Gear type machining tip and tool attaching the same thereon

一种加工工件、顶端的技术,应用在石材加工工具、锯床装置的刀具、制造工具等方向,能够解决柄部弯曲、切削工具损坏、施加过大加工负载等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The preferred embodiments of the present invention will now be described in detail, and the embodiments thereof are shown in these drawings.

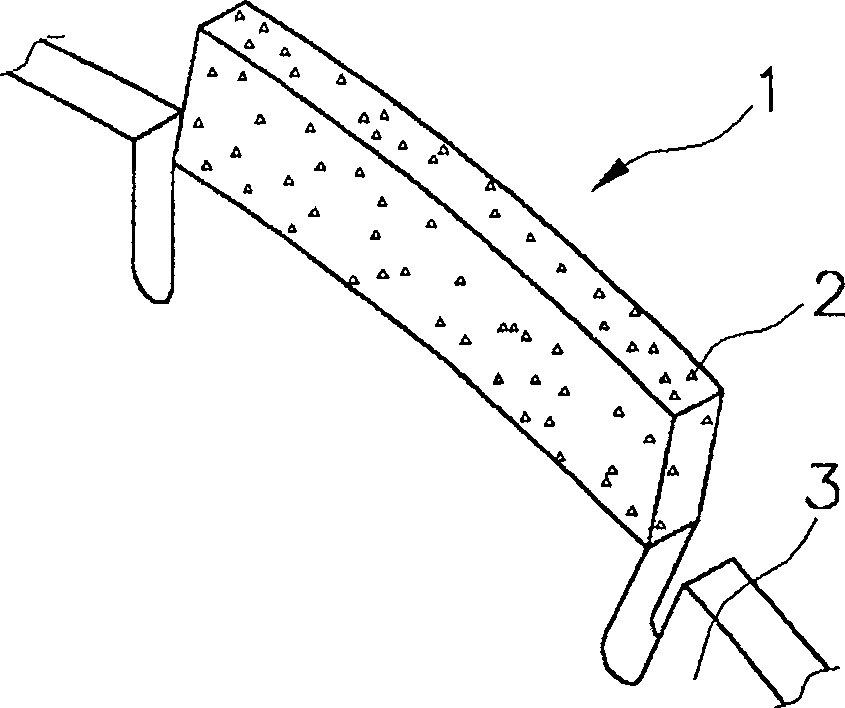

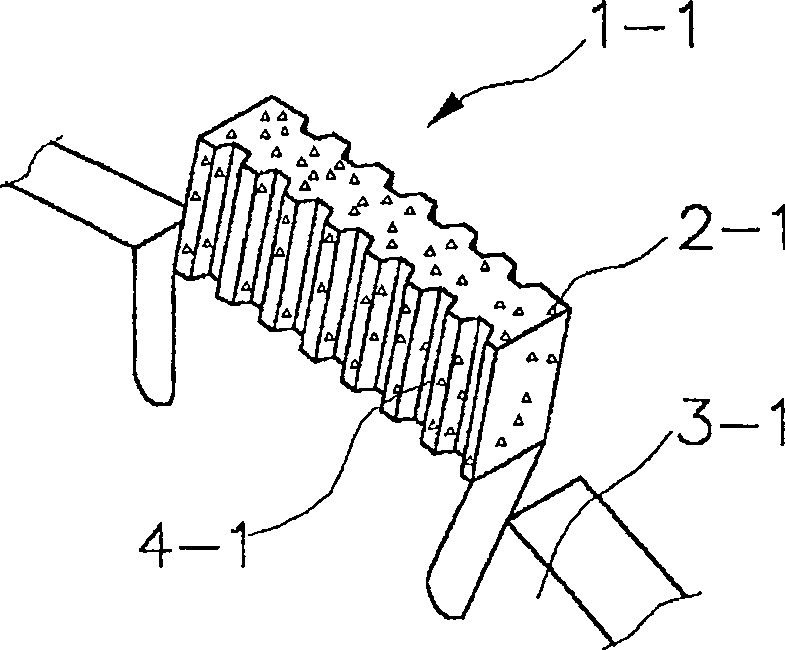

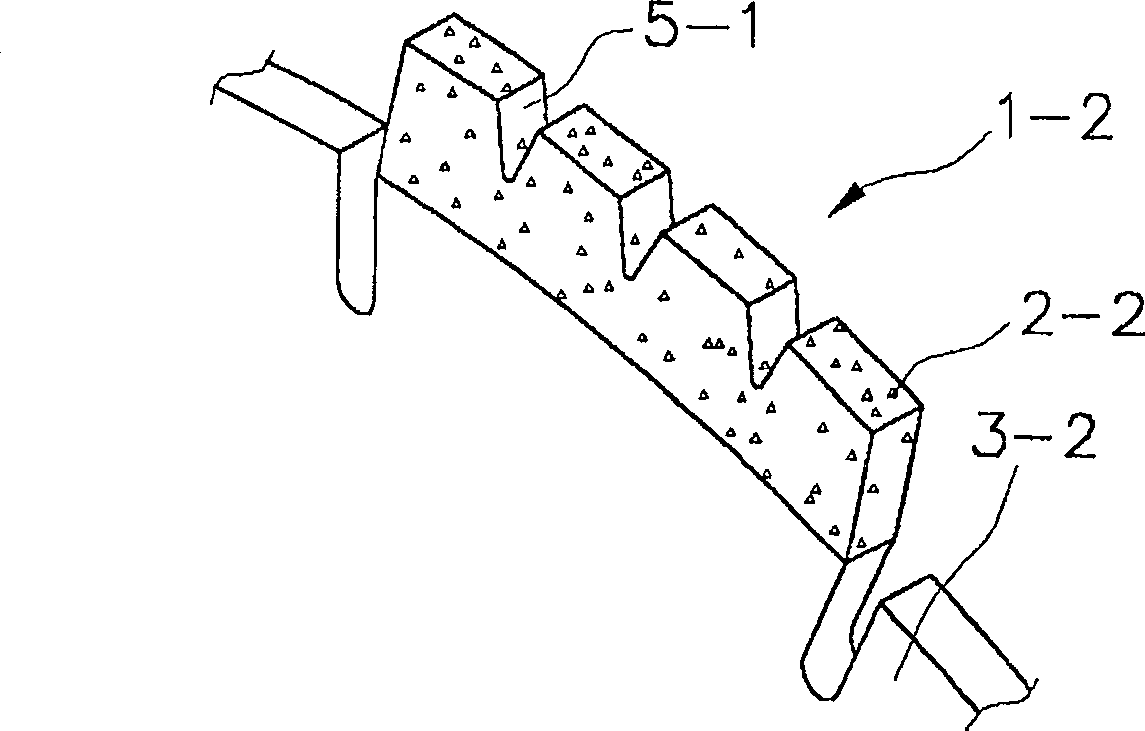

[0071] The zigzag cutting tip of the present invention with a double-layer structure includes: an adhesive layer containing super wear-resistant particles therein and having grooves formed on the working surface in contact with the workpiece; and a spacer layer To install the adhesive layer on the handle. The serrated cutting tip of the present invention is divided into a segmented cutting tip and a continuous rim type cutting tip. In addition, the cutting tip of the present invention is installed on the outer periphery of the cutting tool of the present invention, and the cutting tool is classified into cutting tools, grinding tools, and drilling tools according to functions. The preferred embodiment of the present invention will be described below with reference to the segmented cutting tip, but this is only for illustration.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com