending device (1) and the second rotary receiving and sending device (2) are respectively driven by the first longitudinal movement deviceand the second longitudinal movement device to do longitudinal movements without interference. The invention adopts two sets of rotary receiving and sending devices to alternate operations, which is fast and efficient.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

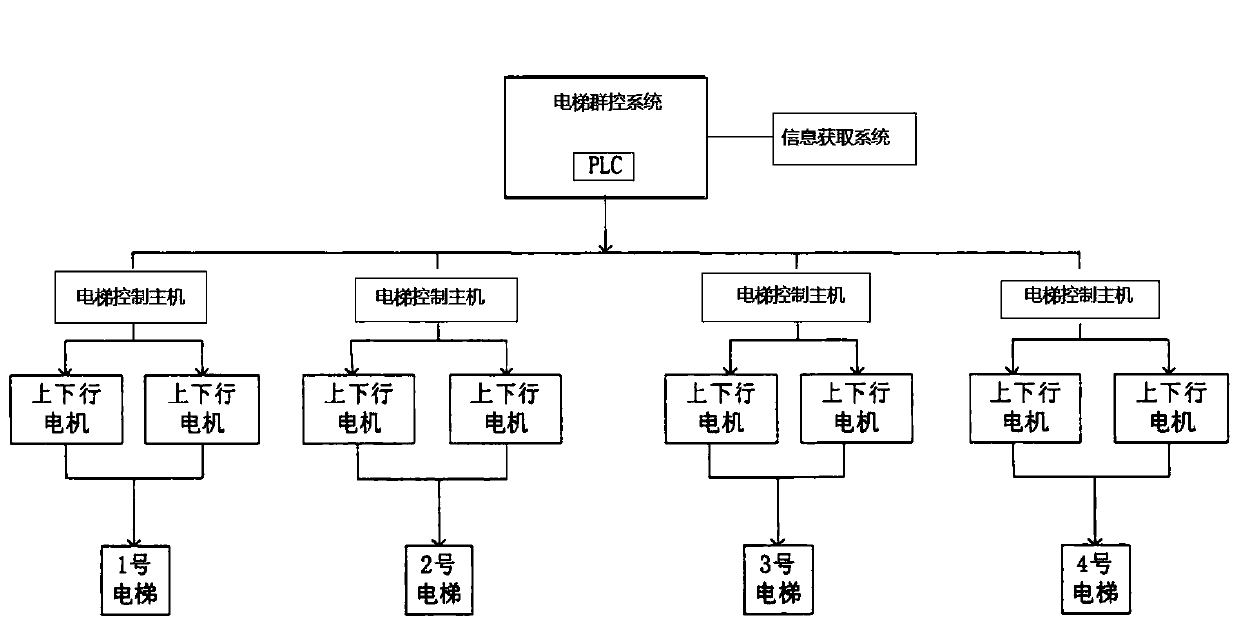

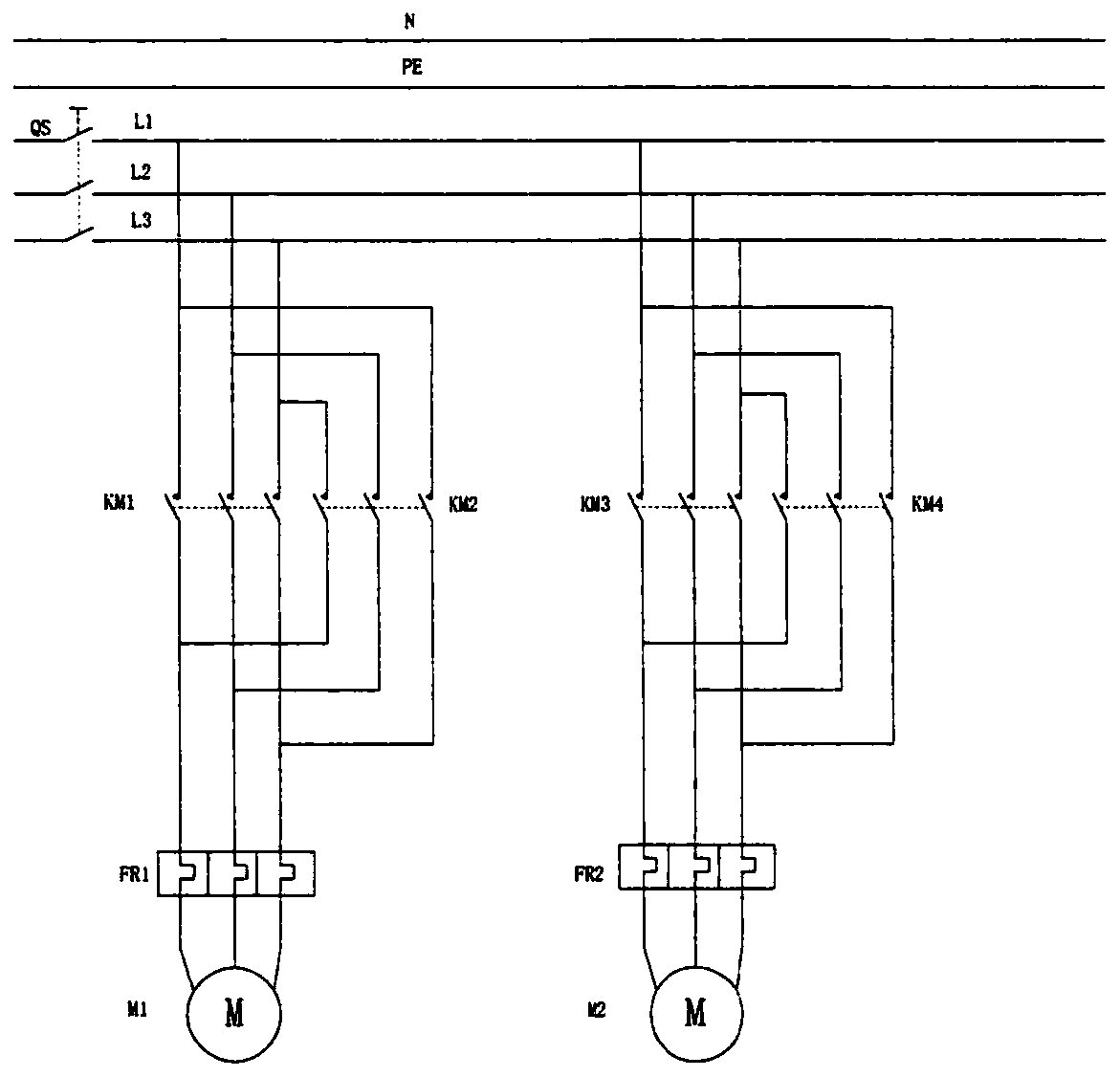

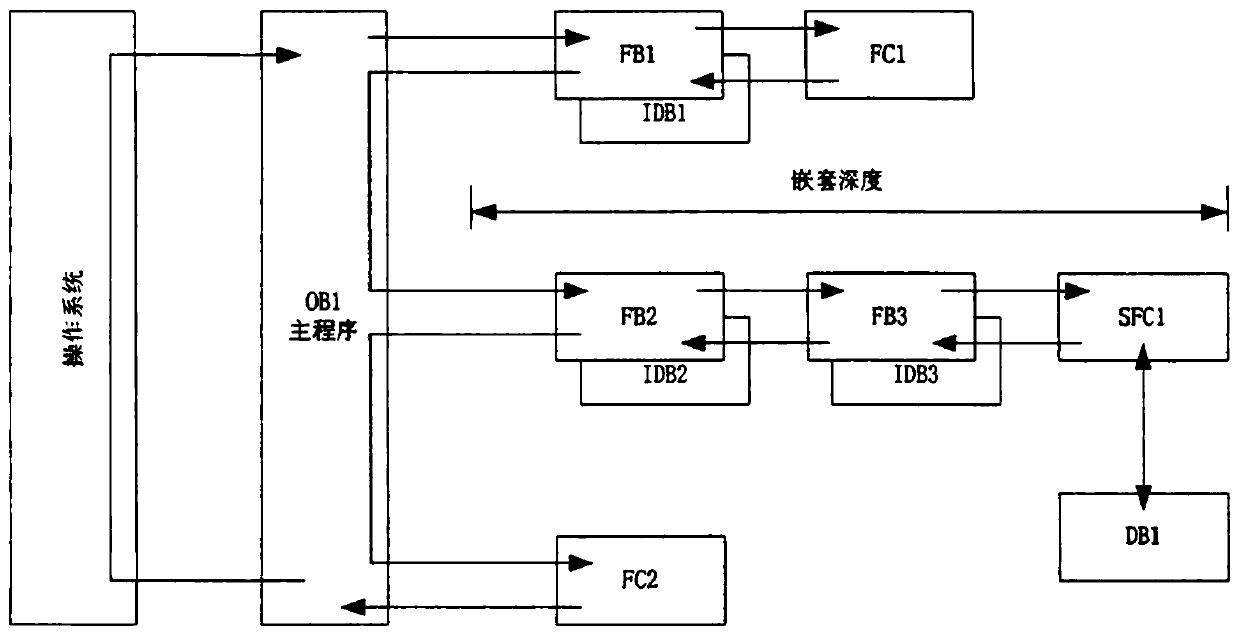

Multi-elevator group control system

InactiveCN110217655AFast and efficient deliveryAvoid wastingElevatorsBuilding liftsMachine controlComputer module

The invention provides a multi-elevator group control system for coordination control of multiple sets of elevators. The multi-elevator group control system comprises an elevator group control system,multiple elevator control main machines and an information obtaining system; the information obtaining system comprises infrared detecting modules arranged in elevator gates, and weight sensors arranged in elevators for obtaining auxiliary information; each elevator control main machine controls one elevator to operate, and records operation data; the elevator group control system comprises a PLCeditor as a main control chip, and an auxiliary circuit; and the elevator group control system is used for receiving the auxiliary information and multiple sets of the operation data, and sending control instructions to the multiple sets of the elevator control main machines to appoint specific elevators to operate after calculation of the auxiliary information and the multiple sets of the operation data. The multi-elevator group control system guarantees reasonable utilization of resources, and guarantees efficient carrying efficiency.

Owner:安徽电梯大叔科技有限公司

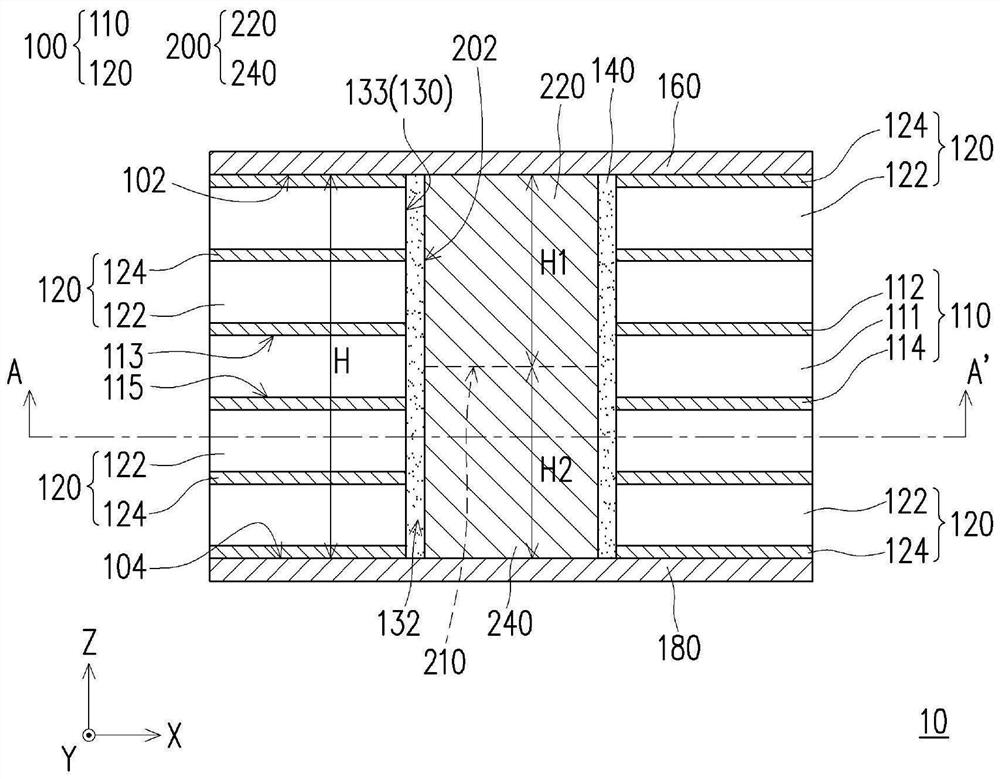

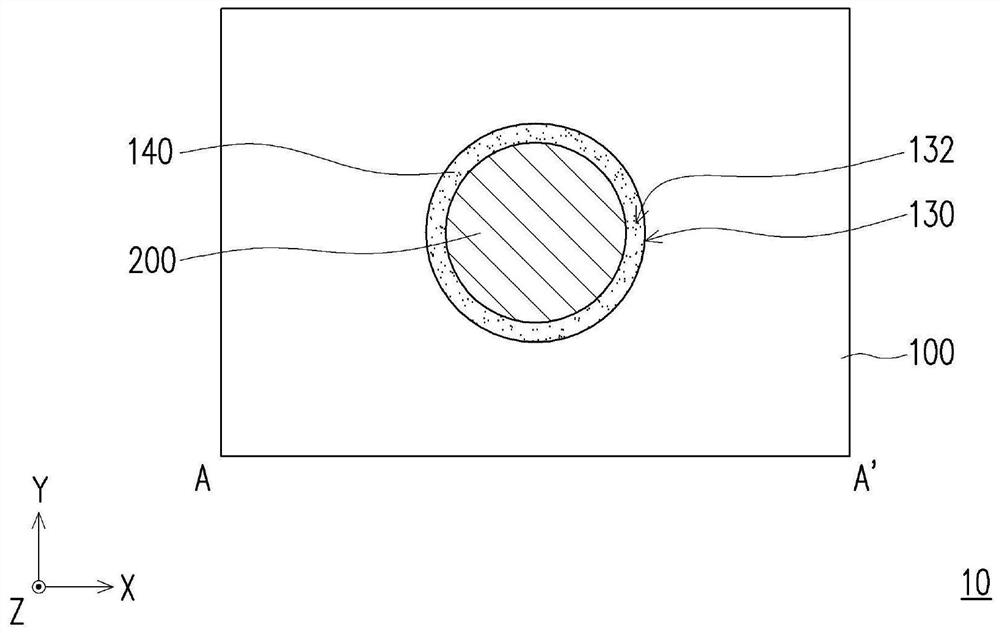

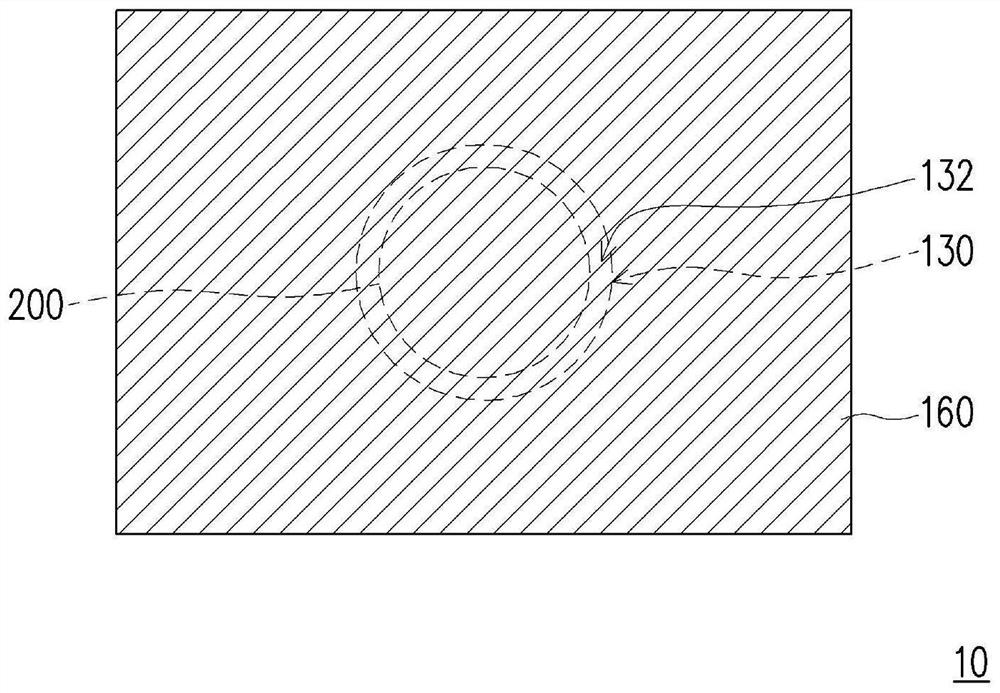

Circuit board structure

ActiveCN113556861AImprove cooling effectSimple processPorous dielectricsPrinted circuit manufactureEngineeringMechanical engineering

A circuit board structure is provided. The circuit board structure includes a circuit board, at least a through hole, and at least a heat dissipating structure. The circuit board has an inner-layer circuit board and a plurality of circuit build-up layers stacked on opposite two surfaces of the inner-layer circuit board. The through hole is disposed in the circuit board, and the through hole penetrates through the circuit board. The heat dissipating structure is disposed in the through hole. The heat dissipating structure includes a first metal block and a second metal block. The first metal block and the second metal block are joined together in the through hole and have an interface.

Owner:UNIMICRON TECH CORP

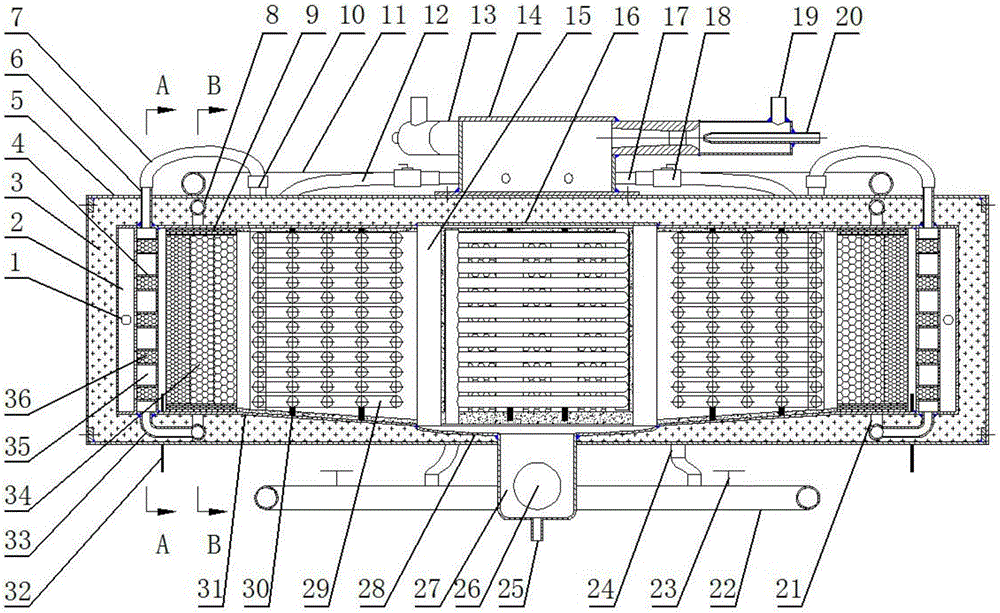

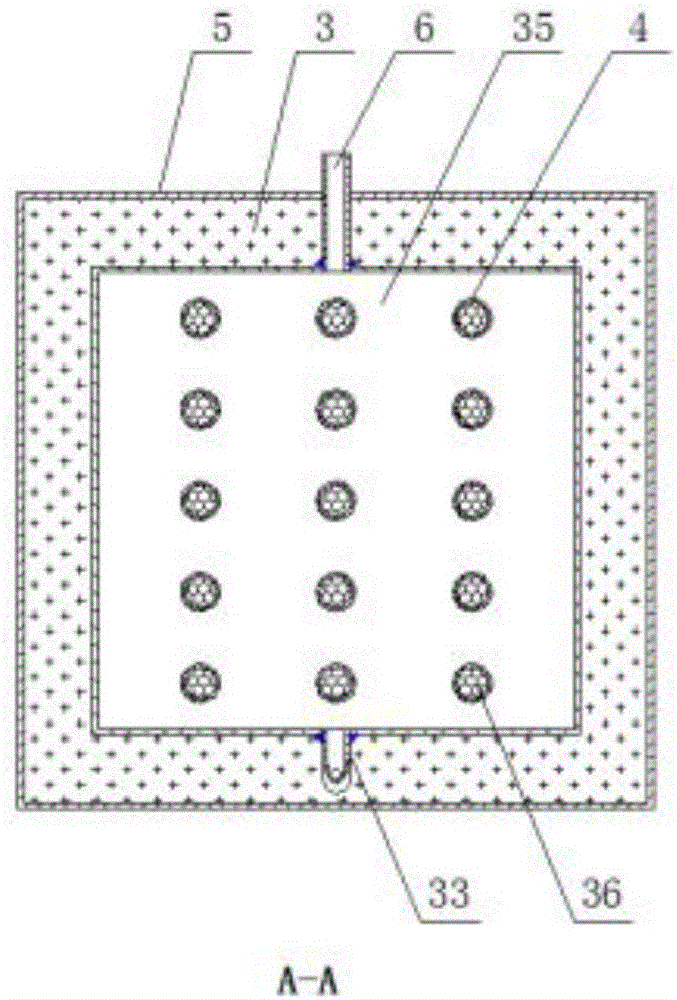

Gas-fired boiler based on porous medium combustion technology

The invention relates to a gas-fired boiler based on a porous medium combustion technology. The gas-fired boiler comprises a premixer, a number of combustion heat exchange units and a connecting box. The combustion heat exchange units are connected through the connecting box. The combustion heat exchange units are distributed around the connecting box in central symmetry. The connecting box and the combustion heat exchange units are wrapped by a shell. The position between the shell and the connecting box and combustion heat exchange units is filled with a heat preservation material. The premixer is arranged on the upper portion of the connecting box. Each combustion heat exchange unit comprises an anti-backfire structure, a combustion chamber, a tail heat exchanger and a gas inlet chamber, and two premixed gas inlet pipes are welded to the side wall face of each gas inlet chamber. Each anti-backfire structure is composed of an anti-backfire water chamber and an anti-backfire gas inlet channel. Each anti-backfire gas inlet channel is embedded into the corresponding anti-backfire water chamber through welding. The front end of each anti-backfire water chamber is connected with the corresponding gas inlet chamber. The rear end of each anti-backfire water chamber is connected with the corresponding combustion chamber. Each tail heat exchanger is arranged at an outlet of the corresponding combustion chamber.

Owner:河北泓碳能源技术有限公司

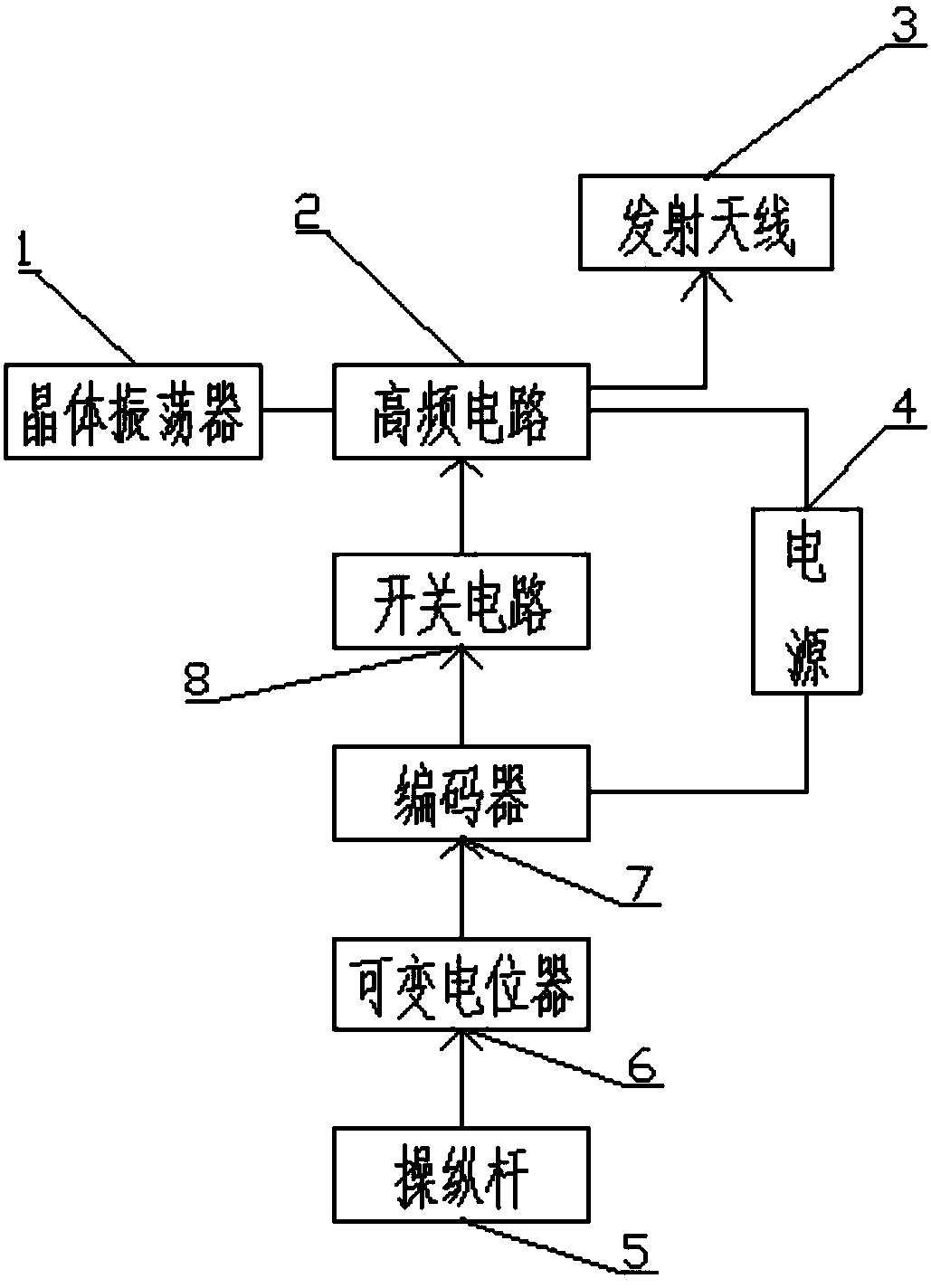

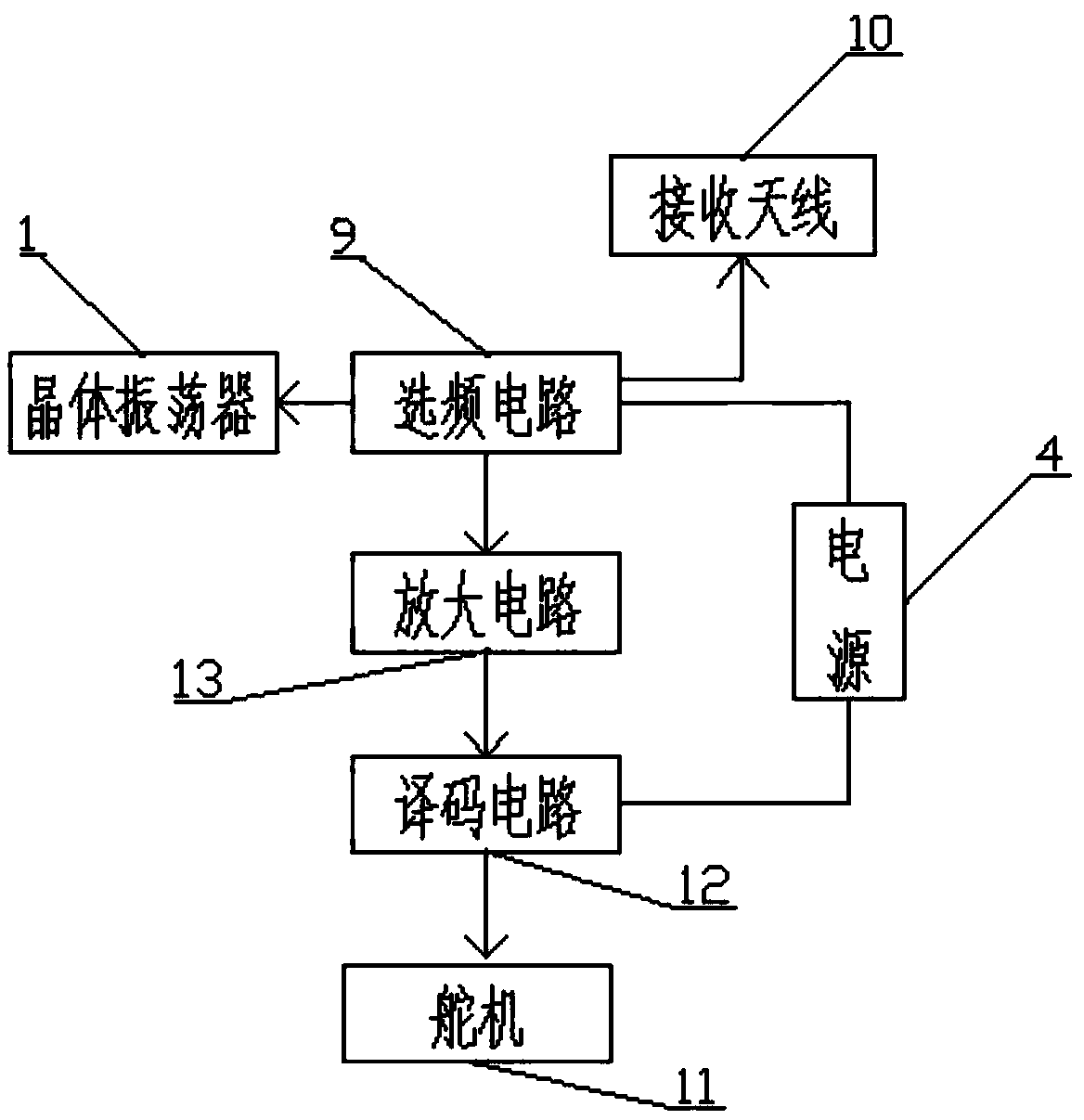

Model airplane remote control system

The invention discloses a model airplane remote control system, belonging to the field of remote control equipment. The model airplane remote control system mainly comprises a crystal oscillator, a high-frequency circuit, a transmitting antenna, a power supply, a control lever, a variable potentiometer, an encoder, a switch circuit, a frequency selection circuit, a receiving antenna, a steering engine, a decoding circuit, and an amplifying circuit, and is characterized in that the control lever is connected with the variable potentiometer, the variable potentiometer is connected with a signalgenerator and the encoder, a signal generated by the encoder passes the switch circuit and then is carried on the high-frequency circuit, the crystal oscillator generates oscillation frequency, and finally, the transmitting antenna sends out the signal. The receiving antenna is connected with the frequency selection circuit, the frequency selection circuit is connected with the crystal oscillatorand the amplifying circuit, the frequency selection circuit selects and transmits a matched signal to the amplifying circuit, the amplifying circuit is connected with the decoding circuit, the signalis amplified and then is converted by the decoding circuit, and the decoding circuit is connected with the steering engine.

Owner:NORTHWEST A & F UNIV

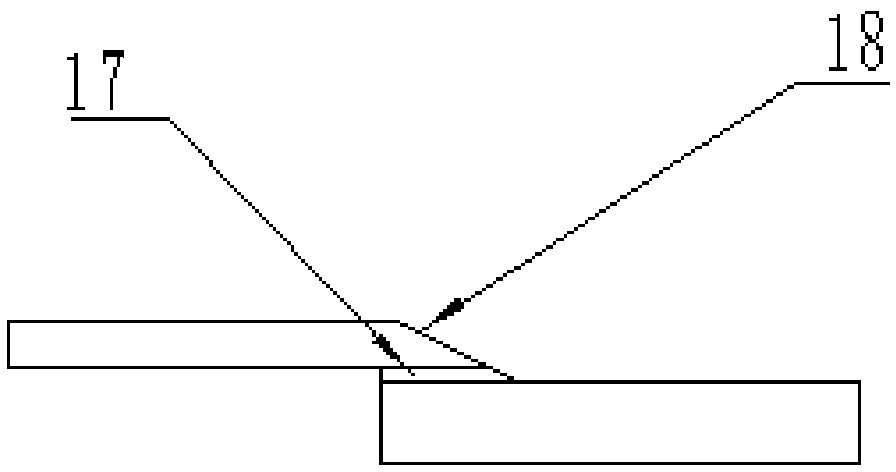

Anti-deviation method and device for conveying belt

InactiveCN103373580AFast and efficient deliveryOffset direction in timeConveyorsRollersEngineeringMechanical engineering

Owner:MESNAC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com