Cyclonic separating apparatus

a technology of cyclonic separation and separating apparatus, which is applied in the direction of isotope separation, combination devices, applications, etc., can solve the problems of reducing the efficiency at which the cyclonic separation apparatus operates, the arrangement of the cyclonic separation apparatus may be less effective, and the separation of dirt and dust will move towards the outlet, so as to reduce the risk of re-entrainment of separated dirt, the risk of fine dirt and dust deposited in the collector can be minimised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

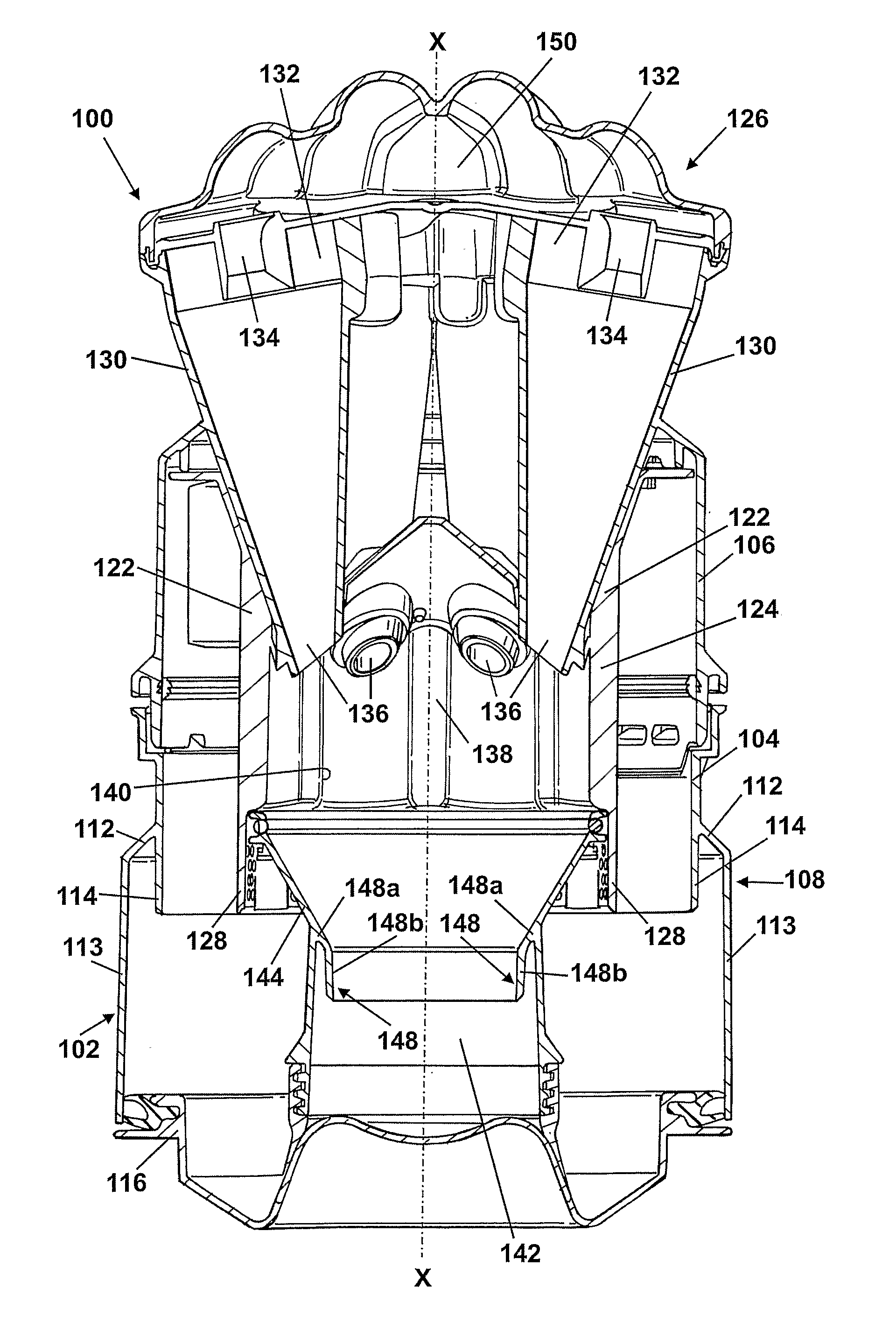

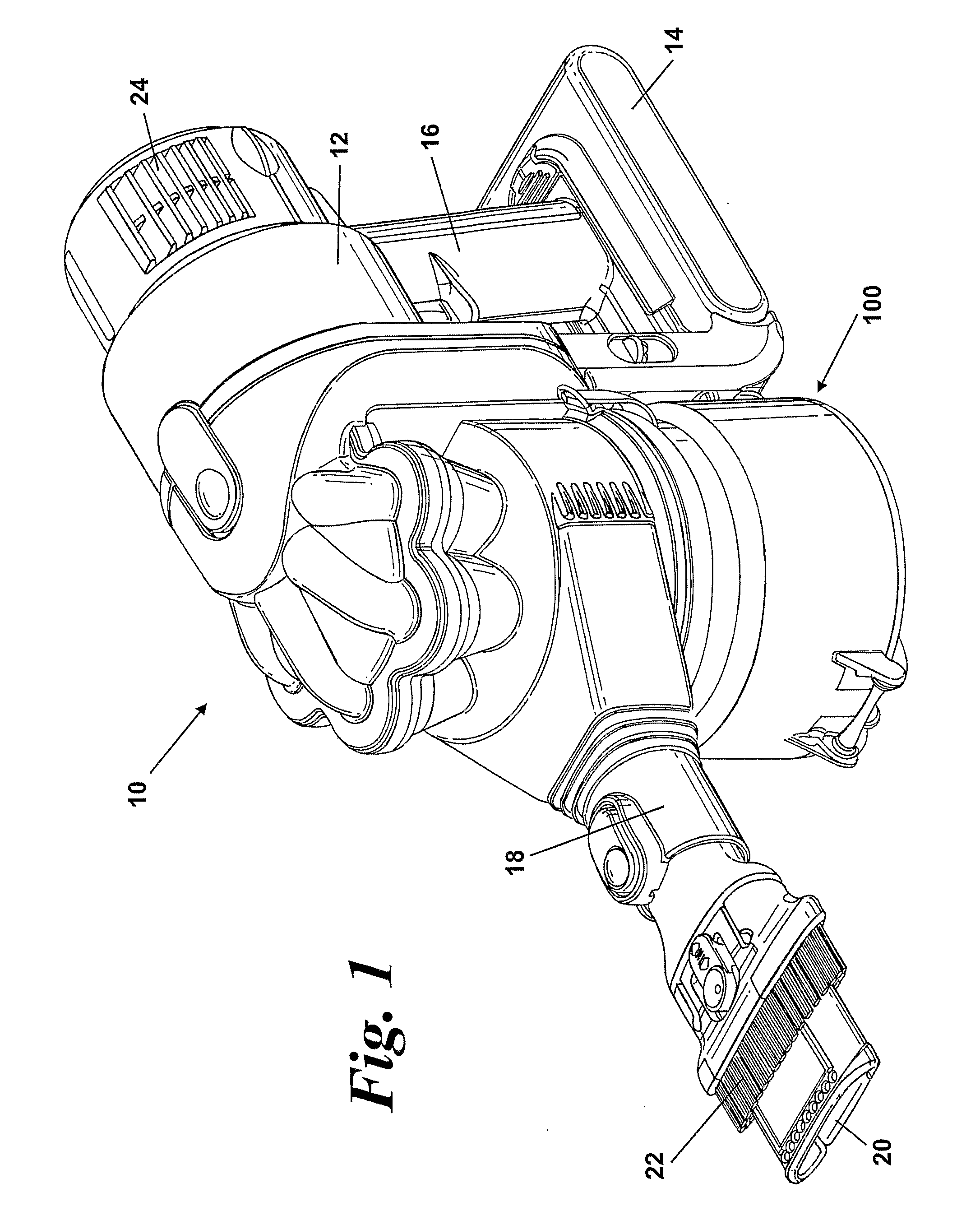

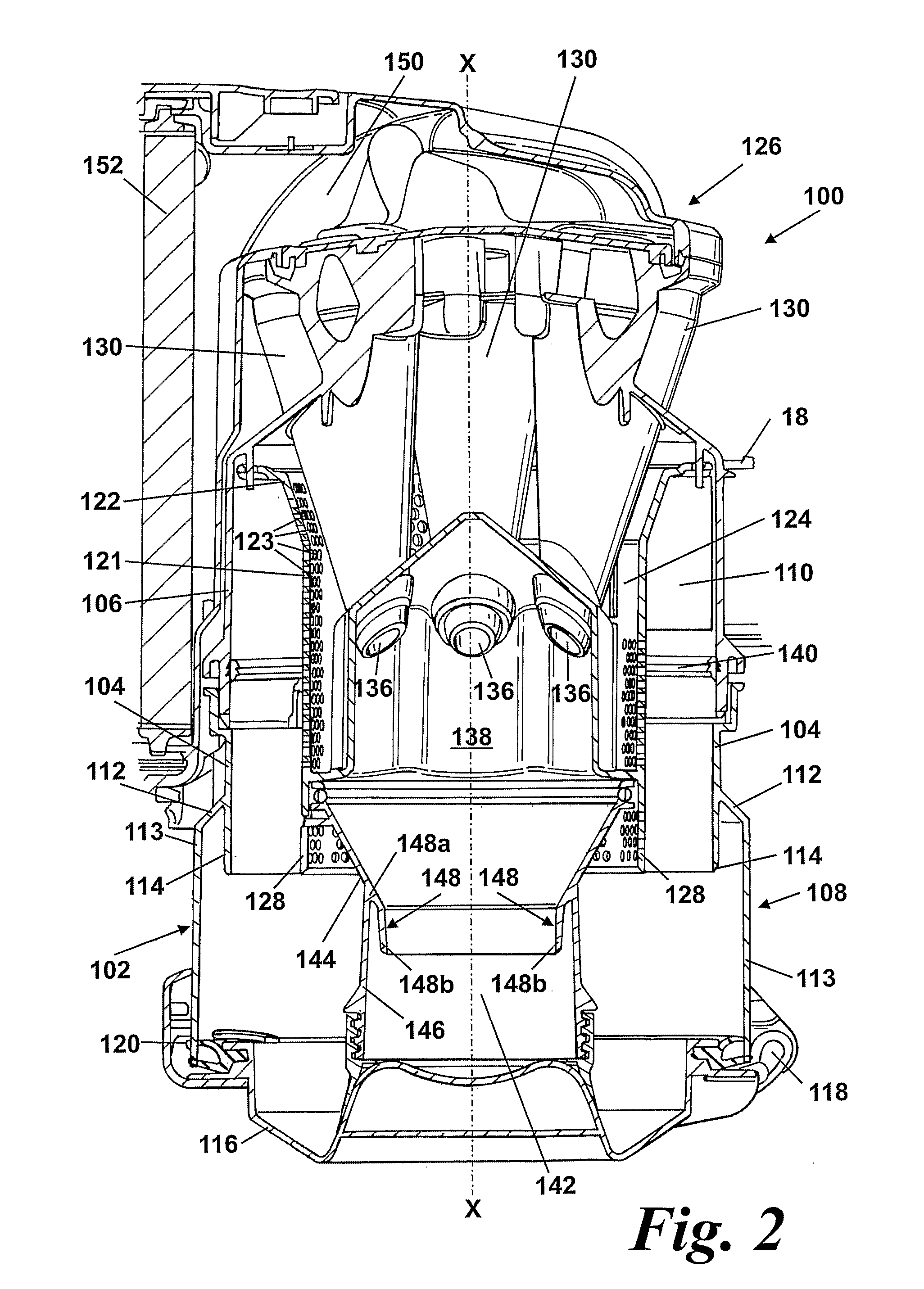

first embodiment

[0033]Both the lip 114 and the further lip 148 may take different configurations or shapes from those shown in the FIGS. 4 to 11 illustrate schematically eight further alternative configurations of the lip or lips which fall within the scope of the invention. In these illustrations, all detail will be omitted other than the general shape of the lip and adjoining wall portions. These configurations of lip may be applied to either the lip in the cyclone or to the further lip in the collector.

second embodiment

[0034]FIG. 4 shows the invention. In this embodiment, the cyclonic separating apparatus 200 includes a lip 202 which extends from a first portion 204 of a wall into a region surrounded by a second portion 206 of the wall. The lip 202 has a plurality of through-holes which allow air to pass but block larger particles of dirt and dust. Otherwise, the lip 202 is the same as the lip 114 described above.

third embodiment

[0035]FIG. 5 shows the invention. In this embodiment, the cyclonic separating apparatus 250 includes a lip 252 which extends from a frustoconically-shaped first portion 254 of a wall into a region surrounded by a second portion 256 of the wall. The second portion 254 of the wall is partly frustoconical-shaped and partly cylindrical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com