Anti-deviation method and device for conveying belt

A conveying device and anti-offset technology, applied in the directions of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as conveyor belt offset, and achieve the effect of improving efficiency, improving conveying efficiency and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

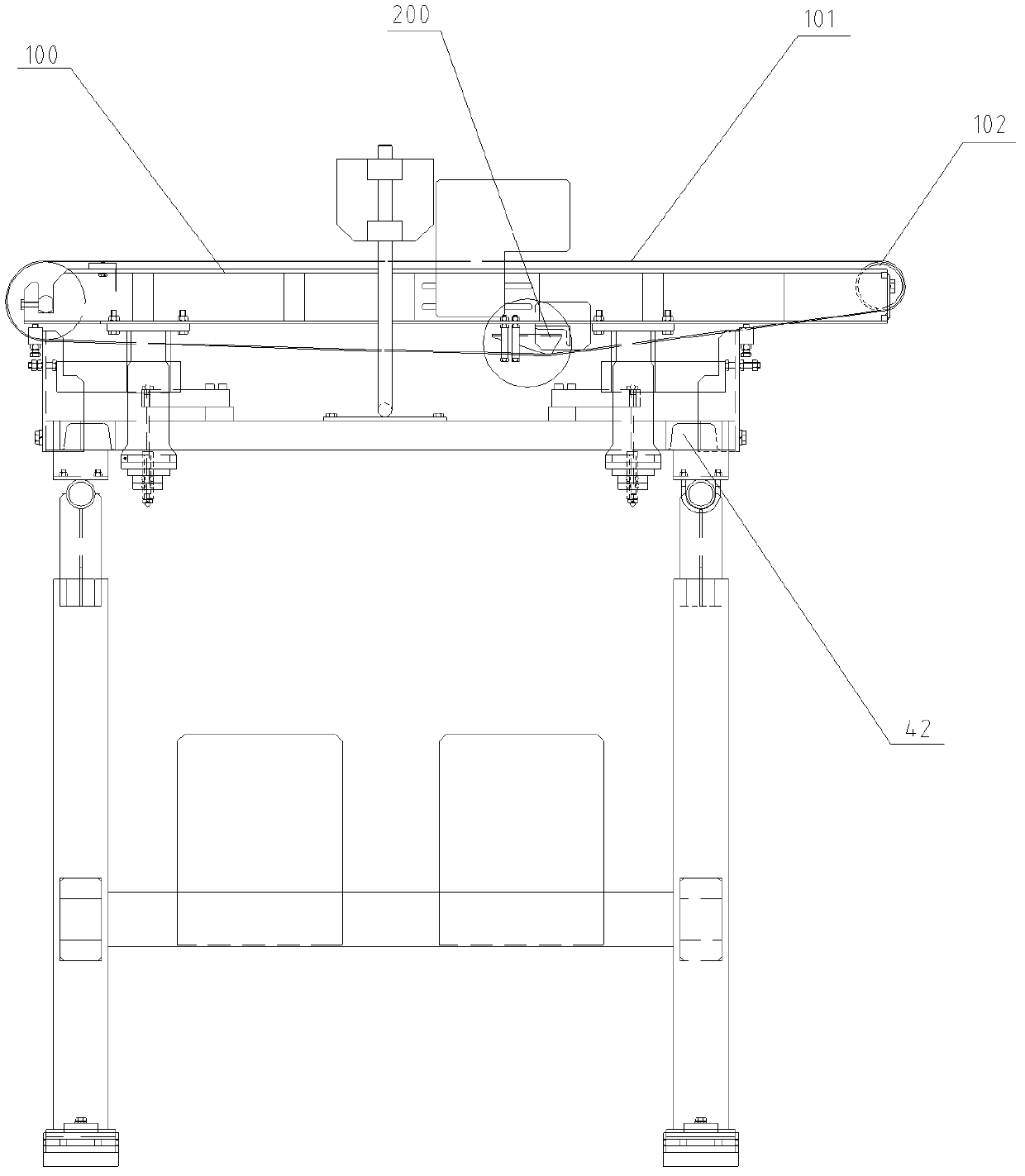

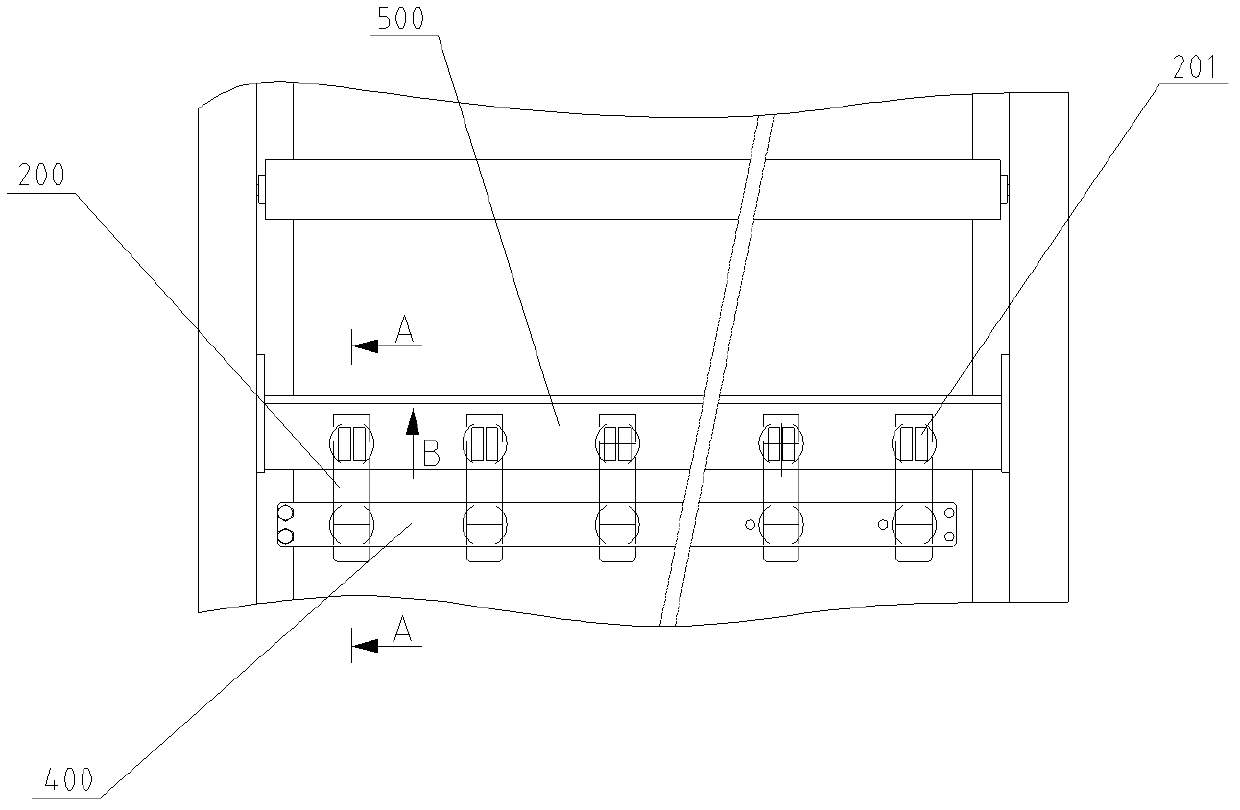

[0026] Example 1, such as Figure 1 to Figure 2 As shown, the method for checking and weighing the material,

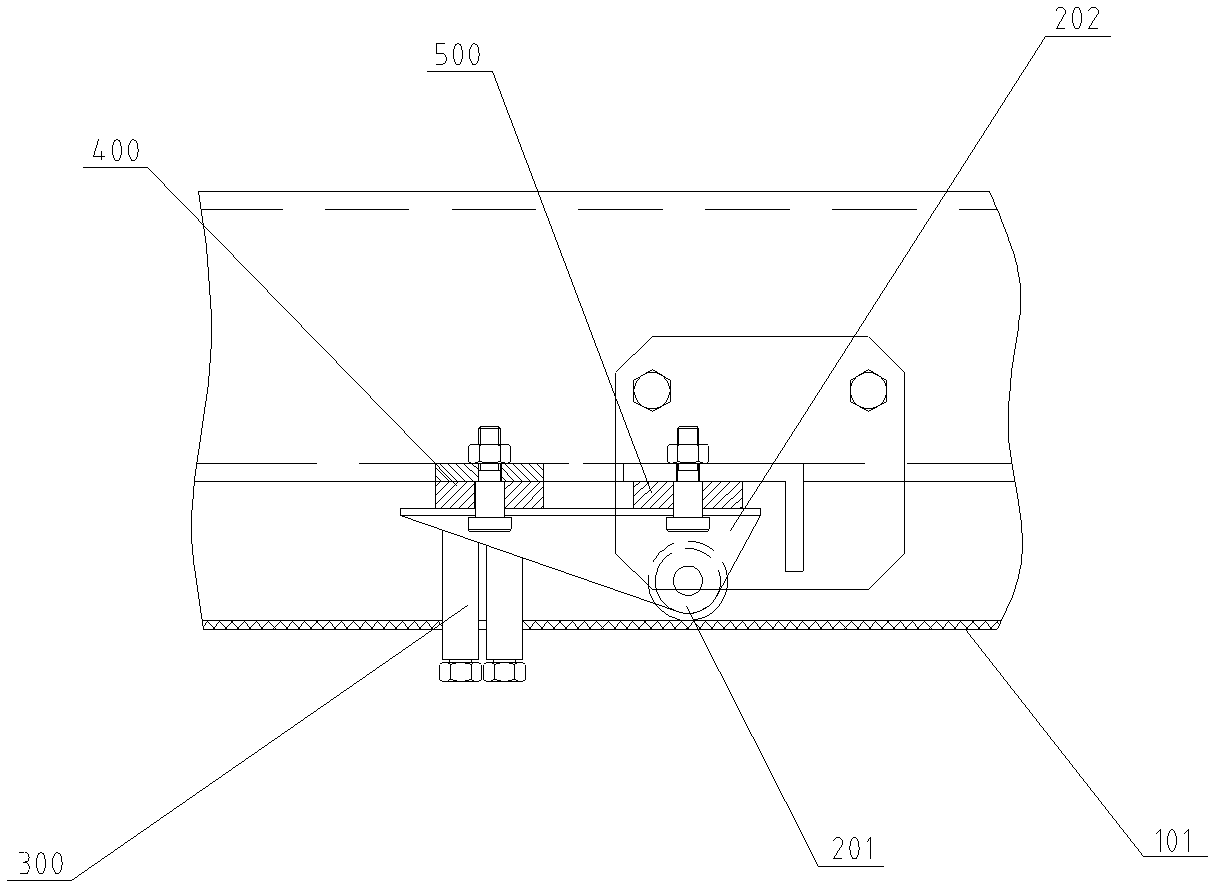

[0027] During the material conveying process, the moving part 101 of the conveying device 100 is axially shifted under the influence of external force, and the deviation correcting mechanism 200 fixed in the frame of the conveying device 100 is under the action of the axial side force of the conveying device 100, and the deviation correcting mechanism 200 The moving end of the moving end deflects in the same direction along the offset direction of the conveying device 100, and the fastening end of the deviation correcting mechanism 200 fastened to the frame of the conveying device 100 moves toward the deviation correcting mechanism 200 under the action of the axial side force exerted by the conveying device 100 Reversely apply a reset force to realize the offset reset of the delivery device 100 .

[0028] The moving part 101 of the conveying device 100 is in friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com