Patents

Literature

868results about "Single direction vortex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

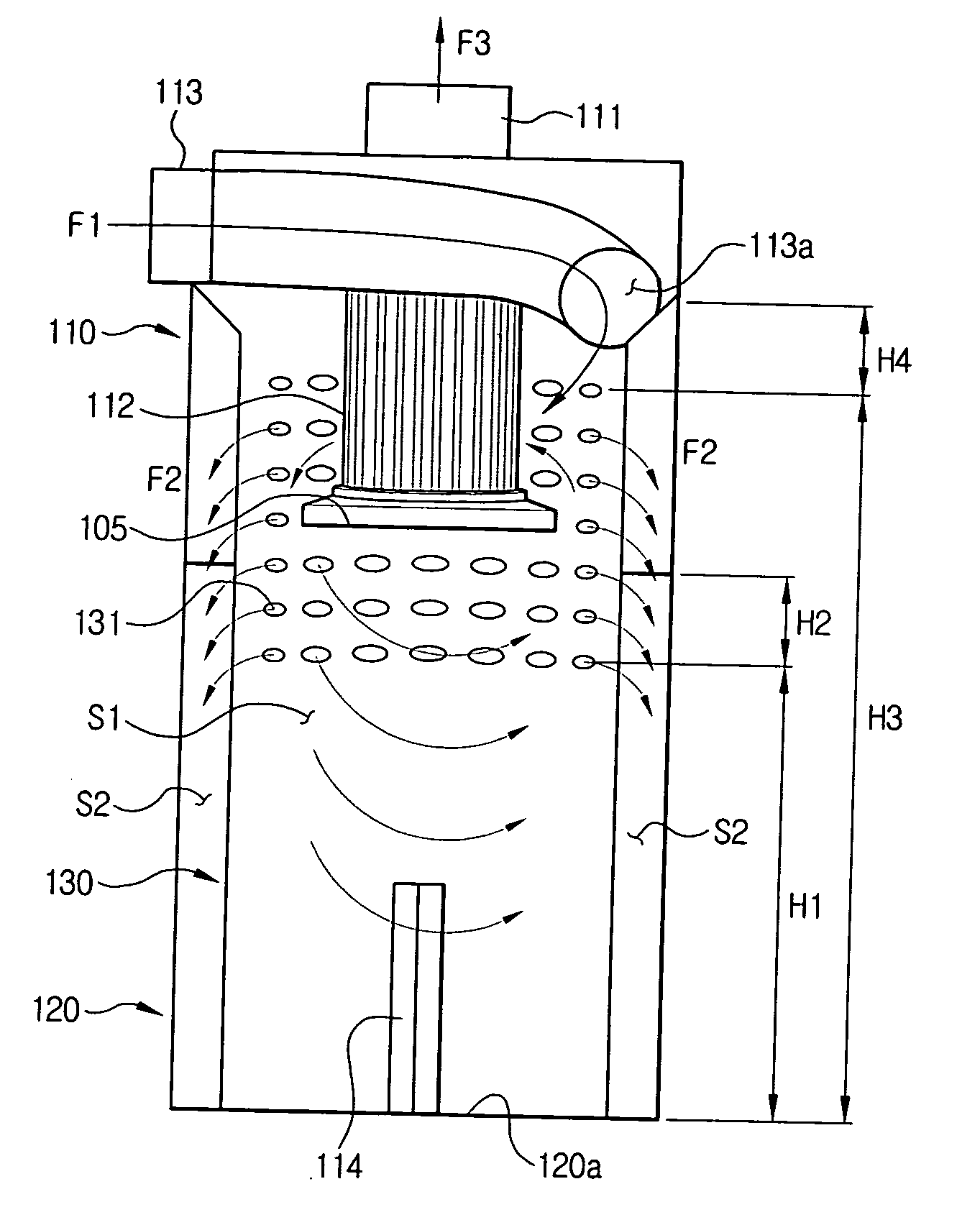

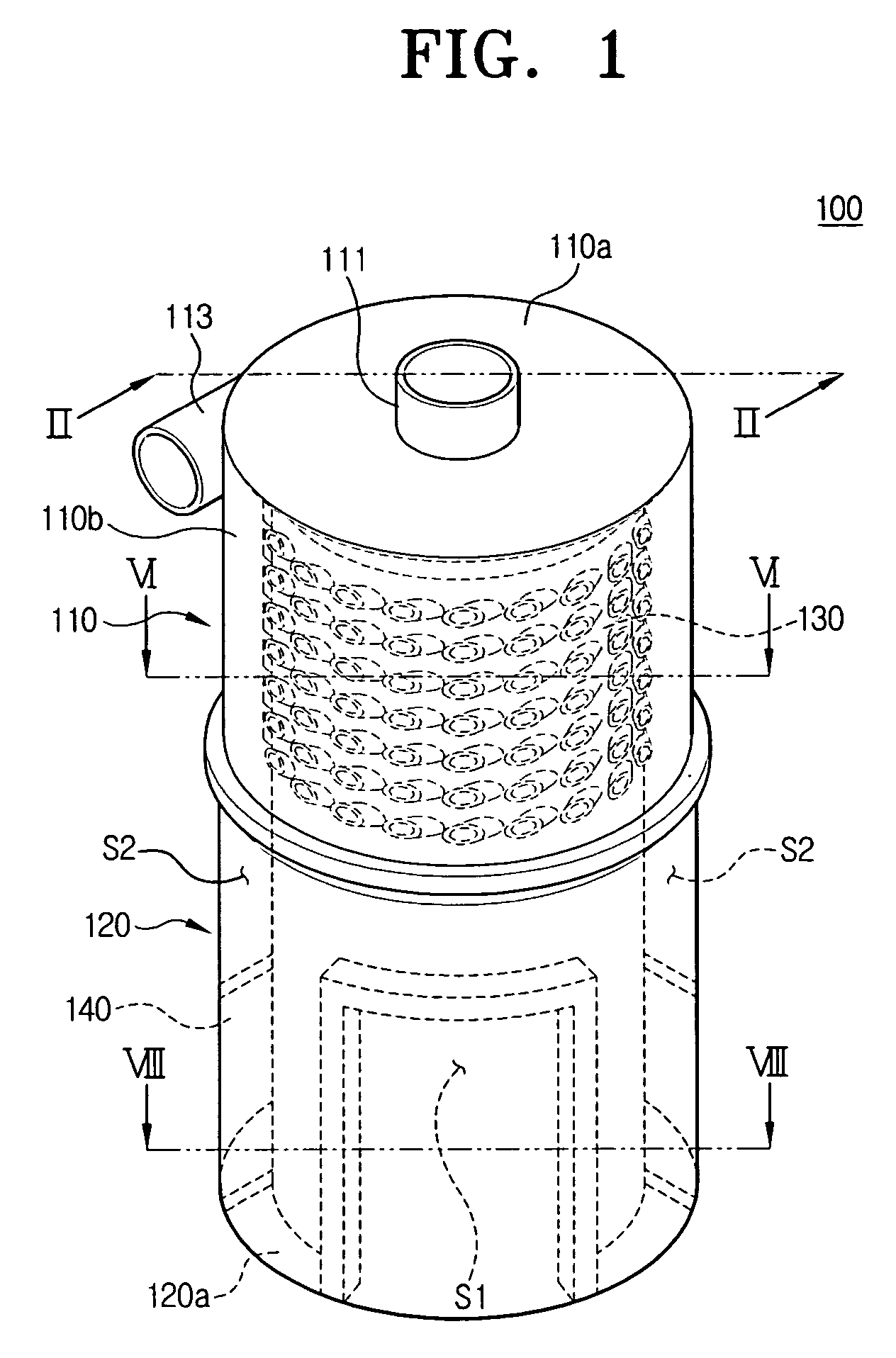

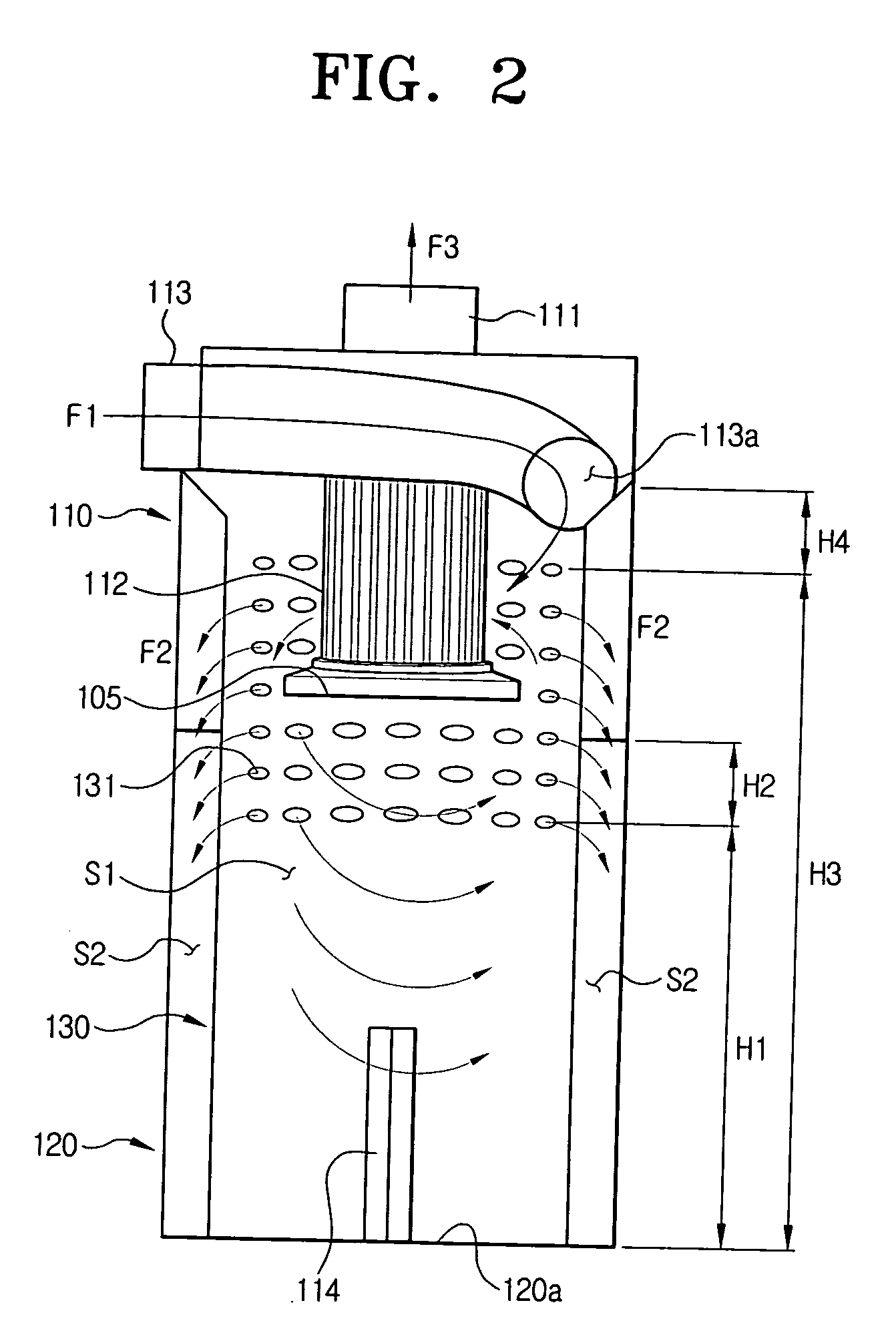

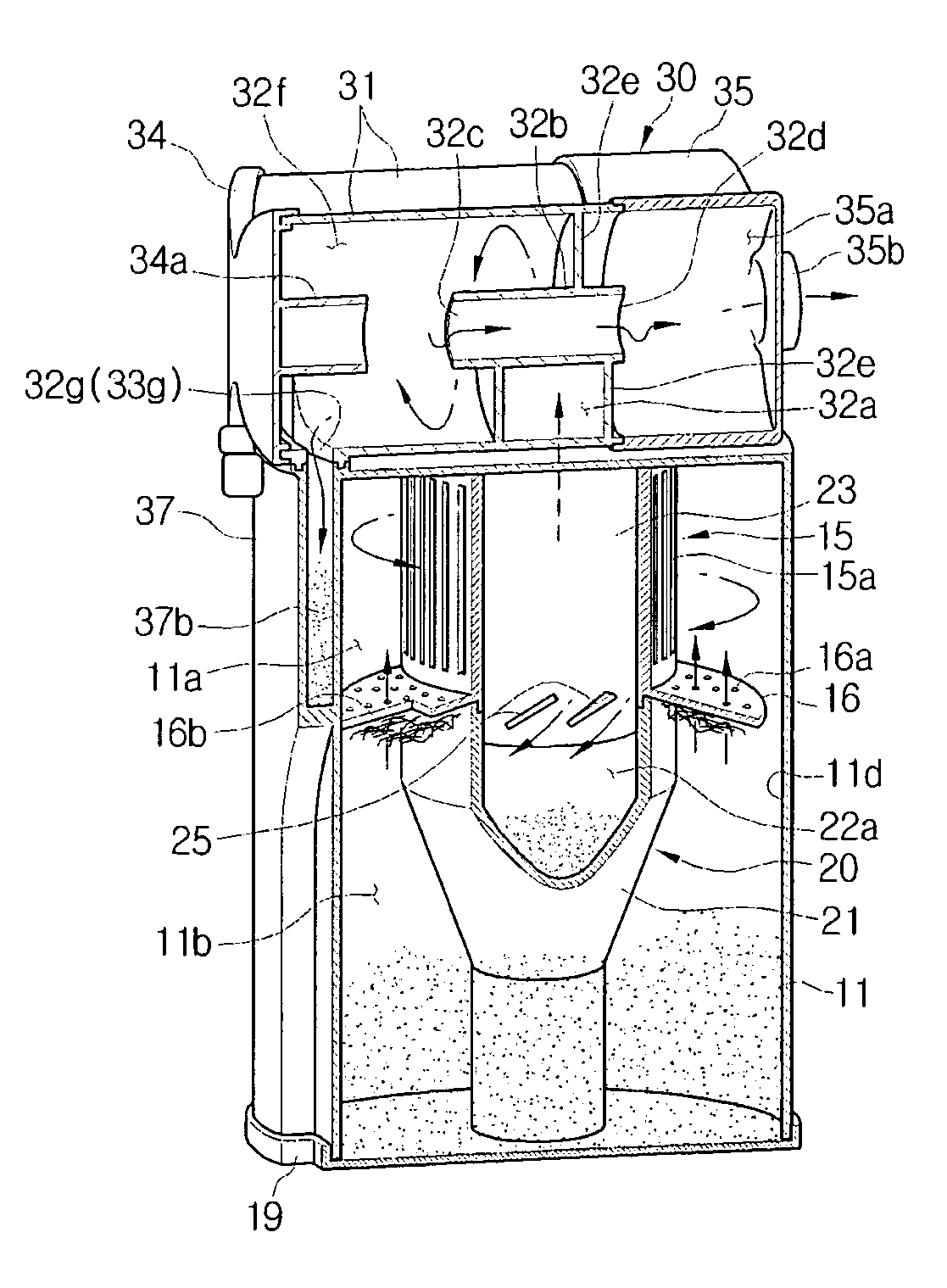

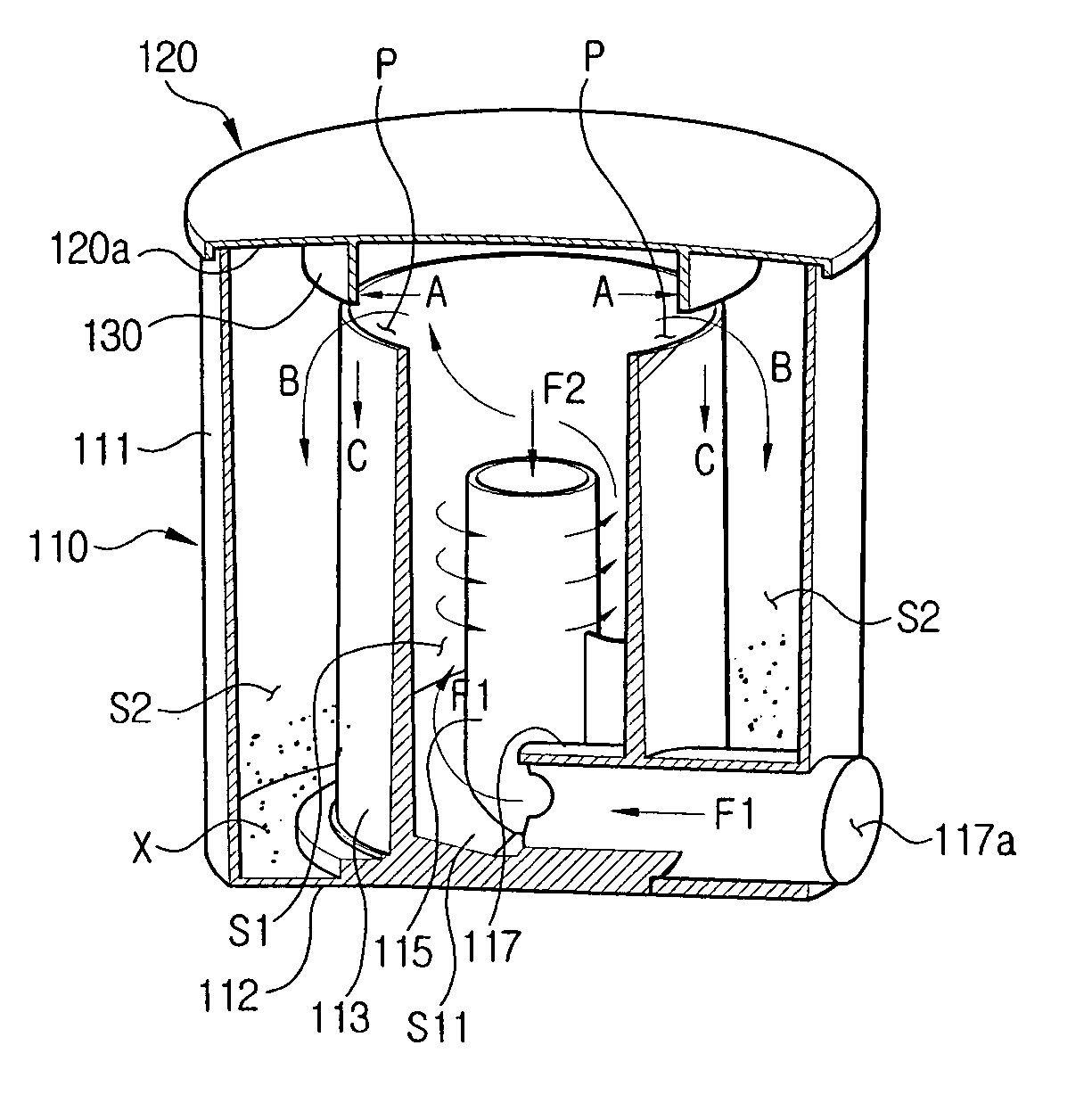

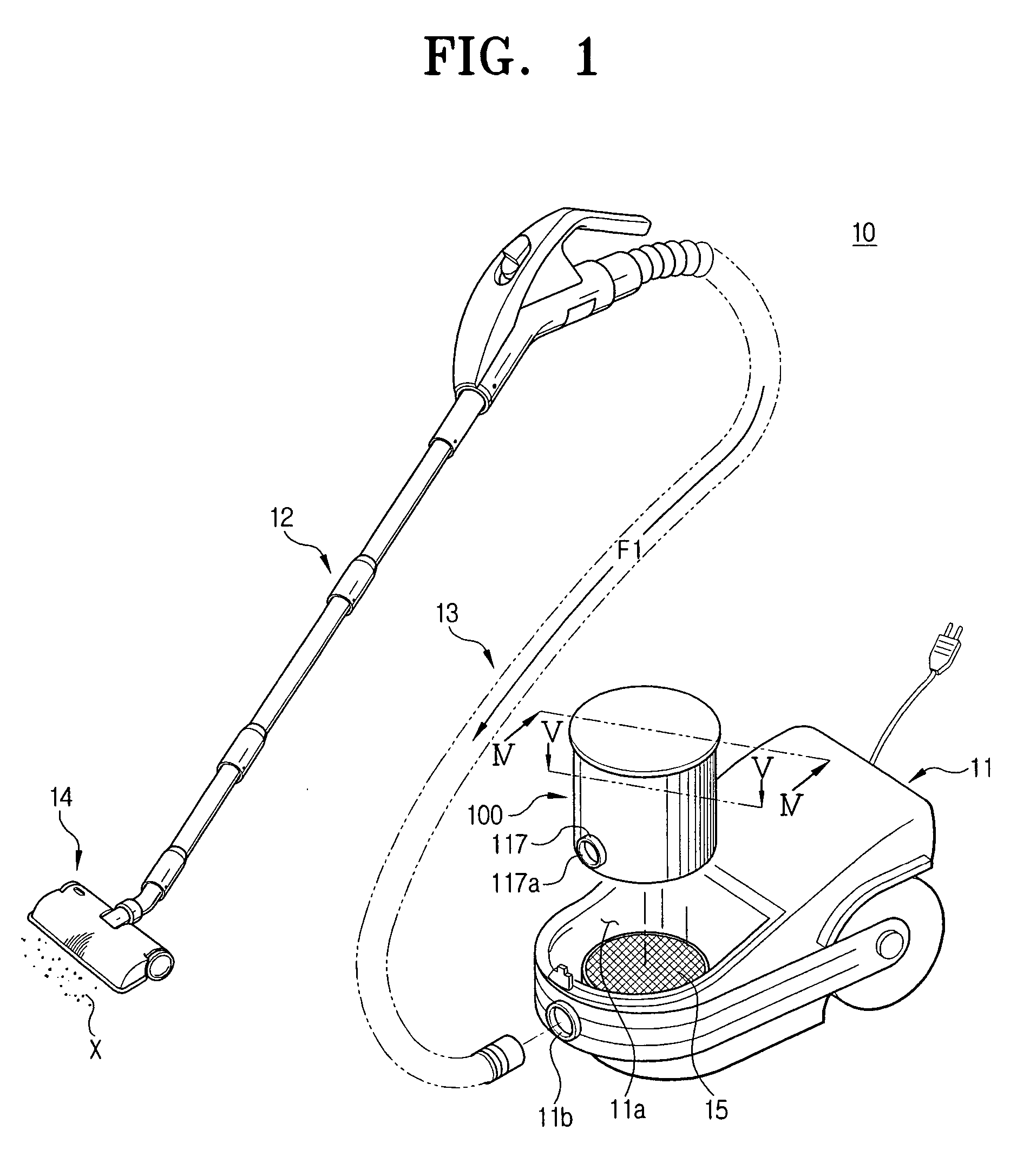

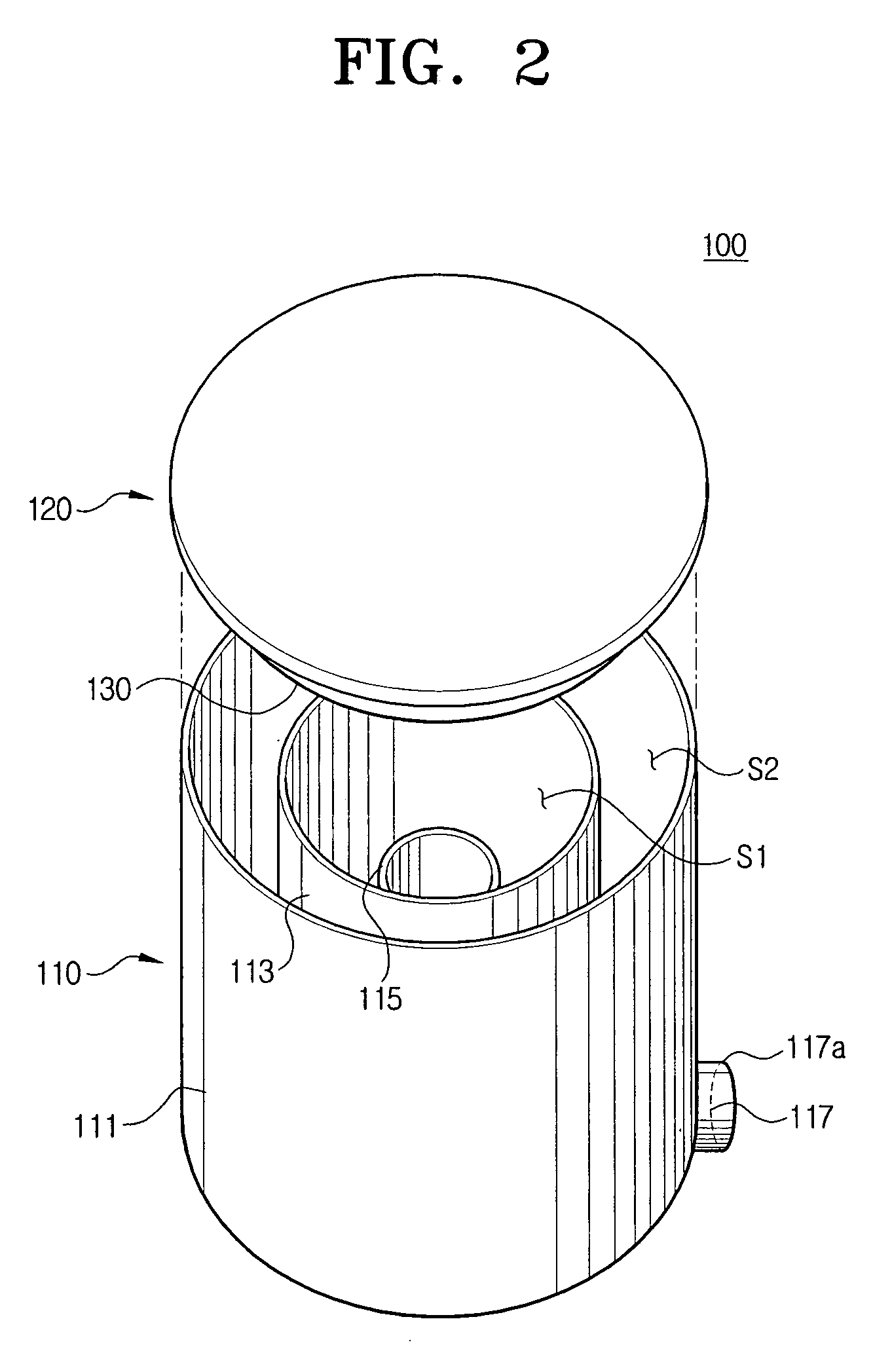

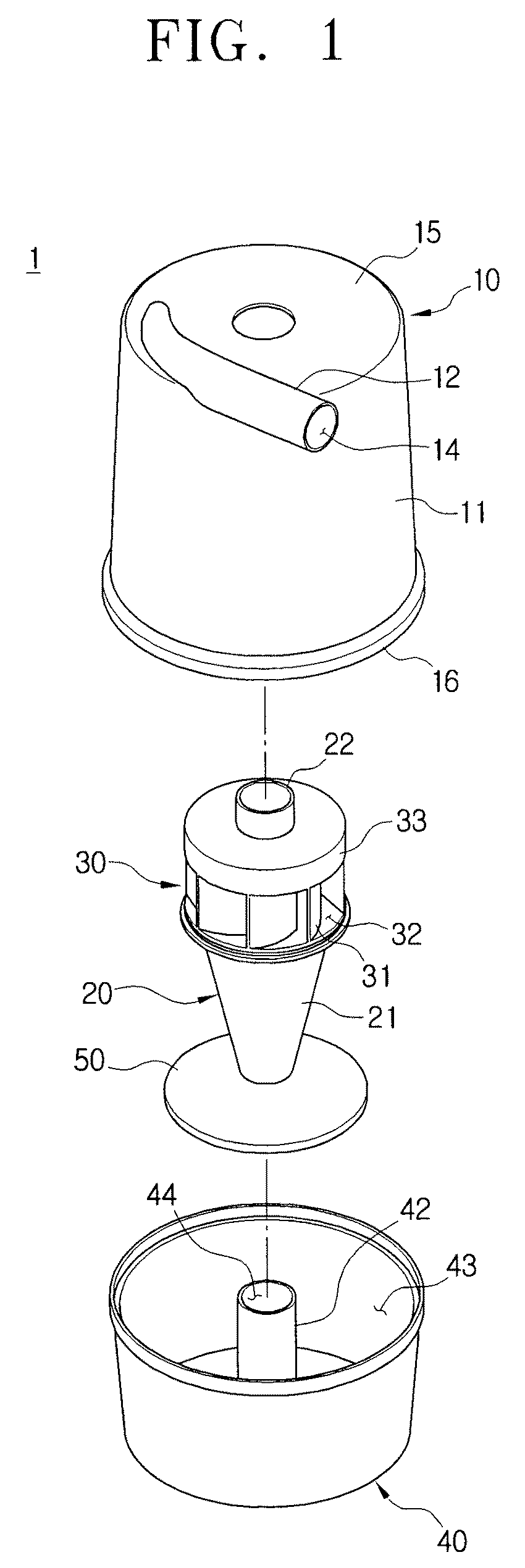

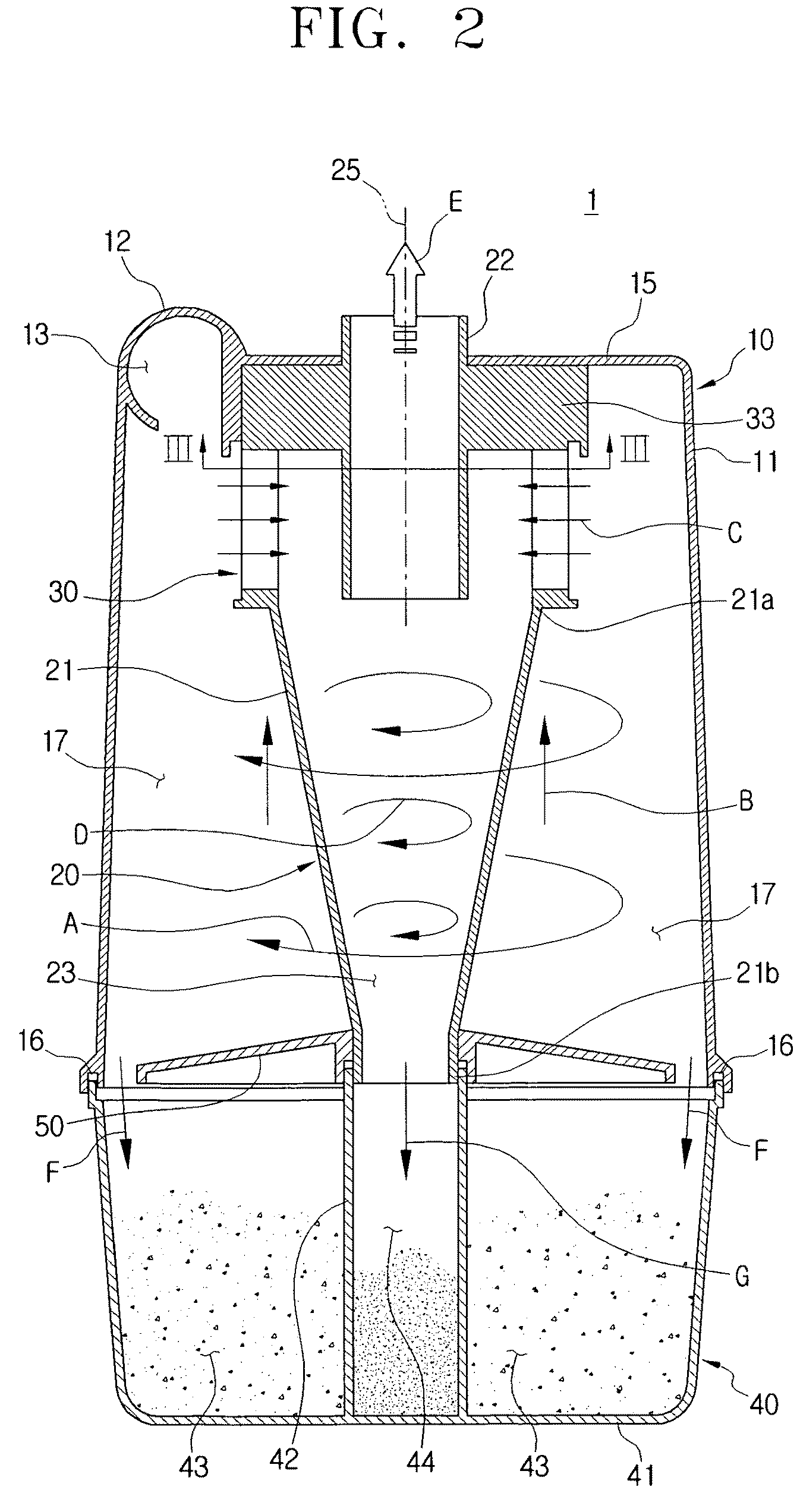

Cyclonic separating apparatus for vacuum cleaner which is capable of separately collecting water from dust

InactiveUS20060162298A1Easy to separatePreventing dispersion and subsequent backflowCombination devicesAuxillary pretreatmentInterior spaceCyclonic separation

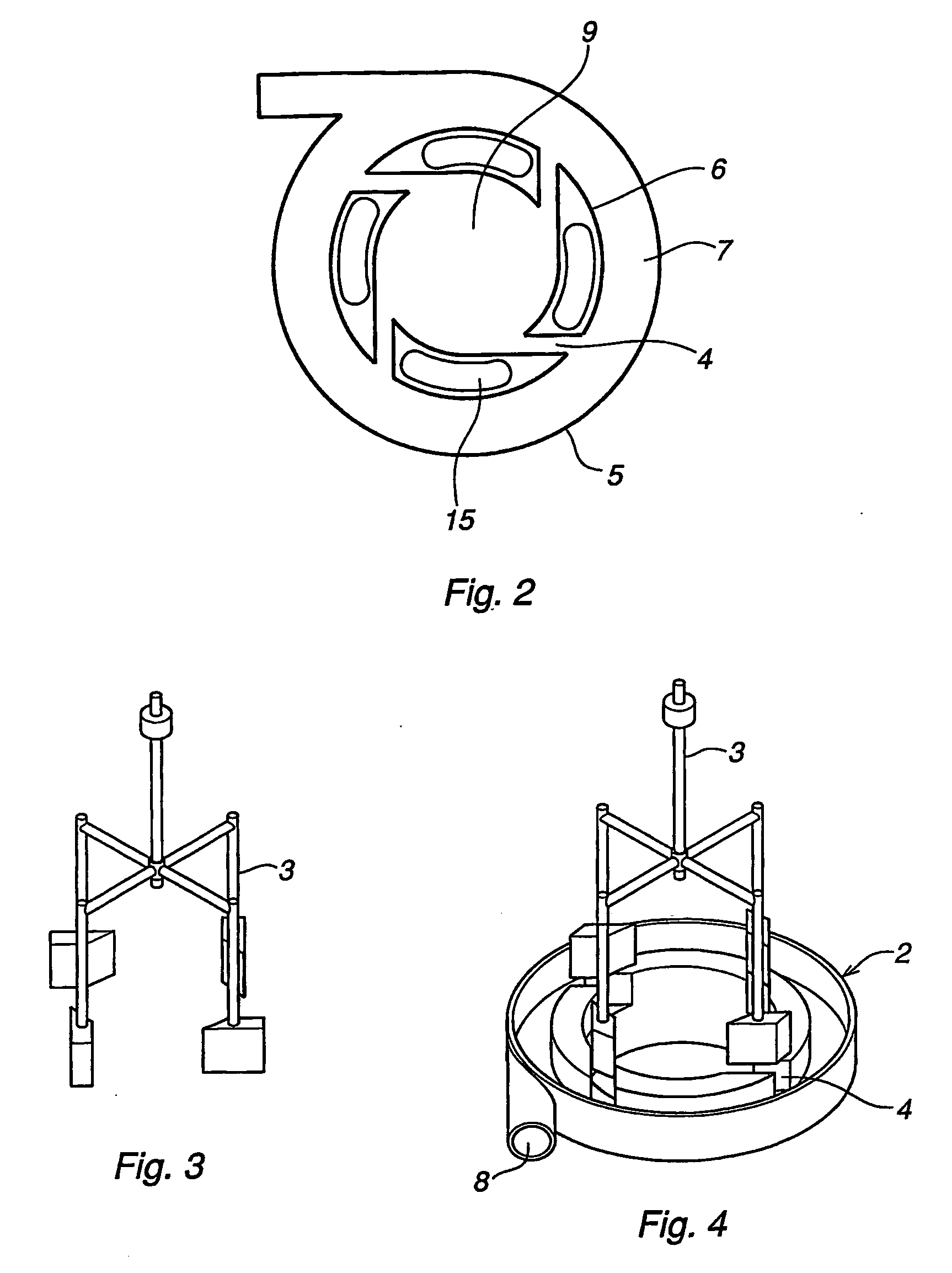

A cyclonic separating apparatus for a vacuum cleaner that can separately collect dust and water. The cyclonic separating apparatus includes: a cyclone body having an air inlet passage and an air discharge passage; a dust receptacle connected to a lower end of the cyclone body; and a screen dividing the cyclone body and interior space of the dust receptacle into a first chamber and a second chamber, the screen having a plurality of passing holes, wherein drawn air rotates in the first chamber and water separated from the air moves to the second chamber through the passing holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

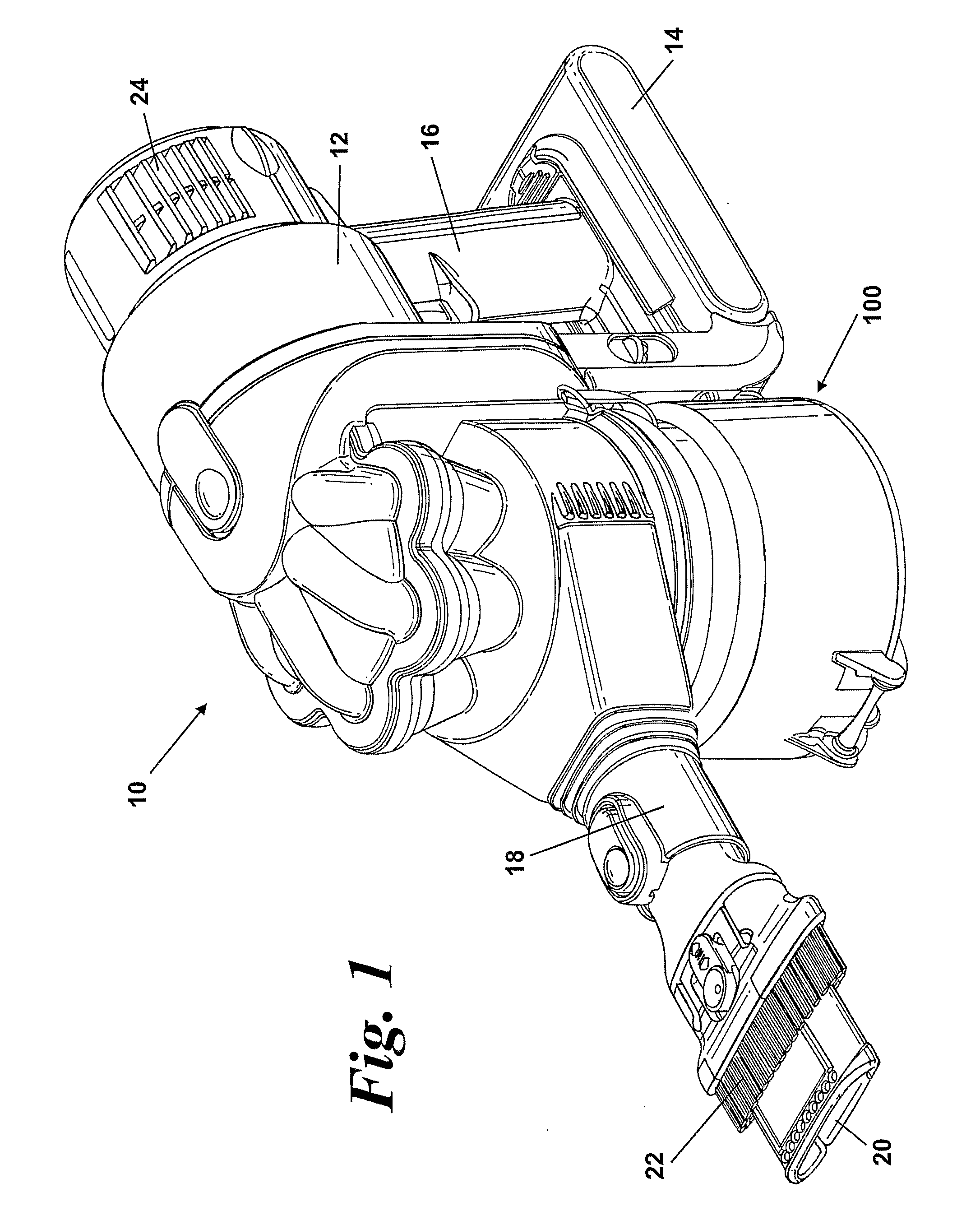

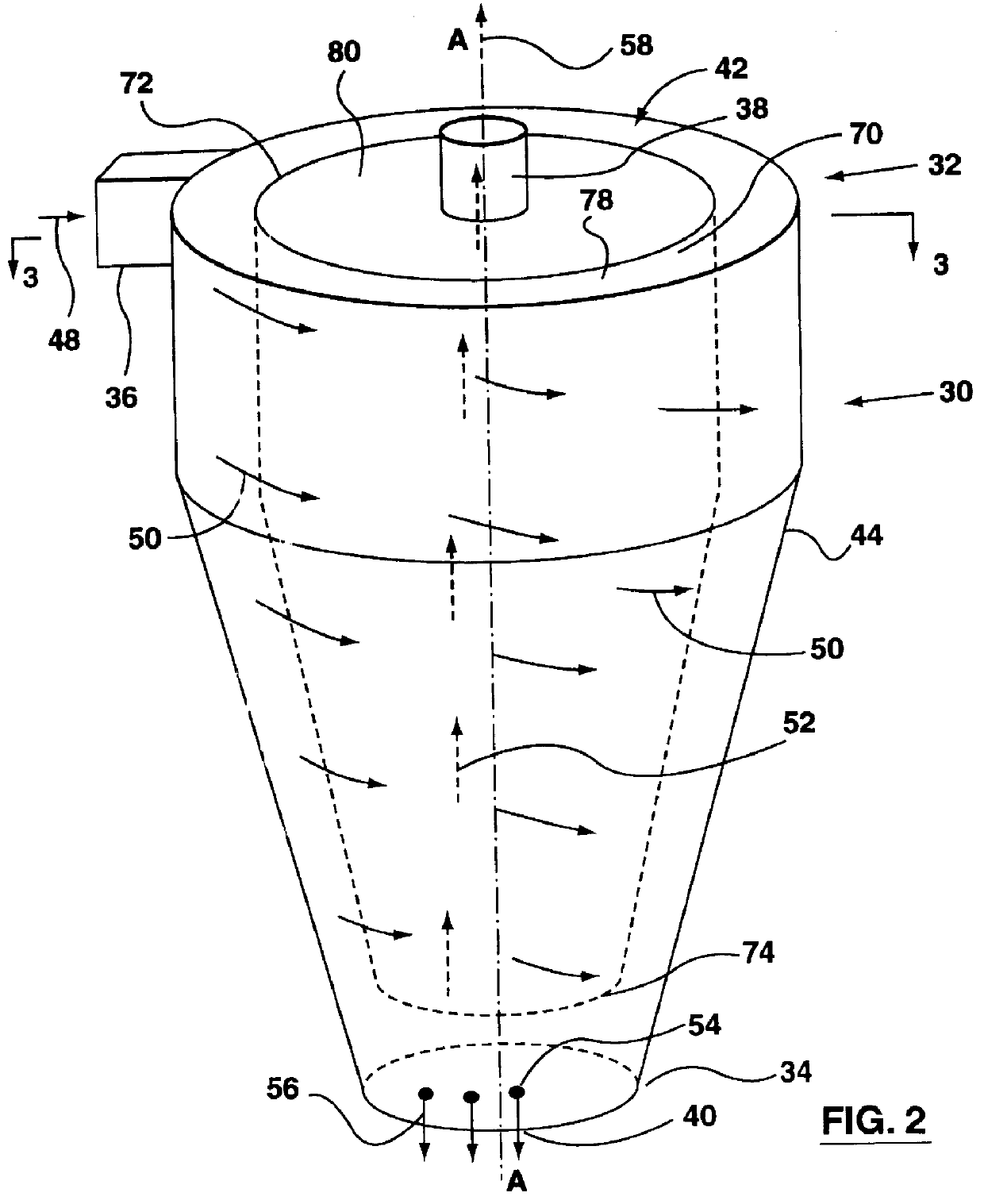

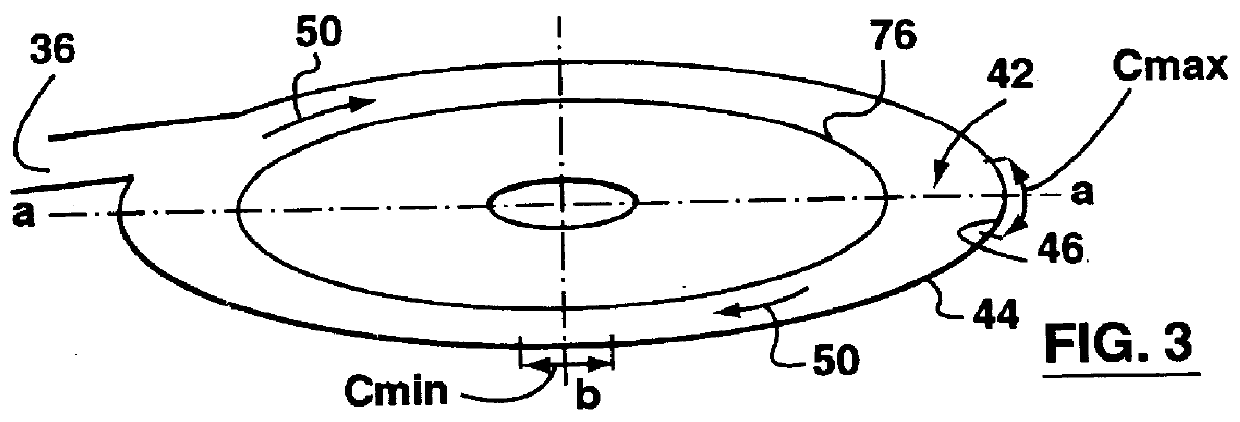

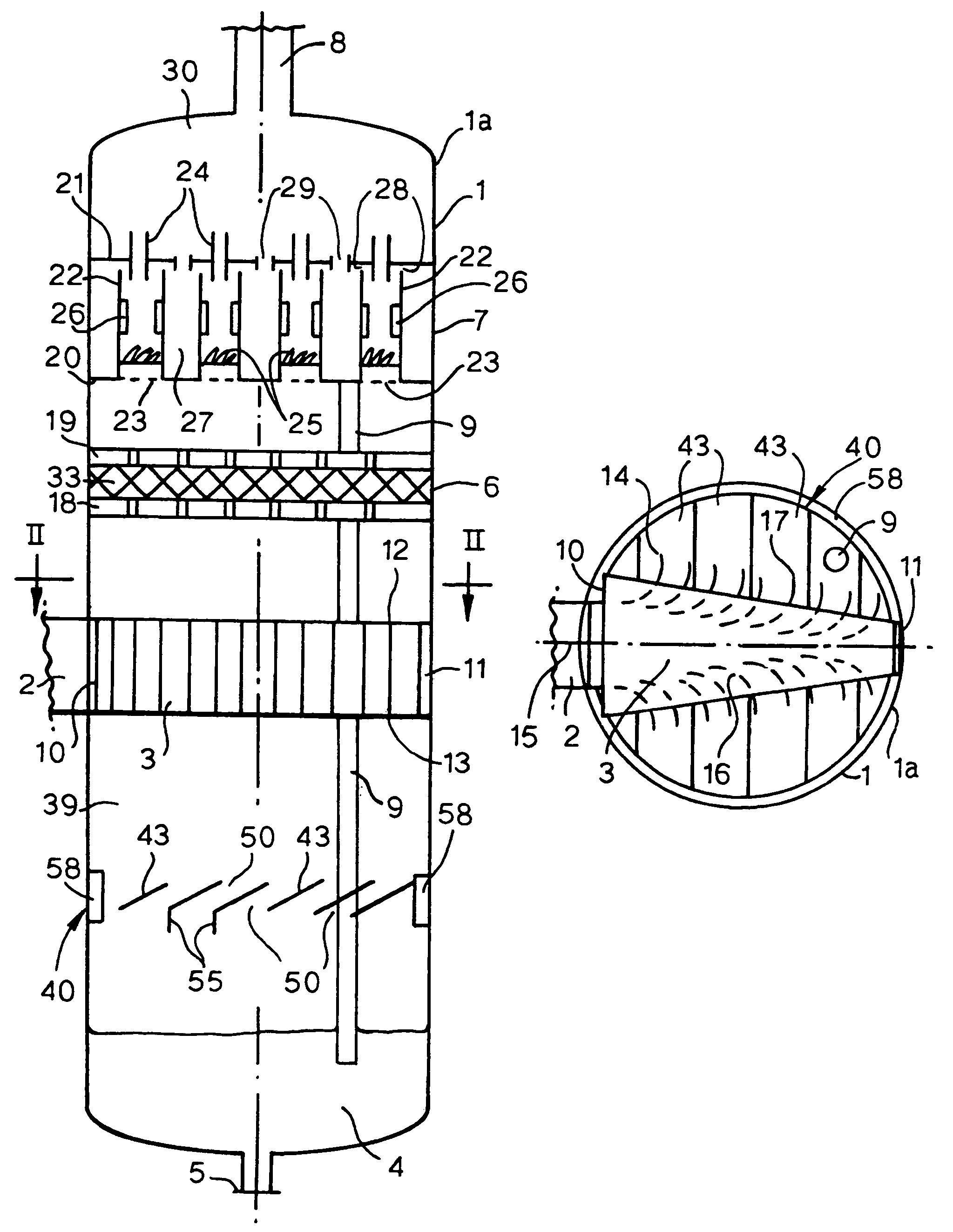

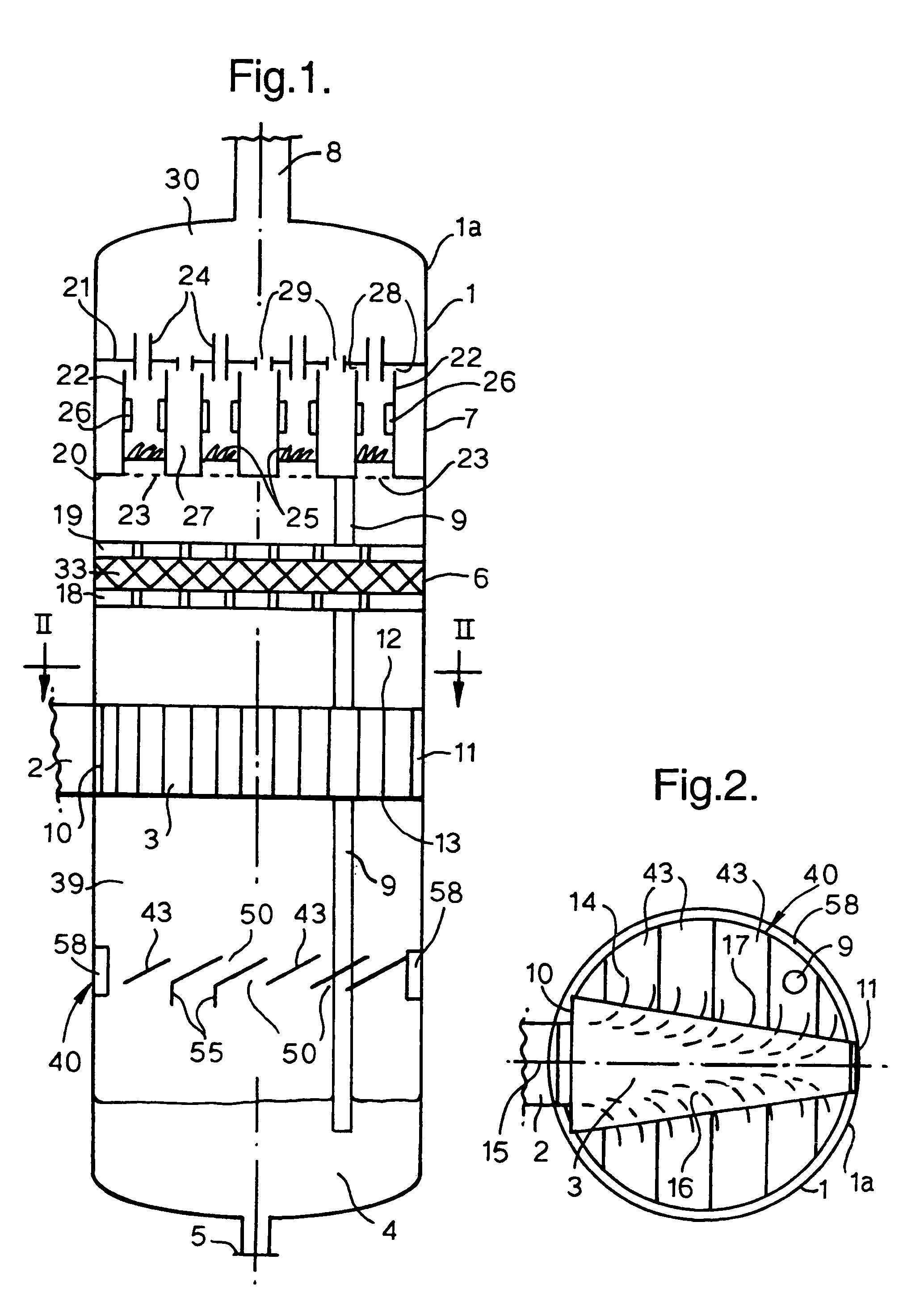

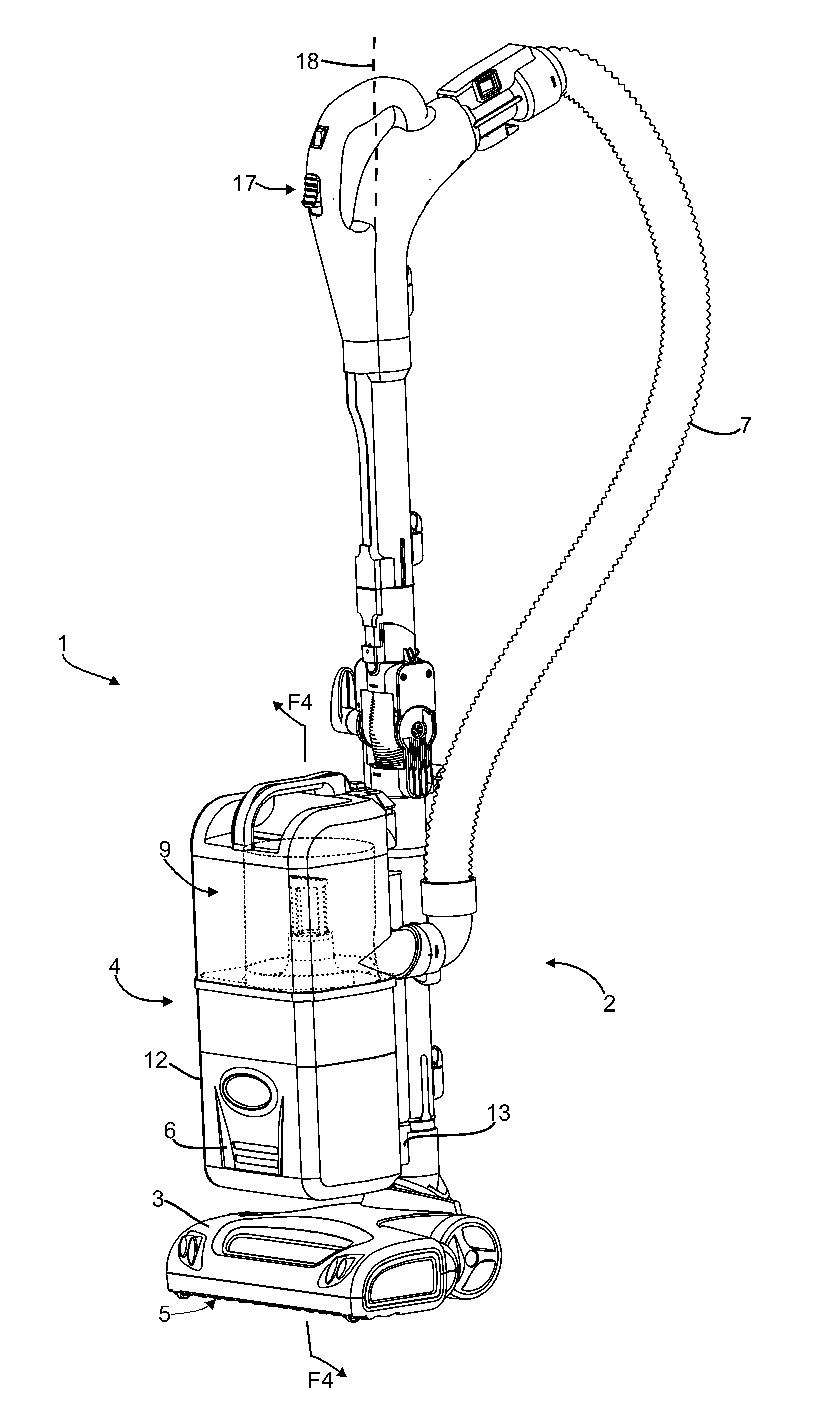

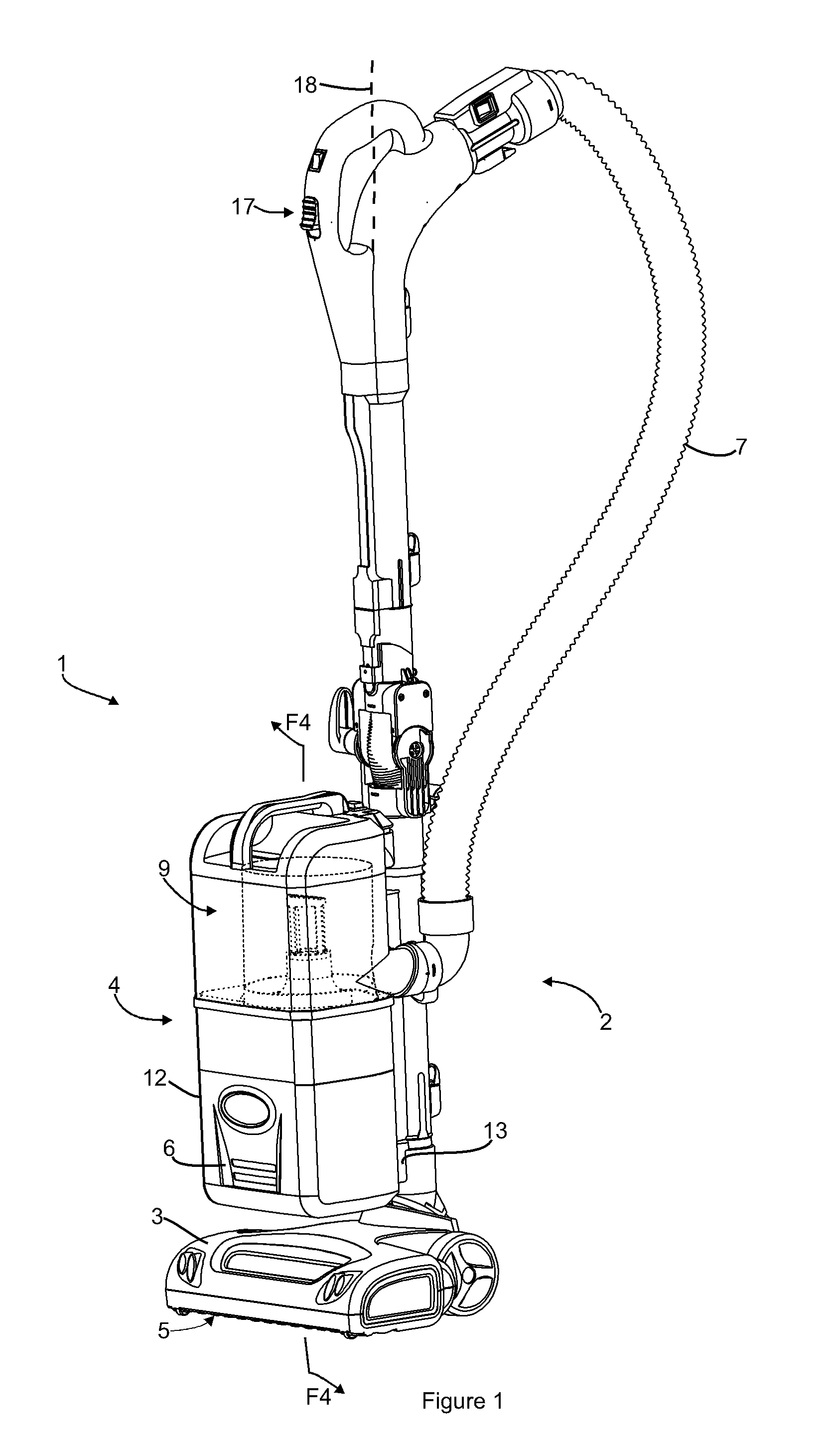

Cyclonic separating apparatus

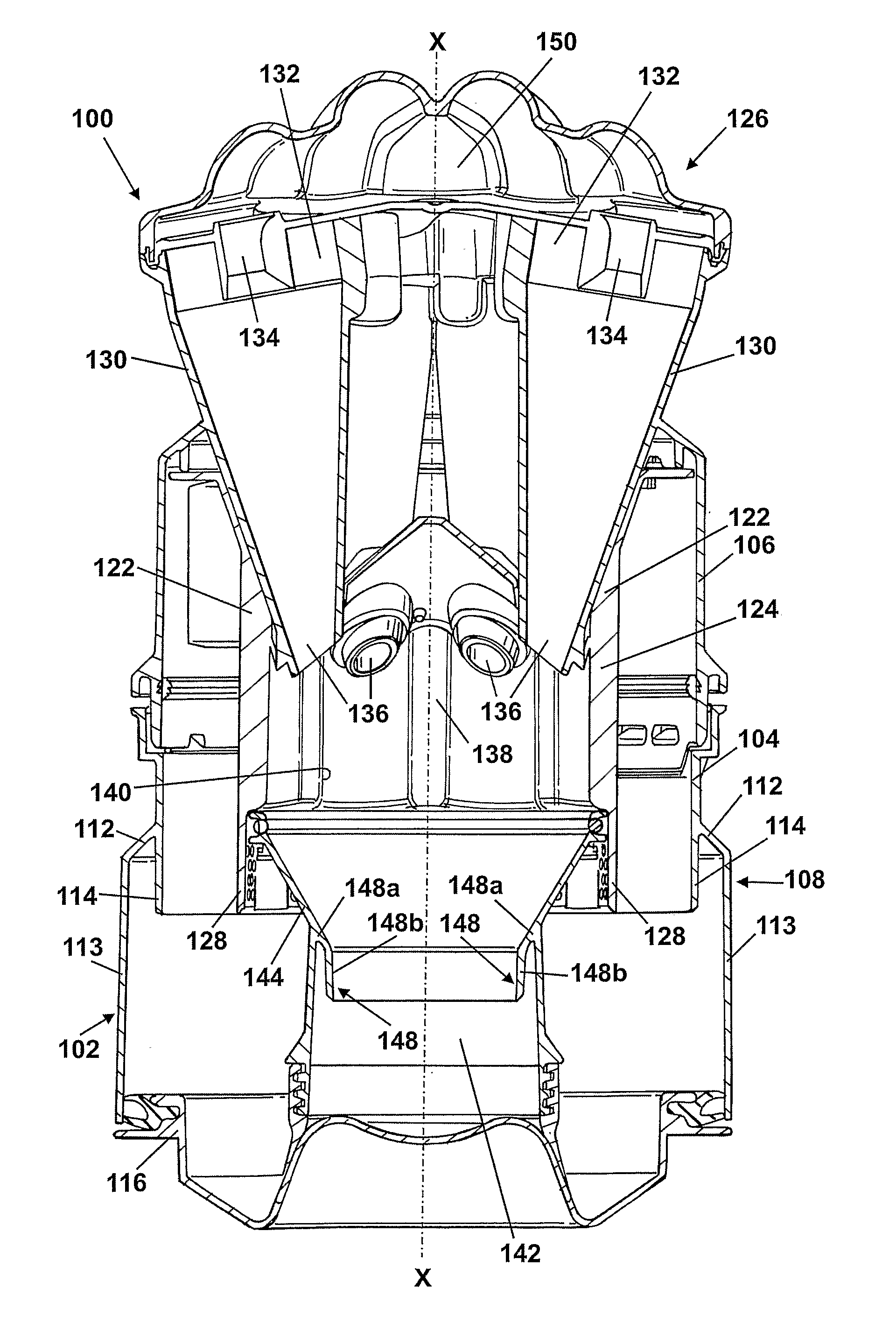

InactiveUS20090313958A1Reduces risk of re-entrainmentMinimize impactCombination devicesSuction filtersCycloneCyclonic separation

A cyclonic separating apparatus for separating particles from a dirt-laden airflow includes a cyclone for separating and collecting dirt and dust from the dirt-laden airflow. The cyclone has an air inlet, an air outlet, a longitudinal axis and a wall. The wall includes a first portion and a second portion spaced farther from the longitudinal axis than the first portion, the first and second portions being spaced along the longitudinal axis. The cyclone also includes at least one lip extending from the first portion of the wall into a portion of the cyclone surrounded by the second portion of the wall. By providing a cyclone with a wall having two portions of different sizes and a lip extending from the portion with the smaller size into the portion with the larger size, the risk of blockages due to re-entrainment and movement of dirt and dust within the cyclonic separating apparatus is reduced.

Owner:DYSON TECH LTD

Cyclone dust separating apparatus

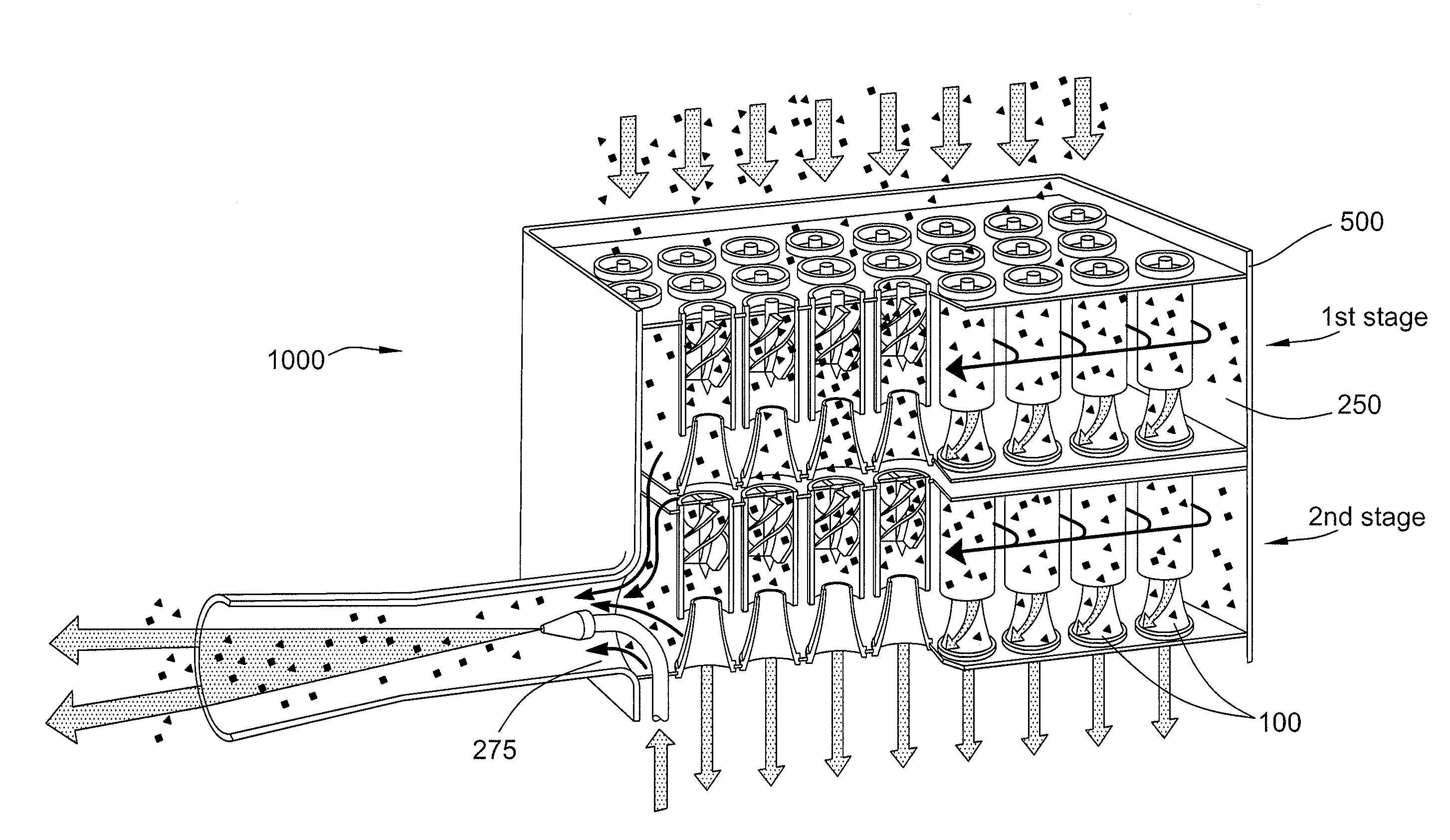

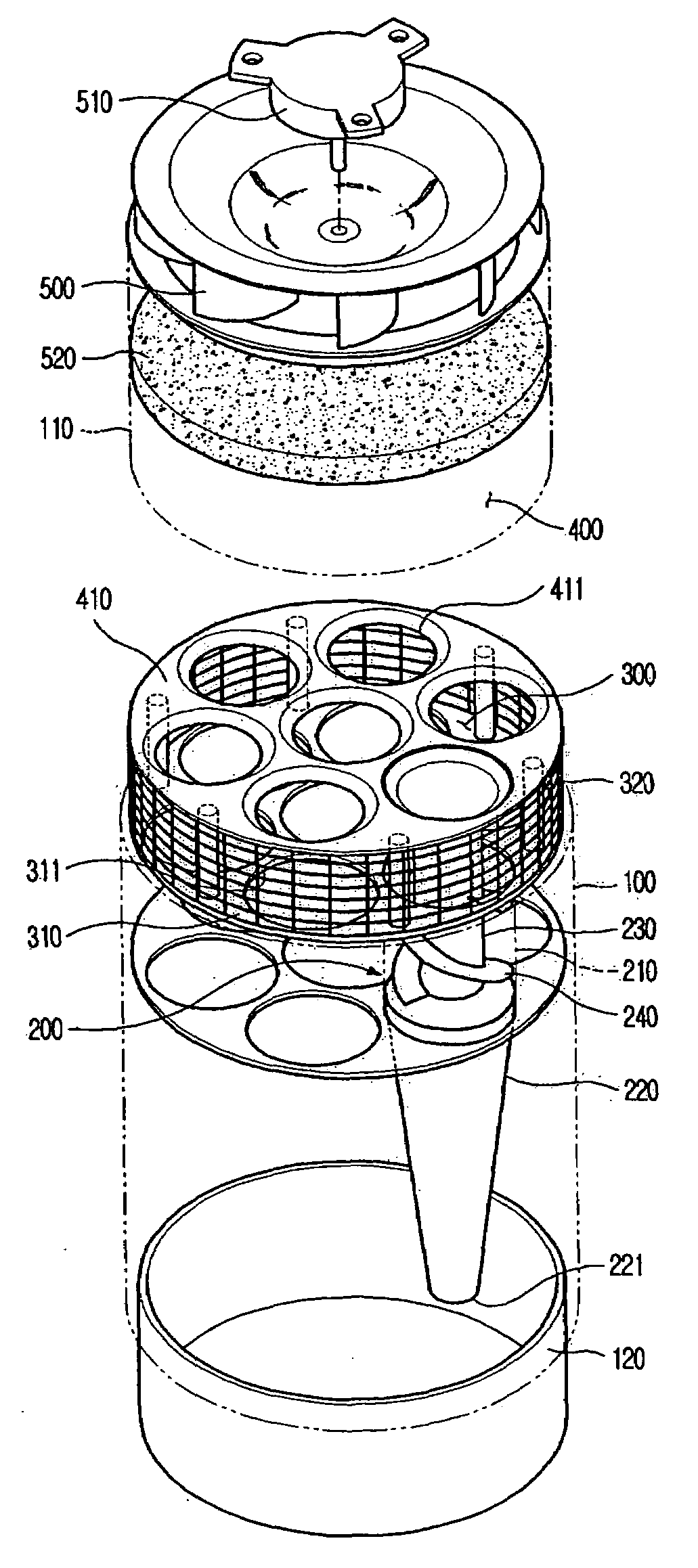

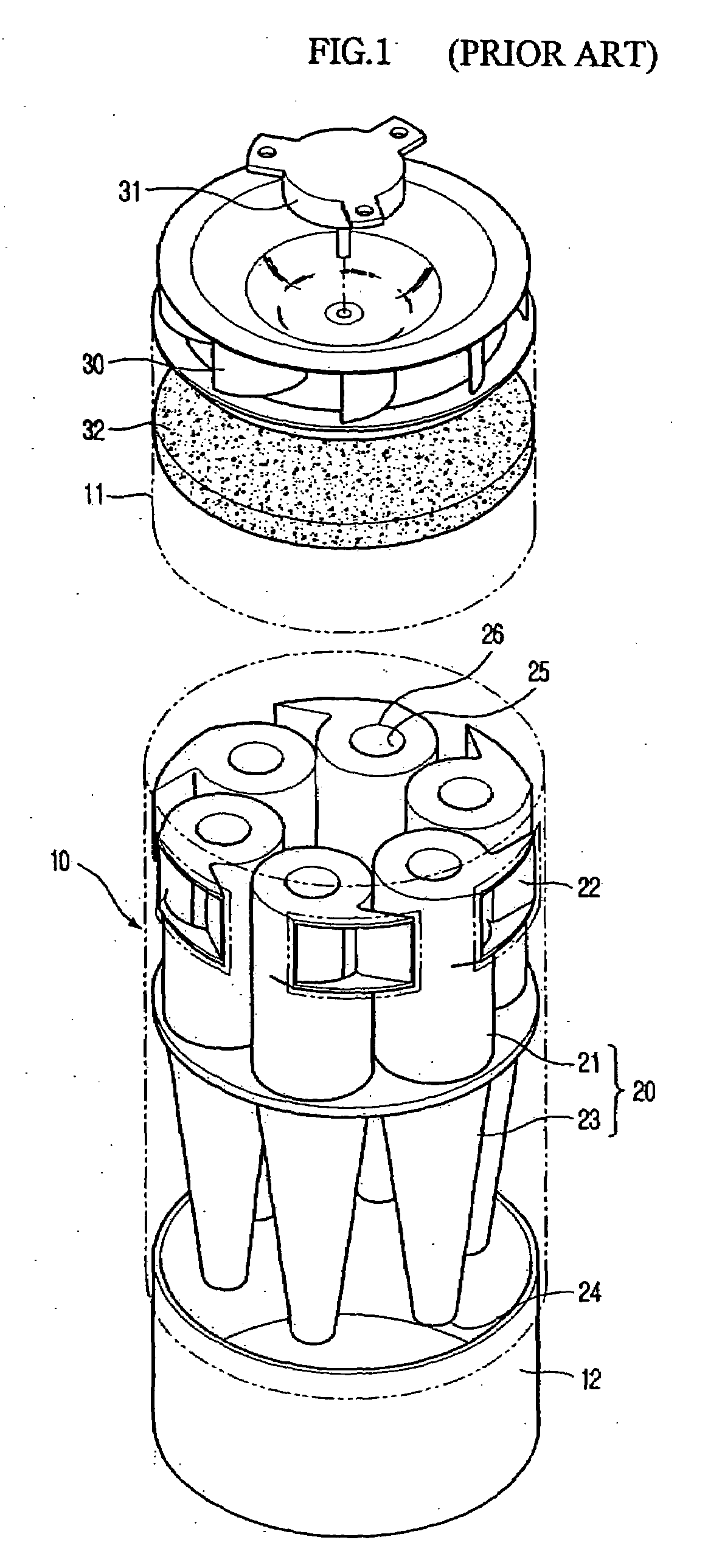

ActiveUS20060230726A1Improve cleaning efficiencyReduce lossesCleaning filter meansSuction filtersCycloneEngineering

A cyclone dust separating apparatus for separating dust from external air drawn in thereto and discharging the separated dust, comprises at least one first cyclone body having a tubular shape and forming a first cyclone chamber where the external air is rotated; and at least one second cyclone body forming a second cyclone chamber where the air discharged from the first cyclone chamber is rotated again to separate dust, wherein the external air is drawn in through a lower end of the first cyclone chamber and discharged through an upper end of the first cyclone chamber, and the air discharged from the first cyclone chamber is drawn in through an upper end of the second cyclone chamber and discharged through an upper end of the second cyclone chamber.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

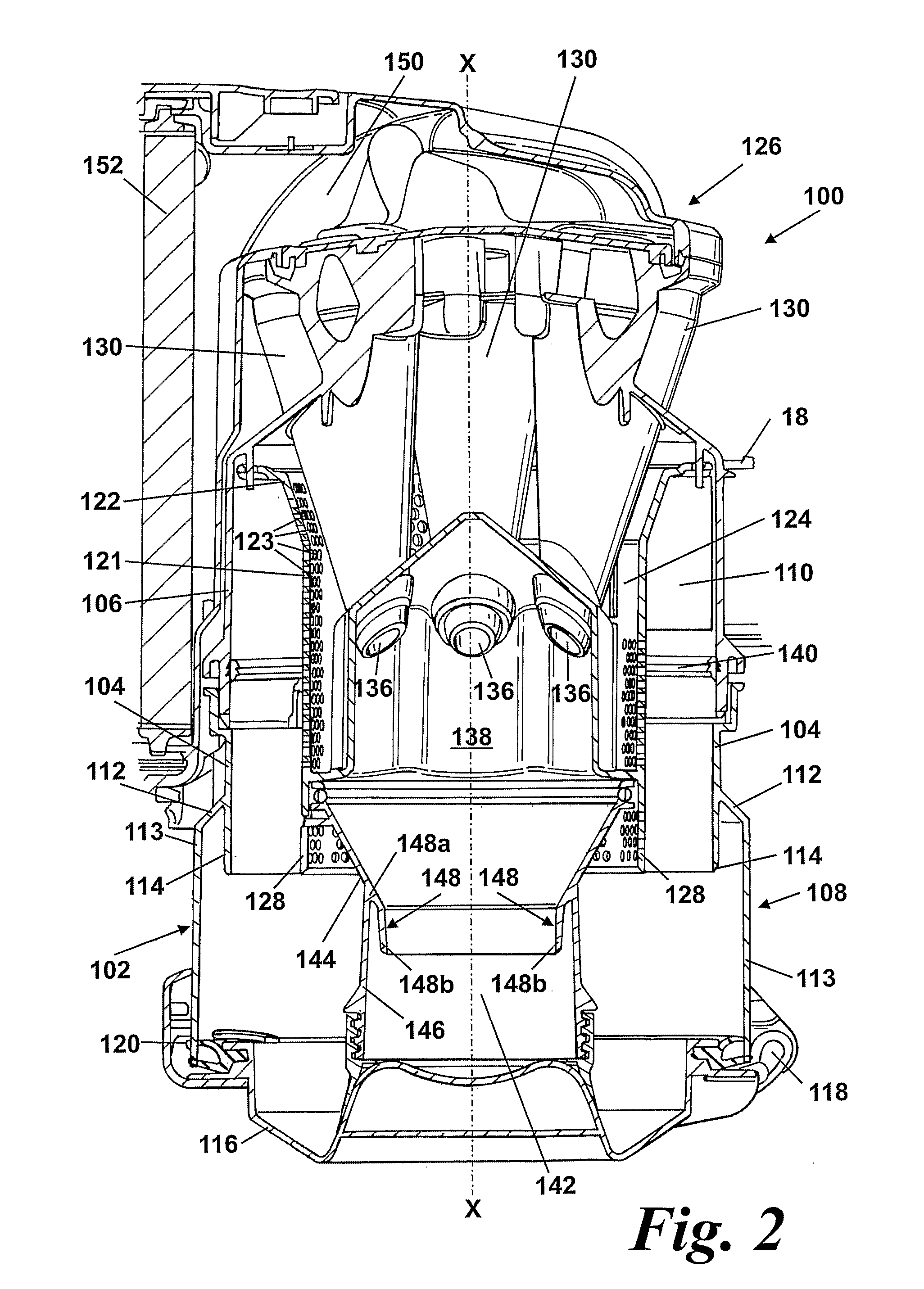

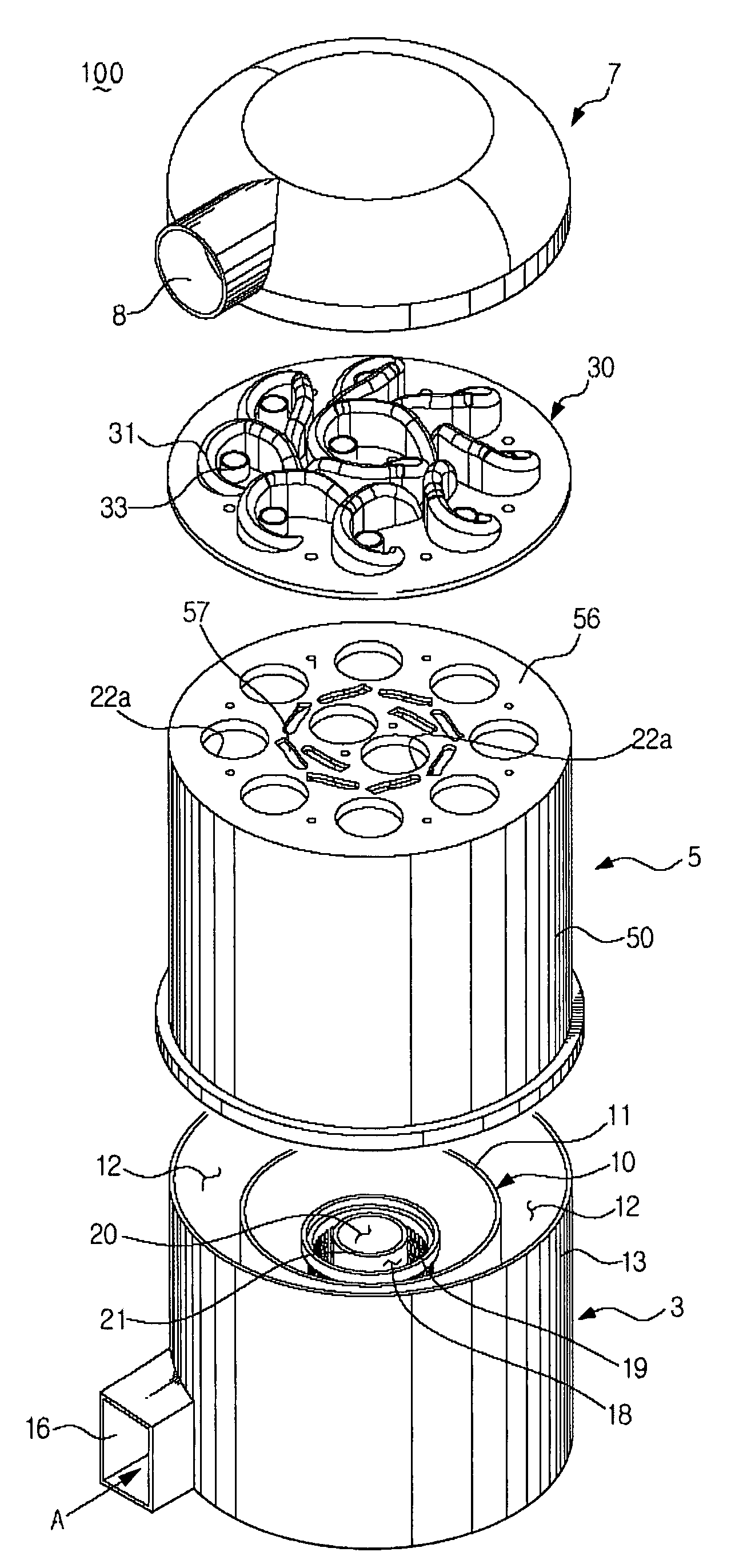

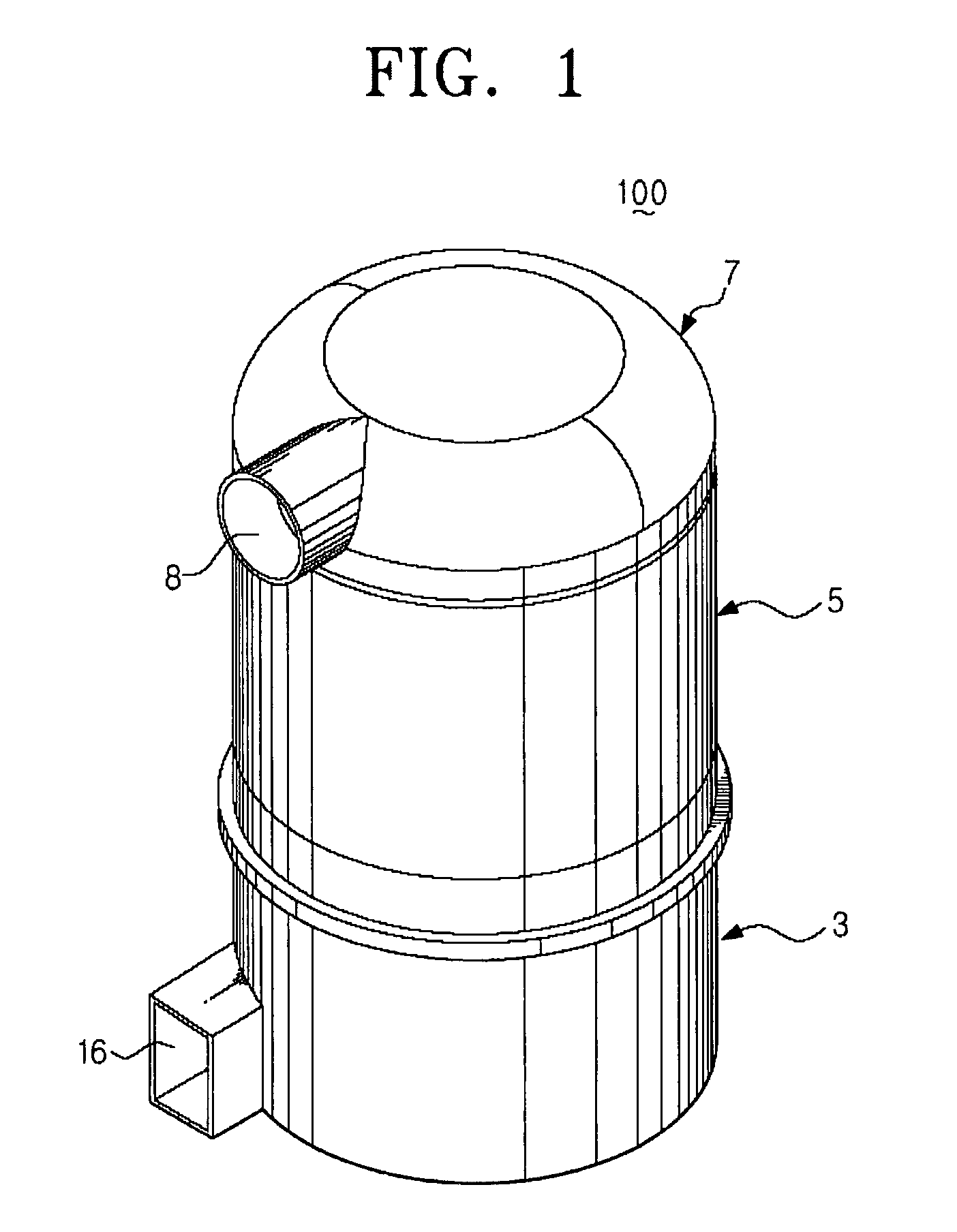

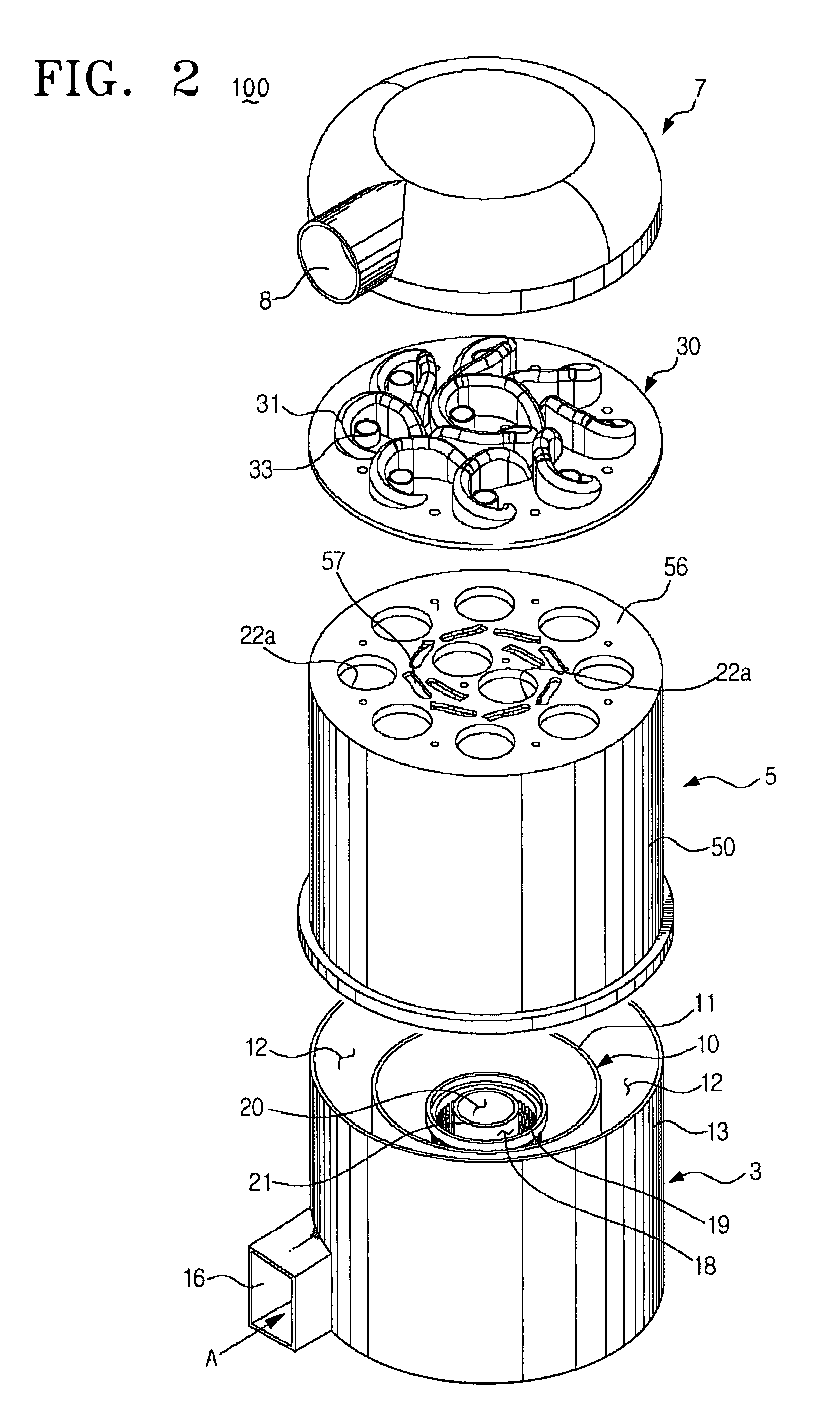

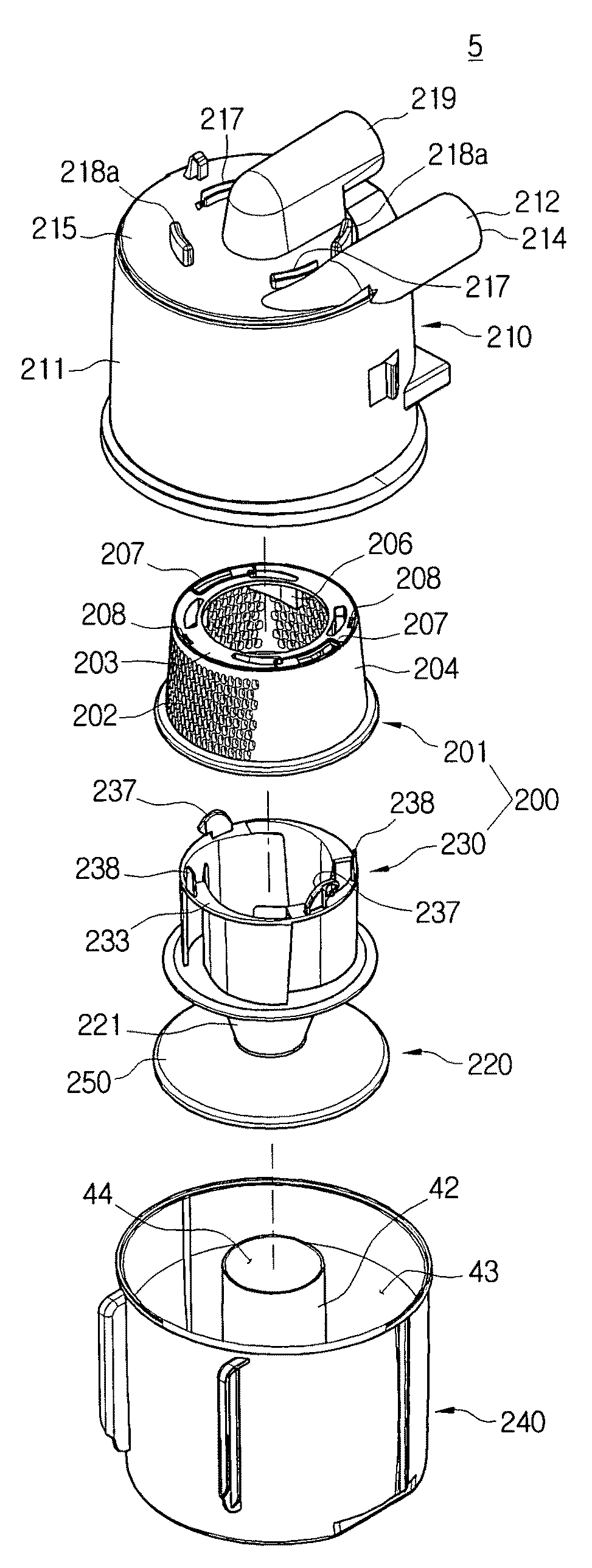

Cyclone dust-collecting apparatus

InactiveUS7691161B2High dust collecting efficiencyLow pressure lossCleaning filter meansCombination devicesCycloneCentrifugal force

A cyclone dust-collecting apparatus to separate dust from air drawn in through a suction port body of a vacuum cleaner using a centrifugal force and to collect the separated dust is provided. The cyclone dust-collecting apparatus includes a primary cyclone unit to separate dust from air drawn in through the suction port body; a secondary cyclone unit disposed inside the primary cyclone unit to separate dust from air discharged from the primary cyclone unit; and a tertiary cyclone unit disposed above the primary cyclone unit at an angle different from the primary and secondary cyclone units.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

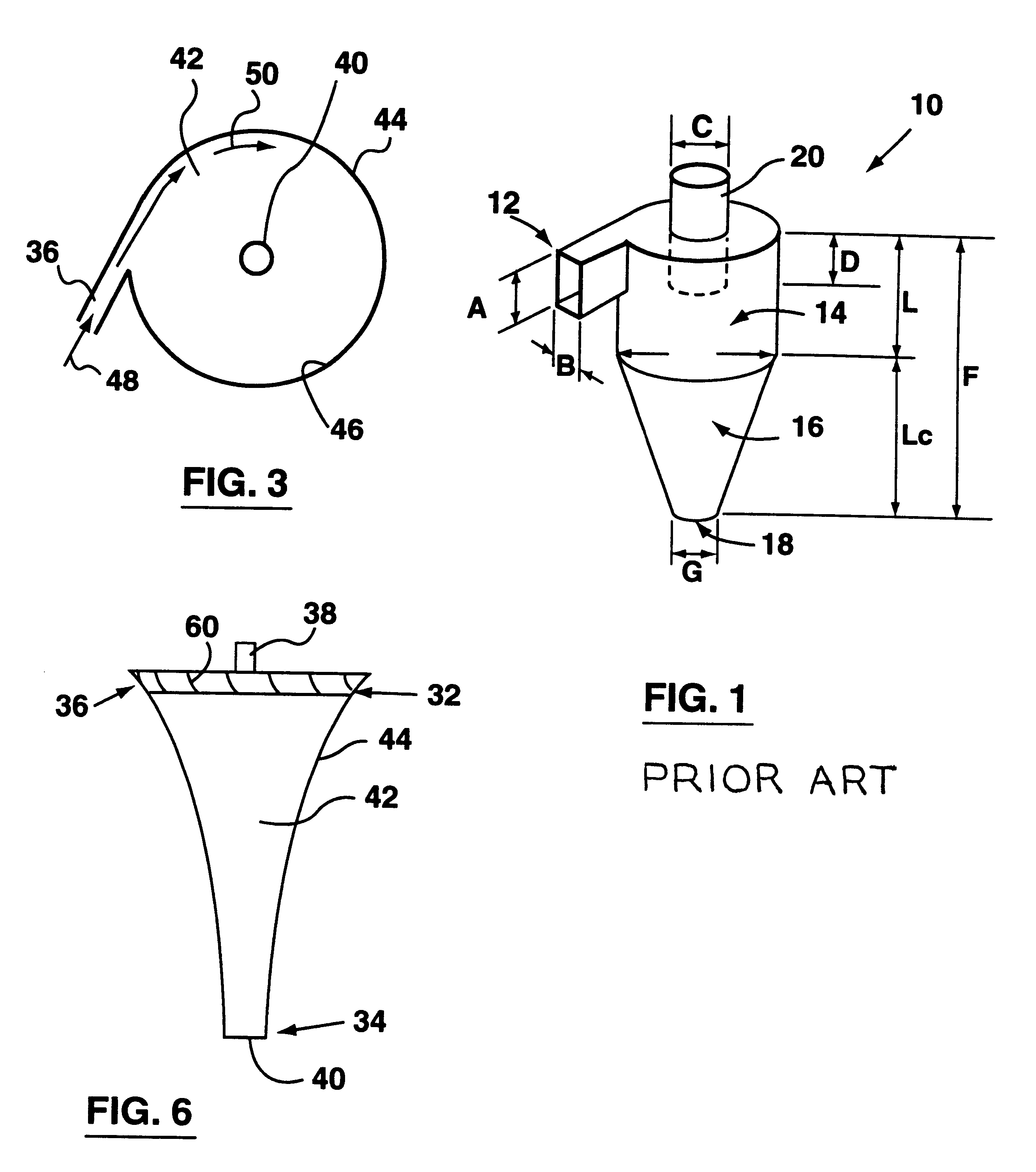

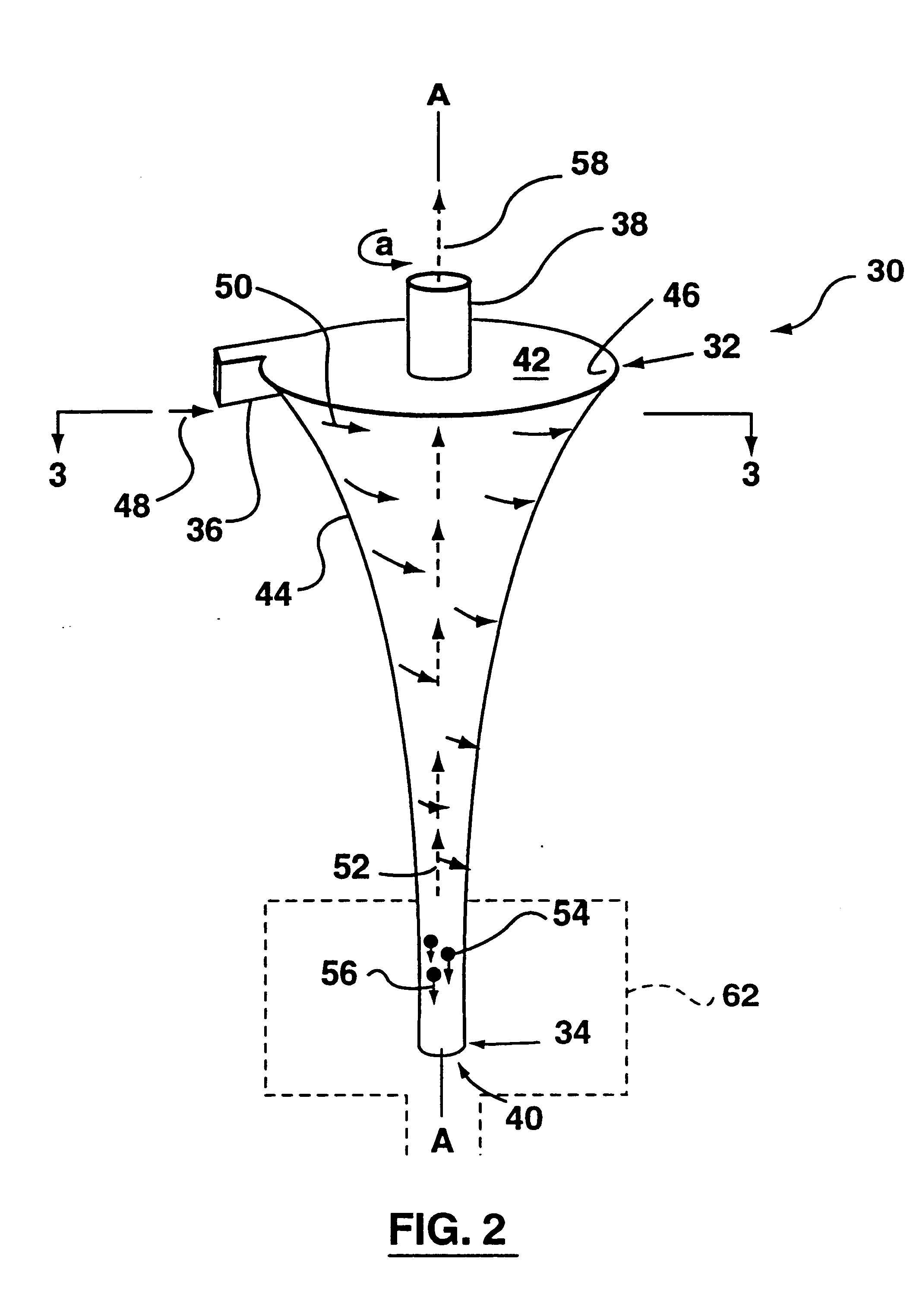

Terminal insert for a cyclone separator

InactiveUS6129775AReduce the numberEasy to separateCombination devicesSuction filtersEngineeringPhencyclone

A terminal insert for a cyclone separator for separating a material from a fluid. The terminal insert has a distinct member positioned within the cyclone separator to impinge upon at least a portion of the fluid as it rotates within the cyclone separator to destructively interfere with the rotational motion of the fluid within the cyclone separator.

Owner:OMACHRON INTPROP

Cyclone dust-separating apparatus

ActiveUS20060156699A1Prevent backflowEasy constructionCombination devicesAuxillary pretreatmentCycloneEngineering

A cyclone dust-separating apparatus including a cyclone body having a cyclone chamber and a dirt-collecting chamber enclosing an outer circumference of the cyclone chamber, an upper cover disposed on an upper end of the cyclone body to form a connection passage between the cyclone chamber and the dirt-collecting chamber, and a backflow prevention protrusion formed on an inner wall of the upper cover, for preventing dirt collected in the dirt-collecting chamber from flowing back to the cyclone chamber.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

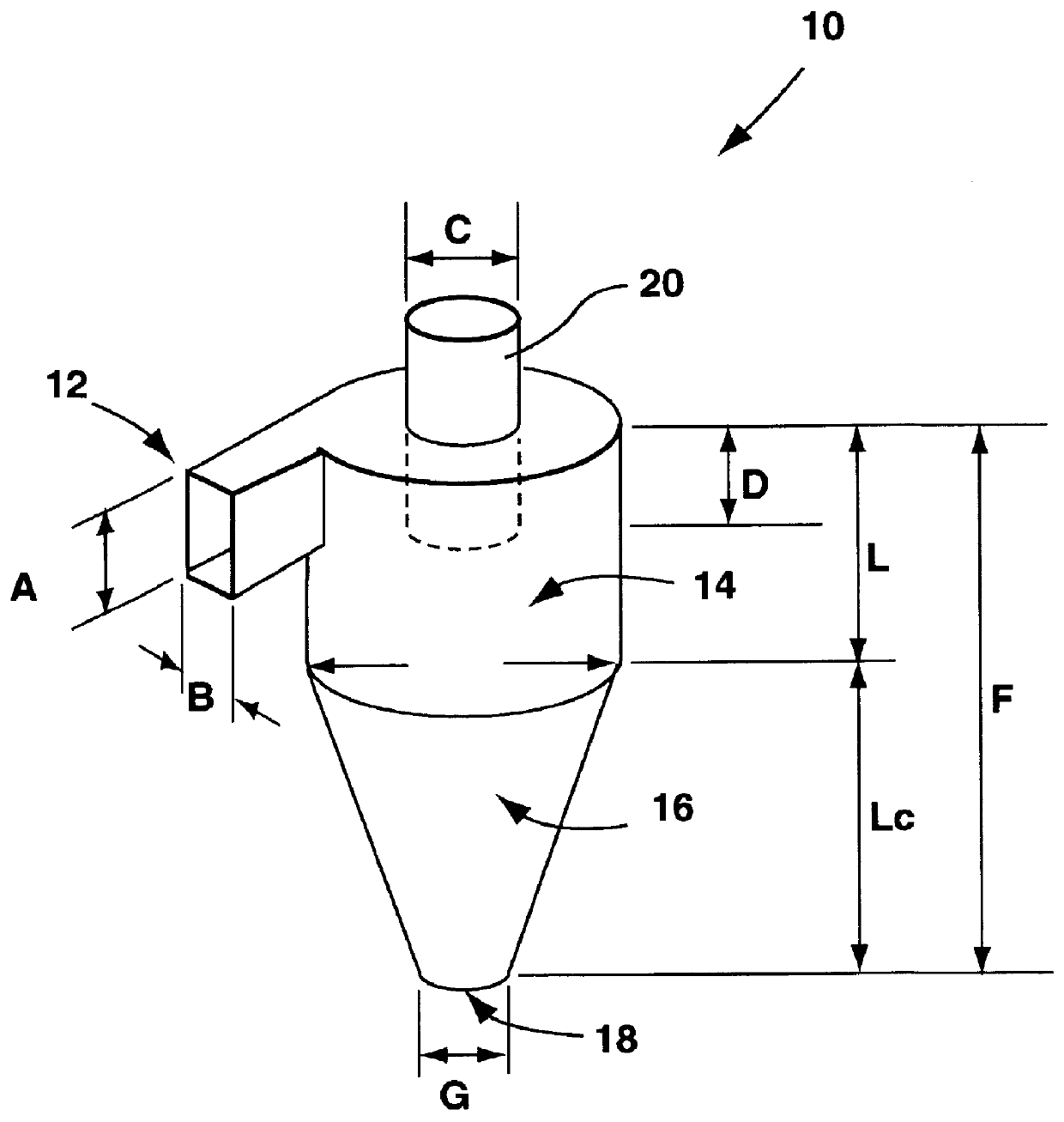

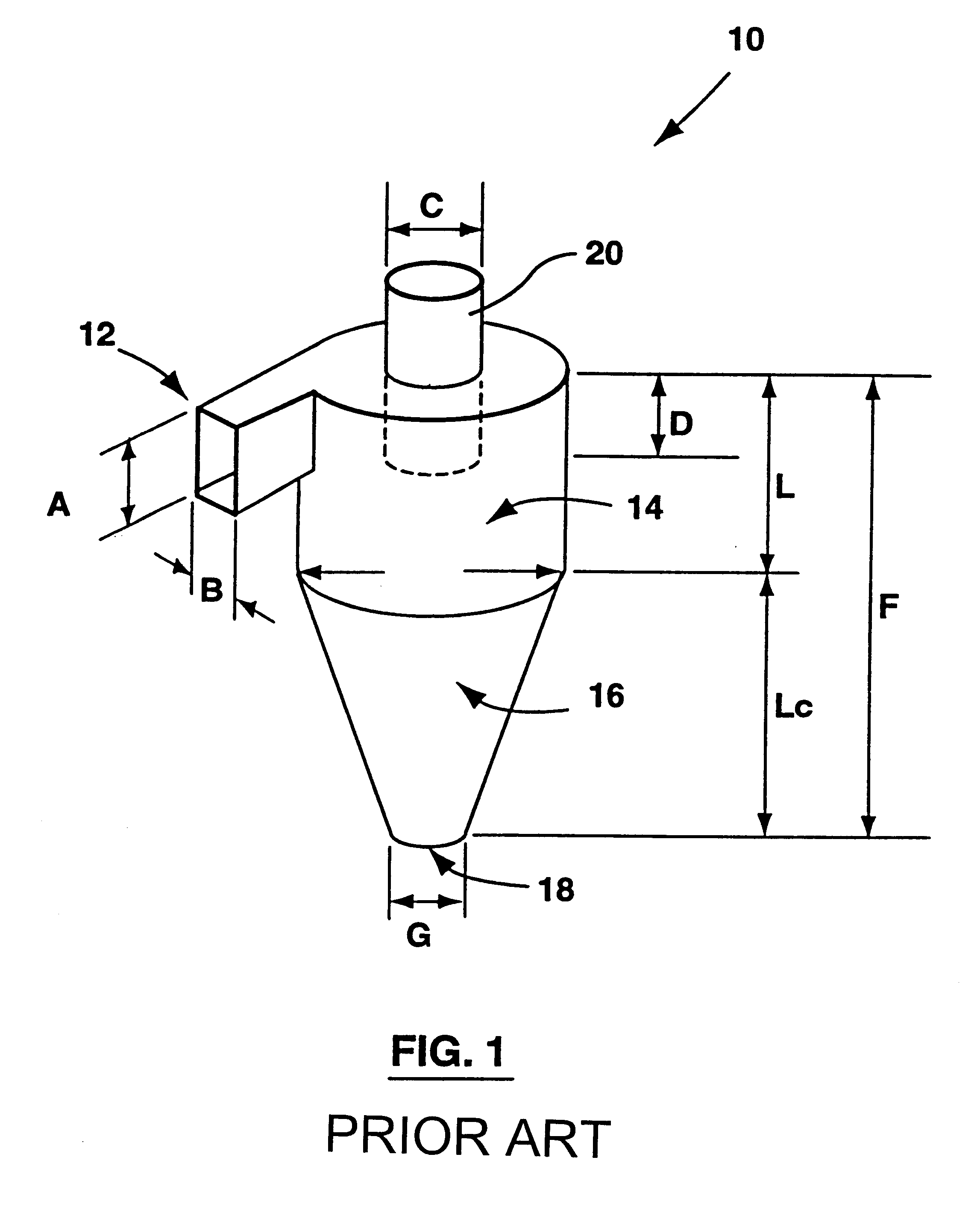

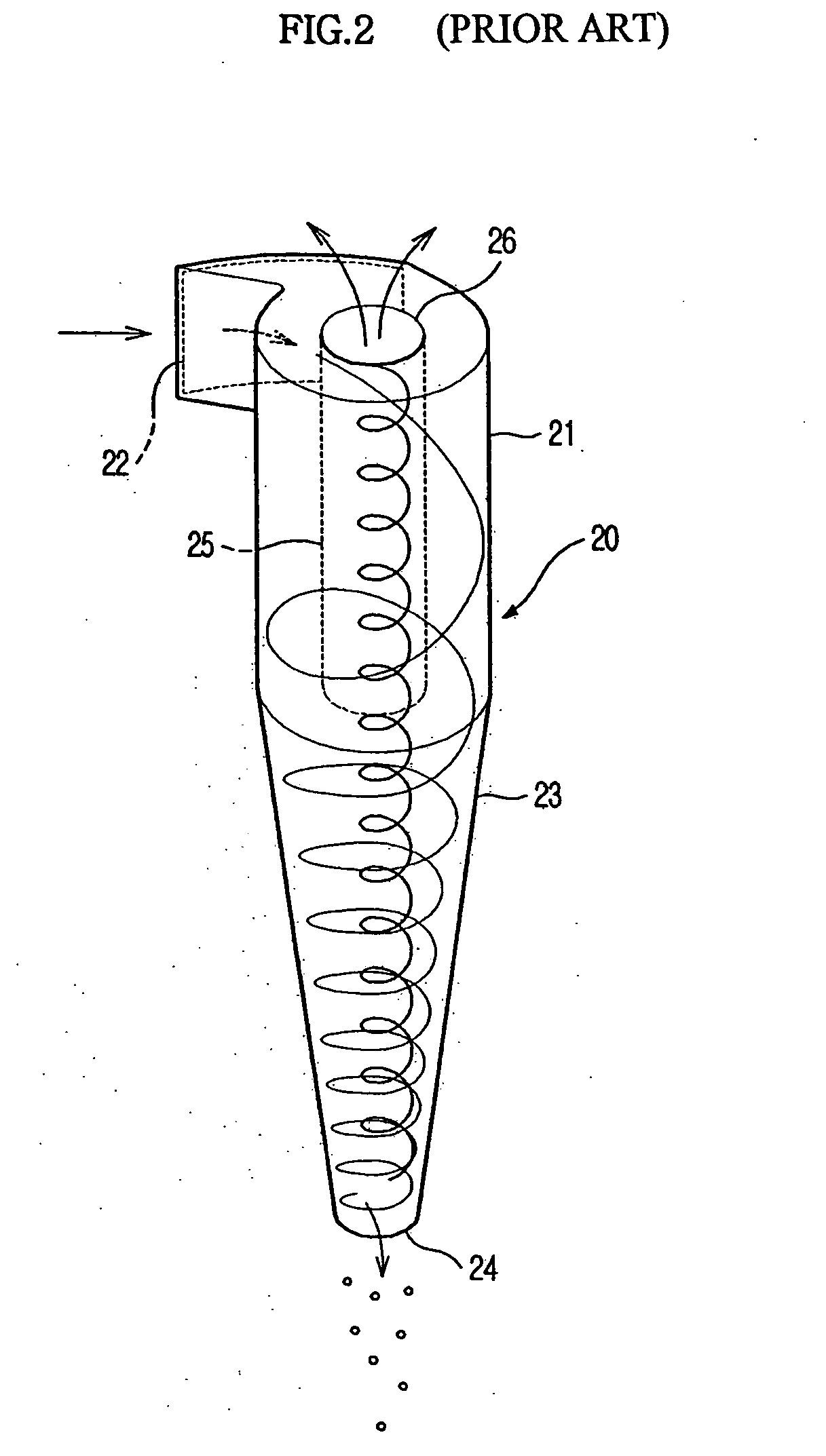

Cyclone separator having a variable longitudinal profile

InactiveUS6277278B1Reduce the numberEasy to separateReversed direction vortexDispersed particle filtrationCycloneEngineering

Owner:OMACHRON INTPROP

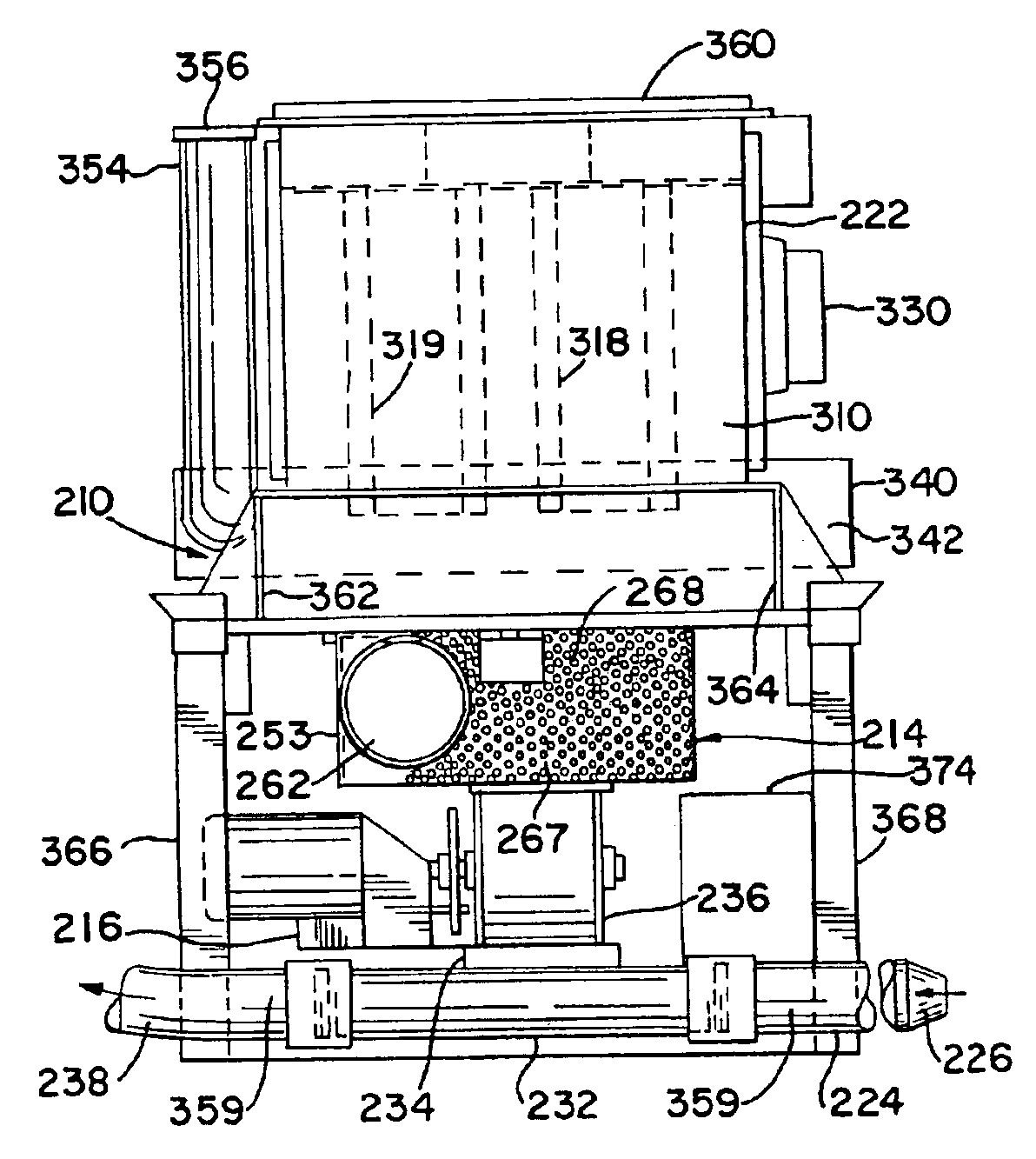

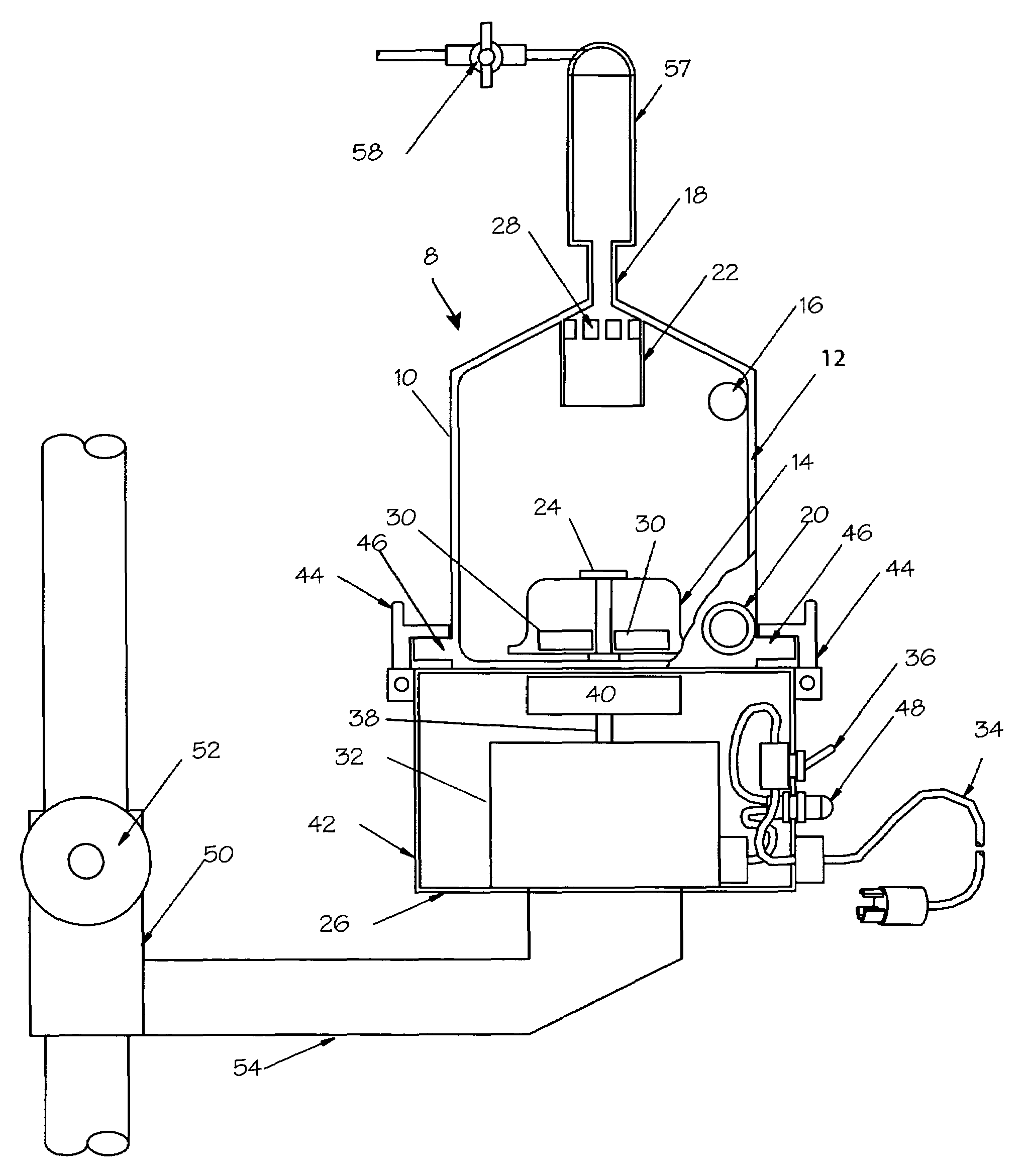

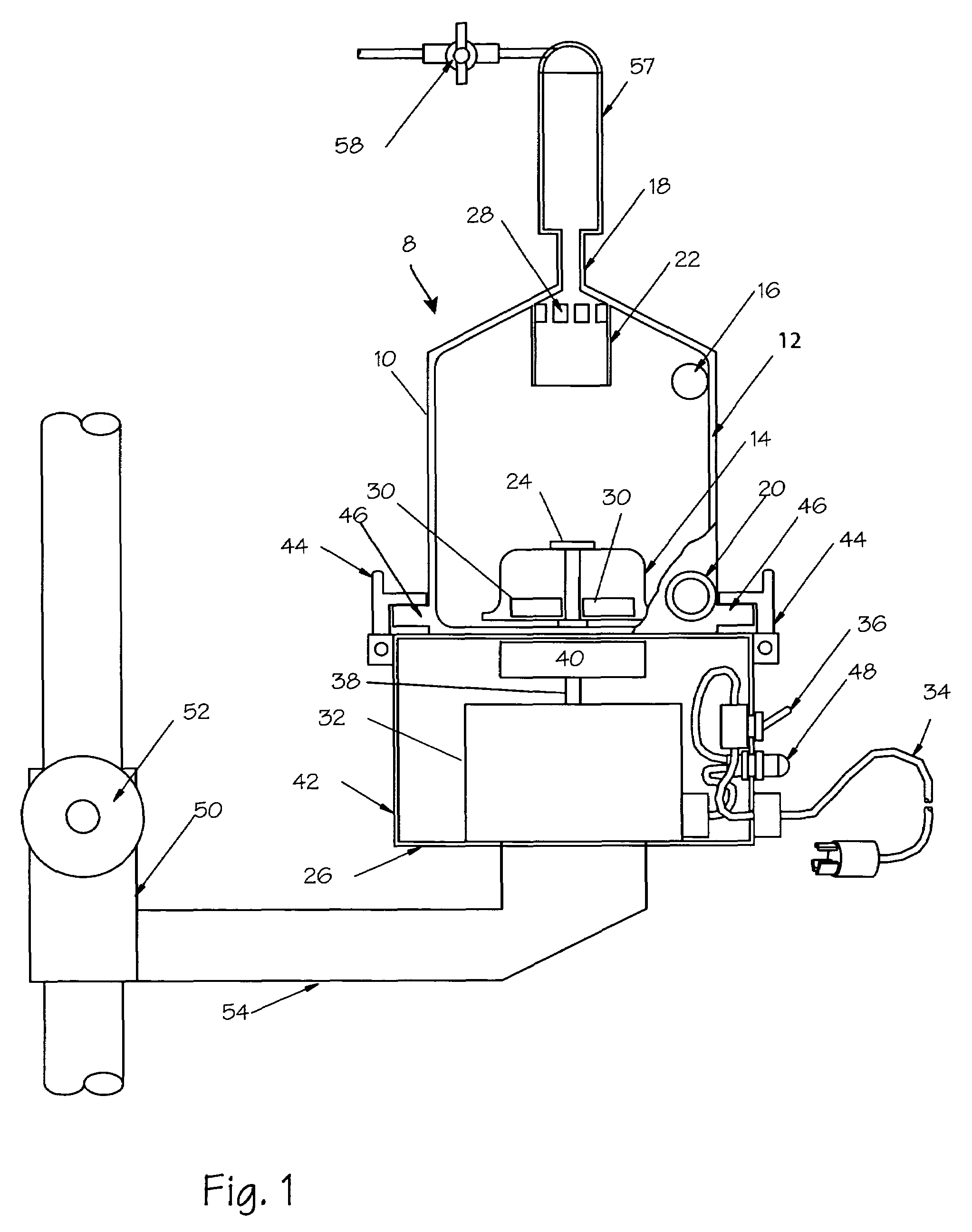

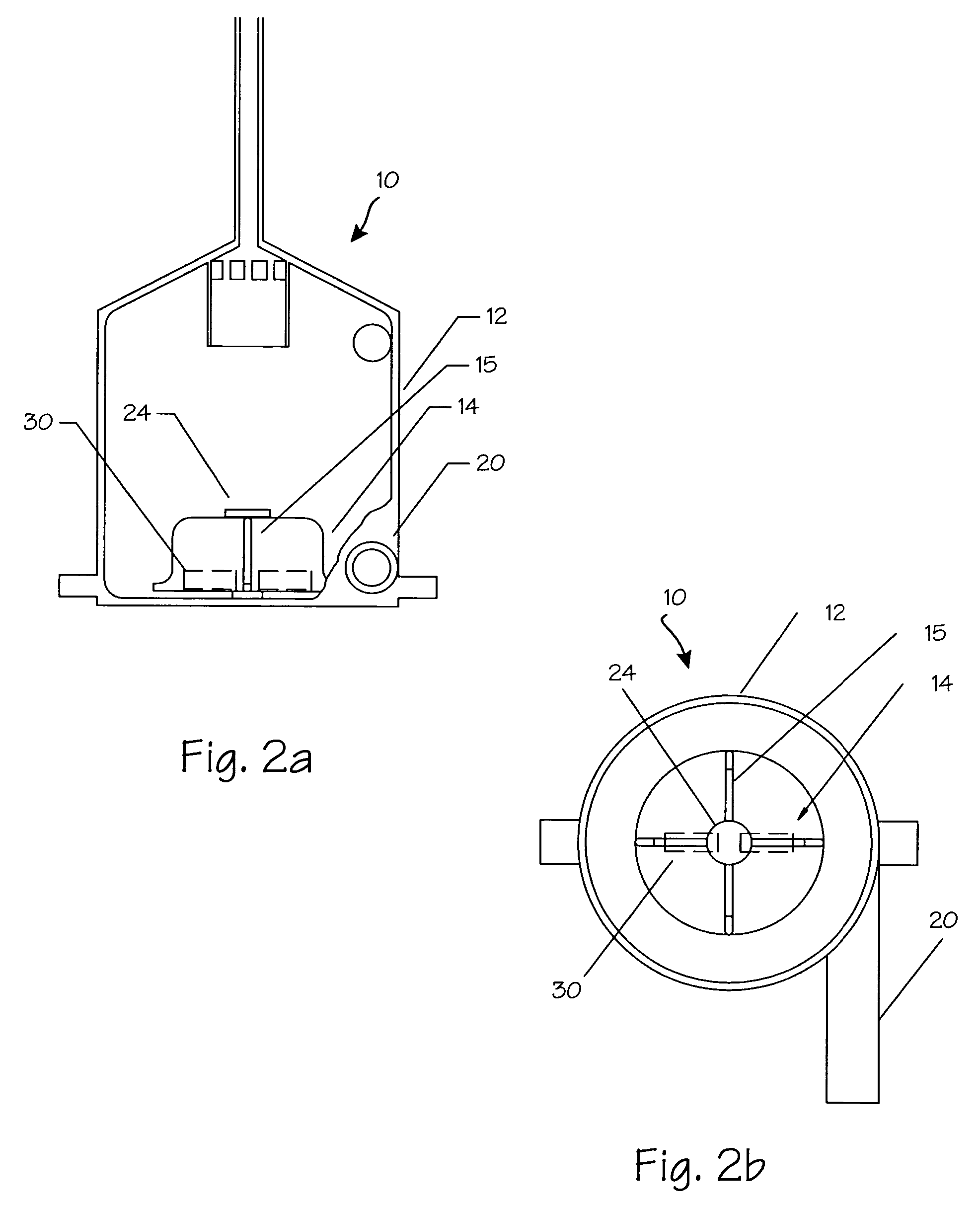

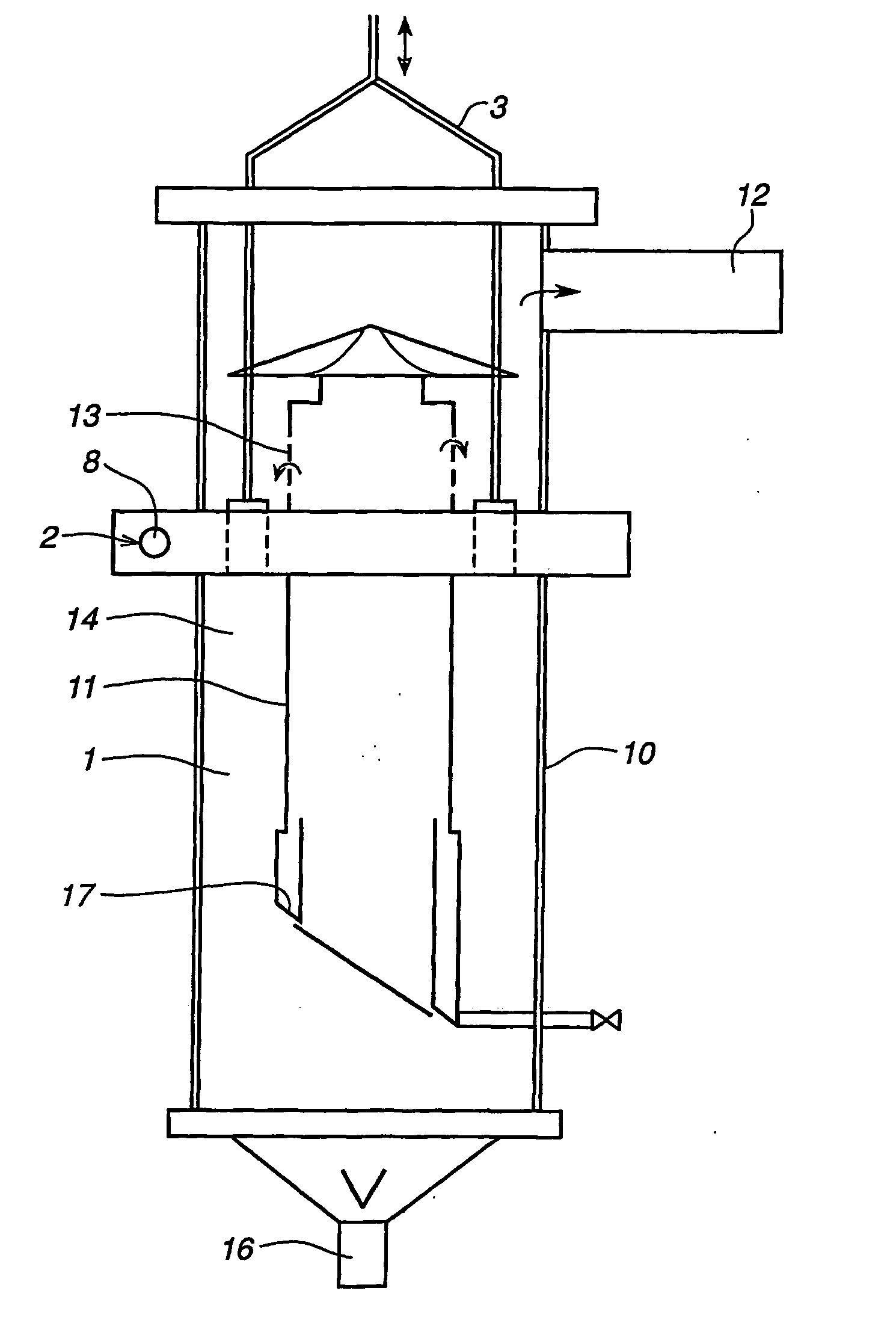

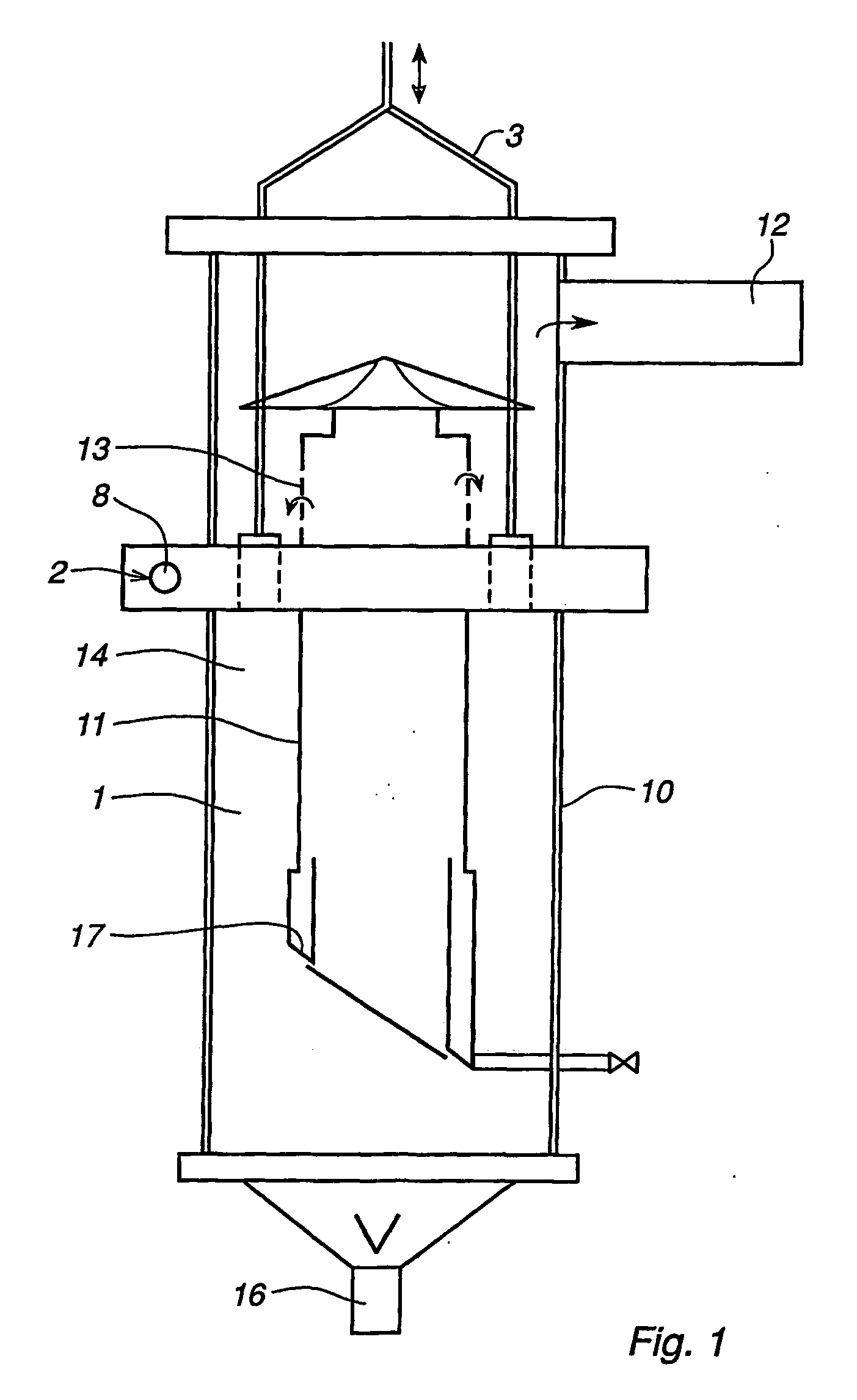

Vacuum loader

InactiveUS6936085B2Efficient and effective and safeCombination devicesAuxillary pretreatmentCycloneFiber

A specially arranged vacuum loader and industrial dust collector with a perforated plate tangential cyclone separator is provided to efficiently remove, readily collect, effectively separate and safely dispose of wet, dry and fibrous materials, including liquids and slurries. The special vacuum loader and industrial dust collector has a solids-gas separation compartment comprising a tangential cyclone separator, preferably a perforated plate tangential separator, which is positioned generally alongside and laterally offset from one or more filtering compartments to minimize turbulence and re-entrainment of the collected particulate material.

Owner:DEMARCO VACUUM CORP

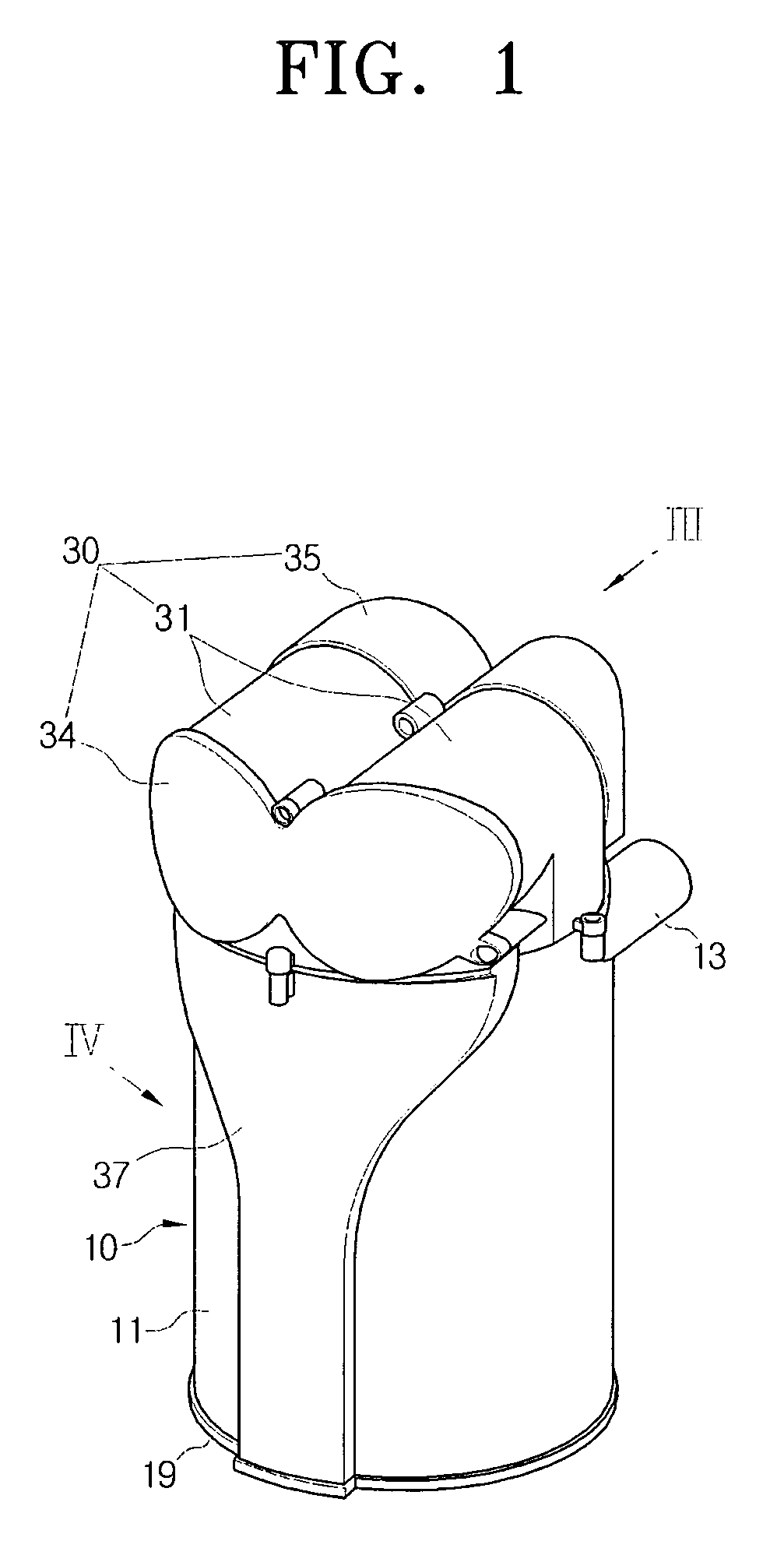

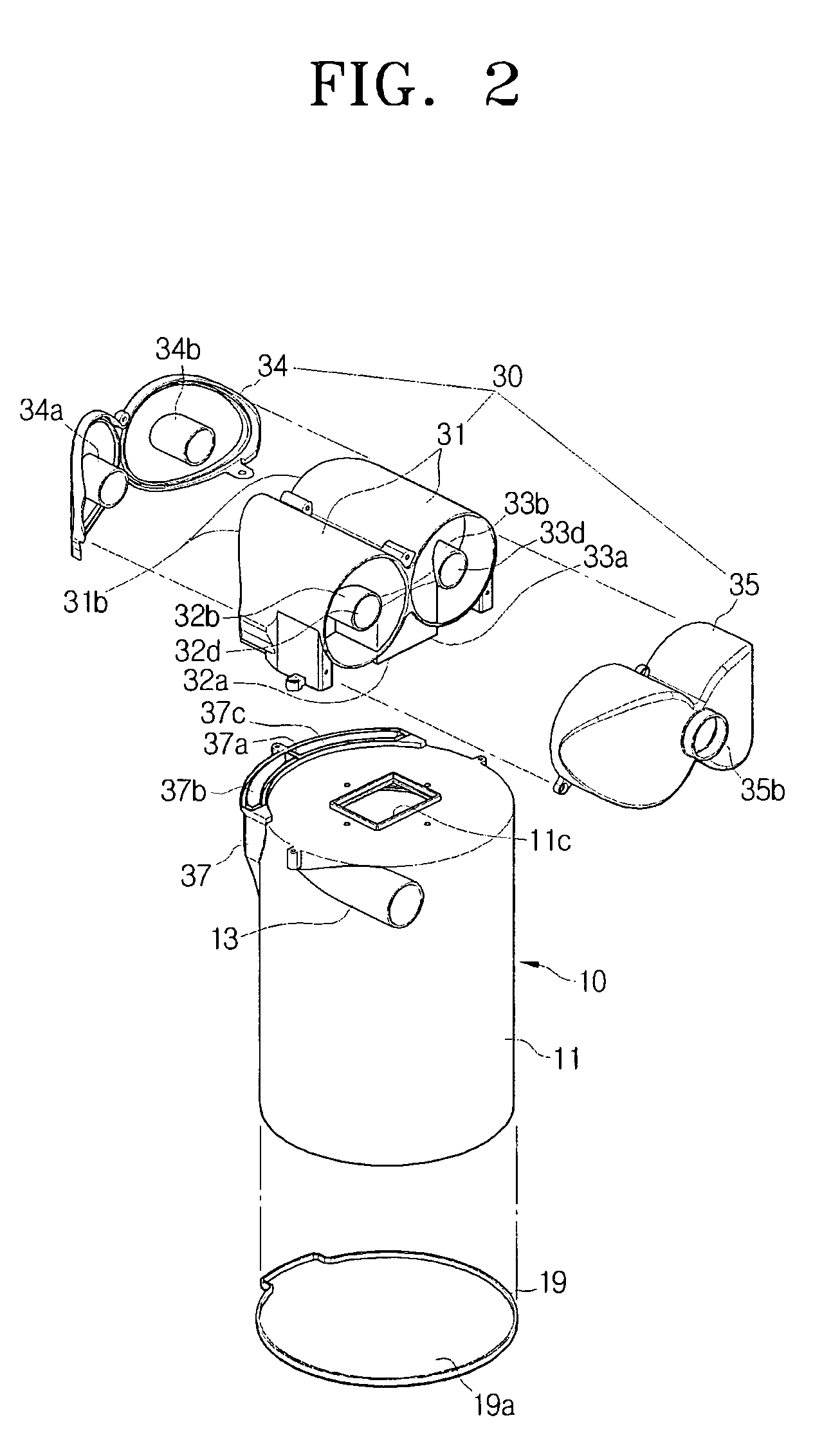

Cyclone separating apparatus for a vacuum cleaner

InactiveUS20080184681A1Efficient separationSuction filtersDispersed particle filtrationCycloneCyclonic separation

A cyclone separating apparatus for a vacuum cleaner includes a first cyclone having an inclined part and adapted for separating dust and air; a first dust chamber adapted to be disposed substantially around the first cyclone and to be in fluid communication with the first cyclone; at least one second cyclone for separating dust and air adapted to be disposed above the first cyclone and to be in fluid communication with the first cyclone; and a second dust chamber adapted to be in disposed within the first cyclone and to be in fluid communication with the second cyclone.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

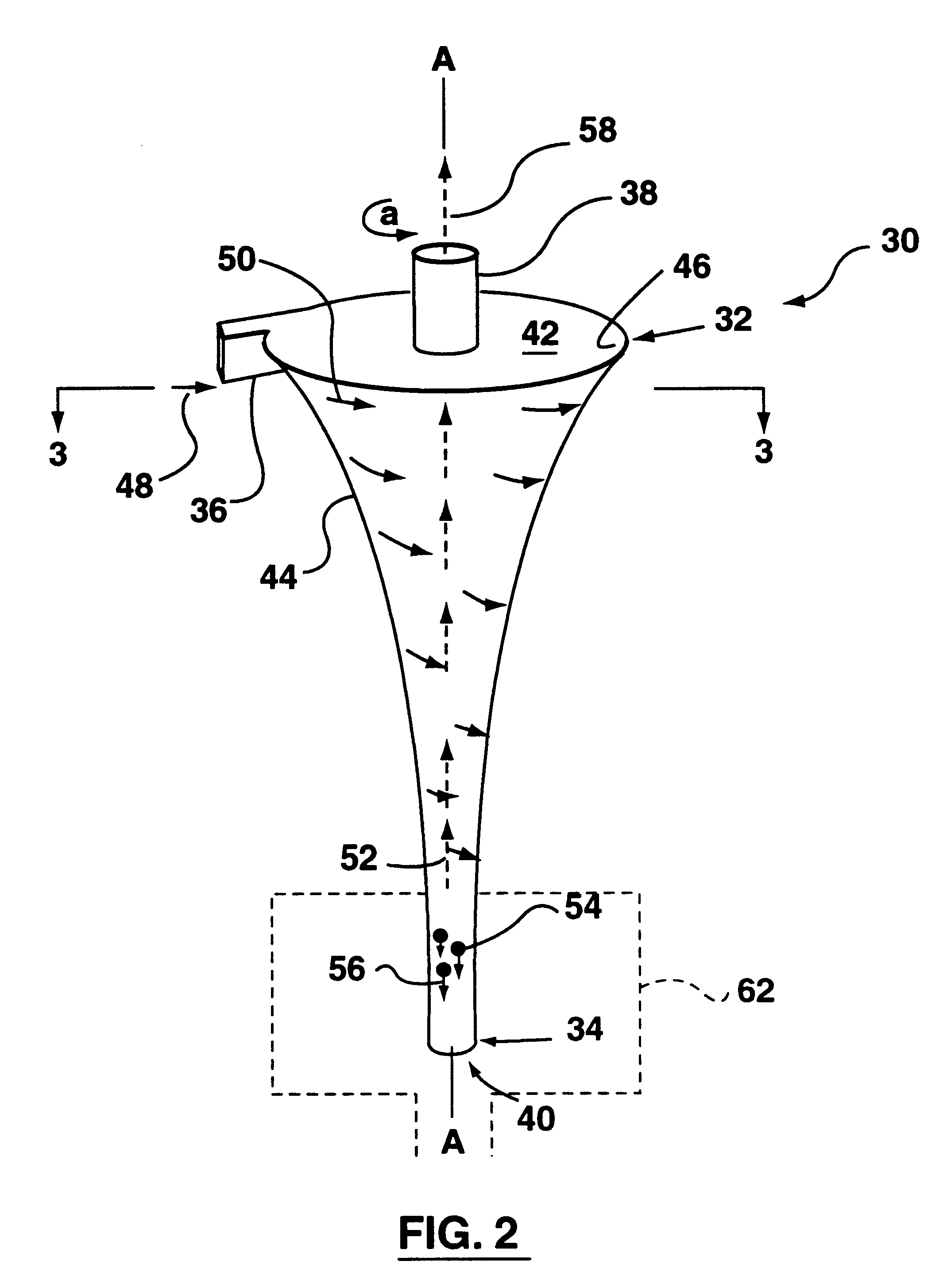

Method and apparatus for removal of gas bubbles from blood

InactiveUS7488448B2Semi-permeable membranesReversed direction vortexAssisting proceduresAssisted procedure

A system for removing gas bubbles from blood during circulatory assist procedures. An active filter apparatus forces the bubbles to the center of the system where they are removed from the blood before the blood exits the filter.

Owner:INDIAN WELLS MEDICAL

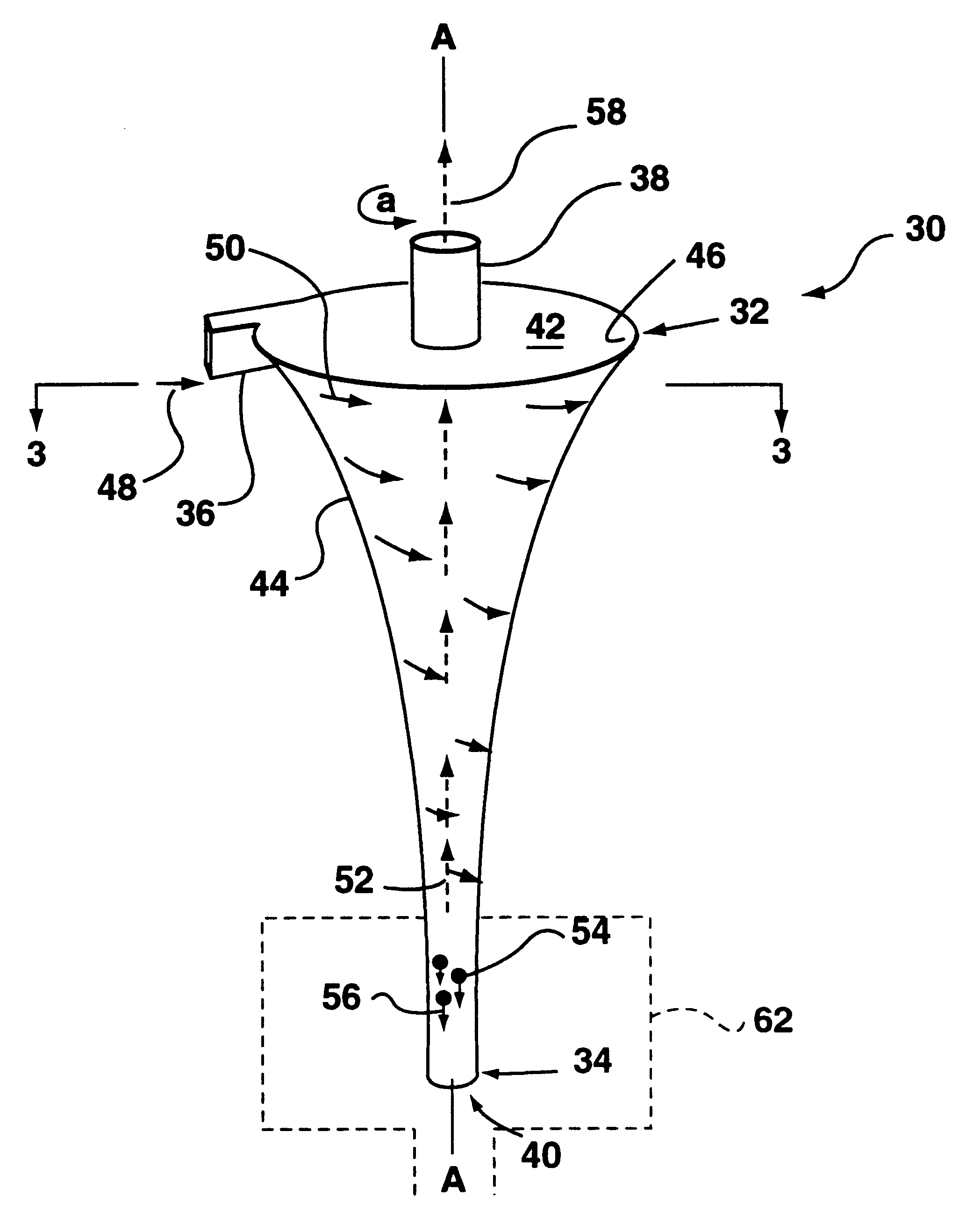

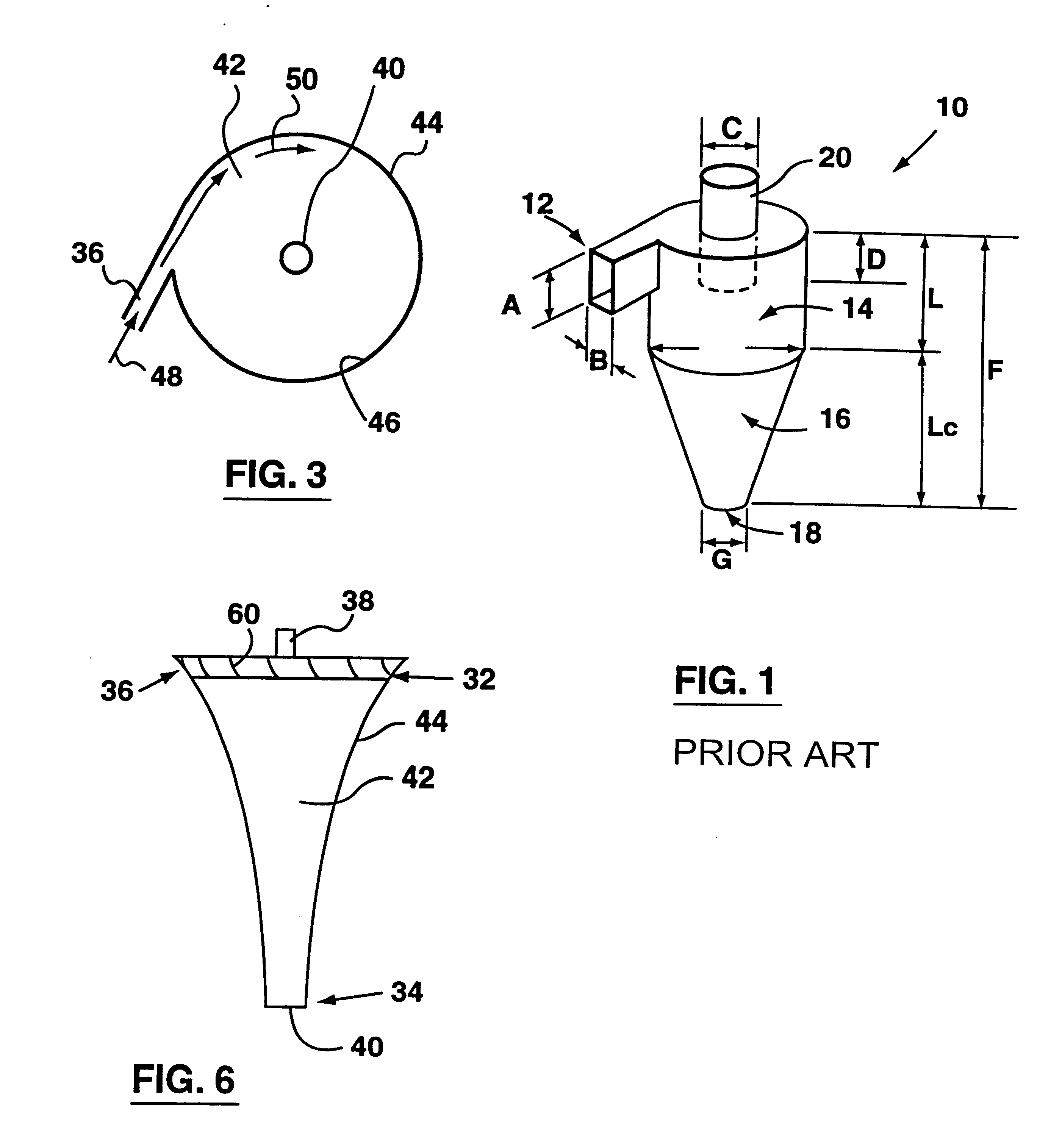

Insert for a cyclone separator

InactiveUS6312594B1Reduce the numberEasy to separateWater/sewage treatment by centrifugal separationSuction filtersEngineeringAcceleration Unit

A cyclone separator having an improved efficiency to remove a broader spectrum of contained particles is disclosed. The cyclone separator is provided with a member positioned to interact with at least the inner portion of a fluid circulating within the cyclone cavity to impart changes in the acceleration of the fluid as it rotates within the cyclone cavity.

Owner:OMACHRON INTPROP

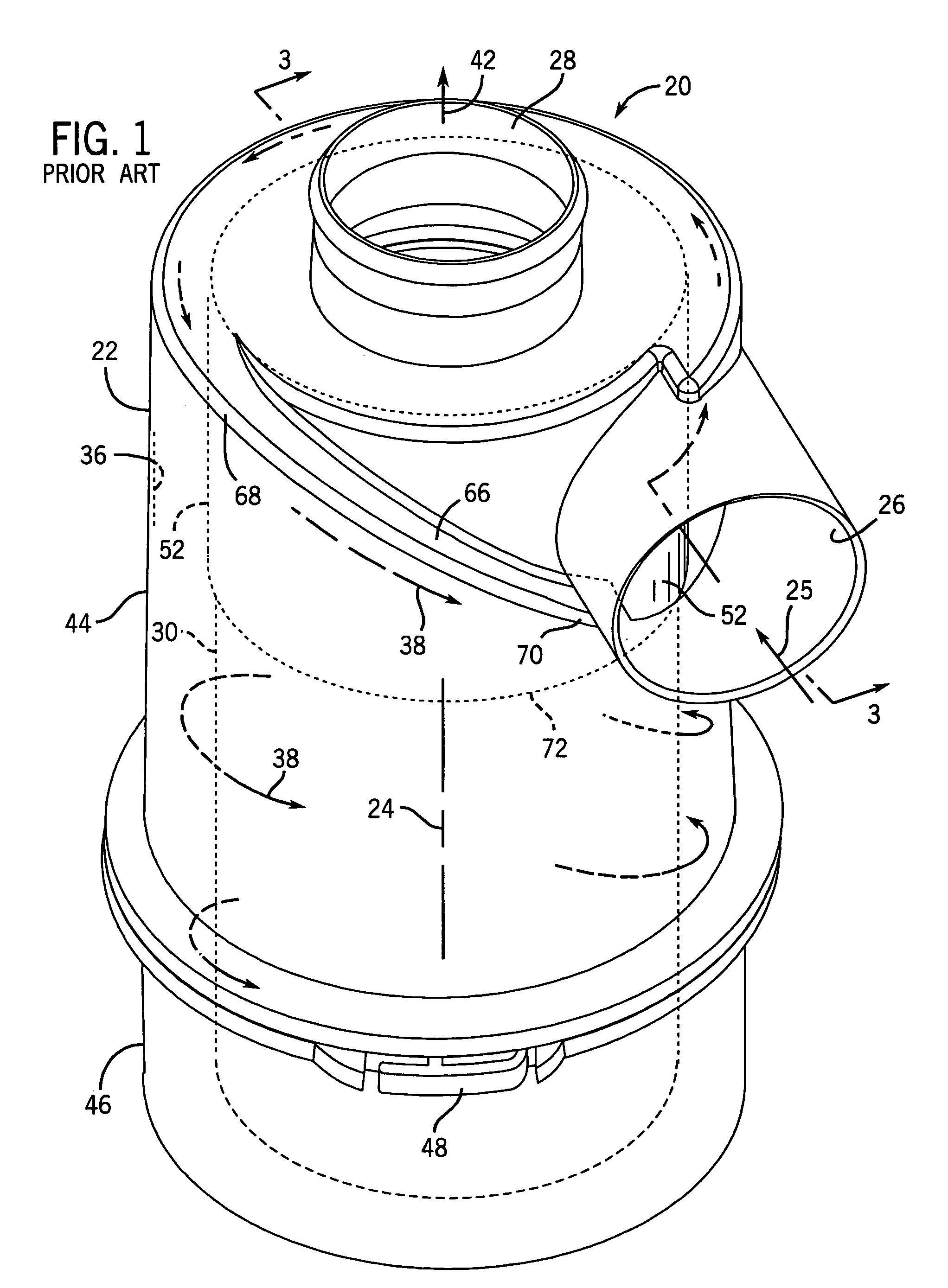

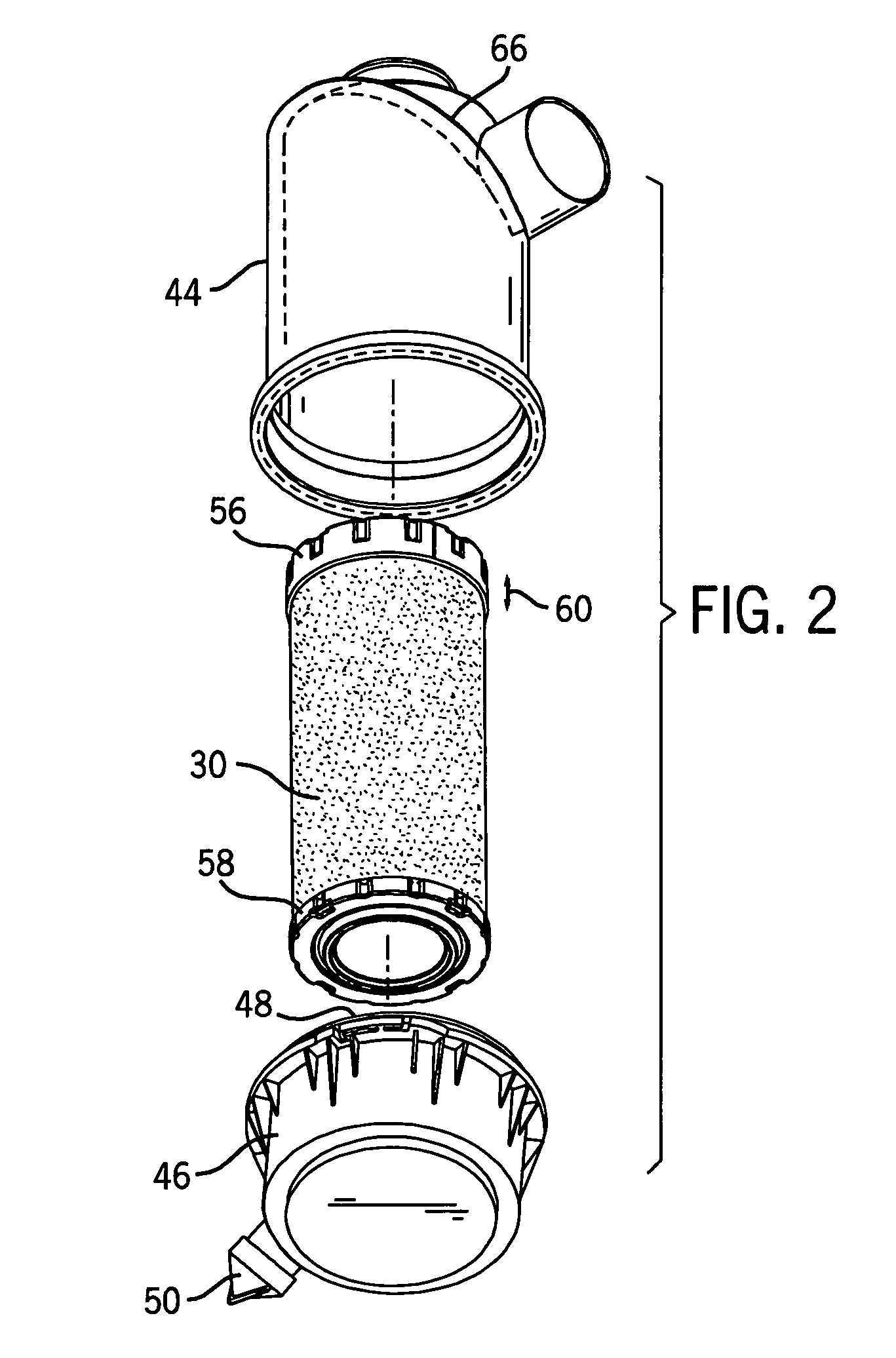

Air cleaner with reduced restriction precleaner

ActiveUS6958083B1Reduces entry restrictionPrecise positioningCombination devicesDispersed particle filtrationEngineeringFilter element

An air cleaner is provided with a reduced restriction precleaner cooperating with a tangential inlet and centering and locating an annular filter element, and reducing inlet restriction.

Owner:CUMMINS FILTRATION INC

Removing solids from a fluid

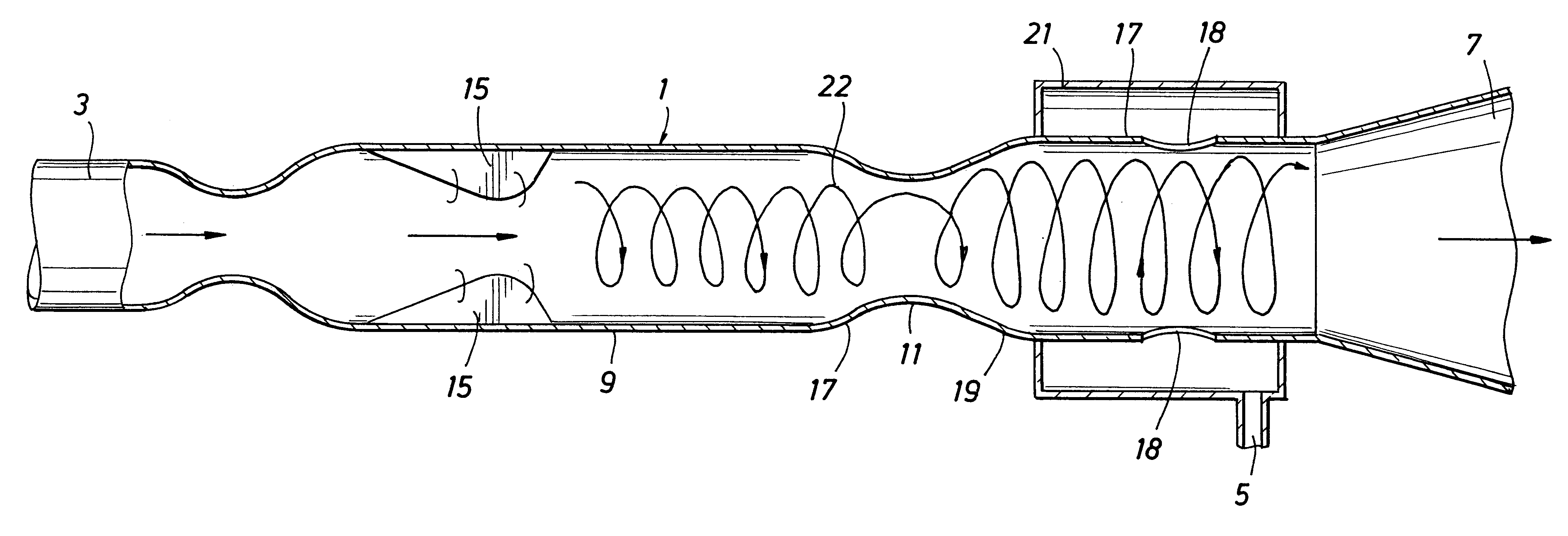

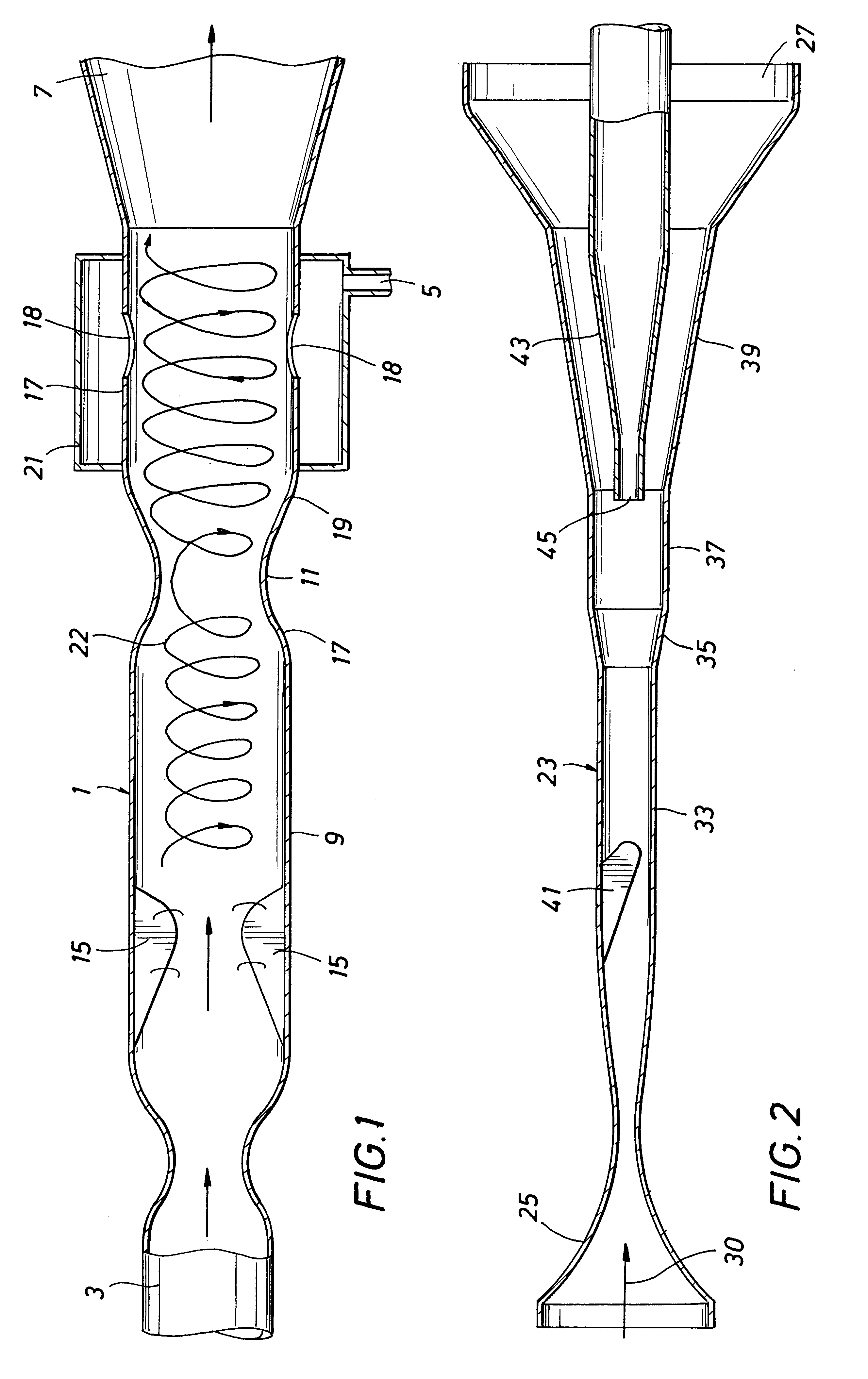

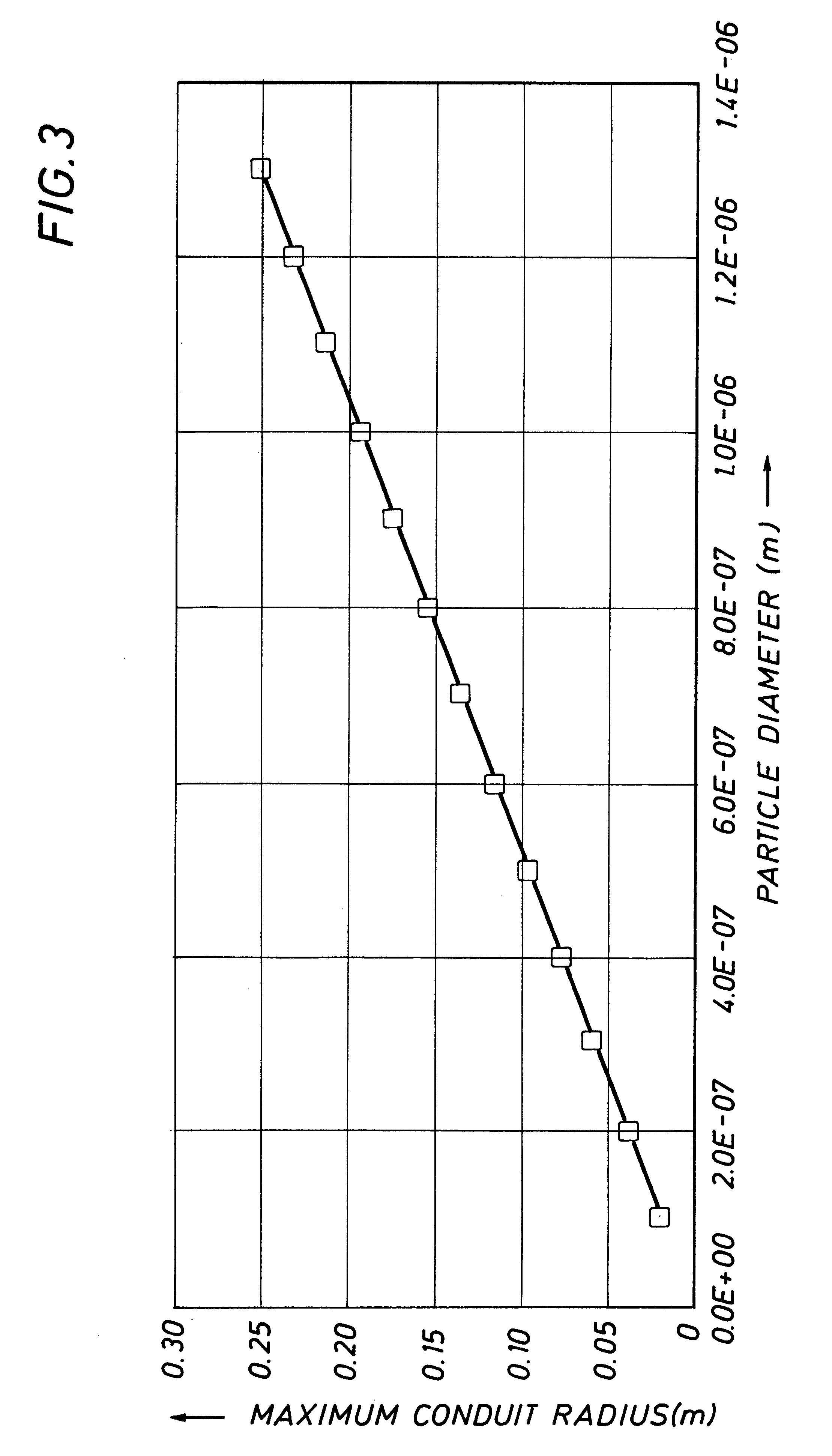

InactiveUS6280502B1Large kinetic energyEasy to separateCombination devicesAuxillary pretreatmentEngineeringSolid particle

A method and apparatus are provided for removing solid particles from a particle containing stream of fluid, the method including the steps of: inducing the stream to flow at supersonic velocity through a conduit; inducing a swirling motion to the supersonic stream of fluid thereby causing the particles to flow to a radially outer section of a collecting zone in the stream; and extracting the solid particles into an outlet stream from the radially outer section of the collecting zone. The apparatus is an apparatus effective for performance of this method.

Owner:TWISTER BV

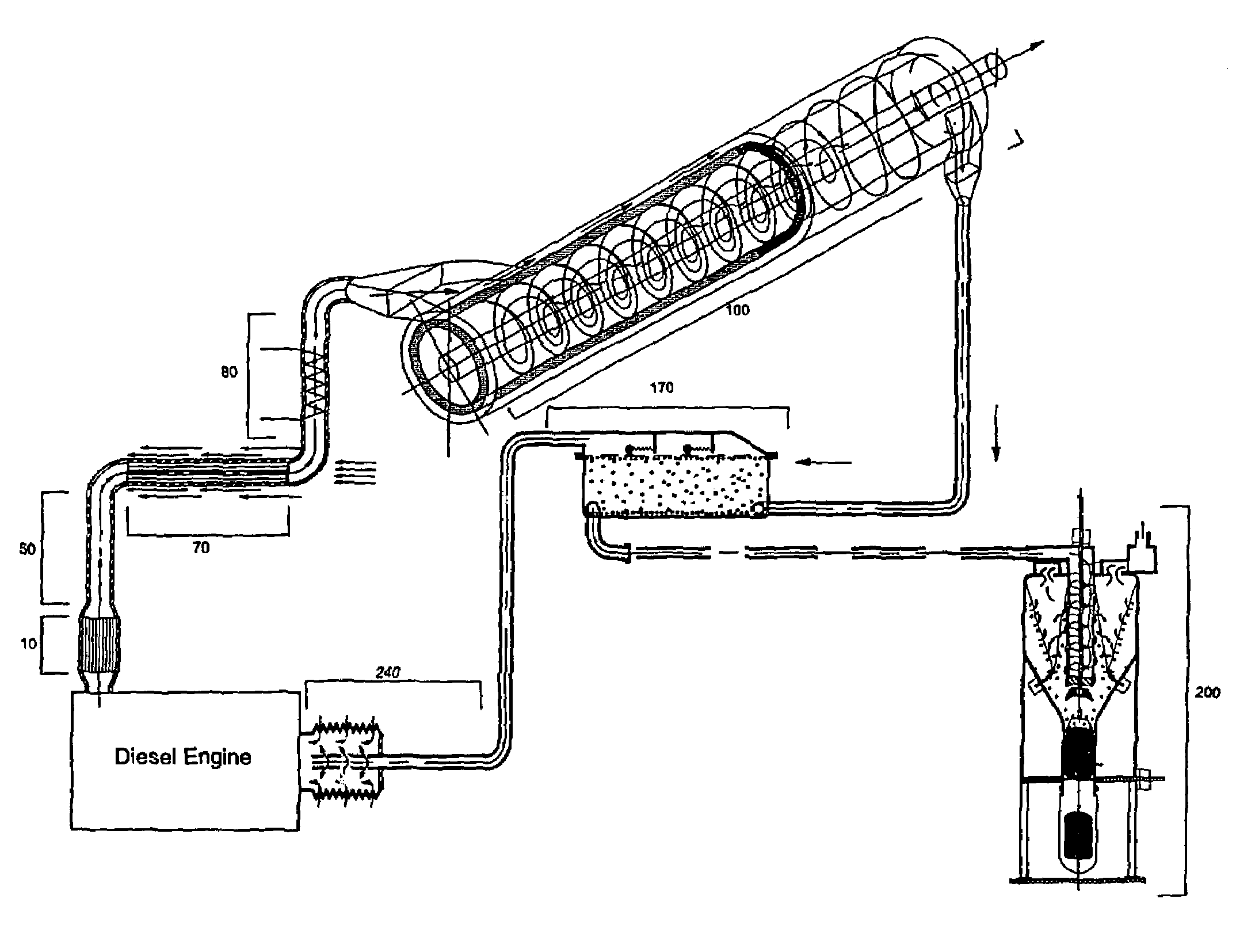

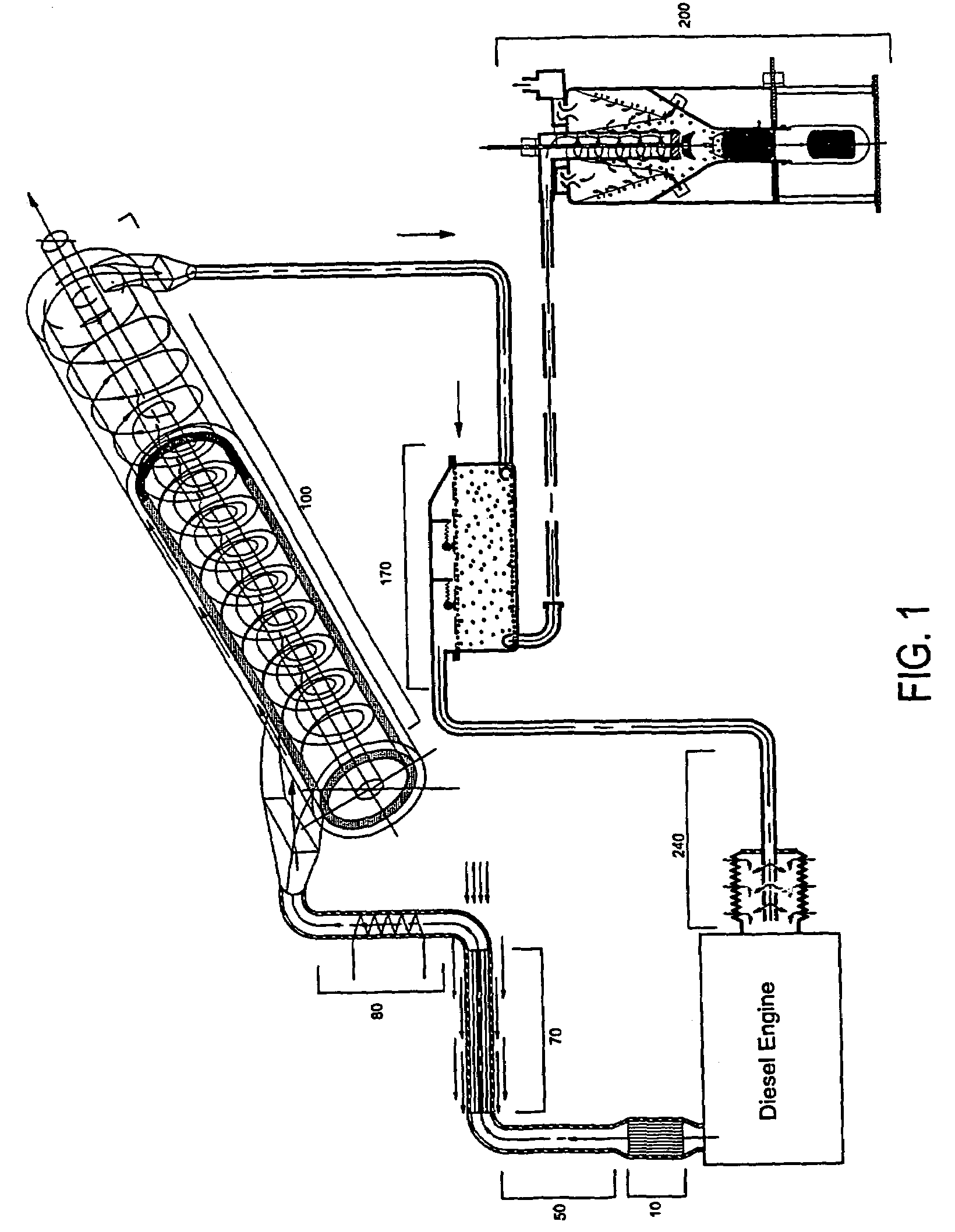

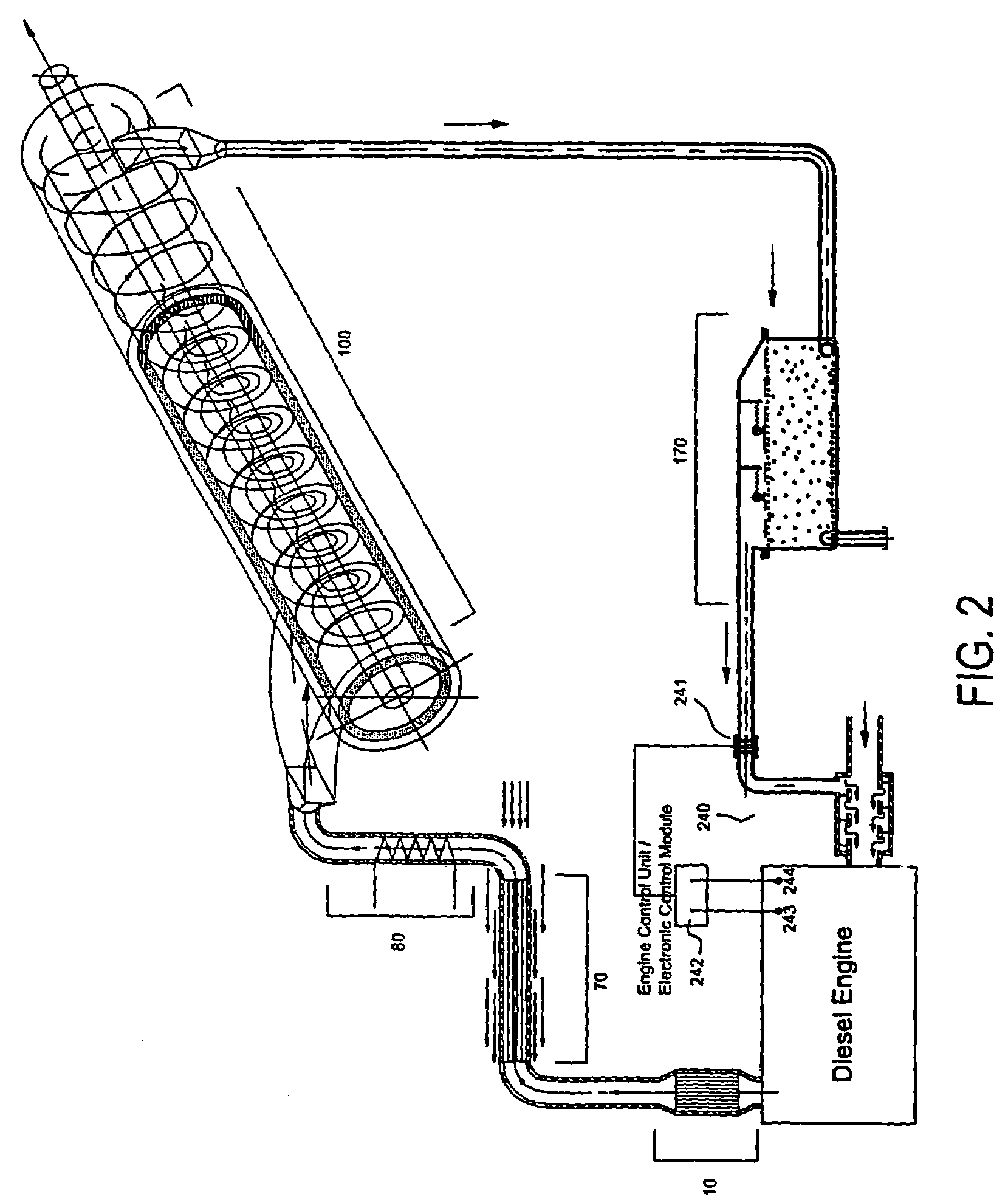

Exhaust after-treatment system for the reduction of pollutants from diesel engine exhaust and related method

InactiveUS7266943B2Easy to separateLower overall pressure dropCombination devicesInternal combustion piston enginesParticulatesAfter treatment

Exhaust after-treatment system for the reduction of particulate, NOx, HC, CO, VOCs, nano-particle count and sulfur dioxide from diesel exhaust. System employs diesel oxidation catalyst, exhaust cooling system, particulate converter, soot collection chamber, soot processing drum, EGR and water scrubber.

Owner:KAMMEL REFAAT

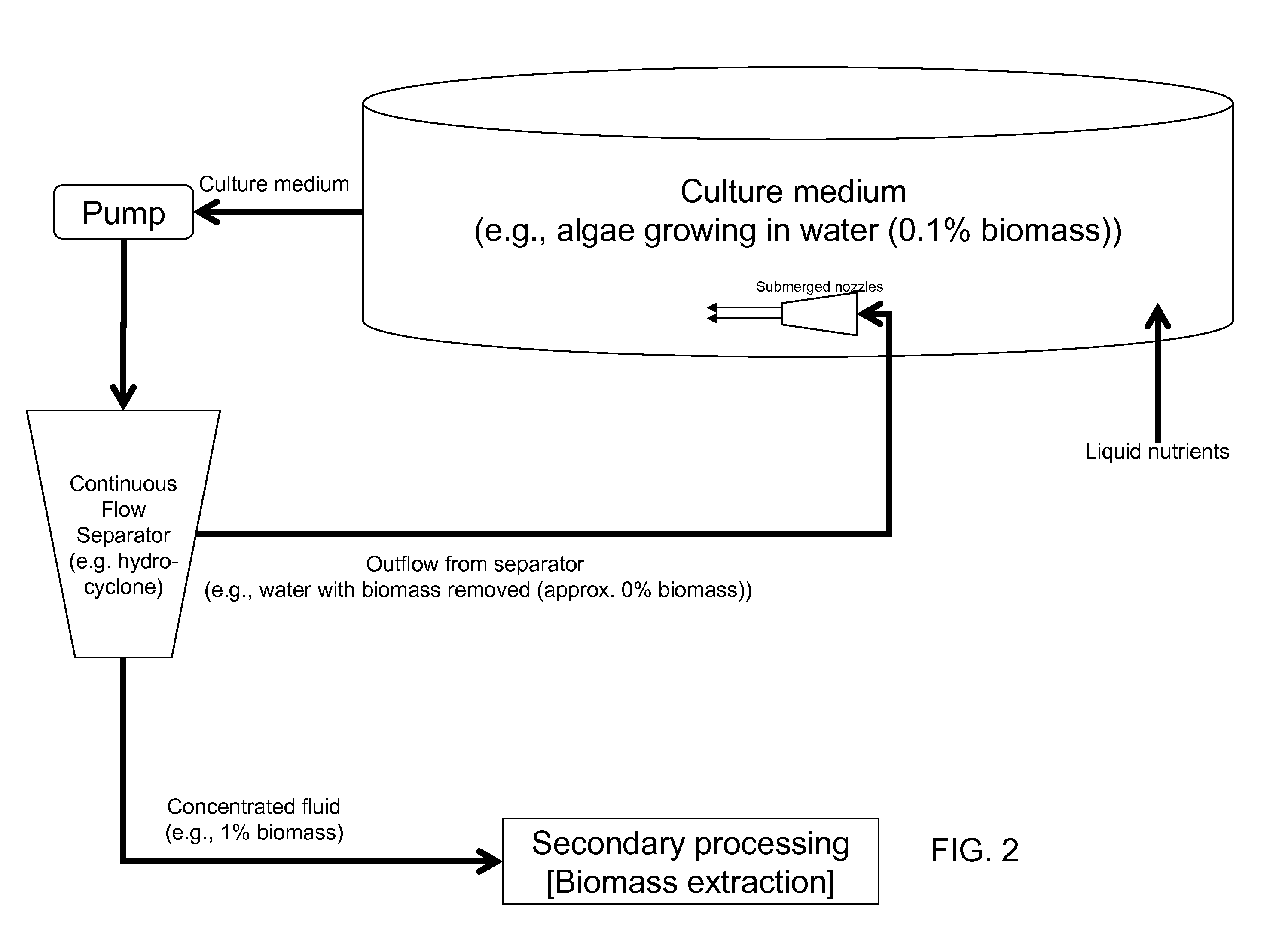

System and related method for concentrating biological culture and circulating biological culture and process fluid

InactiveUS20100210003A1Reduce needBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous flowBiological materials

A system and related method for concentrating biological culture and circulating biological culture and process fluid is provided. The system includes a continuous flow separator that removes excess fluid from the culture medium, resulting in a “concentrated medium” of fluid. The concentrated medium is then passed along for further processing to capture the biomass. The overflow, i.e., the extracted fluid, from the continuous flow separator is reintroduced into the container in a manner to circulate the culture medium. Thus, energy from the concentration step is utilized to circulate the culture medium, alleviating the need for significant additional structure for circulating the culture medium. In this manner, the system grows and captures biological material in an energy and capital efficient manner.

Owner:COMBINED POWER LLC DBA HYPERLIGHT ENERGY

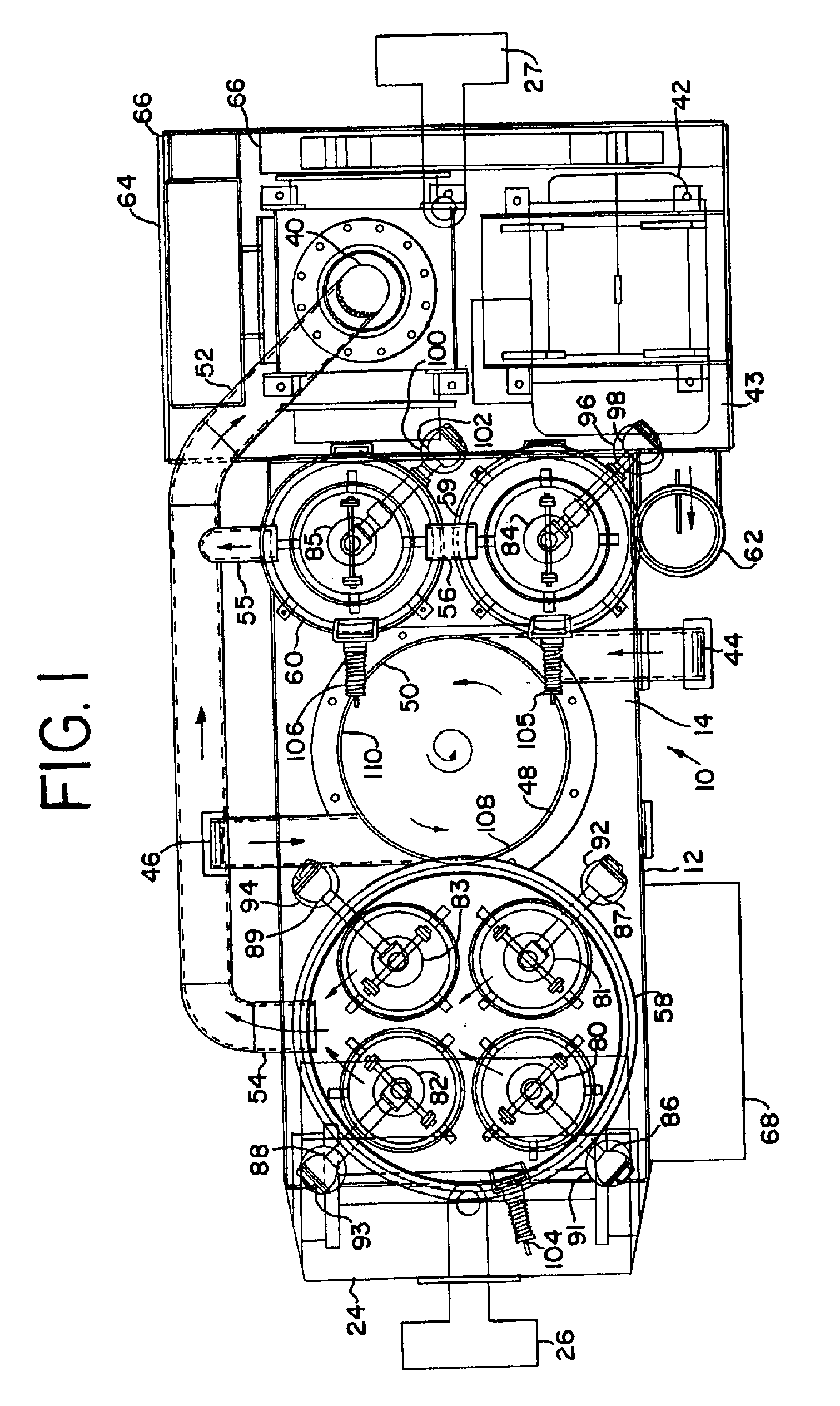

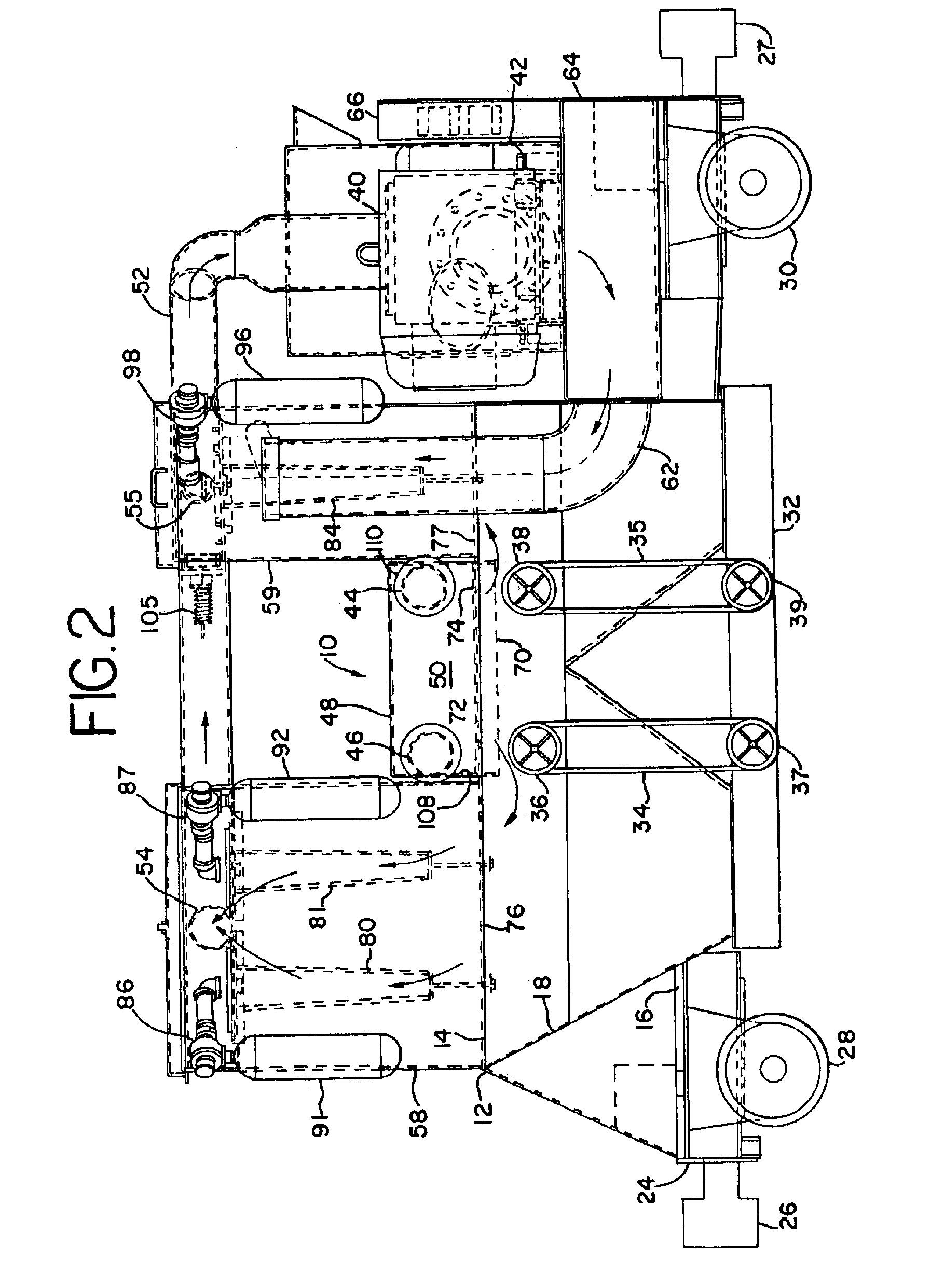

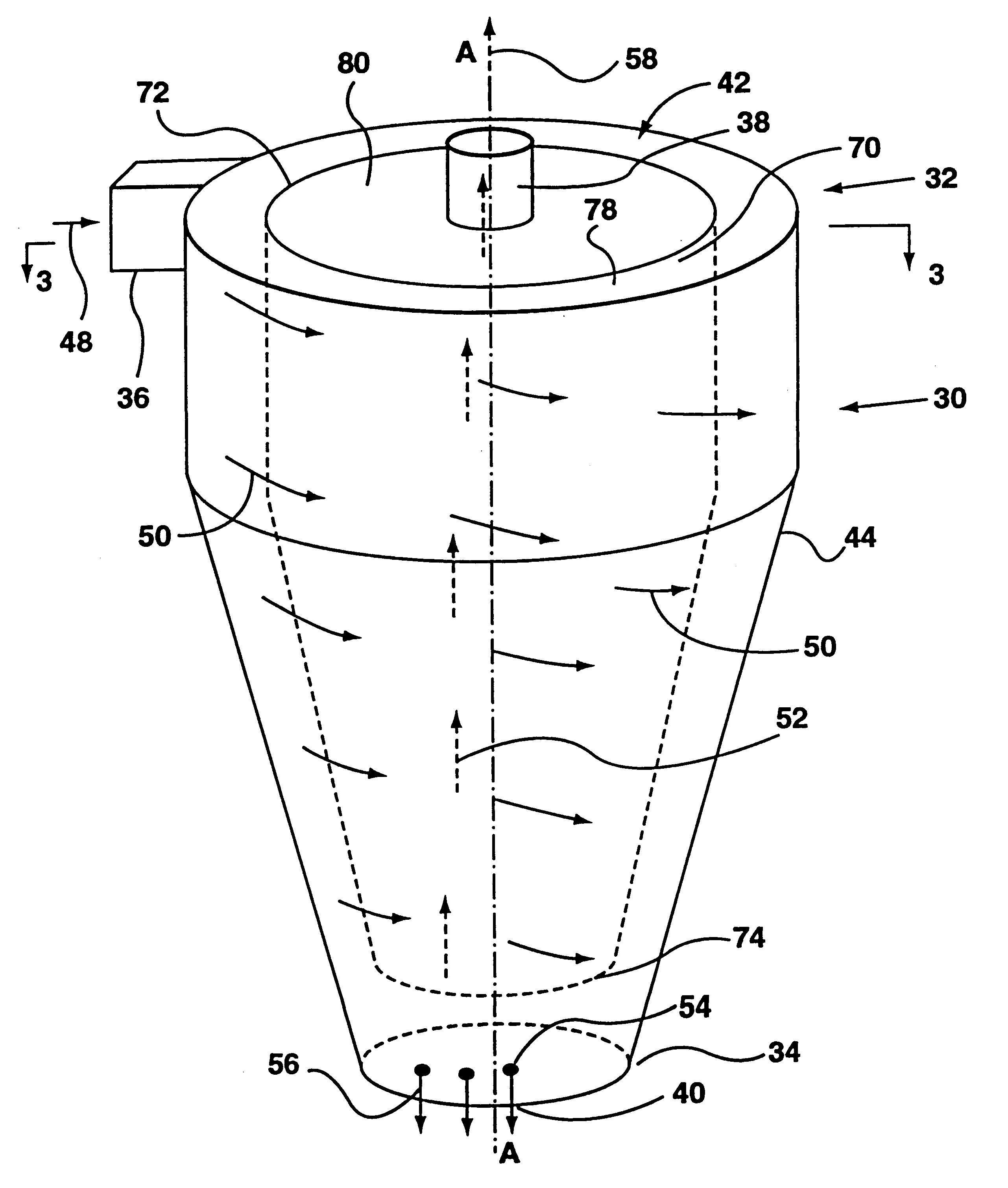

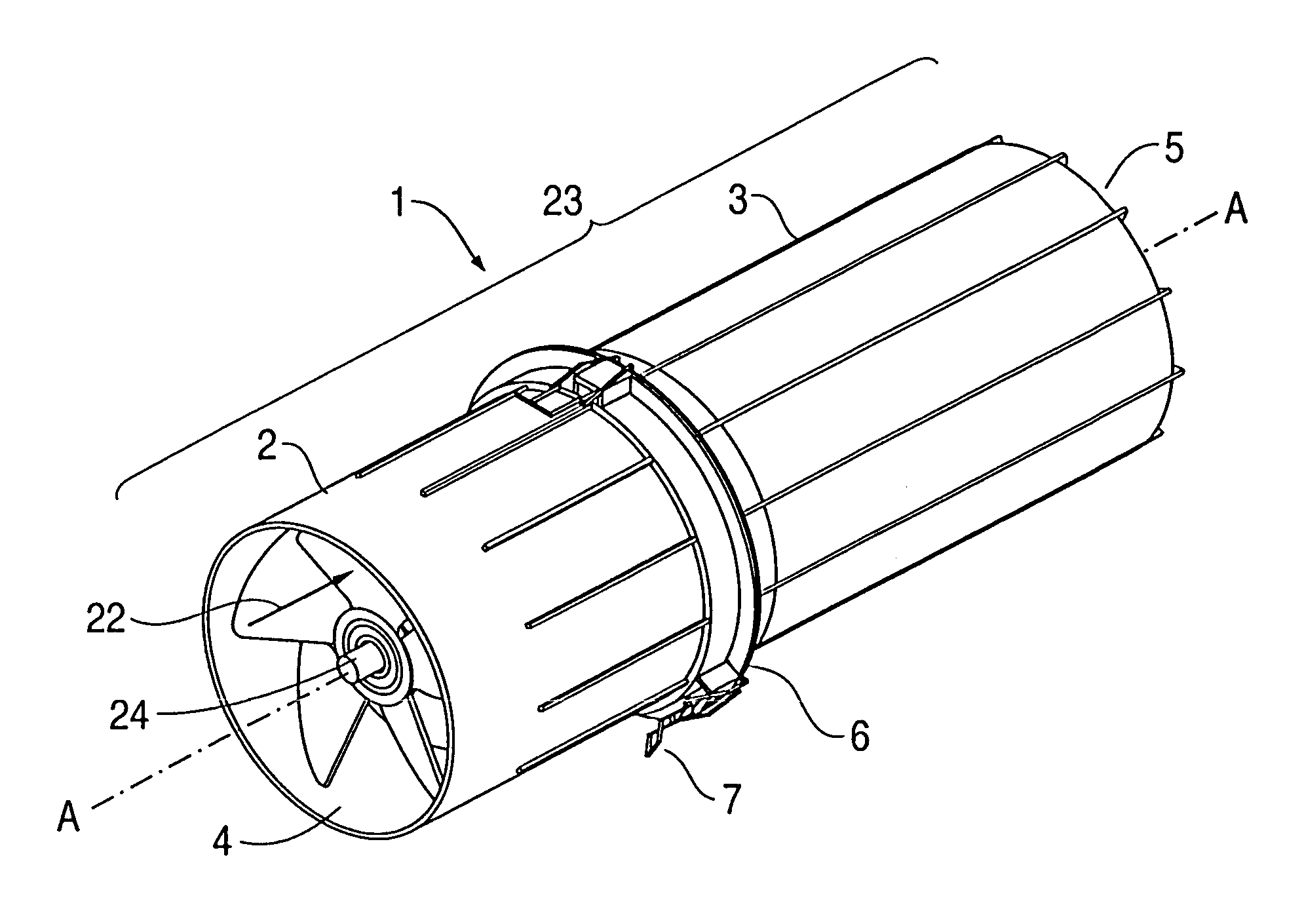

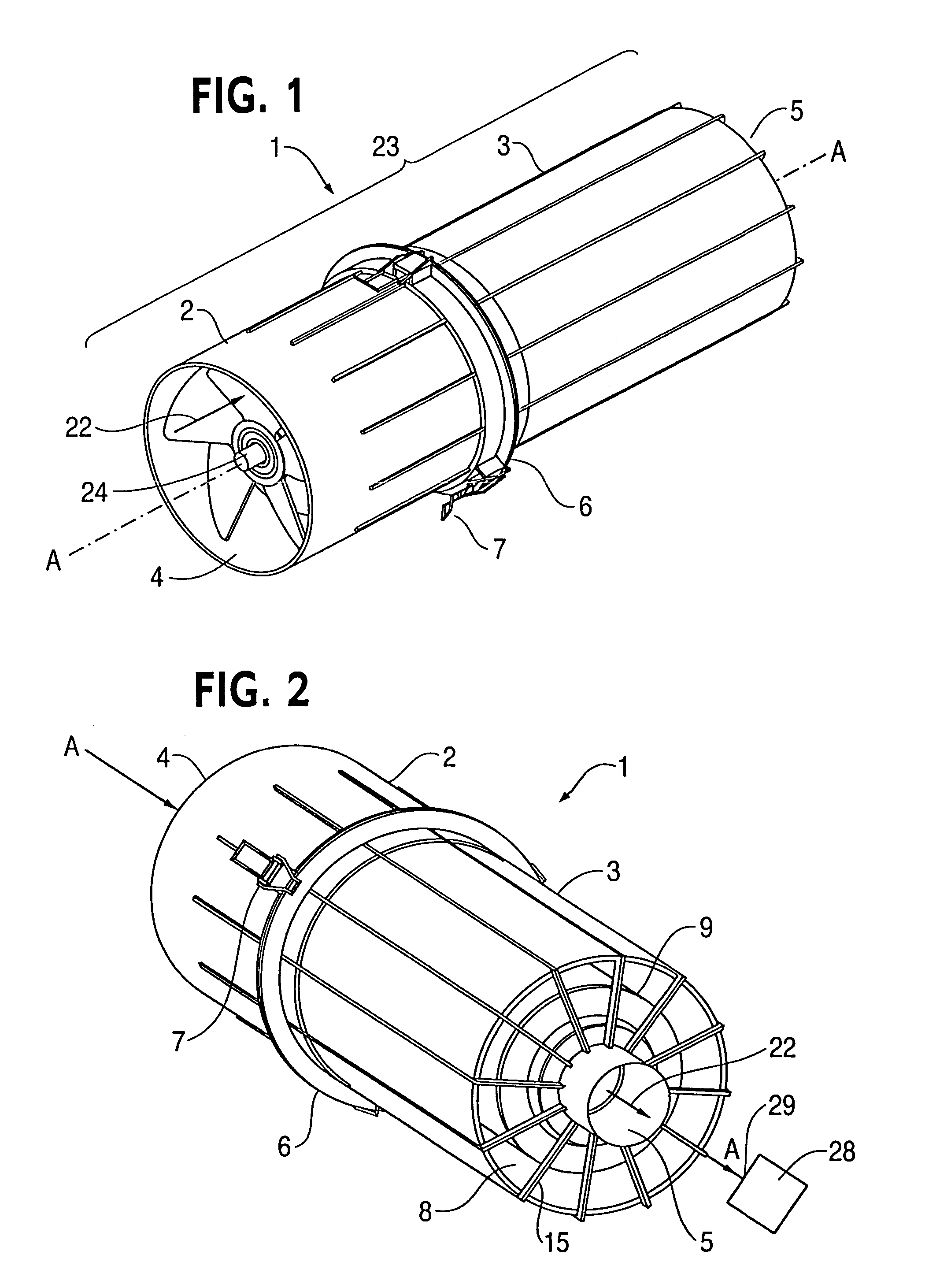

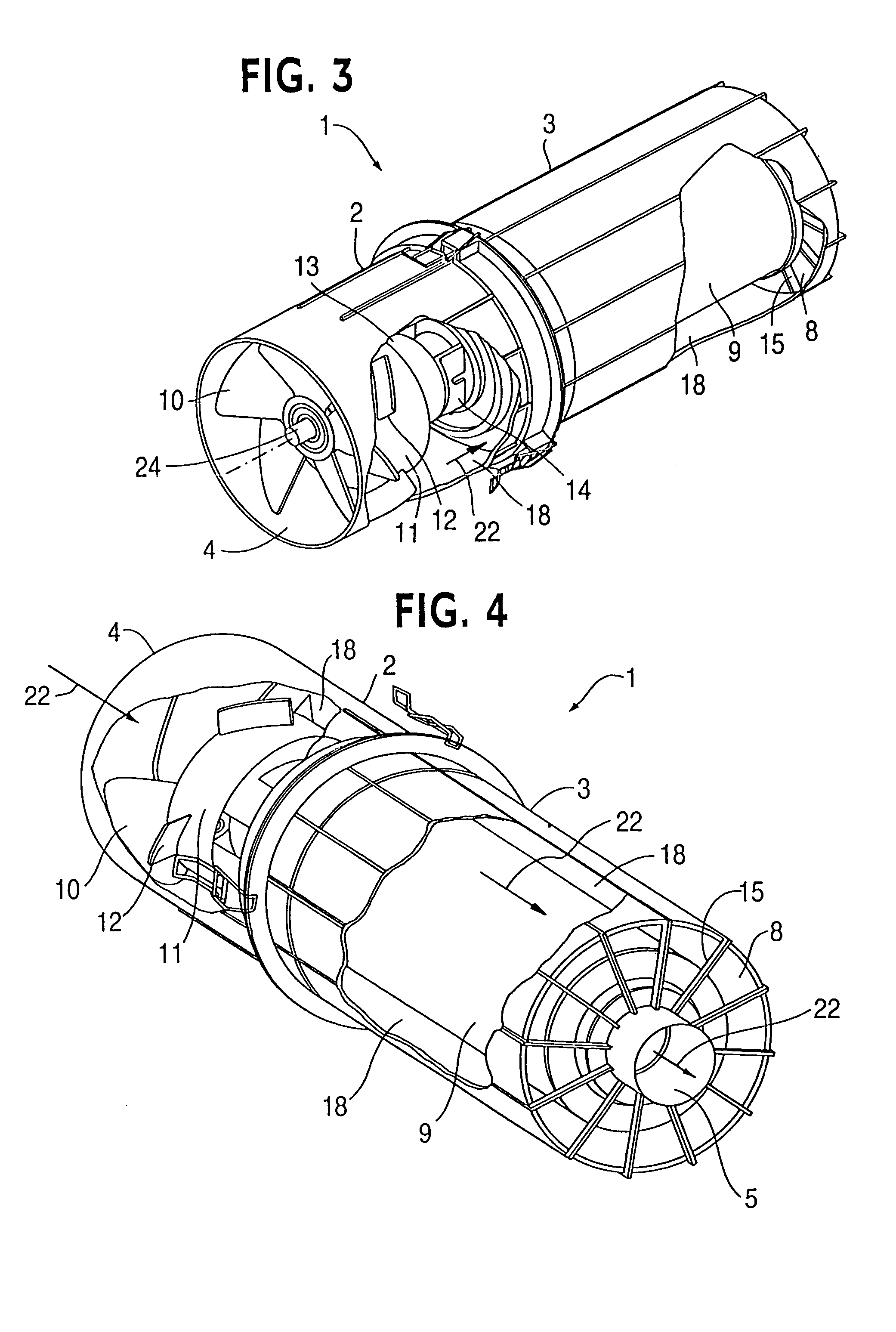

Powered air cleaning system and air cleaning method

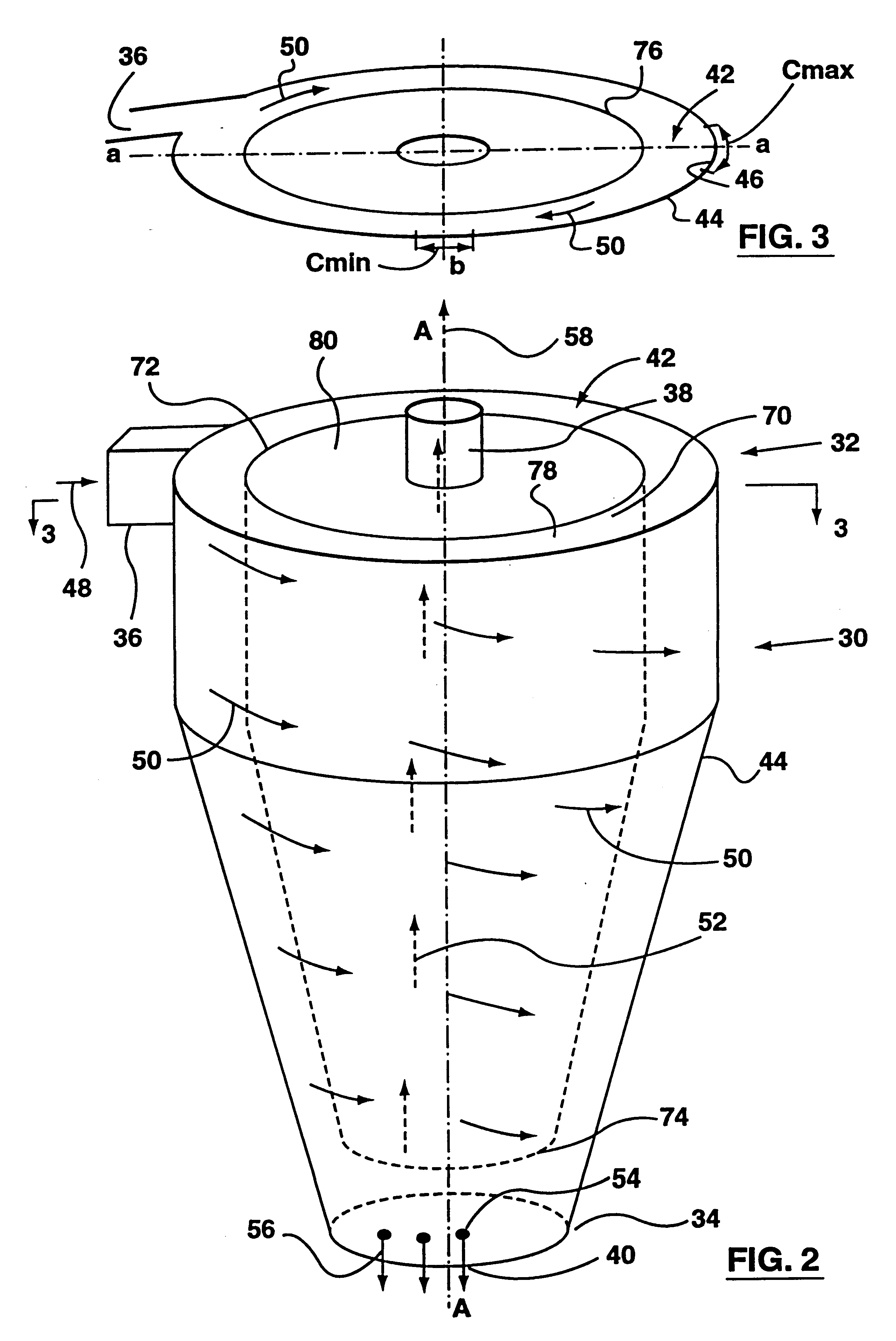

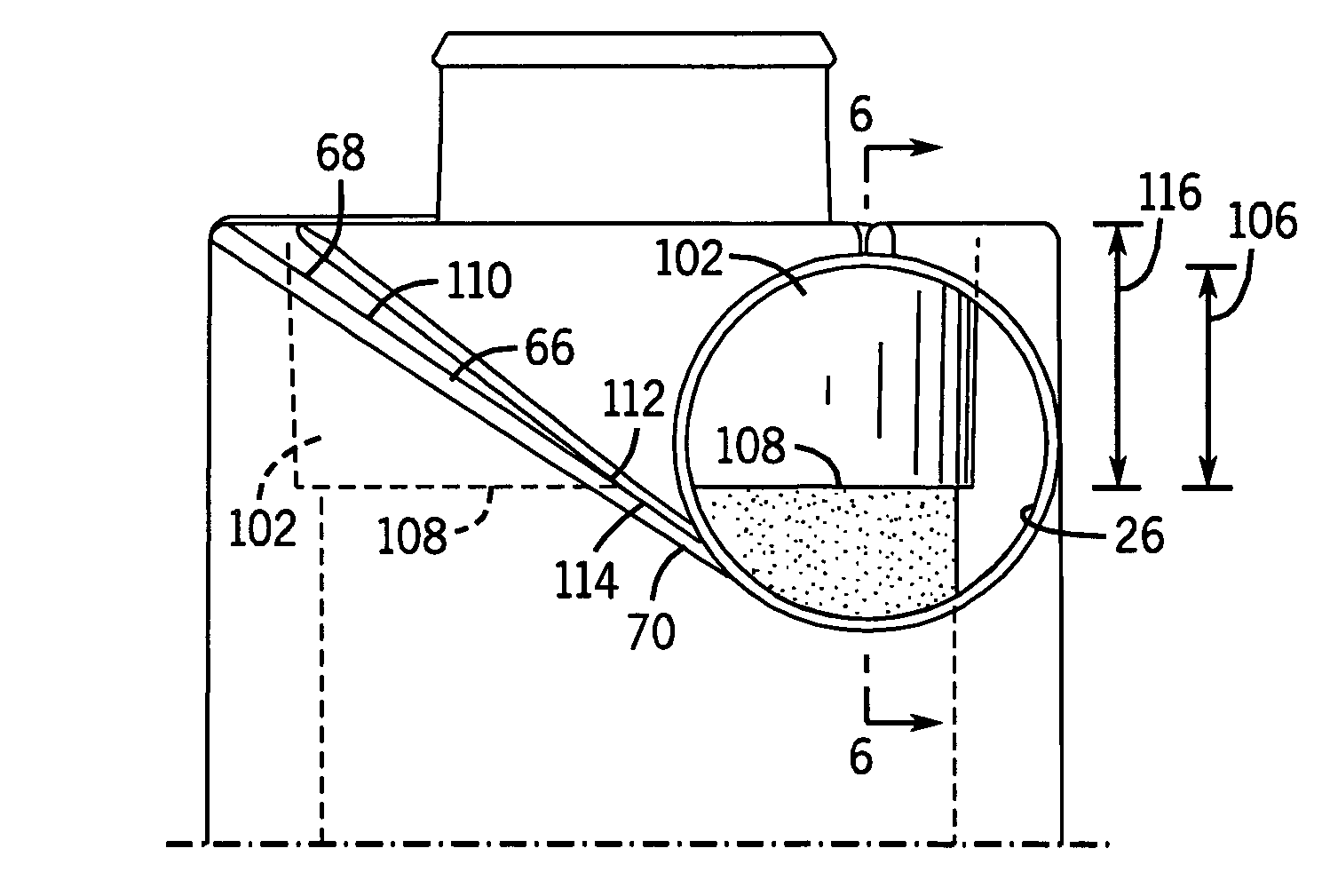

InactiveUS7056368B2Efficient removalAvoids and reduces problemCombination devicesLiquid degasificationParticulate debrisHeavy particle

A powered air cleaning system (1) and air cleaning method are disclosed. The system has a flow path (22) extending through the system from an air inlet (4) to a clean air outlet (5). A motor-driven fan (24) located along the flow path draws particulate debris laden air into the inlet and rotates it about an axis (A—A) to form a rotating flow that stratifies the debris laden air with the heaviest particles in the outermost orbits of the rotating flow. An ejector port (25) is provided for ejecting particulate debris laden air from the stratified rotating flow in the system to the environment. An air filter (9) located within the rotating flow and across the flow path upstream of the outlet filters air from the innermost orbits of the stratified rotating flow. The motor-driven fan is operated to maintain a positive air pressure in the system on the filter even with cyclic air flow demands so that the rotating air flow continually sweeps the outside surface of the air filter to minimize buildup of debris on the filter.

Owner:SY KLONE

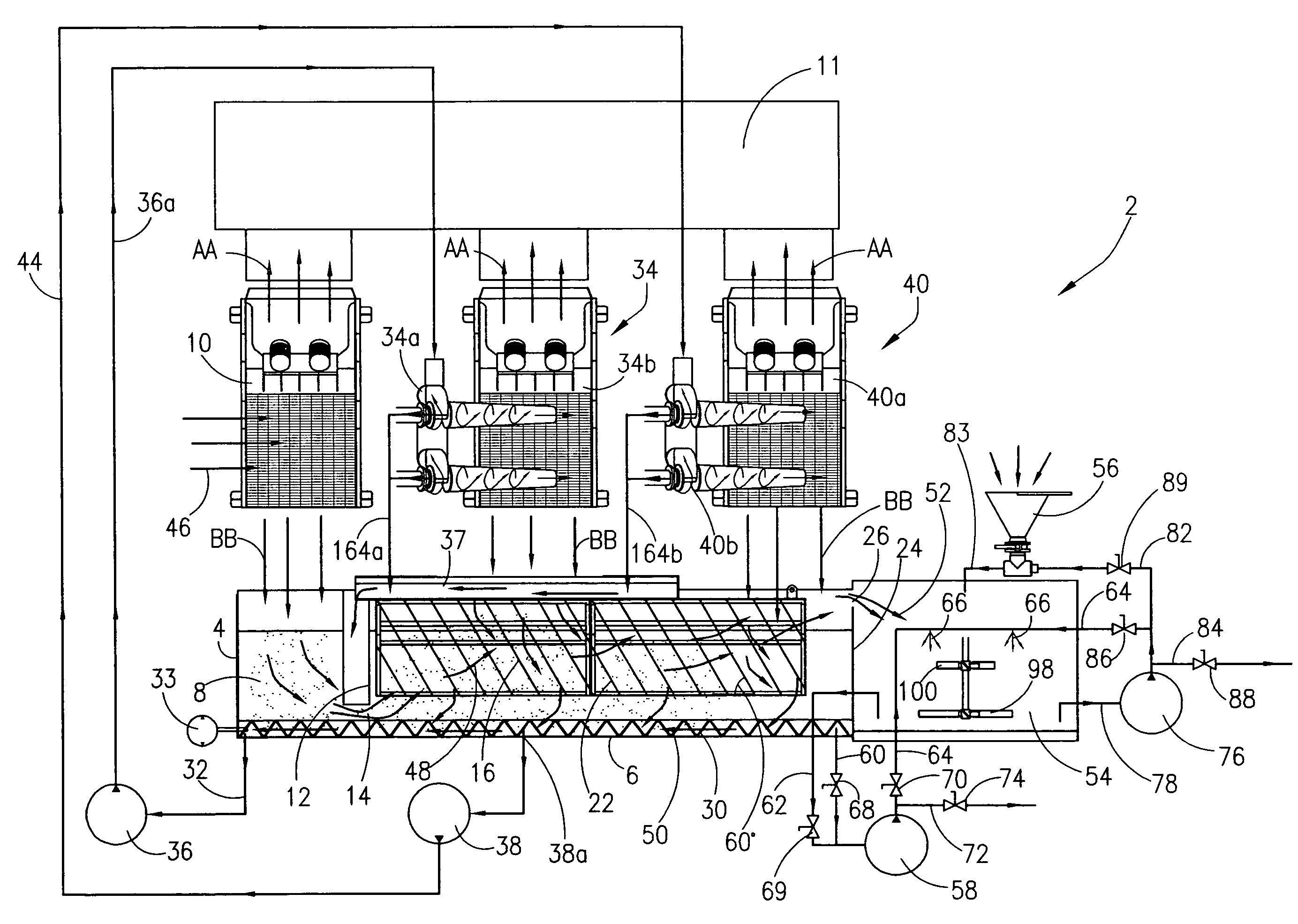

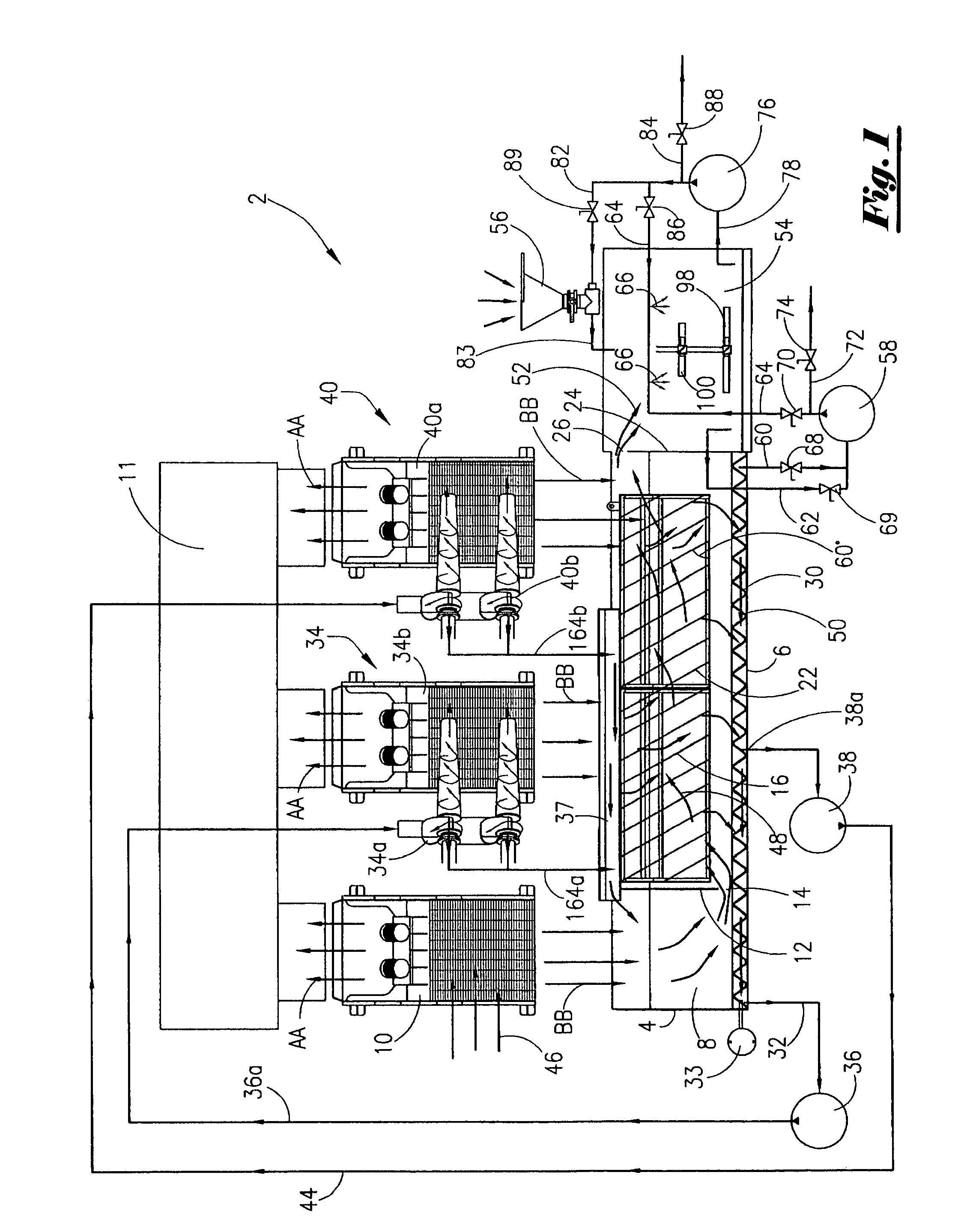

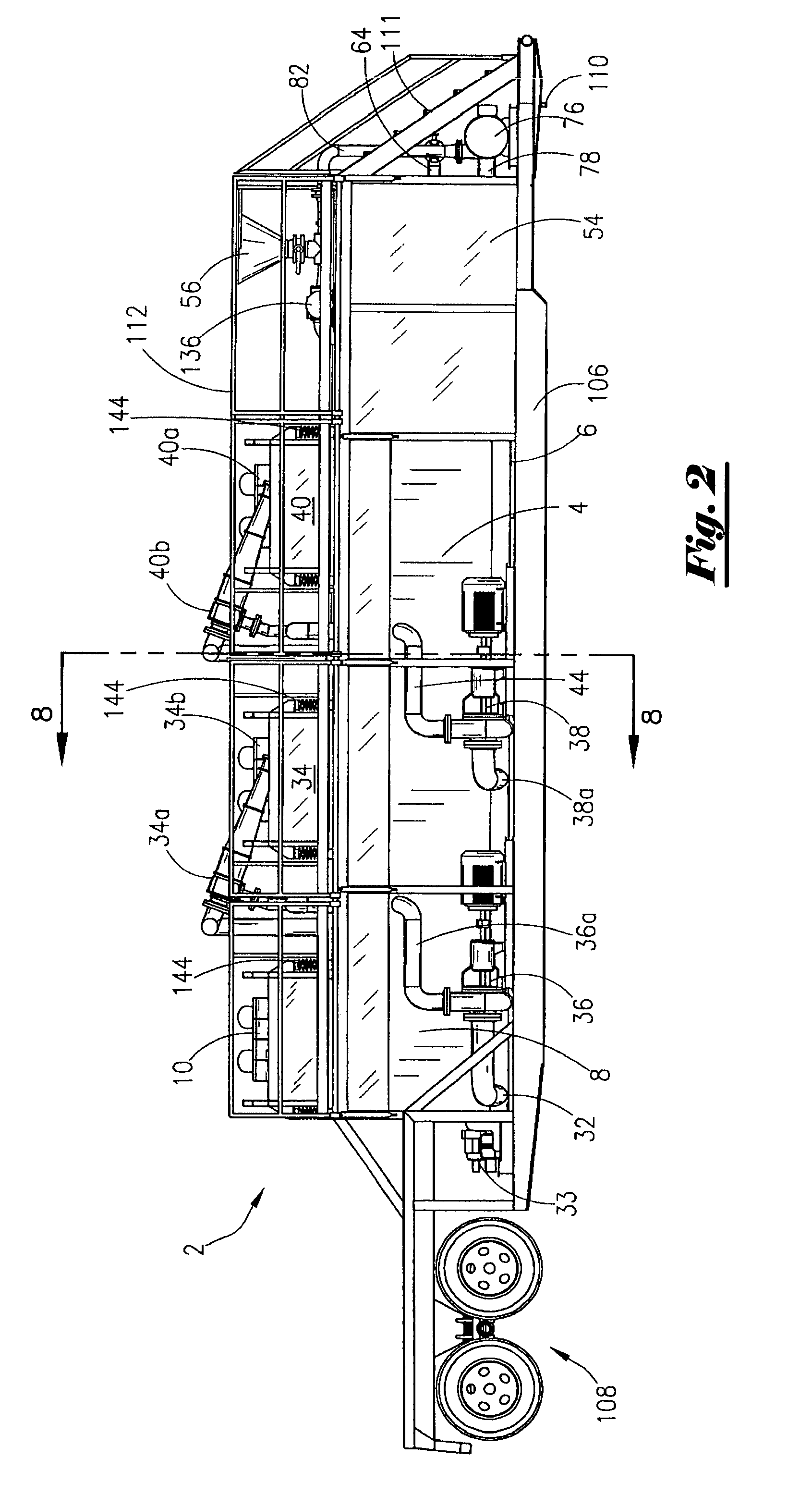

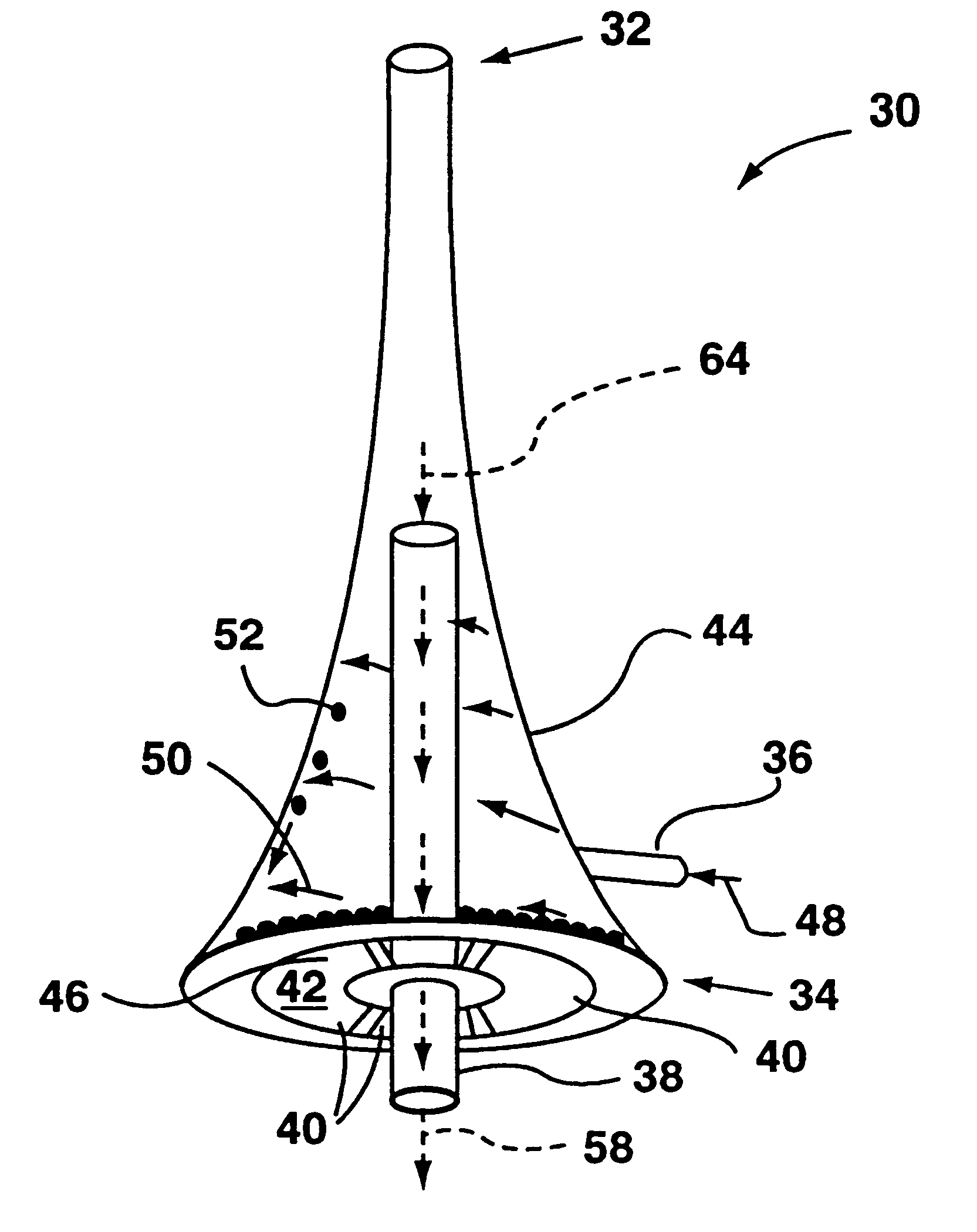

System for separating solids from a fluid stream

InactiveUS7514011B2Easy to transportMaximize impactLiquid separation auxillary apparatusSingle direction vortexSpiral bladeSlurry

Owner:DEL

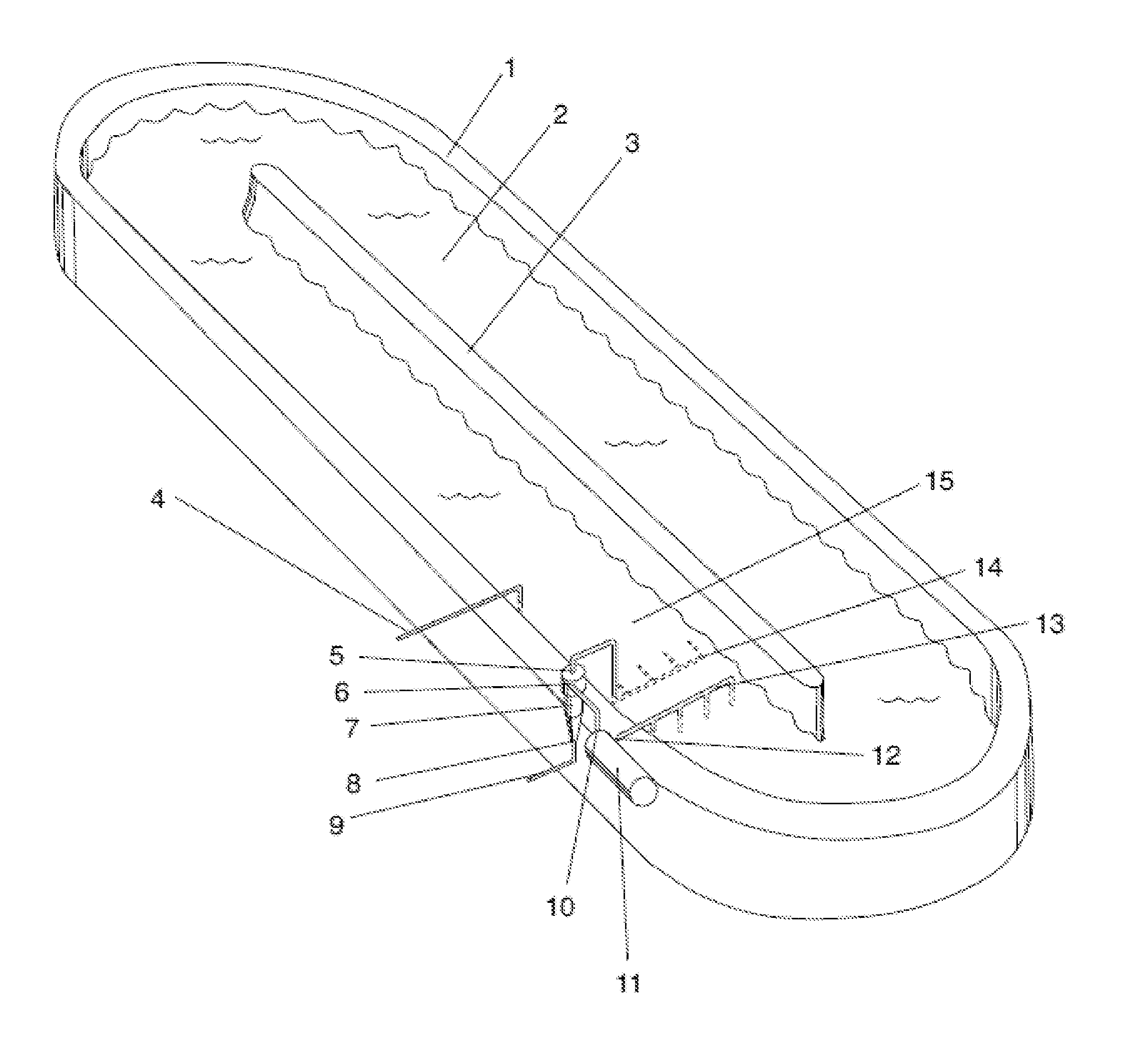

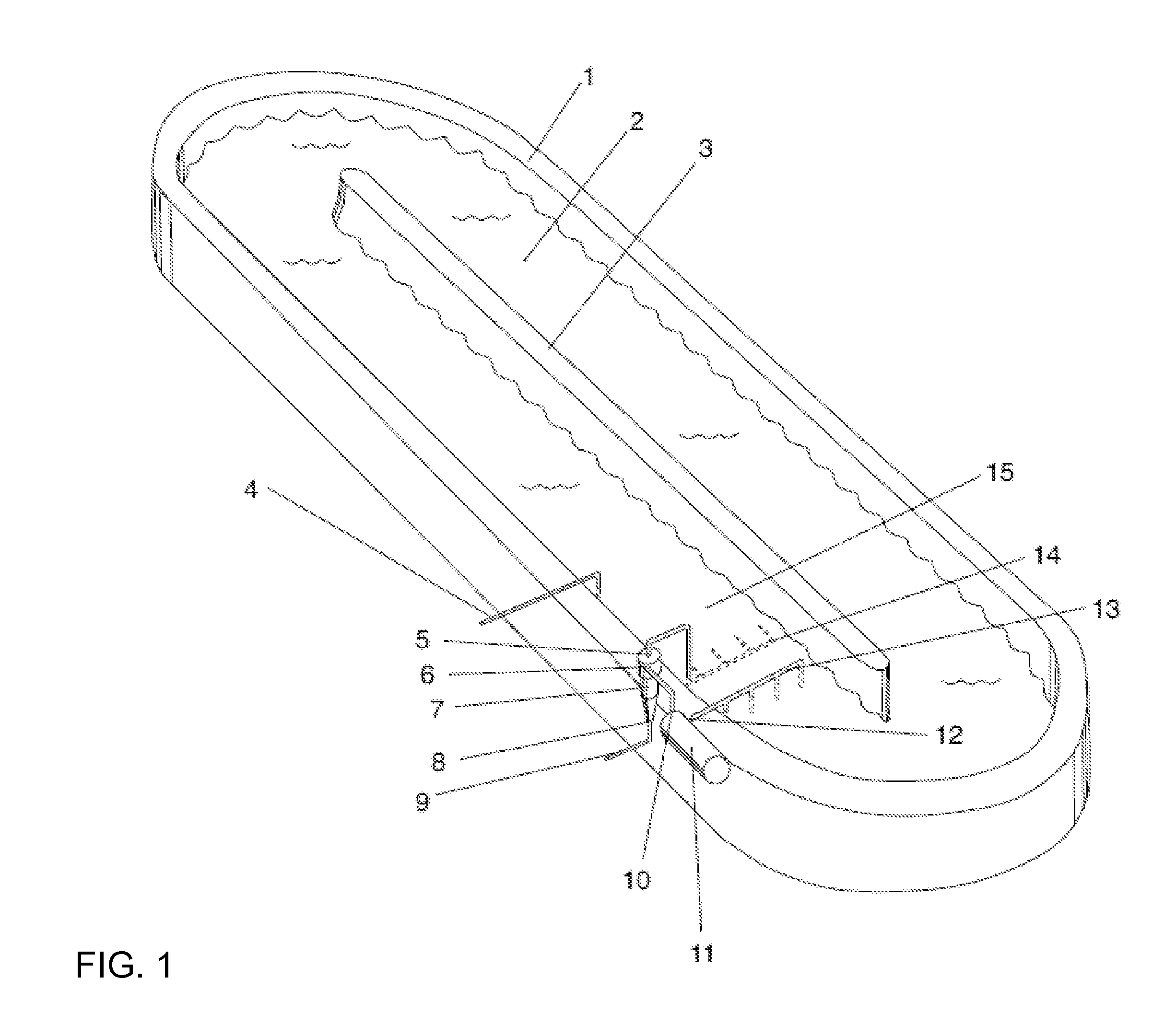

Inertial separator

An inertial separator comprising a tubular body, the tubular body comprises a composition comprising a polymer selected from the group consisting of a cyclic olefin polymer and a cyclic olefin copolymer, and, a polyhedral oligomeric silsesquioxane and / or a flame retardant and / or an anti-static additive, is disclosed.

Owner:PALL CORP

Cyclone separator having a variable longitudinal profile

InactiveUS6596046B2Easy to separateReduce the numberReversed direction vortexDispersed particle filtrationCycloneEngineering

Owner:OMACHRON INTPROP

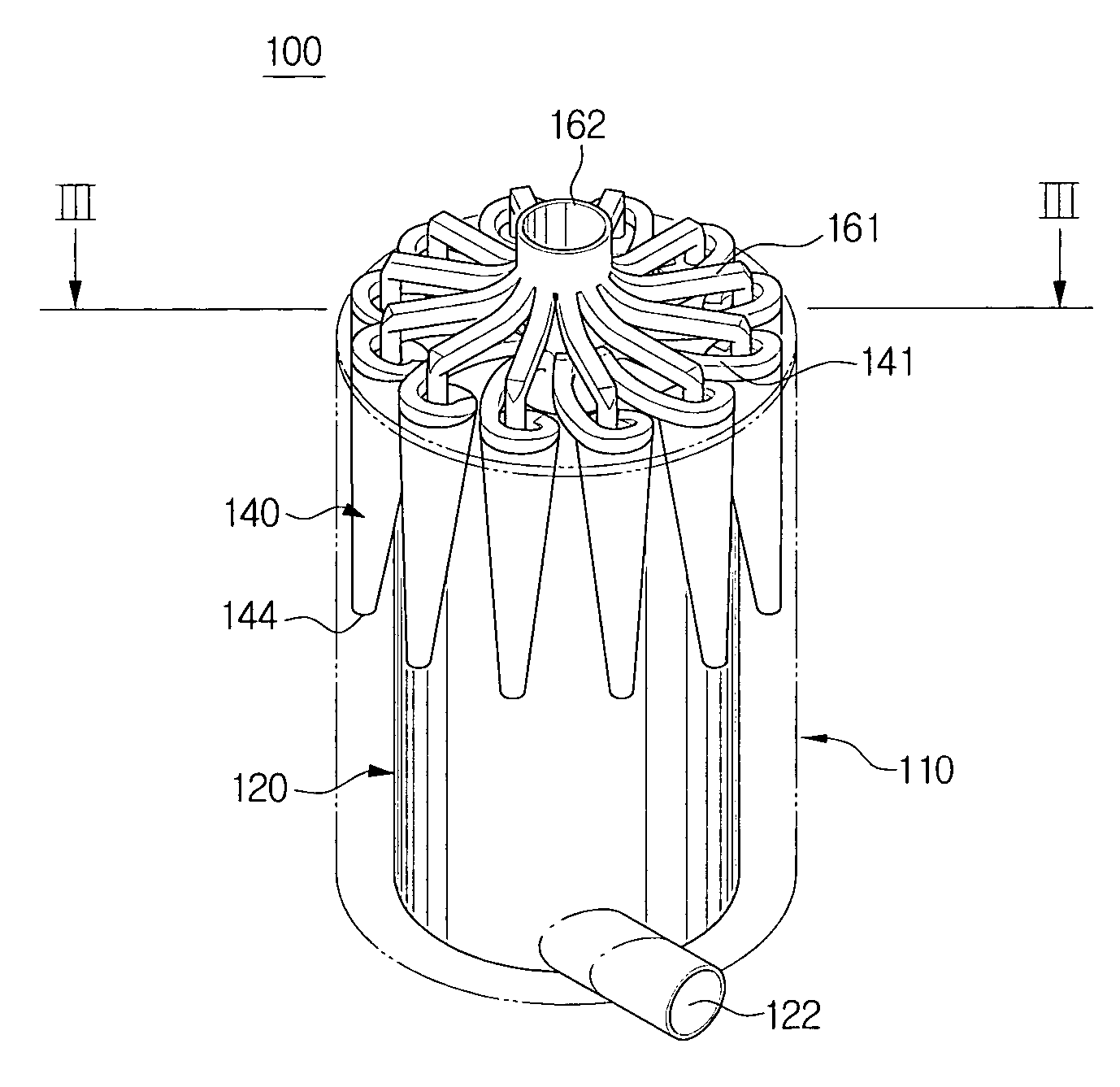

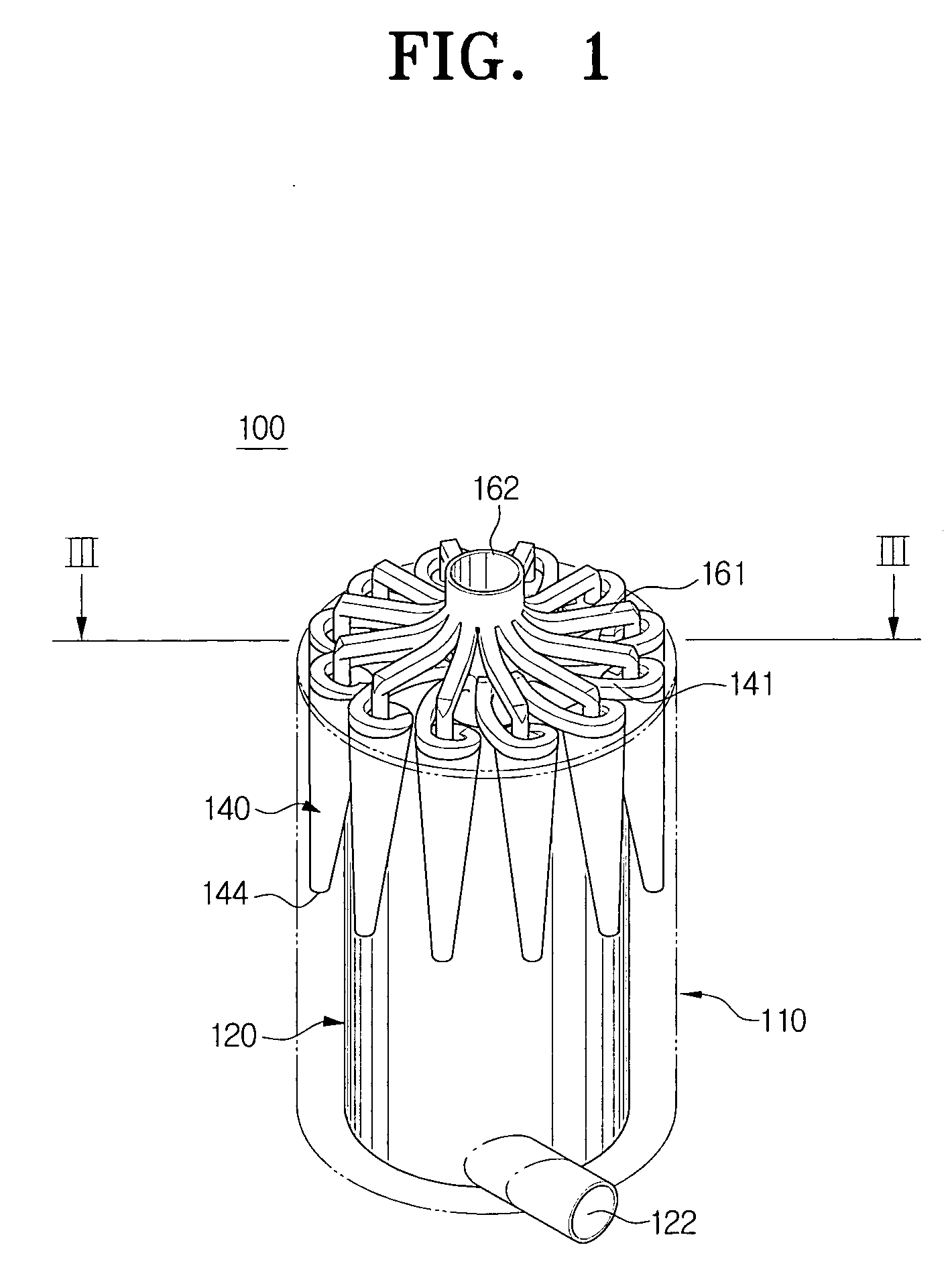

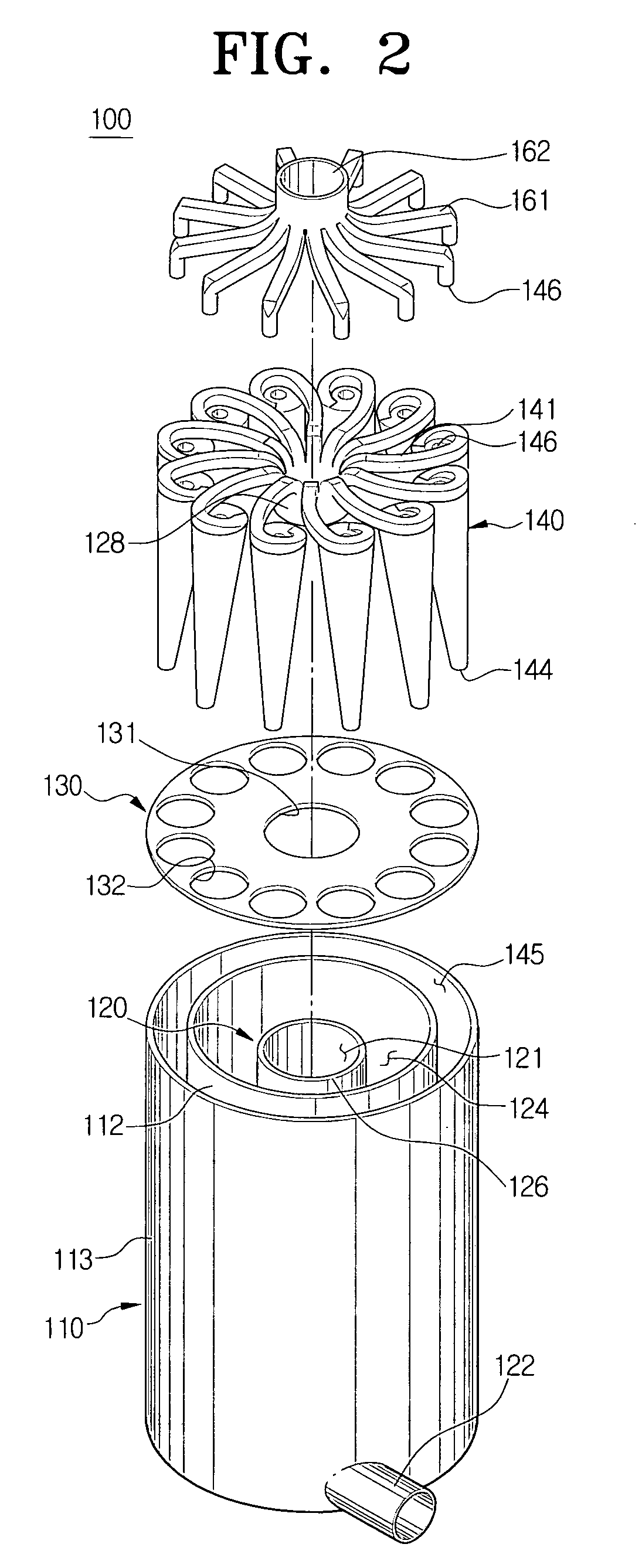

Cyclone dust collecting apparatus for vacuum cleaner

ActiveUS7722693B2Small pressure lossHigh fine dust collecting efficiencyCleaning filter meansCombination devicesCycloneMechanical engineering

A cyclone dust collecting apparatus for a vacuum cleaner includes a first cyclone, a second cyclone disposed inside the first cyclone, and an air guiding member to form an entrance of the second cyclone through which semi-clean air discharged from the first cyclone enters. The air guiding member includes a grill member to have a plurality of holes, and a plurality of guiding blades disposed inside the grill member.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Gas/liquid separator

InactiveUS7594942B2Increase spacingPrevent re-entrainmentCombination devicesIsotope separationProduct gasEngineering

A gas / liquid separator comprising a vertical vessel having an inlet for a gas / liquid mixture; a gas / liquid separation device arranged within the vessel, which separation device has an inlet in fluid communication with the inlet of the vessel, and an outlet means for at least partially separated gas and liquid; an outlet for gas from the vessel, above and in fluid communication with the outlet means of the separation device; a liquid collection space in the vessel, below and in fluid communication with the outlet means of the separation device; and an outlet for liquid from the vessel, having a receiving end in the liquid collection space, wherein the gas / liquid separation device is a vane inlet device and wherein between the separation device and the liquid collection space a liquid collection promoter tray is arranged, forming a receiving area for liquid impinging on the tray from above and having a passage for liquid received on the receiving area to flow to the liquid collection space; and the use of such a gas / liquid separator.

Owner:SHELL OIL CO

Inlet device and a method of controlling the introduction of a fluid into a separator

InactiveUS20070095032A1Easy to carryEasy to installAuxillary pretreatmentLiquid degasificationEngineeringPartial closure

An inlet device to a separator including a generally tubular outer wall and a generally tubular inner wall. The walls define at least a part of a first annular path between them. An inlet opening provides for the passage of a fluid through the outer wall into the first annular path. At least one communication channel provides for the passage of a fluid from the first annular path into the second annular path. At least one movable closing element provides for at least partial closure of the fluid passage from the first path into the second path. The communication channel(s) is / are arranged to extend along the outside of the inner wall downwards from the first path into the second path, wherein the second path is arranged below the first path.

Owner:SULZER MANAGEMENT AG

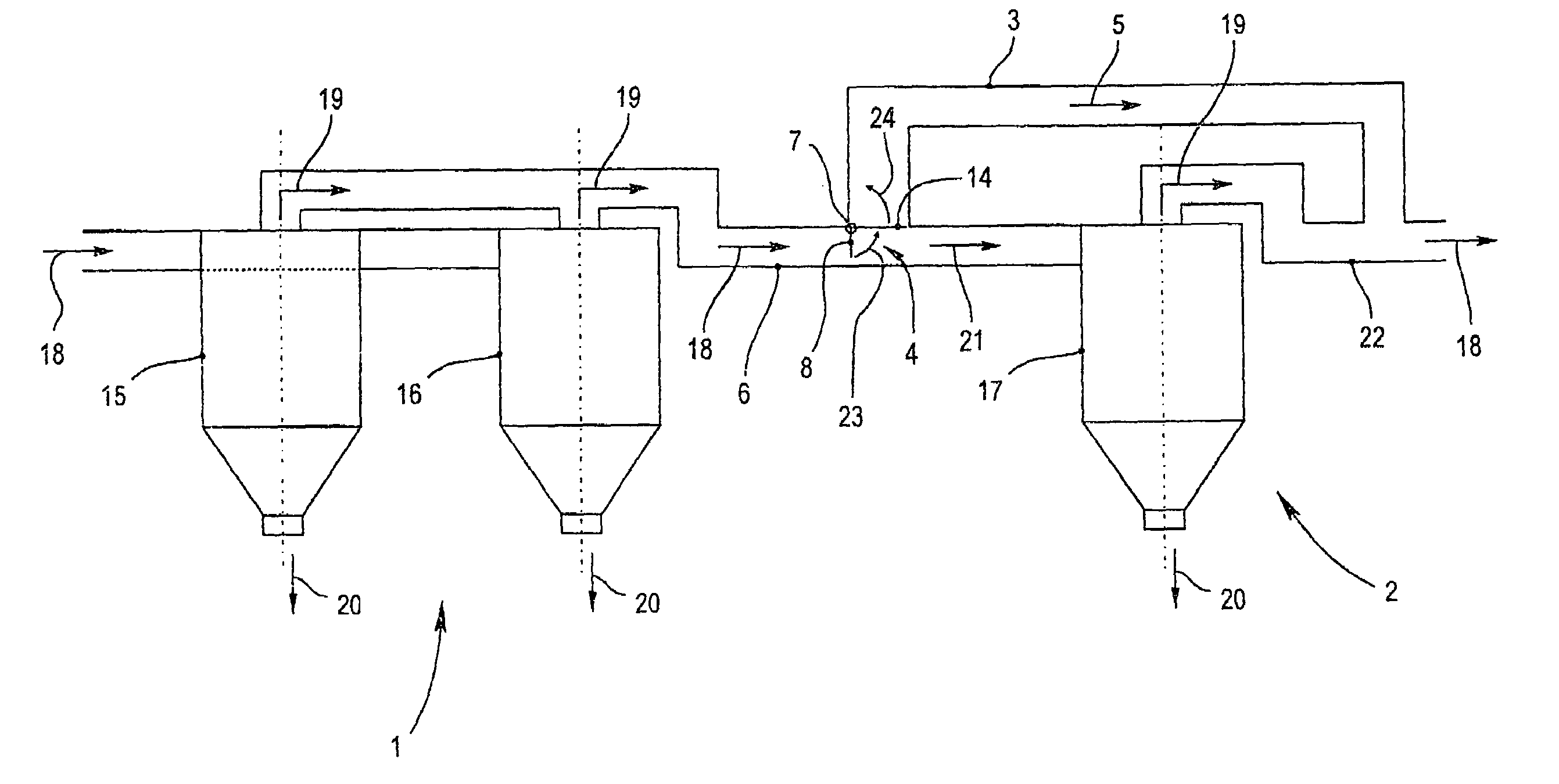

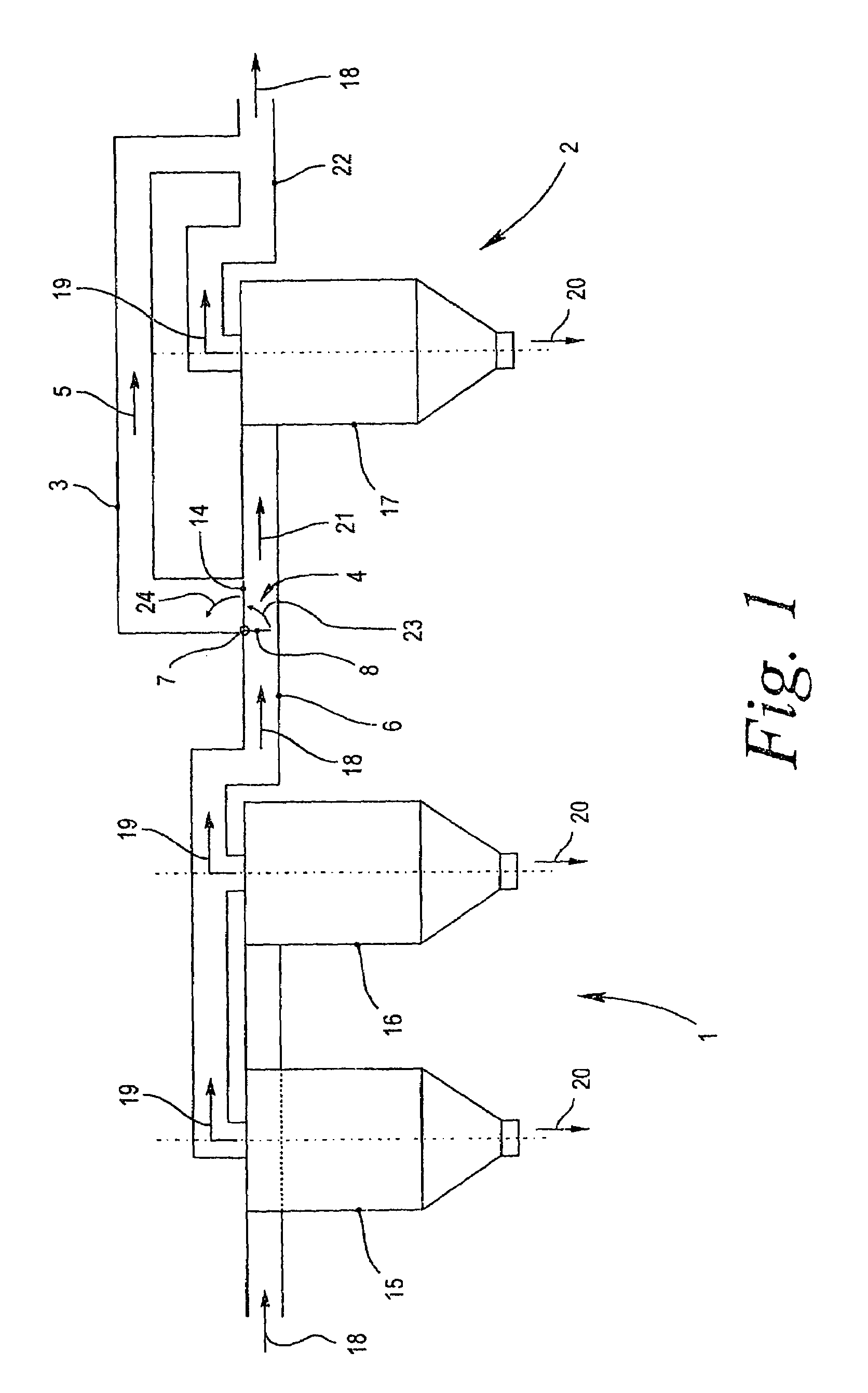

In-line cyclone separator

InactiveUS20080006011A1Avoid excessive changesOperating means/releasing devices for valvesLiquid degasificationCycloneEngineering

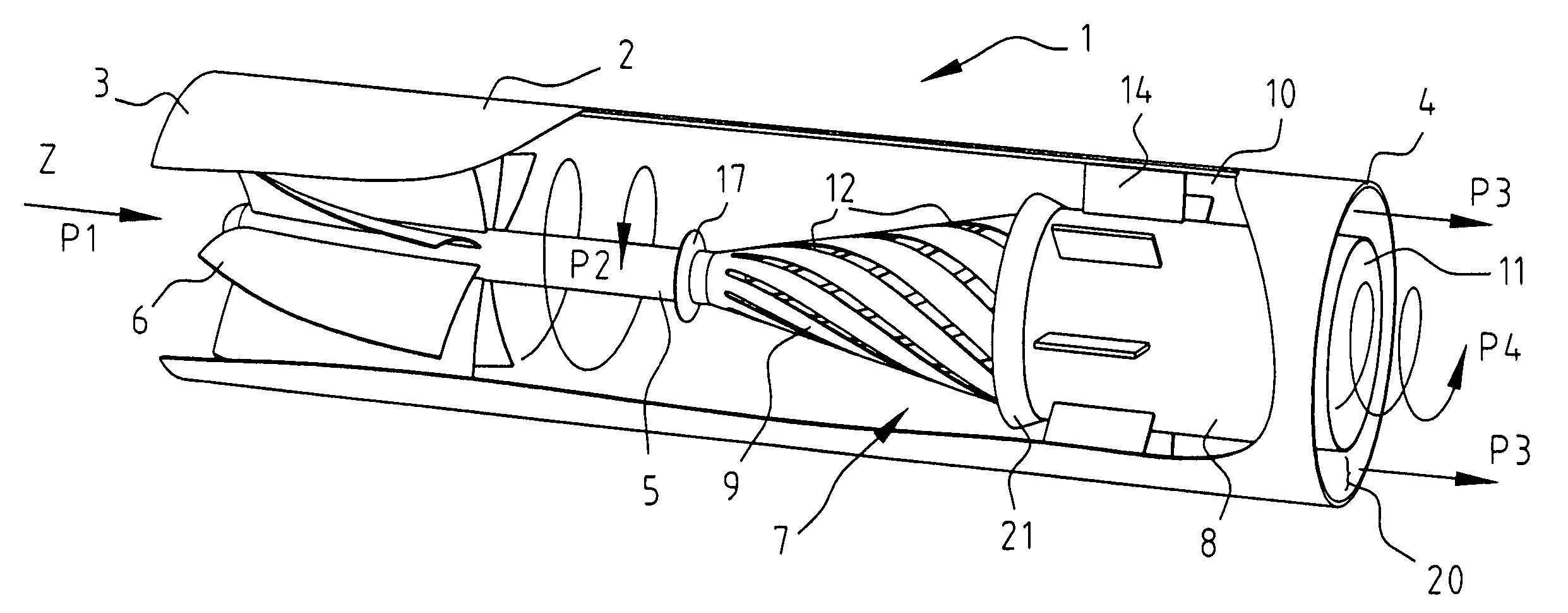

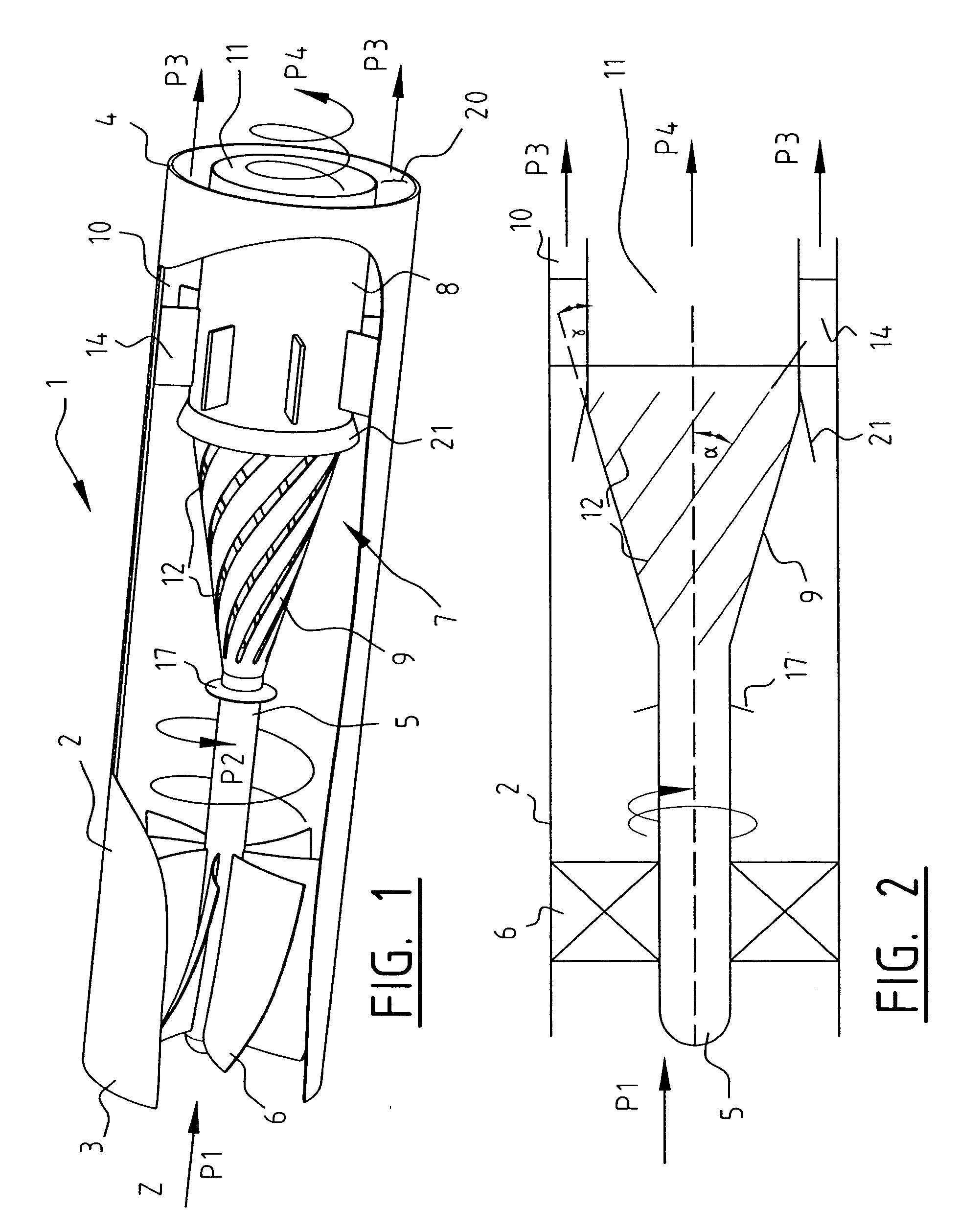

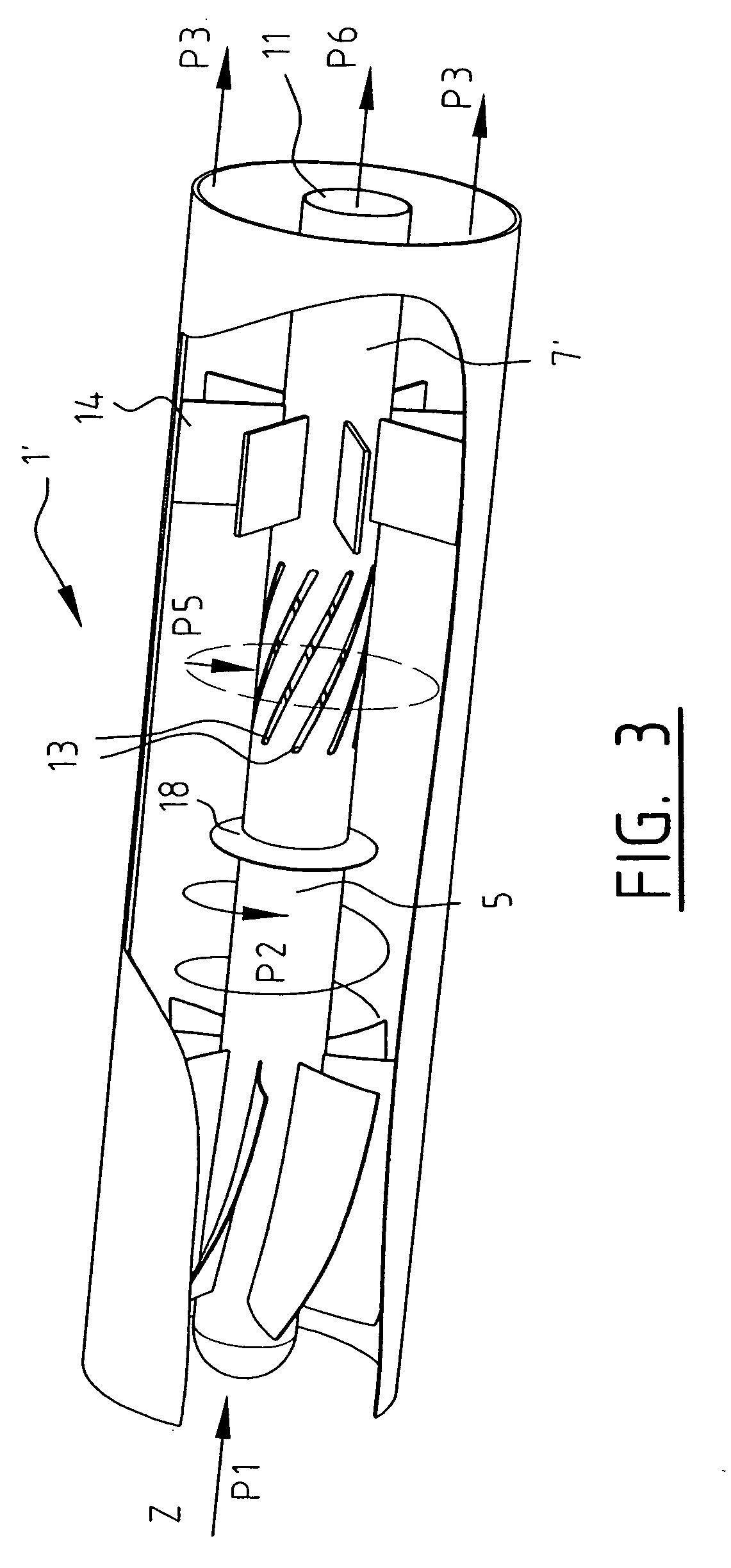

A cyclone separator for separating a mixture containing solid particles, liquid and / or gas into a heavy fraction and a light fraction. the cyclone separator including an outer casing defining a flow space through which, the mixture is to flow and having an inlet for an incoming mixture. A first outlet for the separated light fraction and a second outlet for the separated heavy fraction and a flow body arranged in the outer casing and along which the mixture to be separated is carried. at least one swirl element arranged in the outer casing and between the flow body and the outer casing for setting the mixture into a rotating movement for the purpose of separating the mixture into the heavy and light fractions. an outlet element having a central, axially extending inner passage connected to the first outlet for discharge of the light fraction and an outer surface which, together with an inner surface of the outer casing, defines an outer passage connected to the second outlet for discharge of the heavy fraction, the outlet element being provided with one or more elongated openings through which the light fraction can enter the inner passage, the one or more elongate openings extending obliquely with respect to an axial direction of the outlet element.

Owner:FMC TECH CV

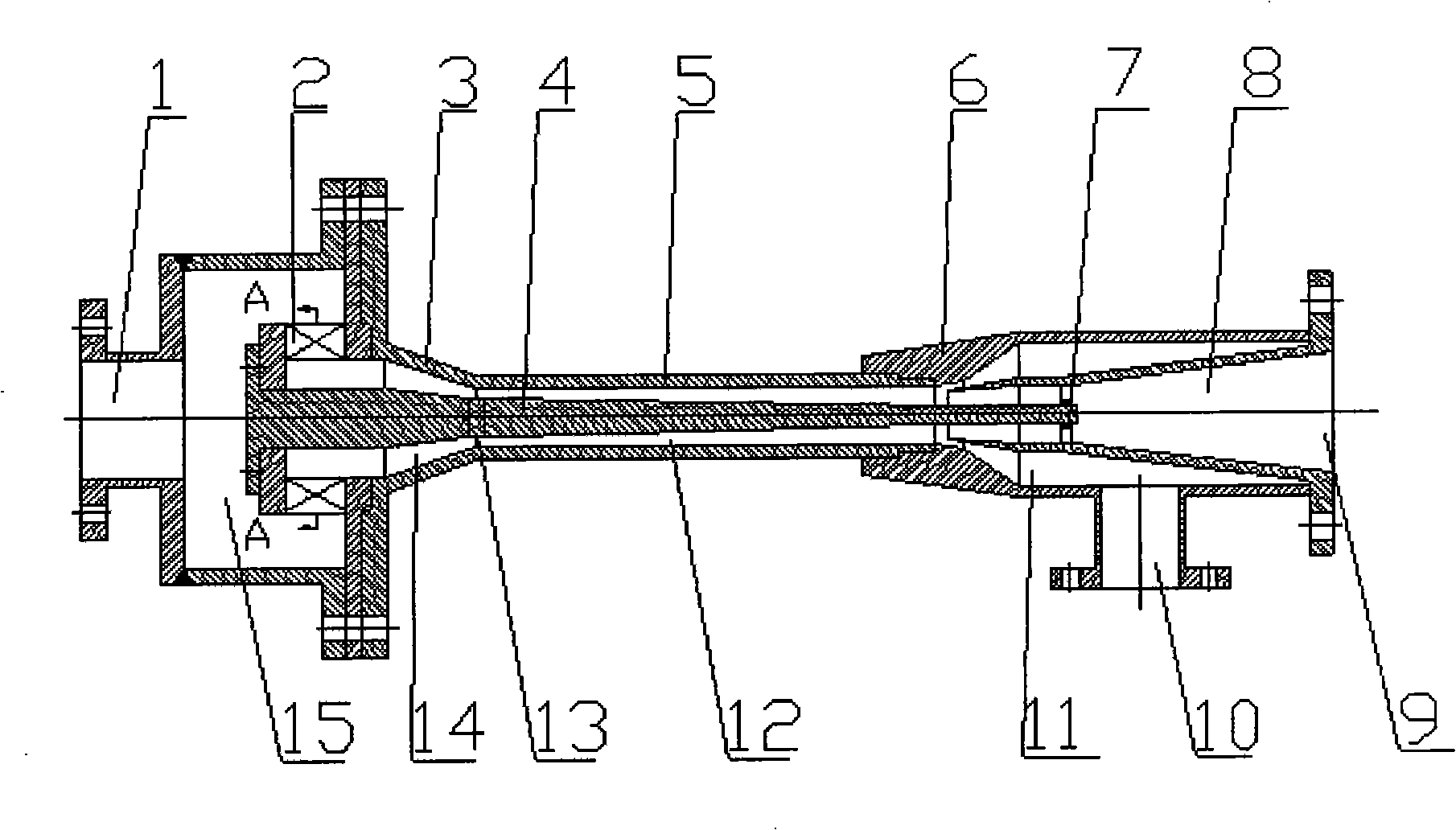

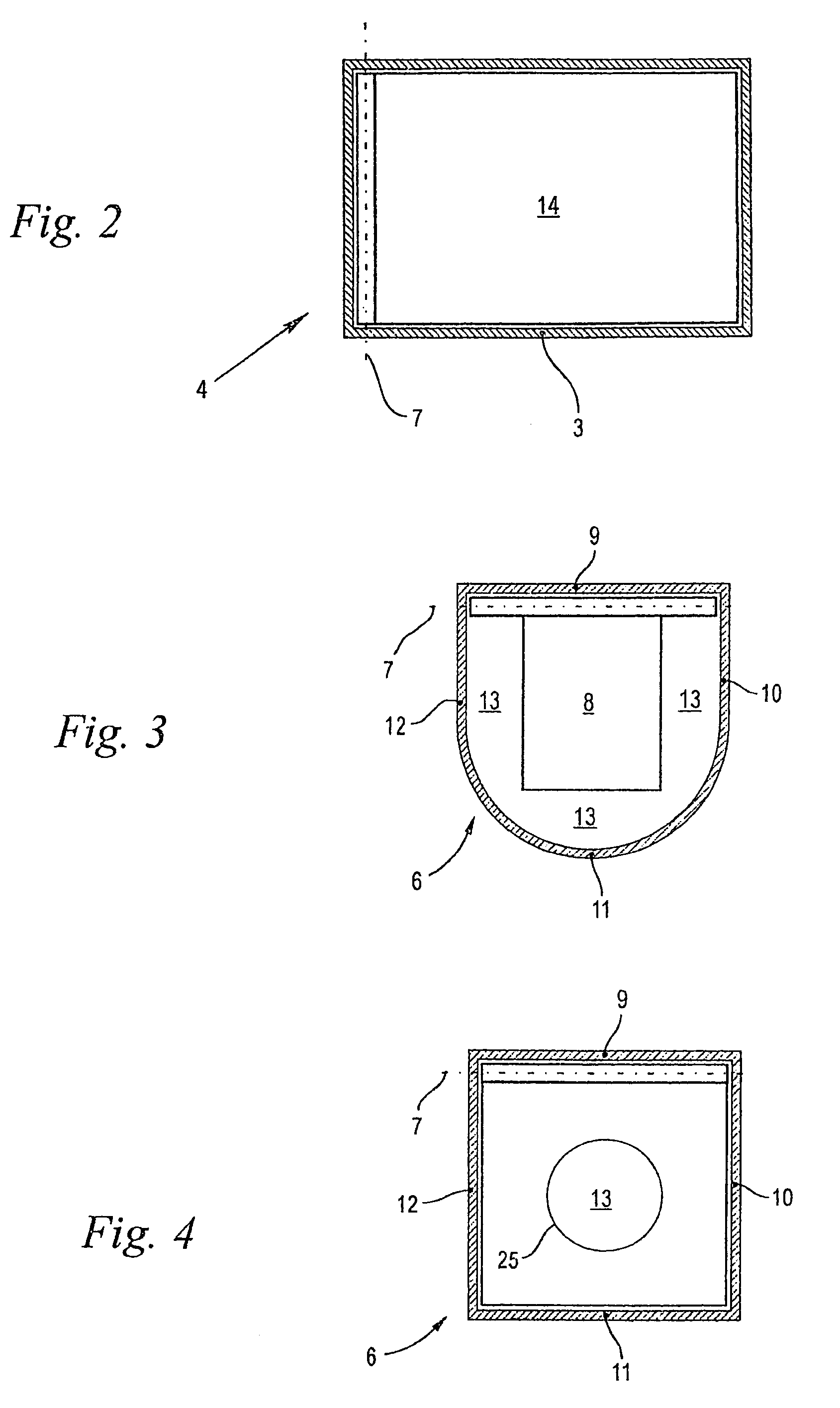

Cyclone such as for use in a surface cleaning apparatus

ActiveUS20140237956A1Reduce the soundReduce noiseCombination devicesSuction filtersCycloneSurface cleaning

A cyclone comprises a cyclone chamber having an air inlet, an air outlet, a first end wall, a second end wall and a sidewall, the air inlet has an inlet end having a shape and a cross sectional area in a plane transverse to a direction of airflow through the air inlet, and the air inlet is provided at a first juncture of the sidewall and the first end wall, wherein the first juncture downstream of the inlet is configured to at least approximate a portion of the shape of the air inlet that is adjacent the first juncture.

Owner:OMACHRON INTPROP

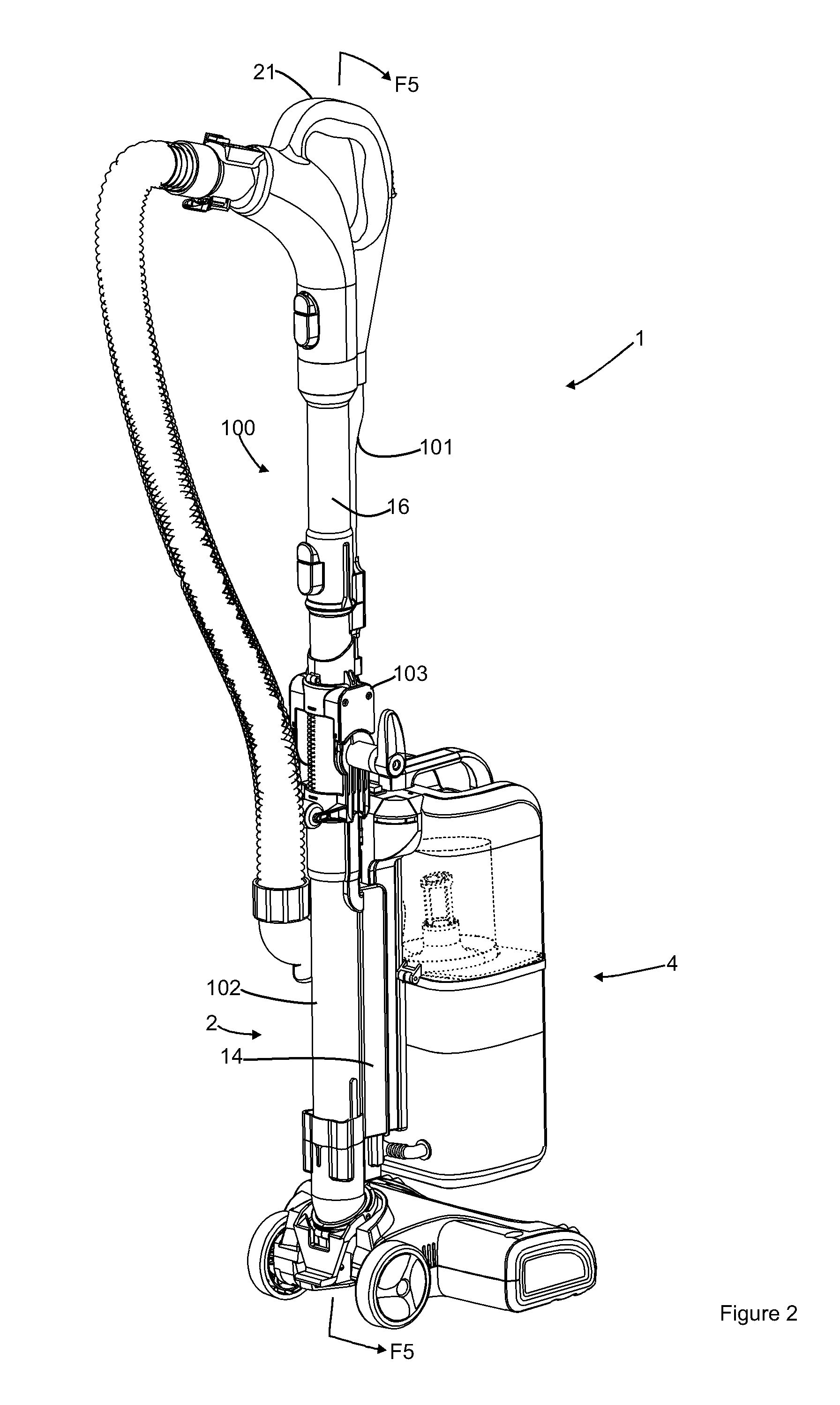

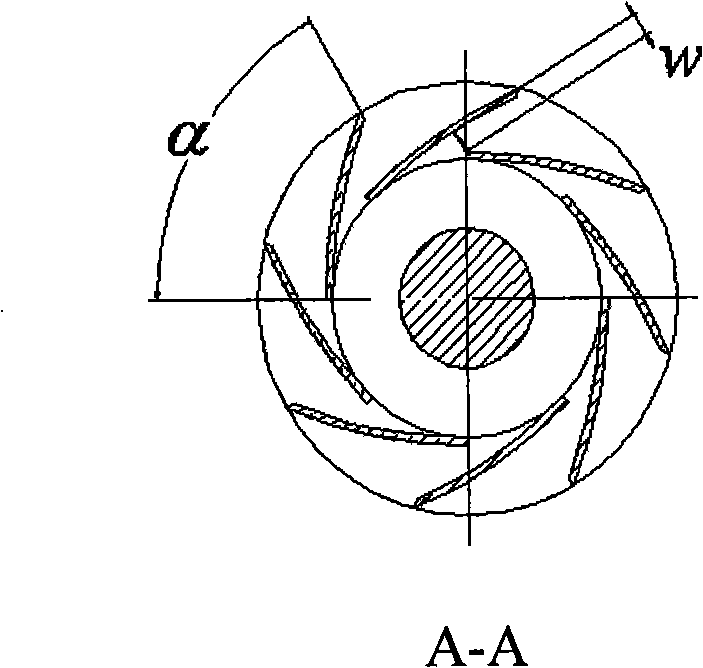

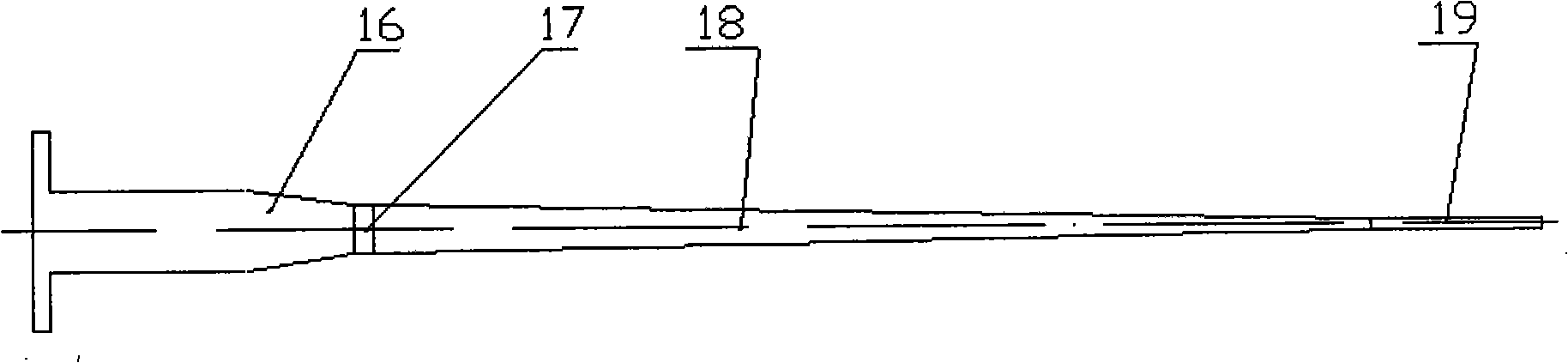

Conical core type supersonic condensing cyclone separator

ActiveCN101264470AHigh precisionEasy to separateDispersed particle separationVapor condensationCycloneSeparation technology

The invention relates to a taper core type supersonic condensation cyclone separator, belonging to the technical field of expansion refrigeration and condensation separation of pressure gas. The taper core is inserted in a passage, and the diameter of the taper core is changed at different places, so as to form the passage with a gradually decreased section part, a constant throat part and a gradually increased section part; therefore, a constant diameter inner hole can be adopted to avoid gradually increased small taper pipe passage which is difficult to be machined, so that the spin strength is not weakened due to the diameter increase. The taper core type supersonic condensation cyclone separator enables low-temperature working condition by means of pressure expansion and cooling of the gas, and reinforces spin by means of diameter decrease to generate strong centrifugal force field. The pressure can be increased after separation. The taper core type supersonic condensation cyclone separator has the advantages of no moving pieces, no need of external drive, energy saving, compact size, low cost, stable and reliable operation, and applicability to condensation separation of mixed gas with high pressure and low flow rate and separation of heavy components of natural gas and petroleum gas, in particular to offshore platform and other occasions with limited space due to compact size.

Owner:DALIAN UNIV OF TECH

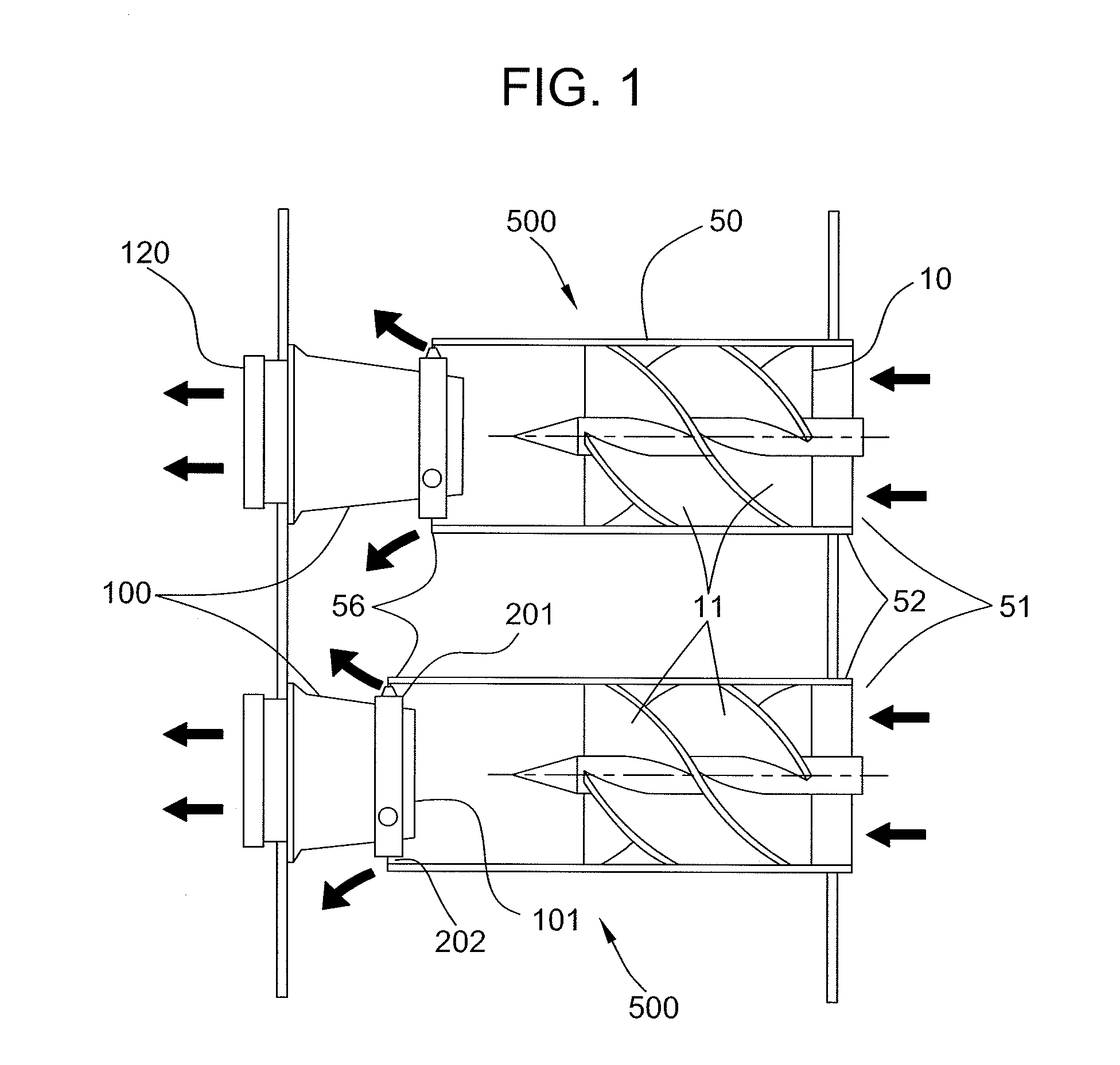

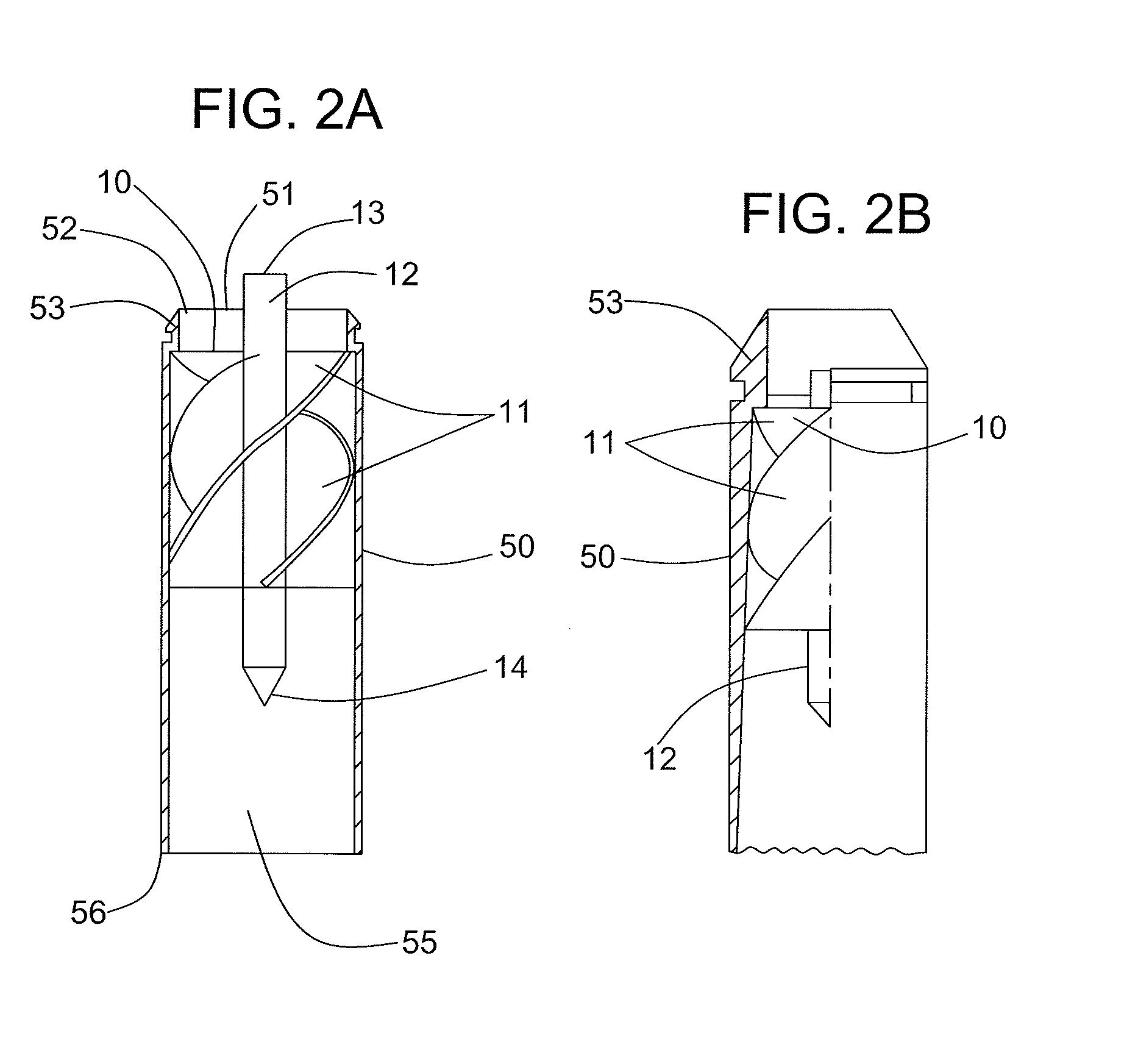

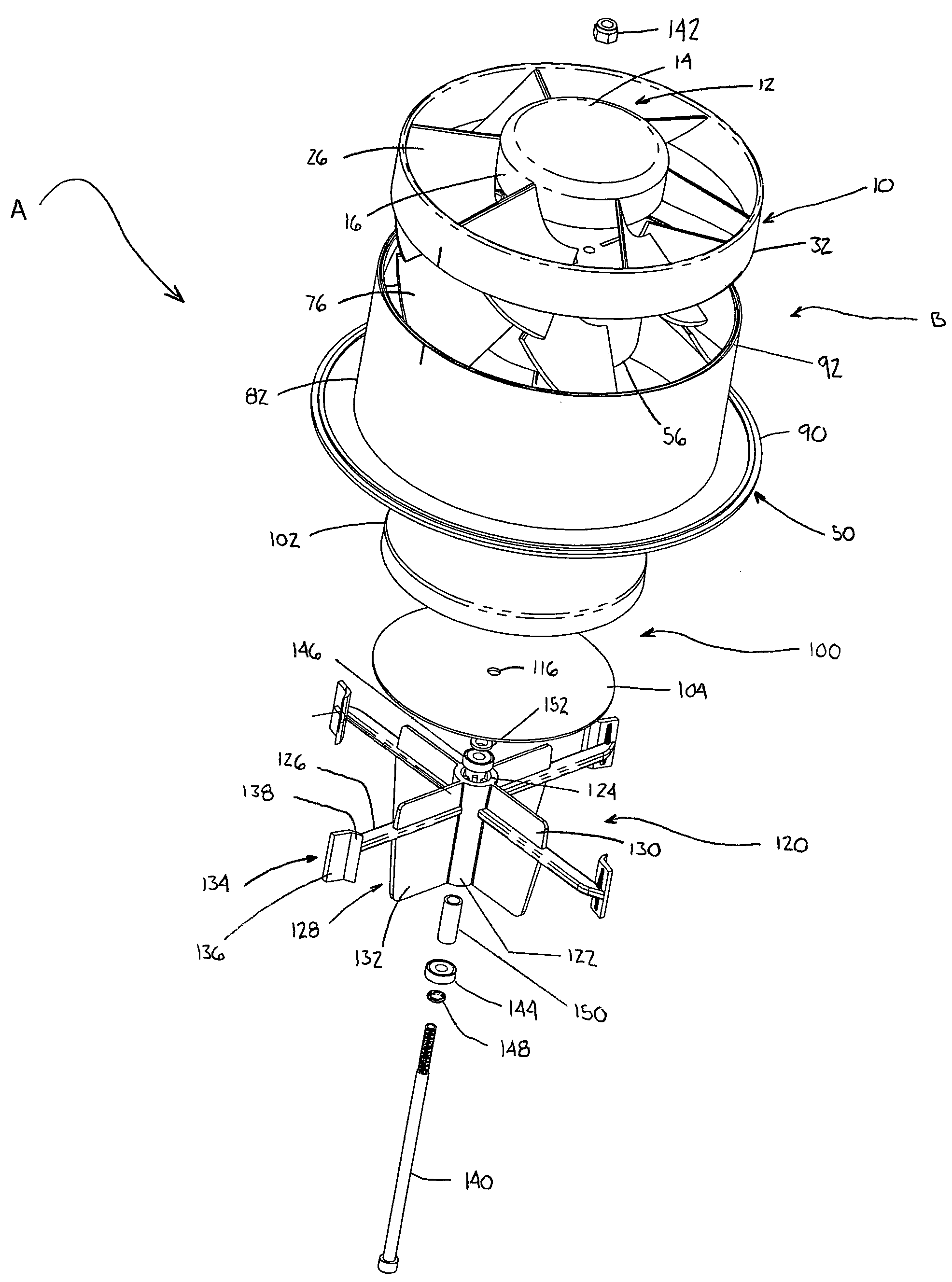

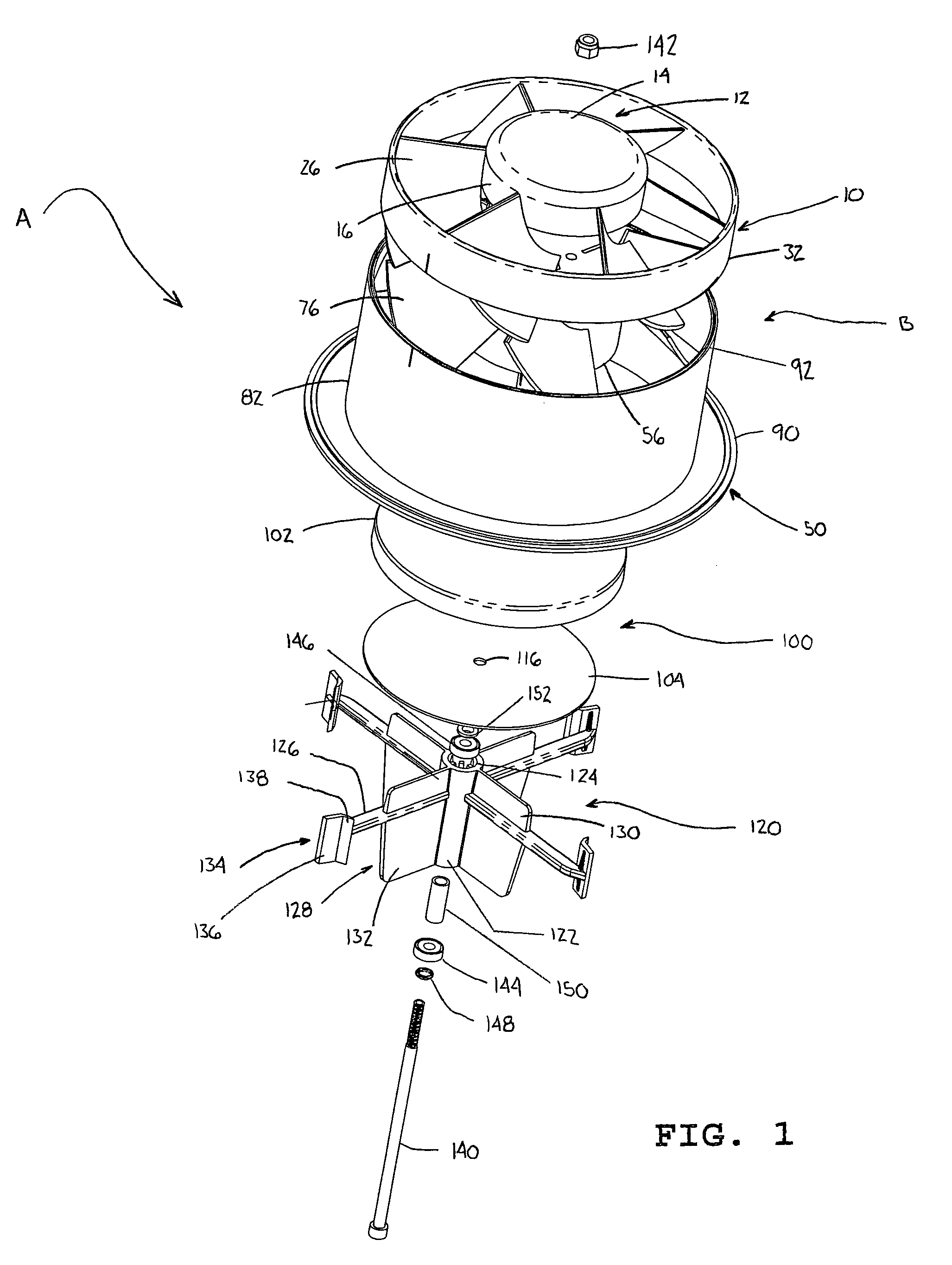

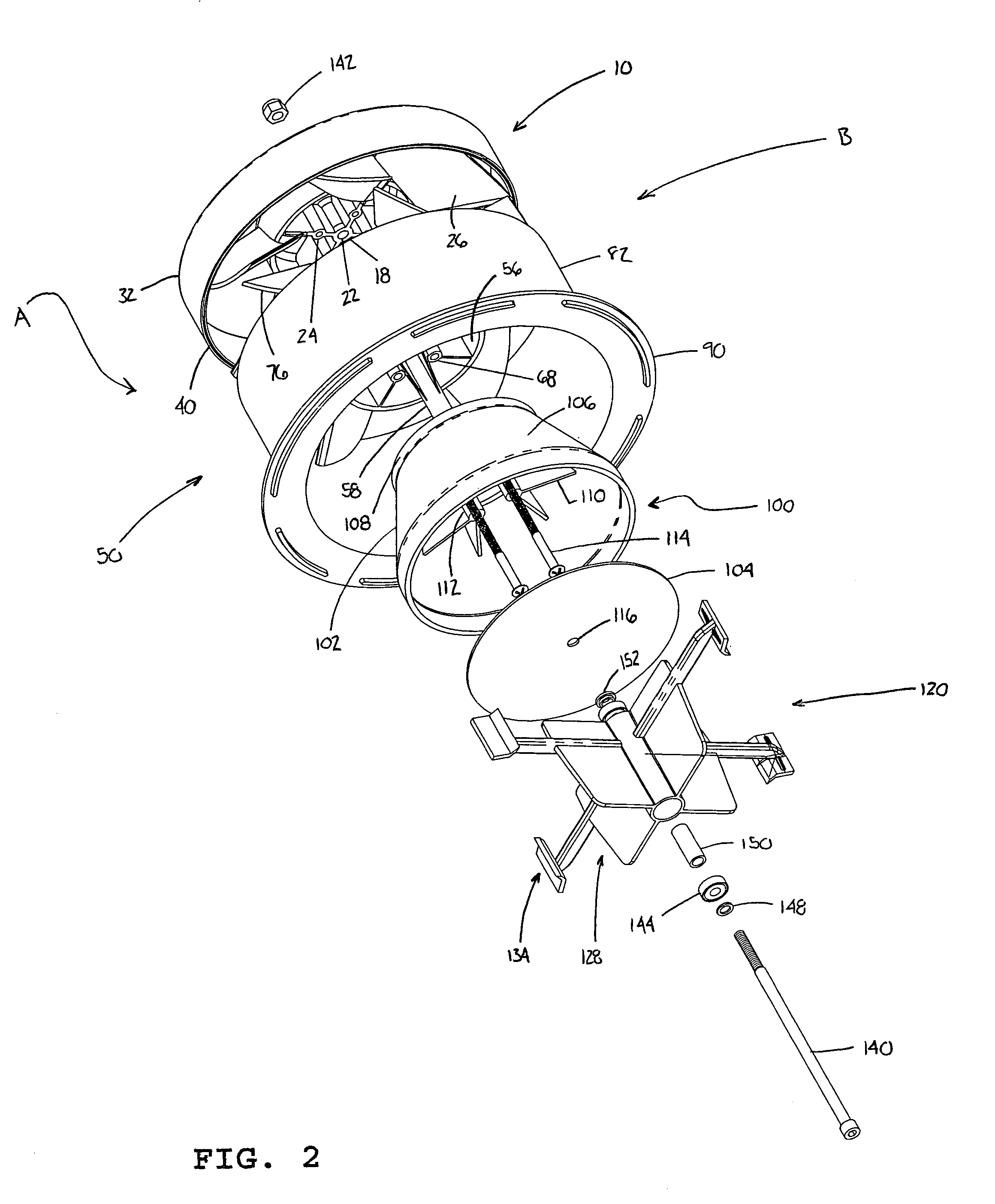

Inlet vane for centrifugal particle separator

A centrifugal particle separator includes a first vane assembly and a second vane assembly. The first vane assembly includes a centrally positioned hub, a collar encircling the hub and a plurality of first vanes. Each first vane can have an inner end connected to the hub and an outer end connected to the collar, wherein a trailing edge of at least one of the plurality of first vanes can extend past an edge of the collar. The second vane assembly includes a centrally positioned hub, a collar encircling the hub and a plurality of second vanes circumferentially disposed about the hub. Each second vane can have an inner end connected to the hub and an outer end connected to the collar, wherein a leading edge of at least one of the plurality of second vanes can extend past an edge of the collar. When the first and second vane assemblies are secured together, at least one of the plurality of first vanes protrudes into the second vane assembly.

Owner:DREISON INT

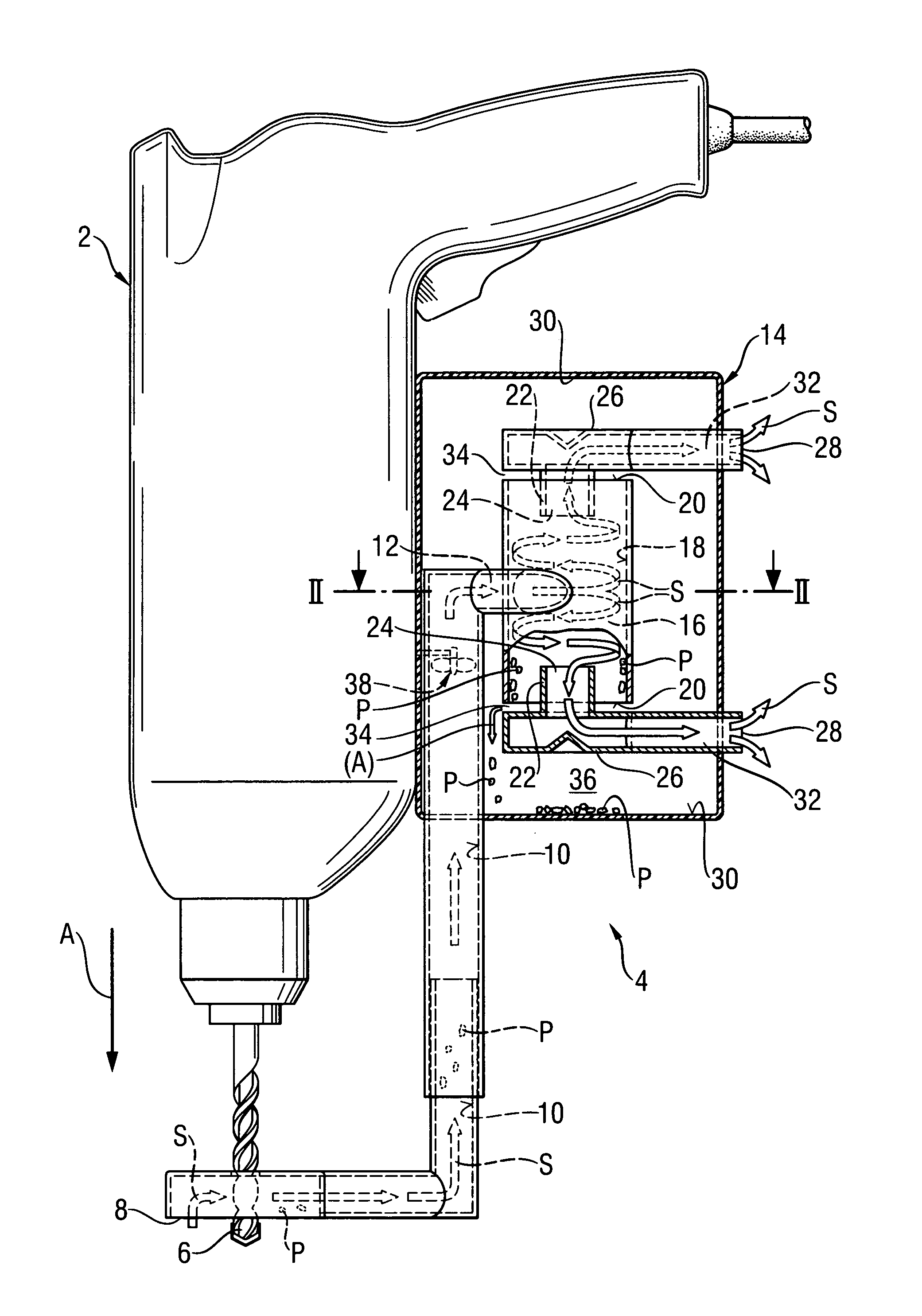

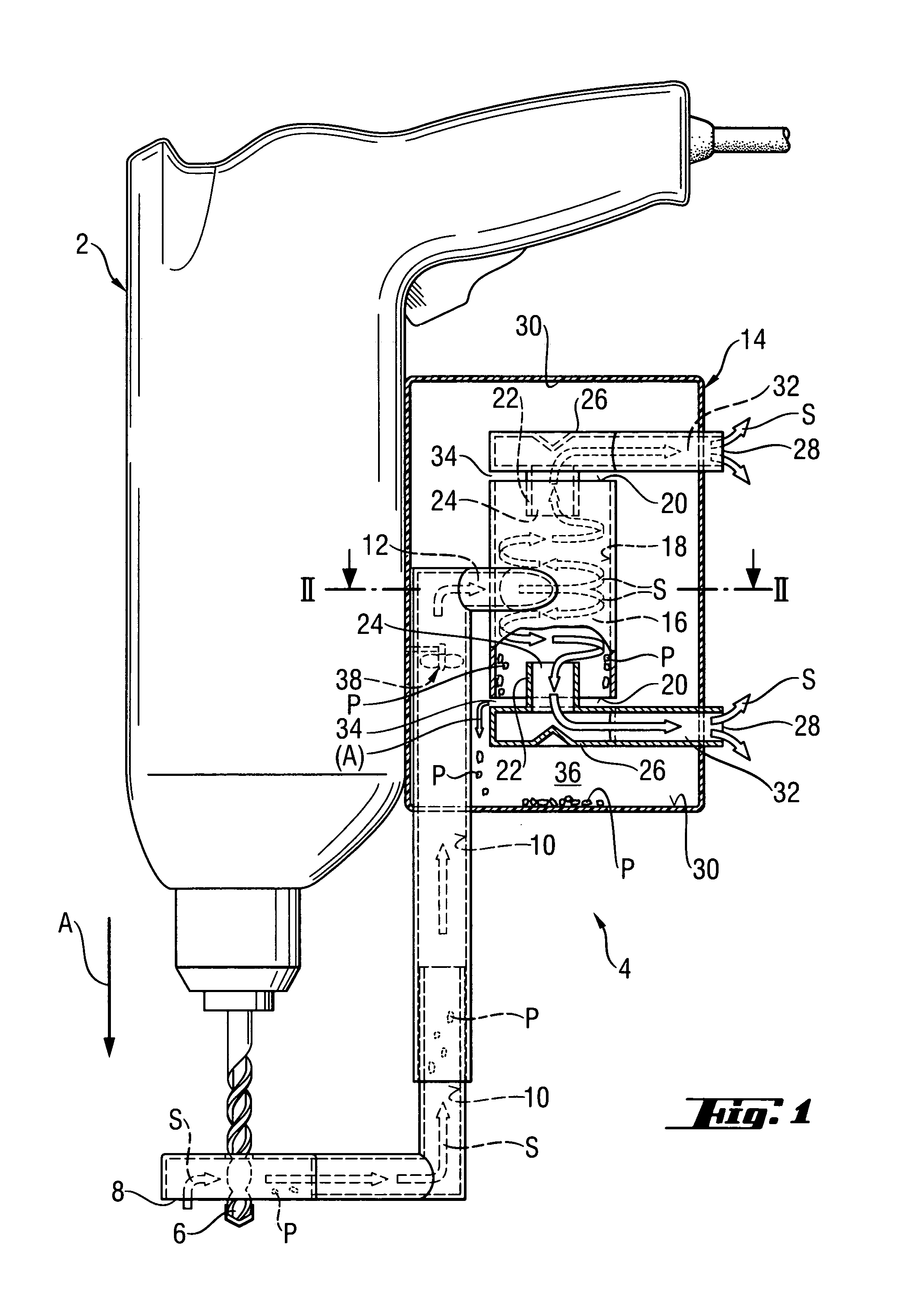

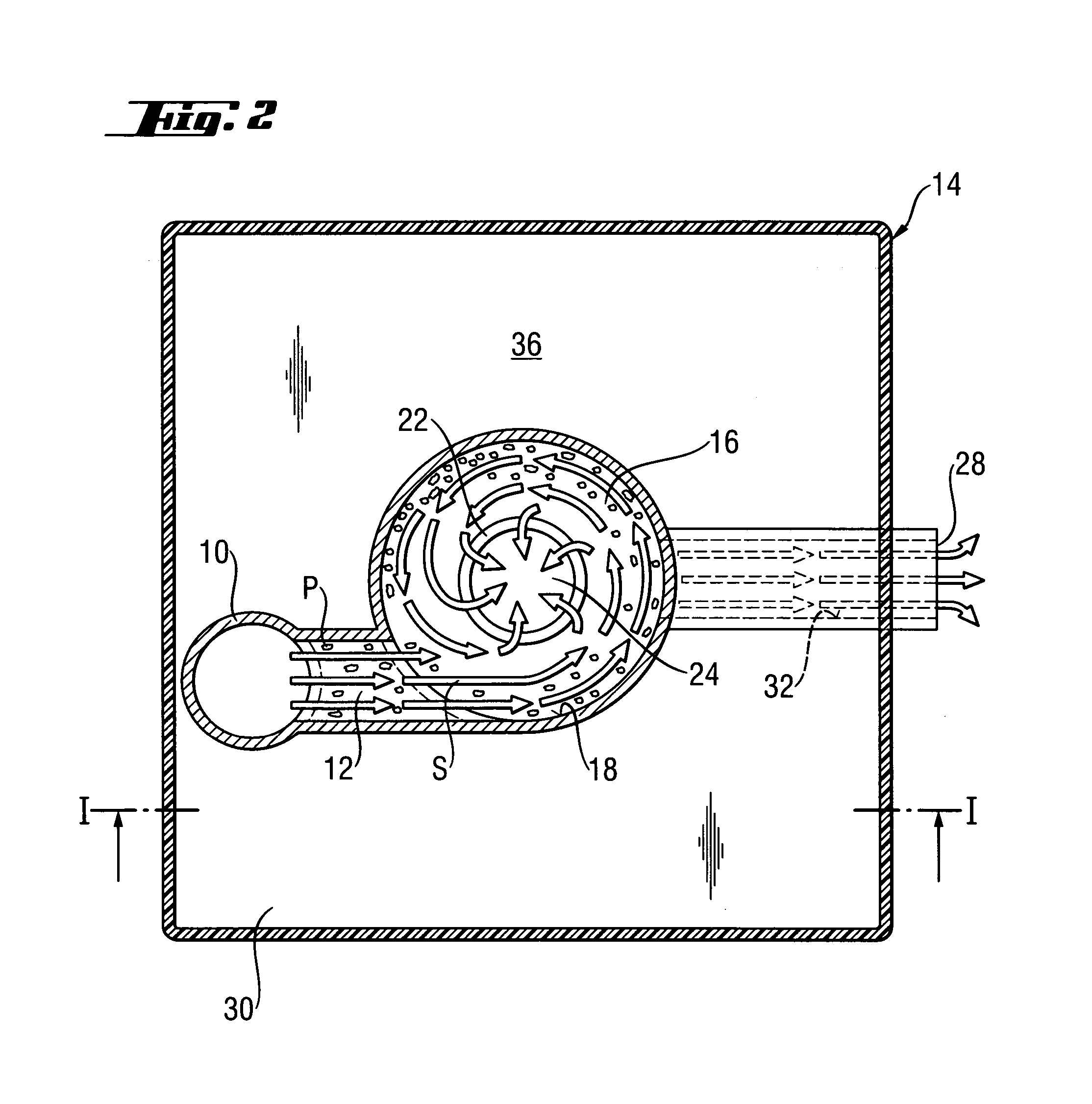

Cyclone separator

A cyclone separator (14) for use in a suction apparatus (4) of a hand-held power tool (2) includes a dirty air inlet (12), a suction ventilator (38) for aspirating, through a suction opening (8) which is connected with the dirty air inlet (12), abrasion particle-carrying suction air, a pure air outlet for letting out purified air, a vortex chamber (16) arranged between the dirty air inlet (12) and the pure air outlet, with the dirty air inlet (12) opening substantially tangentially into the vortex chamber (16) for generating a swirling stream in a direction toward the pure air extraction element (24), a collection chamber (36), and particle outlet having at least two particle outlet openings and connecting the vortex chamber with a collection chamber (36), with the dirty air inlet opening into the vortex chamber between the two particle outlet openings.

Owner:HILTI AG

Cyclone separator

InactiveUS7159723B2Easy to separateWide range of operationsReversed direction vortexDispersed particle separationCycloneEngineering

A cyclone separator including an initial cyclone arrangement (1) arranged first in relation to a flow direction (18) through the separator; a second cyclone arrangement (2) connected in series with the initial cyclone arrangement; a bypass channel (3) bypassing the second cyclone arrangement (2), and a volumetric flow controlled valve device (4) for selectively directing a partial stream (5) through the bypass channel (3).

Owner:MANN HUMMEL GMBH

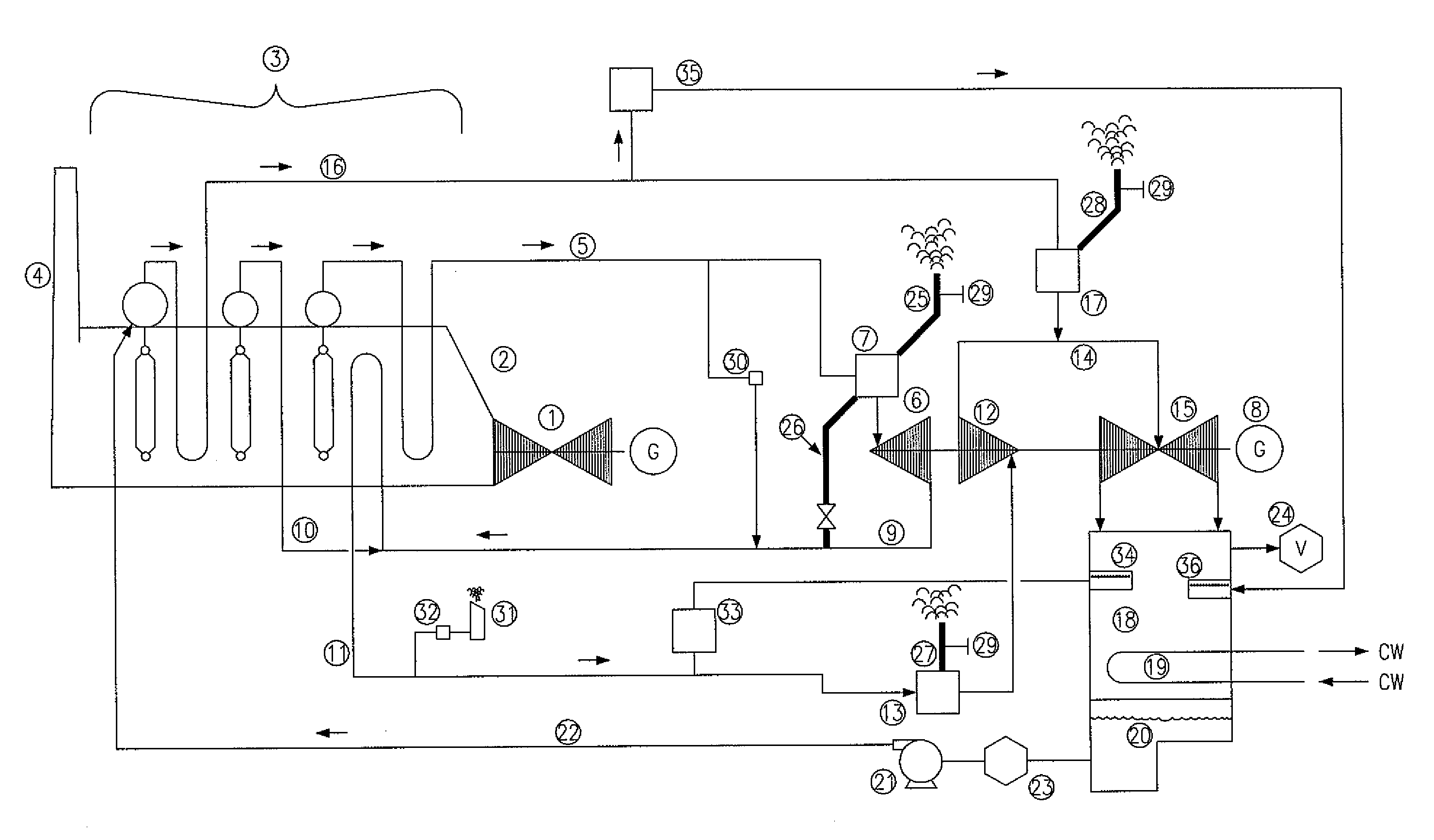

Method and apparatus for commissioning power plants

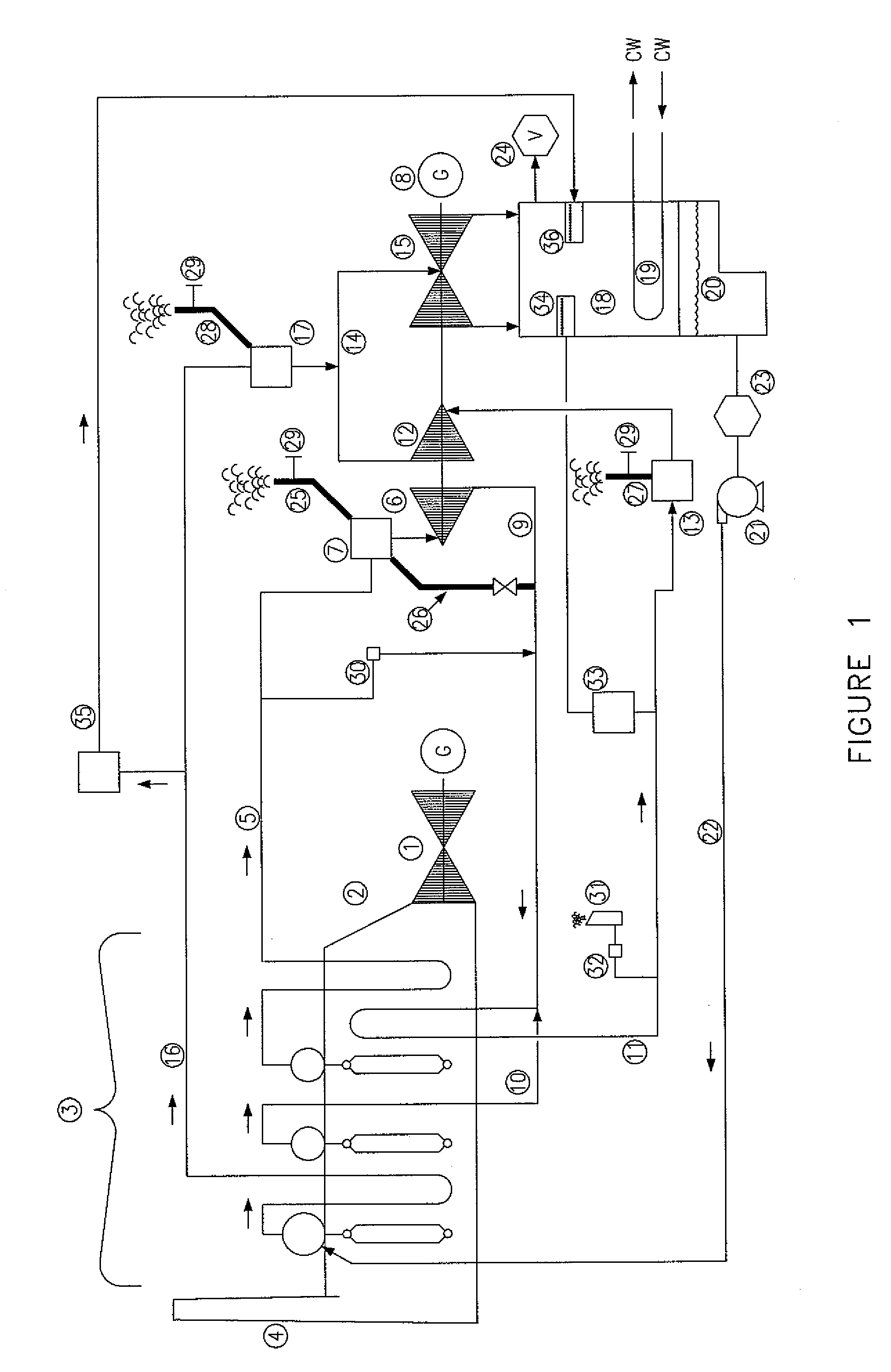

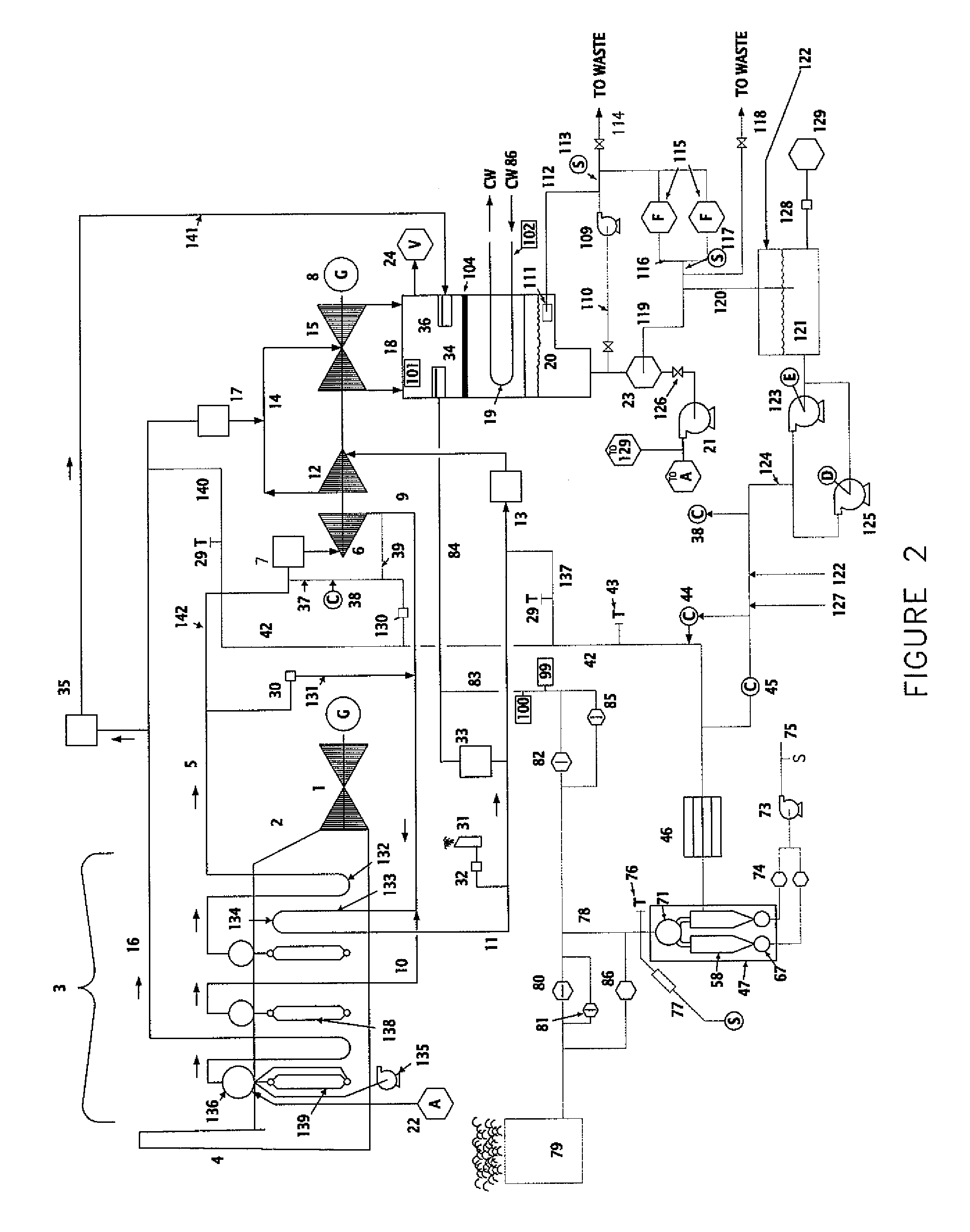

ActiveUS20080236616A1Reduce fuel consumptionReduce water consumptionLiquid degasificationDrying solid materials without heatPower stationEngineering

An apparatus and method for commissioning steam turbine generator power plants to advance the cleanliness of the complete steam cycle by the conditioned discharge of steam to the plant surface condenser.

Owner:BEST ENERGY SERVICES INC

Cyclone and cyclone air purifier and method of air purification thereof

InactiveUS20070234691A1Improve air purification effectImprove noise reductionMechanical apparatusReversed direction vortexCycloneEngineering

A cyclone and a cyclone air purifier include a device with an inlet port structure such that a suction area through which a fluid is suctioned into the cyclone is increased, pressure loss is reduced, and a centrifugal force applied to the fluid is increased, to improve performance of air purification and to reduce noise. The cyclone includes a cylinder into which a fluid is suctioned, a guide extended from the cylinder, an outlet pipe provided in a center of the cylinder to guide a fluid that inversely rises to be discharged, and a vortex induction member provided between the cylinder and the outlet pipe to form vortex channels.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com