Circulating sludge biological fermentation tank, processing system and processing method

A technology of biological fermentation and fermentation tower, which is applied in the directions of biological sludge treatment, biological organic part treatment, dehydration/drying/thickened sludge treatment, etc., which can solve the problems of high energy consumption, long cycle, and low efficiency of sludge microbial fermentation treatment, etc. problem, to achieve the effect of good drying effect, short cycle and easy automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

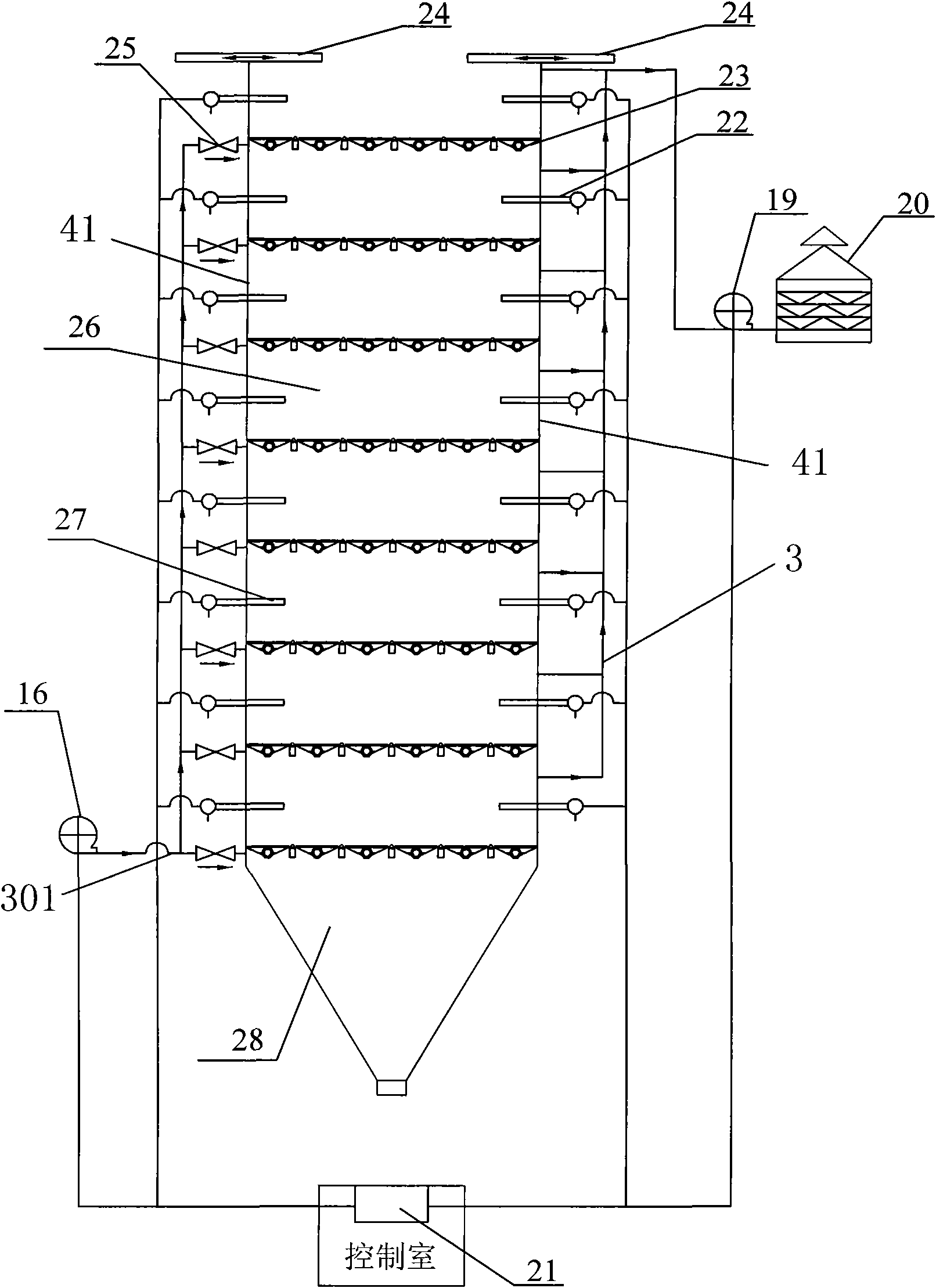

[0021] Such as figure 1 As shown, the preferred embodiment of the circulating sludge biological fermentation tower proposed by the present invention, the fermentation tower includes a tower body 41, an openable tower cover 24 located at the top of the tower body, and a storage material located at the bottom of the tower body tank 28. An eight-layer rotatable fermentation device arranged in parallel in the tower body. The fermentation device divides the inner cavity of the tower body 41 into eight layers of fermentation bins 26 along its axial direction. The bottom of each layer of fermentation device is provided with a ventilation and oxygen supply pipeline 301 communicated with a blower 16. The air outlet pipeline 3 connected with the fan 19, the upper part of each fermentation device is equipped with a monitoring device, and is controlled by the control room 21 with a computer system; control.

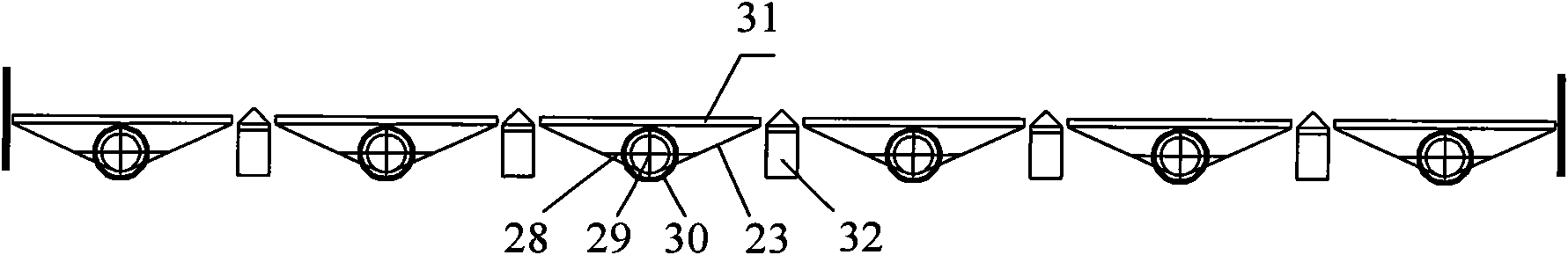

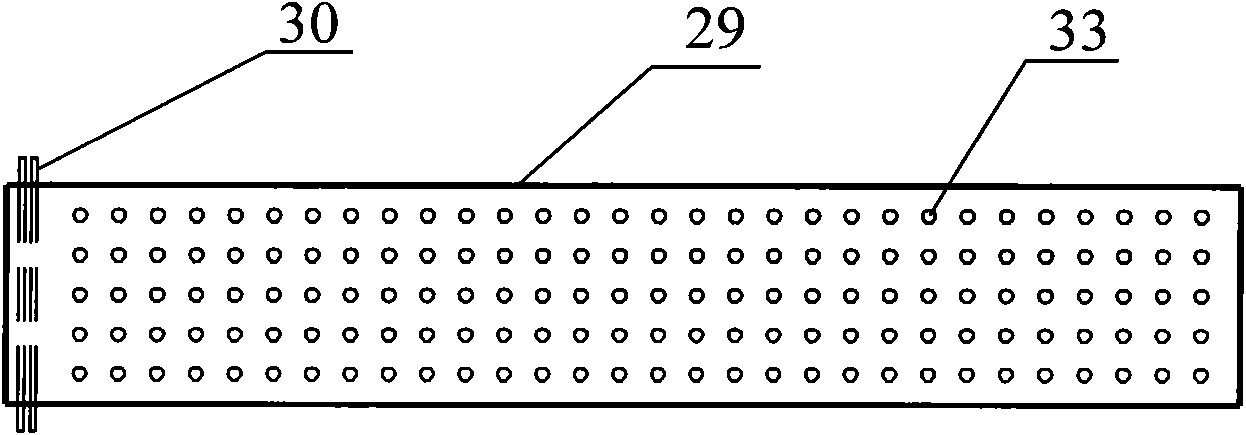

[0022] In this example, please combine figure 2 , the fermenting device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com