Closed henhouse ventilating system and air flow organization method

A ventilation system and closed technology, which is applied in animal houses, poultry cages or houses, and poultry farming, etc., can solve the problems of turbulent airflow, large ventilation resistance, and increased ventilation resistance, so as to improve airflow speed and increase ventilation. Efficiency, the effect of reducing ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

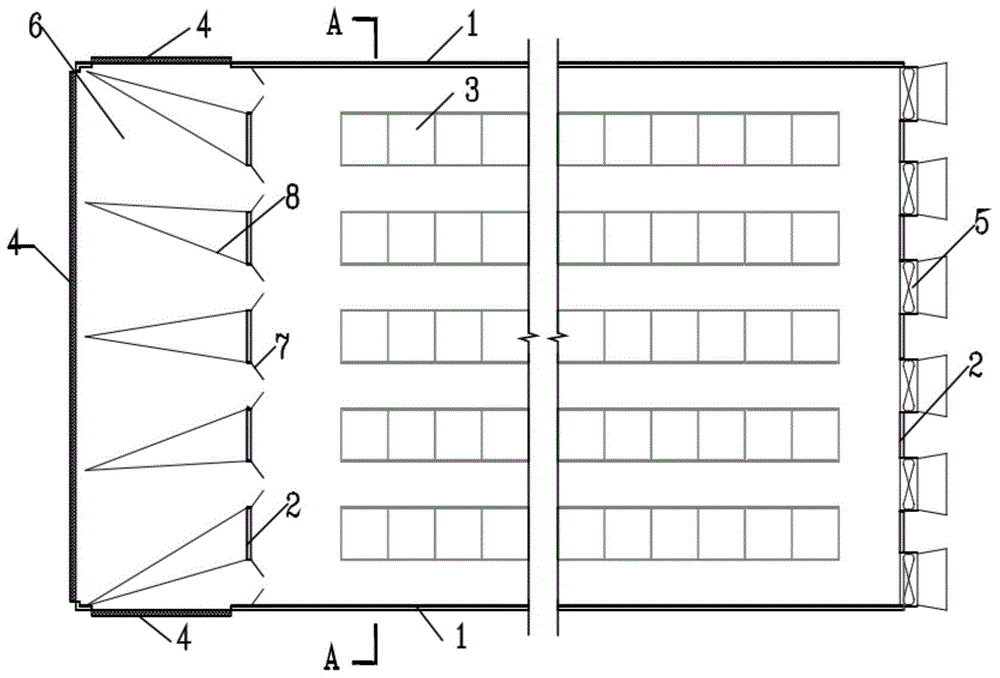

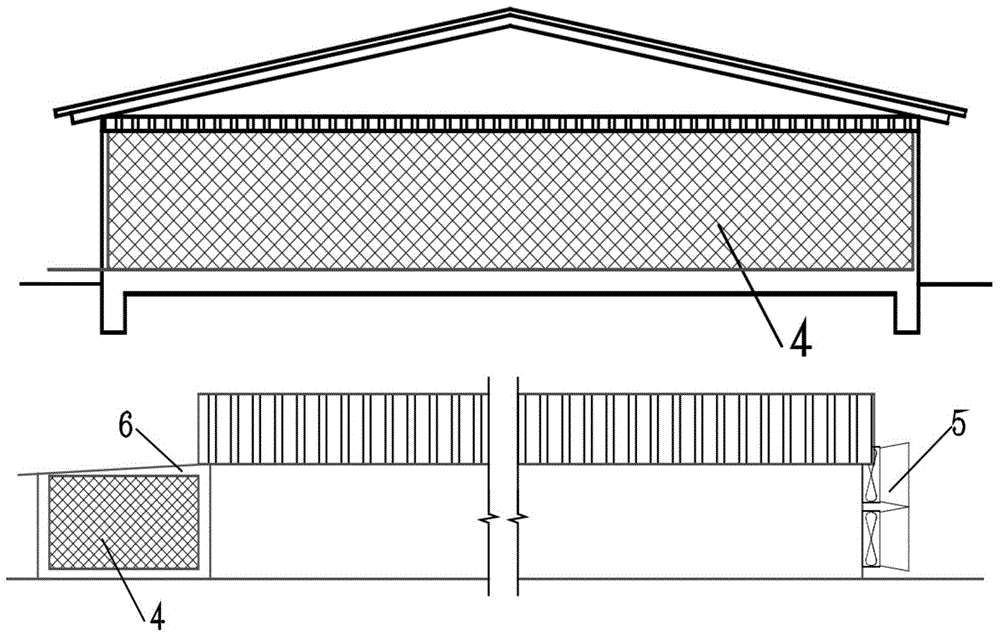

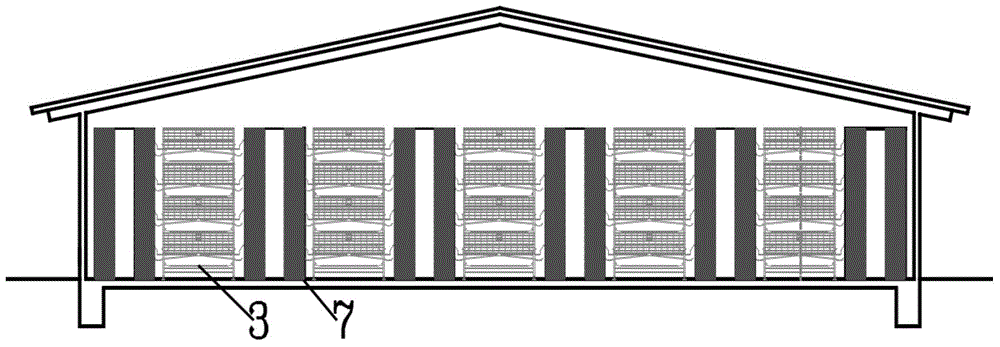

[0036] Such as figure 1 , 2 As shown, the airtight chicken house ventilation system of the present invention includes a vertical wall 1, a gable wall 2, a wet curtain cooling device 4, a negative pressure fan 5, a compartment 6, an air inlet double-fan deflector 7 and a deflector 8.

[0037] Wherein, the chicken cages 3 are arranged in rows along the vertical wall 1, and passages are formed between different rows of chicken cages 3 and between the outermost chicken cages 3 and the vertical wall 1, and the passages form the passage ventilation in the present invention. Negative pressure fan 5 is installed on the gable wall 2 at one end, as the air outlet of the airtight chicken house ventilation system of the present invention. On the outside of the gable 2 at the other end corresponding to it, a compartment 6 is arranged, and a wet curtain cooling dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com