Swirling self-cleaning filter

A self-cleaning filter and cyclone technology, applied in filtration and separation, filtration circuits, chemical instruments and methods, etc., can solve the problems of inconvenient installation and maintenance of filters, single filtration form, low separation efficiency, etc., and reduce equipment maintenance. pressure, improved separation efficiency, and improved usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

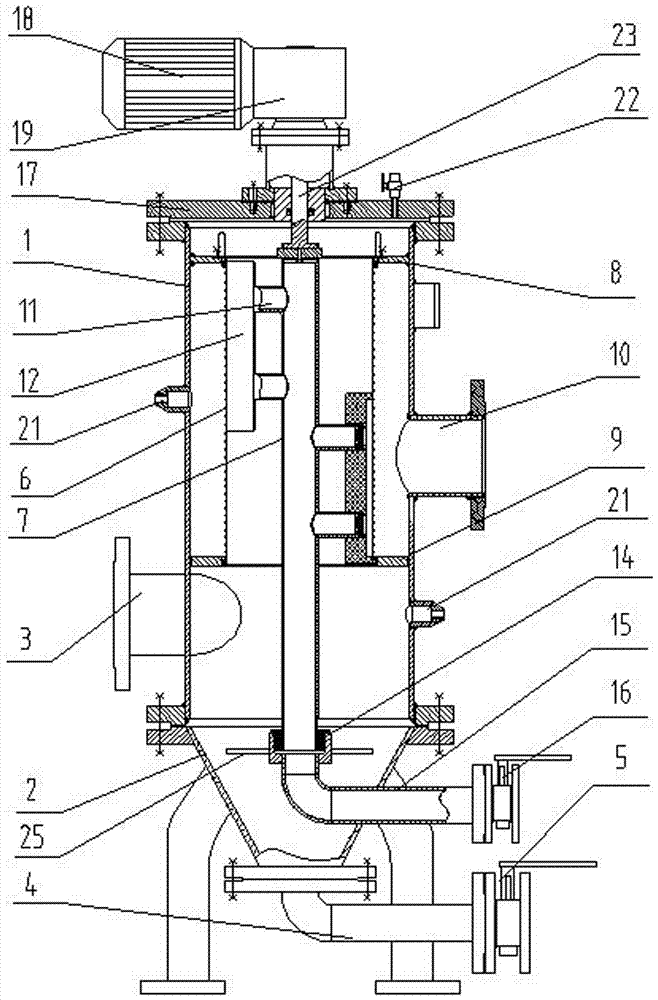

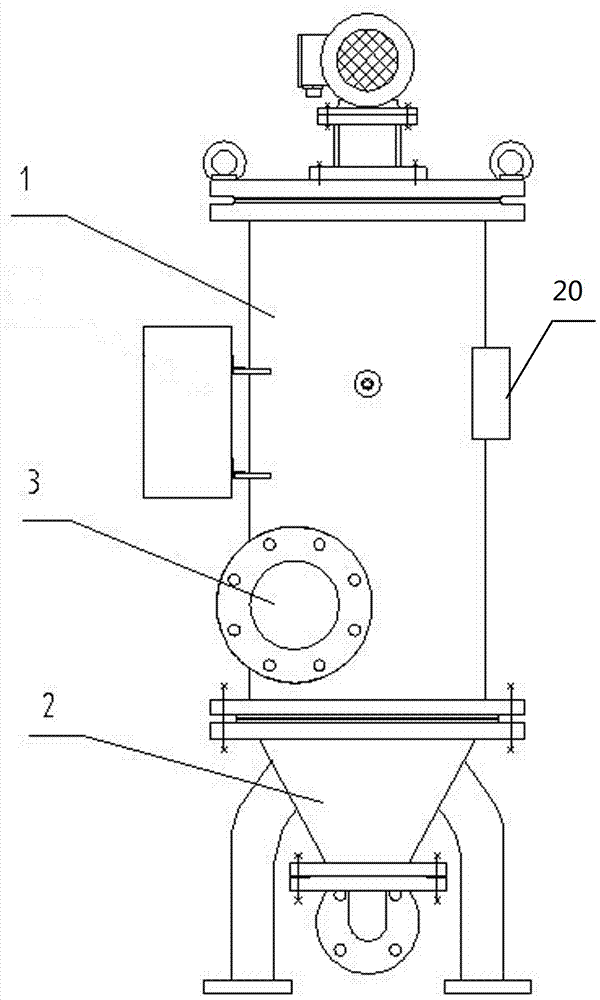

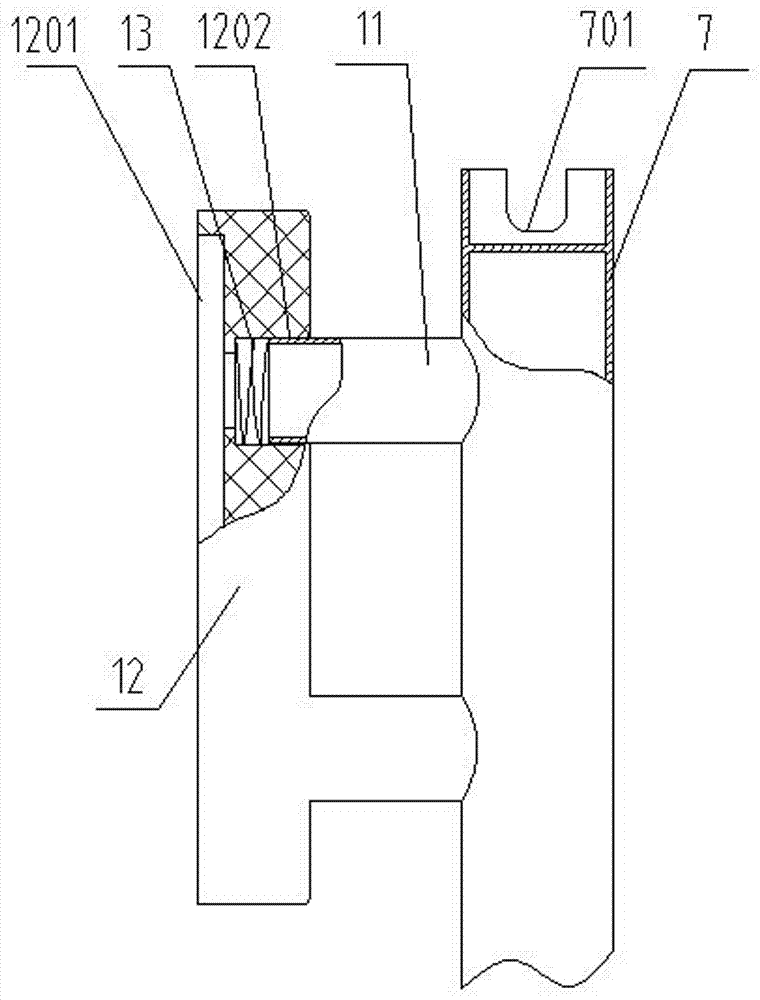

[0025] like Figure 1 to Figure 4 As shown, a cyclone self-cleaning filter of the present invention includes a straight cylinder 1 and a cone cylinder 2 connected to the lower end of the straight cylinder 1. The lower part of the straight cylinder 1 and the cone cylinder 2 communicate with each other and form a spiral Flow sewage system, the upper inner cavity of the straight cylinder 1 is provided with a self-cleaning adsorption sewage system. The combination of cyclone filtration and adsorption filtration not only greatly improves the separation efficiency, but also reduces the operating pressure of the filter in the adsorption filtration system, prolonging the maintenance interval and service life.

[0026] The swirl sewage system also includes a sewage inlet pipe 3 arranged on the lower wall of the straight cylinder 1 along the tangential direction and a swirl sewage pipe 4 arranged at the lower end of the cone cylinder 2, and a swirl sewage discharge pipe 4 is provided. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com