Material receiving device for multi-mold-cavity injection molding products

A material receiving device and injection molding product technology, which is applied in the field of injection molding machine production technology, can solve the problems that the work effect cannot be achieved well and the work efficiency needs to be improved, and achieve the effect of strong practicability, high work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0027] The problem to be solved by the present invention is to provide an efficient and convenient multi-cavity injection molding product receiving device.

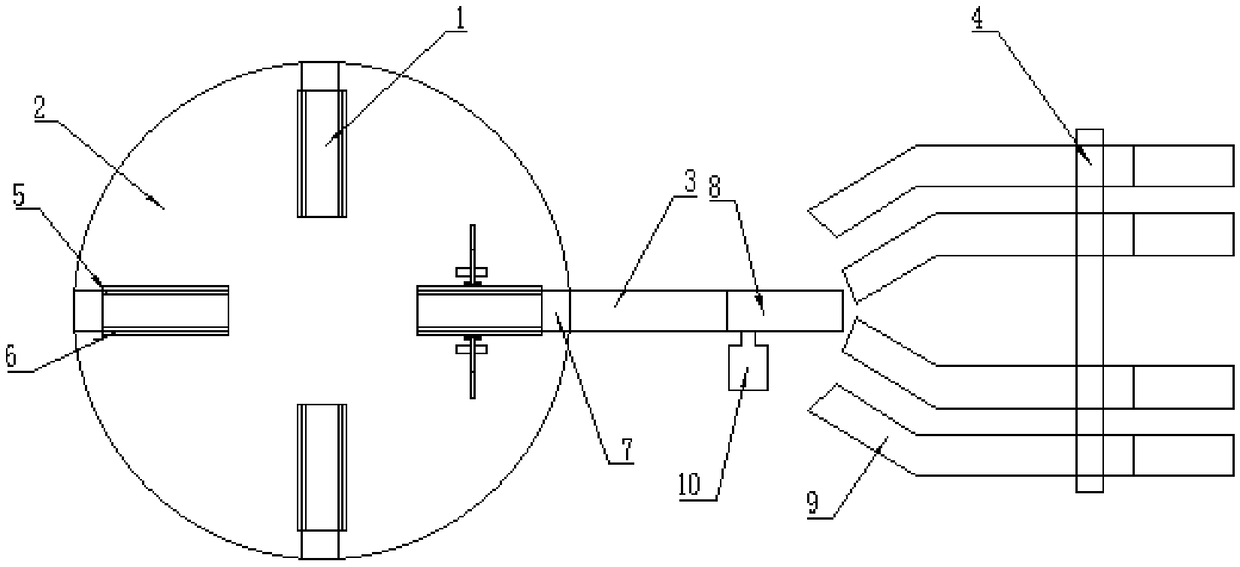

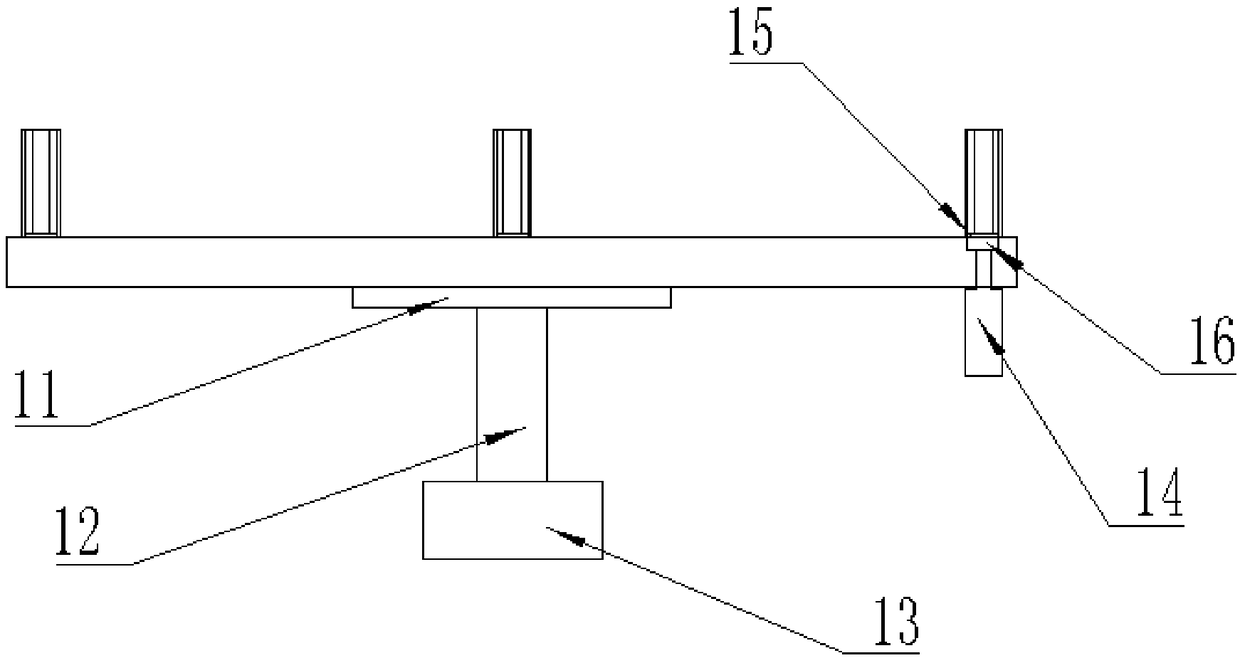

[0028] Such as figure 1 As shown, in order to ensure efficient and stable material receiving during work, the present invention relates to a material receiving device for multi-cavity injection molding products, including: a material bag 1, a rotating disk 2, a transmission track 3, and a material receiving device 4;

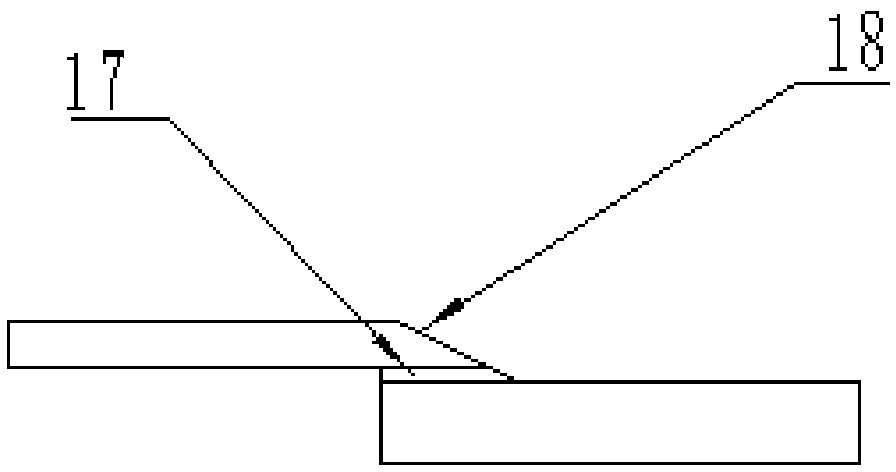

[0029] The rotating disk 2 is provided with a material bag placement tray 5; the material bag 1 is placed on the material bag placement tray 5; the material bag placement tray 5 is arranged to rotate on the center line of the rotating disk 2, and the rotation angle is 90° degree; the front end of the material bag placement tray 5 is provided with a transition road 7, which is used to tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com