Patents

Literature

169results about How to "Reduce filter pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making PH value-sensitive polyvinylidene fluoride hollow fibre intelligent film and products thereby

InactiveCN1594405ASimple processEase of industrial implementationSemi-permeable membranesWater bathsHollow fibre

Disclosed is a method for making pH sensitive PVDF hollow fiber intelligent film and products made thereby, wherein the making process comprises the steps of, (1) steeping the film in pure water for 24 hours, (2) preparing 10-20% alkali solution, and charging 3-4gl / L of tetrabutylammonium bromide, charging immersed film in alkali solution, heating by water bath, (3) preparing 1-2 mol / L of AAC solution, charging dimethyl formamide solution by 40-50ml / L, mixing uniformly, charging alkali-treated film in the mixed solution, steeping 10-20 minutes at room temperature, preparing solution of crosslinking agent 0.01-0.09mol / L and K2S2O3 0.1-0.3g, charging the readily made film into the solution, filling N2 and sealing, water-bathing, heating and washing with deionized water, the crosslinking agent is MBAA or diacrylic acid ethylene glycol ester.

Owner:TIANJIN POLYTECHNIC UNIV

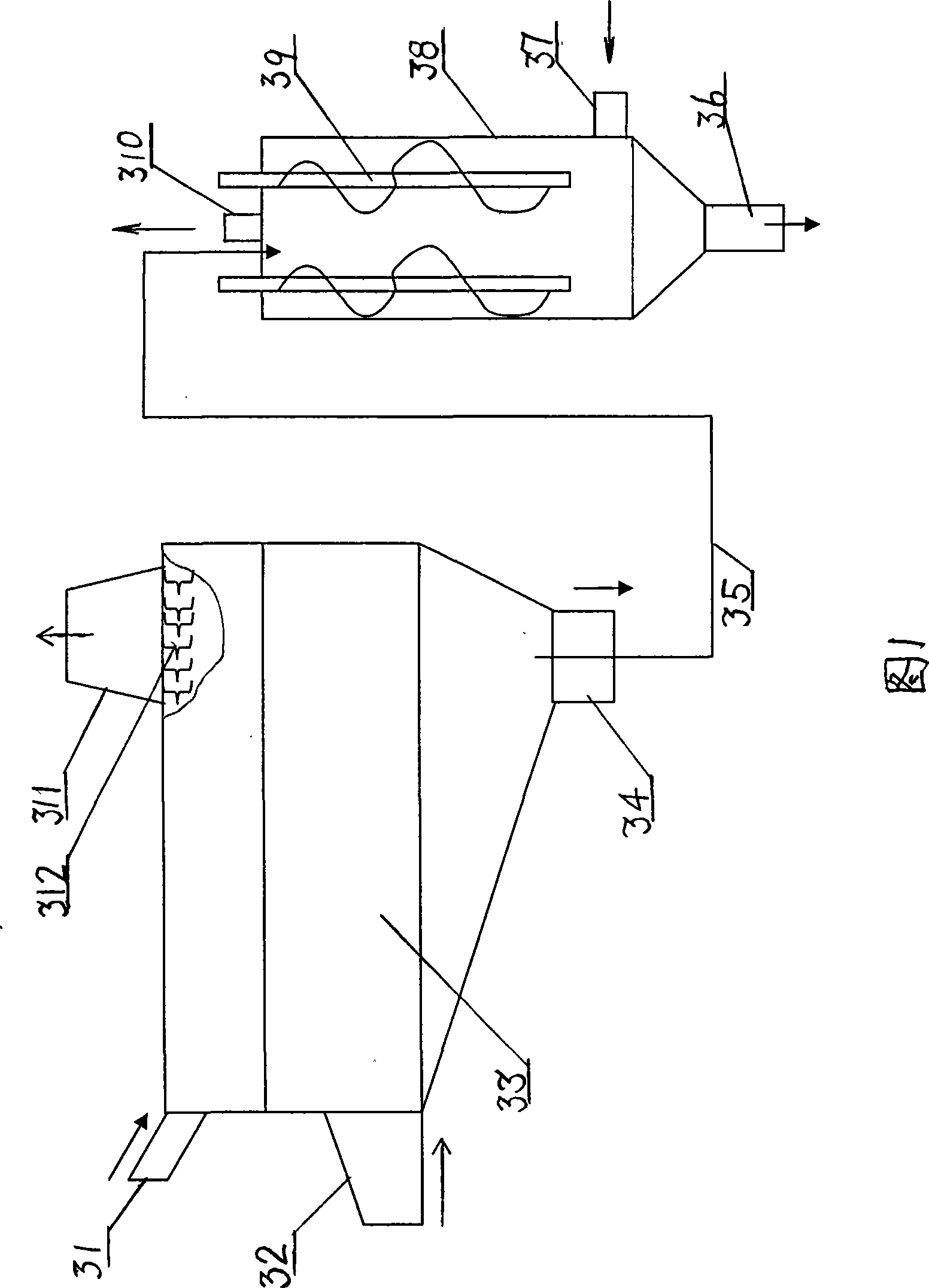

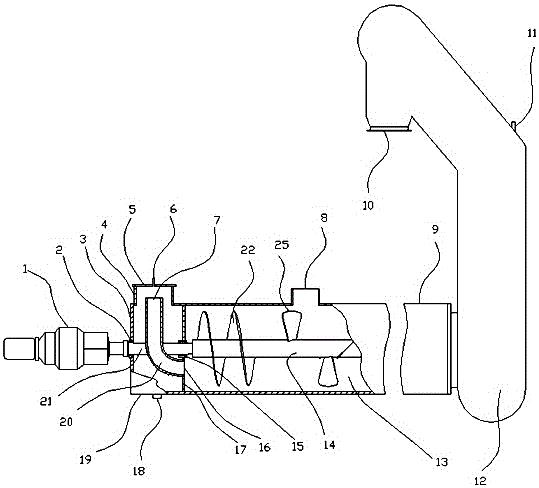

Method for producing terylene POY filament in scale by recycling PET bottle sheet material

ActiveCN101435113ASolve the problem of water content inconsistencyHigh meshSolid waste disposalMelt spinning methodsEngineeringBottle

The invention provides a method for producing polyester POY filament in scale by recycling PET bottle chip. Recycled waste PET bottles are crushed into flaky bottle chip, dried after cleaning, and then sent into a crystallizing bed body; under the action of hot air entering the crystallizing bed body, crystallization is carried out, a crystallizing layer is formed on the bottle chip surface, and then the bottle chip is sent into a drying tower for drying; the dried bottle chip enters a screw extruder for melt extrusion, and the obtained melt is sent into a two-stage filtering device for filtering and then enters a spinning box; and a high-speed spinning process is adopted for spinning to produce the polyester POY filament. The method for producing the polyester POY filament adopts a filling type drying mode, the drying is even and the operating cost is low; a screw mixer is arranged in the drying tower, which solves the problem of 'arching' that happens to the recycled PET bottle chip during the drying process; and the two-stage filtering device is adopted, which ensures the filtering quality. Therefore, the high-end product-polyester POY filament can be continuously produced in large scale.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

Method for making temperature-sensitive polyvinylidene fluoride hollow fibre intelligent film and products thereby

InactiveCN1594404ASimple processEase of industrial implementationSemi-permeable membranesFiberHollow fibre

Disclosed is a method for making temperature-sensitive PVDF hollow fibre intelligent film and products made by chemical grafting and copolymerization of NIPA on PVDF film surface, and the making process comprises the steps of, (1) steeping the film in pure water for 24 hours, (2) preparing 10-20% alkali solution, and charging 3-4gl / L of tetrabutylammonium bromide, charging immersed film in alkali solution, water-bathing, heating and washing for later use, the alkali solution is one of KOH, NaOH or LiOH, (3) preparing 1-2 mol / L of NIPA solution, charging dimethyl formamide solution by 40-50ml / L, mixing uniformly, charging alkali-treated film in the mixed solution, steeping at room temperature, preparing solution of crosslinking agent 0.01-0.09mol / L and K2S2O3 0.1-0.3g, charging the readily made film into the solution, filling N2 and sealing, water-bathing, heating and washing with deionized water, the crosslinking agent is MBAA or diacrylic acid ethylene glycol ester.

Owner:TIANJIN POLYTECHNIC UNIV

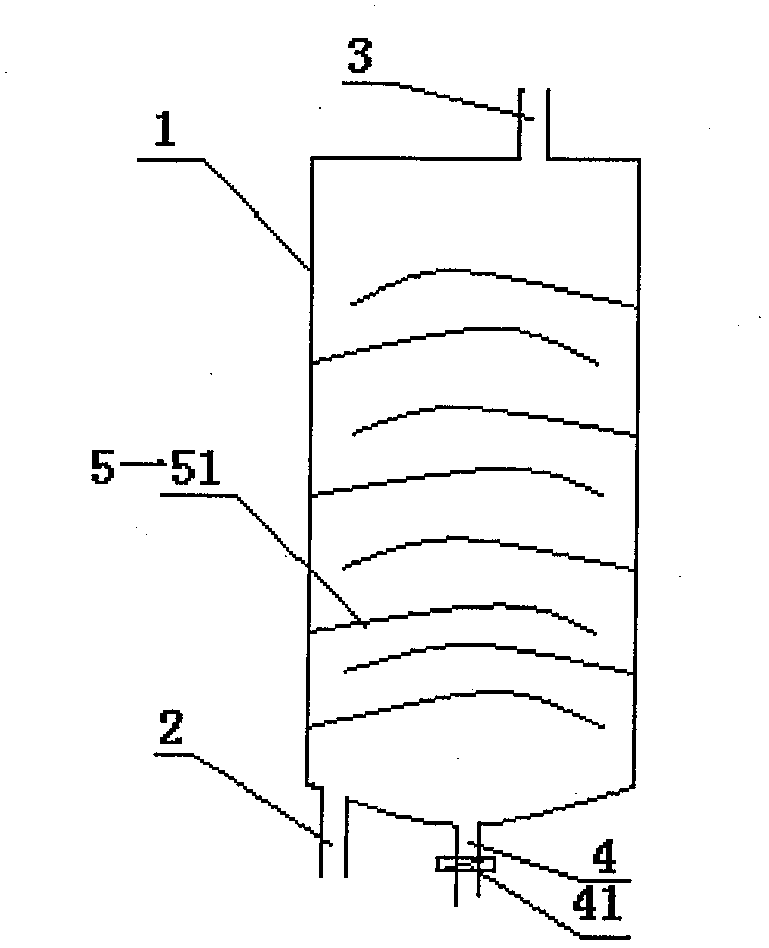

Method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on scale

ActiveCN102605454ASolve the problem of water content inconsistencyGuaranteed Filtration QualityFilament forming substance formingMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate

The invention provides a method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on a scale. The method comprises the steps of crushing the recycled PET bottles into chips, washing and drying, sending into a crystallization bed body for crystallization, forming crystallization layers on the surfaces of the bottle chips, sending the crystallizedbottle chips into a drying tower which is provided with a pair of spiral agitators, leading the dried bottle chips to enter a screw extruder for melting and extrusion, sending the obtained melt into a two-stage filtration device consisting of a coarse filter, a fine filter and a pressure pump between the coarse filter and the fine filter for filtration, leading the melt which is filtrated by two stages to enter a liquid phase tackifying kettle, conducting polycondensation reaction in the liquid phase tackifying kettle, leading the melt after being subjected to liquid phase tackifying to entera spinning box, and spinning by adopting a high-speed spinning process, thus obtaining the industrial polyester filament. In the method for producing the industrial polyester filament, the liquid phase tackifying step is added in the production process, so that the problems of low viscosity and poor stability of the PET bottle chip melts are solved.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

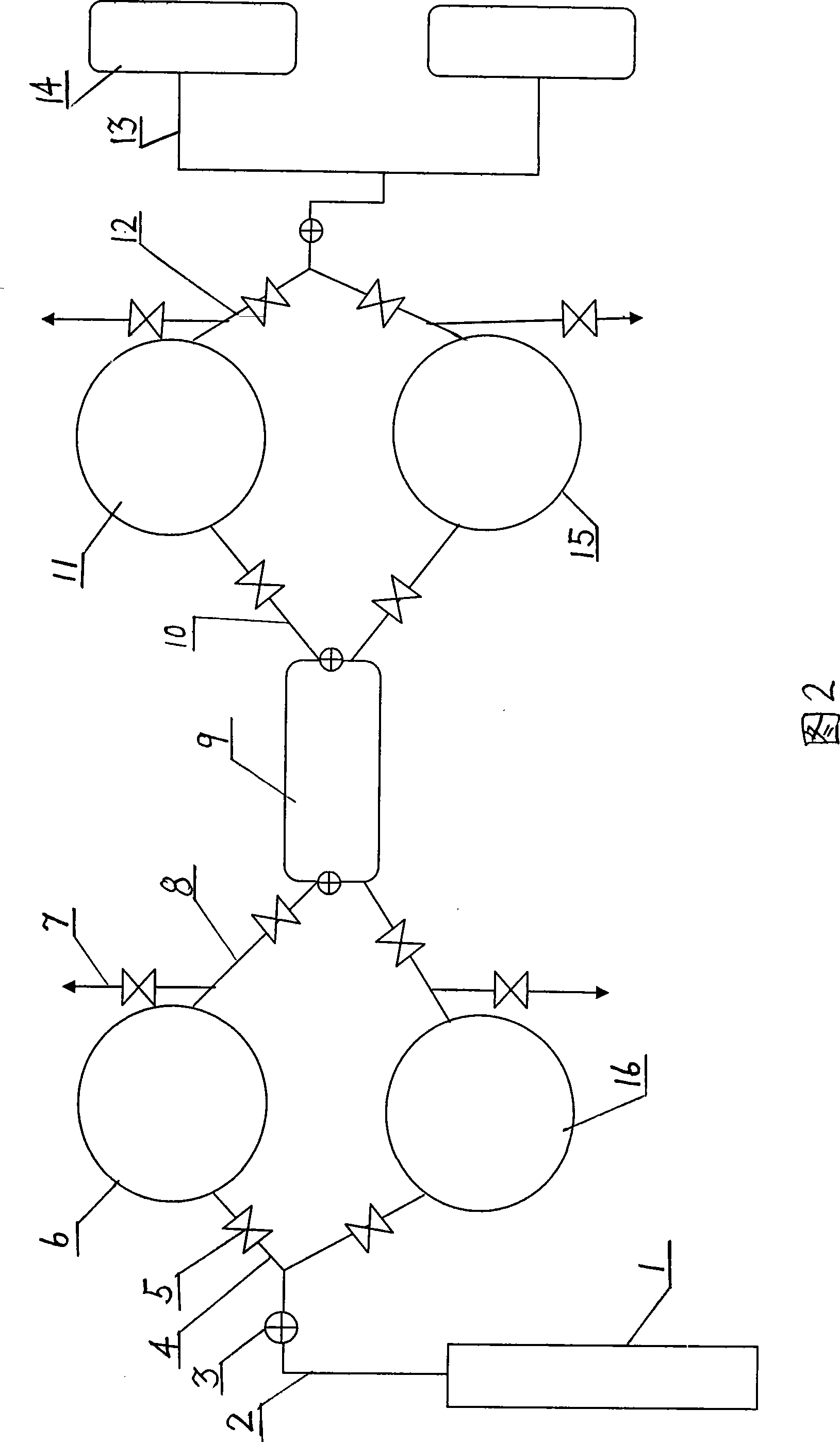

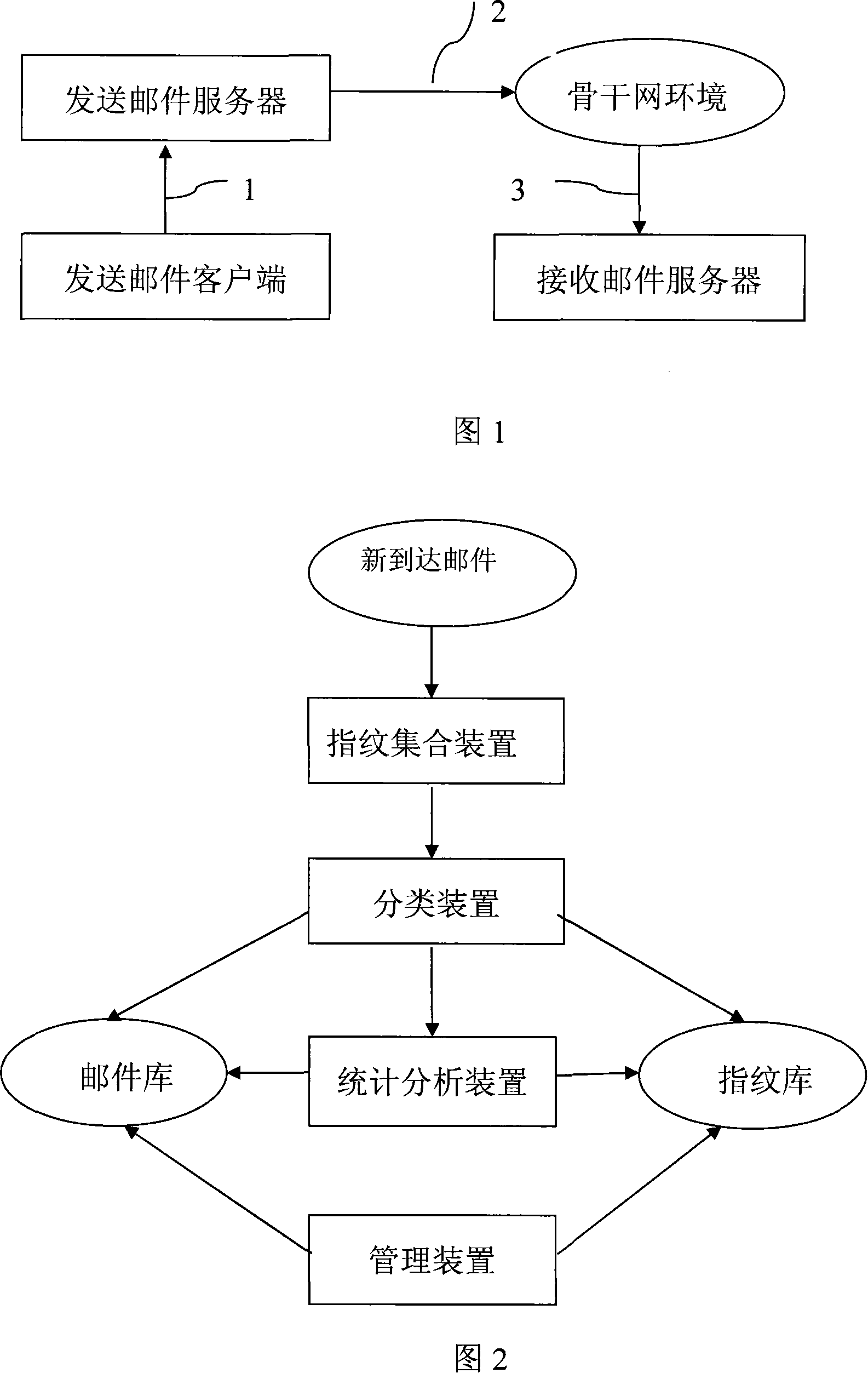

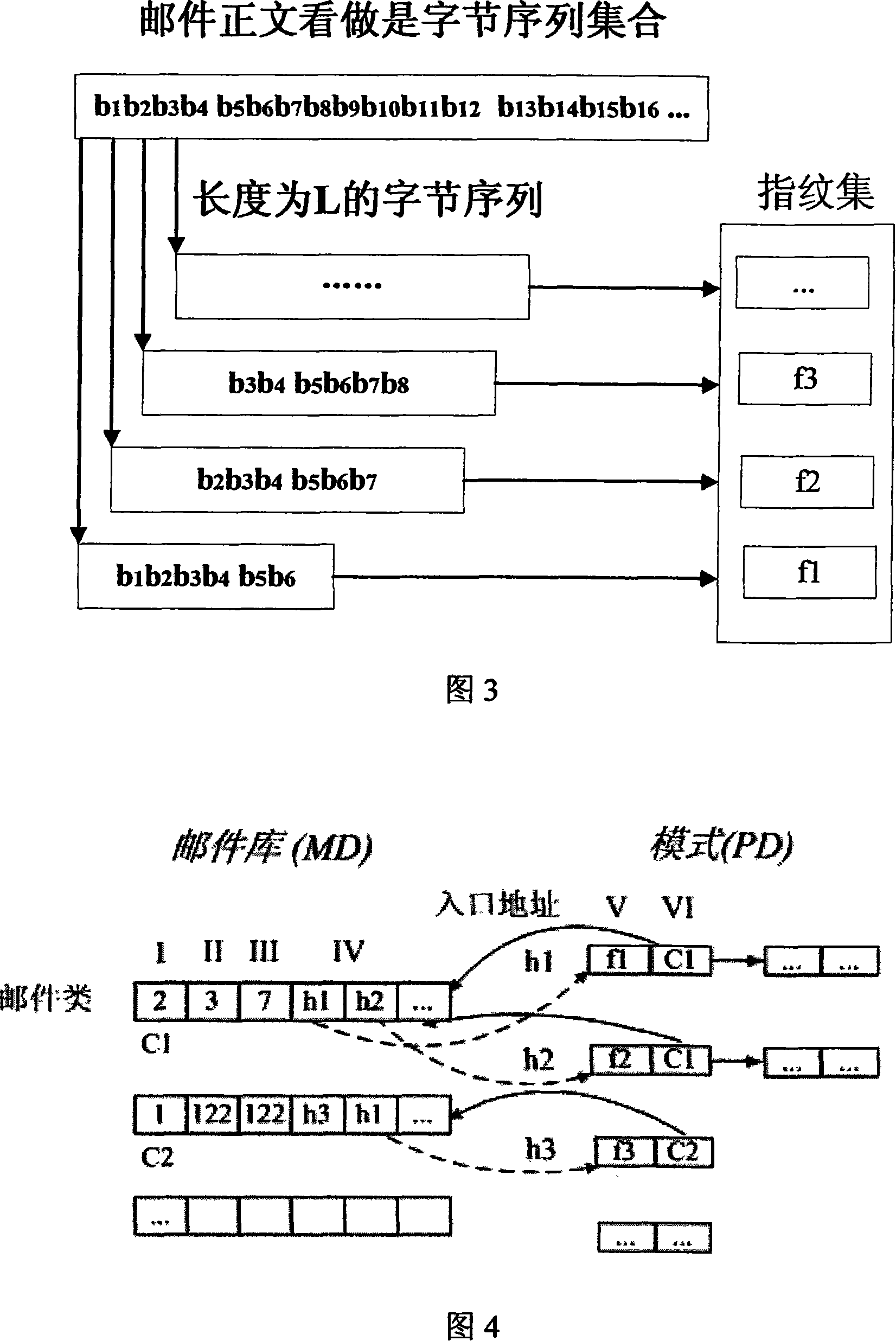

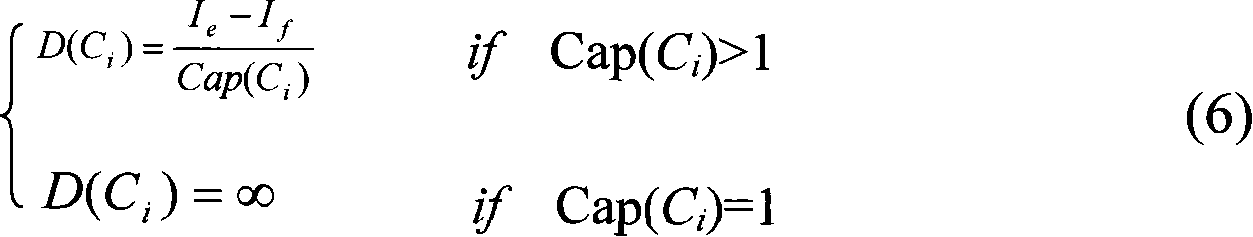

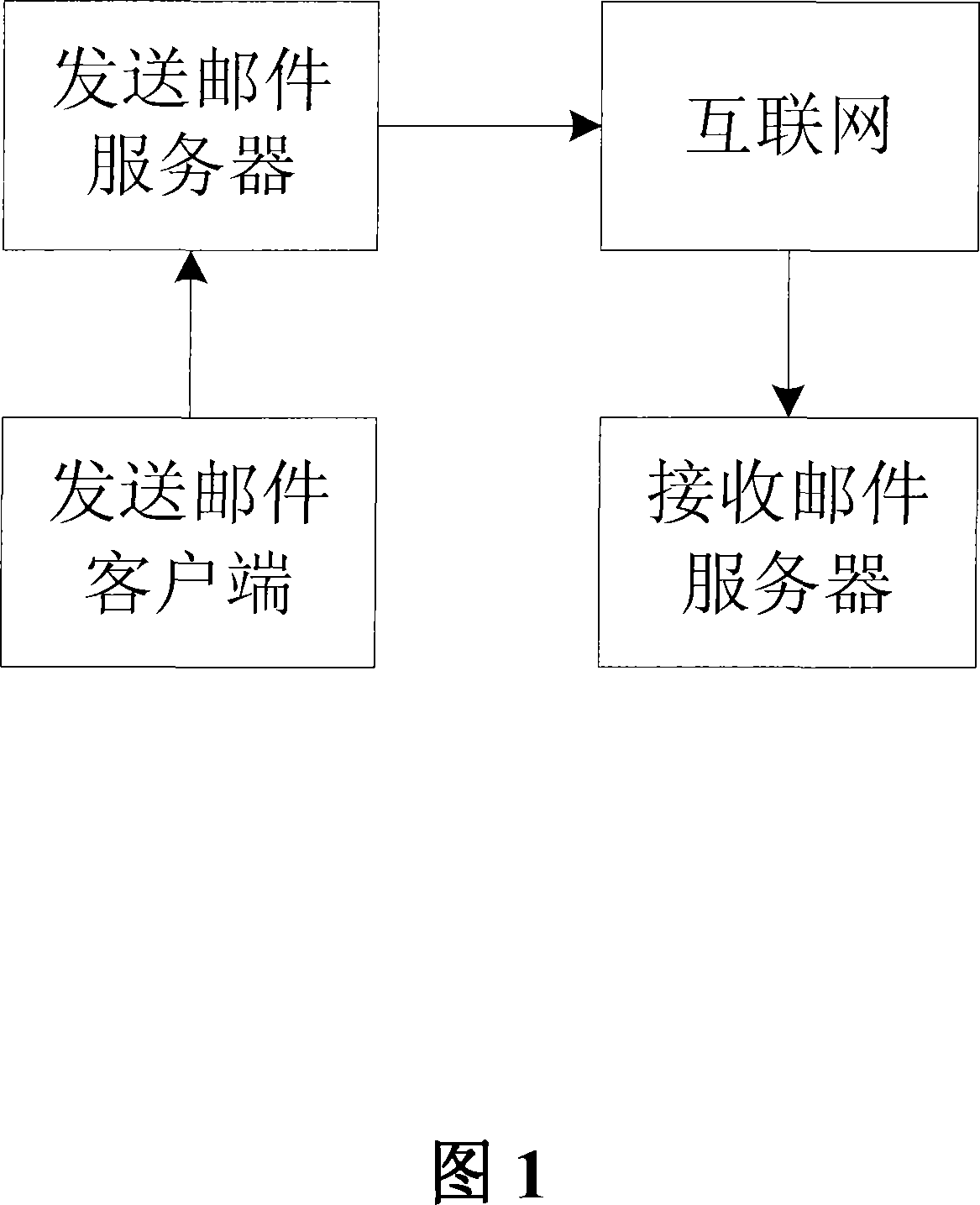

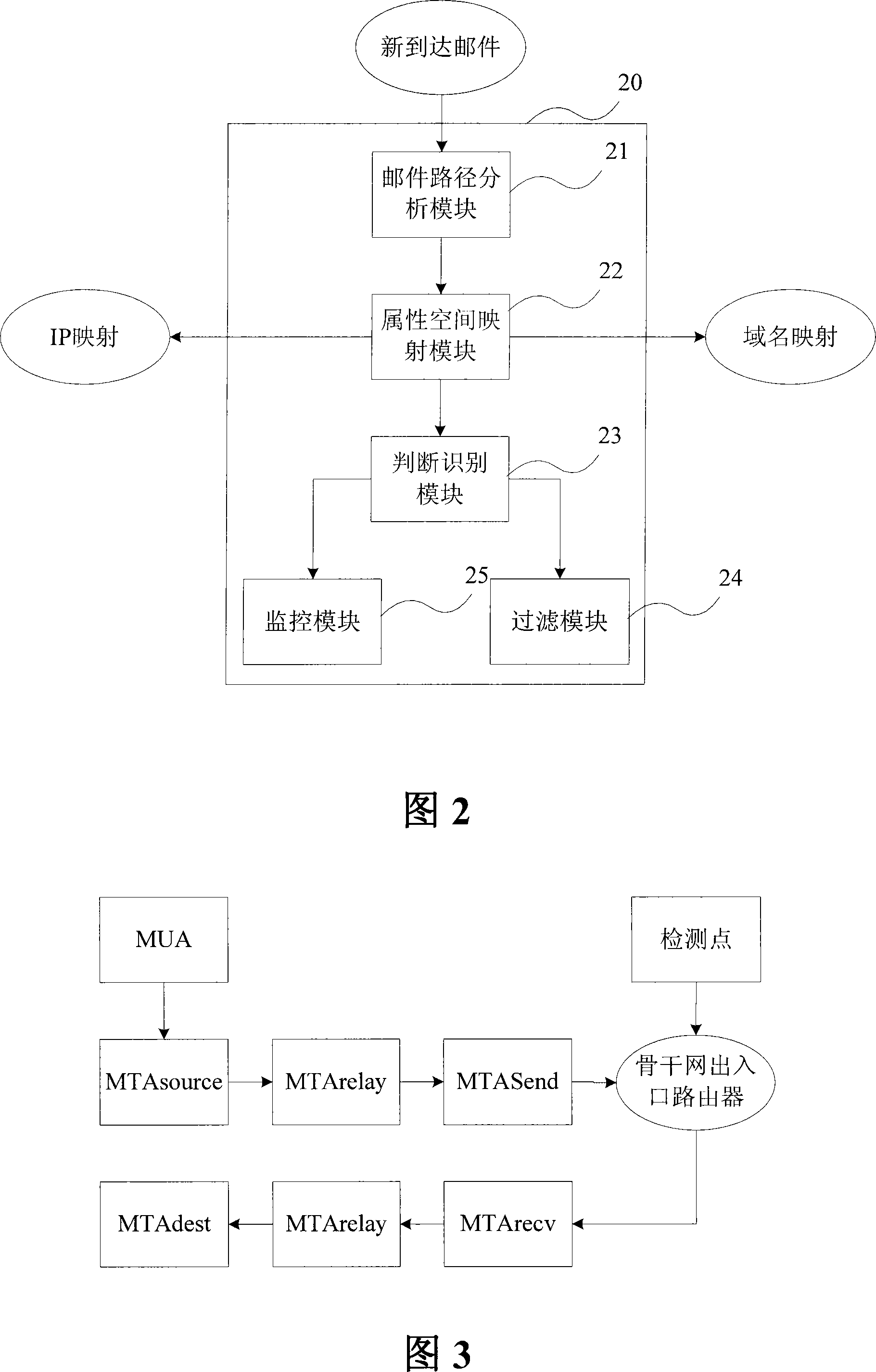

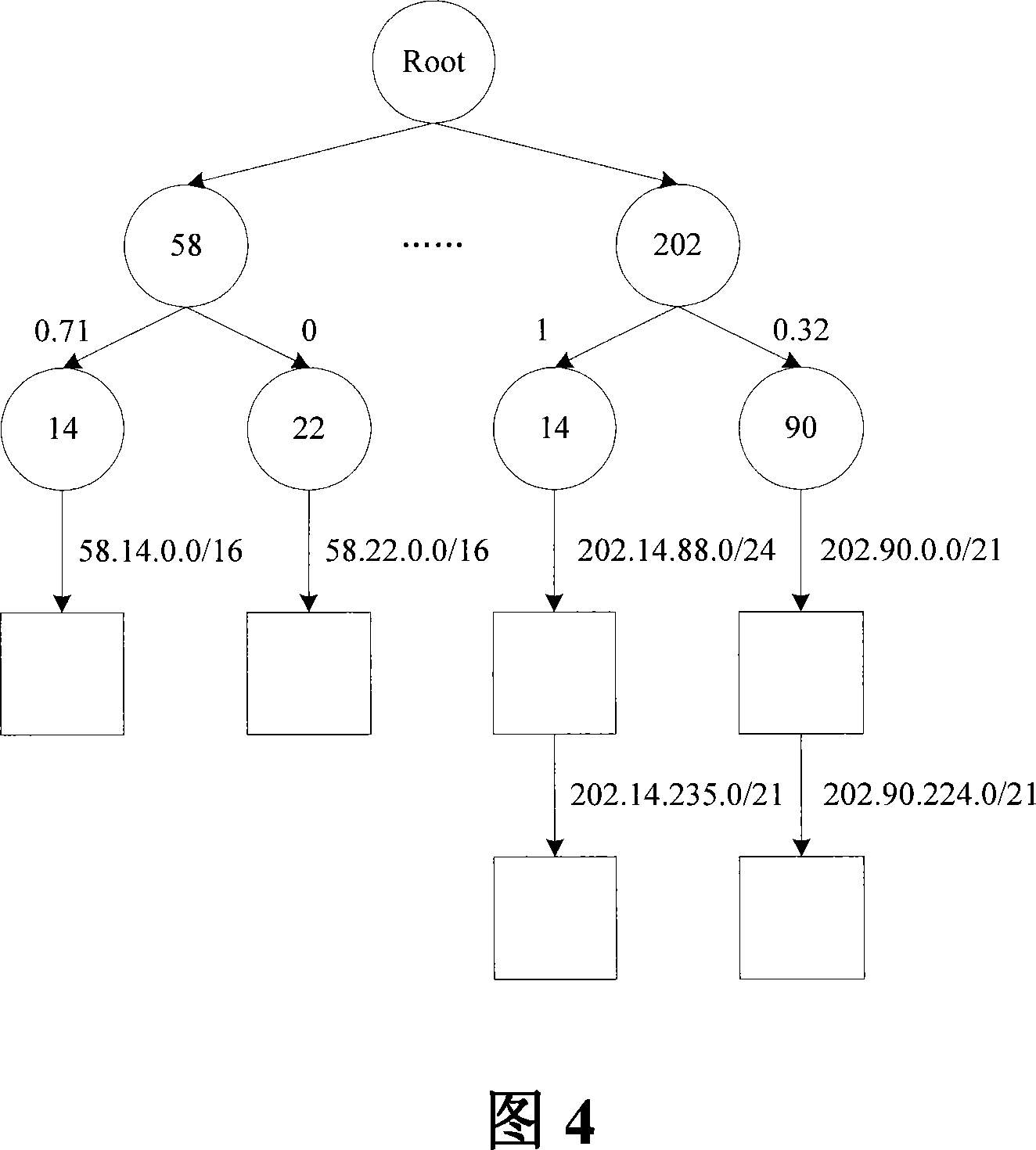

Real-time rubbish mail filtering method and system used for transmission influx stage

InactiveCN101141416ALimit transmissionMeet the needs of filtrationData switching networksFiltrationFilter system

The present invention relates to a method and a system for filtering a real-time junk mail. A mail text and mail description information are extracted first, an algorithm is generated by adopting an efficient characteristic pattern to switch the mail text to be a combination of a plurality of fingerprints, to represent an original mail. If the memory has no mail with the similar content with the current mail, a mail class is created in the memory, and the information about fingerprint and description of the current mail is preserved; only the description information in the mail class is updated, if the mail number contained in the mail class exceeds the predefined threshold value of the junk mail, the mail class is taken as a junk mail class, and the mails distributed to the class at later times are determined as junk mails by a filtering system. The present invention can effectively identify the junk mail with a small amount of fingerprints, the maintenance cost is low, and the user privacy is not violated; the present invention has perfect performance in the execution efficiency and in the memory expenses, the present invention is used for filtering the junk mails under a great flow capacity environment, the problem that the junk mains occupy the network band width is abated, thus the utilization ratio of the network resources is improved, and simultaneously the filtration pressure of the client side is reduced.

Owner:BEIJING VENUS INFORMATION TECH

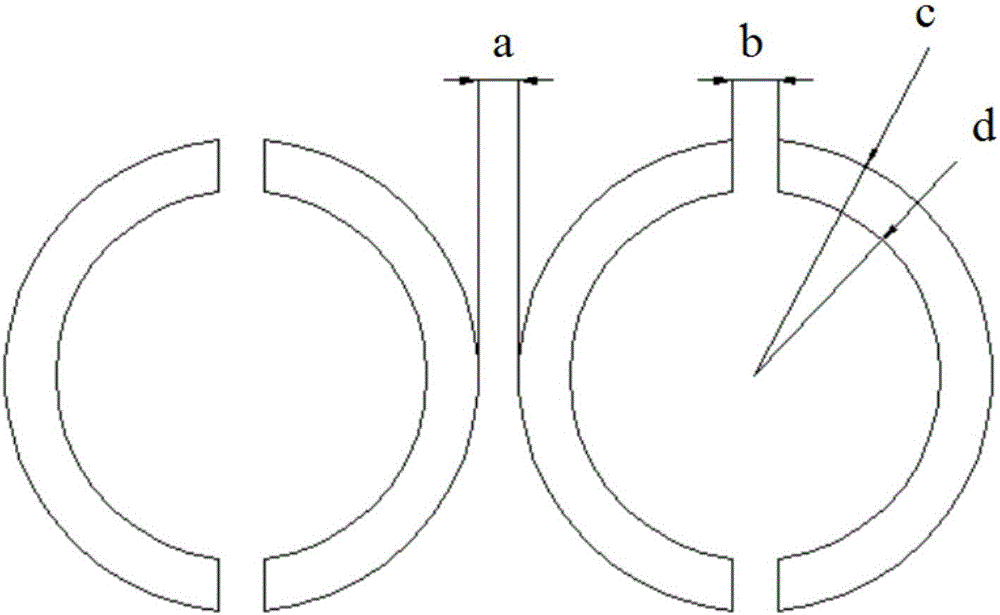

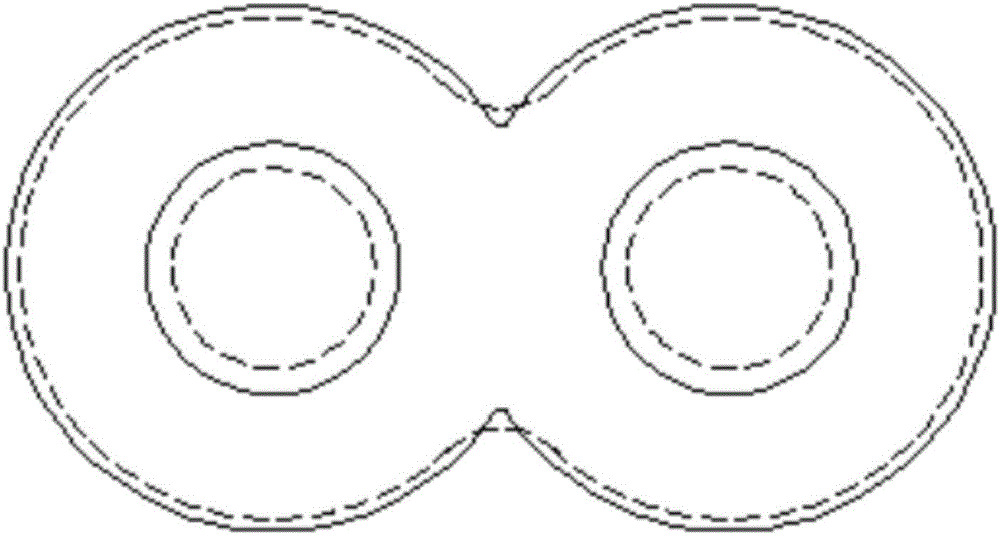

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

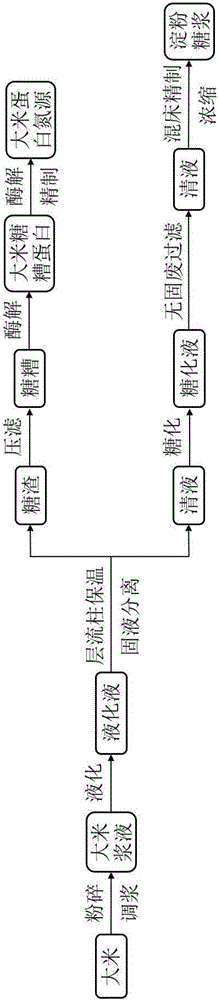

A real time spam filtering method and system

The invention relates to a filtration method of real-time junk e-mails, and the method is used for filtering a junk e-mail at a network interconnection point. The method comprises the following steps: step one, a path combination P is constructed according to the routing information in the e-mail, and the path combination P is a sending correspondent and a receiving correspondent, and / or a sending correspondent and an information destination; step two, attribute space mapping is performed to the IP address or the domain name of the elements in the path combination P according to IP address mapping or domain name mapping; steps three, whether the current e-mail is a junk e-mail is determined according to the attribute space mapping result of each element in the path combination P, if the e-mail is a junk e-mail, step four is executed, otherwise, the current e-mail is not processed; step four, the current e-mail is filtered. In the invention, only the mail order and the content in the header are analyzed, the processing speed is quick, the network resource utilization rate can be improved, and simultaneously, the filtration pressure at a user terminal can be relieved.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

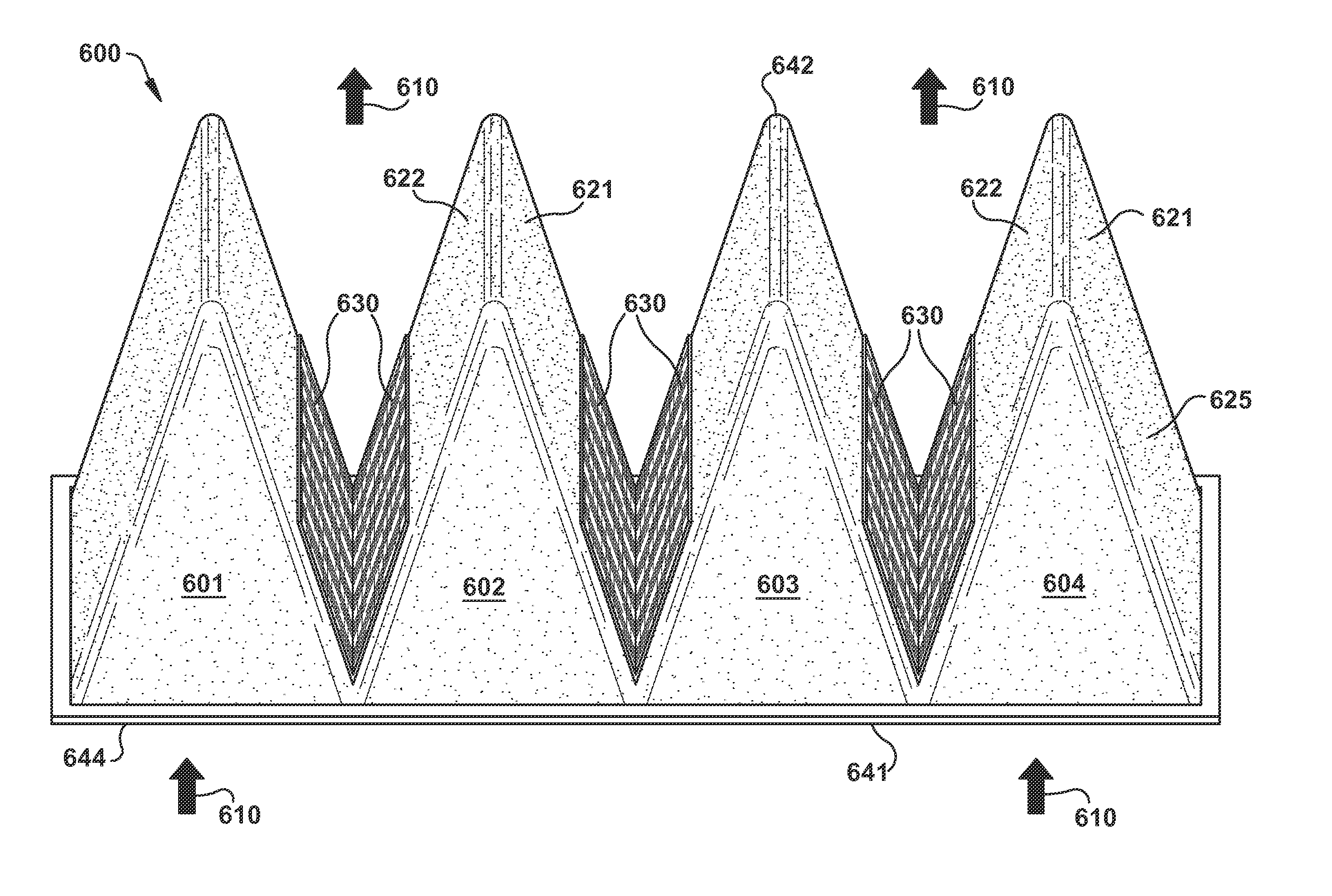

Production process for preparing starch syrup from rice

ActiveCN106191159AIncrease added valueHigh solid contentFermentationHigh concentrationAdditional values

The invention discloses a production process for preparing starch syrup from rice. The production process comprises the following steps: (1) crushing and pulping; (2) liquefying; (3) carrying out column laminar flow heat preservation and solid-liquid separation; (4) extracting a rice protein nitrogen source; (5) saccharifying; (6) carrying out solid-waste-free filtering; (7) carrying out mixed bed refining and concentrating. According to the process disclosed by the invention, in a process of preparing the starch syrup, the energy consumption is reduced through blending high-concentration starch syrup, a pulping water temperature is controlled and the liquefying time is shortened; residual sugar is recycled from sugar-free grains produced in a production process and fat in the sugar-free grains is hydrolyzed by adopting alkaline lipase; protein of the rice sugar-free grains is hydrolyzed by proteinase to prepare an organic nitrogen source, and fermentation raw materials for foods and medicines. The process disclosed by the invention is remarkably better than a traditional process for preparing the starch syrup from the rice; the production cost is low and an additional value of a product is improved; the content of produced solid wastes is extremely less and the production process is economical and environmentally friendly.

Owner:双桥(湖北)有限公司

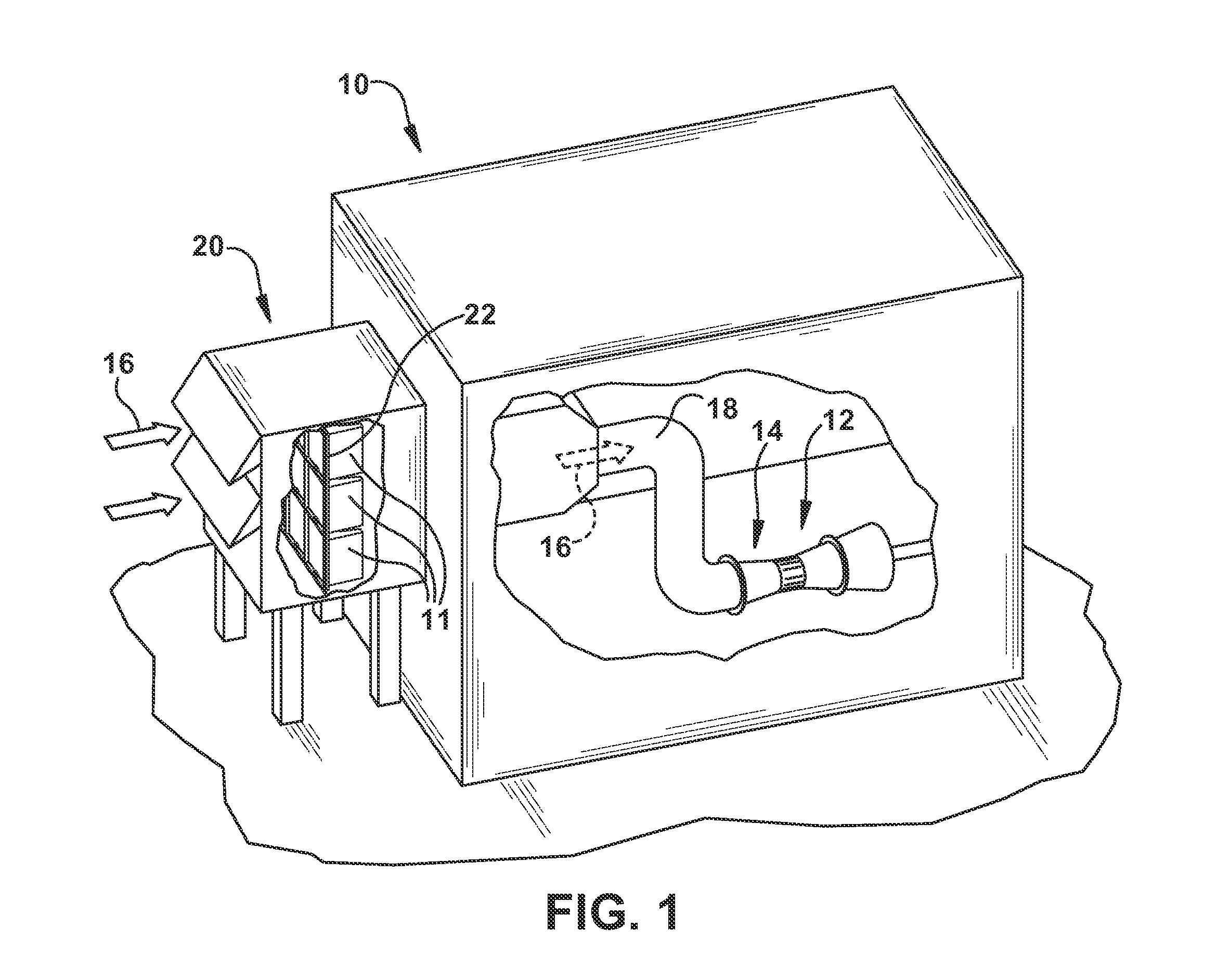

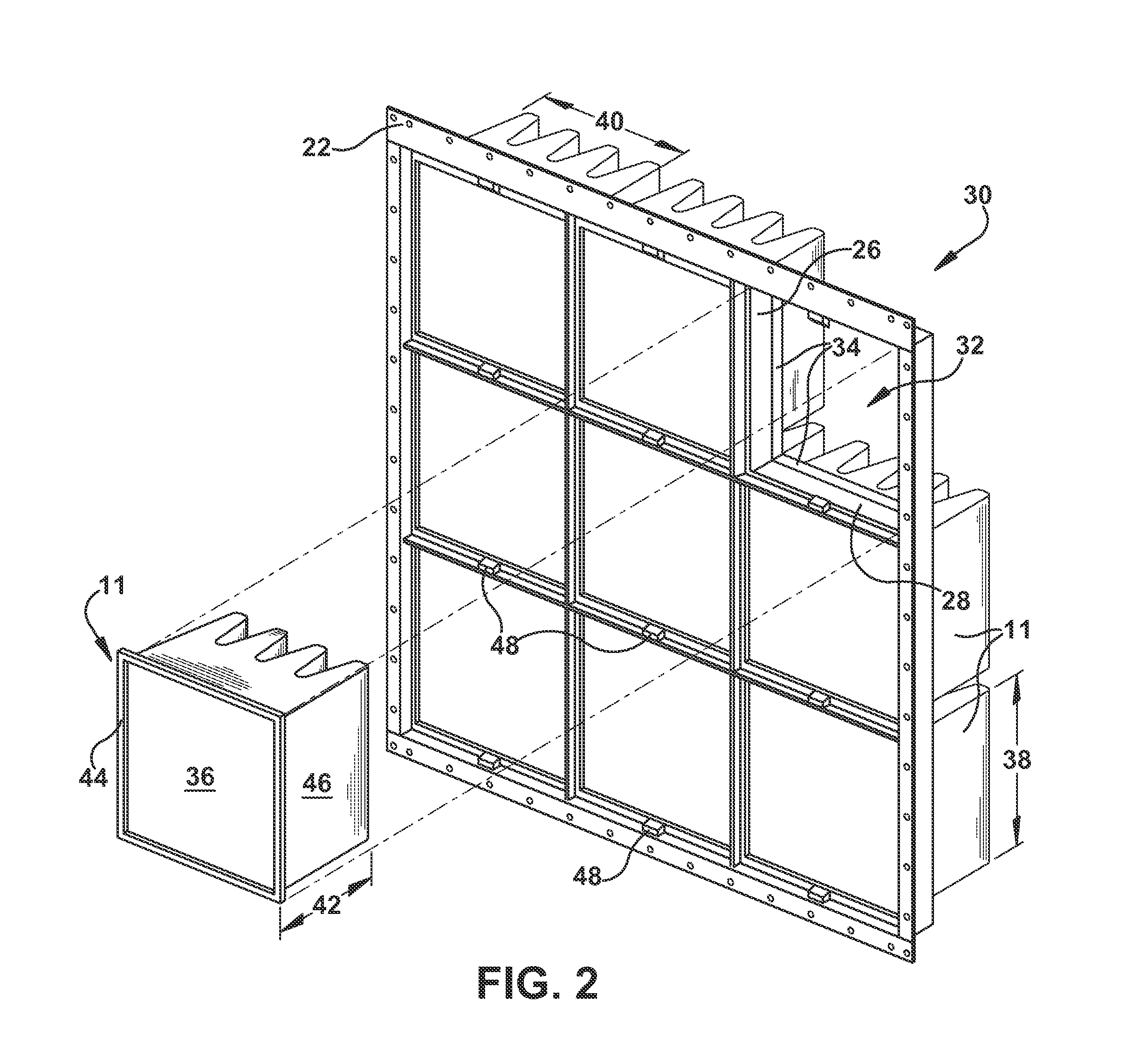

Filter bag assembly with rigid mesh for reducing filter pressure loss

InactiveUS20150202560A1Reduce filter pressure lossReduce filter pressureDispersed particle filtrationEngineeringFilter material

A filter bag assembly includes a first filter bag having at least two sidewalls of filter material extending from an open end to a closed end of the first filter bag at which the sidewalls connect to close the first filter bag. Two of the sidewalls of filter material are opposed to each other across the first filter bag and spaced from each other at the open end of the first filter bag. The two sidewalls are configured to form a tapered pocket, and the first filter bag includes a plurality of tapered pockets. A substantially rigid mesh is in contact with the first filter bag. The mesh is configured in a substantially V-shape and located near the open end of the first filter bag. The mesh is configured to maintain a shape of the tapered pockets and reduce filter pressure loss during use of the filter bag assembly.

Owner:BHA ALTAIR

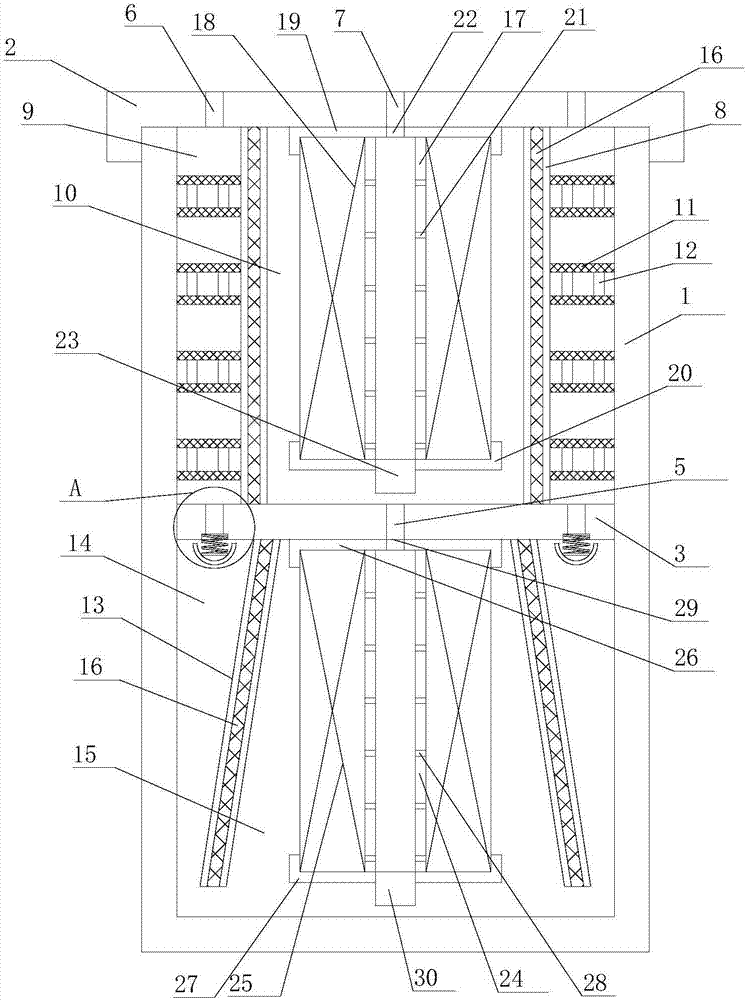

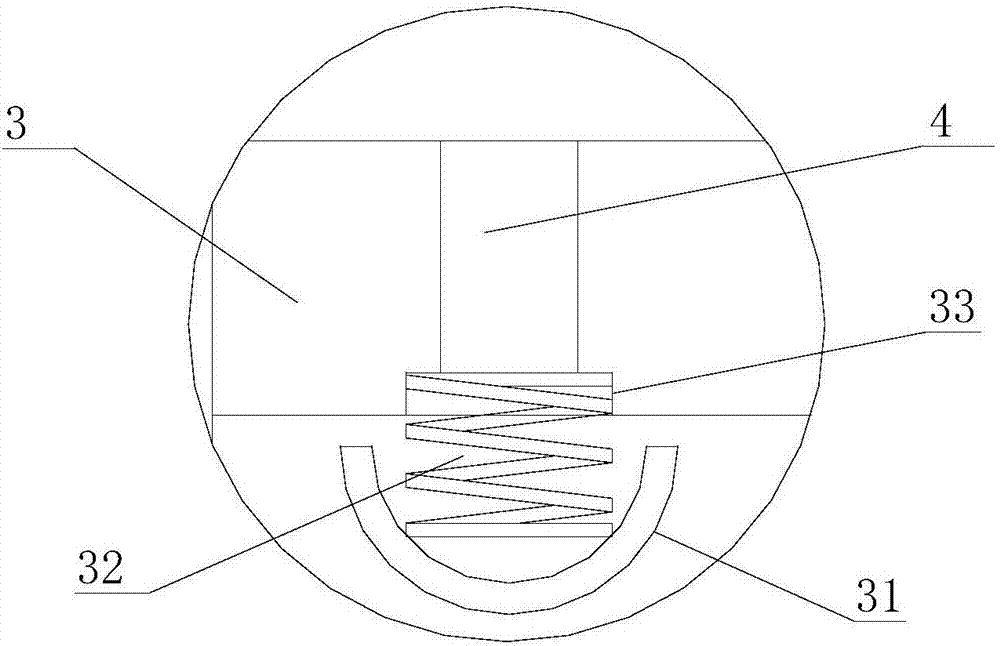

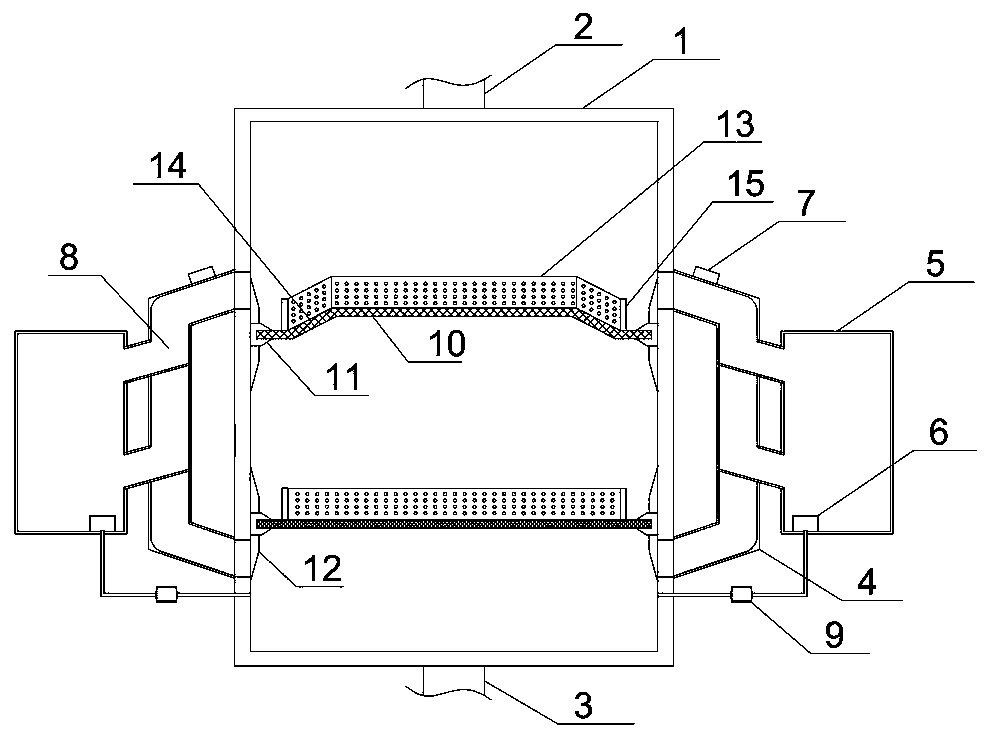

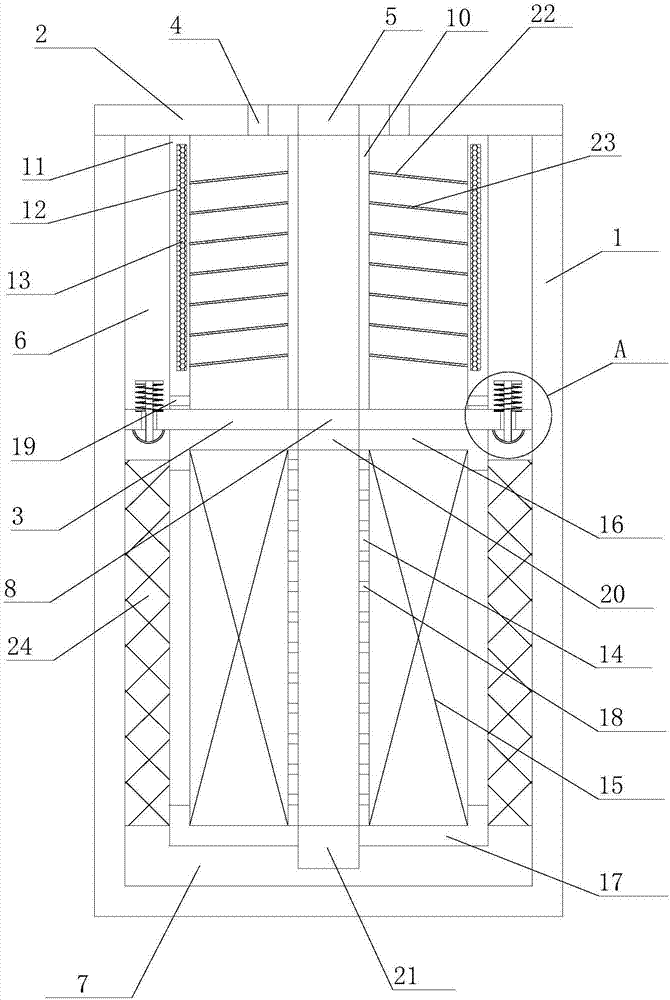

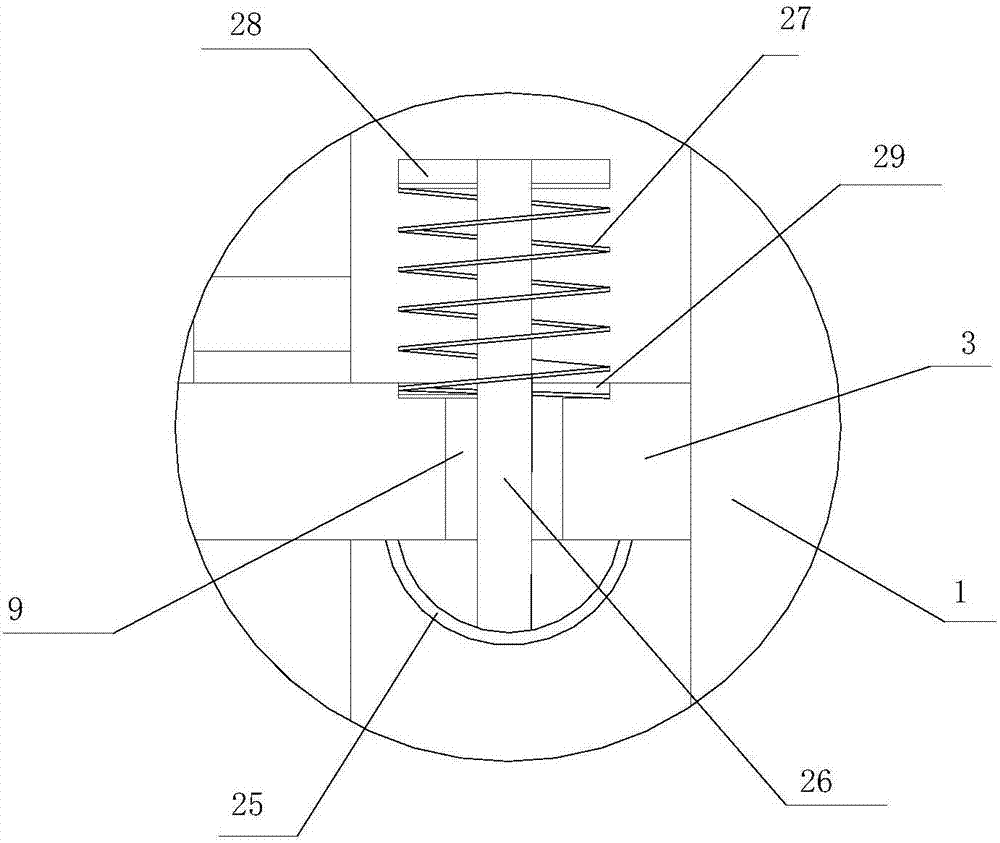

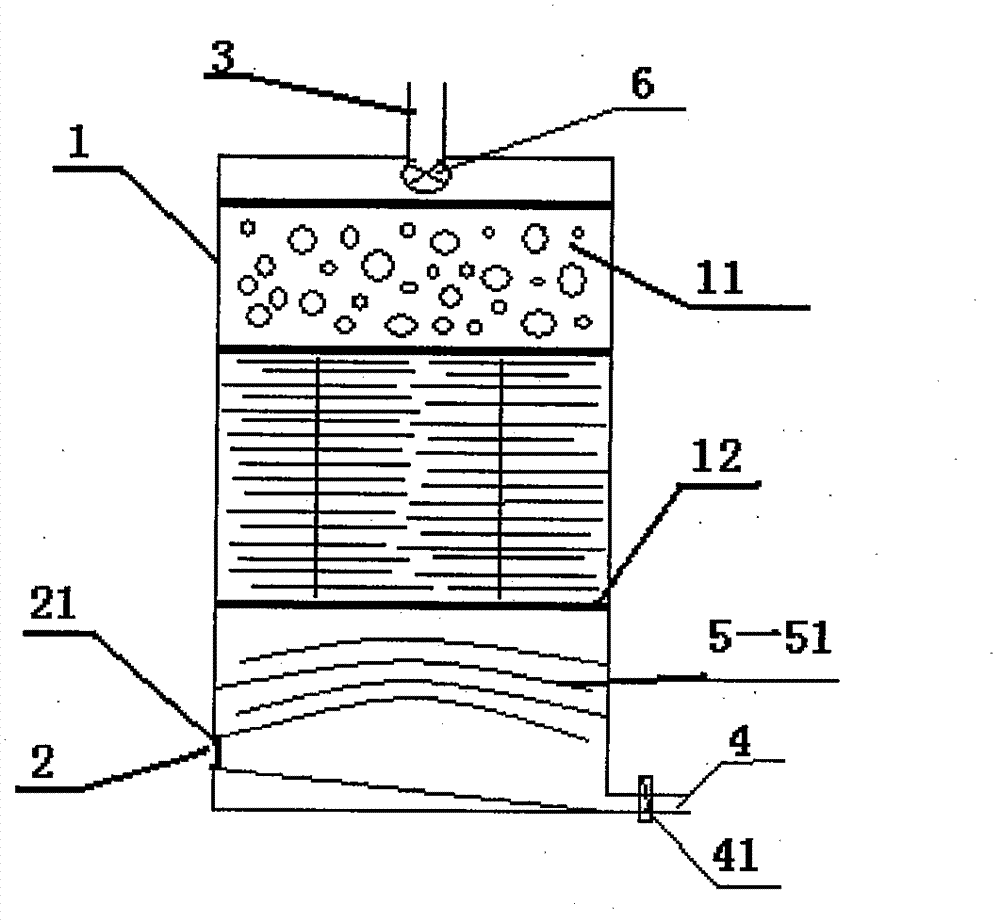

Anti-blockage oil filter

InactiveCN107023344AReduce filter pressureExtend the life cycleLubricant mounting/connectionPressure lubricationMetal impuritiesFilter effect

The invention provides an anti-blockage oil filter. The anti-blockage oil filter comprises a shell, a bottom plate, a first filtering mechanism and a second filtering mechanism. A partition board divides an inner cavity of the shell into a first chamber and a second chamber. The first filtering mechanism is arranged in the first chamber. The first filtering mechanism comprises a first magnetic adsorption device and a first filter element. The second filtering mechanism is arranged in the second chamber. The second filtering mechanism comprises a second magnetic adsorption device and a second filter element. The anti-blockage oil filter adsorbs and filters out different sizes of metal impurities in engine oil through the first magnetic adsorption device and the second magnetic adsorption device so as to reduce the filter pressure of the first filter element and the second filter element, prolong the service cycle of the first filter element and the second filter element and improve the filtering effect of the first filter element and the second filter element. Metal impurities adsorbed by the first magnetic adsorption device can completely stay in a first filtering chamber. Metal impurities adsorbed by the second magnetic adsorption device can be adsorbed onto a second barrel and cannot go into a fourth filtering chamber and a second filtering chamber.

Owner:BENGBU FENGCHI FILTER

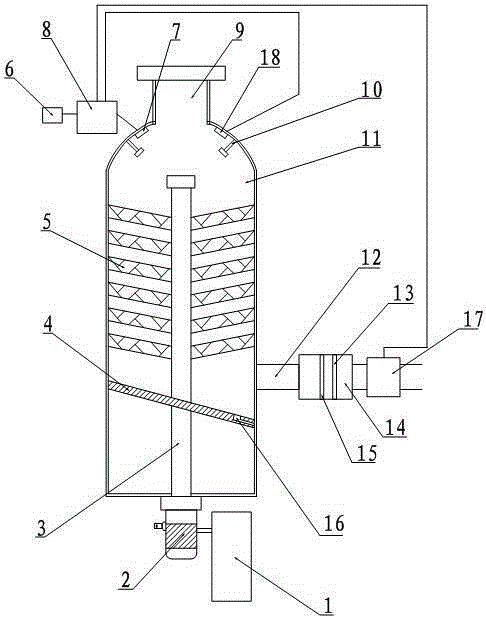

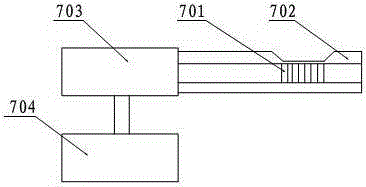

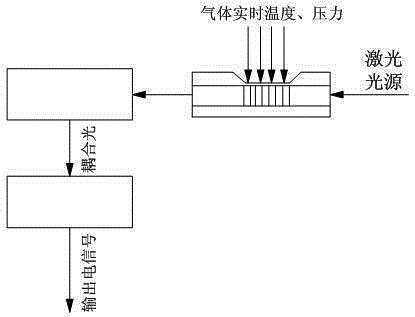

Water spray purifying system applied to industrial flue gas dedusting

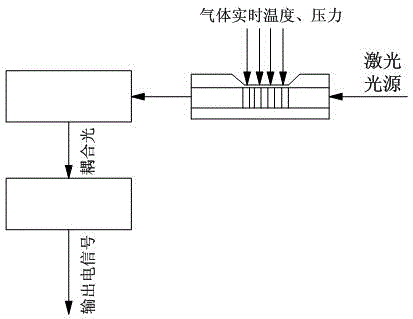

InactiveCN105396404AReasonable designSimple structureHuman health protectionCombination devicesLaser transmitterSprayer

The invention discloses a water spray purifying system applied to industrial flue gas dedusting. The water spray purifying system applied to industrial flue gas dedusting comprises a machine body, a sprayer, a filtering screen, a flue gas charge pipeline, a drive mechanism, a temperature and pressure data acquiring device, a gas pressure regulating valve, an alarm, a laser transmitter 1, a laser transmitter 2, a sewage diversion baffle and a primary filtering device, wherein the top of the machine body is provided with a clean air discharge pipeline; the sprayer and the filtering screen are both arranged in the machine body; the flue gas charge pipeline is communicated with the side wall of the machine body; the drive mechanism is connected with the machine body and is used for controlling the filtering screen to drive; the temperature and pressure data acquiring device stretches into the machine body and is connected with a PLC; the gas pressure regulating valve, the alarm and the laser transmitter 1 are all connected with the PLC; the laser transmitter 2 is connected with the temperature and pressure data acquiring device and the PLC; the sewage diversion baffle is arranged in the machine body and is positioned below the filtering screen; the sprayer is positioned above the filtering screen; the sewage diversion baffle is of a slope structure, and the bottom of the slope is provided with a water drainage channel; light sources of the laser transmitters are directed to the temperature and pressure data acquiring device. The water spray purifying system applied to industrial flue gas dedusting is reasonable in design, is simple in structure, effectively enhances the flue gas purifying effect, and enhances the dedusting efficiency.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

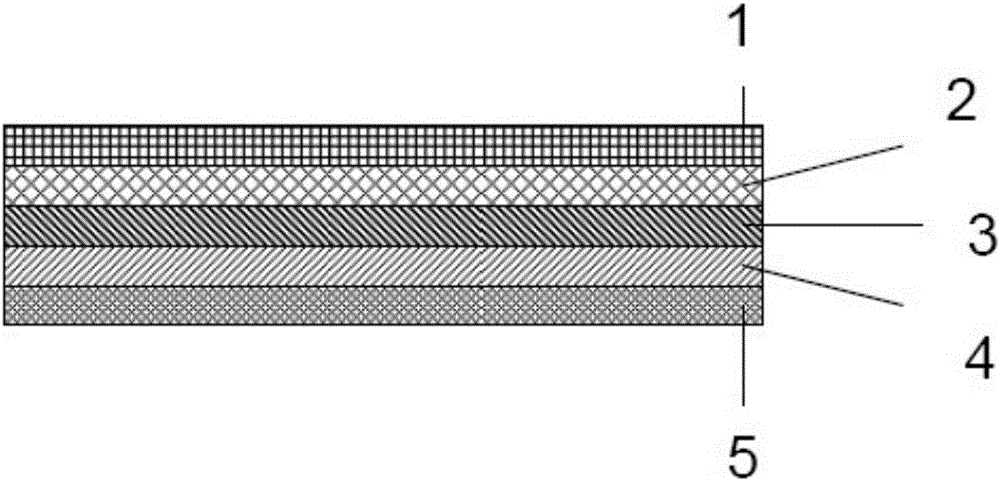

Preparation method of antibacterial type PM2.5 (Particulate Matter2.5) composite filter material and application of antibacterial type PM2.5 composite filter material

ActiveCN106621568AExtended service lifeImprove adsorption capacityBreathing filtersLighting and heating apparatusParticulatesPorosity

The invention relates to an antibacterial type PM2.5 (Particulate Matter2.5) filter material and application thereof. The antibacterial type PM2.5 filter material is mainly characterized by sequentially consisting of a windward layer, a primary filter layer, a sterilization layer, an active carbon filter layer and a fine filter layer, wherein the primary filter layer and the fine filter layer are nuclear pore films. The sterilization layer is provided with nano sliver particles; and the purpose of blocking PM 2.5 particles is effectively realized by utilizing the characteristics of uniform film hole diameter, uniform hole density and high porosity of the nuclear pore films and additionally arranging the sterilization layer through multi-layer filtration and adsorption effect; a filter element and a respirator, which are manufactured by the filter material, block the PM 2.5 particles more effectively in comparison with a conventional respirator, are long in service live, are good in gas permeability, meet characteristics of environmental-friendly requirements, and are worthy of being produced and popularized.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

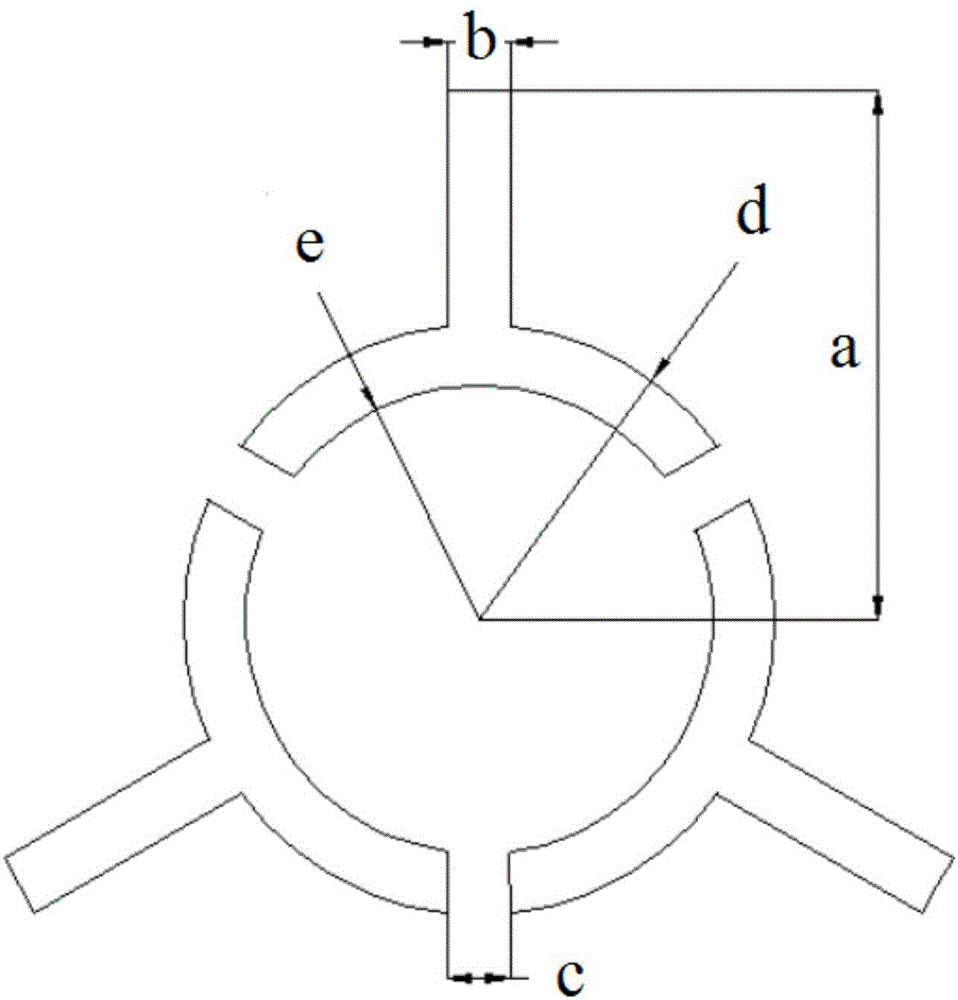

Multilobal hollow polyester fiber FDY (fully drawn yarn) and preparation method thereof

ActiveCN106835334AReduce extrusion swelling effectReduce surface tensionHollow filament manufactureMonocomponent polyesters artificial filamentFiberYarn

The invention belongs to the field of polyester spinning, and relates to a multilobal hollow polyester fiber FDY (fully drawn yarn) and a preparation method thereof. A spinning melt comprises a saturated fatty acid metal salt and modified polyester according to a mass ratio of (0.0005 to 0.002) to 1; the saturated fatty acid metal salt is a fatty acid metal salt with carbon atom number of 12 to 22, melting point of 100 to 180 DEG C, and dynamic viscosity less than or equal to 1Pa.s; a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a rigid structure chain segment, the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02 to 0.05) to 1, the extrusion swelling ratio of the spinning melt is 1.20 to 1.31, and the post-filtering pressure is 80 to 120kg / cm<2> during spinning. The prepared multilobal hollow polyester fiber FDY has higher hollow degree and a better shape preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

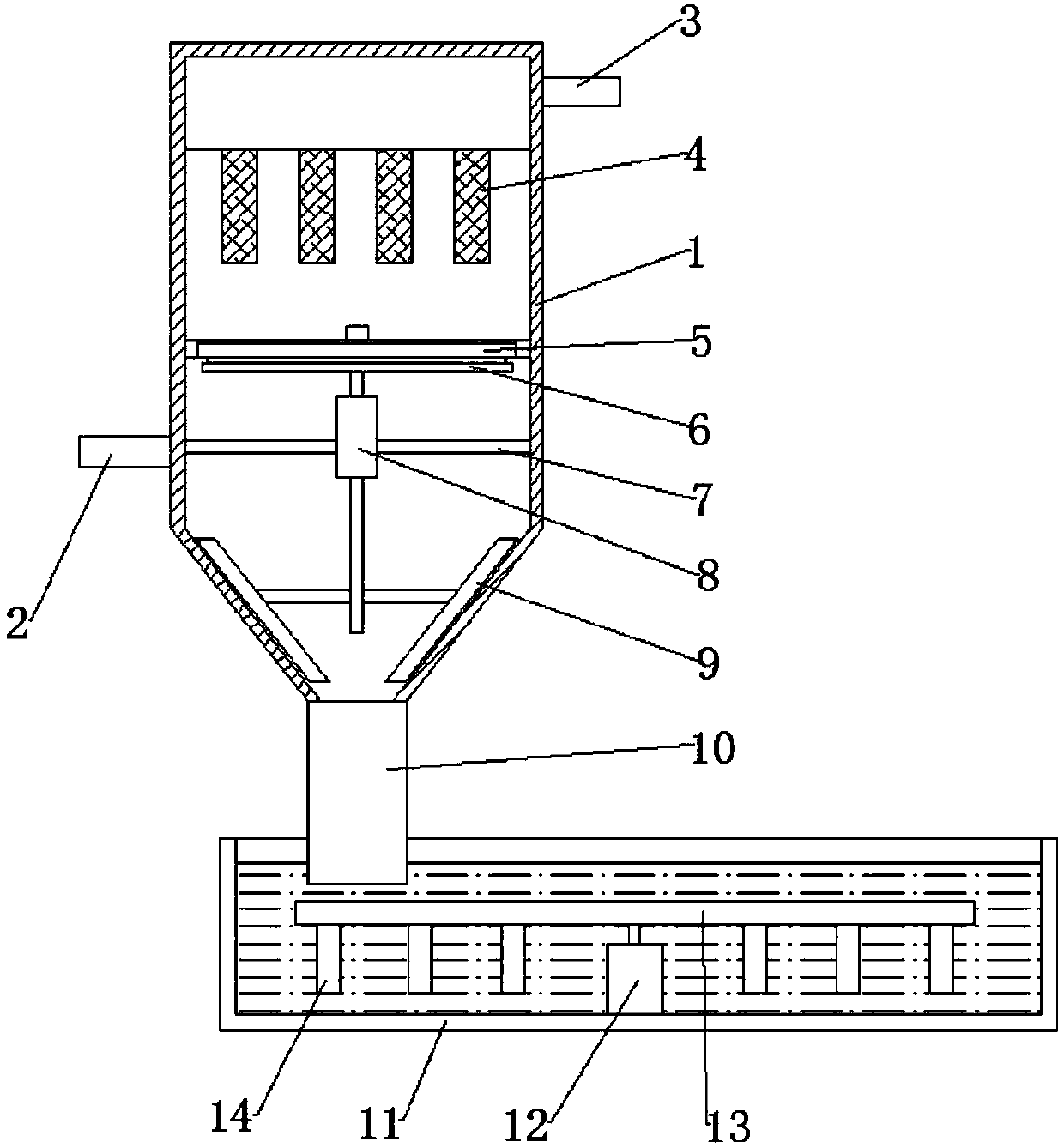

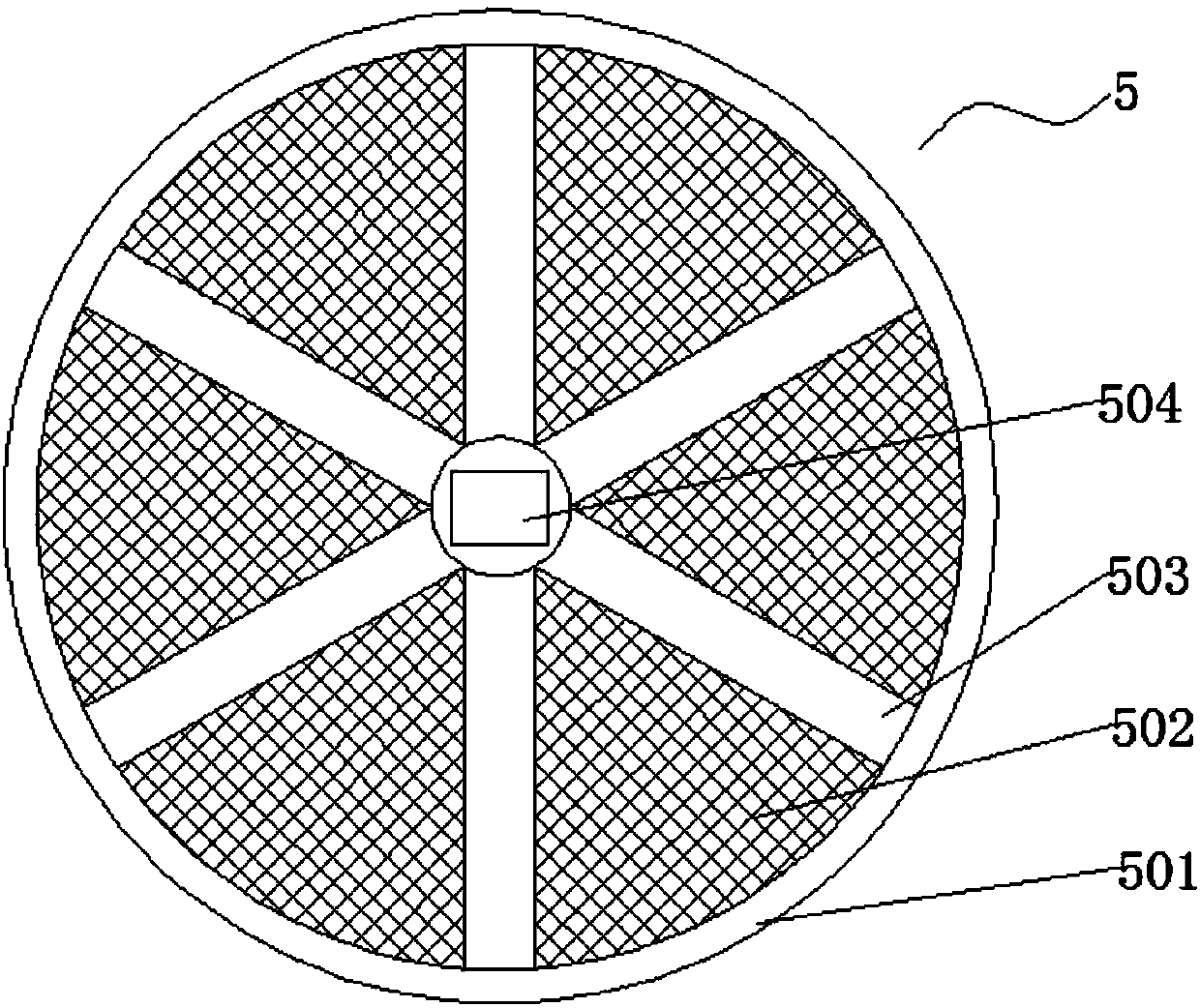

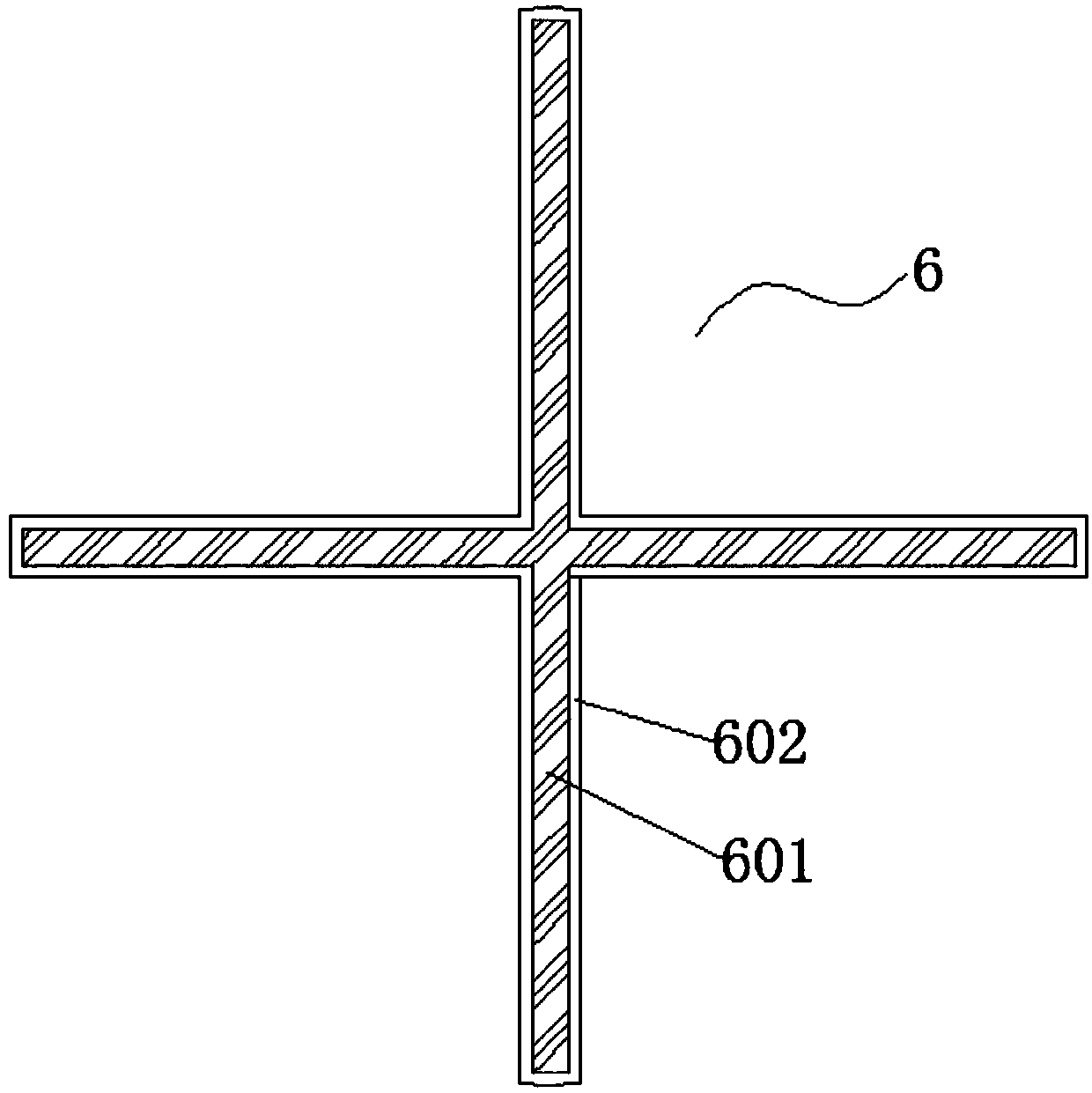

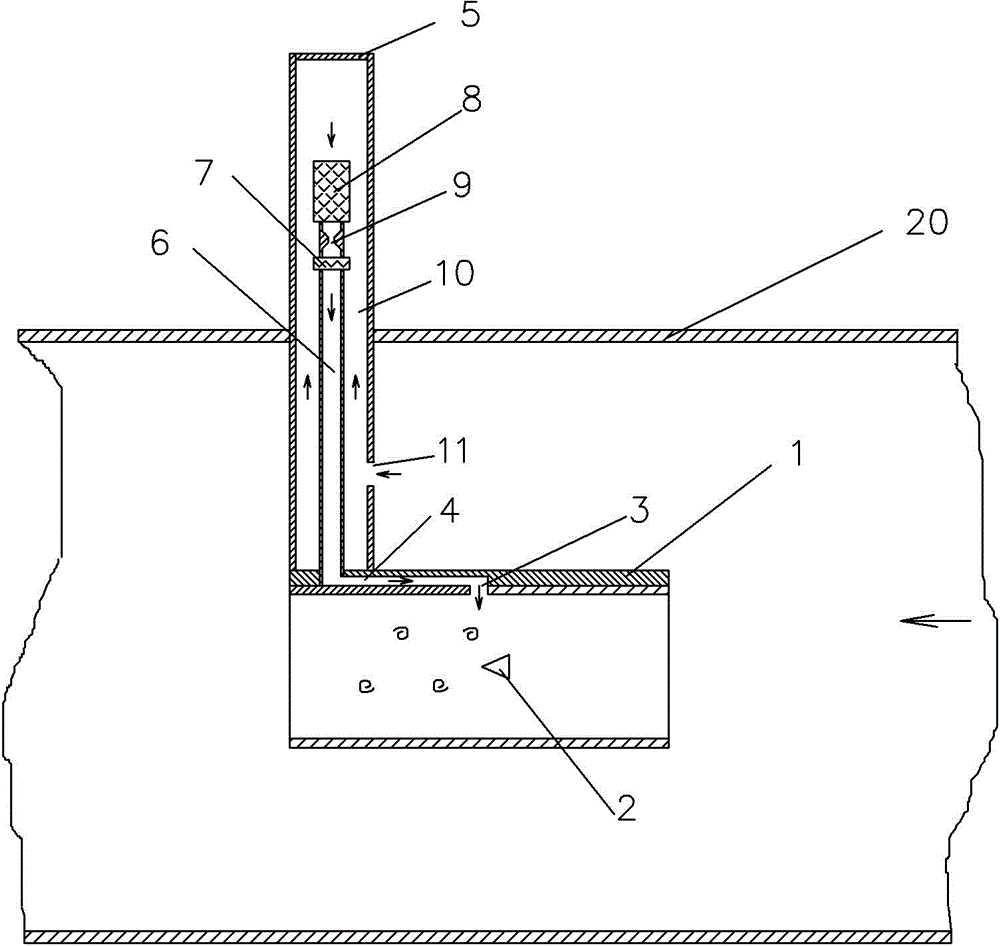

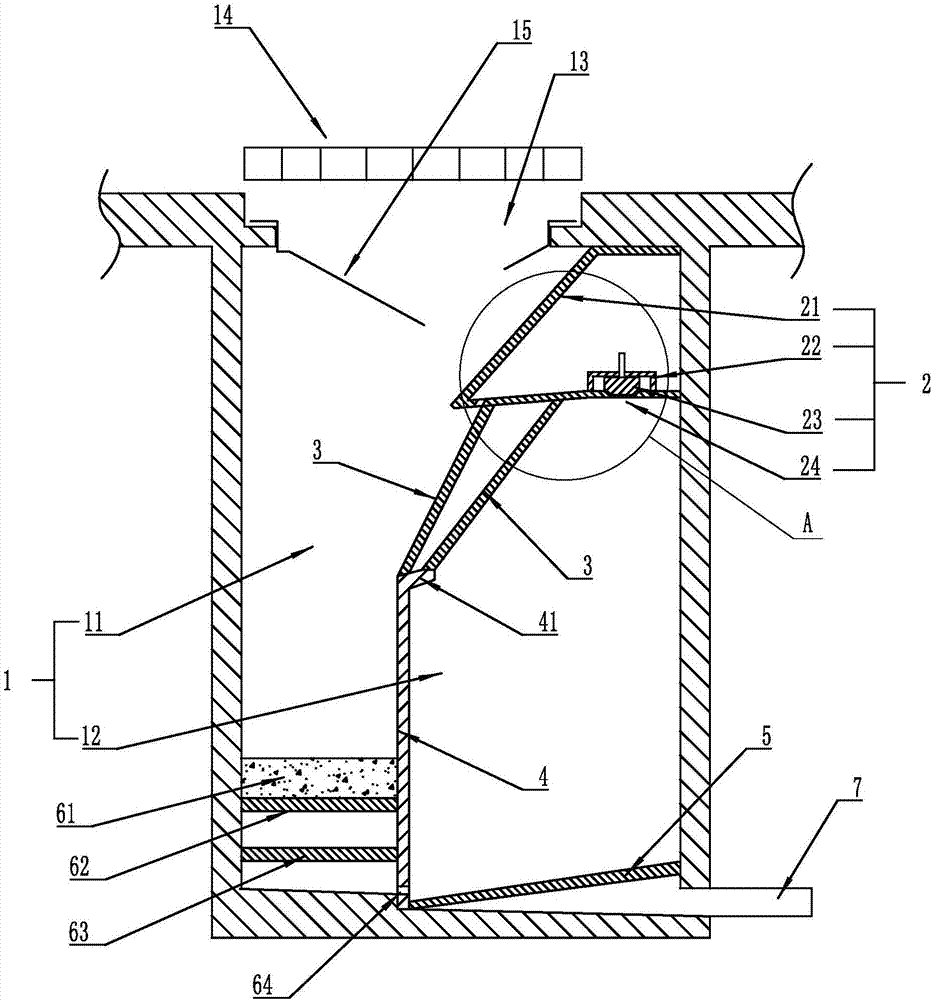

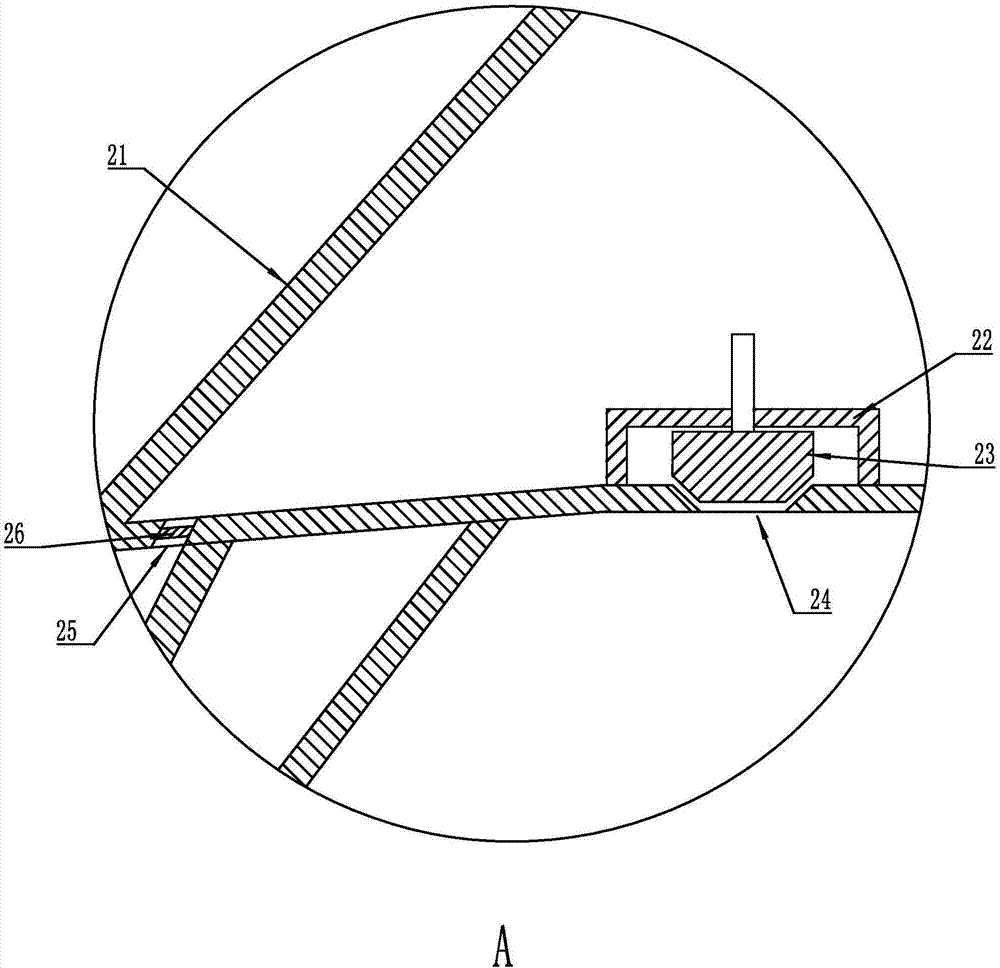

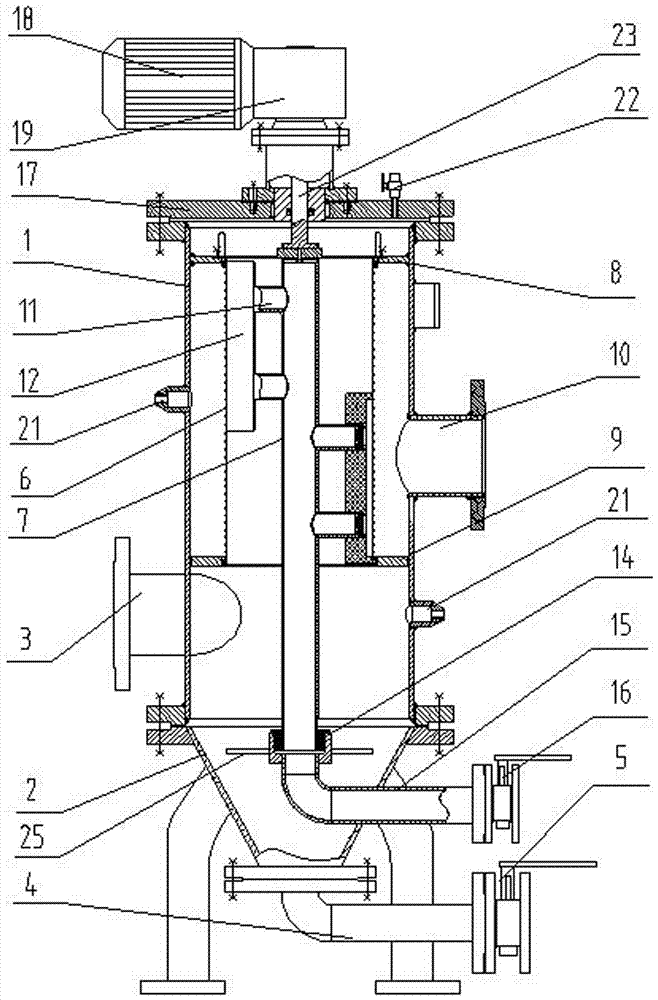

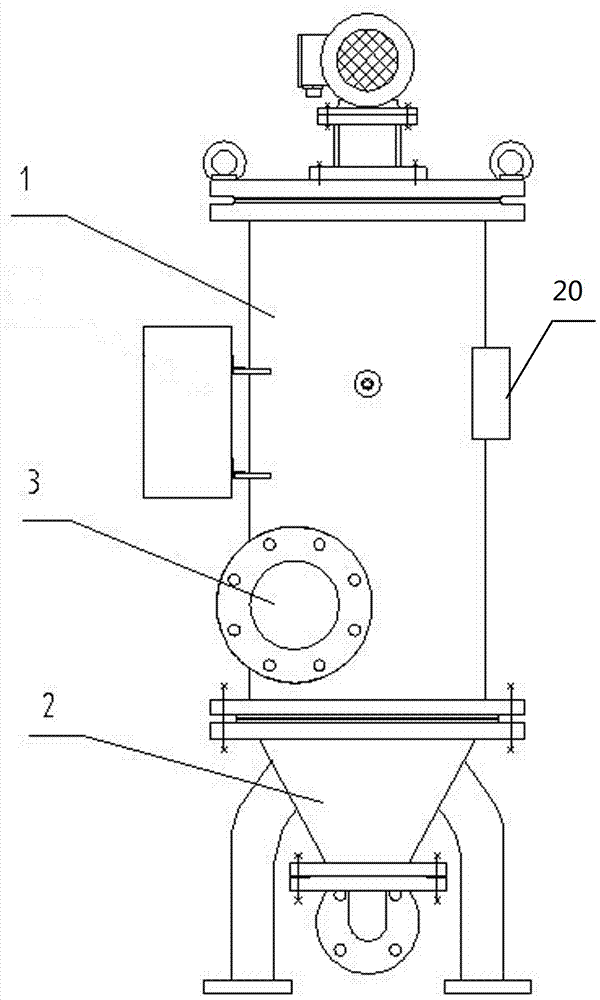

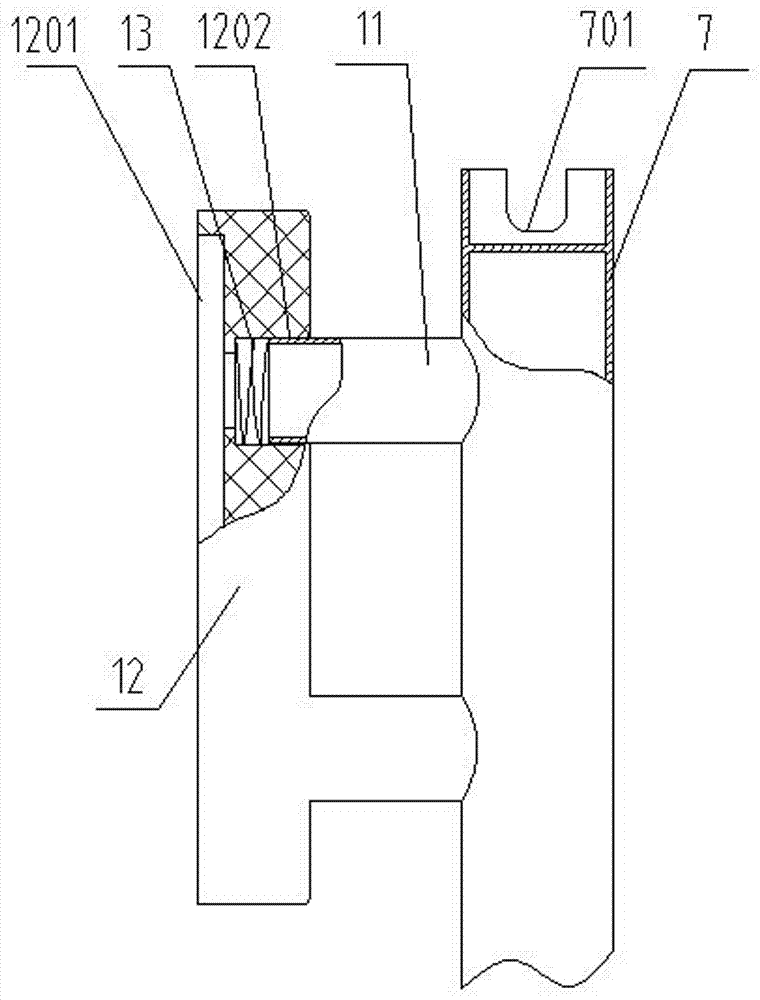

LCDM long-bag low-voltage pulse bag dust remover

InactiveCN108031195AReduce filter pressureEasy to clean mud manuallyDispersed particle filtrationTransportation and packagingLow voltageEngineering

The invention discloses an LCDM long-bag low-voltage pulse bag dust remover in the technical field of bag dust removers. The long-bag low-voltage pulse bag dust remover comprises a dust remover; an air inlet is arranged in the bottom part of the side wall of the dust remover; an air outlet is arranged in the top part of the side wall of the dust remover; cloth bags, a filter screen body and a double-head motor are arranged in the inner cavity of the dust remover; the filter screen body is arranged below the cloth bags; the power output end of the double-head motor is provided with a cleaning head; the double-head motor is fixed to the inner wall of the dust remover through a fixing frame; and the bottom of the dust remover is provided with a shrinkage funnel end. According to the invention, the dust of the low-voltage pulse bag dust remover can be filtered twice conveniently, so that the filtering pressure of the cloth bags is reduced, and the service life is prolonged; the fallen dustis cleaned out, and the dust dissolves in a sedimentation tank, so that the artificial mud cleaning can be carried out conveniently, and the environment is protected.

Owner:ANHUI HANSHAN COUNTY TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

Wild jujube juice and its processing method

InactiveCN1775110ATypical fresh jujube flavorSimple processing methodPlant ingredientsFood scienceFruit juiceBrix

The present invention relates to a spiny jujube juice. It is a natural spiny jujube juice which is a bronzing clear transparent liquor, has the original flavour of spiny jujube, its soluble solids content is 6deg. Brix-8deg. Brix, and its pH value is 3.4-3.6. Besides, said invention also provides its processing method and concrete steps.

Owner:HEBEI AGRICULTURAL UNIV.

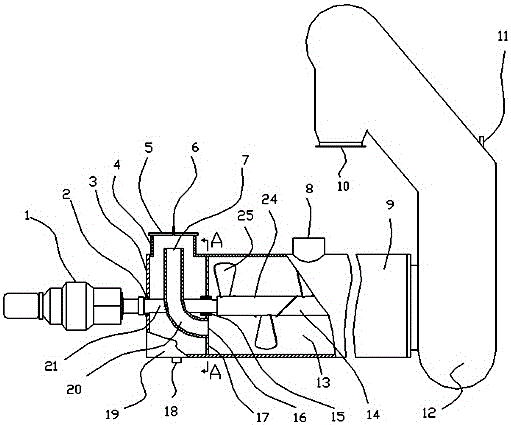

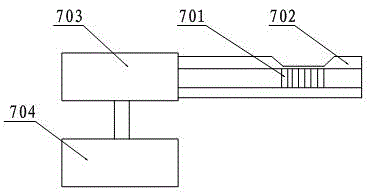

Anti-smudginess inserted vortex shedding flowmeter

ActiveCN102721448AReduce filter pressureAvoid cloggingVolume meteringVolume/mass flow by dynamic fluid flow effectEngineeringFilter element

The invention discloses an anti-smudginess inserted vortex shedding flowmeter which comprises a measuring head internally provided with a fluid passageway. A vortex generating body is fixedly arranged in the measuring head; a pressure tapping is arranged on the measuring head; an inner conduit communicated with the pressure tapping is fixedly arranged on the measuring head; a filtering element and a thermosensitive element are sequentially arranged on the inner conduit from top to bottom; a sedimentation tube which is coaxially sleeved outside the inner conduit is fixedly arranged on the measuring head; the lower end of the sedimentation tube is plugged by the measuring head and the upper end of the sedimentation tube is of a sealed structure; a gas inlet hole is arranged at the position at the front side of the sedimentation tube, which is close to the measuring head; the gas inlet hole is positioned below the filtering element; a sedimentation passage communicated with the gas inlet hole is arranged in the sedimentation tube; and the sedimentation passage is communicated with an inner cavity of the inner conduit by the filtering element. Before entering the filtering element to be filtered, the to-be-measured gas flow is subjected to sedimentation treatment by the sedimentation passage, so that the filtering pressure of the filtering element is reduced, the requirement on the frequent replacement of the filtering element is avoided and the working efficiency of the flowmeter is improved.

Owner:GL TECH CO LTD

Rainwater channel sewage blocking screen for initial rainwater filtration

ActiveCN107386413AAvoid accumulationReduce filter pressureSewerage structuresClimate change adaptationWater filterEngineering

The invention discloses a rainwater channel sewage blocking screen for initial rainwater filtration. The screen comprises a rainwater channel of which the lower portion is communicated with a municipal pipe, a water inlet is formed in the upper end of the rainwater channel, a rainwater strainer is arranged in the water inlet in an erection mode, and the rainwater channel comprises a sundry area which is horizontally divided and communicated with the water inlet and a water purification area which is communicated with a municipal pipe; the sundry area is communicated with the upper end of the rainwater channel; the sundry area and the water purification area are communicated with one or more layers of separation filter screens which downwards incline vertically or toward the sundry area; the rainwater channel sewage blocking screen has the advantages that a filtering structure is automatically cleaned, and the water filtering rate and filtering effect of the filtering structure are guaranteed.

Owner:温州垠星建设有限公司

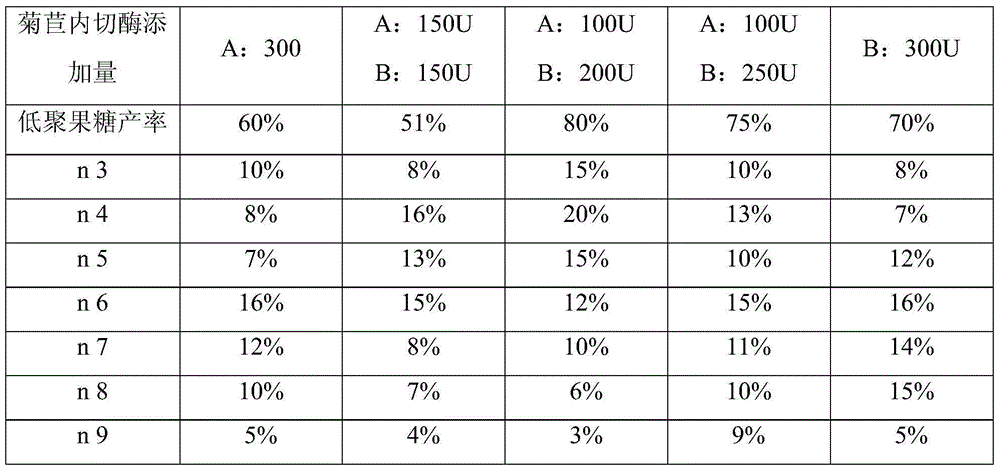

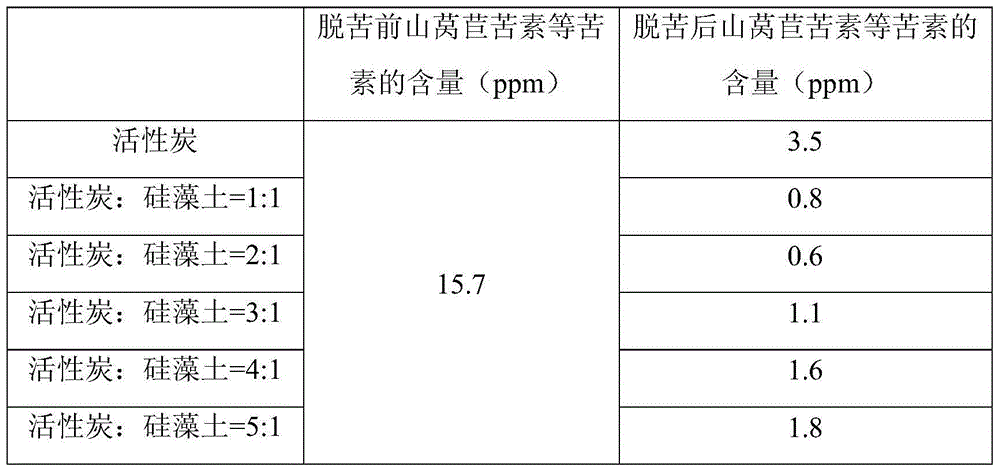

Preparation method for high purity fructooligosaccharides

InactiveCN104928332AGood decolorizationGood relief from bitternessFermentationDesalinationNanofiltration

The invention discloses a preparation method for high purity fructooligosaccharides. The method comprises the steps that 1, inulase is utilized for hydrolyzing endives to obtain a primary fructooligosaccharides solution; 2, decoloration, debitterizing and desalination treatment are conducted on the primary fructooligosaccharides solution to obtain a secondary fructooligosaccharides solution; 3, beta-D-fructosyltransferase is added into the secondary fructooligosaccharides solution, reaction is conducted for 1-8 h under the condition of 20-35 DEG C, and a third fructooligosaccharides solution is obtained; 4, a nanofiltration membrane is used for processing the third fructooligosaccharides solution obtained in the step 3, percolate is collected, and the fructooligosaccharides with the purity greater than 99% is obtained. The fructooligosaccharides is high in purity and few in impurities, the content of the fructooligosaccharides is larger than 99%, and the high purity fructooligosaccharides has important industrial application prospect.

Owner:WEIDE QINGHAI BIOTECH

Countercurrent extraction apparatus

A countercurrent extraction apparatus comprises an extraction tube; a propeller is disposed within the extraction tube; the propeller comprises a shaft and blades. The apparatus is characterized in that the blades are sheet-shaped, and the blades are arranged at interval on the surface of the shaft along the axial direction and in spiral arrangement. The sheet-shaped blades arranged spaced axially and spirally play the role of advancing the materials; the materials under the effect of such blades churn and spread out, so as to play a role in stirring; the materials churn from one side to the other side with the rotation of the propeller; although part of the materials rotate with the blades in place, the materials do not accumulate to one side at the same time because of spaced blades; continuous closely packed body can not be formed, and journal sticking effect can be avoided, so that blockage does not form in the extraction tube. Several tests prove that even if the total volume of the materials is greater than 80% of the total volume of the extraction tube, blockage does not appear, so that the efficiency of the extraction tube plays to the maximum, and the cost performance has been significantly improved.

Owner:JINING SINOBEST BIOLOGICAL MACHINERY

Method for producing dacron FDY (Fully Drawn Yarn) filaments in large scale by utilizing recycled PET (Poly Ethylene Terephthalate) bottle chips

ActiveCN102605455ASolve the problem of water content inconsistencyImprove stabilityFilament forming substance formingMonocomponent polyesters artificial filamentEngineeringBottle

The invention provides a method for producing dacron FDY (Fully Drawn Yarn) filaments in large scale by utilizing recycled PET (Poly Ethylene Terephthalate) bottle chips. The method comprises the following steps: crushing recycled PET bottles into chips; cleaning and then drying; feeding the chips into a crystallizing bed so as to crystallize, and then drying; pouring the dried bottle chips into a screw extruder for performing fusion extrusion; causing the filtered flux to enter into a homogenizing kettle and performing condensation polymerization for 1.4-1.5 hours, thereby homogenizing the flux in the homogenizing kettle; causing the homogenized flux to enter into a spinning box; and spinning according to a high-speed spinning technology, thereby obtaining the dacron FDY filaments. A homogenizing step is added in the producing method, so that the problems of big viscosity fluctuation and inferior stability of the flux of the PET bottle chips are solved, and the continuous and large-scale production of the FDY filament products by taking the recycled PET bottle chips as raw materials is realized.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

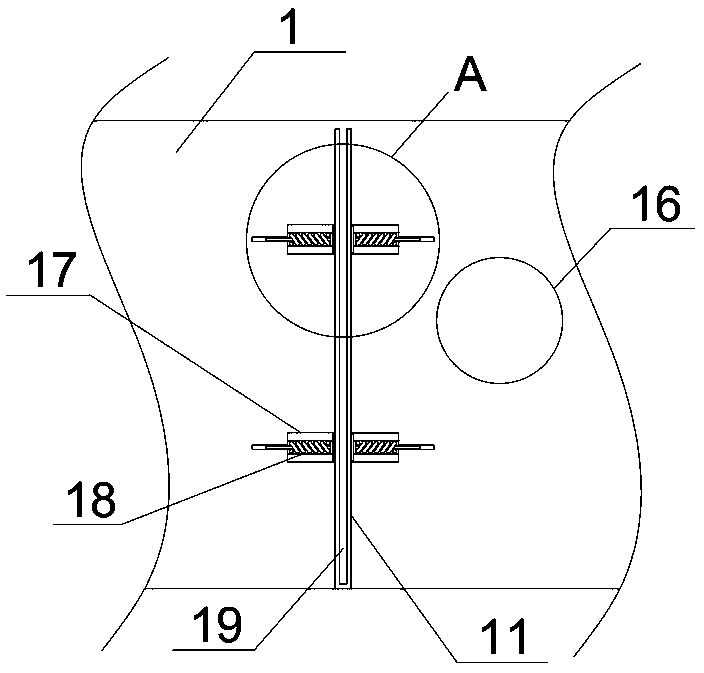

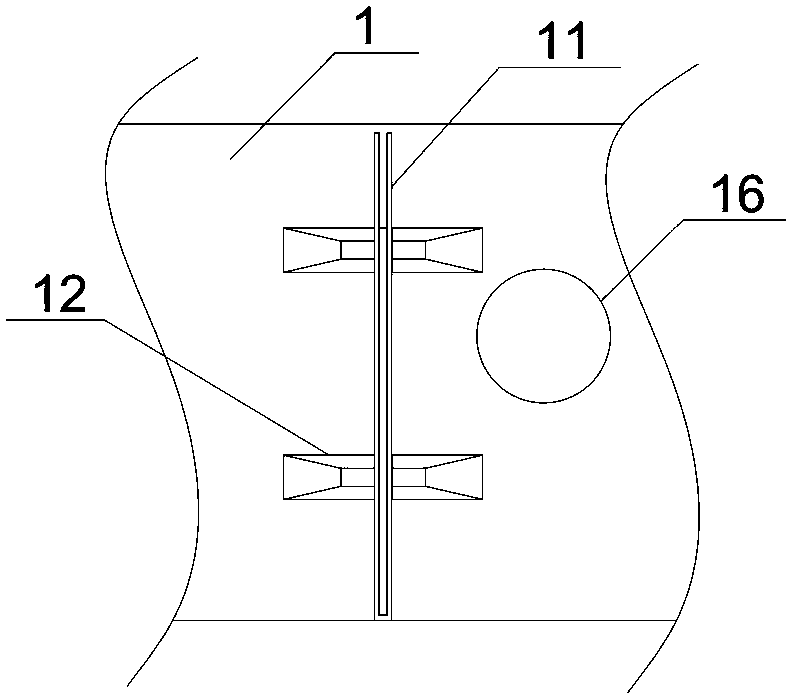

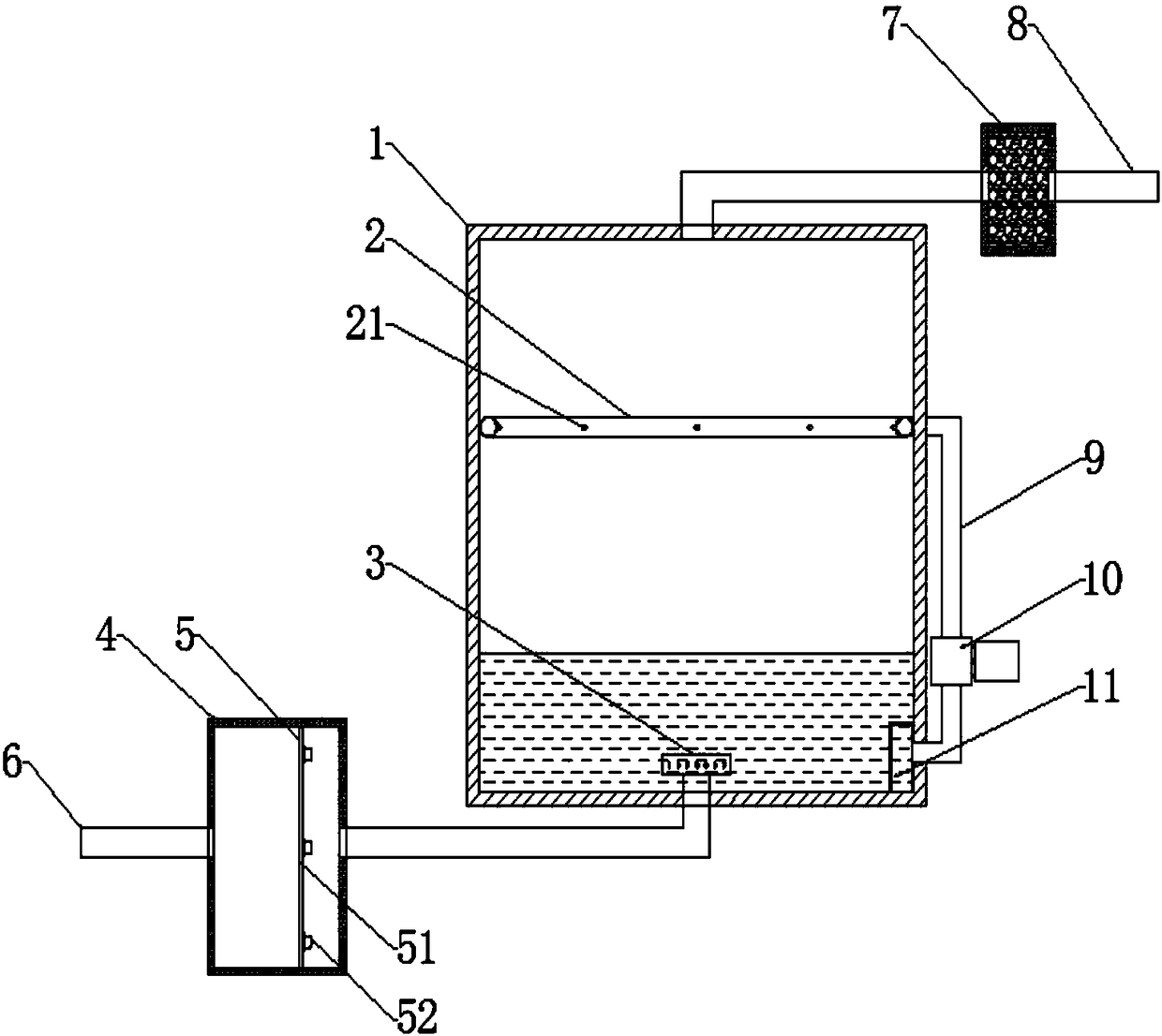

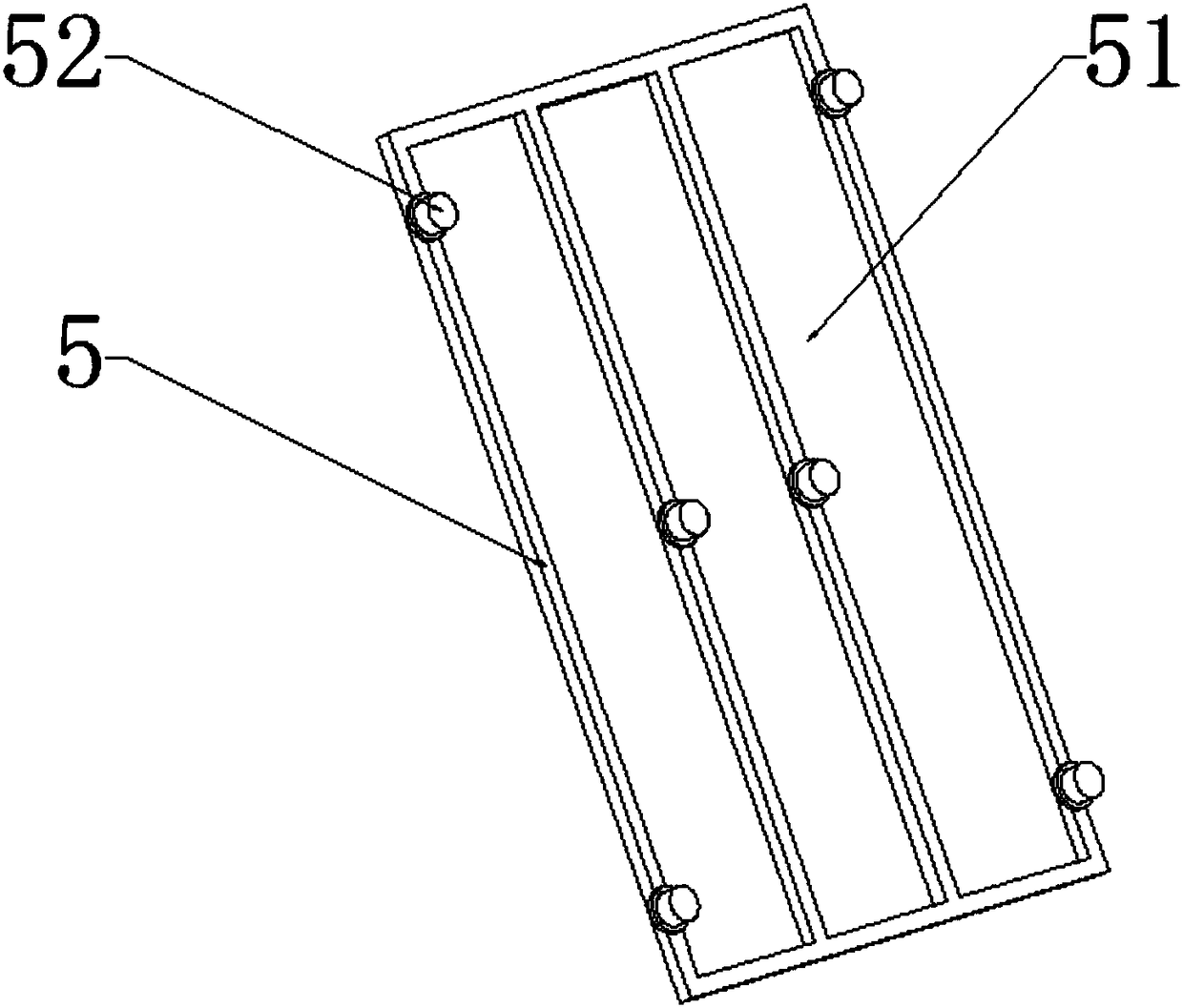

Anti-blocking device of sewage cyclone

ActiveCN110882570AReduce filter pressureReduce jam frequencyStationary filtering element filtersFiltrationWastewater

Belonging to the technical field of blockage prevention of sewage cyclones, the invention discloses an anti-blocking device of a sewage cyclone. The anti-blocking device comprises a box body with an open top, and an inlet and an outlet that are respectively disposed at the front end and rear end of the box body, the outlet is connected to the sewage cyclone, the box body is internally equipped with a filter screen unit comprising a plurality of filter screens, two sides of the box body are respectively equipped with an auxiliary filter unit communicated with the box body, water inlets of the auxiliary filter units are communicated with the front side of the filter screen unit, and water outlets of the auxiliary filter units are communicated with the rear side of the filter screen unit; impurity discharge ports of the auxiliary filter units are communicated with impurity treatment boxes; and a filter screen at the most front end in the filter screen unit has guide parts adjacent to thewater inlets of the auxiliary filter units at both ends close to the side wall of the box body. The anti-blocking device provided by the invention can perform auxiliary filtration while filtering wastewater in the box body through the filter screens, reduces the filtration pressure of the first filter screen, and effectively reduces the occurrence rate of blockage.

Owner:HAITIAN WATER GRP CO LTD

Method for producing dacron FDY (Fully Drawn Yarn) filaments in large scale by utilizing recycled PET (Poly Ethylene Terephthalate) bottle chips

ActiveCN102605455BSolve the problem of water content inconsistencyImprove stabilityFilament forming substance formingMonocomponent polyesters artificial filamentEngineeringBottle

The invention provides a method for producing dacron FDY (Fully Drawn Yarn) filaments in large scale by utilizing recycled PET (Poly Ethylene Terephthalate) bottle chips. The method comprises the following steps: crushing recycled PET bottles into chips; cleaning and then drying; feeding the chips into a crystallizing bed so as to crystallize, and then drying; pouring the dried bottle chips into a screw extruder for performing fusion extrusion; causing the filtered flux to enter into a homogenizing kettle and performing condensation polymerization for 1.4-1.5 hours, thereby homogenizing the flux in the homogenizing kettle; causing the homogenized flux to enter into a spinning box; and spinning according to a high-speed spinning technology, thereby obtaining the dacron FDY filaments. A homogenizing step is added in the producing method, so that the problems of big viscosity fluctuation and inferior stability of the flux of the PET bottle chips are solved, and the continuous and large-scale production of the FDY filament products by taking the recycled PET bottle chips as raw materials is realized.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

Dust collection device for ventilation installation

InactiveCN108379990AImprove filtering effectLow area costCombination devicesDispersed particle filtrationAir filterSpray nozzle

The invention discloses a dust collection device for ventilation installation. The dust collection device comprises a dust collection box, a spray pipe, a filter box and a water pump. The spray pipe is wound around the middle of the inner side wall of the dust collection box; a plurality of spray nozzles are uniformly arranged on the spray pipe; a dispersion disc is arranged at the inner bottom ofthe dust collection box. According to the dust collection device, air is filtered primarily through a dust filter frame and a filter cloth arranged in a deposition box, most of dust is filtered out and dust on the filter cloth is vibrated through an electromagnetic vibrator to fall to be collected, and thus workload of filtering of follow-up work is reduced greatly; besides, the dispersion disc can disperse air carrying dust into water to achieve filtering of the dust; the spray pipe which is wound improves air filtering effect, and air is purified in the filter box finally. Air is filtered through the simple structure, and space occupation and input cost of the dust collection device are reduced.

Owner:DEQING JINGYING INFORMATION TECH CO LTD

Automatic industrial flue gas purifying system

InactiveCN105344194AReasonable designSimple structureHuman health protectionCombination devicesLaser transmitterControl system

The invention discloses an automatic industrial flue gas purifying system. The automatic industrial flue gas purifying system comprises a body, and the top of the body is equipped with clean air discharging pipe. The automatic industrial flue gas purifying system comprises a spray thrower and a filtering screen, and the spray thrower and the filtering screen are arranged in the body. The automatic industrial flue gas purifying system comprises a flue gas input pipe communicated with the side wall of the body, a transmission mechanism connected with the body and used for controlling rotation of the filtering screen, a temperature and pressure data collection device extending into the body and connected with a PLC controller, a gas pressure regulating valve, a liquid flow control system and a laser emitter. The gas pressure regulating valve, the liquid flow control system and the laser emitter are connected with the PLC controller. The automatic industrial flue gas purifying system also comprises a spray water box connected with the liquid flow control system, a laser emitter connected with the temperature and pressure data collection device and the PLC controller, a sewage drainage separation plate arranged inside the body and located under the filtering screen and a primary filtering device. The automatic industrial flue gas purifying system is reasonable in design, is simple in structure, improves flue gas purifying effects effectively and raises the dedusting efficiency.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

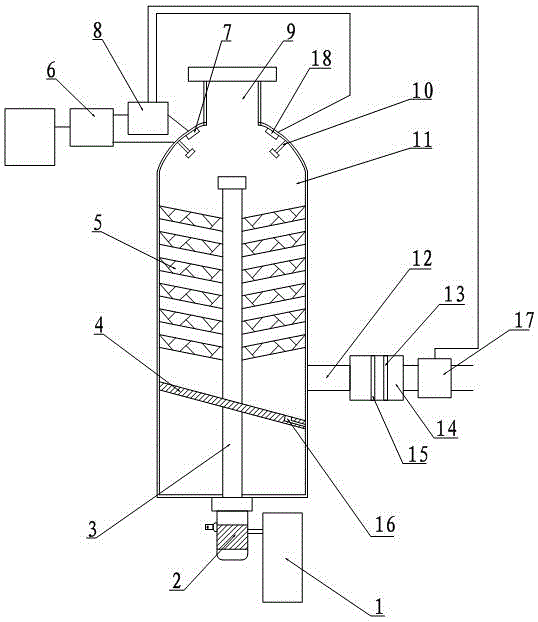

Swirling self-cleaning filter

InactiveCN107398114AAchieve pre-separationReduce filter pressureFiltration circuitsSewage treatmentFilter effect

The invention relates to the field of sewage treatment equipment, in particular to a swirling self-cleaning filter. The filter comprises a straight cylinder and a conical cylinder, wherein a swirling sewage discharge system is formed between the lower part of the straight cylinder and the conical cylinder and comprises a sewage inlet pipe arranged at the lower part of the straight cylinder in the tangential direction and a swirling sewage outlet pipe arranged at the lower end of the conical cylinder; a self-cleaning adsorption drainage system is arranged at the upper part of the straight cylinder and comprises a cylindrical filter element fixed in the straight cylinder and a hollow rotating shaft, a clean water outlet tube is arranged on the wall of the straight cylinder, and a plurality of sewage suction pipes are arranged on the hollow rotating shaft at intervals in the axial direction; a sewage suction head and an elastic element for tightly pressing the sewage suction head on the inner wall of the cylindrical filter element are arranged at one end, away from the hollow rotating shaft, of each sewage suction pipe; an adsorption sewage discharge pipe is connected to the lower end of the hollow rotating shaft through a rotary joint, one end, away from the hollow rotating shaft, of the adsorption sewage discharge pipe extends out of the wall of the conical cylinder, and a pressure control valve is arranged at the end. The filter is good in filtering effect and easy to maintain, and has a self-cleaning function.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

Anti-blockage engine oil filter for automobile

ActiveCN106958473AExtend the life cycleImprove filtering effectPressure lubricationLubricant mounting/connectionMetal impuritiesFilter paper

The invention provides an anti-blockage engine oil filter for an automobile. The anti-blockage engine oil filter comprises a shell, a bottom plate and a transverse partition plate. The transverse partition plate is arranged in the shell and divides the interior of the shell into a first filtering cavity and a second filtering cavity. The transverse partition plate is provided with a first oil conducting port communicating with the first filtering cavity and the second filtering cavity, and a plurality of first through holes communicating with the first filtering cavity and the second filtering cavity. A first filter element is arranged in the first filtering cavity, an annular containing cavity is formed in a second barrel of the first filter element, and the annular containing cavity is filled with metal impurity adsorption materials. The second filtering cavity is internally provided with a second filter element, a bypass valve is arranged on a second end cover of the second filter element, an inlet of the bypass valve communicates with the second filtering cavity, and an outlet of the bypass valve communicates with an inner cavity of a third barrel. According to the anti-blockage engine oil filter, the metal impurity adsorption materials are used for adsorbing and filtering out large-particle metal impurities in engine oil, the filtering pressure of filter paper is reduced, the using cycle of the second filter element is prolonged, and the filtering effect of the second filter element is improved.

Owner:安徽宏辉滤清器有限公司

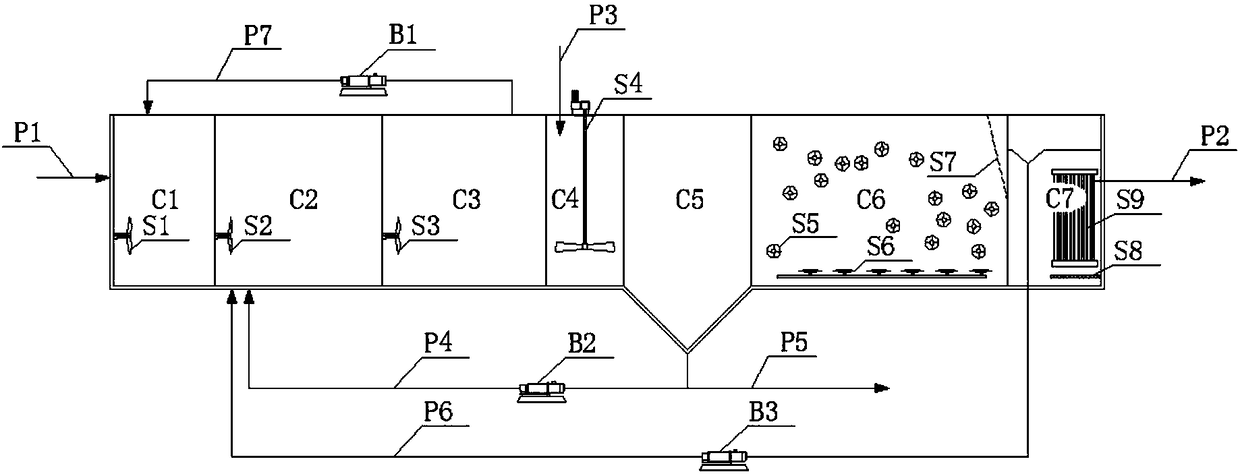

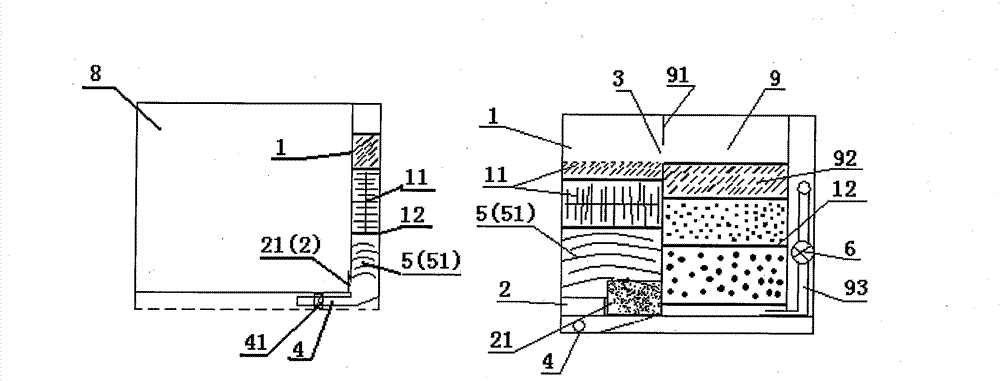

MBBR (Moving Bed Biofilm Reactor) sewage treatment system and treatment process

PendingCN108585385AReduce SS concentrationReduce wearWater treatment parameter controlSpecific water treatment objectivesFlocculationReflux

The invention discloses an MBBR (Moving Bed Biofilm Reactor) sewage treatment system and a treatment process and belongs to the technical field of sewage treatment. The problems in the prior art thata treatment process of the traditional sewage treatment plant is long in procedure, low in integration level, low in load, high in carbon source requirement and common in effect of removing nitrogen,phosphorus and SS are solved. The sewage treatment system comprises an anaerobic zone, an anoxic zone I, an anoxic zone II, a flocculation zone, a settling zone, a biofilm zone, an effluent zone and pipelines for connecting the zones. According to operations of adjusting reflux, controlling the sludge concentration, setting parameters of the suspended carrier filling rate in the biofilm zone and DO, setting the membrane flux of a membrane assembly in the effluent zone and aeration density and the like, by utilizing the characteristic of denitrifying phosphate-accumulating organisms, the settling zone is arranged on a middle section of biochemical treatment, the biofilm process is coupled to the denitrification filter process, and the sewage treatment system disclosed by the invention has the advantages of being high in integration level, capable of synchronously removing nitrogen and phosphorus and saving the carbon source, low in concentration of the nitrogen, phosphorus and SS in theeffluent, high in load and long in equipment service life.

Owner:QINGDAO SPRING WATER TREATMENT

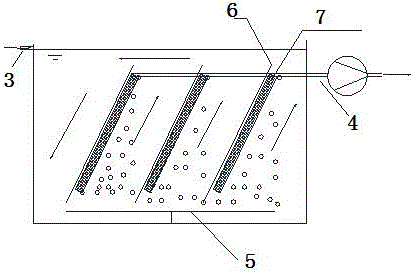

Water-pollutant separation device

ActiveCN102726337AImprove sewage discharge capacityReduce workloadPisciculture and aquariaFiltrationWater quality

The invention relates to a water-pollutant separation device. The water-pollutant separation device comprises a box body, as well as a water inlet pipe, a water outlet pipe and a pollutant discharge pipe which are respectively communicated with the separation box body, wherein a separation structure is arranged in an inner cavity of the box body, the separation structure comprises a plurality of spoilers, one side of each spoiler is fixed on the side wall of the box body, each spoiler is slightly smaller than the box body, a water inlet is arranged below the separation structure, the spoilers are sequentially mounted on the periphery of the inner side wall of the box body from the water inlet from bottom to top, and a plurality of open holes or slots for producing slow flow to disturb water flow are formed in each spoiler. By adopting the technical scheme, the preferential water-pollutant separation device is additionally arranged before filtration of a fish tank, thus most of pollutants in water can be easily separated and discharged, the accumulation of the pollutants relative to the filter material can be greatly reduced, and the water quality and stability can be improved.

Owner:常君斌

Method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on scale

ActiveCN102605454BSolve the problem of water content inconsistencyGuaranteed Filtration QualityFilament forming substance formingMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate

The invention provides a method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on a scale. The method comprises the steps of crushing the recycled PET bottles into chips, washing and drying, sending into a crystallization bed body for crystallization, forming crystallization layers on the surfaces of the bottle chips, sending the crystallized bottle chips into a drying tower which is provided with a pair of spiral agitators, leading the dried bottle chips to enter a screw extruder for melting and extrusion, sending the obtained melt into a two-stage filtration device consisting of a coarse filter, a fine filter and a pressure pump between the coarse filter and the fine filter for filtration, leading the melt which is filtrated by two stages to enter a liquid phase tackifying kettle, conducting polycondensation reaction in the liquid phase tackifying kettle, leading the melt after being subjected to liquid phase tackifying to enter a spinning box, and spinning by adopting a high-speed spinning process, thus obtaining the industrial polyester filament. In the method for producing the industrial polyester filament, the liquid phase tackifying step is added in the production process, so that the problems of low viscosity and poor stability of the PET bottle chip melts are solved.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

Oblique plate type membrane-biological integrated wastewater treatment device and treatment method thereof

PendingCN106430582AEasy to separatePrevent subsidenceTreatment with aerobic and anaerobic processesSustainable biological treatmentWater qualityReaction zone

The invention belongs to the field of wastewater treatment, in particular to an oblique plate type membrane-biological integrated wastewater treatment device and a treatment method thereof. The oblique plate type membrane-biological integrated wastewater treatment device comprises a membrane separation system and a biological treatment system, wherein the biological treatment system comprises an anaerobic / anoxic reaction zone and an aerobic reaction zone, a water inlet is formed in the anaerobic / anoxic reaction zone, and an oblique plate settlement water outlet is formed in the aerobic reaction zone; the membrane separation system is connected with the oblique plate settlement water outlet; an aerating system is mounted at the bottom of the aerobic reaction zone, an oblique plate assembly is mounted above the aerating system and comprises multiple parallel oblique plates, and a membrane assembly is mounted below each oblique plate and is parallel to the corresponding oblique plate. According to the wastewater treatment device, the membrane separation system and an oblique plate settlement and activated sludge system form the integrated biological wastewater treatment device, membrane pollution can be effectively reduced while the biological treatment efficiency and the effluent water quality are improved, and the membrane cleaning time is prolonged.

Owner:宜兴市产品质量监督检验所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com