Flat type fuel cell module and flow field plate thereof

A fuel cell and flow field plate technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., can solve problems affecting fuel cell performance, uneven concentration distribution, etc., to avoid uneven concentration distribution, Improve overall performance and reduce flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

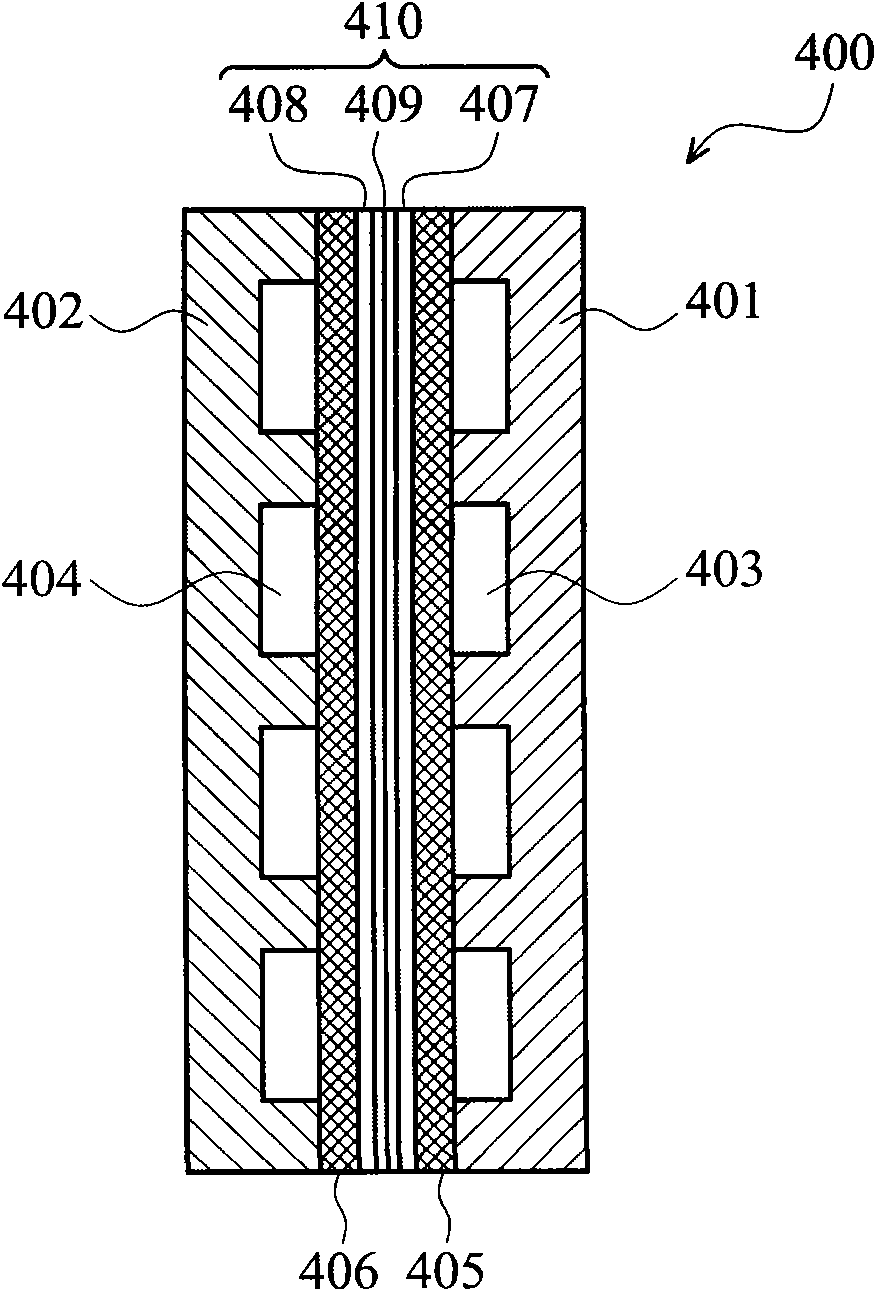

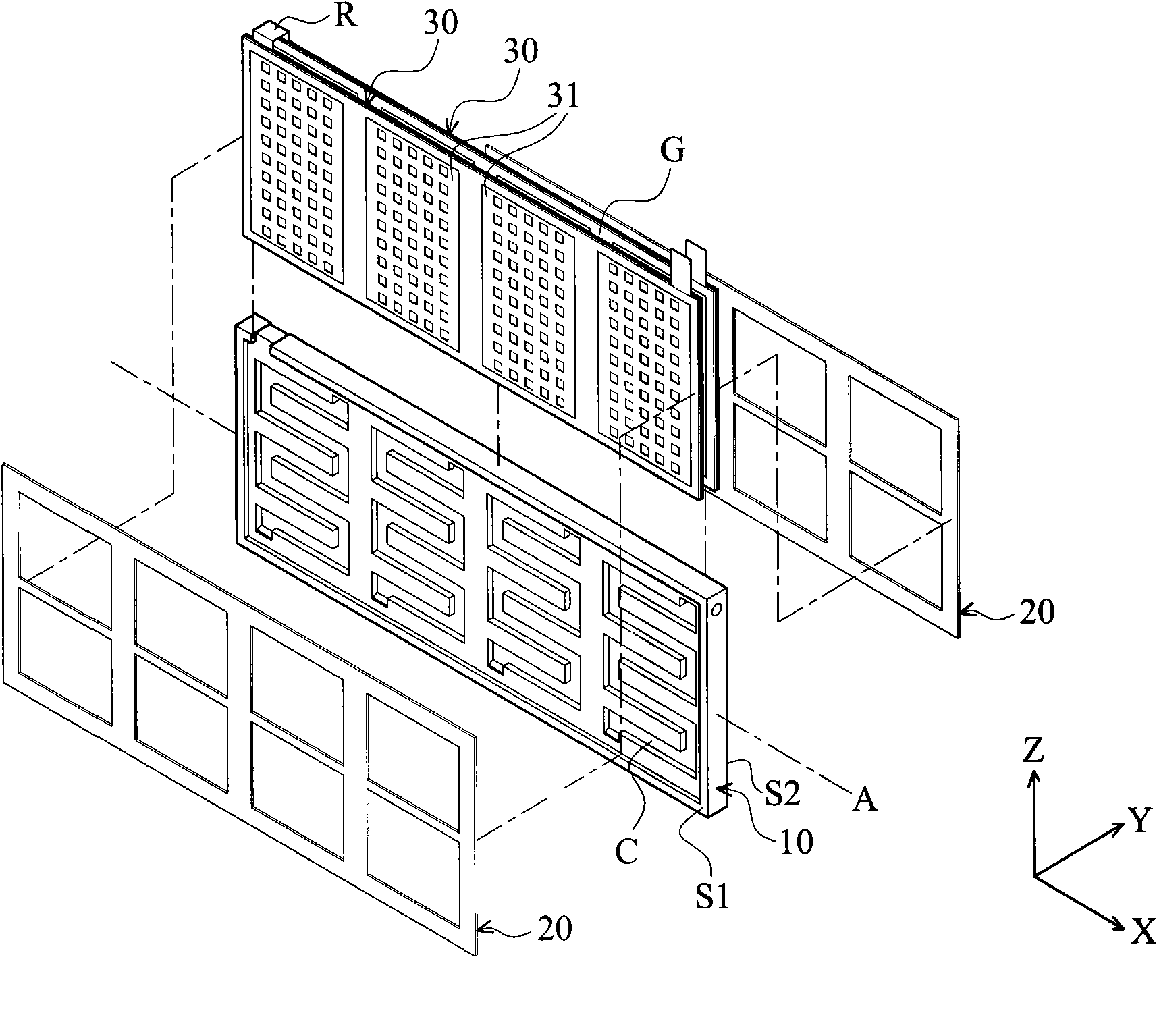

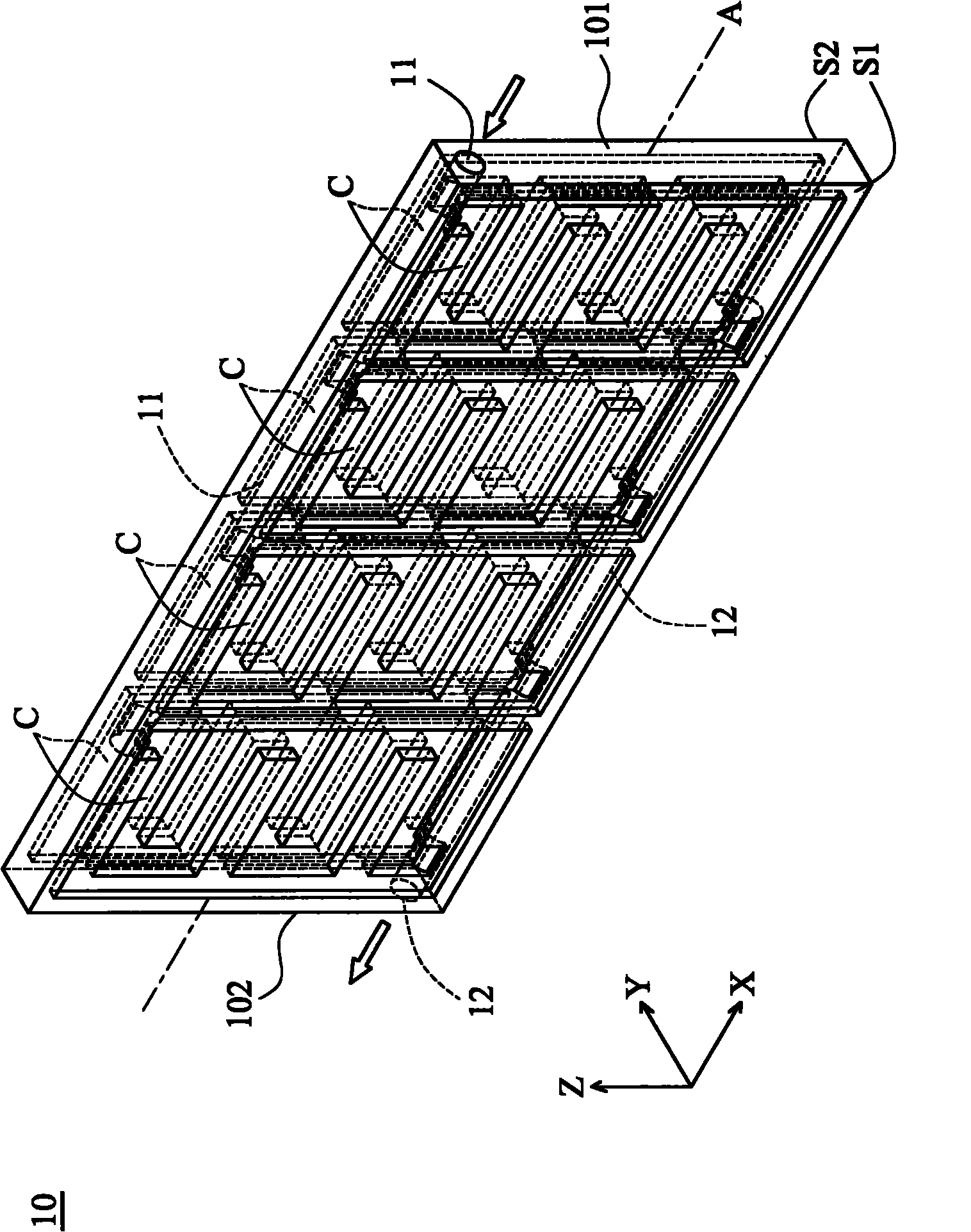

[0048] see figure 2 The flat-plate fuel cell module according to an embodiment of the present invention mainly includes a flow field plate 10, two sealing members 20 (sealing members) and two core units 30, and each core unit 30 consists of a membrane electrode group, two Composed of a gas diffusion layer and a plurality of collector elements 31, the structure of the membrane electrode group and the gas diffusion layer can refer to figure 1 Membrane electrode assembly 410 and gas diffusion layers 405,406 are shown. In the core unit 30 of this embodiment, the gas diffusion layer and the collector element 31 are arranged on both sides (the anode side and the cathode side) of the membrane electrode group, and the collector element 31 is exposed on the surface of the core unit 30 to facilitate fuel flow. Electrochemical reactions inside the battery module.

[0049] like figure 2 As shown, the flow field plate 10 is sandwiched in the gap G between two core units 30, wherein at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com