Patents

Literature

33results about How to "Avoid secondary wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

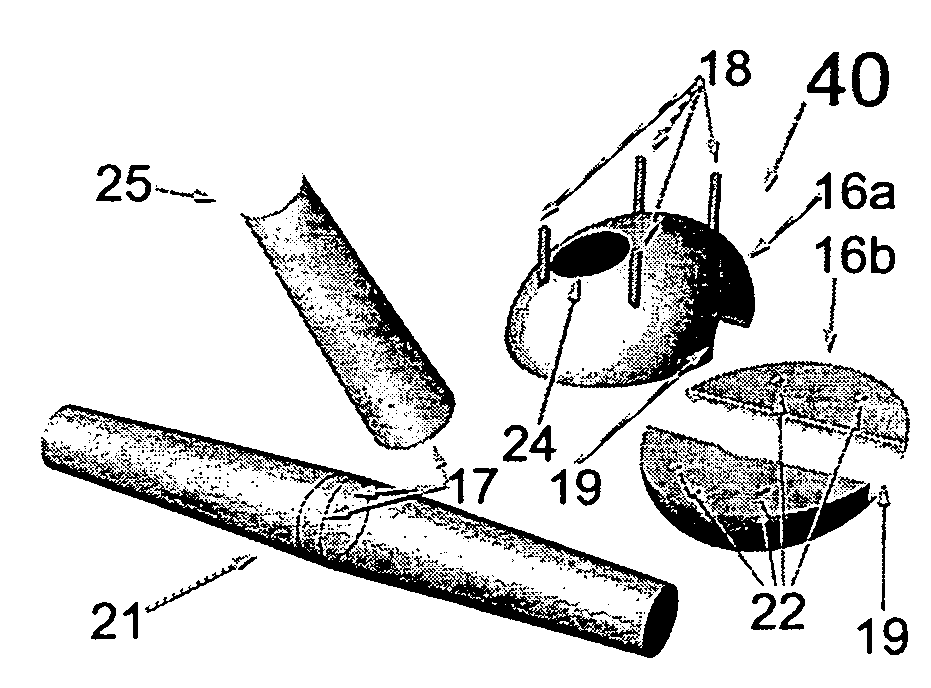

Patient specific anatomically correct implants to repair or replace hard or soft tissue

InactiveUS20060136058A1Reduce timeReduce amount of timeMedical simulationAdditive manufacturing apparatusPatient specificLiving body

The present invention relates to a system of preparing a one of a kind artificial or biological implant to repair or replace a bone or a tissue part in a living individual, the system comprising: pre-operatively constructing an anatomically correct, affected area 7-unique scan implants geometry, wherein the implants geometry is unknown before the acquisition of the individual's data; and using a process derived from rapid prototyping to construct a geometrically and anatomically correct duplication of the functional attributes of the bone or tissue part to be replaced from the dataset created by scans of the recipients scans. This system can also be used to modify, pre-operatively, existing FDA approved implants.

Owner:PIETRZAK WILLIAM

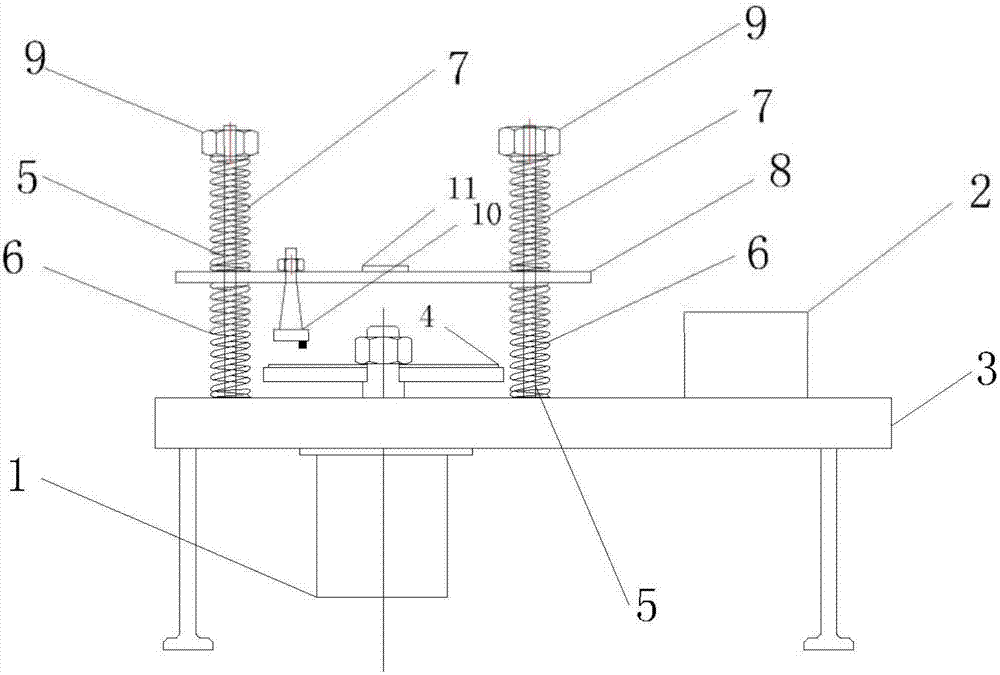

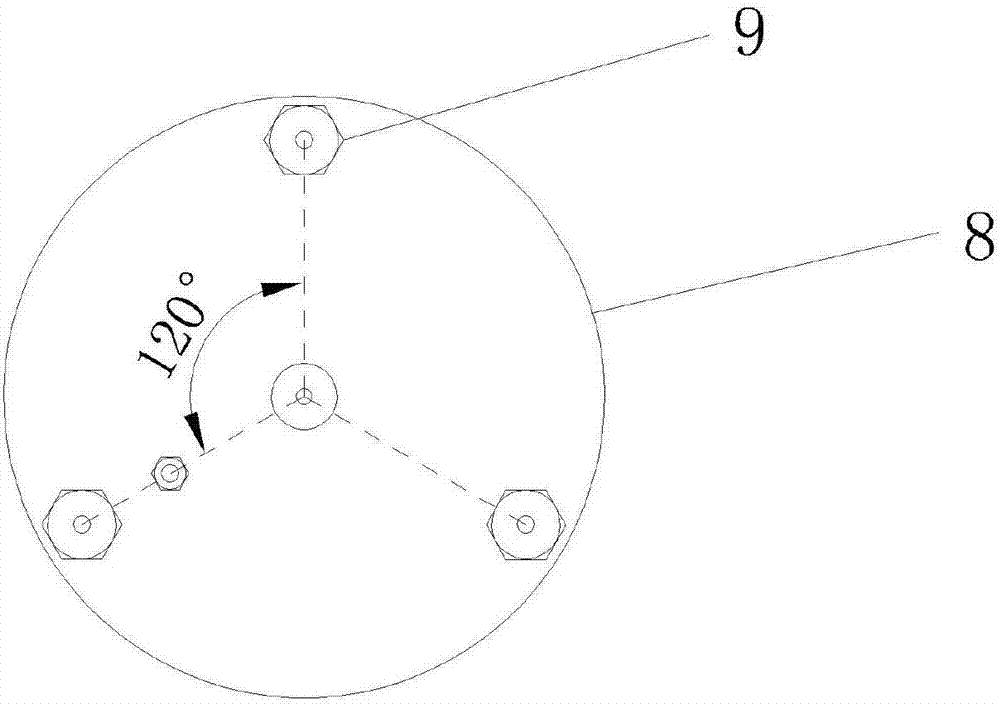

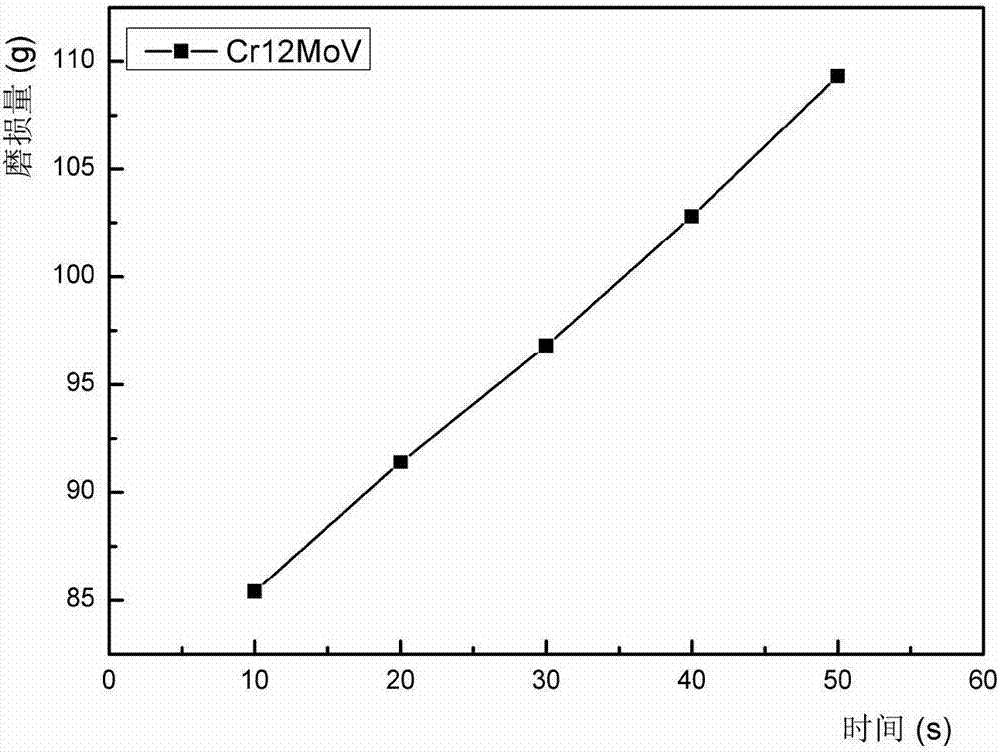

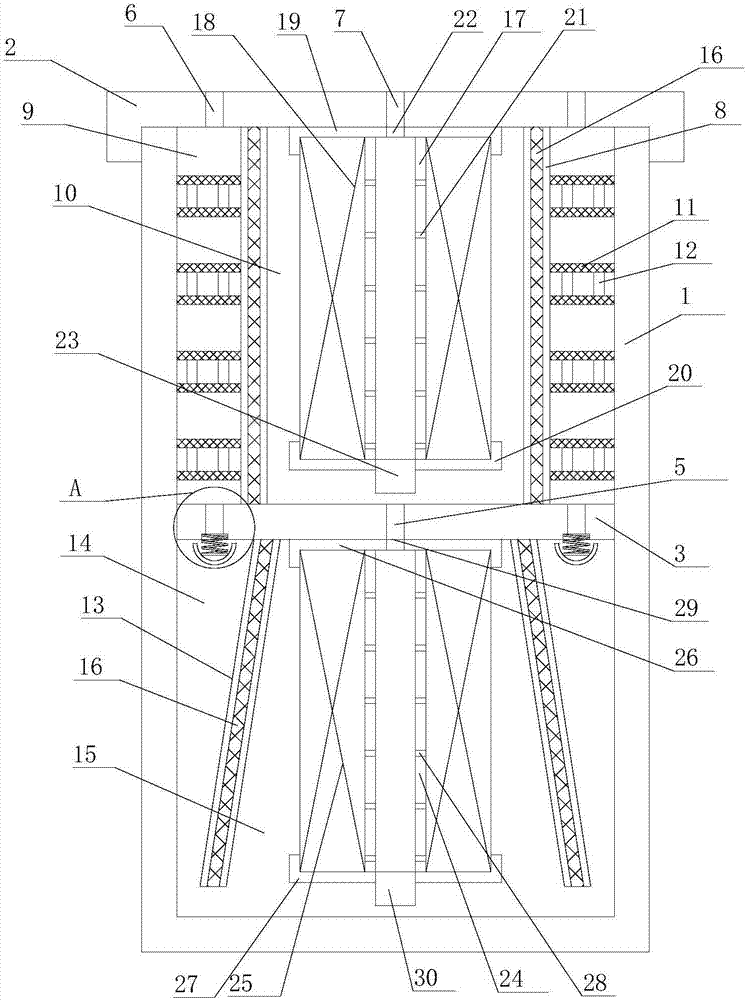

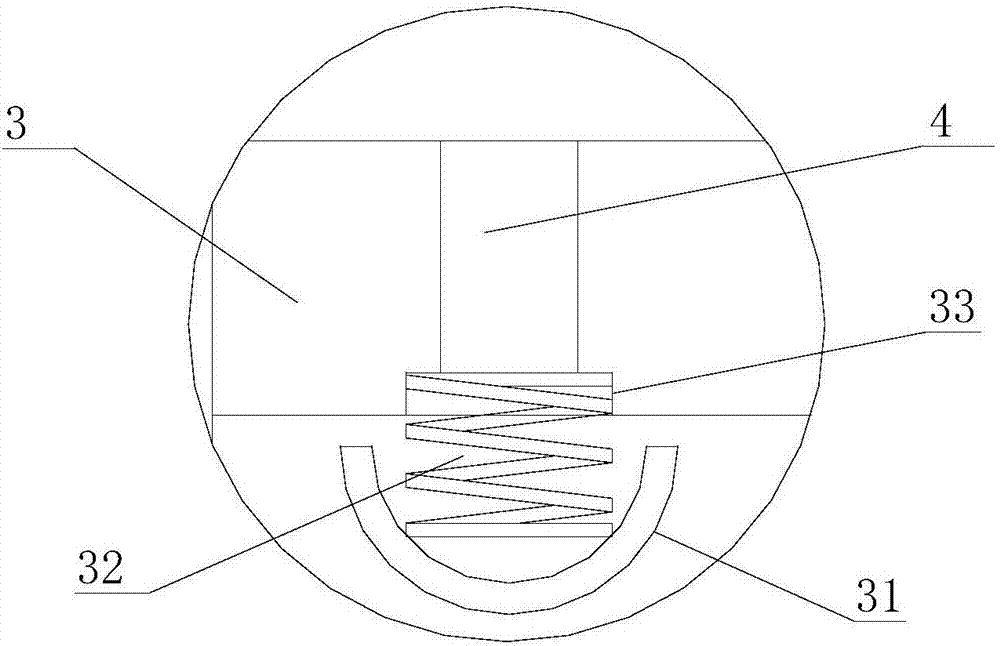

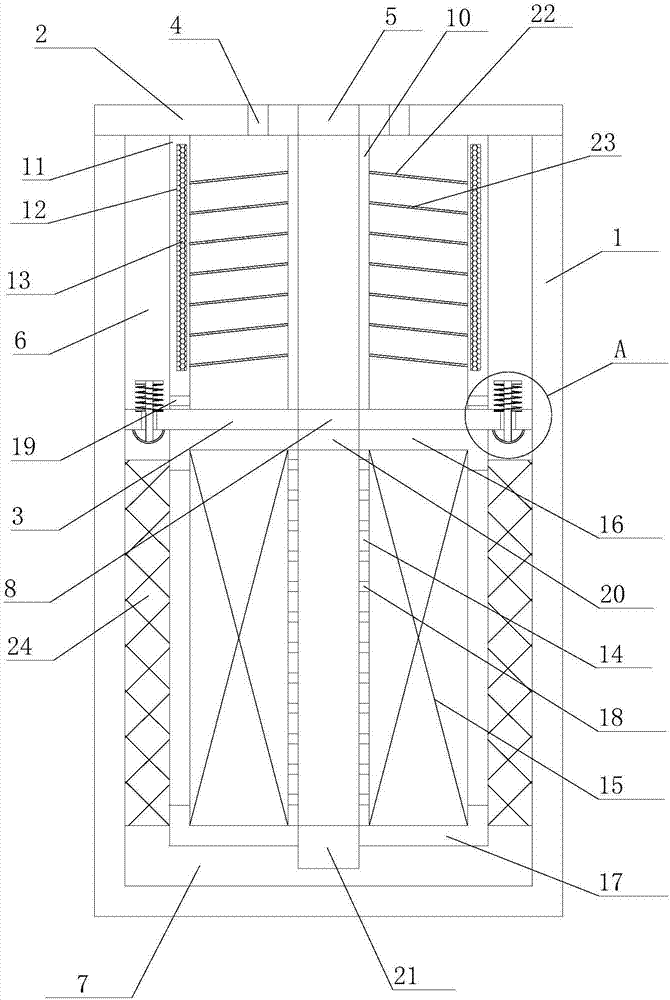

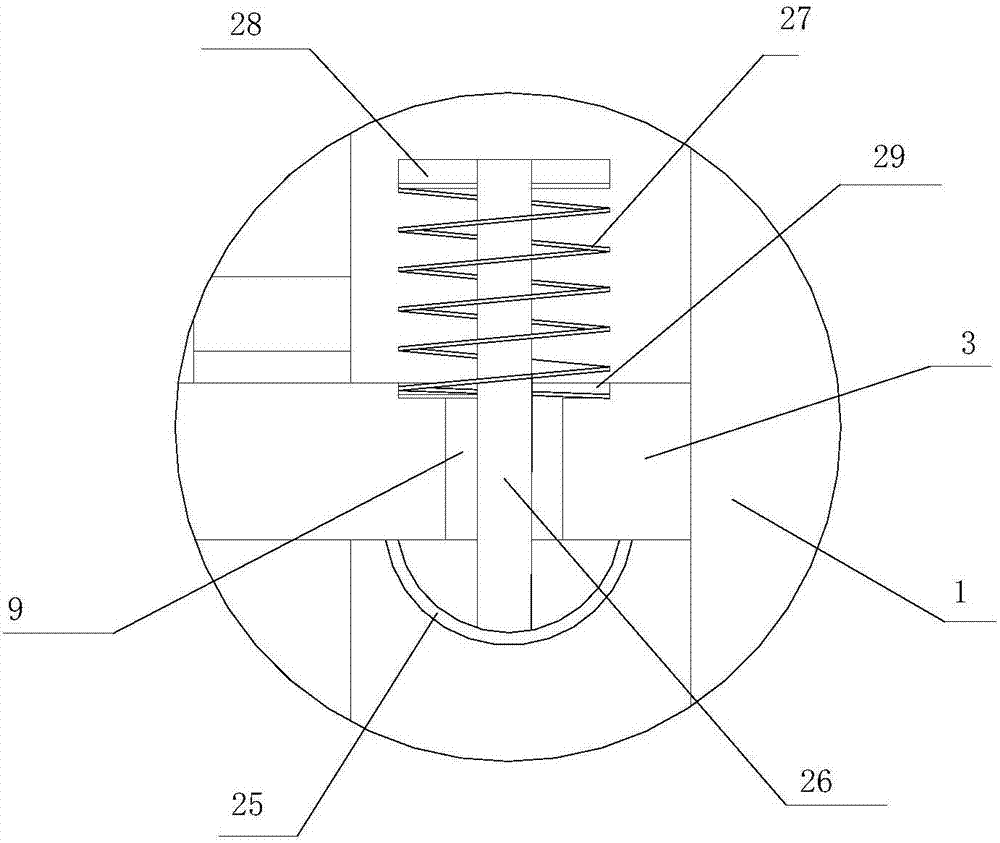

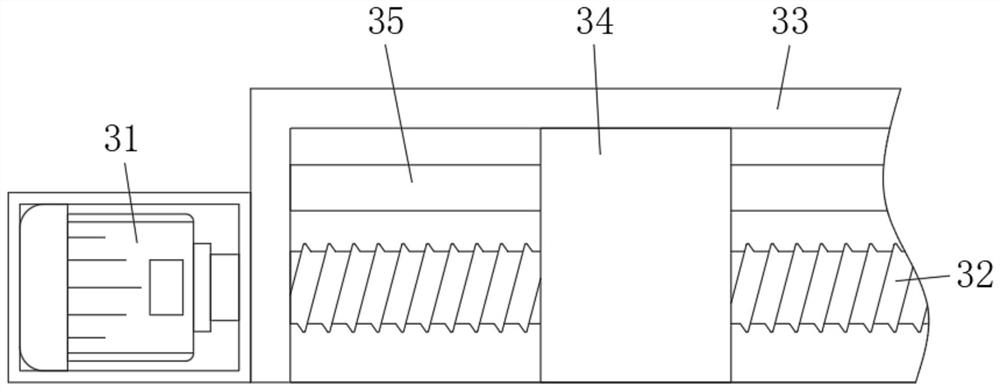

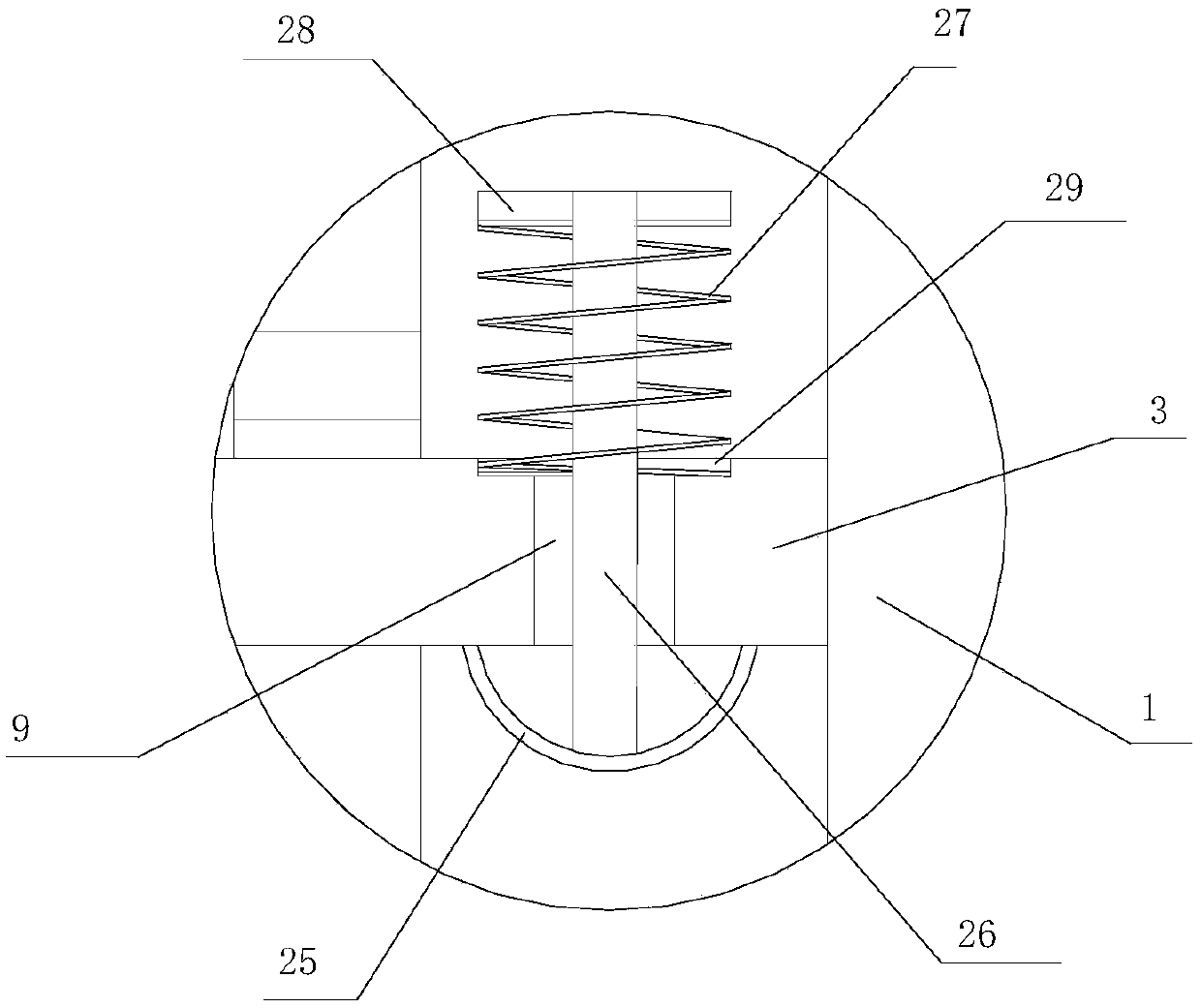

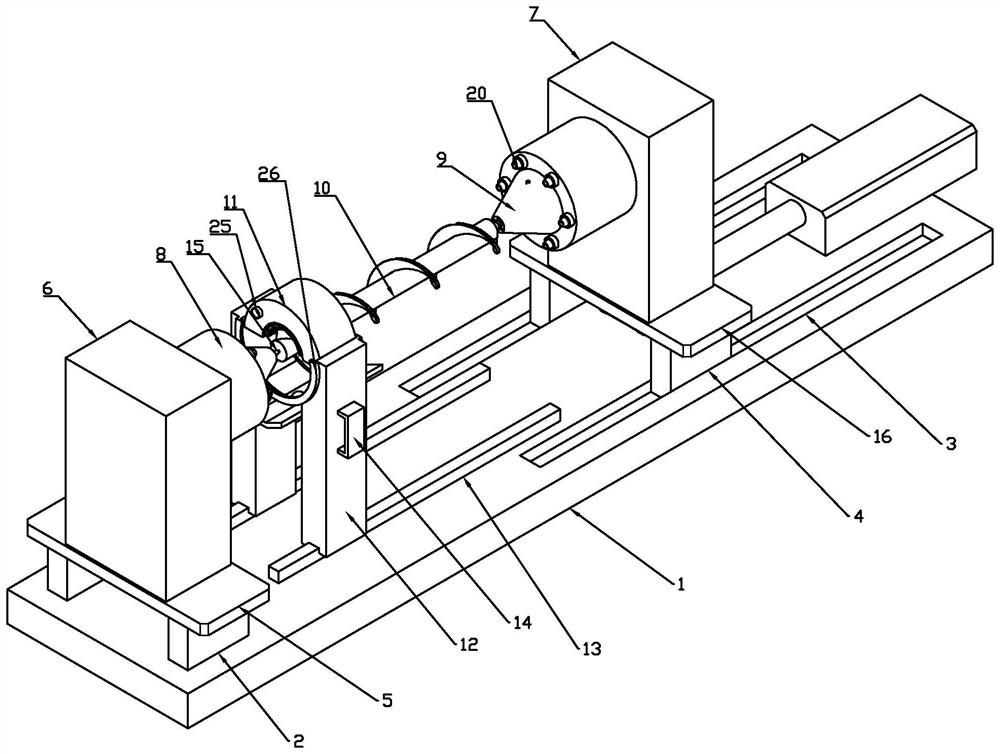

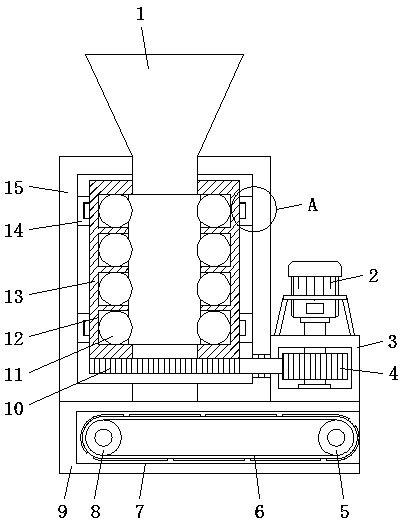

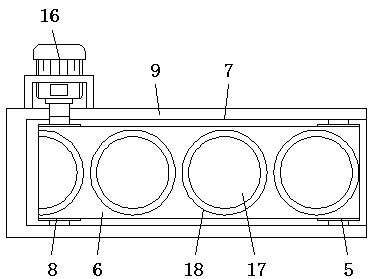

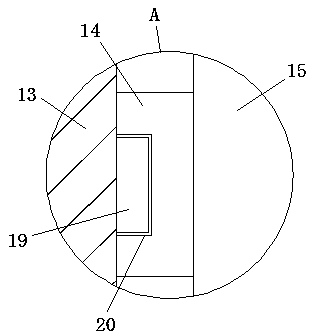

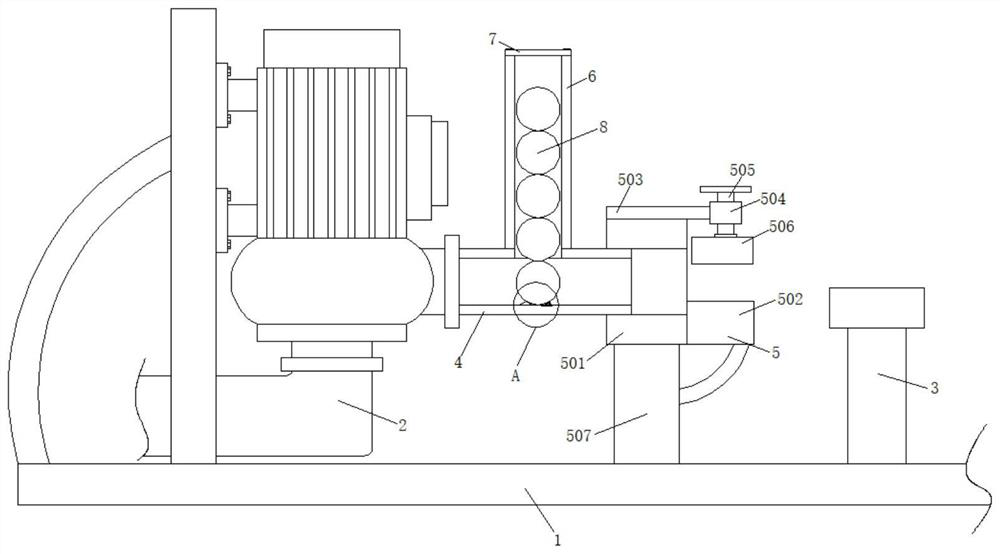

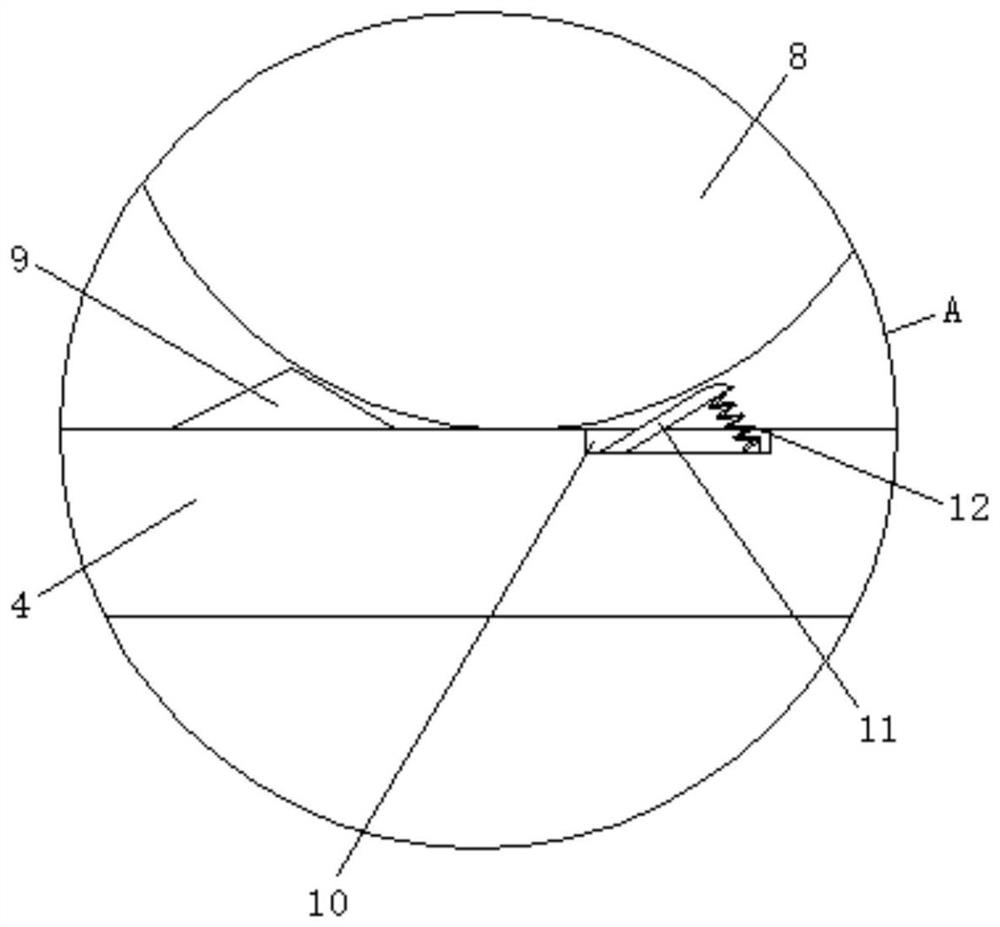

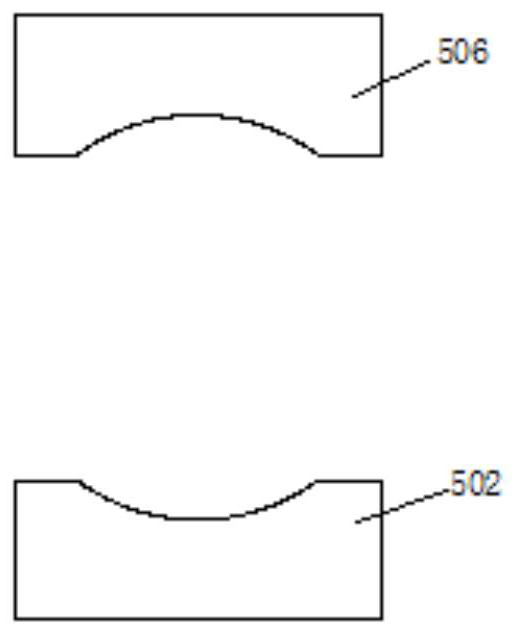

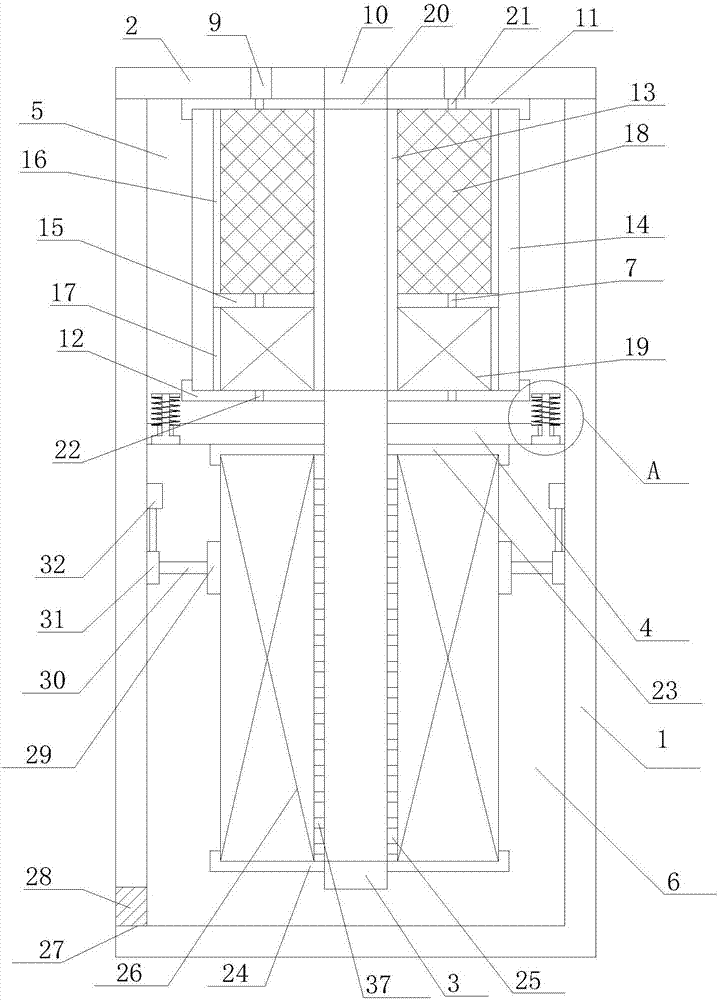

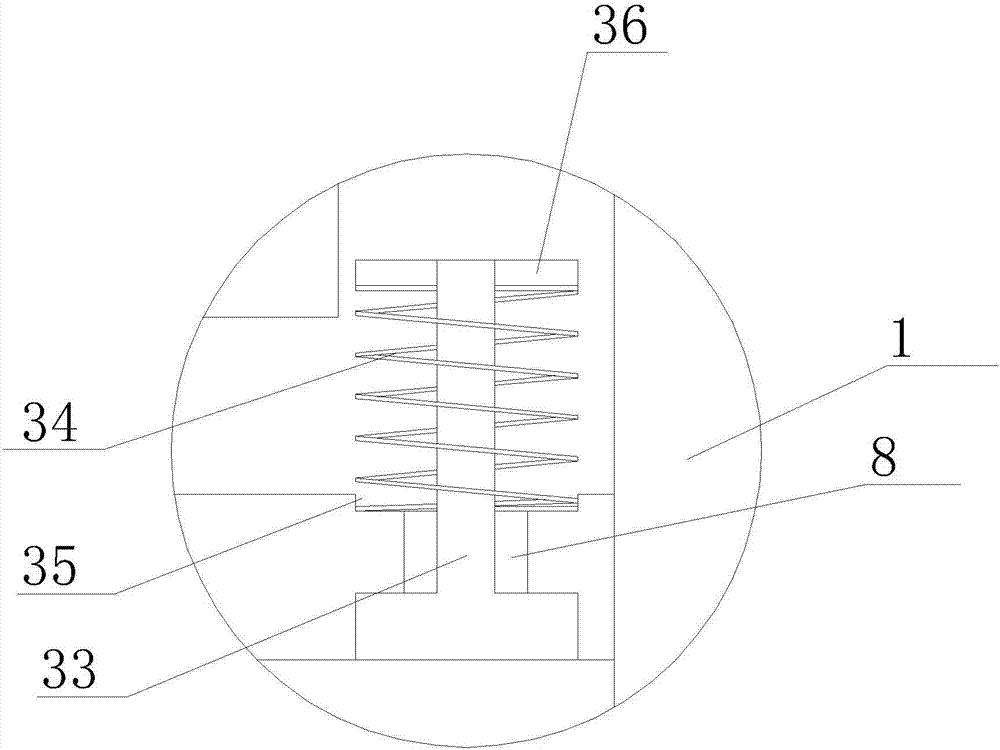

Frictional wear testing machine for hard alloy or wear-resistant coating and frictional wear testing method

ActiveCN107036923ASimple structureLow costInvestigating abrasion/wear resistanceWear testingWear resistant

The invention discloses a frictional wear testing machine for a hard alloy or a wear-resistant coating and a frictional wear testing method. The frictional wear testing machine comprises a motor, a frequency converter, a rack and an abrasive disc, wherein the motor is mounted below the rack and connected with the frequency converter; the abrasive disc is fixedly connected onto an output shaft of the motor in a sleeving manner by virtue of a screw hole in the center of a circle; moreover, a plurality of screw supporting arms are vertically arranged on the rack, supporting springs are mounted at the lower parts of the screw supporting arms in a sleeving manner, and loading springs are mounted at the upper parts of the screw supporting arms in a sleeving manner; and an upper clamping plate is horizontally arranged above the rack, fixedly clamped through the supporting springs and the loading springs and is used for adjusting the level and load through adjusting nuts at the tops of the screw supporting arms. The device disclosed by the invention can be used for adjusting the pressure by changing the elongation of each loading spring, and is simple in structure, low in construction cost, suitable for a frictional wear test on the hard alloy or the surface wear-resistant coating, short in experimental time and saved in time and labor.

Owner:HEFEI UNIV OF TECH

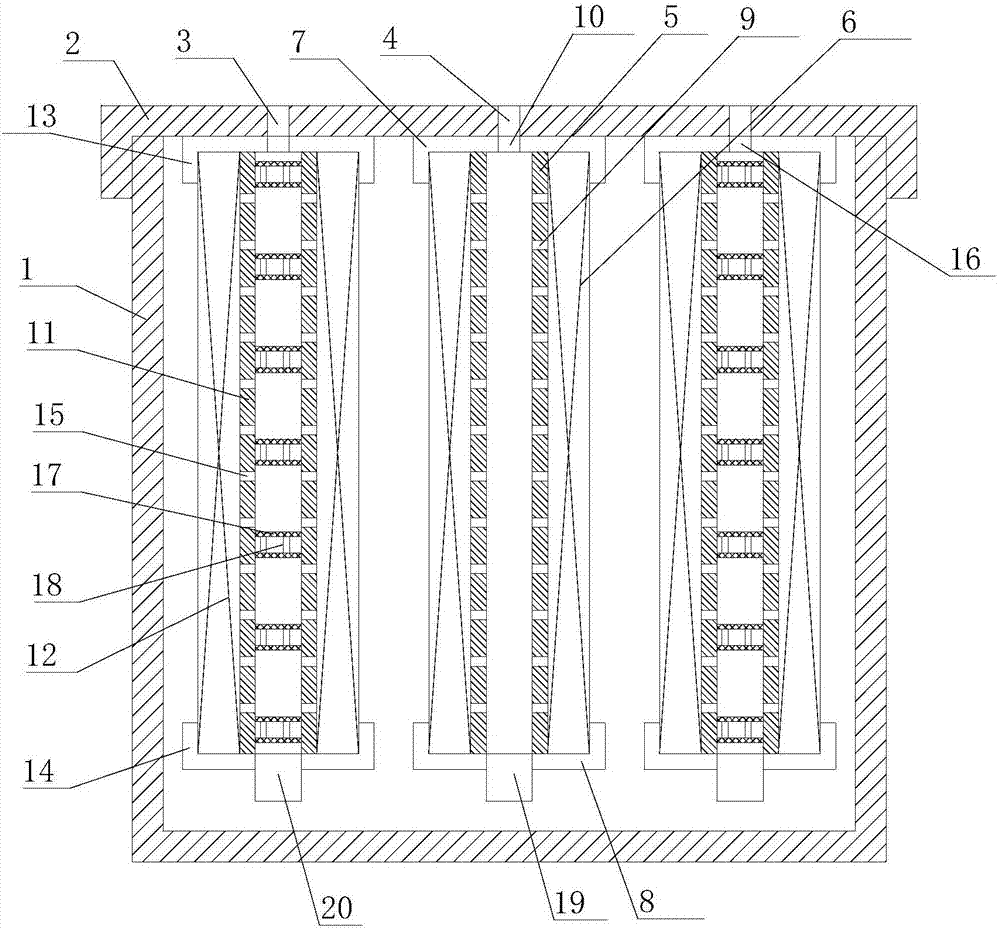

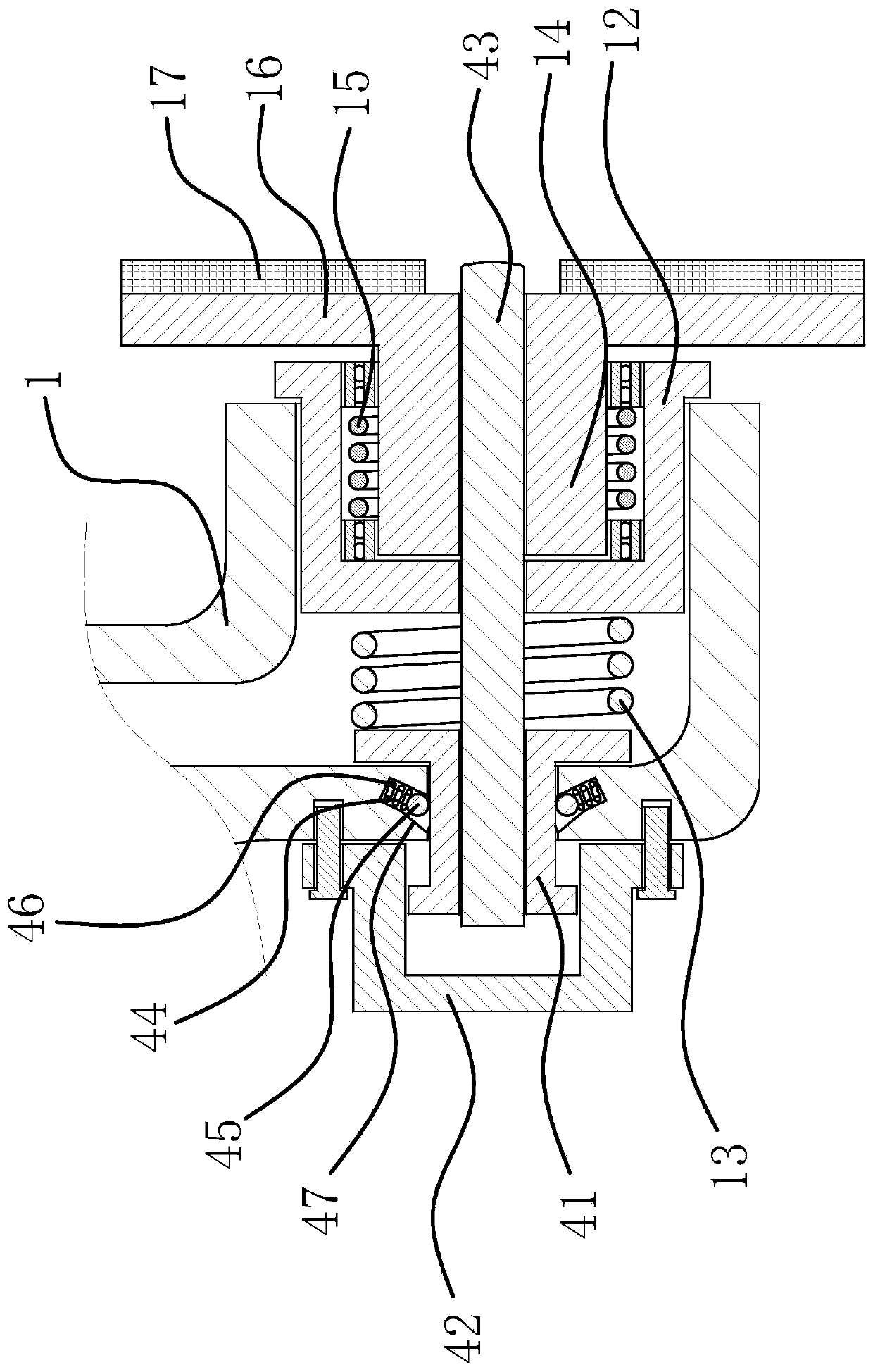

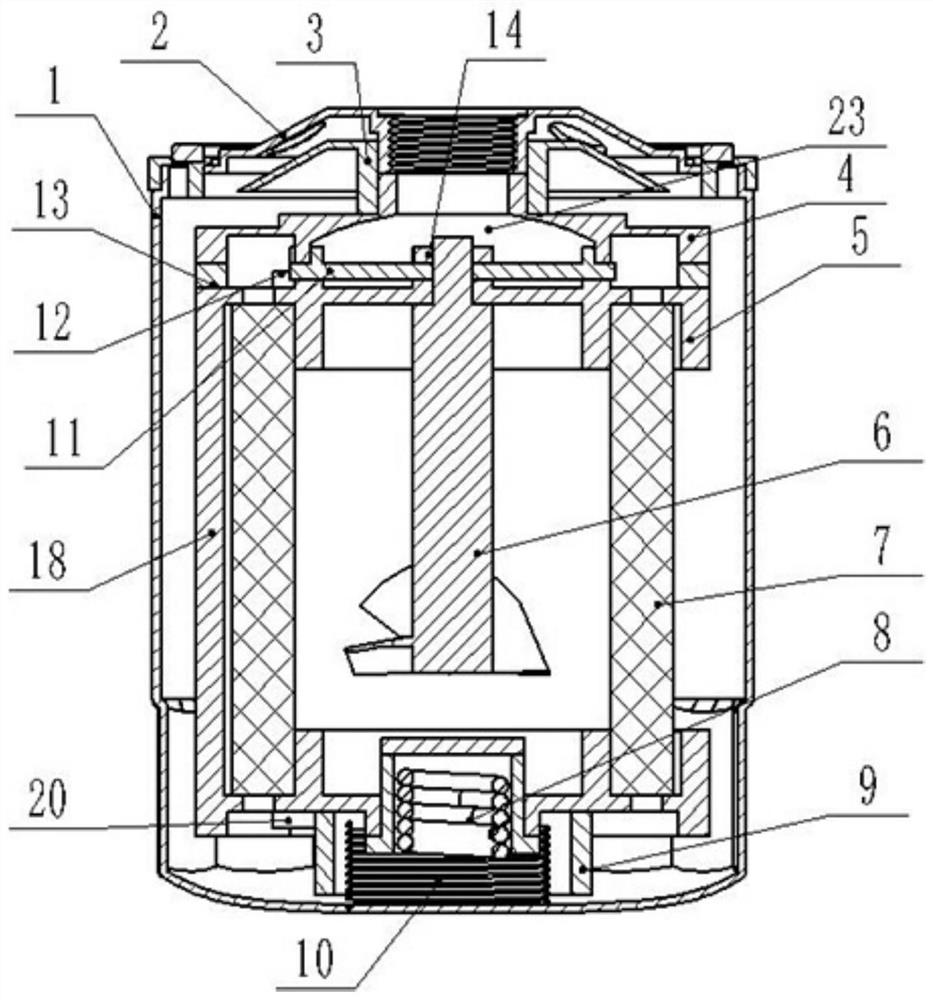

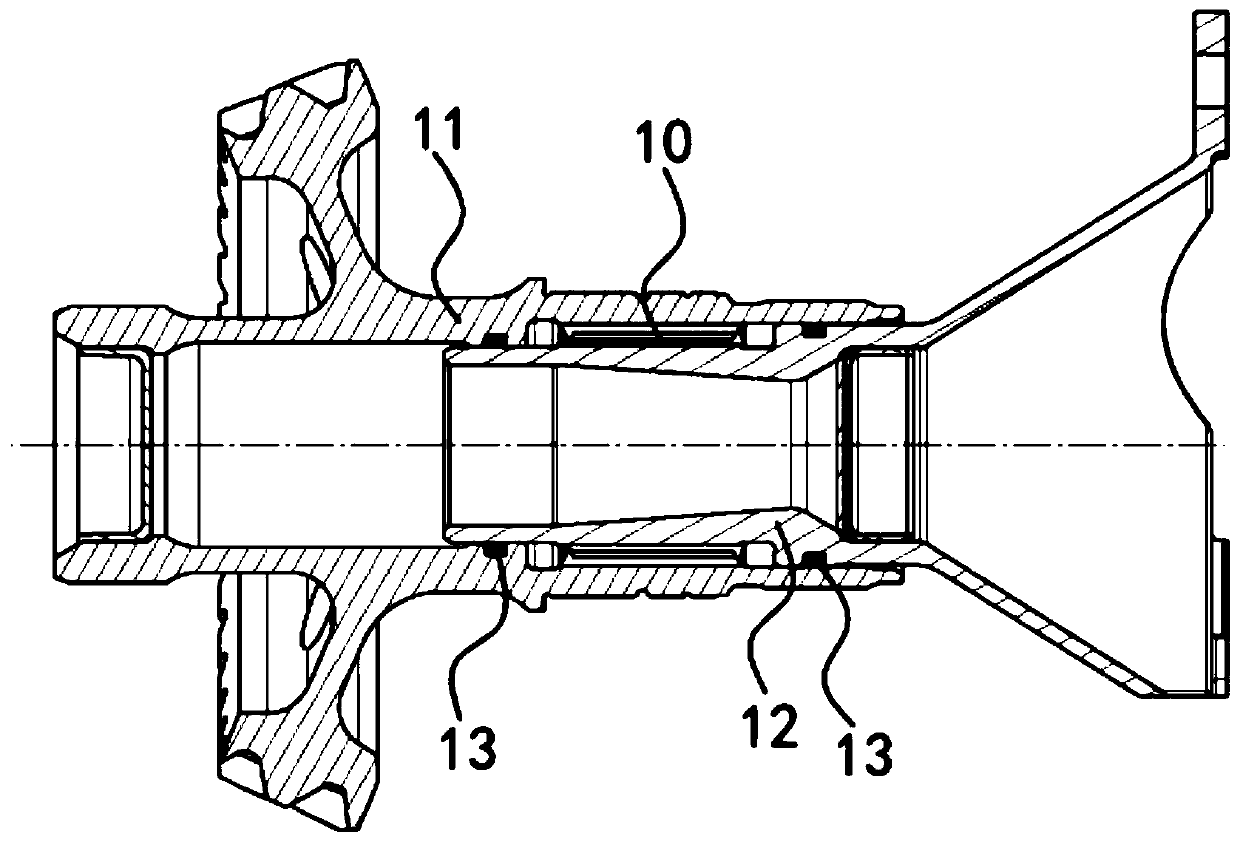

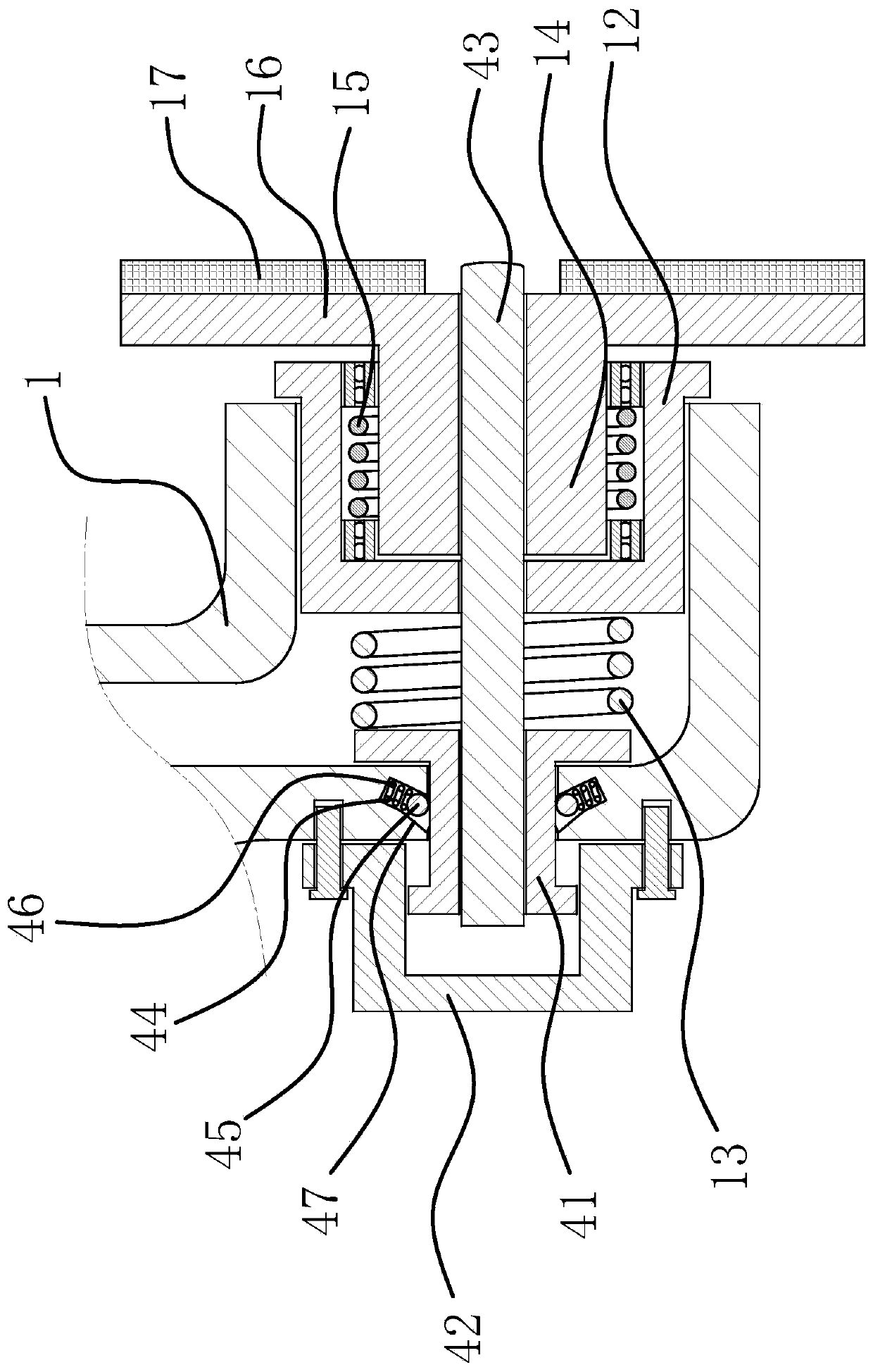

Anti-blockage oil filter

InactiveCN107023344AReduce filter pressureExtend the life cycleLubricant mounting/connectionPressure lubricationMetal impuritiesFilter effect

The invention provides an anti-blockage oil filter. The anti-blockage oil filter comprises a shell, a bottom plate, a first filtering mechanism and a second filtering mechanism. A partition board divides an inner cavity of the shell into a first chamber and a second chamber. The first filtering mechanism is arranged in the first chamber. The first filtering mechanism comprises a first magnetic adsorption device and a first filter element. The second filtering mechanism is arranged in the second chamber. The second filtering mechanism comprises a second magnetic adsorption device and a second filter element. The anti-blockage oil filter adsorbs and filters out different sizes of metal impurities in engine oil through the first magnetic adsorption device and the second magnetic adsorption device so as to reduce the filter pressure of the first filter element and the second filter element, prolong the service cycle of the first filter element and the second filter element and improve the filtering effect of the first filter element and the second filter element. Metal impurities adsorbed by the first magnetic adsorption device can completely stay in a first filtering chamber. Metal impurities adsorbed by the second magnetic adsorption device can be adsorbed onto a second barrel and cannot go into a fourth filtering chamber and a second filtering chamber.

Owner:BENGBU FENGCHI FILTER

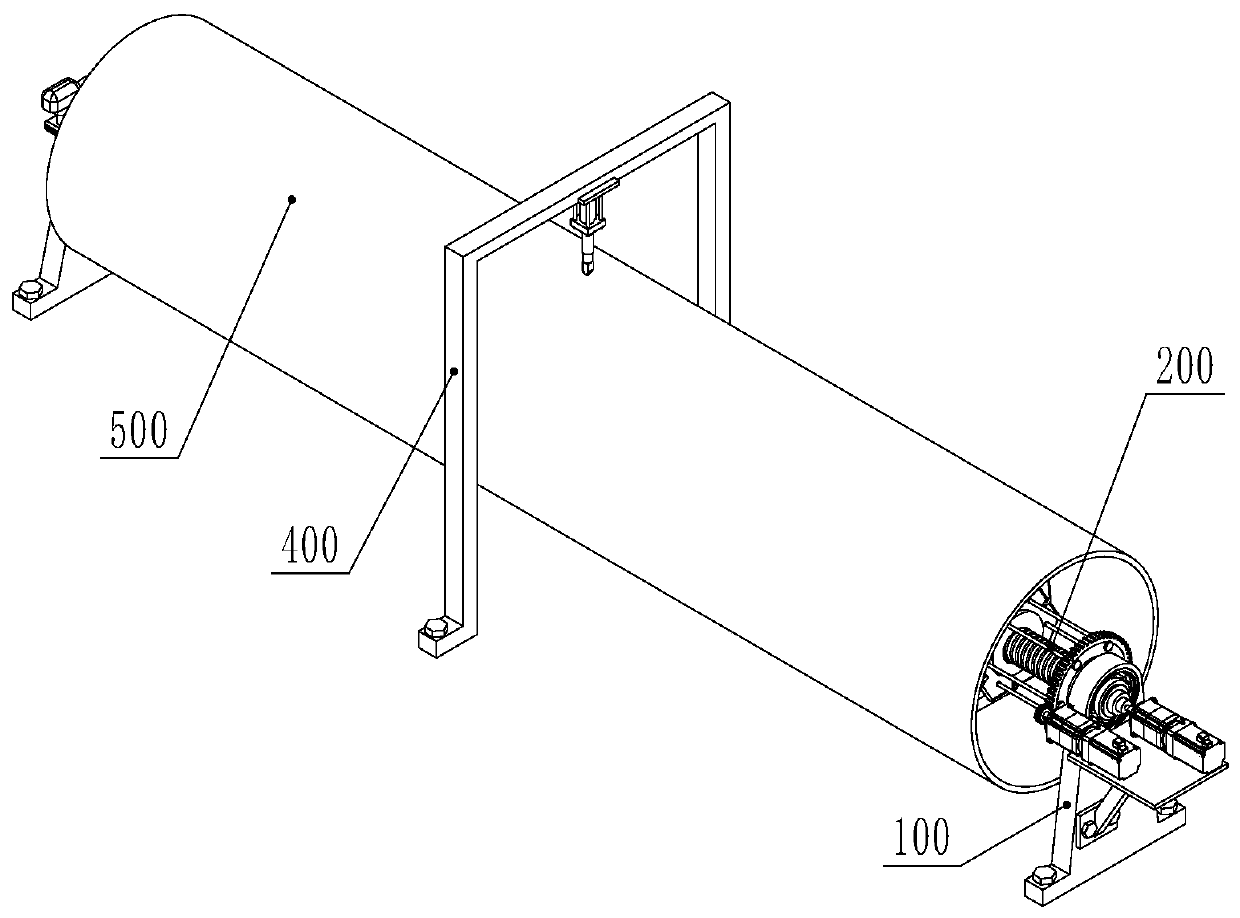

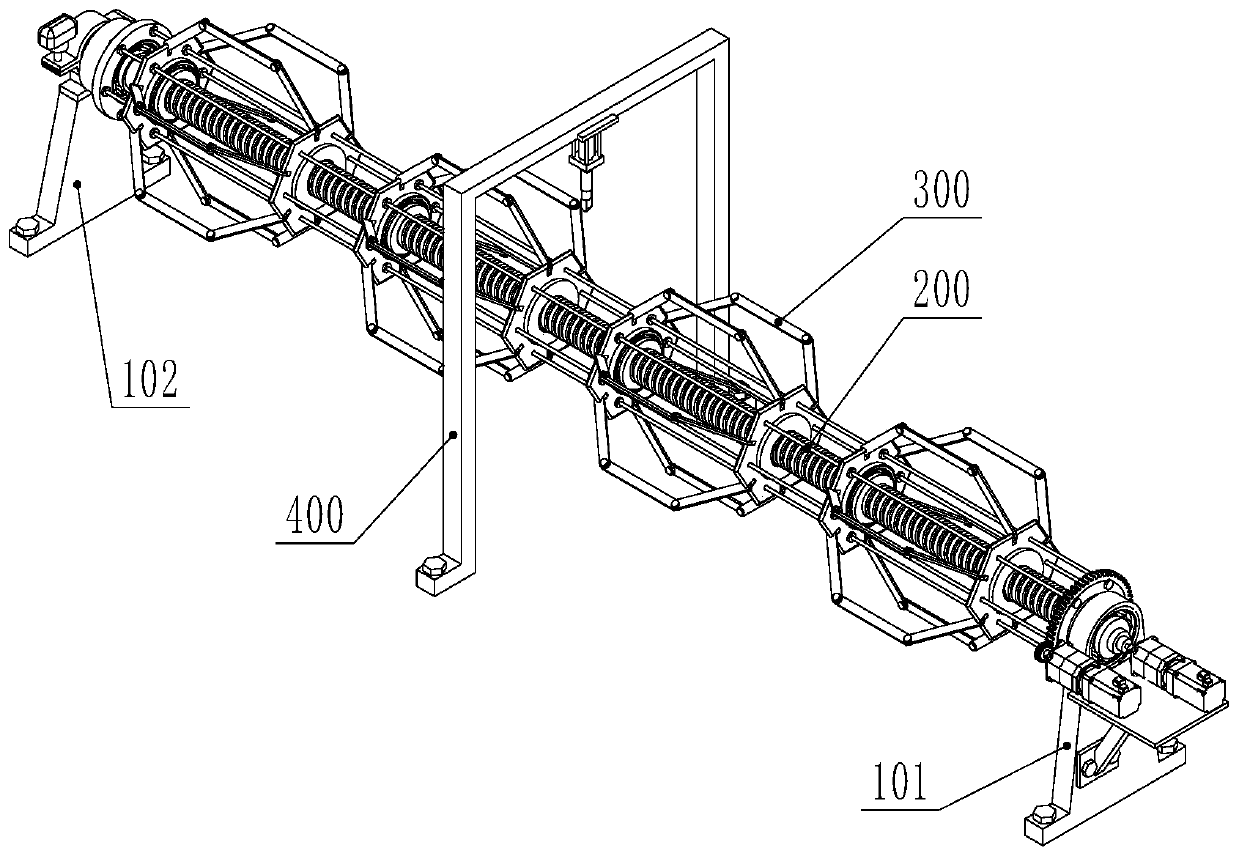

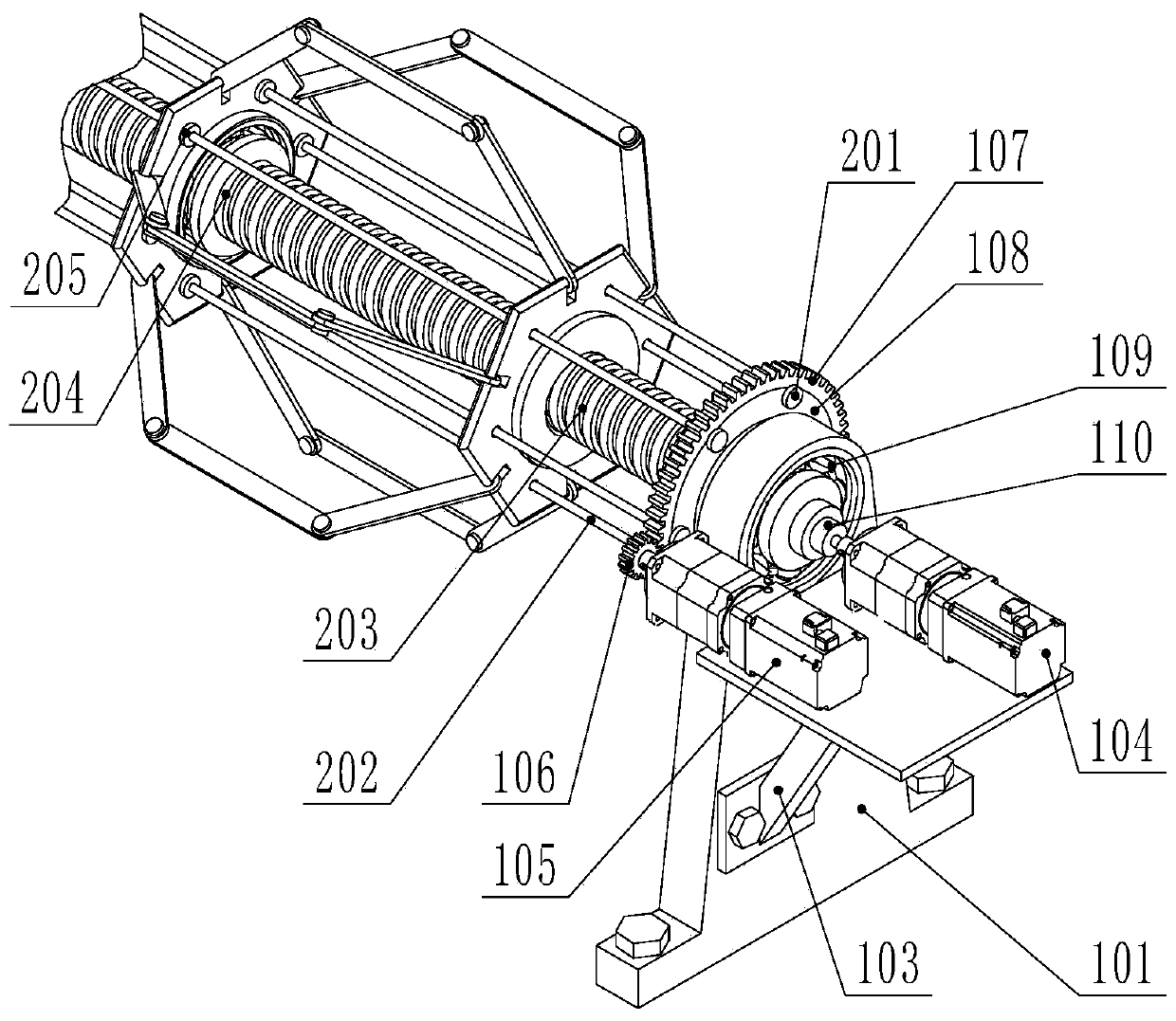

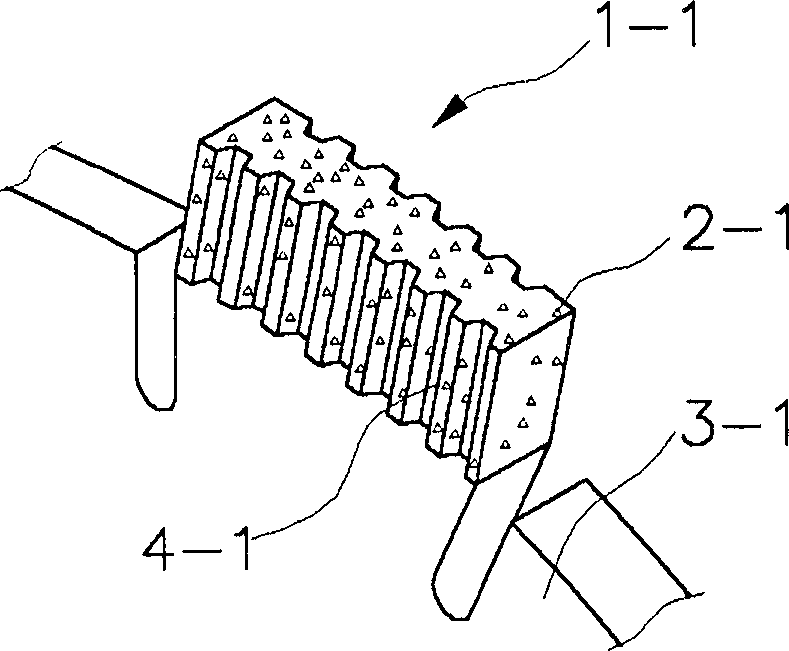

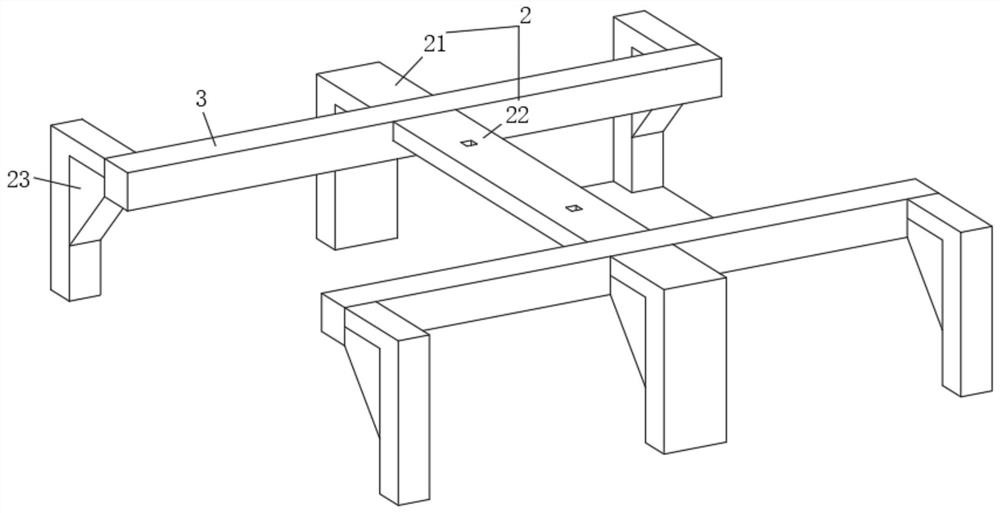

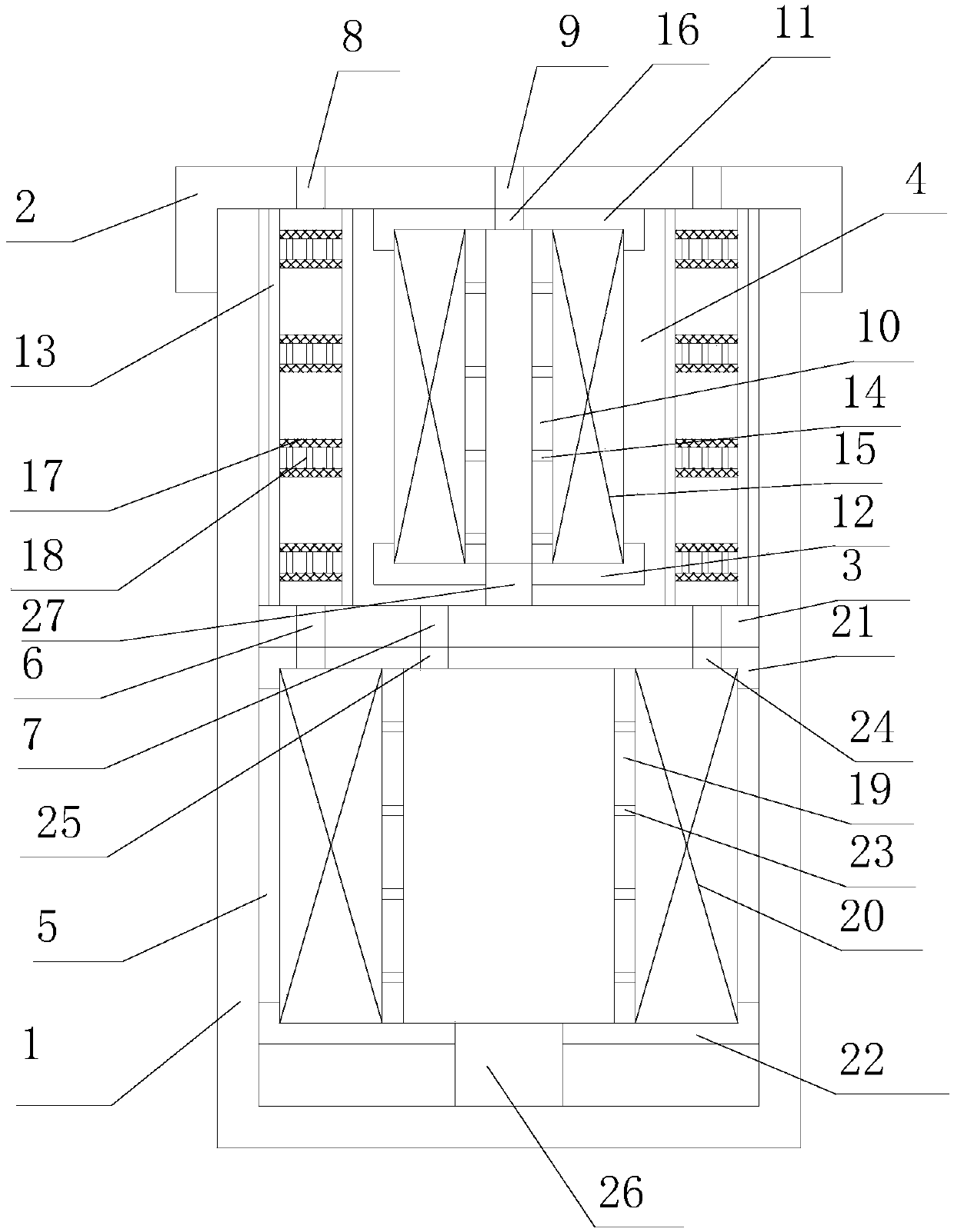

Lead screw clamping type metal hard tube rotary cutter

The invention provides a lead screw clamping type metal hard tube rotary cutter comprising a supporting device, a lead screw device, at least two expanding devices and a cutting device. The supportingdevice is located at the front and back ends of the whole cutter and fixedly connected with the ground. The front and back ends of the lead screw device are erected on the supporting device and can rotate relative to the supporting device. The expanding devices are both arranged on the lead screw device in a sleeving manner and connected with the lead screw device through threads. The expanding devices are sleeved with a to-be-cut metal hard tube. The cutting device is arranged between the two adjacent expanding devices. The supporting device is provided with an early operation motor and a later operation motor. The two motors can control the lead screw and the expanding devices to rotate correspondingly. The cutter is provided with multiple connection rod structures adopting expanding connection rods and front and back rockers to clamp the metal hard tube, a longer contact area is obtained in the length direction of the metal hard tube, and therefore the lead screw clamping type metal hard tube rotary cutter is suitable for to-be-cut metal hard tubes of different lengths, guarantees reliable clamping and avoids deformation.

Owner:HEBEI UNIV OF TECH

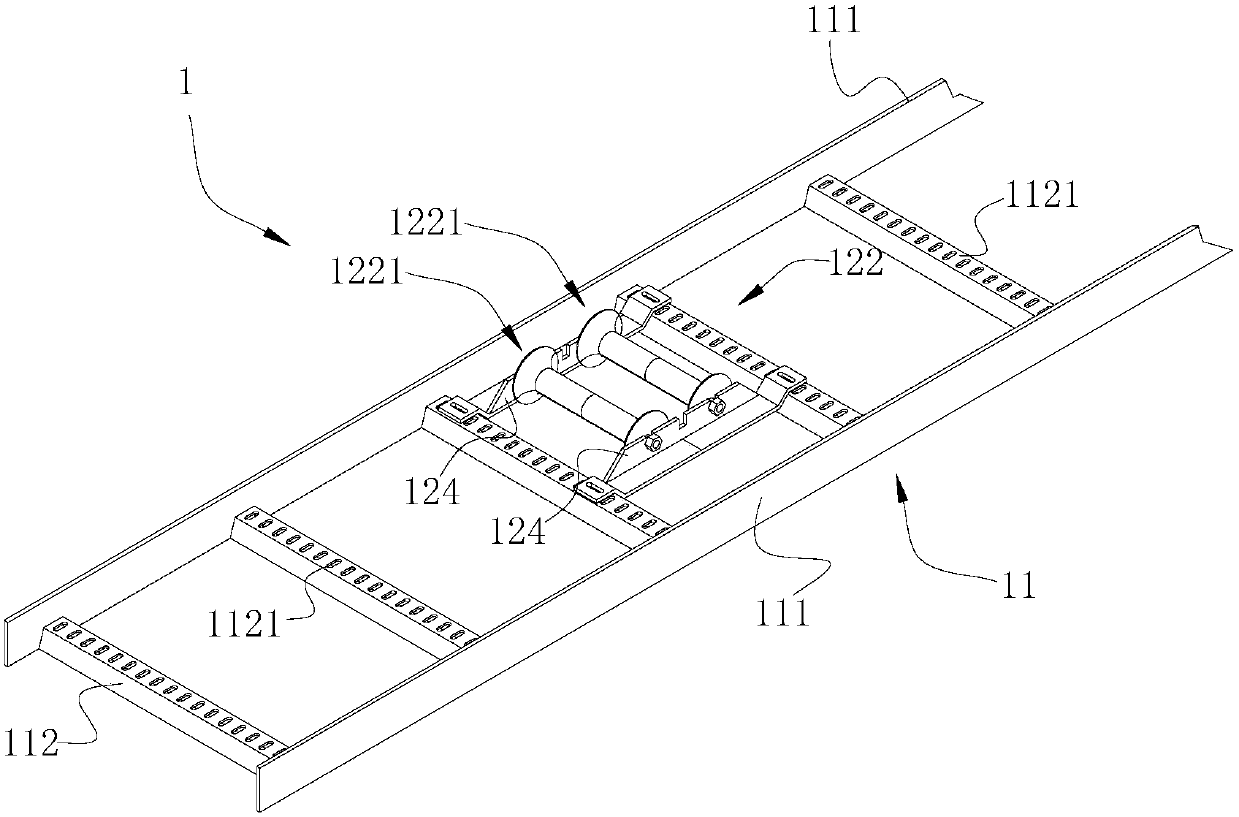

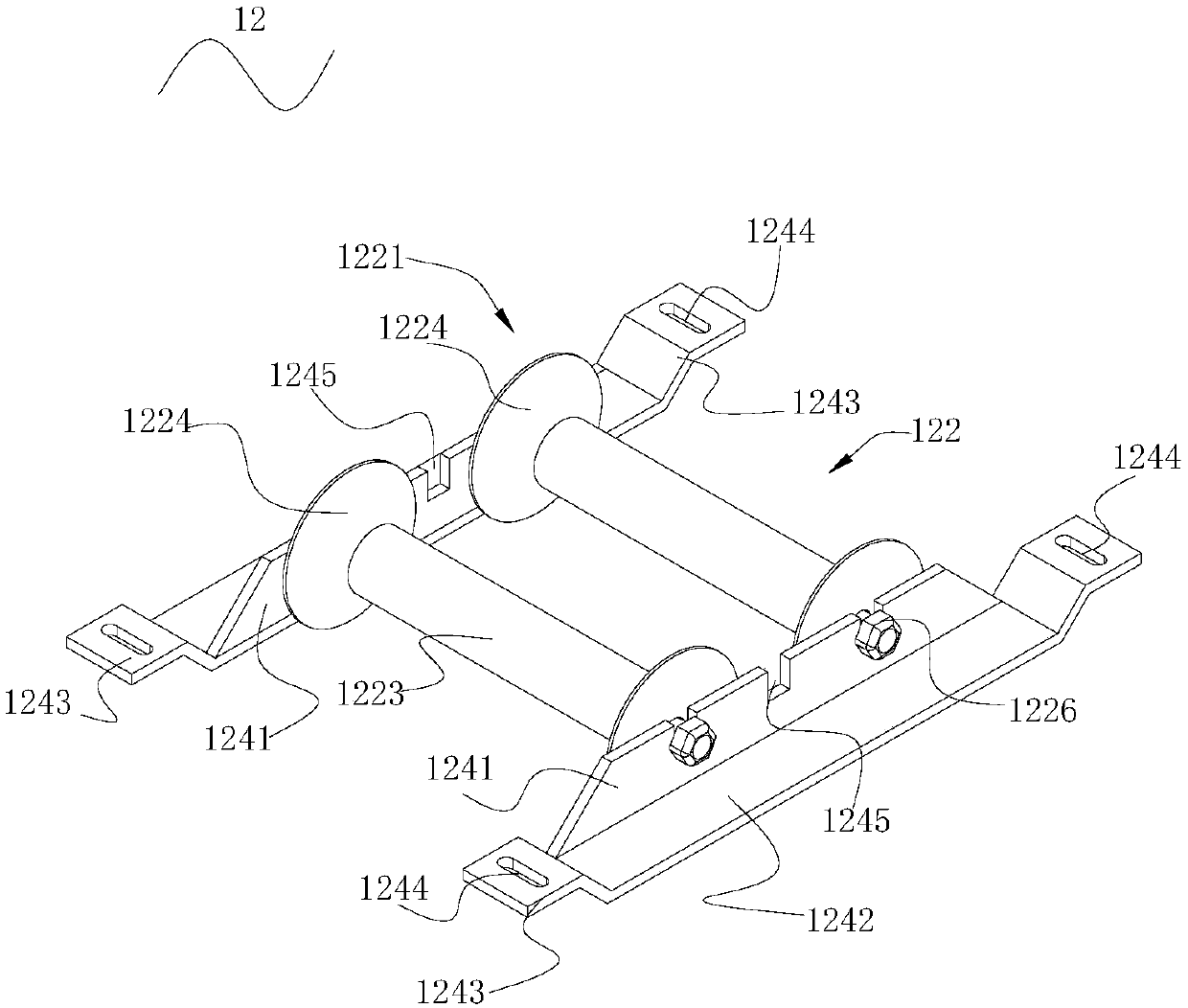

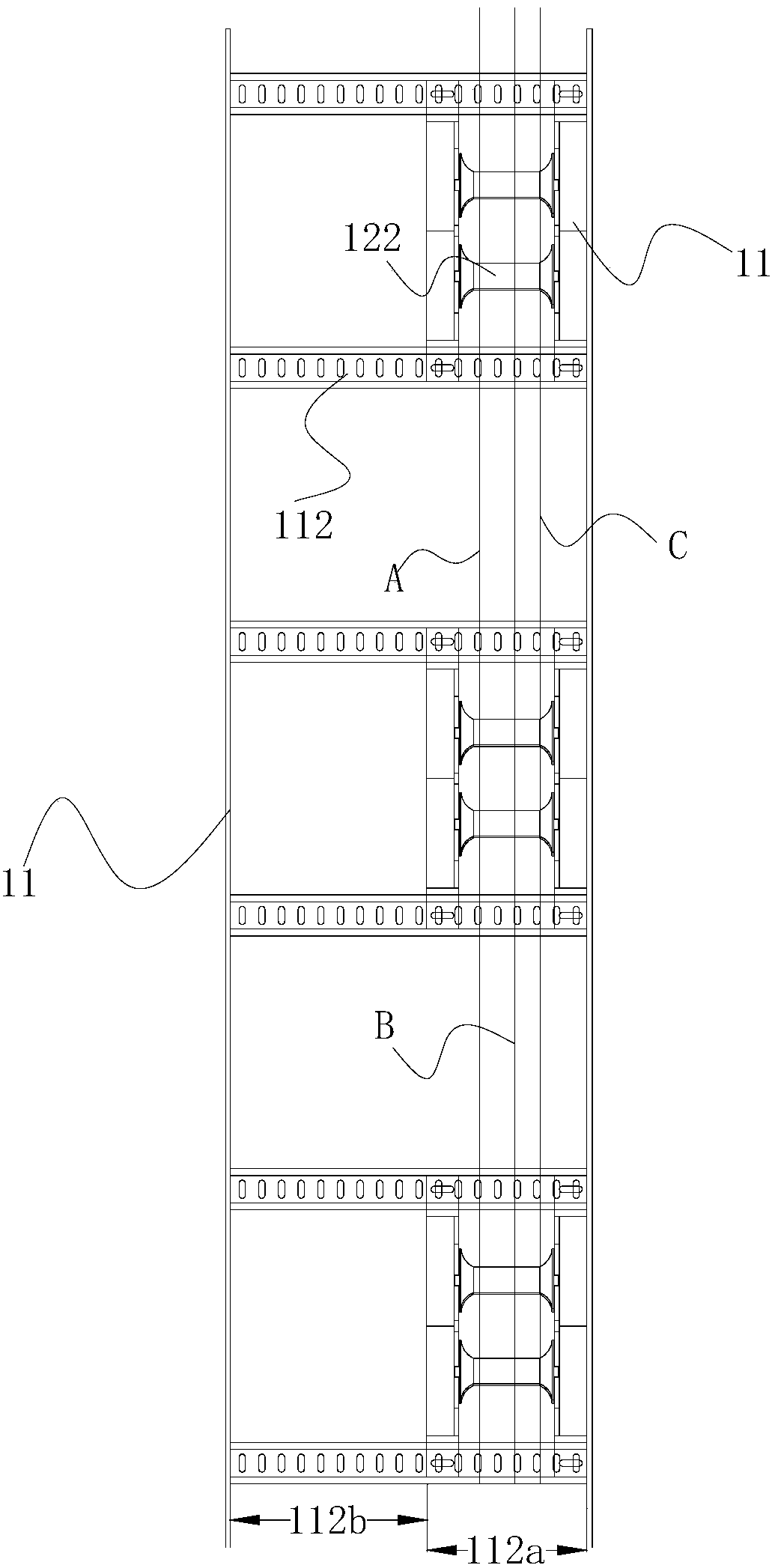

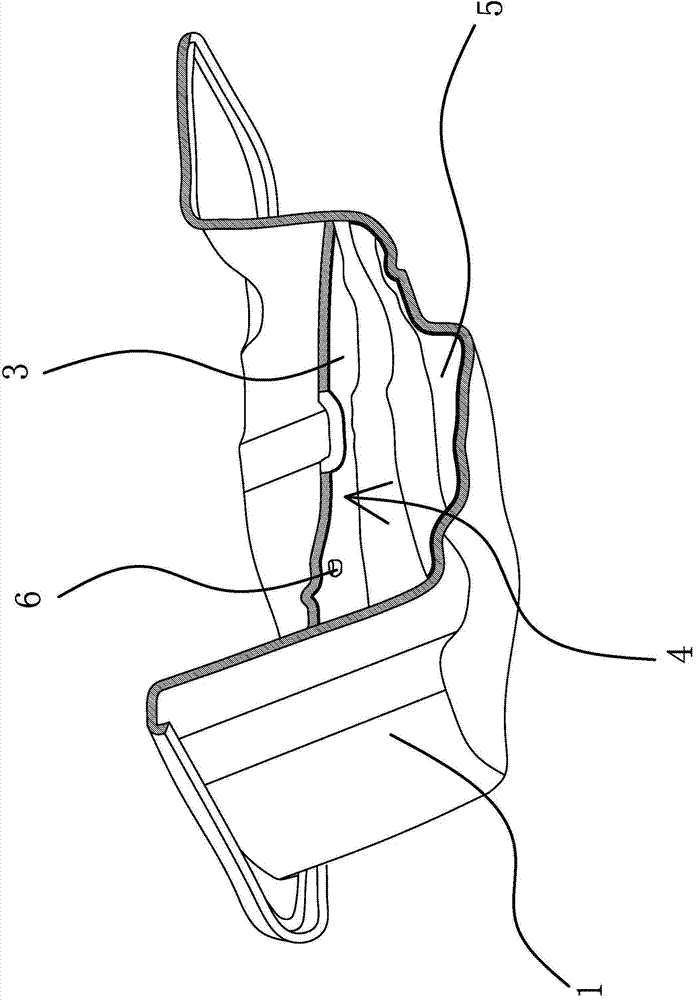

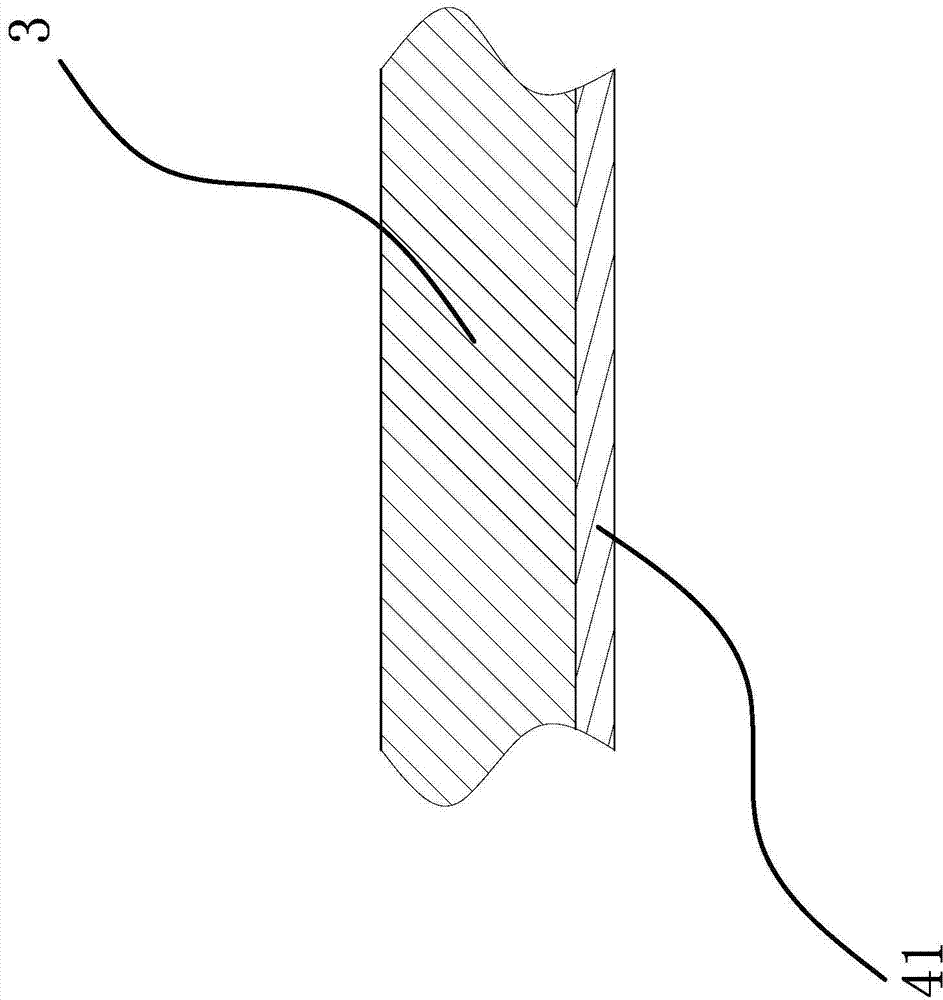

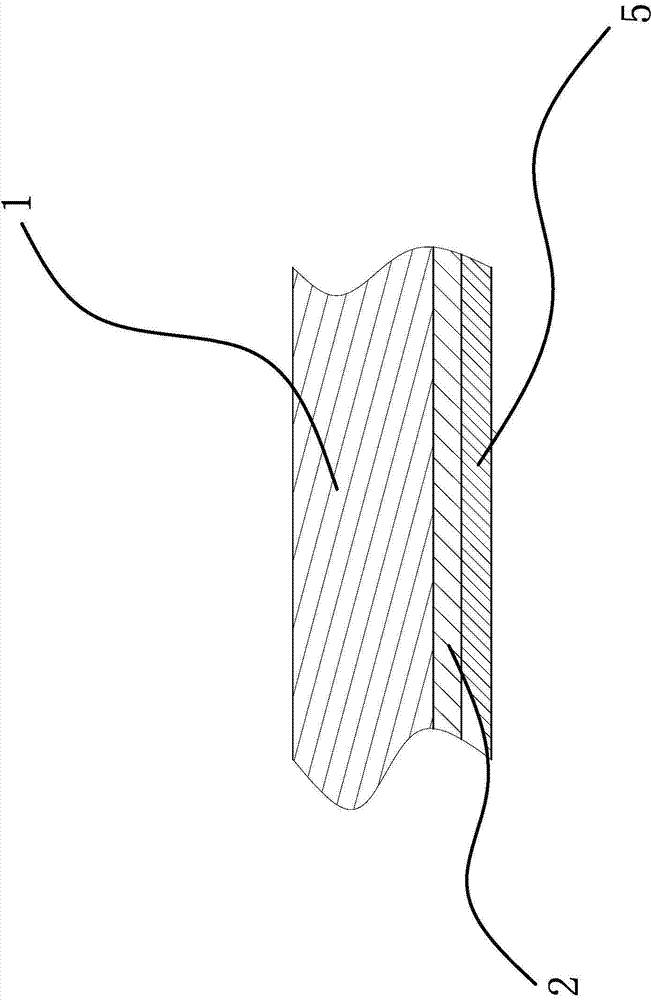

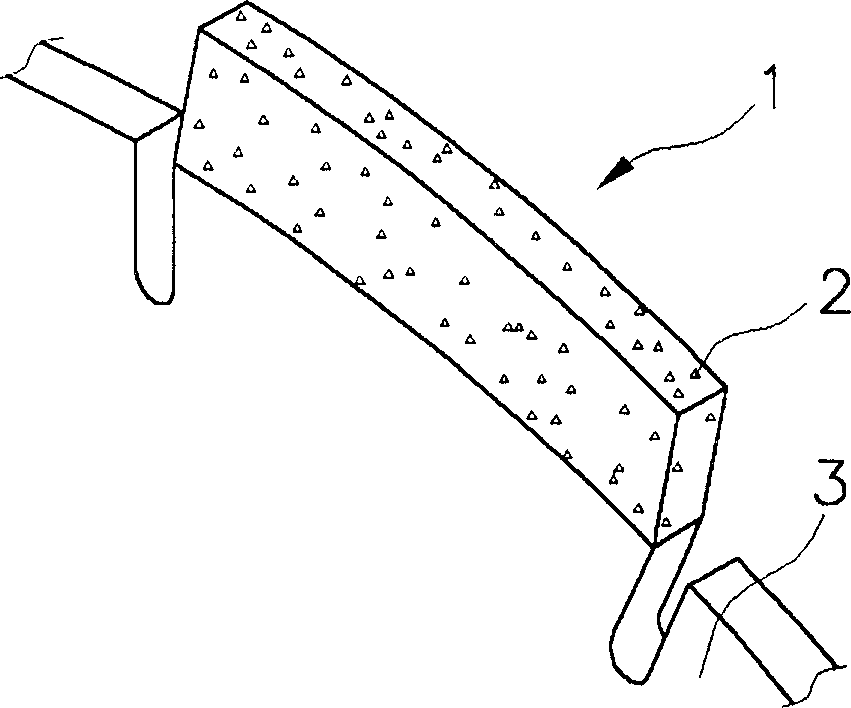

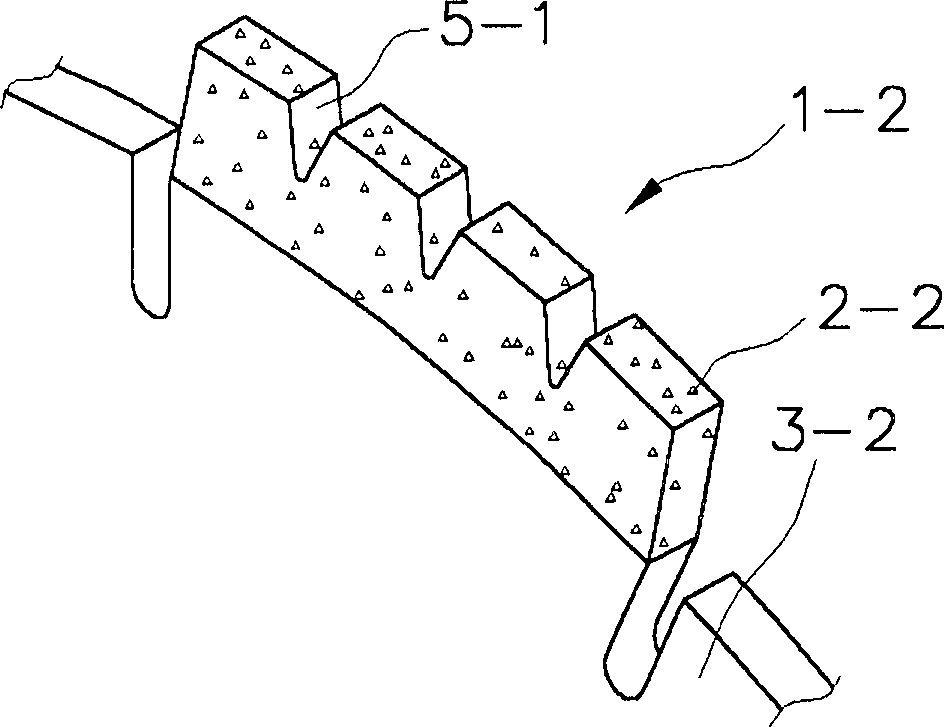

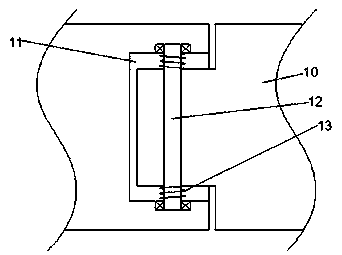

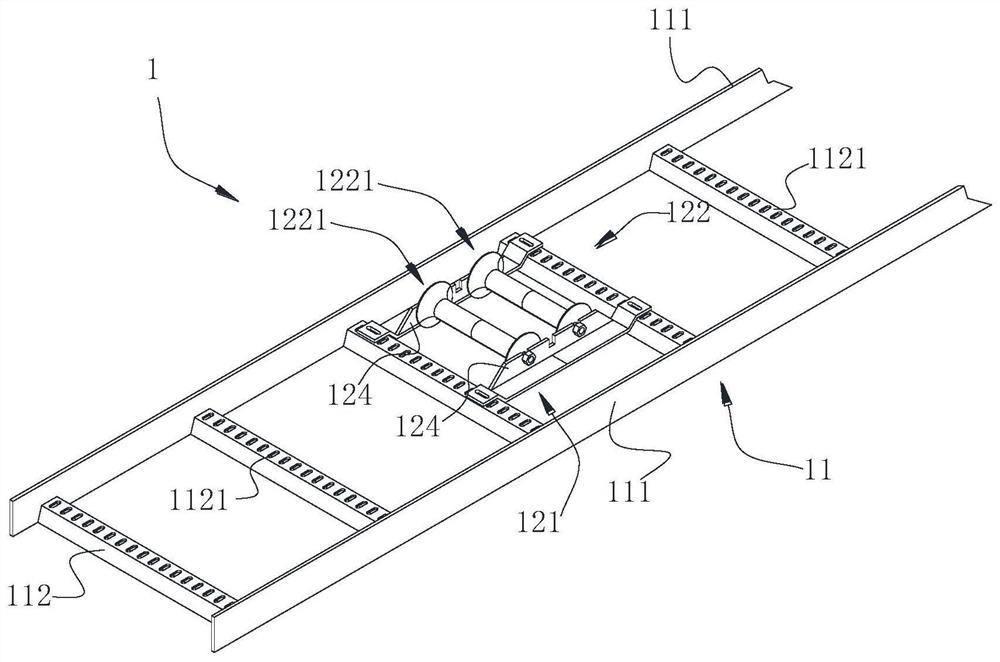

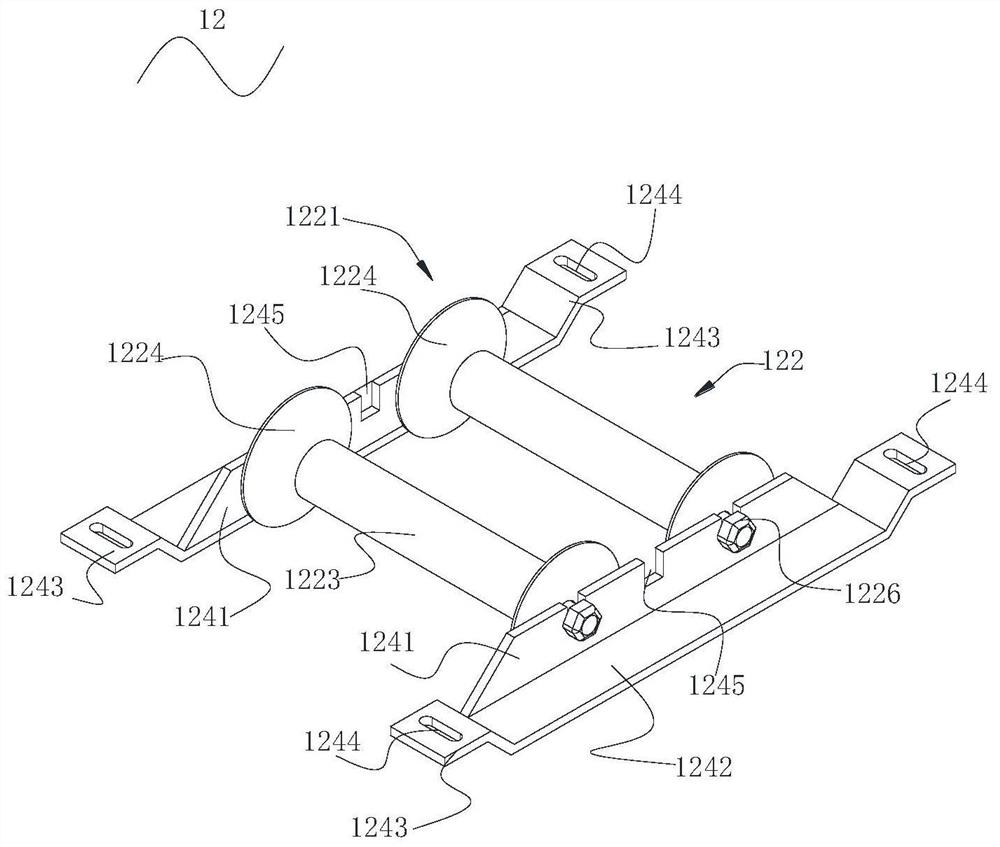

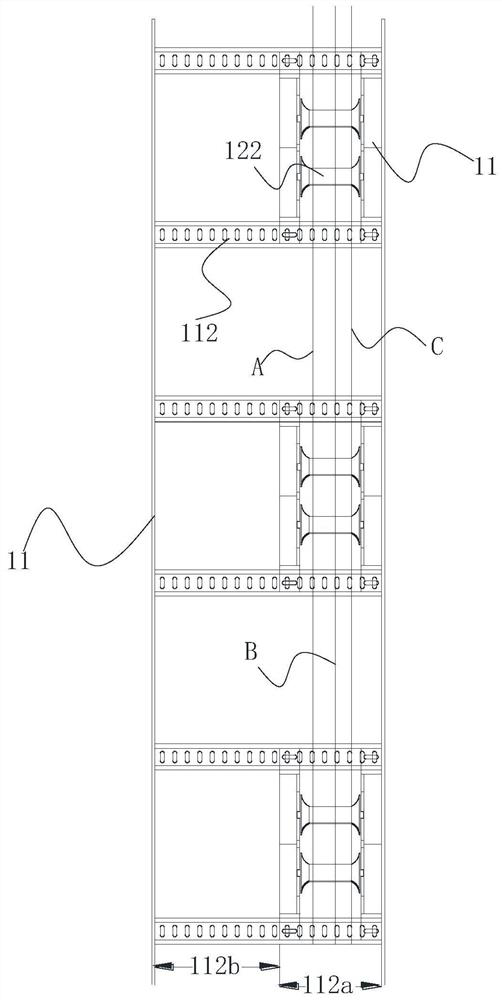

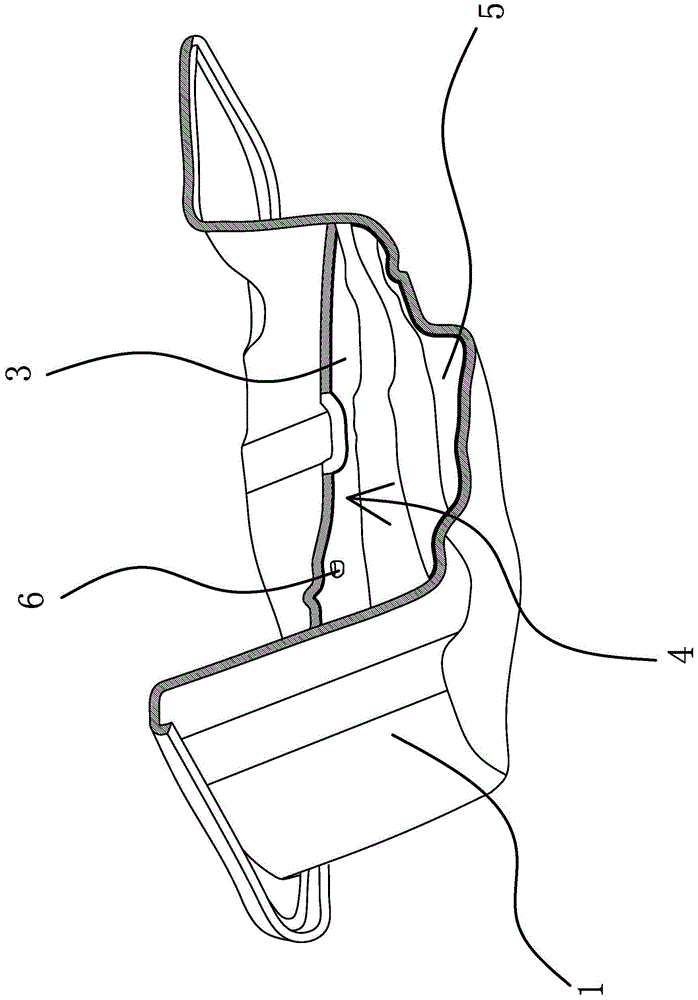

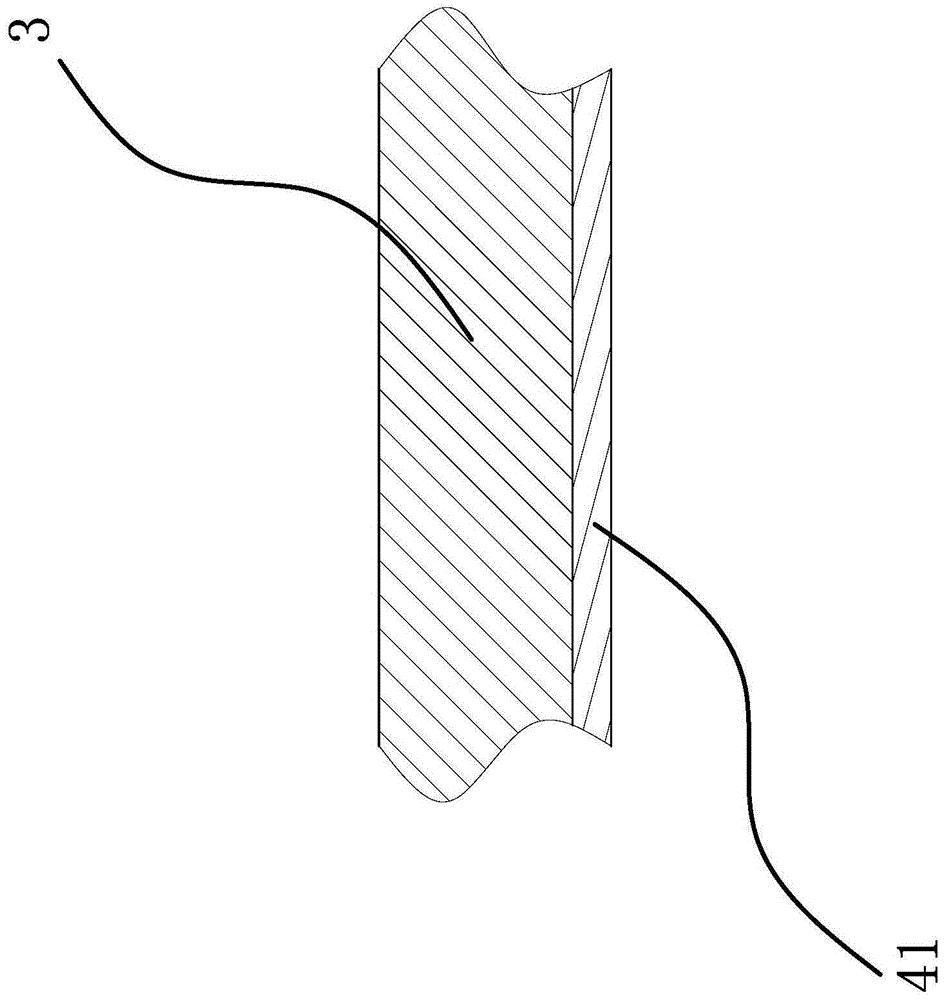

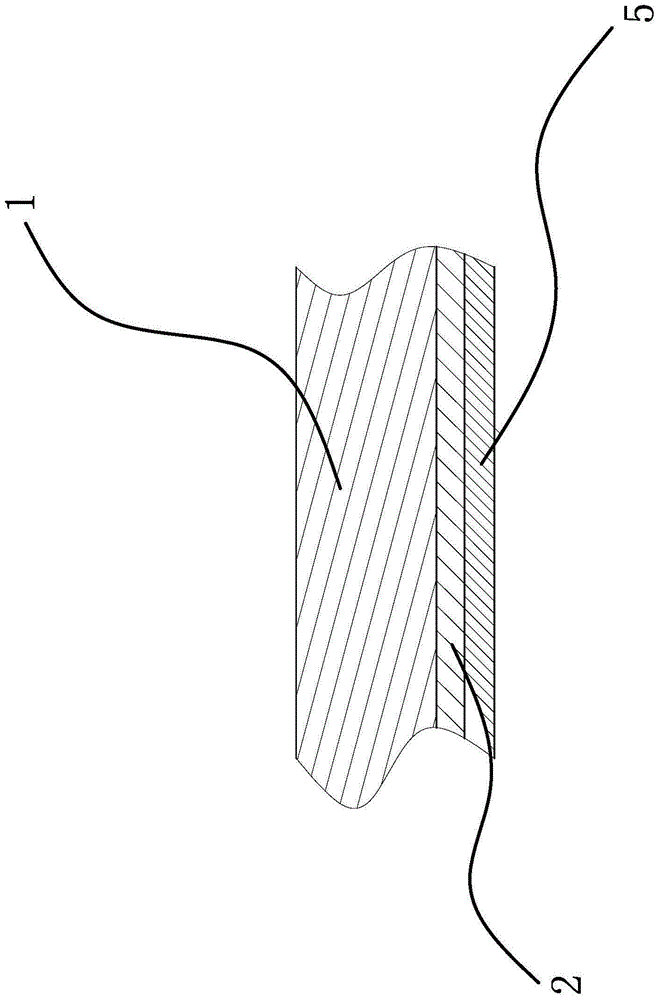

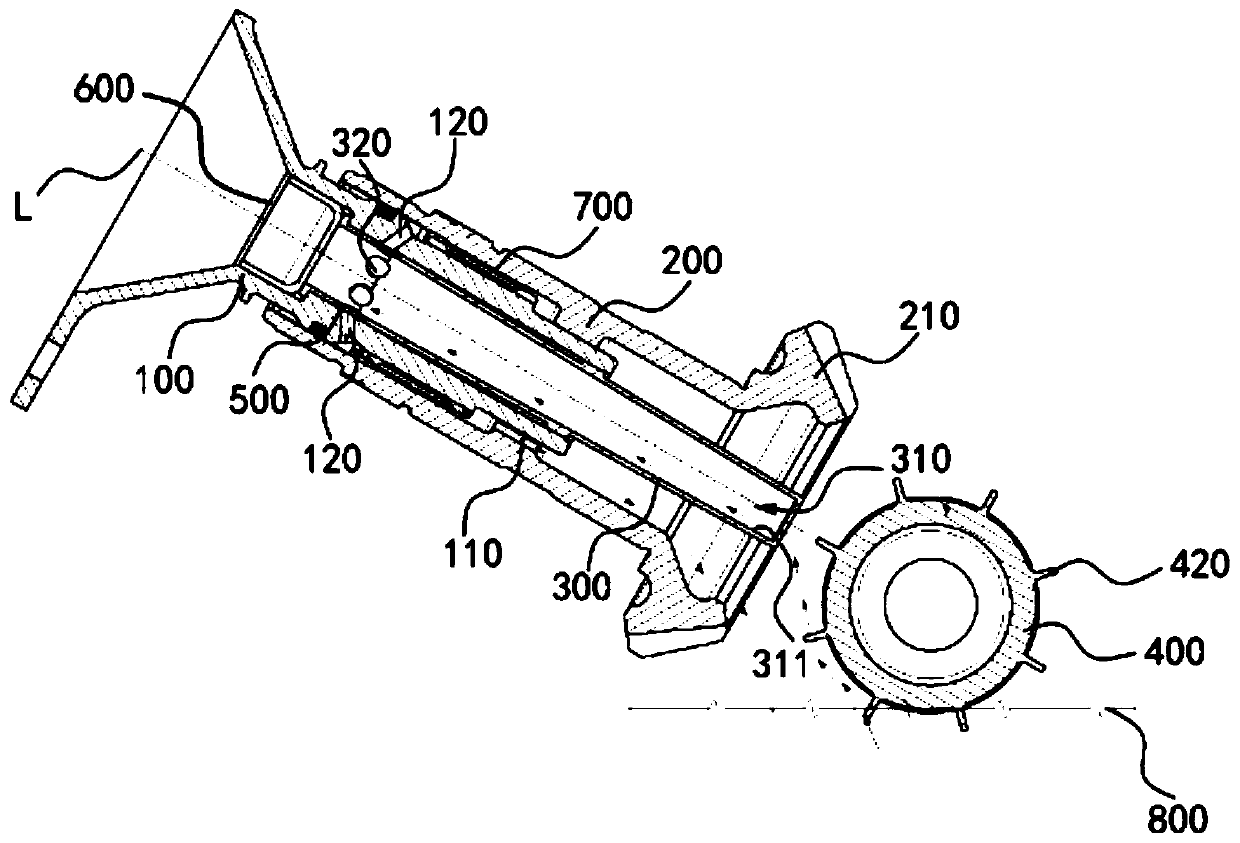

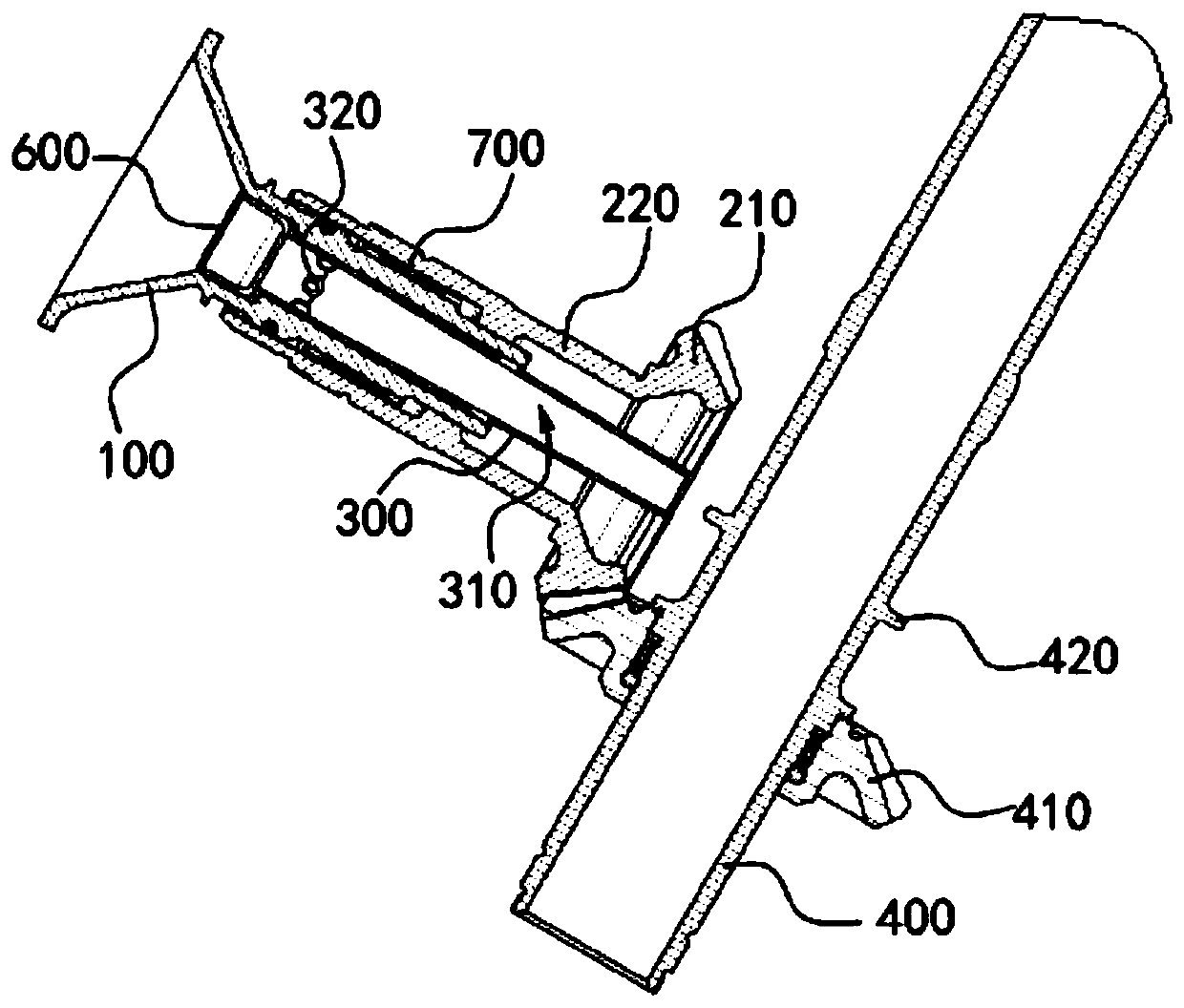

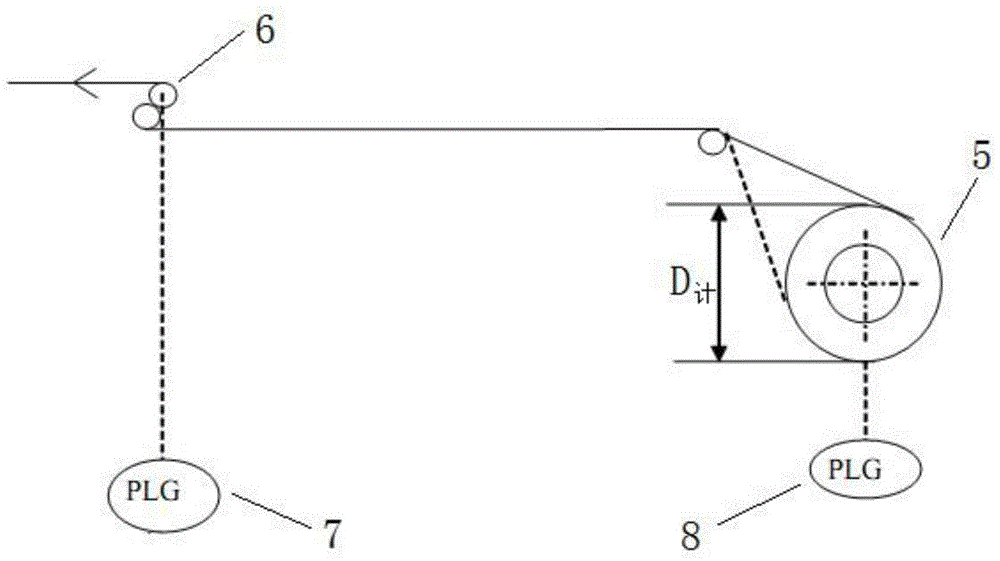

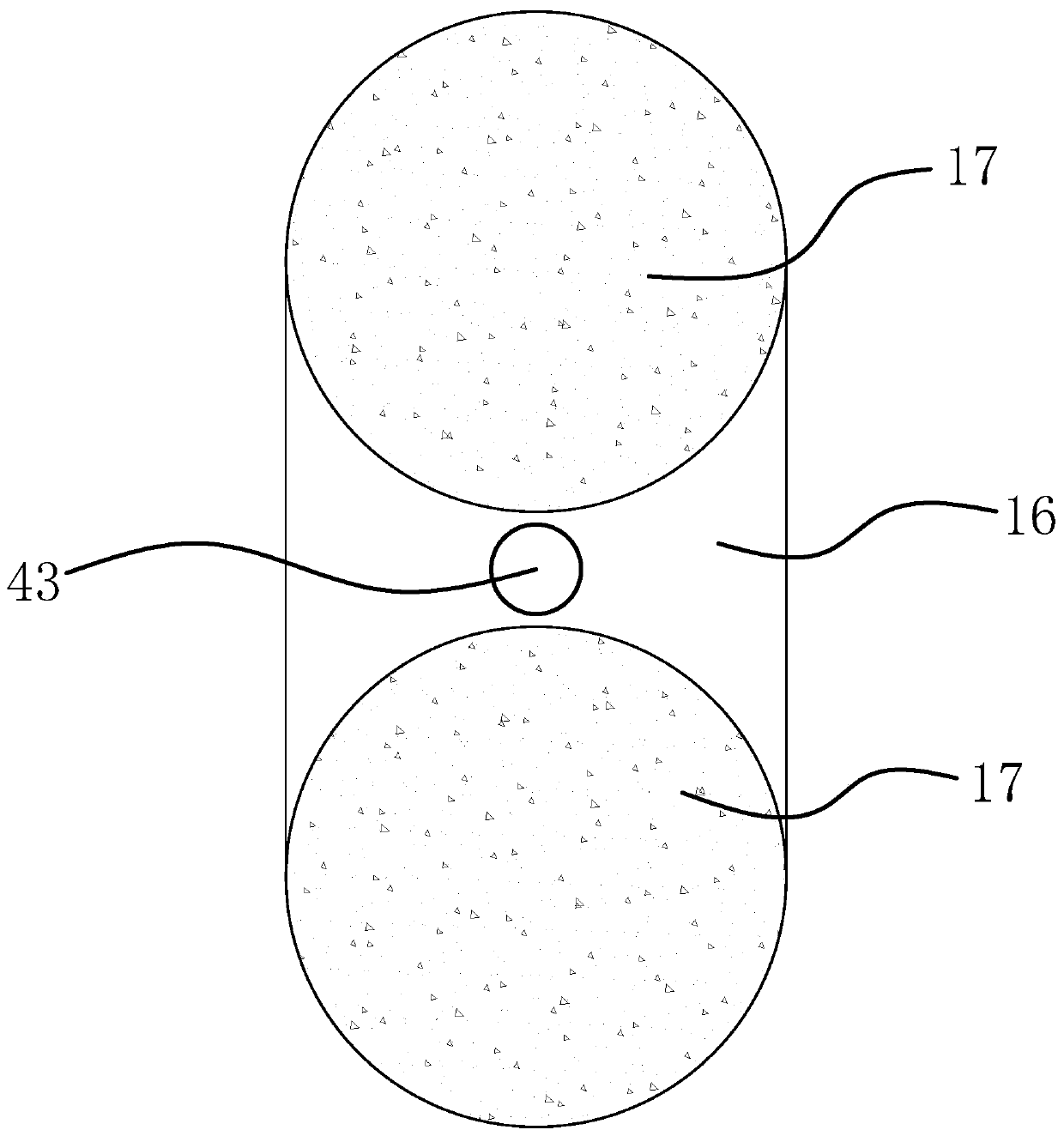

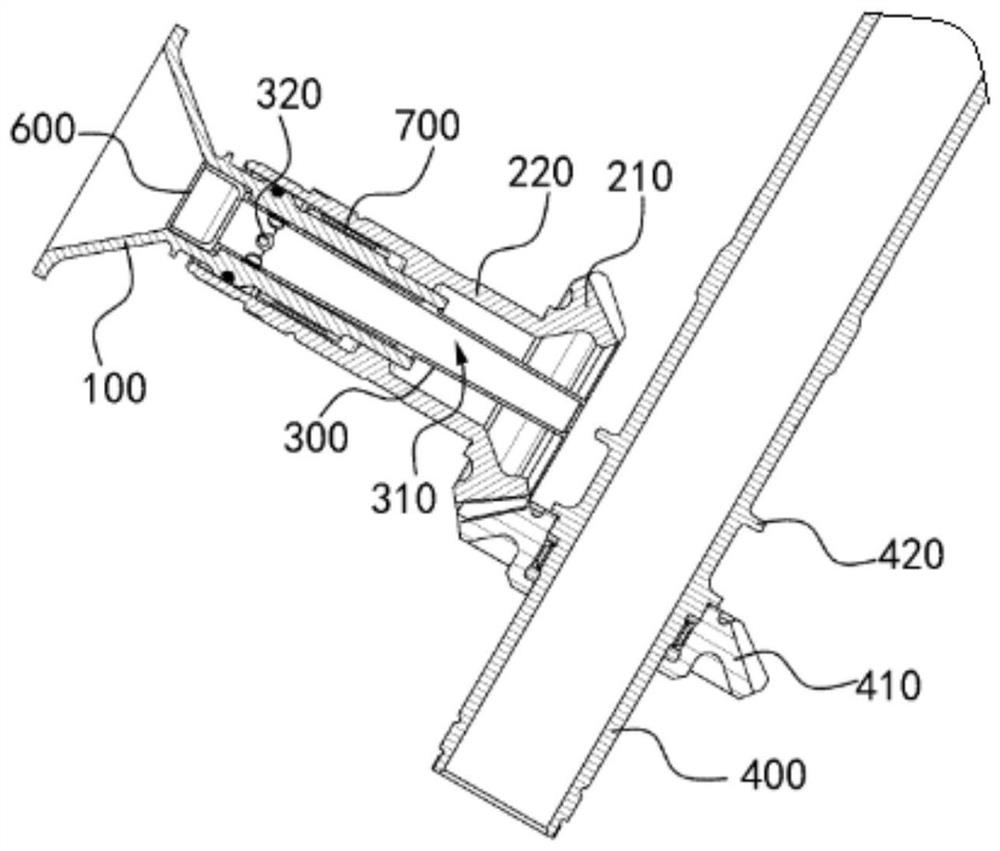

Cable erection assisting device, cable erection device and cable erecting and bundling method

ActiveCN107872028AReduce breakage rateAvoid secondary wearCable installation apparatusBundle methodCable tray

The invention provides a cable erection assisting device, cable erection device and cable erecting and bundling method. In a cable erection device, the cable erection assisting device can be mounted between any two cross supports of a cable tray in a dismountable manner and includes a support and a plurality of rollers. The support includes a pair of support pieces arranged in parallel. Two ends of each support piece are provided with mounting parts used for detachable connection with the cross supports. The interval between the two support pieces is smaller than the width of the cable tray. The rollers are arranged at intervals along the length direction of the support pieces. The two ends of each roller are connected to the two support pieces respectively. The rollers can rotate around their rotary axes which are perpendicular to the length direction of the support pieces. By adopting the devices and the method provided by the invention, simple and convenient operation is achieved, abrasion of cables is reduced and labor strength is reduced greatly, labor power is saved and working efficiency is improved.

Owner:YANTAI RAFFLES SHIPYARD +1

Anti-blockage engine oil filter for automobile

ActiveCN106958473AExtend the life cycleImprove filtering effectPressure lubricationLubricant mounting/connectionMetal impuritiesFilter paper

The invention provides an anti-blockage engine oil filter for an automobile. The anti-blockage engine oil filter comprises a shell, a bottom plate and a transverse partition plate. The transverse partition plate is arranged in the shell and divides the interior of the shell into a first filtering cavity and a second filtering cavity. The transverse partition plate is provided with a first oil conducting port communicating with the first filtering cavity and the second filtering cavity, and a plurality of first through holes communicating with the first filtering cavity and the second filtering cavity. A first filter element is arranged in the first filtering cavity, an annular containing cavity is formed in a second barrel of the first filter element, and the annular containing cavity is filled with metal impurity adsorption materials. The second filtering cavity is internally provided with a second filter element, a bypass valve is arranged on a second end cover of the second filter element, an inlet of the bypass valve communicates with the second filtering cavity, and an outlet of the bypass valve communicates with an inner cavity of a third barrel. According to the anti-blockage engine oil filter, the metal impurity adsorption materials are used for adsorbing and filtering out large-particle metal impurities in engine oil, the filtering pressure of filter paper is reduced, the using cycle of the second filter element is prolonged, and the filtering effect of the second filter element is improved.

Owner:安徽宏辉滤清器有限公司

Automobile magnetic oil pan

ActiveCN103573329AExtended service lifeAvoid secondary wearCasingsMachines/enginesScrapMagnetic layer

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

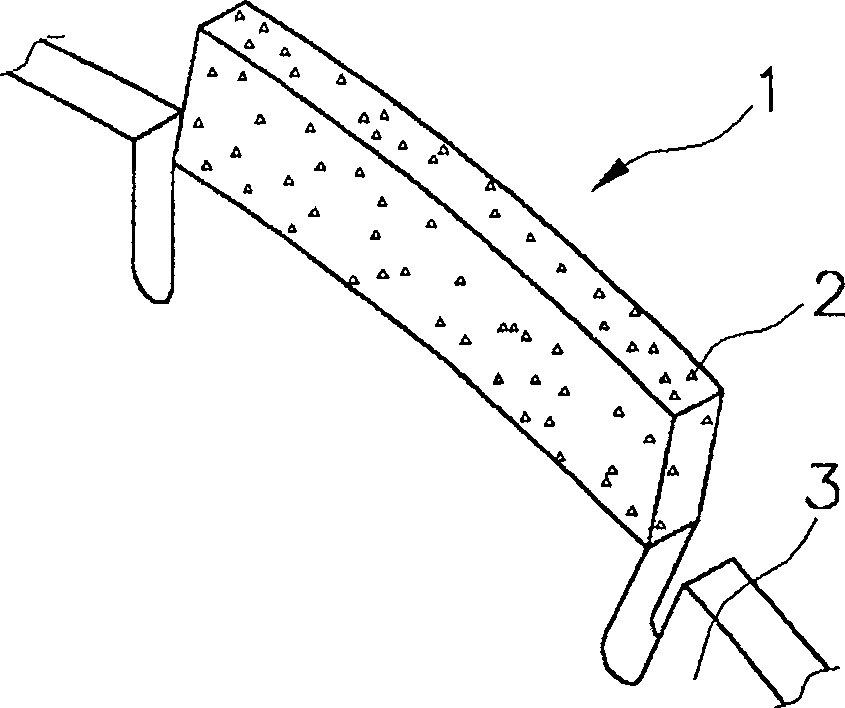

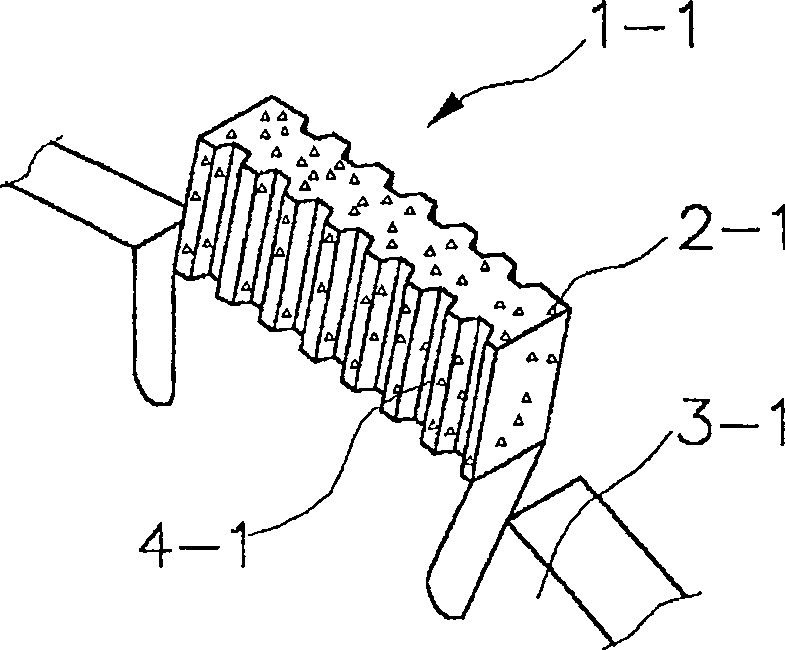

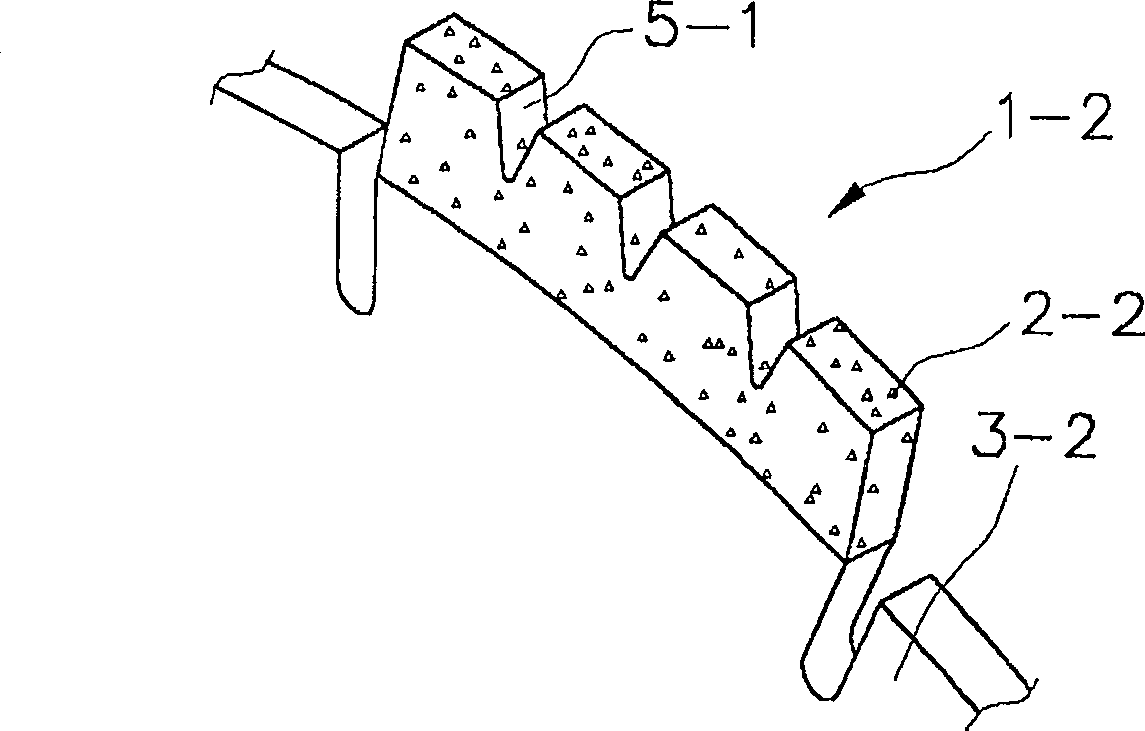

Gear type machining tip and tool attaching the same thereon

InactiveCN1741878AExtend your lifeSame areaMetal sawing toolsBonded abrasive wheelsEngineeringMachining

The invention relates to a serrated cutting tip and a serrated cutting tool having the cutting attached thereto capable of working a work piece at a fixed workability. The cutting tip includes a bond layer, which has super abrasive particles contained therein and grooves formed on a face which is in contact with the work piece, and a blank layer for strongly supporting the bond layer, by which a working plane of the cutting tip contacting the work piece is uniformly maintained during working use and debris can be readily discharged. As a result, workability is improved and lifetime is prolonged.

Owner:NIWA DAIYAMONDO INDS

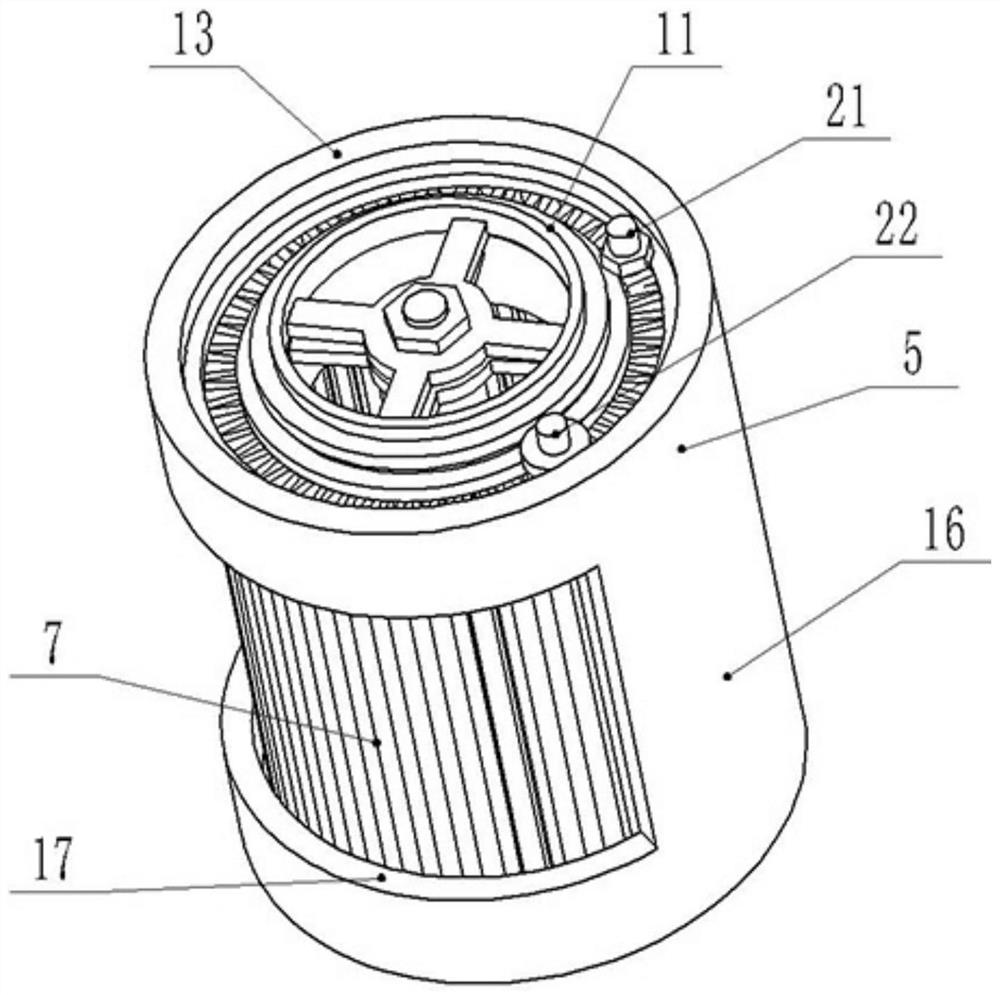

Oil filter with multiple filter elements

InactiveCN107218102AReduce filter pressureExtend the life cyclePressure lubricationLubricant mounting/connectionFilter paperMetal impurities

The invention provides an oil filter with multiple filter elements. The oil filter comprises a shell, a bottom plate, a first filter element and multiple second filter elements. Oil in an engine can respectively flow in second central pipes of multiple second filter elements from multiple oil inlets; after metal filling is magnetically adsorbed by magnetic filtration modules of the second central pipes, the oil is filtered for the second time by a second filter paper group and then flows in the inner chamber of the shell; after being filtered by a first filter paper group, the oil flows in a first central pipe through a first through hole and finally flows back into the engine through a first oil guide hole and an oil outlet. The metal impurities of varying sizes are filtered in an adsorbing mode by multiple magnetic filtration modules in multiple second filter elements, therefore the filtration pressure of the first filter paper group and the second filter paper group is reduced, the service cycle of the first filter paper group and the second filter paper group is prolonged, and the filtration effect of the first filter element and the second filter elements is improved. The metal impurities adsorbed by the magnetic filtration modules can completely stay in the second central pipes and cannot flow in the inner chamber of the shell along with the oil.

Owner:王雨

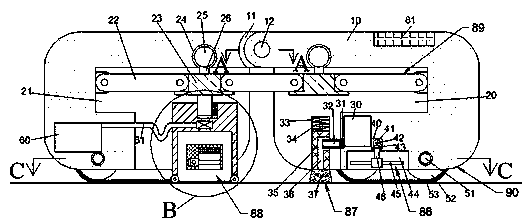

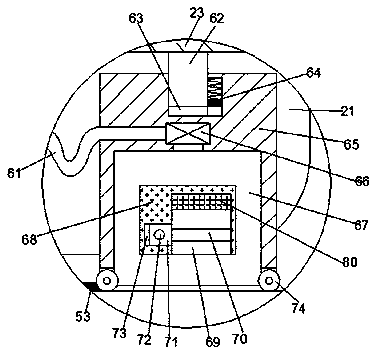

Rust removing and painting device for ship

ActiveCN110681523AImprove the protective effectAvoid secondary wearLiquid surface applicatorsCoatingsMarine engineeringMachine

The invention discloses a rust removing and painting device for a ship. The rust removing and painting device includes a machine body arranged in a left and right hinge manner, a traveling device is arranged at the lower end of the machine body, the traveling device includes two rotatable caterpillar bands, the caterpillar bands have magnetism and can be attracted to the outer surface of the ship,and rotation of the caterpillar bands can drive the machine body to move. According to the rust removing and painting device, the caterpillar bands which have magnetism and can be attracted to the surface of the ship drive the machine body to move, the surface of the ship is protected through a rust removing device and a painting device, rust removing areas can be selected, secondary wear on thesurface of the ship is avoided; and in the process of traveling or climbing of the machine body, walking in pits or protruding areas can be carried out, the rust removing device and the painting device are always in contact with the surface of the ship, rust removal and painting work is continuous, influences of the surface smoothness and the position are avoided, the surface of the ship is fullyprotected, full-automatic operation is carried out, and the work efficiency is high.

Owner:广州明创生物科技有限公司

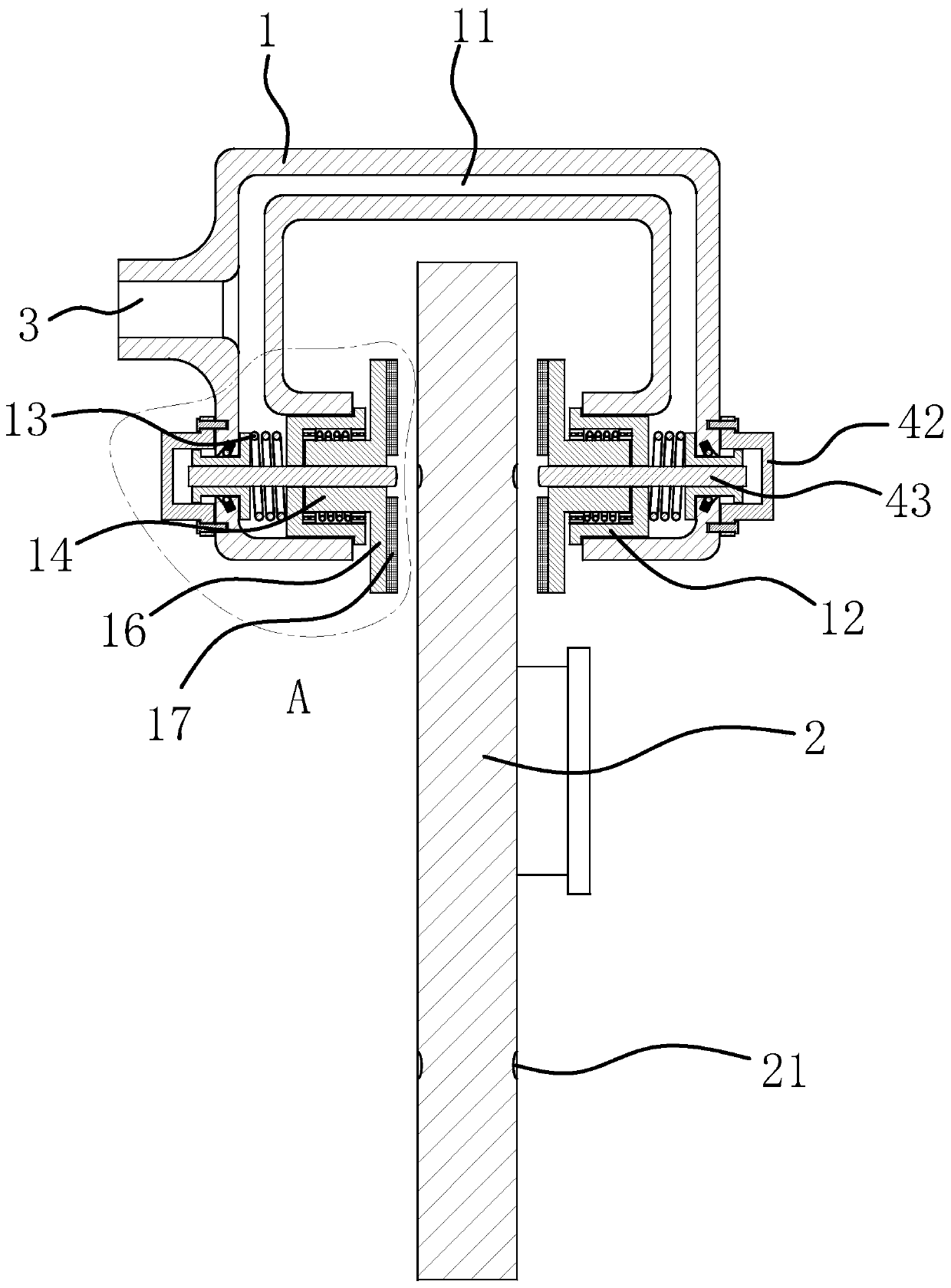

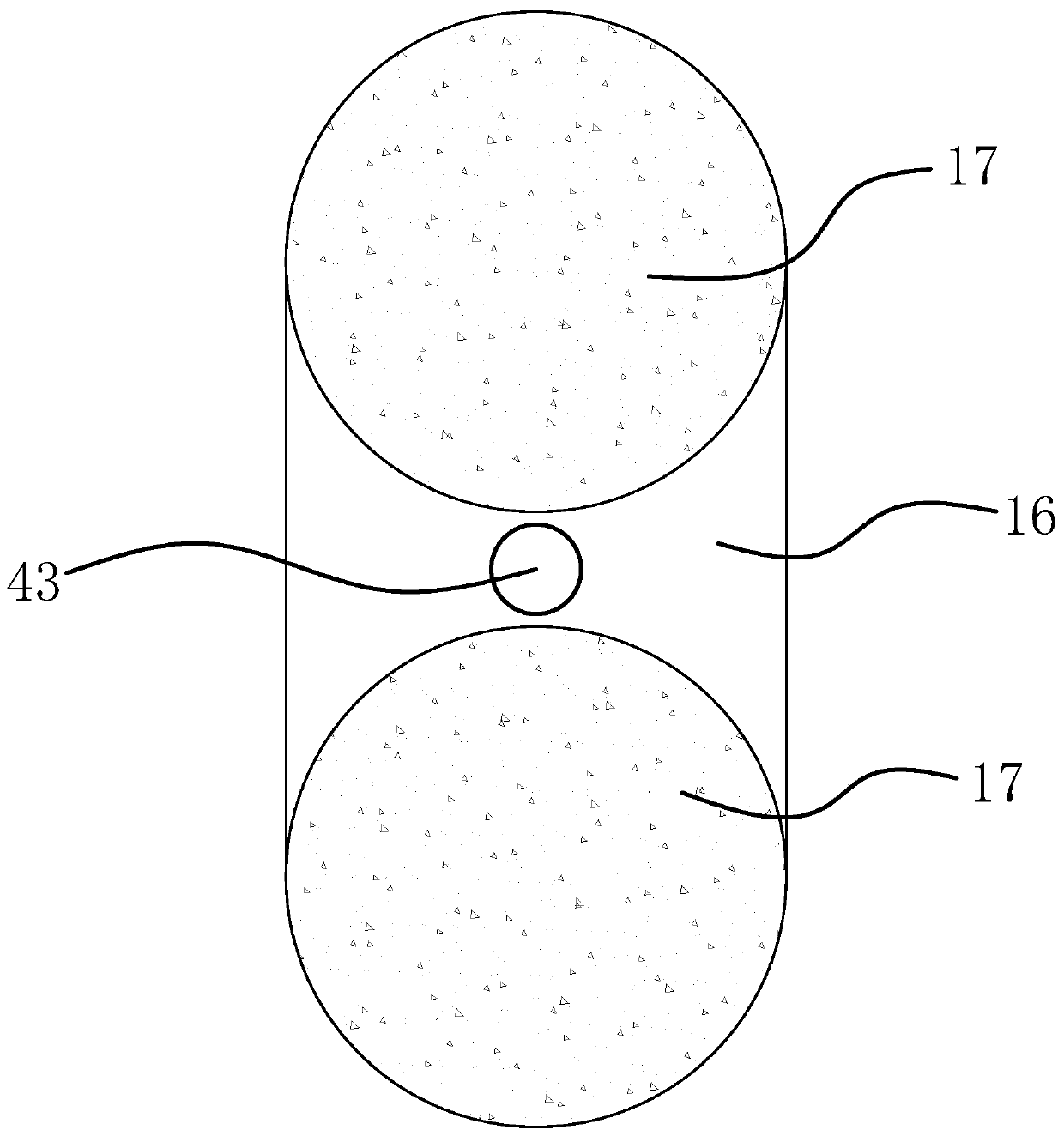

Automobile disc-type brake system

ActiveCN109915511AImprove cooling effectAvoid secondary wearBrake actuating mechanismsSlack adjustersEngineeringCalipers

The invention provides an automobile disc-type brake system, and belongs to the technical field of automobile parts. Brake ends located at the two sides of a brake disc are arranged at the two ends ofa brake caliper clamp separately; each brake end is provided with a valve hole communicating with a hydraulic channel and vertical to the brake disc; a brake piston is slidably connected into each valve hole; a return spring is connected between the outer end of each brake piston and the inner wall of the hydraulic channel; a guide hole is formed in the inner end of each brake piston; a torsionalspring sleeving an installation shaft is arranged between two bearings; the two ends of the torsional spring are connected with the inner walls of the guide holes and the outer wall of the installation shaft separately; a waist-shaped installation plate parallel to the brake disc is arranged at the other end of the installation shaft; and two circular brake sheets are fixedly arranged on the inner side surface of the installation plate. In a return state of the brake pistons, the connection line between the two brake sheets on the same installation plate forms an inclination angle of less than 90 degrees with the radial line of the brake disc. The automobile disc-type brake system has the advantages of being capable of providing pre-brake before brake, and the like.

Owner:HUBEI UNIV OF SCI & TECH

Gear type machining tip and tool attaching the same thereon

InactiveCN100486788CExtend your lifeSame areaMetal sawing toolsBonded abrasive wheelsEngineeringMachining

The invention relates to a serrated cutting tip and a serrated cutting tool having the cutting attached thereto capable of working a work piece at a fixed workability. The cutting tip includes a bond layer, which has super abrasive particles contained therein and grooves formed on a face which is in contact with the work piece, and a blank layer for strongly supporting the bond layer, by which a working plane of the cutting tip contacting the work piece is uniformly maintained during working use and debris can be readily discharged. As a result, workability is improved and lifetime is prolonged.

Owner:NIWA DAIYAMONDO INDS

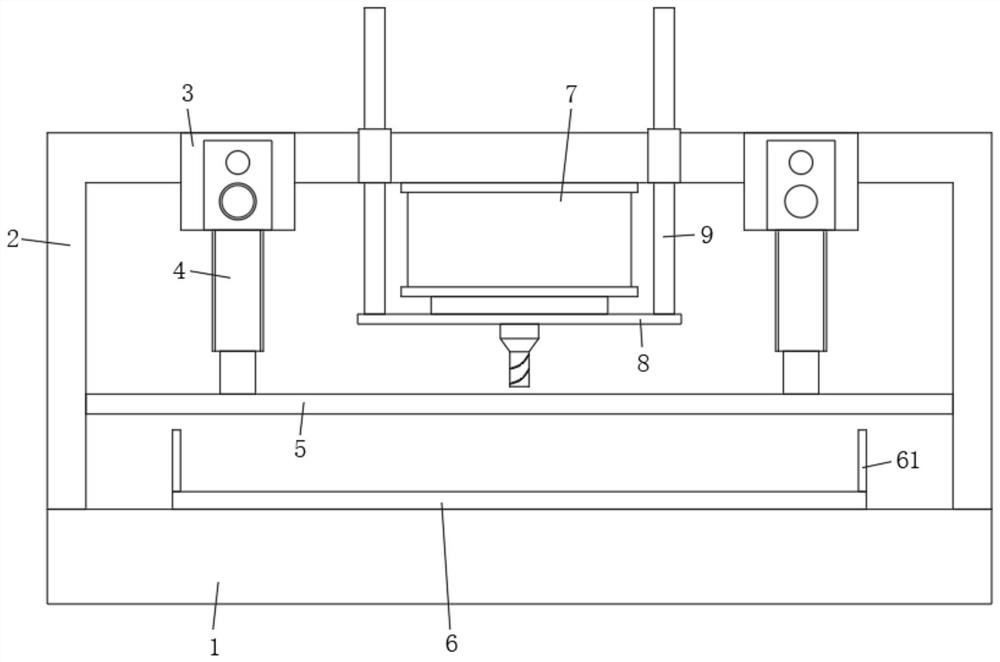

Punching and discharging all-in-one machine

PendingCN111633245ASimple structureLow costPositioning apparatusMetal working apparatusPunchingStructural engineering

The invention belongs to the technical field of machining, and discloses a punching and discharging all-in-one machine. The punching and discharging all-in-one machine comprises a base and a rack, wherein a punching mechanism is installed in the middle of the top of the rack; moving devices are installed at the positions, positioned on the two sides of the punching mechanism, of the top of the rack; lifting air cylinders are installed at the bottoms of the two moving devices; an upper pressing plate is connected to the bottoms of the two lifting air cylinders; a guide hole and two limiting grooves are formed in the upper pressing plate; the two limiting grooves are symmetrically positioned in the two sides of the guide hole; a movable lower pressing plate is arranged at the top of the base; limiting blocks are vertically fixed to the two sides of the lower pressing plate; and the limiting blocks correspond to the limiting grooves. According to the punching and discharging all-in-one machine, an automatic discharging structure of a workpiece is arranged, and therefore automatic discharging can be effectively formed after punching of the workpiece is completed; and the automatic discharging structure is composed of the movable lower pressing plate and a plurality of discharging rollers, and the punching and discharging all-in-one machine has the beneficial effects of being simplein structure and low in cost.

Owner:镇江市惠灵顿膜业有限公司

Engine oil filter used for automobile engine

InactiveCN106968757AImprove filtering effectReduce filter pressurePressure lubricationLubricant mounting/connectionMetal impuritiesFilter paper

The invention provides an engine oil filter used for an automobile engine. The engine oil filter comprises a shell, a bottom plate, a first filter element and a second filter element. A transverse partition plate divides the interior of the shell into a first filtering cavity and a second filtering cavity. The filter element is arranged in the first filtering cavity and comprises a first central pipe, a first filter paper set, a first end cover, a second end cover and a plurality of second central pipes. The multiple second central pipes are circumferentially distributed around the first central pipe with the first central pipe being the center. A plurality of filtering assemblies are arranged in each second central pipe at intervals in the vertical direction. Each filtering assembly comprises two filtering nets arranged oppositely. A plurality of magnet blocks are arranged between every two filtering nets. The second filtering element is arranged in the second filtering cavity. Metal impurities with various sizes are attached and filtered through of the multiple filtering assemblies in the second central pipes, so that the filtering pressure of the first filter paper set and a second filter paper set is reduced, the using periods of the first filter element and the second filter element are prolonged, and the filtering effects of the first filter element and the second filter element are improved.

Owner:王雨

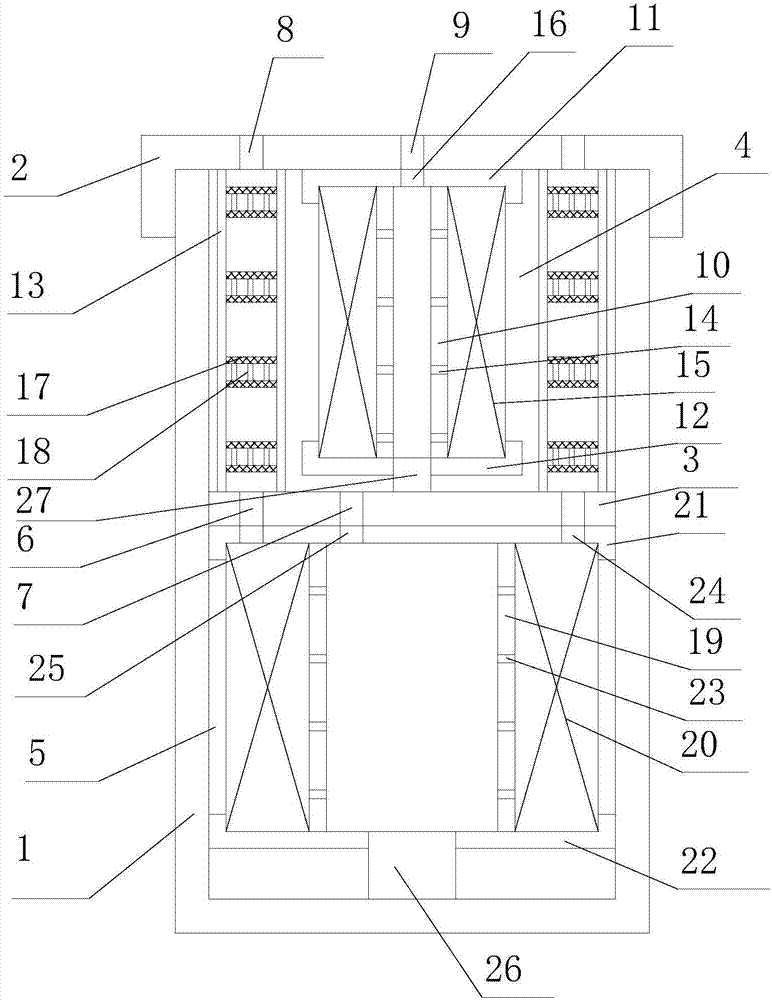

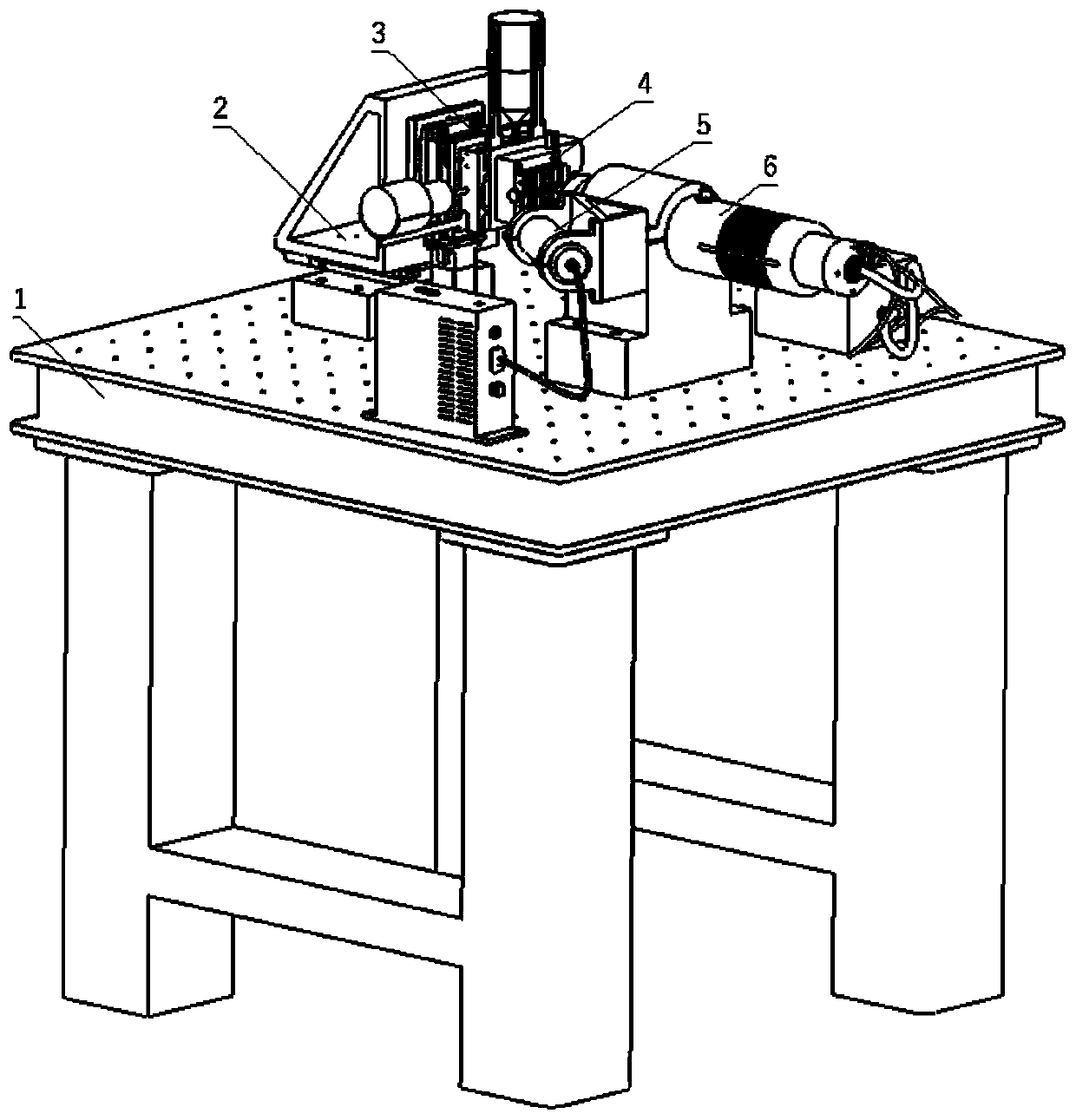

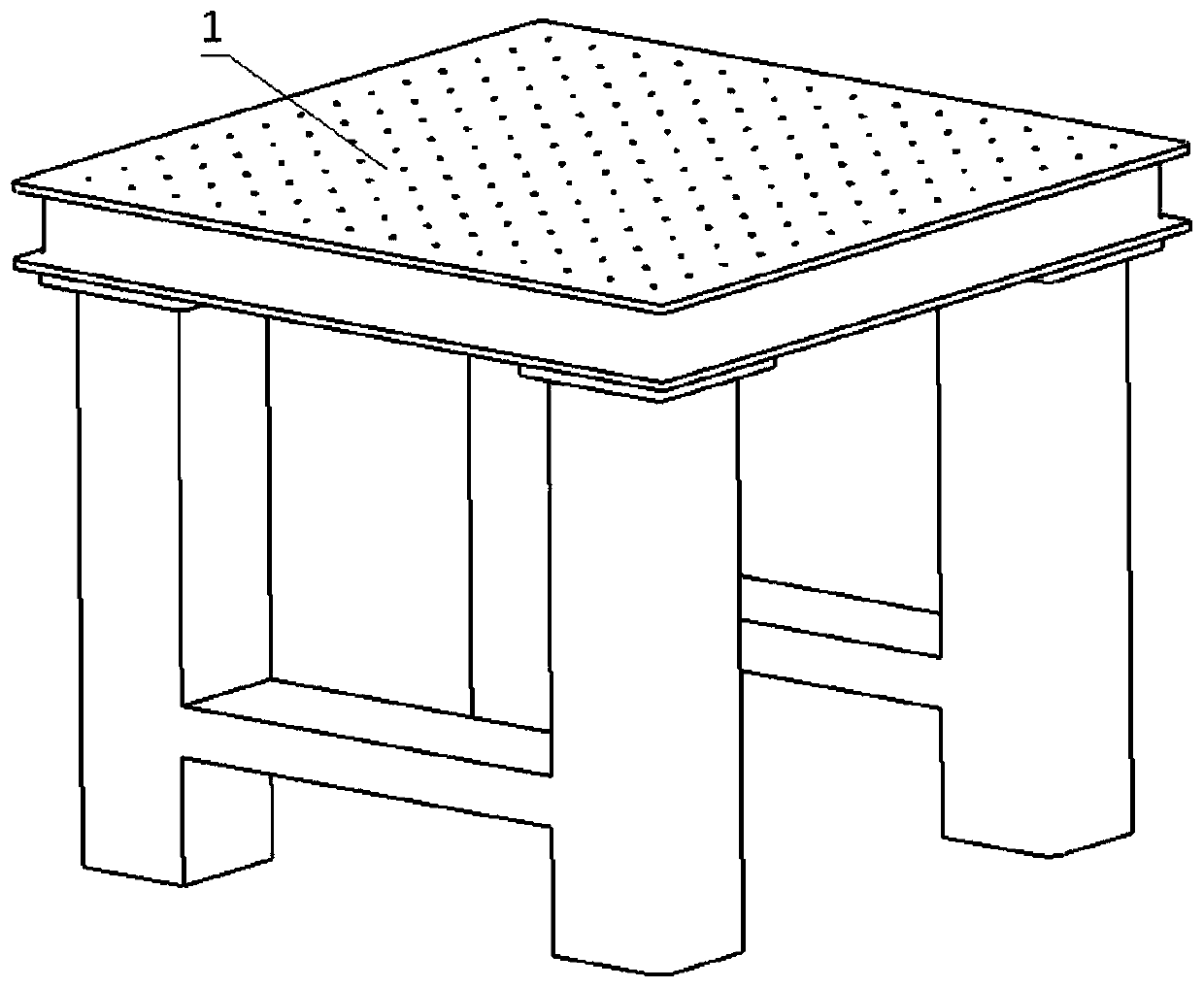

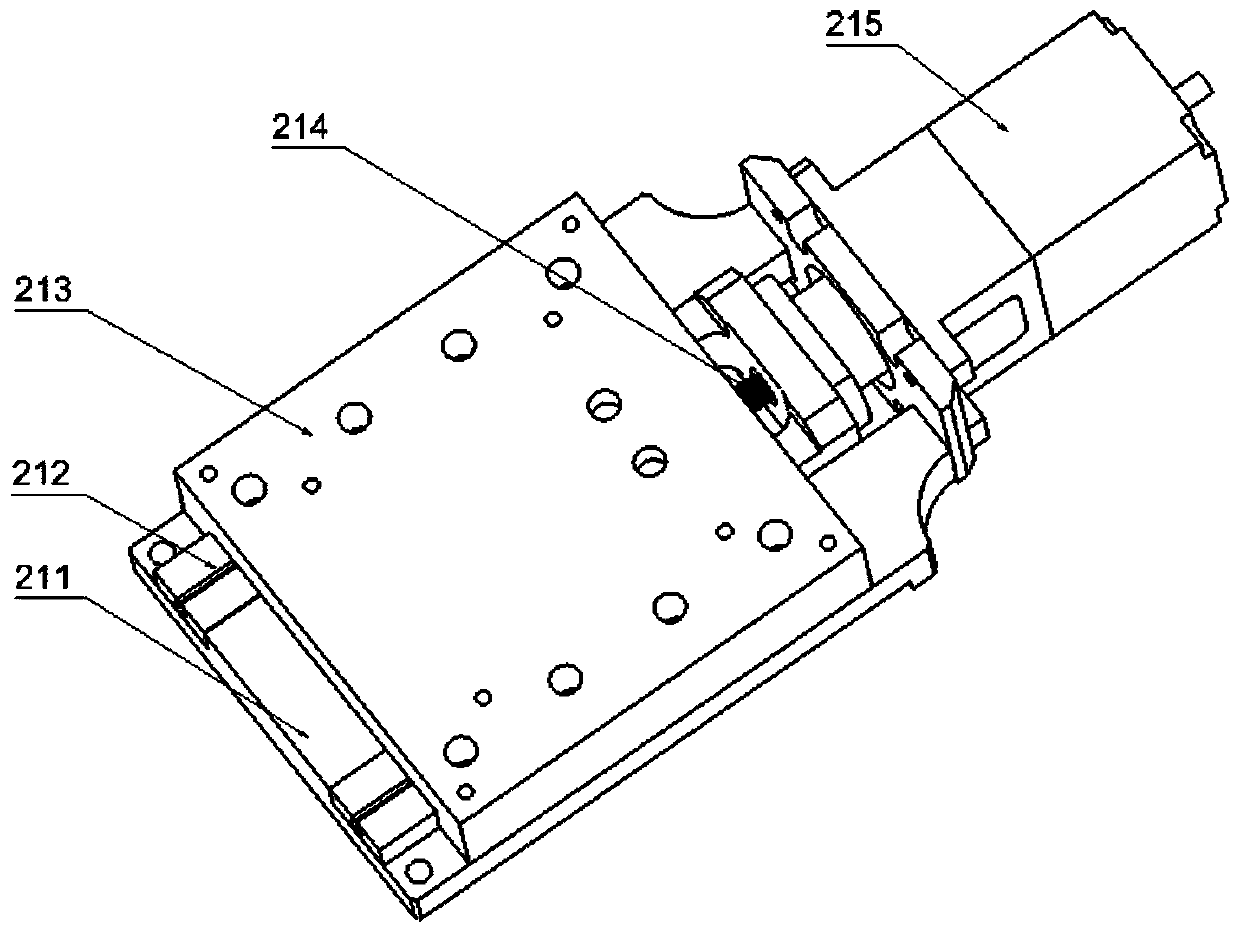

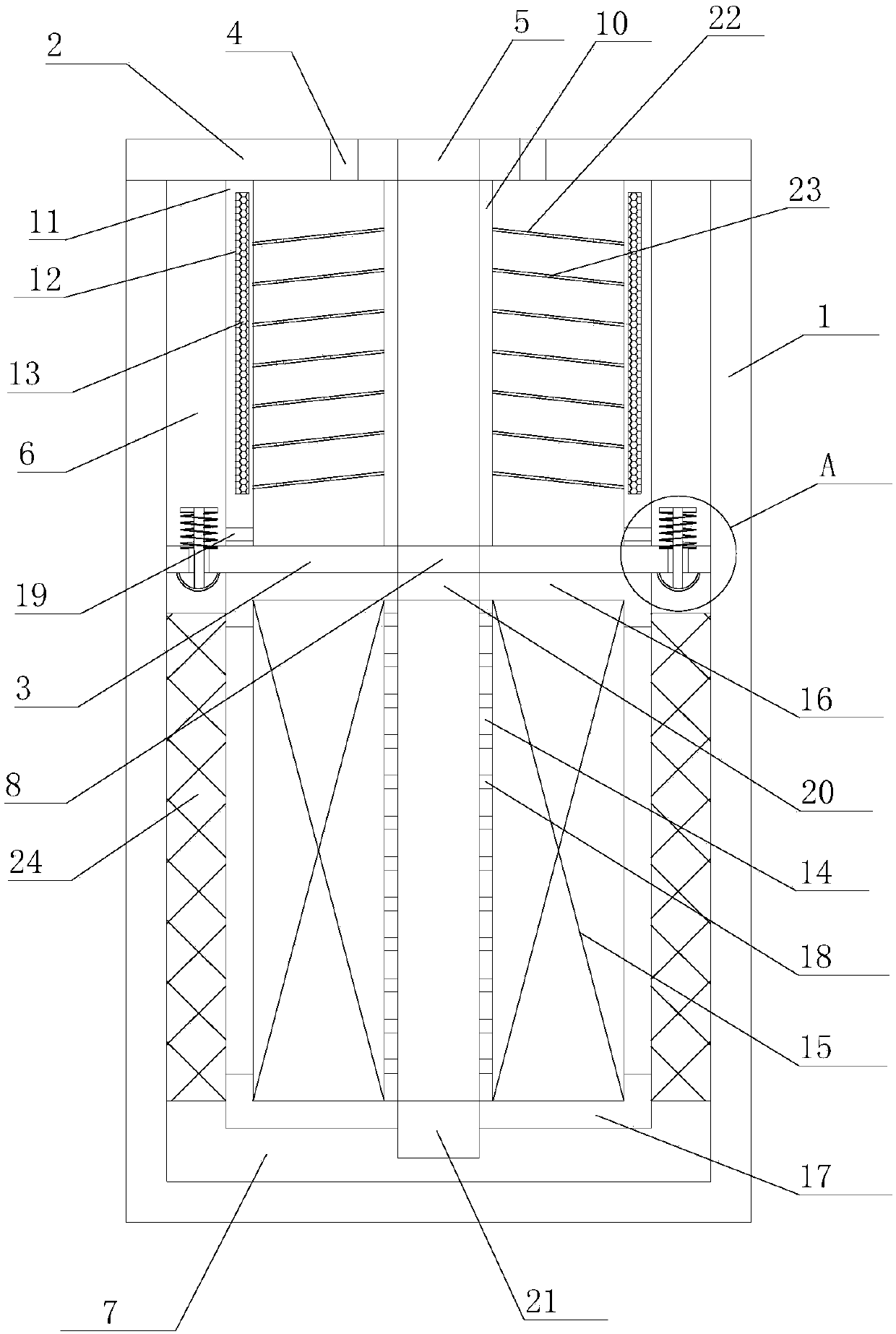

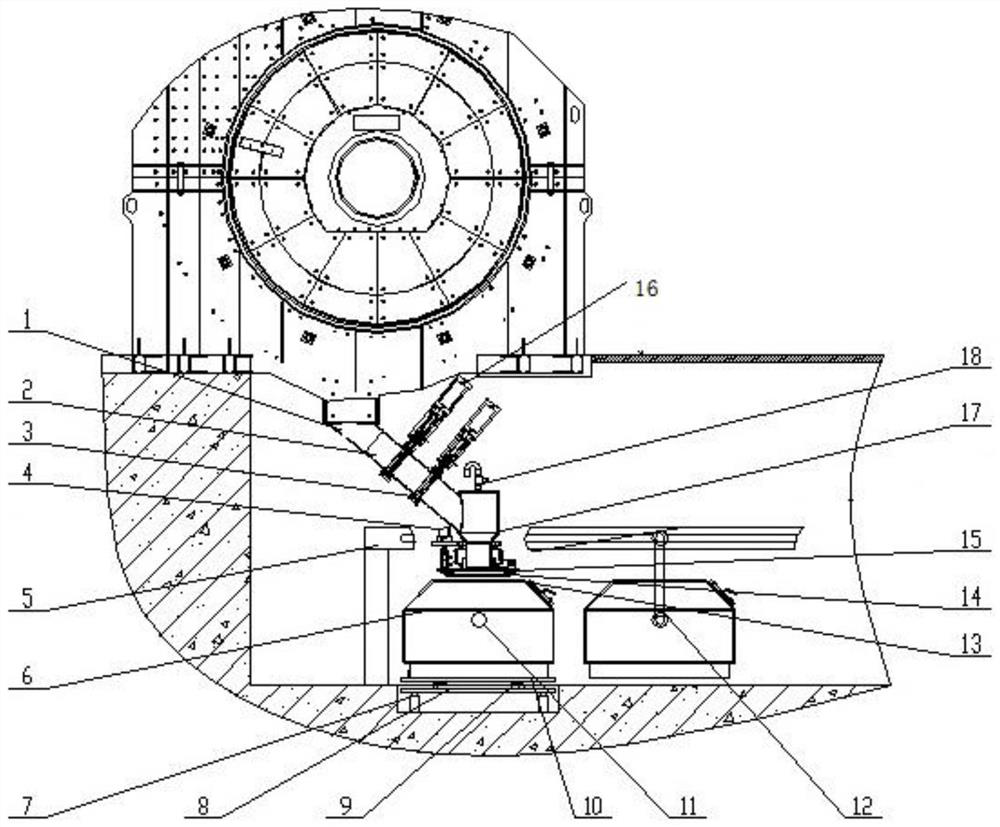

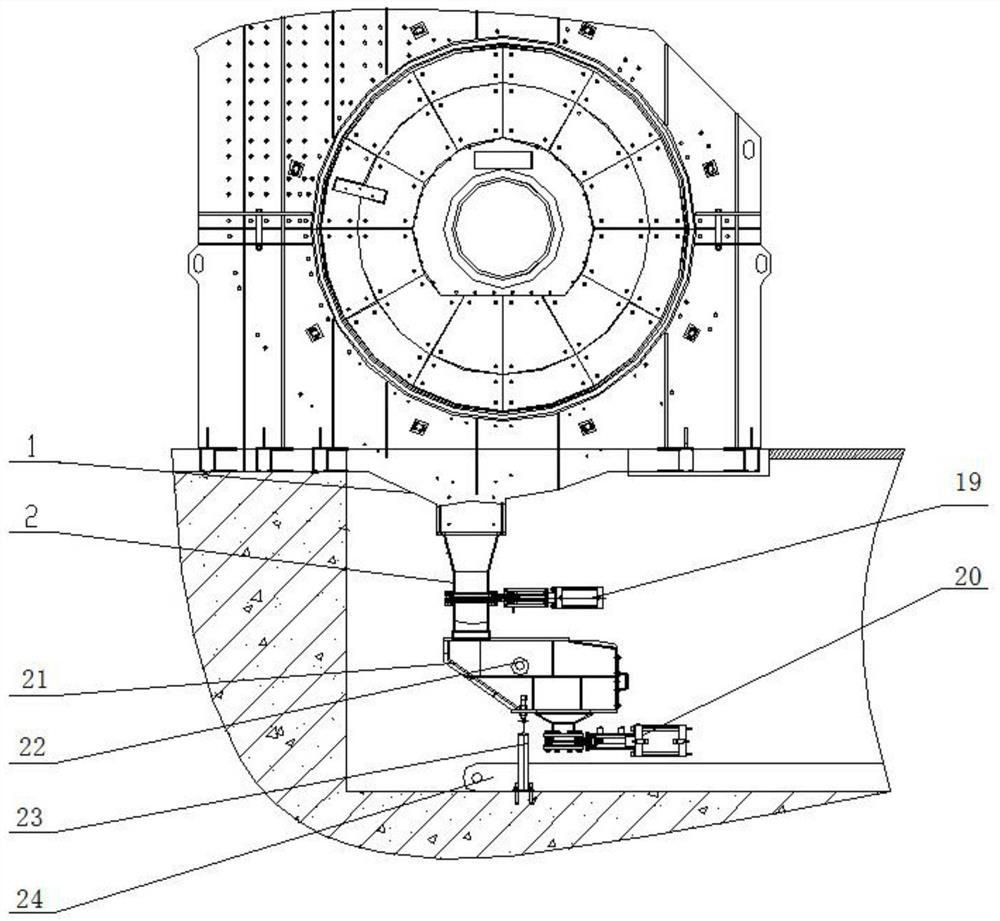

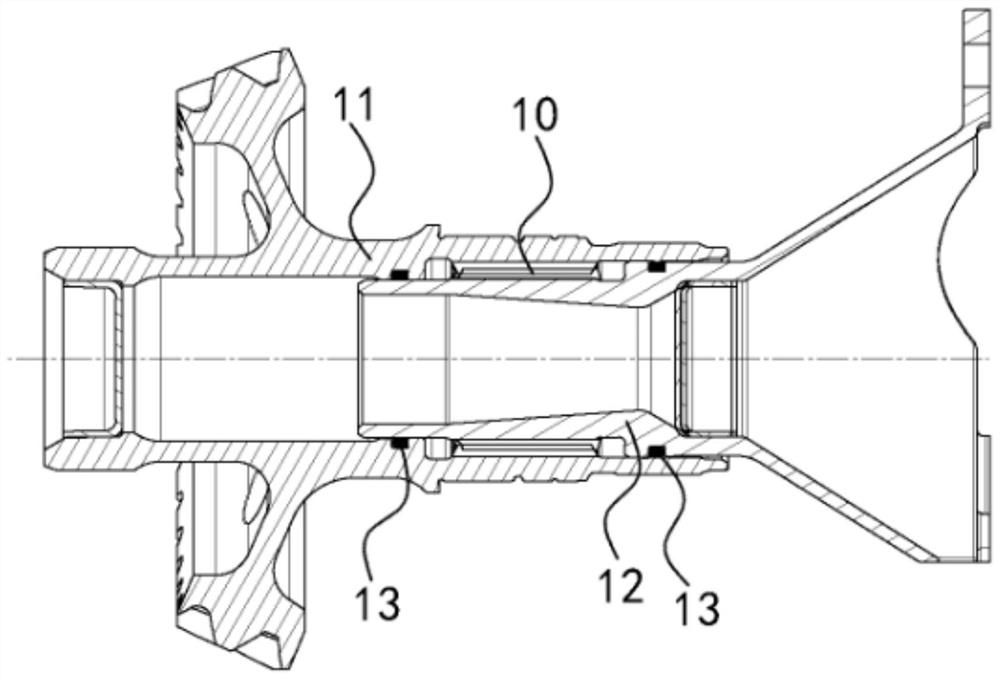

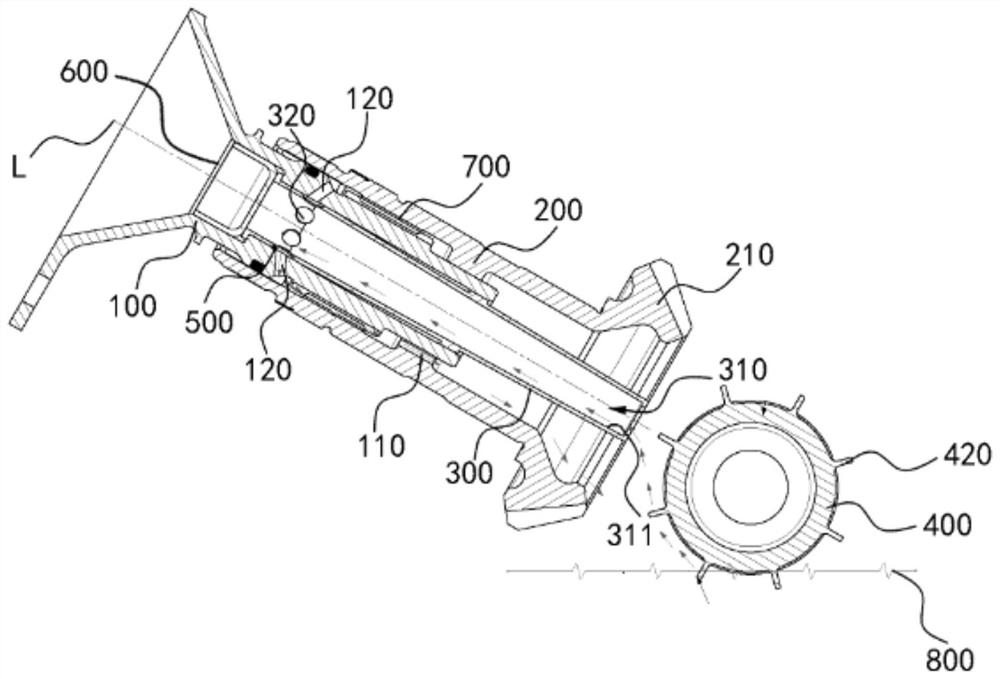

Laser-assisted horizontal three-dimensional ultrasonic elliptical vibration milling machine equipment and its working method

ActiveCN108526912BAvoid secondary wearImprove flowFeeding apparatusLarge fixed membersControl systemClosed loop

A laser-assisted horizontal three-dimensional ultrasonic elliptical vibration milling machine and its working method belong to the field of ultrasonic vibration cutting technology, including an air-floating platform, an XYZ moving assembly, a micro-motion unit, a workpiece fixture, a laser-assisted processing device, and an ultrasonic electric spindle assembly to make. The laser-assisted horizontal three-dimensional ultrasonic elliptical vibration milling machine involved in the present invention solves the problem that only one-dimensional or two-dimensional ultrasonic vibration can be performed in the mainstream ultrasonic elliptical vibration milling machine in the market. The coupling problem during vibration, through the real-time monitoring and adjustment of the closed-loop control system, accurately controls the vibration trajectory of the ellipse, and through the combination of laser-assisted processing technology, the overall stability of the machine tool is strengthened, and the processing effect is further improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Anti-clogging engine oil filter for automobile

ActiveCN106958473BExtend the life cycleImprove filtering effectLubricant mounting/connectionPressure lubricationMetal impuritiesFilter paper

The invention provides an anti-blockage engine oil filter for an automobile. The anti-blockage engine oil filter comprises a shell, a bottom plate and a transverse partition plate. The transverse partition plate is arranged in the shell and divides the interior of the shell into a first filtering cavity and a second filtering cavity. The transverse partition plate is provided with a first oil conducting port communicating with the first filtering cavity and the second filtering cavity, and a plurality of first through holes communicating with the first filtering cavity and the second filtering cavity. A first filter element is arranged in the first filtering cavity, an annular containing cavity is formed in a second barrel of the first filter element, and the annular containing cavity is filled with metal impurity adsorption materials. The second filtering cavity is internally provided with a second filter element, a bypass valve is arranged on a second end cover of the second filter element, an inlet of the bypass valve communicates with the second filtering cavity, and an outlet of the bypass valve communicates with an inner cavity of a third barrel. According to the anti-blockage engine oil filter, the metal impurity adsorption materials are used for adsorbing and filtering out large-particle metal impurities in engine oil, the filtering pressure of filter paper is reduced, the using cycle of the second filter element is prolonged, and the filtering effect of the second filter element is improved.

Owner:安徽宏辉滤清器有限公司

Oil filter for automobile engine

InactiveCN106968757BImprove filtering effectReduce filter pressurePressure lubricationLubricant mounting/connectionMetal impuritiesFilter paper

The invention provides an engine oil filter used for an automobile engine. The engine oil filter comprises a shell, a bottom plate, a first filter element and a second filter element. A transverse partition plate divides the interior of the shell into a first filtering cavity and a second filtering cavity. The filter element is arranged in the first filtering cavity and comprises a first central pipe, a first filter paper set, a first end cover, a second end cover and a plurality of second central pipes. The multiple second central pipes are circumferentially distributed around the first central pipe with the first central pipe being the center. A plurality of filtering assemblies are arranged in each second central pipe at intervals in the vertical direction. Each filtering assembly comprises two filtering nets arranged oppositely. A plurality of magnet blocks are arranged between every two filtering nets. The second filtering element is arranged in the second filtering cavity. Metal impurities with various sizes are attached and filtered through of the multiple filtering assemblies in the second central pipes, so that the filtering pressure of the first filter paper set and a second filter paper set is reduced, the using periods of the first filter element and the second filter element are prolonged, and the filtering effects of the first filter element and the second filter element are improved.

Owner:王雨

Auxiliary device for cable pulling and releasing, cable pulling and releasing device and method for cable pulling and releasing and bundling

ActiveCN107872028BReduce breakage rateAvoid secondary wearCable installation apparatusCable trayCable carrier

The invention provides a cable erection assisting device, cable erection device and cable erecting and bundling method. In a cable erection device, the cable erection assisting device can be mounted between any two cross supports of a cable tray in a dismountable manner and includes a support and a plurality of rollers. The support includes a pair of support pieces arranged in parallel. Two ends of each support piece are provided with mounting parts used for detachable connection with the cross supports. The interval between the two support pieces is smaller than the width of the cable tray. The rollers are arranged at intervals along the length direction of the support pieces. The two ends of each roller are connected to the two support pieces respectively. The rollers can rotate around their rotary axes which are perpendicular to the length direction of the support pieces. By adopting the devices and the method provided by the invention, simple and convenient operation is achieved, abrasion of cables is reduced and labor strength is reduced greatly, labor power is saved and working efficiency is improved.

Owner:YANTAI RAFFLES SHIPYARD +1

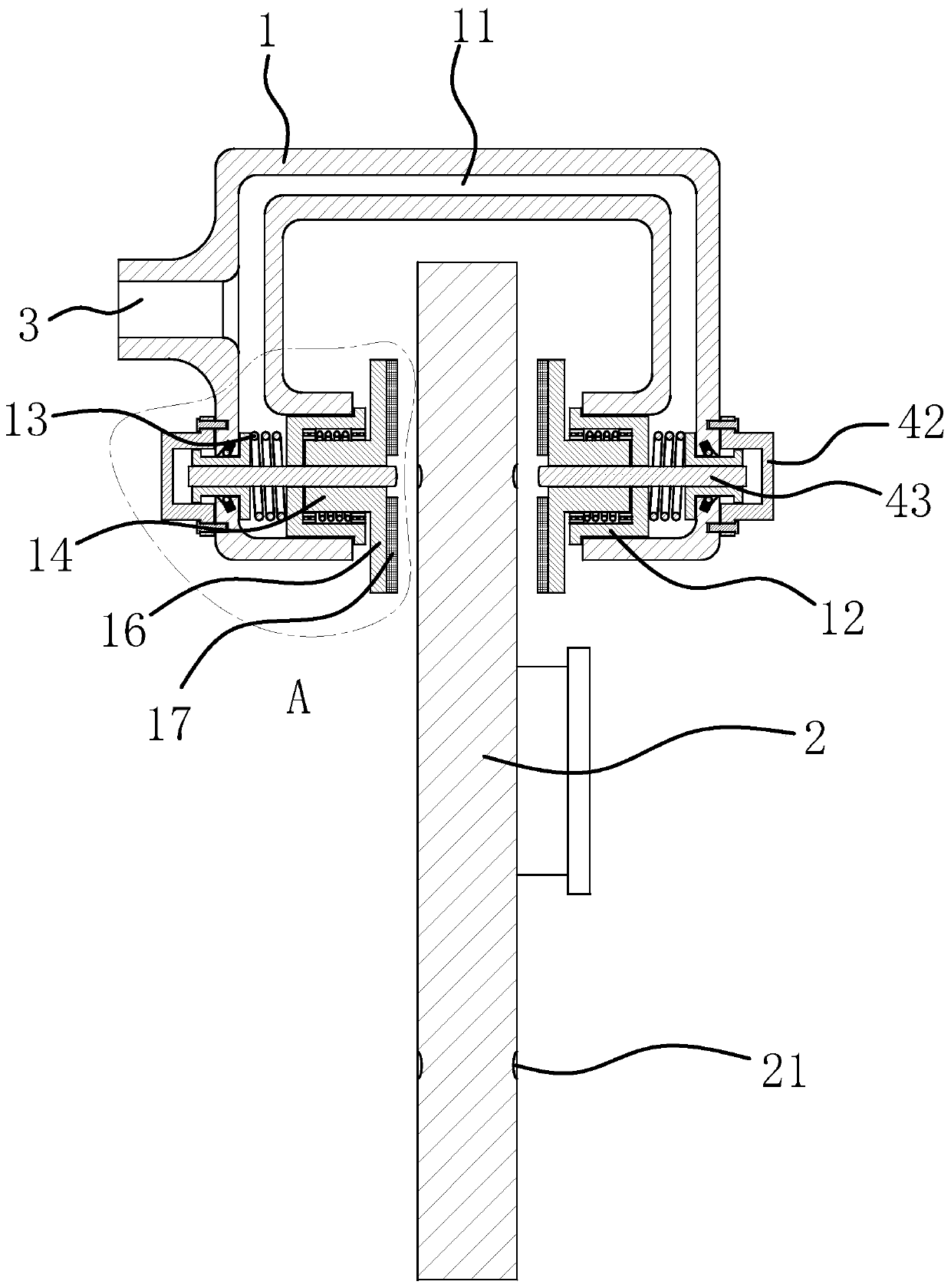

A magnetic oil pan for automobiles

ActiveCN103573329BAvoid secondary wearExtended service lifeCasingsMachines/enginesIron removalMagnetization

The invention provides an automobile magnetic oil pan, and belongs to the technical field of engines. The automobile magnetic oil pan solves the technical problems that an existing oil pan is poor in scrap iron removal effect, cannot perform magnetization on engine oil and the like. According to the automobile magnetic oil pan, a magnetic layer is arranged on the inner wall of the oil pan, an oil baffle is arranged on the upper portion of the oil pan, and an antimagnetic structure used for shielding a magnetic field generated by the magnetic layer is arranged between the oil baffle and the bottom of the oil pan. The automobile magnetic oil pan has the advantages of being good in scrap iron removal effect, can perform magnetization on engine oil and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

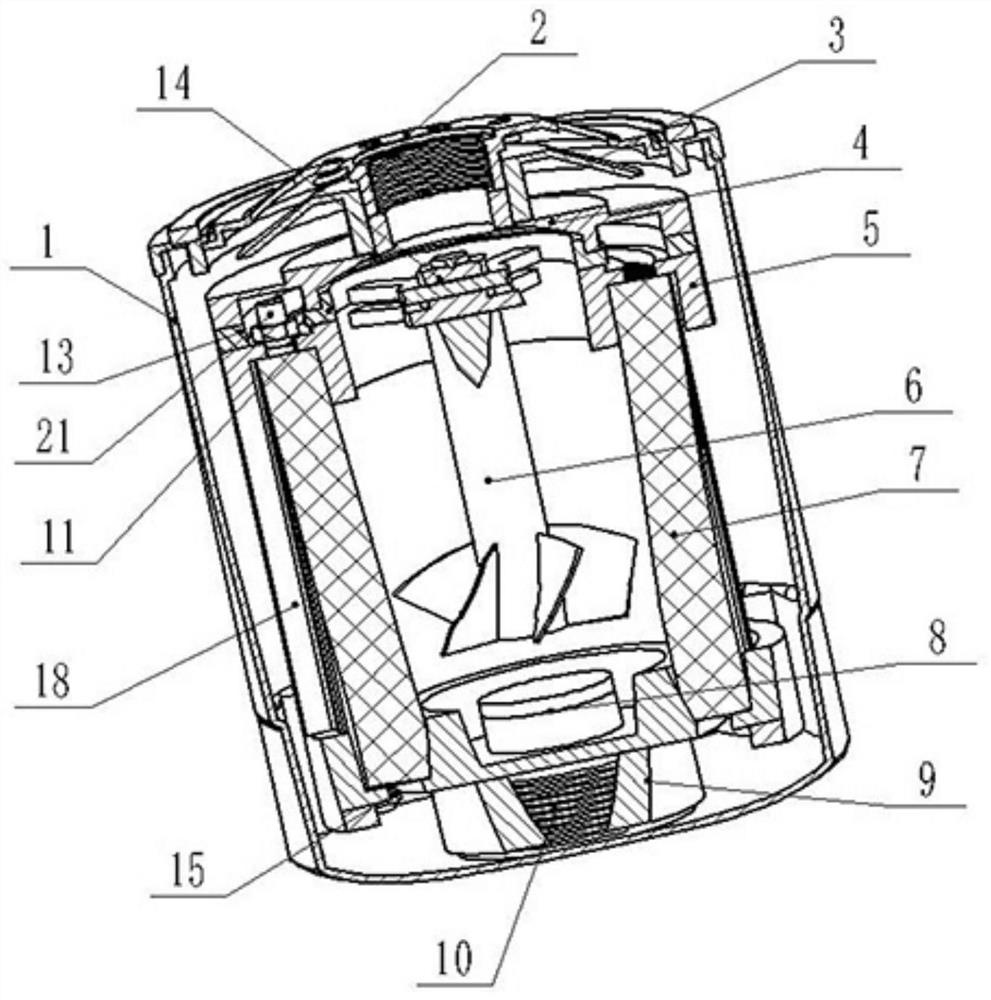

An oil filter capable of automatically replacing filter paper

ActiveCN111577422BExtended service lifeAvoid secondary wearPressure lubricationLubricant mounting/connectionRubber materialProcess engineering

The invention relates to the field of engine oil filtering equipment, in particular to an engine oil filter equipment capable of automatically replacing filter paper. It includes: a shell, a threaded cover, a check valve, an upper end cover, a filter element, a power rod, a secondary filter, and a planetary mechanism; the shell is cylindrical, and an overall space is formed by a threaded cover; the check The valve is made of rubber material and installed on the threaded cover to prevent oil from flowing backward. The invention has a simple structure. By storing the clean filter paper in advance and unfolding it when needed, the service life of the oil filter can be effectively improved and secondary wear can be prevented.

Owner:蚌埠嘉和隆鑫滤清器有限公司

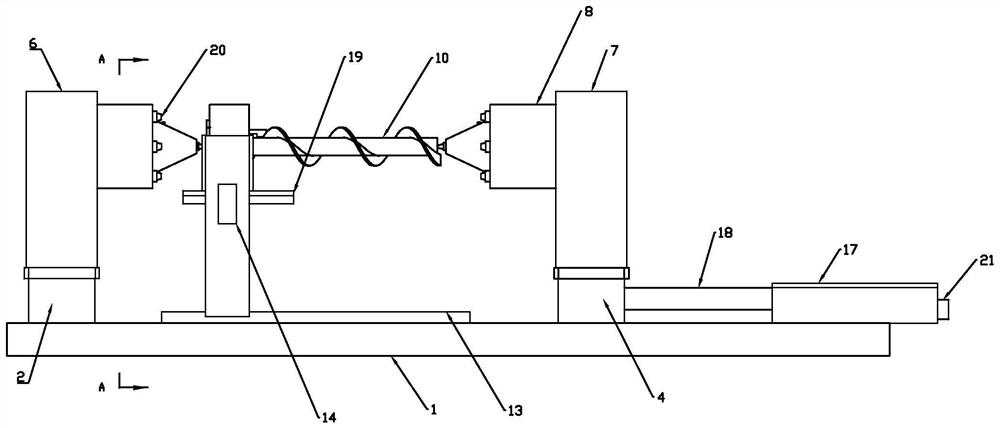

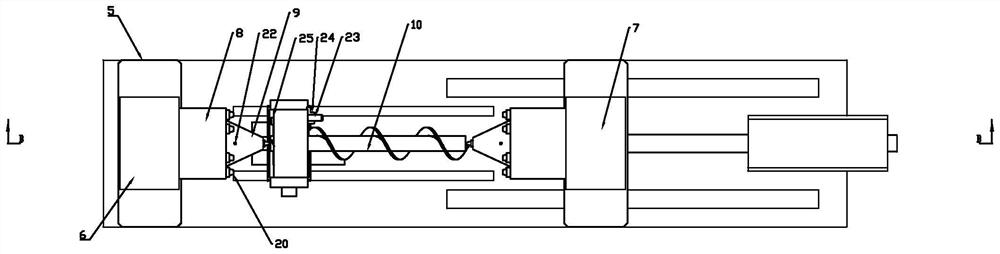

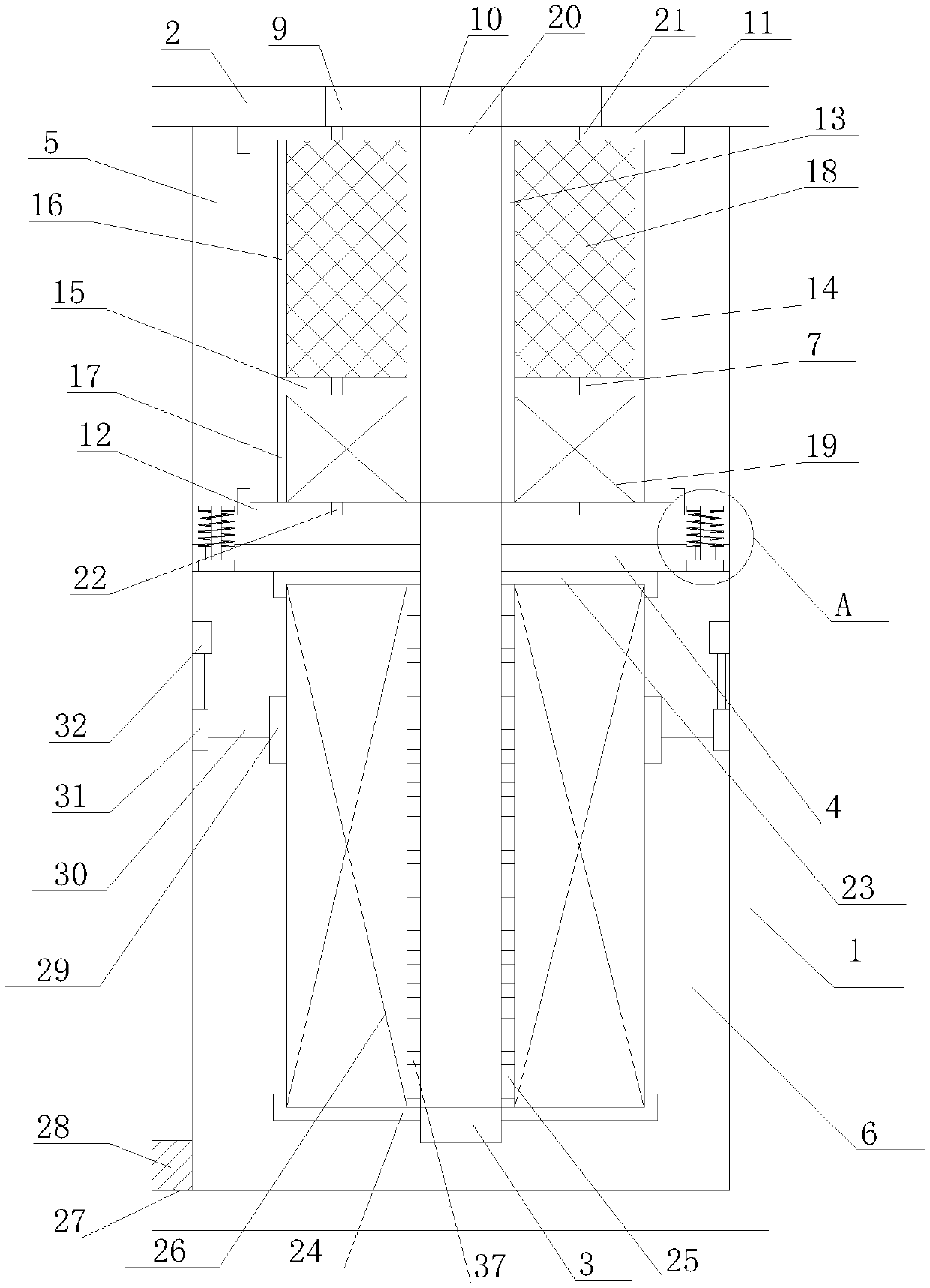

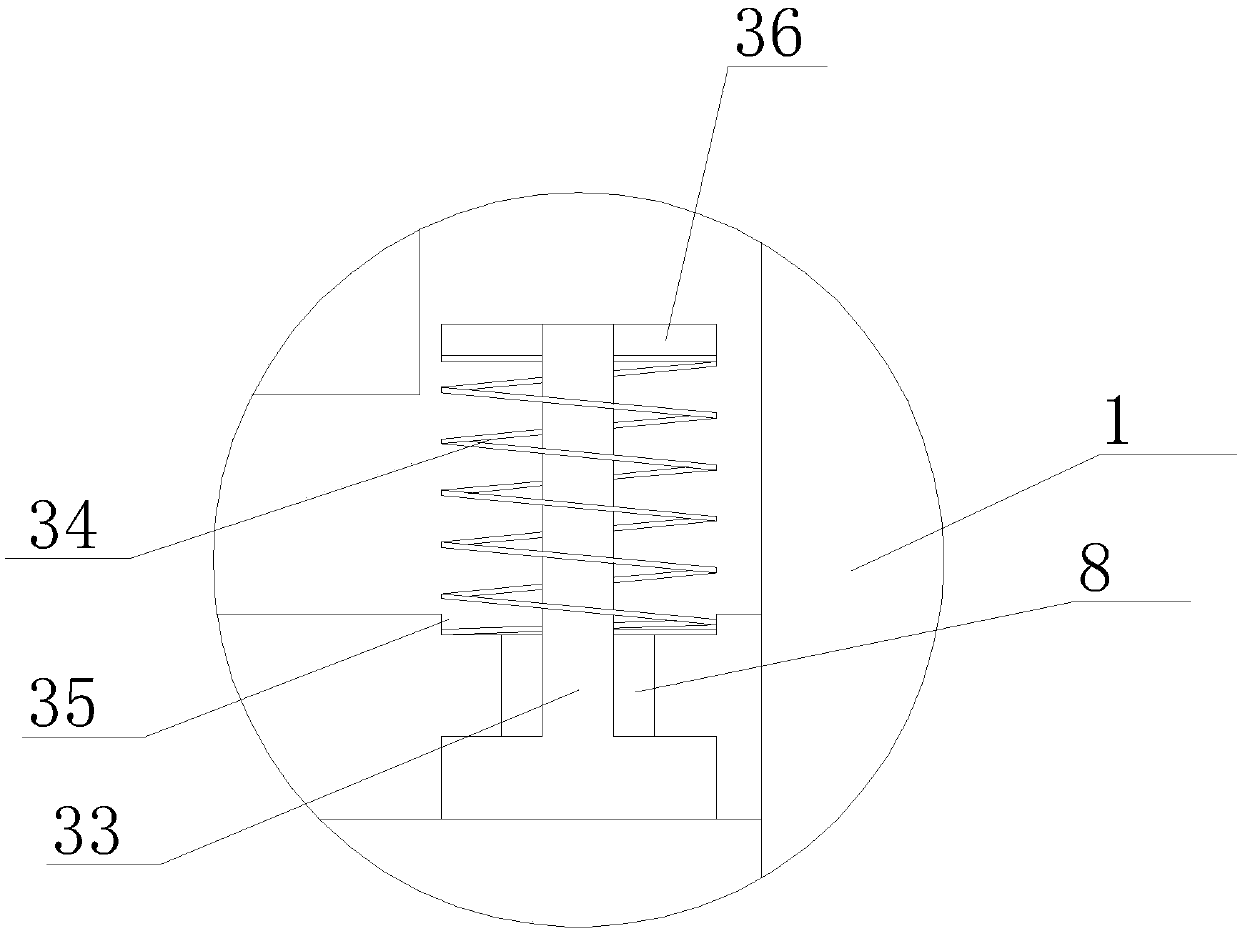

Injection molding machine screw maintenance equipment

ActiveCN114851030AAchieve initial cleanupAvoid malfunctionGrinding carriagesGrinding machinesInjection molding machineMechanical engineering

The invention belongs to the field of injection molding machine maintenance equipment, and relates to injection molding machine screw maintenance equipment which comprises a rack base, a driving box is fixedly arranged on one side of the rack base, a clamping box is slidably arranged on one side of the driving box on the rack base, a roller is rotatably arranged on the face, adjacent to the driving box, of the clamping box, and a clamping conical barrel is slidably arranged on the outward side of the roller. Clamping conical heads used for clamping screws are arranged on the end face of the clamping conical barrel in a sliding mode, two first sliding rails are arranged on the portion, between the two clamping conical heads, of the rack base, second sliding blocks are arranged on the first sliding rails in a sliding mode, a limiting ring is fixedly arranged at the adjacent position of the two second sliding blocks, and a grinding bin is rotationally arranged in the limiting ring. A plurality of polishing blocks are evenly arranged on the inner wall of the polishing bin in the circumferential direction, a horn-shaped second oil spraying opening is formed in the center of the end face of each polishing block, and the bottom of each second oil spraying opening is connected with an oil pipe. The surface lubrication protection of the screw rod can be completed in the screw rod surface derusting and polishing process.

Owner:深圳市星凯科技有限公司

engine oil filter

ActiveCN107013283BReduce filter pressureExtend the life cycleLubricant mounting/connectionLubrication pressure controlMetal impuritiesFilter paper

The present invention provides an oil filter for an engine. The oil filter comprises a housing, a bottom plate, a first filter member, a second filter member and a bypass valve. A diaphragm plate is arranged inside the housing and divides the inside of the housing into a first filter cavity and a second filter cavity, the first filter member is arranged inside the first filter cavity, a metal impurity adsorbing material and a first filter paper are arranged between a first barrel body and a second barrel body of the first filter member, the second filter member is arranged inside the second filter cavity, an entrance of the bypass valve is communicated with a second working cavity, and an exit of the bypass valve is communicated with the inner cavity of a third barrel body. According to the oil filter provided by the invention, large-grain metal impurities in the oil are first filtered out by the metal impurity adsorbing material, so as to reduce filtering pressure of the first filter paper and a second filter paper, prolonging a service cycle of the first filter member and the second filter member, and raising the filter effect of the first filter member and the second filter member. And when the metal impurities adsorbed by the metal impurity adsorbing material reach a certain amount, a user only needs to directly replace the metal impurity adsorbing material.

Owner:安徽宏辉滤清器有限公司

Lubricating structure for transmission mechanism

ActiveCN111503253AAchieve lubricationAchieve coolingGear lubrication/coolingDirt cleaningRotational axisDrive shaft

The invention provides a lubricating structure for a transmission mechanism. The transmission mechanism comprises an inner transmission shaft, an outer transmission shaft sleeved on the outside of theinner transmission shaft, and a rotating shaft, wherein the inner transmission shaft and the outer transmission shaft are connected by a key, and the rotating shaft is linked to the inner transmission shaft or the outer transmission shaft; the lubricating structure comprises an oil collecting cylinder, an oil return channel, a first oil hole and a second oil hole; the oil collecting cylinder is arranged in the inner transmission shaft and has an oil inlet channel, and the oil inlet channel has an inner conical surface; the oil return channel is arranged between the inner transmission shaft and the outer transmission shaft, and the key is located on the path of the oil return channel; the first oil hole is arranged on the inner transmission shaft and connected to the oil return channel; the second oil hole is arranged on the oil collecting cylinder and connected to the oil inlet channel, an oil collecting groove is formed between the outer side wall of the oil collecting cylinder and the inner side wall of the inner transmission shaft, and the oil collecting groove is respectively connected to the first oil hole and the second oil hole; an oil throwing structure, which can throw the lubricating oil in the oil pool into the oil inlet channel, is provided on the outside of the rotating shaft.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Part grinding device based on industrial machinery

InactiveCN108927730AReduce mistakesSolve the problem of continuous grindingGrinding carriagesGrinding machinesElectric machineryEngineering

The invention discloses a part grinding device based on industrial machinery. The part grinding device comprises a base, wherein a driving box and an outer barrel are welded to the top end of the base, the driving box is located on one side of the outer barrel, a driving gear is installed in the driving box, a first motor is installed on the top end of the driving box, the first motor is rotatablyconnected with the driving gear by virtue of a rotating shaft, a discharge hopper is welded to the top end of the outer barrel, a positioning ring is welded to the inner wall of the outer barrel, aninner barrel is connected to the interior of the positioning ring in a sliding mode by virtue of a sliding block and a chute, and a driven gear is welded to the bottom end of the inner barrel. In order to solve the problems of inconvenience in continuous grinding and large grinding error of a traditional grinding device in a grinding process, the invention provides the design of power driven automatic grinding, a workpiece is automatically ground by automatically rotating the inner barrel, and the grinding precision of the workpiece is limited by arranging grinding steel balls of different accuracy gradients.

Owner:潘素云

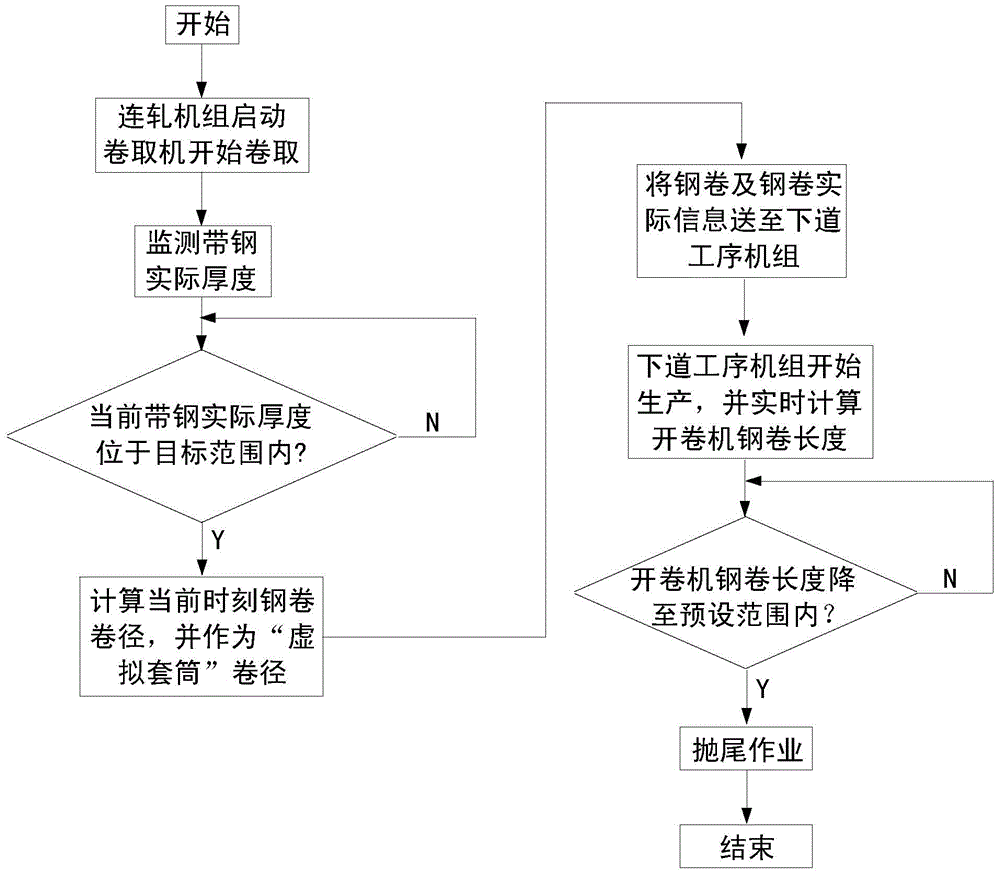

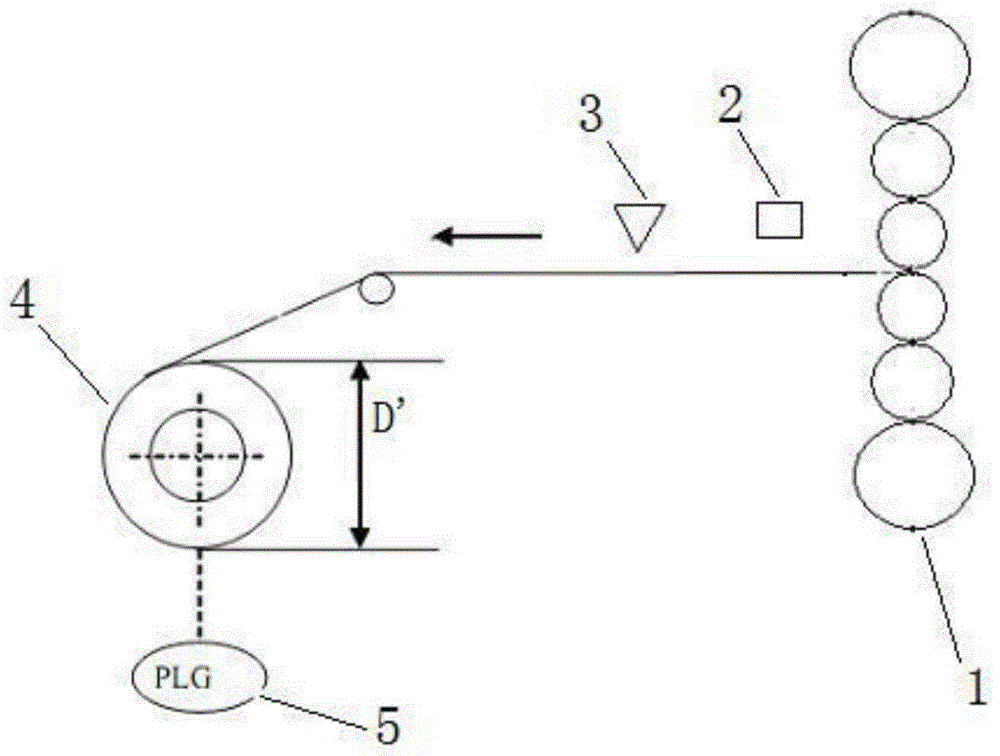

The control method for starting the cold tandem mill regardless of the small coils

ActiveCN104826873BAvoid hidden dangers in production qualityReduce tail throwMetal rolling arrangementsRoll speed control deviceStrip steelContinuous rolling

The invention relates to a control method for starting a cold tandem rolling unit regardless of small coils, comprising: coiling strip steel by an exit coiler of the cold tandem rolling unit; monitoring the actual thickness of the strip steel, and calculating the coil diameter of a "virtual sleeve" when the standard is reached; The unit in the next process calculates the length of the steel coil of the uncoiler in real time in combination with the coil diameter of the "virtual sleeve", and performs the tail throwing operation when it reaches the standard. The control method of the present invention does not need to increase any equipment investment, so that the rolling mill can be started without coil separation, and at the same time, it will not affect the normal production of the next process unit, which is conducive to improving the production efficiency of cold rolling, reducing the production cost per ton of steel and reducing the number of scrapped cold rolling. .

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Deslagging device of fan coal mill

PendingCN113289757AEasy transferSolve difficult-to-clean puzzlesGrain treatmentsLoading/unloadingSlagCoal gangue

The invention discloses a deslagging device of a fan coal mill, and belongs to the technical field of machinery. The deslagging device comprises a deslagging pipeline, a deslagging pneumatic door, a material box, a weighing device and a transfer device; the deslagging pipeline is arranged below an iron accumulation groove of a shell, the deslagging pneumatic door is connected to the deslagging pipeline, the material box is connected to the lower part of the deslagging pipeline, and the weighing device is arranged on the material box; when the weighing device gives out a full box alarm, the deslagging pneumatic door is controlled to act, the material box is conveyed to a dumping place through the transfer device, and dumping of materials is completed. Compared with an original deslagging mode that slag is stacked in an iron accumulation groove, the deslagging device device of the fan coal mill achieves the function of discharging slag such as iron blocks and coal gangue which cannot be ground in the coal mill out of the machine shell in time, and secondary abrasion of the slag, which cannot be ground, to a beating wheel and a lining plate is avoided; and in addition, the deslagging device of the fan coal mill can easily transfer materials through the transfer device, and the problem that an iron accumulation groove of an original fan coal mill is difficult to clean is solved.

Owner:CHANGCHUN POWER GENERATION EQUIP PLANT +2

A kind of automobile disc brake system

ActiveCN109915511BImprove cooling effectAvoid secondary wearBrake actuating mechanismsSlack adjustersControl theoryMechanical engineering

The invention provides an automobile disc-type brake system, and belongs to the technical field of automobile parts. Brake ends located at the two sides of a brake disc are arranged at the two ends ofa brake caliper clamp separately; each brake end is provided with a valve hole communicating with a hydraulic channel and vertical to the brake disc; a brake piston is slidably connected into each valve hole; a return spring is connected between the outer end of each brake piston and the inner wall of the hydraulic channel; a guide hole is formed in the inner end of each brake piston; a torsionalspring sleeving an installation shaft is arranged between two bearings; the two ends of the torsional spring are connected with the inner walls of the guide holes and the outer wall of the installation shaft separately; a waist-shaped installation plate parallel to the brake disc is arranged at the other end of the installation shaft; and two circular brake sheets are fixedly arranged on the inner side surface of the installation plate. In a return state of the brake pistons, the connection line between the two brake sheets on the same installation plate forms an inclination angle of less than 90 degrees with the radial line of the brake disc. The automobile disc-type brake system has the advantages of being capable of providing pre-brake before brake, and the like.

Owner:HUBEI UNIV OF SCI & TECH

Lubrication structure of transmission mechanism

ActiveCN111503253BAchieve lubricationAchieve coolingGear lubrication/coolingDirt cleaningRotational axisDrive shaft

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Derusting equipment for the inner wall of steel pipes for construction

ActiveCN109129062BReduce shakingWon't wear outRevolution surface grinding machinesArchitectural engineeringWater flow

The invention relates to the technical field of building equipment, in particular to equipment for removing rust on the inner wall of a steel pipe for building, and aims to solve the technical problemthat no relatively good equipment can be adopted for removing dust on the inner wall of a steel pipe. In order to solve the above technical problem, the equipment for removing the rust on the inner wall of the steel pipe for building is provided. The equipment for removing the rust on the inner wall of the steel pipe for building comprises a baseplate, wherein a high-pressure water pump and a steel pipe supporting table are fixedly connected with the top of the baseplate from left to right; a water delivery pipe is fixedly connected with a water outlet of the high-pressure water pump througha flange; a steel pipe fixing device is fixedly connected with the end, far away from the high-pressure water pump, of the water delivery pipe; a ball storage pipe is welded to a movable port at the top of the water delivery pipe; and grinding balls are placed inside the ball storage pipe. According to the equipment for removing the rust on the inner wall of the steel pipe for building, the occupied area is reduced, so that more convenience can be brought to people in the handling and carrying process; the force of waterflow to drive the grinding balls to rotate is relatively small, so that the steel pipe can be protected against relatively severe abrasion; and the secondary abrasion caused by scrap iron to the inner wall of the steel pipe can be avoided and the loss of the steel pipe canbe reduced.

Owner:浙江杭海镀锌钢管有限公司

Oil filter for engine

ActiveCN107013283AReduce filter pressureExtend the life cycleLubricant mounting/connectionLubrication pressure controlFilter paperMetal impurities

The present invention provides an oil filter for an engine. The oil filter comprises a housing, a bottom plate, a first filter member, a second filter member and a bypass valve. A diaphragm plate is arranged inside the housing and divides the inside of the housing into a first filter cavity and a second filter cavity, the first filter member is arranged inside the first filter cavity, a metal impurity adsorbing material and a first filter paper are arranged between a first barrel body and a second barrel body of the first filter member, the second filter member is arranged inside the second filter cavity, an entrance of the bypass valve is communicated with a second working cavity, and an exit of the bypass valve is communicated with the inner cavity of a third barrel body. According to the oil filter provided by the invention, large-grain metal impurities in the oil are first filtered out by the metal impurity adsorbing material, so as to reduce filtering pressure of the first filter paper and a second filter paper, prolonging a service cycle of the first filter member and the second filter member, and raising the filter effect of the first filter member and the second filter member. And when the metal impurities adsorbed by the metal impurity adsorbing material reach a certain amount, a user only needs to directly replace the metal impurity adsorbing material.

Owner:安徽宏辉滤清器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com