Frictional wear testing machine for hard alloy or wear-resistant coating and frictional wear testing method

A friction and wear test and wear-resistant coating technology, applied in the field of friction and wear, can solve the problems of high manufacturing cost, large space occupation, long detection time, etc., and achieve the effect of short test time, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and the purpose of the present invention. within the scope covered.

[0035] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the...

Embodiment 1

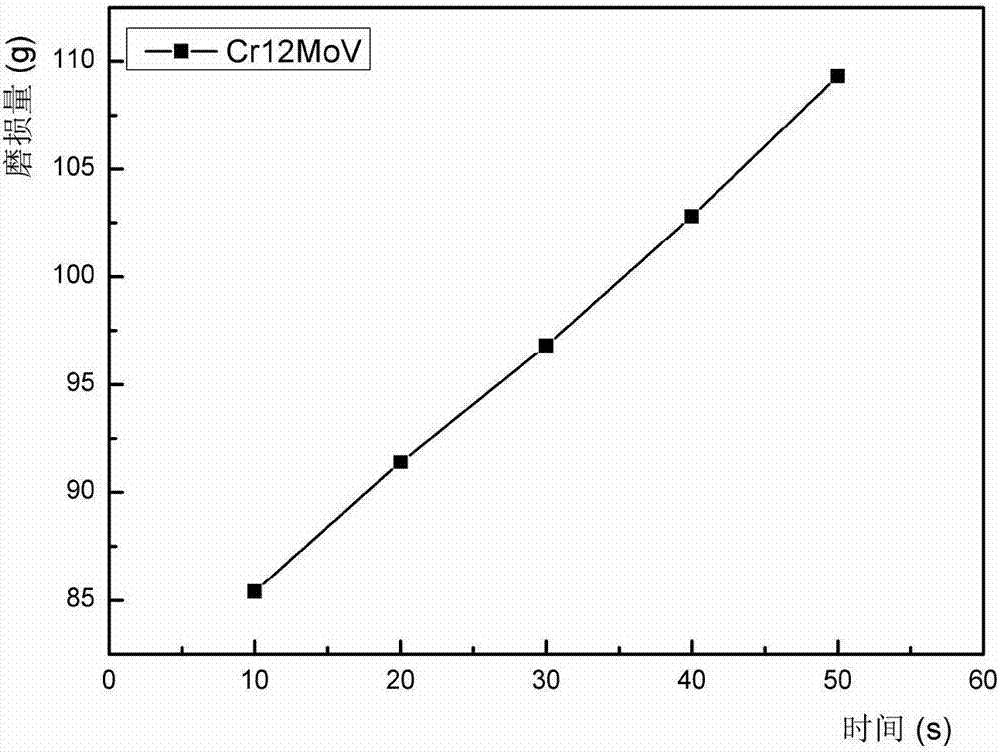

[0047] Select Cr 12 MoV is used as the sample to be tested, and the diamond grinding disc is used for grinding to speed up the experimental process. The friction and wear test method for cemented carbide or wear-resistant coating is as follows:

[0048] Step 1: Weigh the initial mass m of the sample to be tested with an electronic balance 0 5114.4 mg;

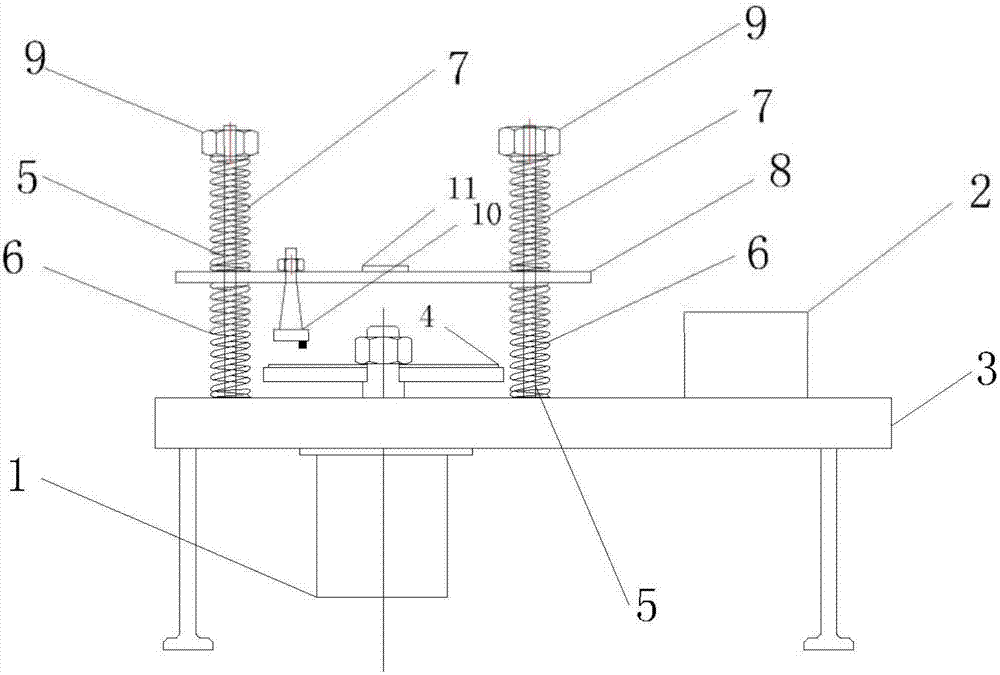

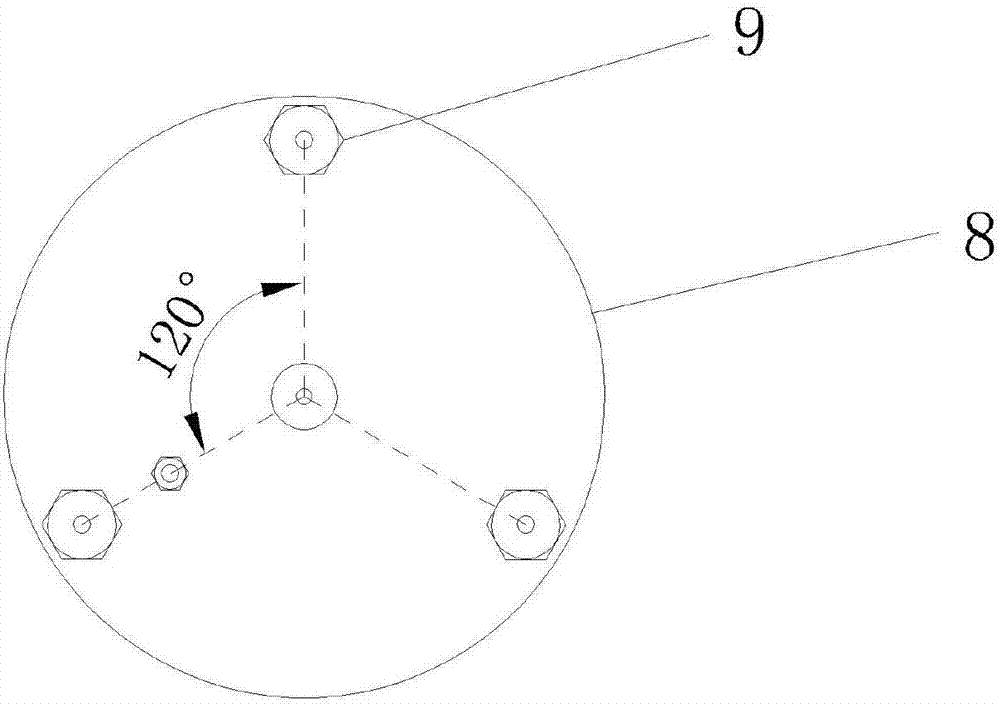

[0049] Step 2: Clamp the sample to be tested to the fixture of the friction and wear testing machine, and adjust the length of the support spring and the loading spring through the adjustment nut to make the upper splint level. At this time, the sample to be tested cannot be in contact with the abrasive tool; adjust the frequency conversion Reduce the rotation frequency of the grinding disc to 100-200 rpm, slowly adjust the adjusting nut, compress the spring, keep the upper splint horizontal during the adjustment process, until the sample to be tested is in contact with the grinding disc, turn off the switch, the state at thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com