Laser-assisted horizontal three-dimensional ultrasonic elliptical vibration milling machine equipment and its working method

A laser-assisted, elliptical vibration technology, applied to milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problem of unsolvable micro-motion unit decoupling, difficult to accurately control elliptical vibration trajectory, amplitude and preset value deviation, etc. problem, to achieve the effect of inhibiting the accumulation of nodules and burrs, reducing the electrochemical influence, reducing the cutting force and cutting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

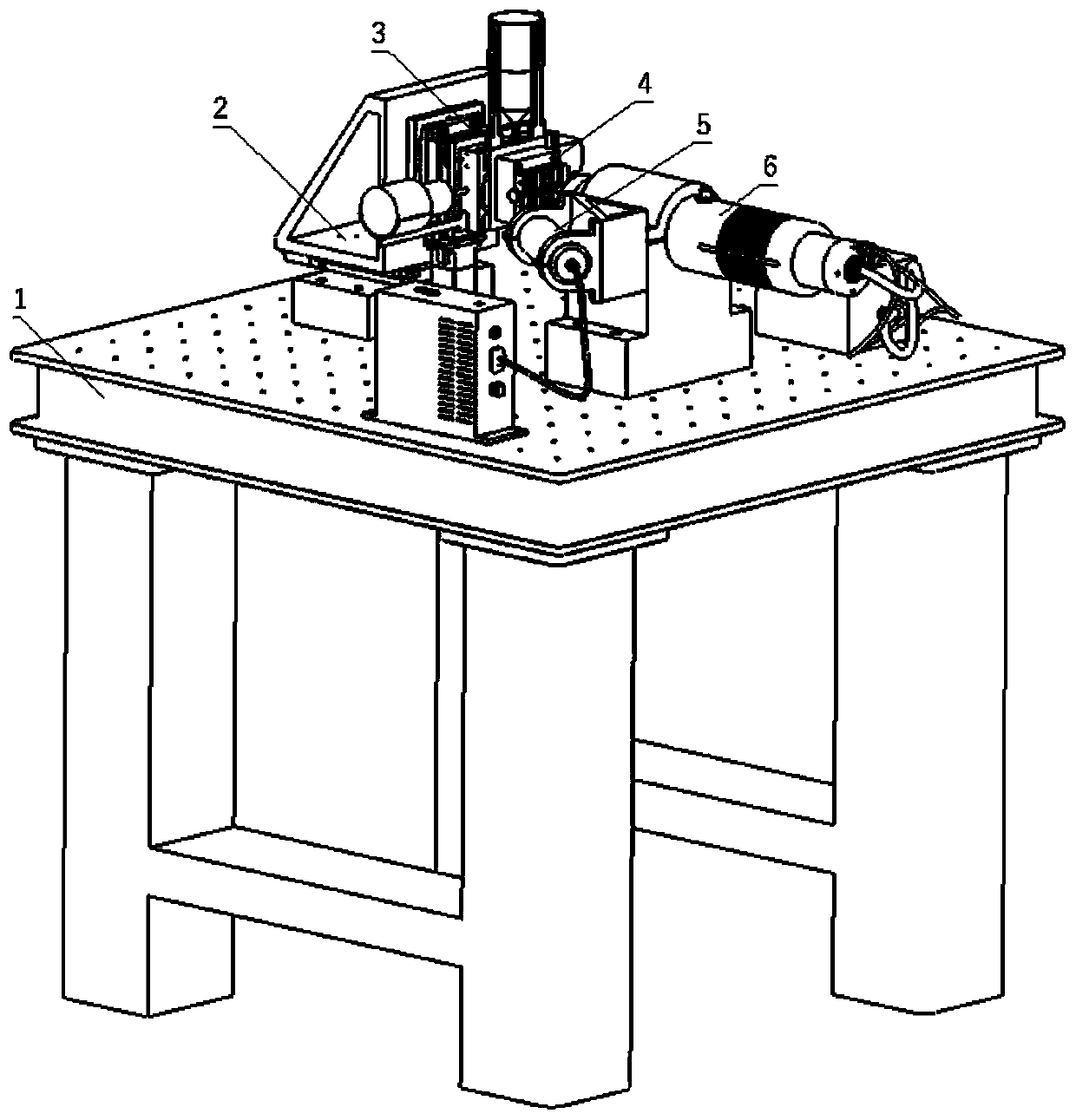

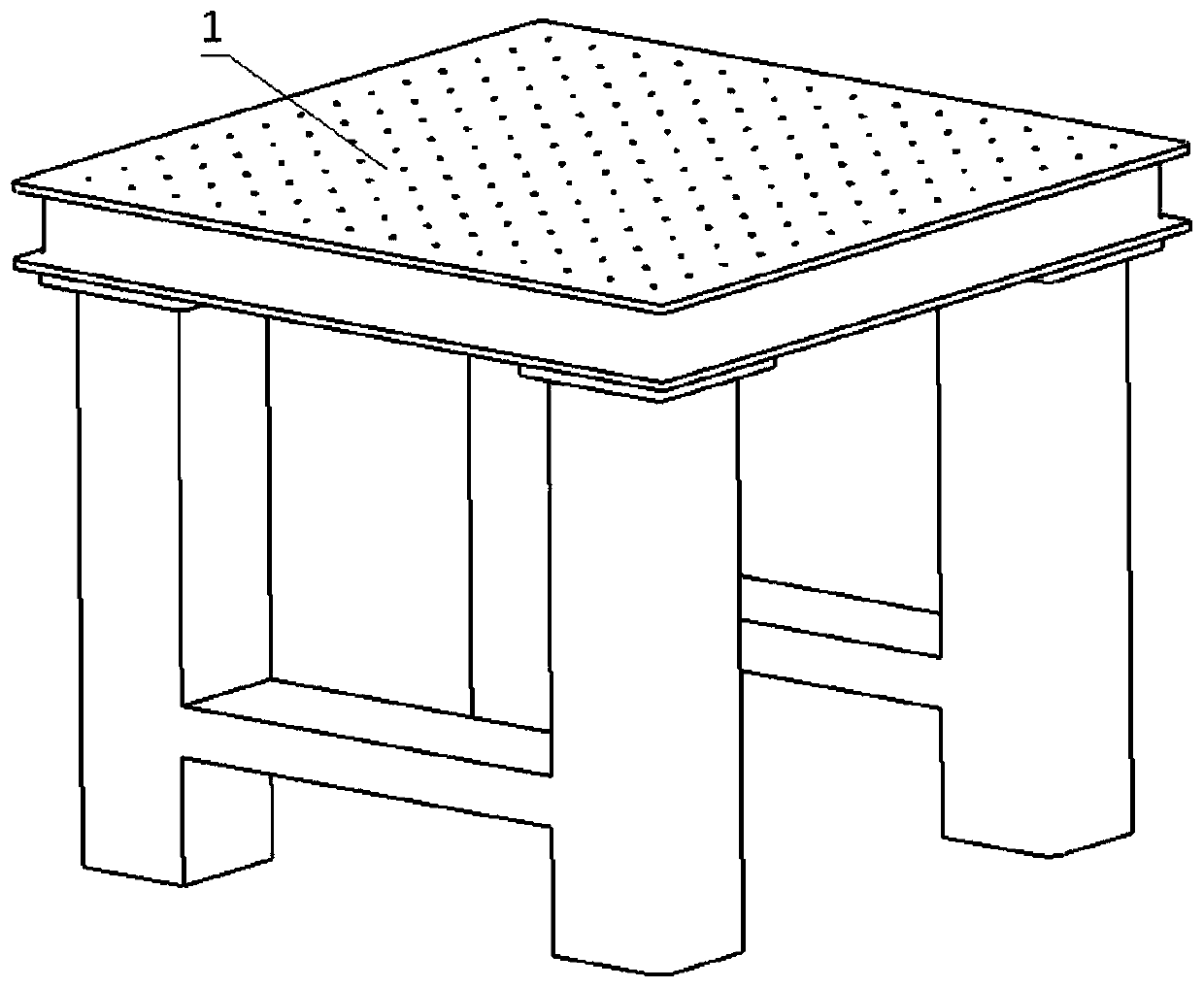

[0040]Laser-assisted horizontal three-dimensional ultrasonic elliptical vibration milling machine equipment and its working method, such as figure 1 with figure 2 As shown, its structure consists of an air-floating platform 1, an XYZ moving assembly 2, a micro-motion unit 3, a workpiece fixture 4, a laser-assisted processing device 5, an ultrasonic electric spindle assembly 6 and other auxiliary components. The air-floating platform 1 is the implementation basis of the present invention, and the XYZ moving assembly 2, the micro-motion unit 3, the workpiece fixture 4, the laser auxiliary processing device 5, the ultrasonic electric spindle assembly 6 and other auxiliary parts are all based on this.

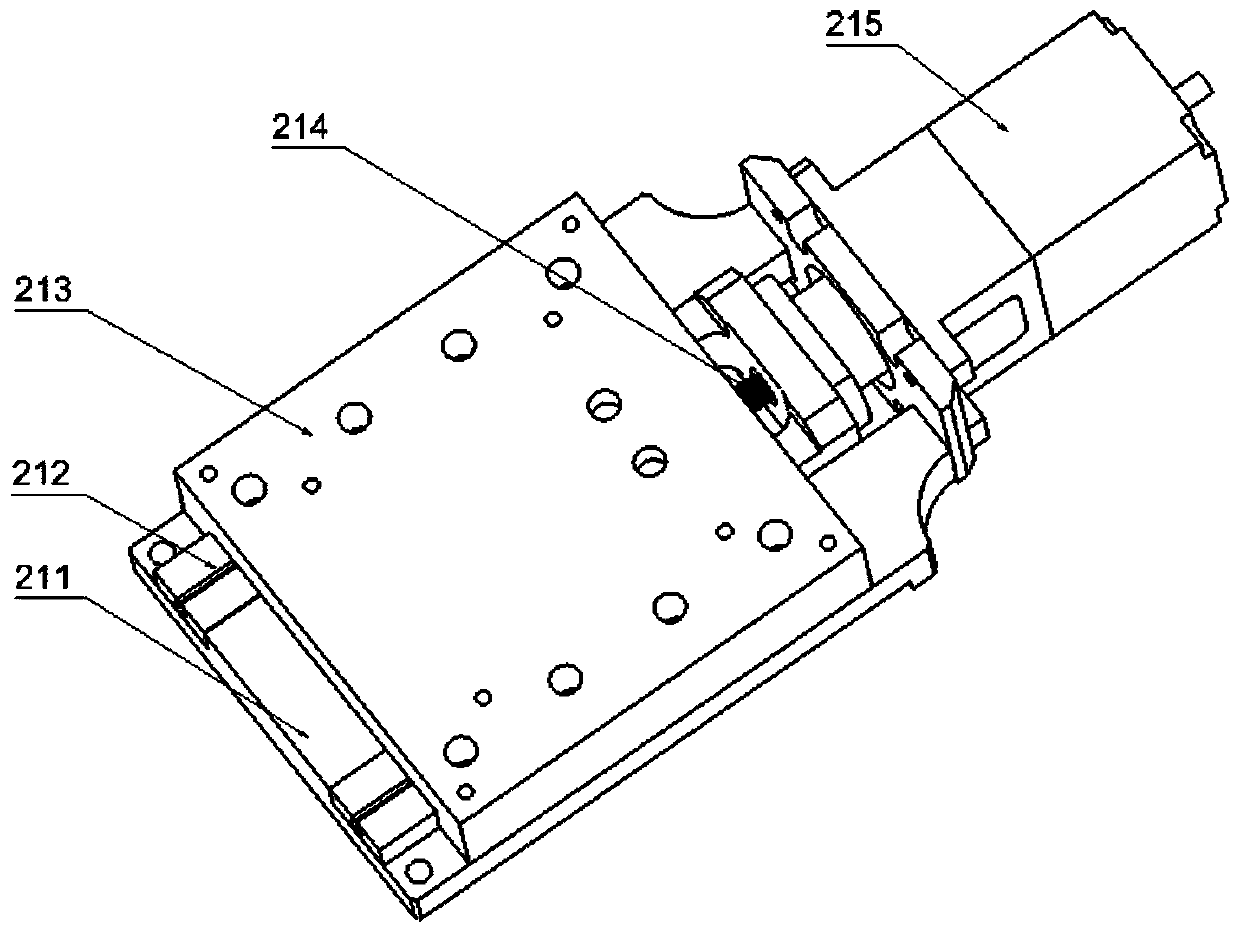

[0041] Such as image 3 As shown, the X-direction mobile unit 202, the Y-direction mobile unit 206 and the Z-direction mobile unit 205 all include a base plate 211, a guide rail 212, a slider 213, a lead screw 214 and a motor 215, and the motor 215 is connected to the lead screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com