Conical core type supersonic condensing cyclone separator

A cyclone separator and supersonic technology, applied in the direction of cyclone device, separation method, dispersed particle separation, etc., can solve the problems of reducing the effect of gas-liquid separation, reducing the total pressure efficiency, secondary volatilization of liquid droplets, etc., to achieve improved Effect, reduction of energy loss, effect of static temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

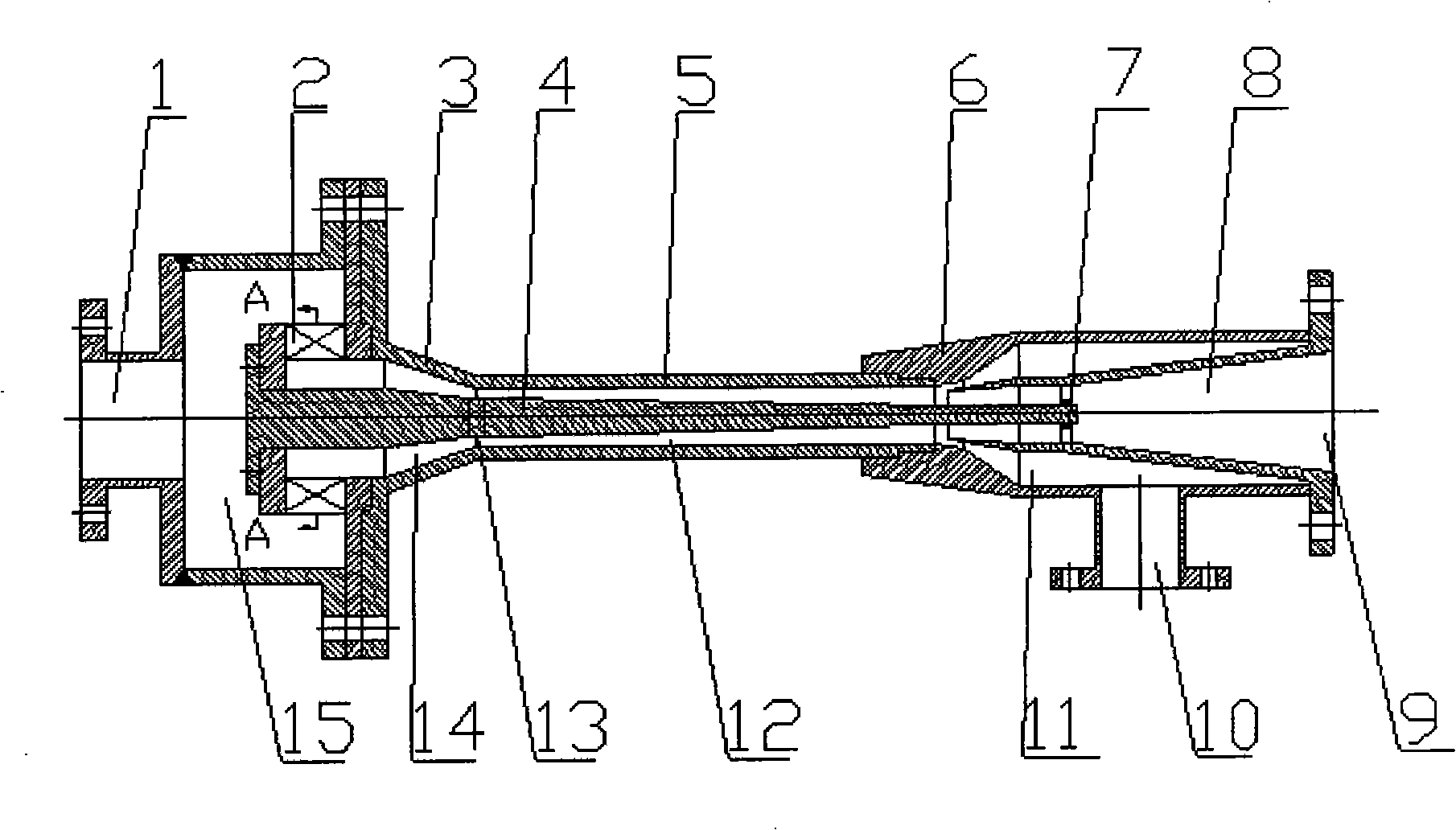

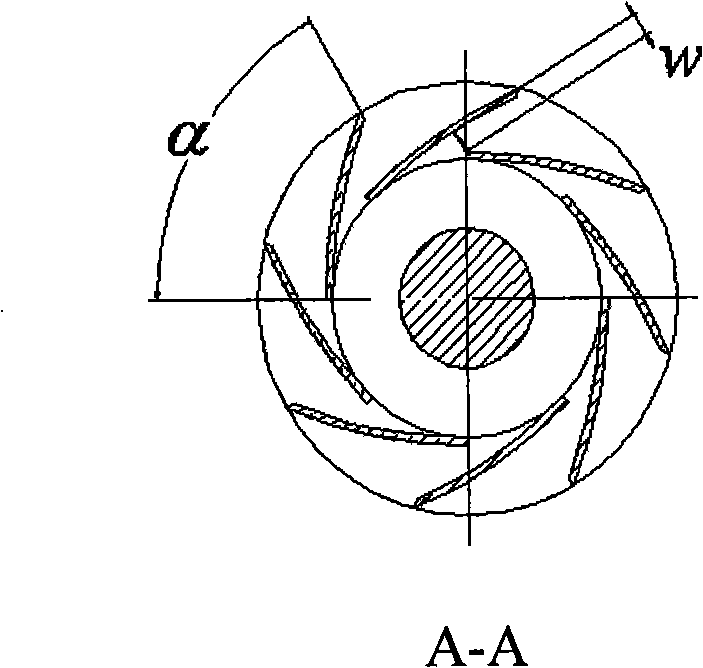

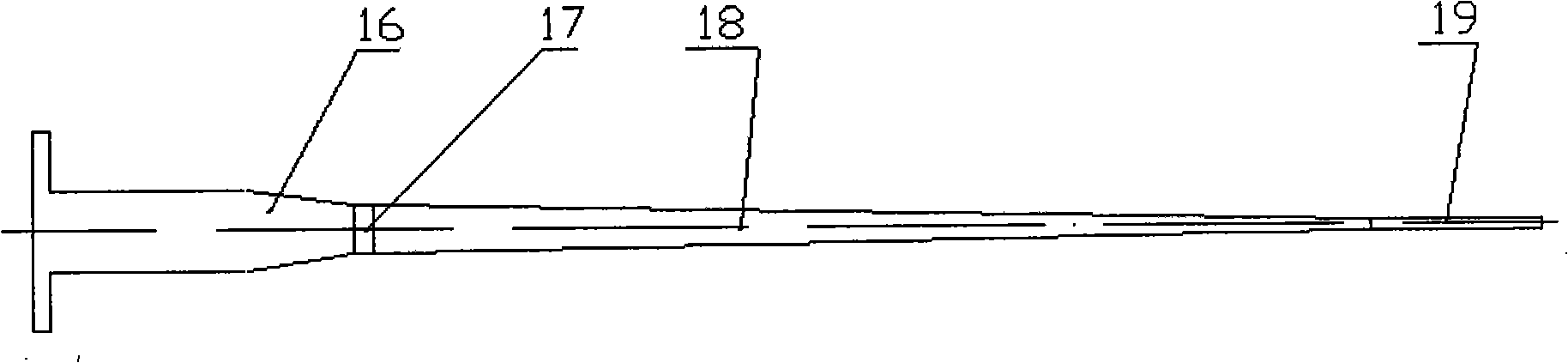

[0024] The conical core type supersonic condensation cyclone separator proposed by the present invention is mainly composed of a swirl generator 2, a shell cone tube 3, a cone core 4, a shell column tube 5, a liquid guide 6, a bracket 7, and a plug-in gas outlet channel 8. It is composed of a liquid collection chamber 11, a supersonic cooling separation channel 12, a throat channel 13, a subsonic and swirl acceleration channel 14, and a pressure stabilizing chamber 15.

[0025] The shell of the acceleration and separation flow channel is composed of different discs, the shell cone tube 3, and the shell column tube 5, which are welded in sections, and then the tapered and cylindrical inner hole flow channels are machined. The liquid guide 6 is also welded by the shell, the connecting pipe and the flange. After machining, it cooperates with the acceleration and separation flow channel through the inner and outer holes for alignment, thread connection, and O-ring seal. The inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Contraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com