Patents

Literature

65 results about "Re entrainment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

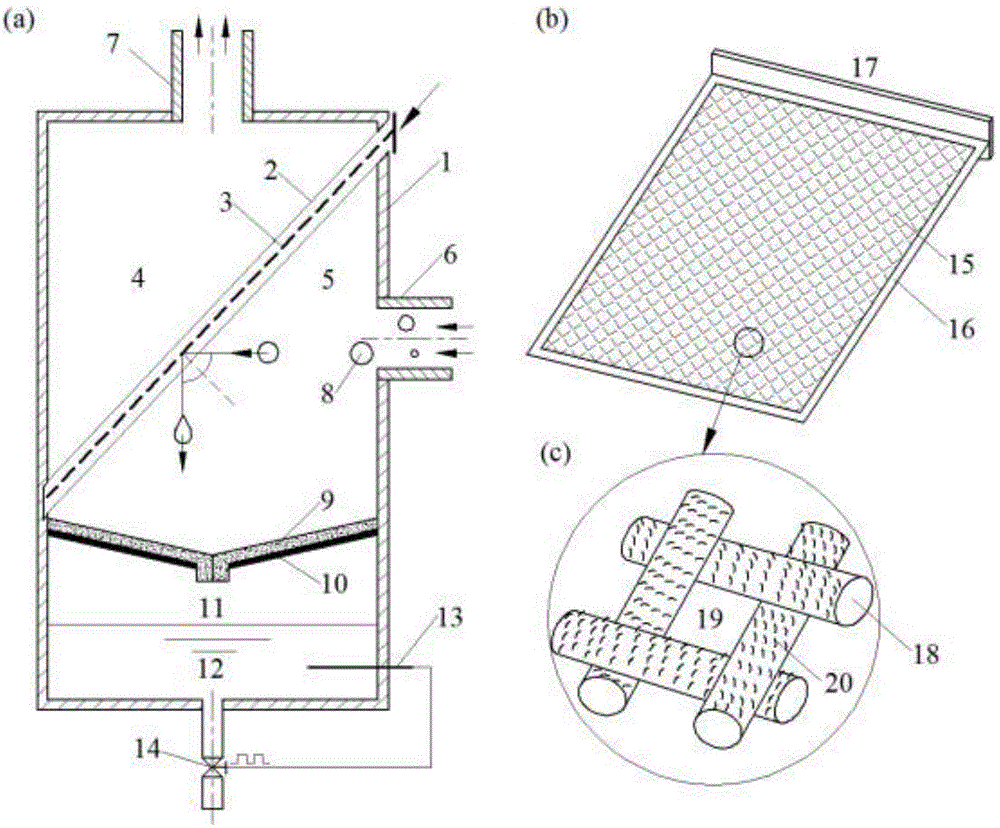

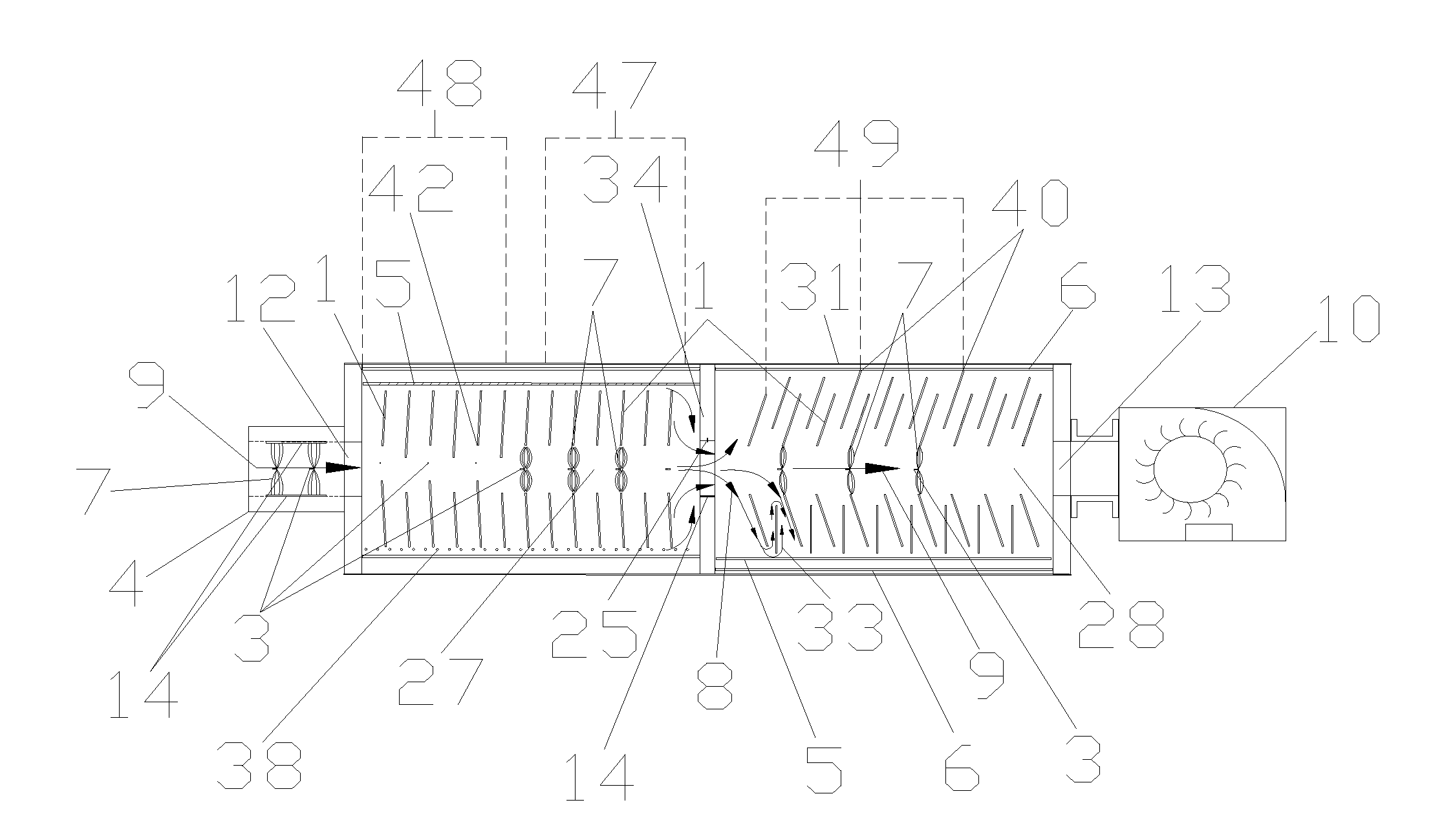

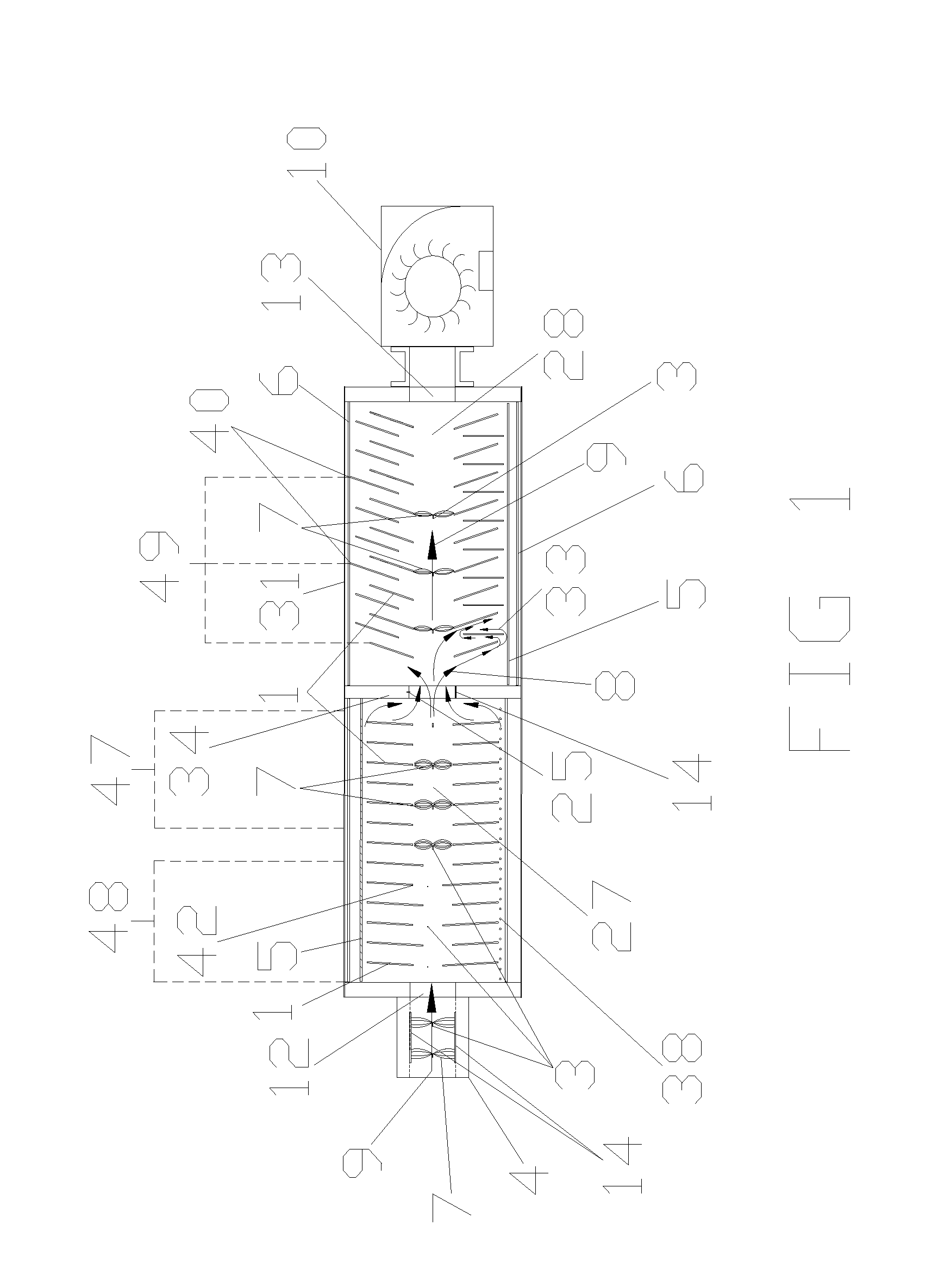

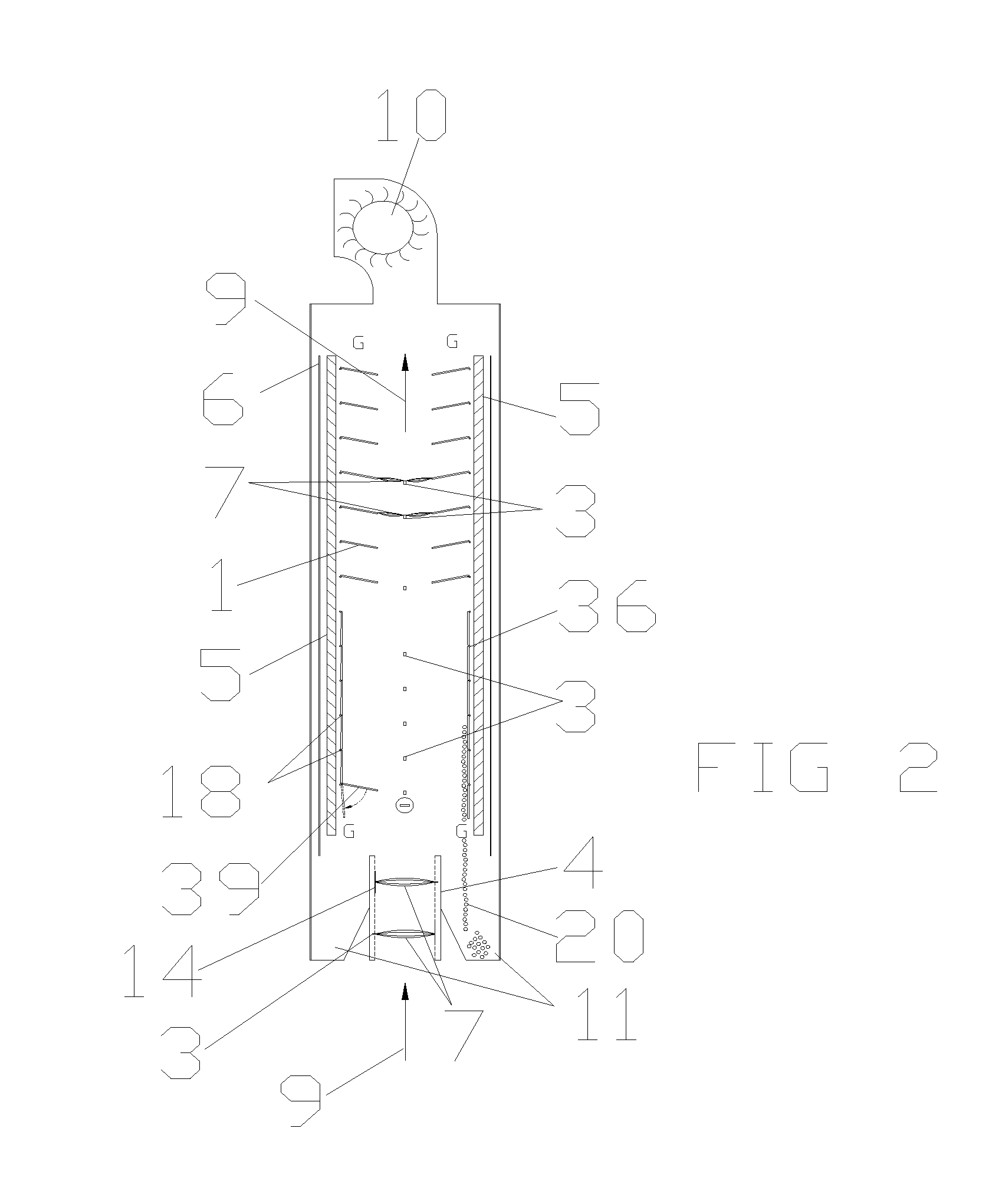

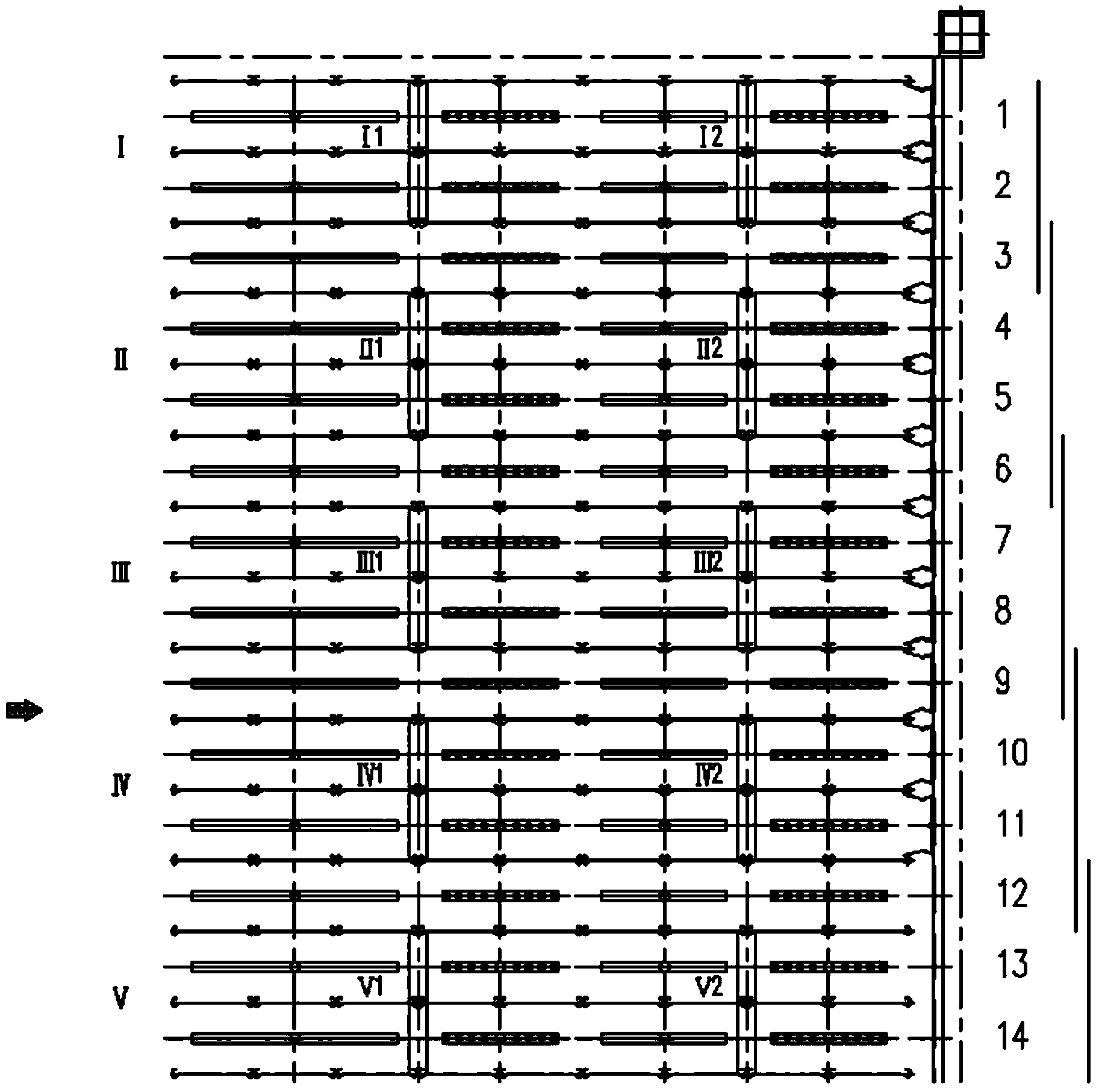

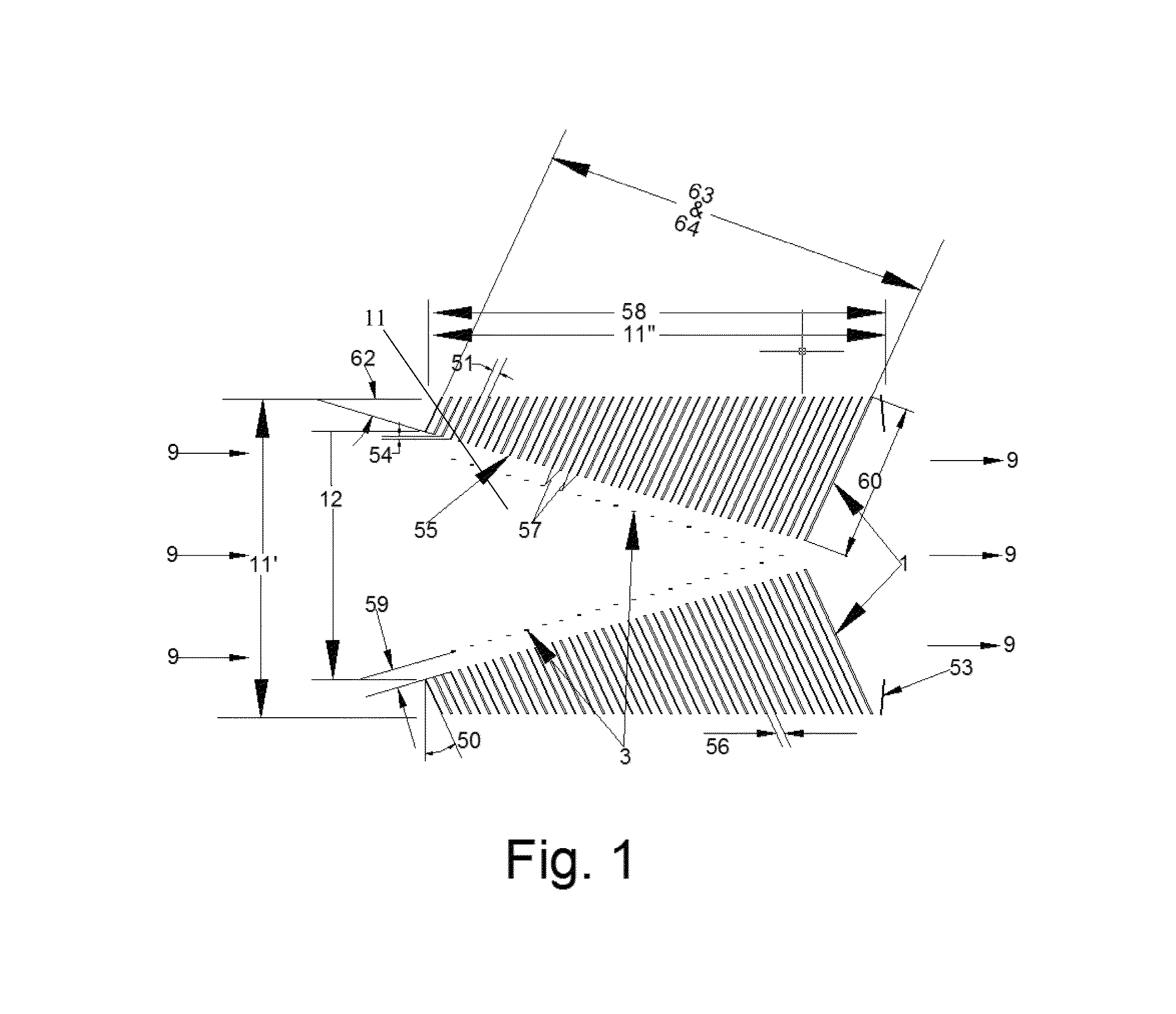

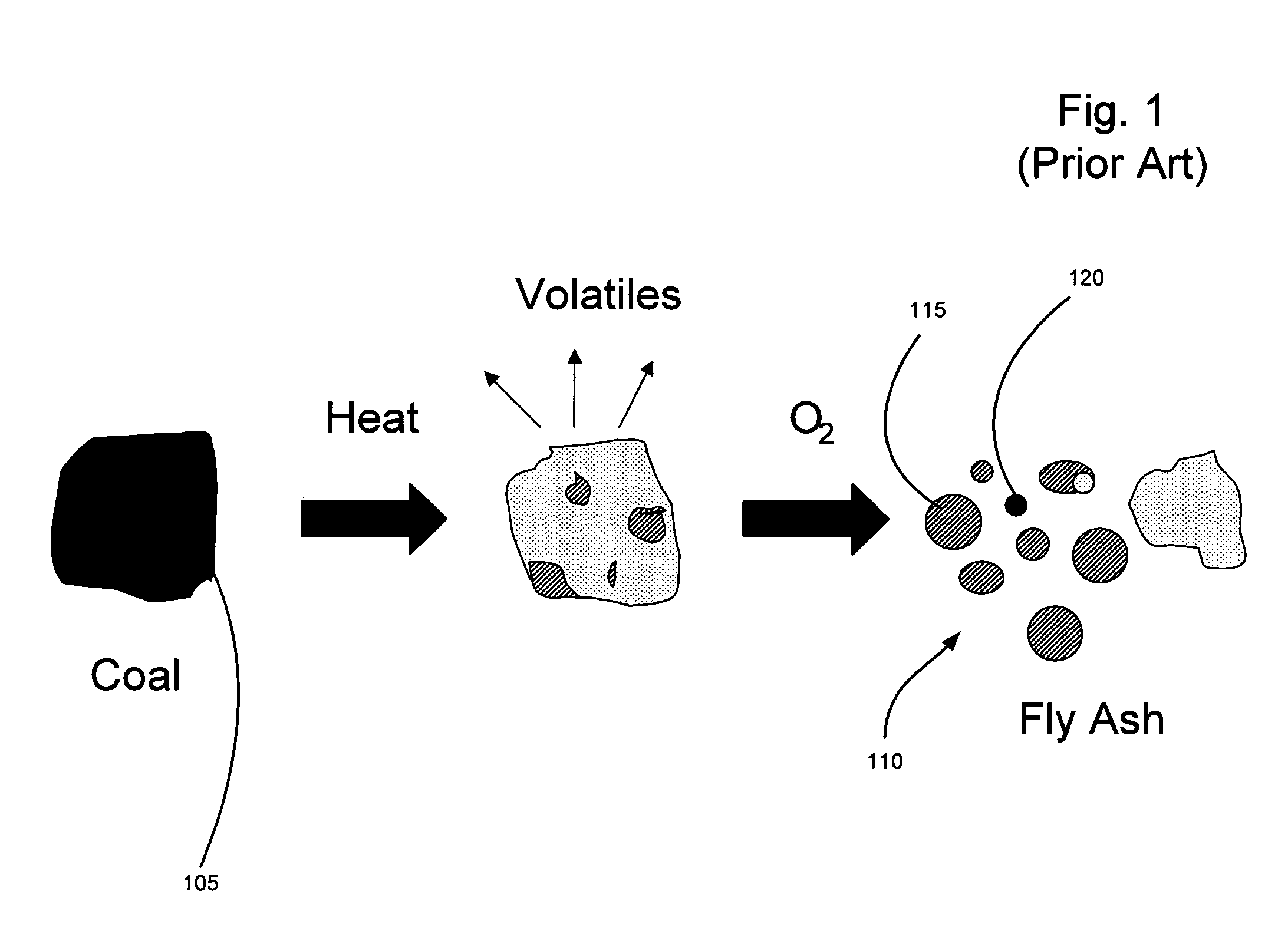

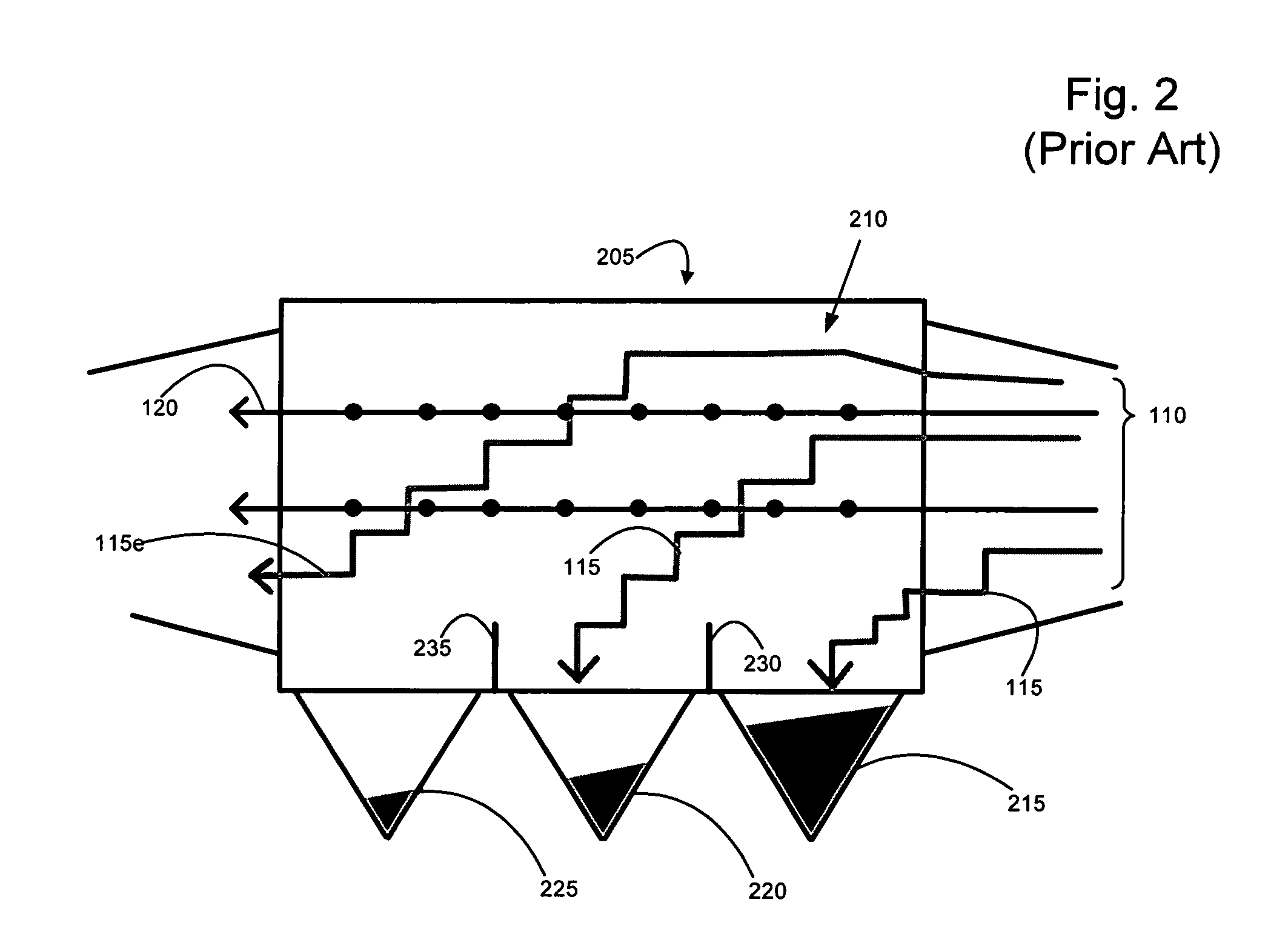

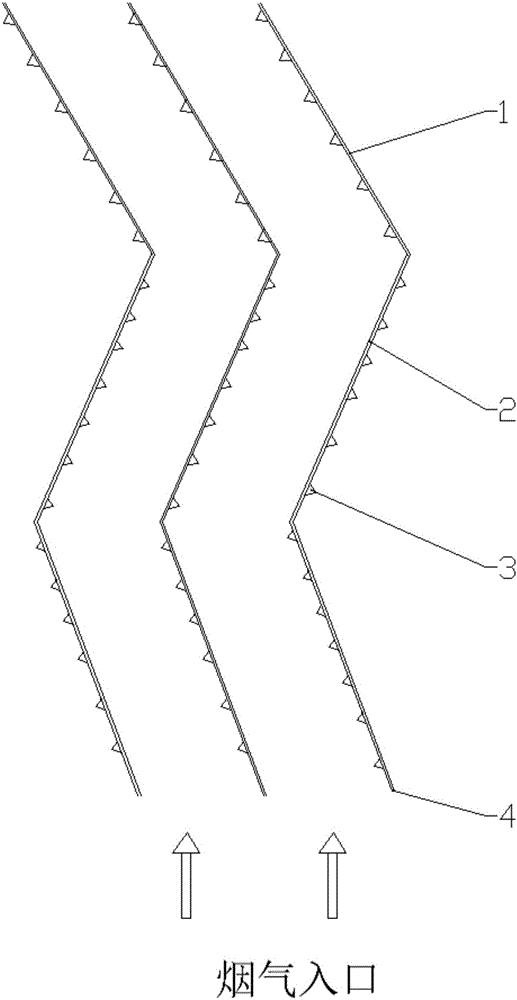

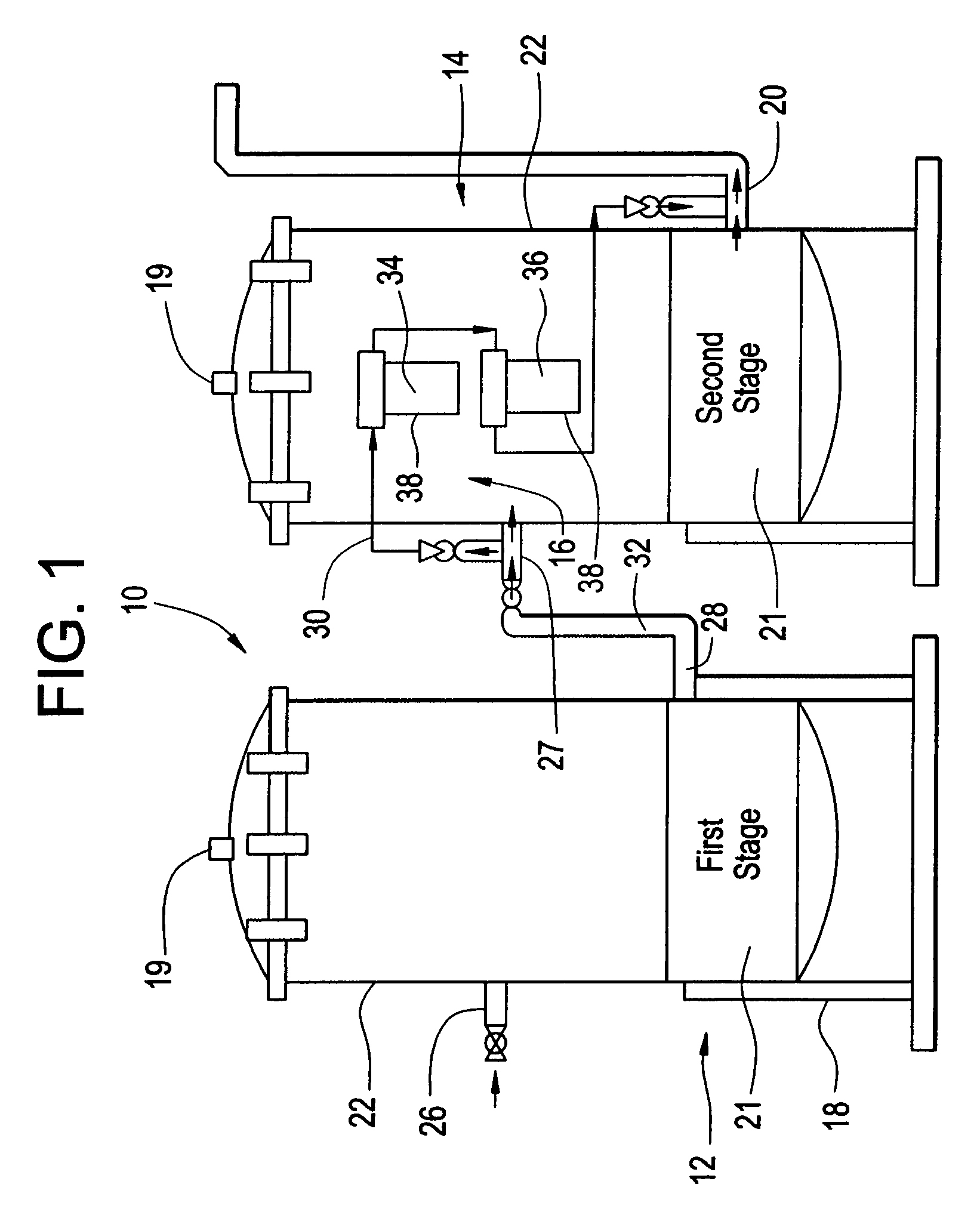

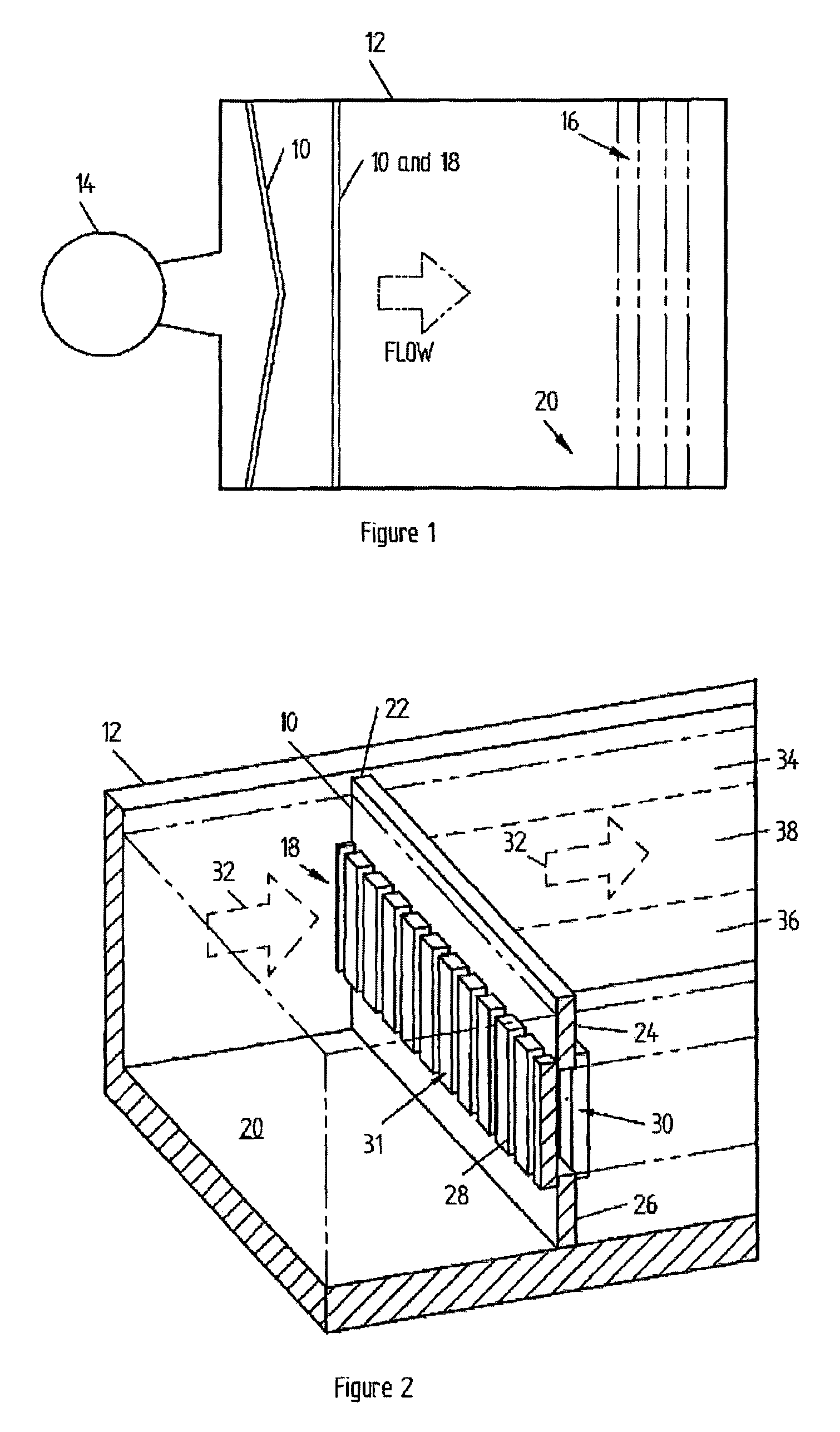

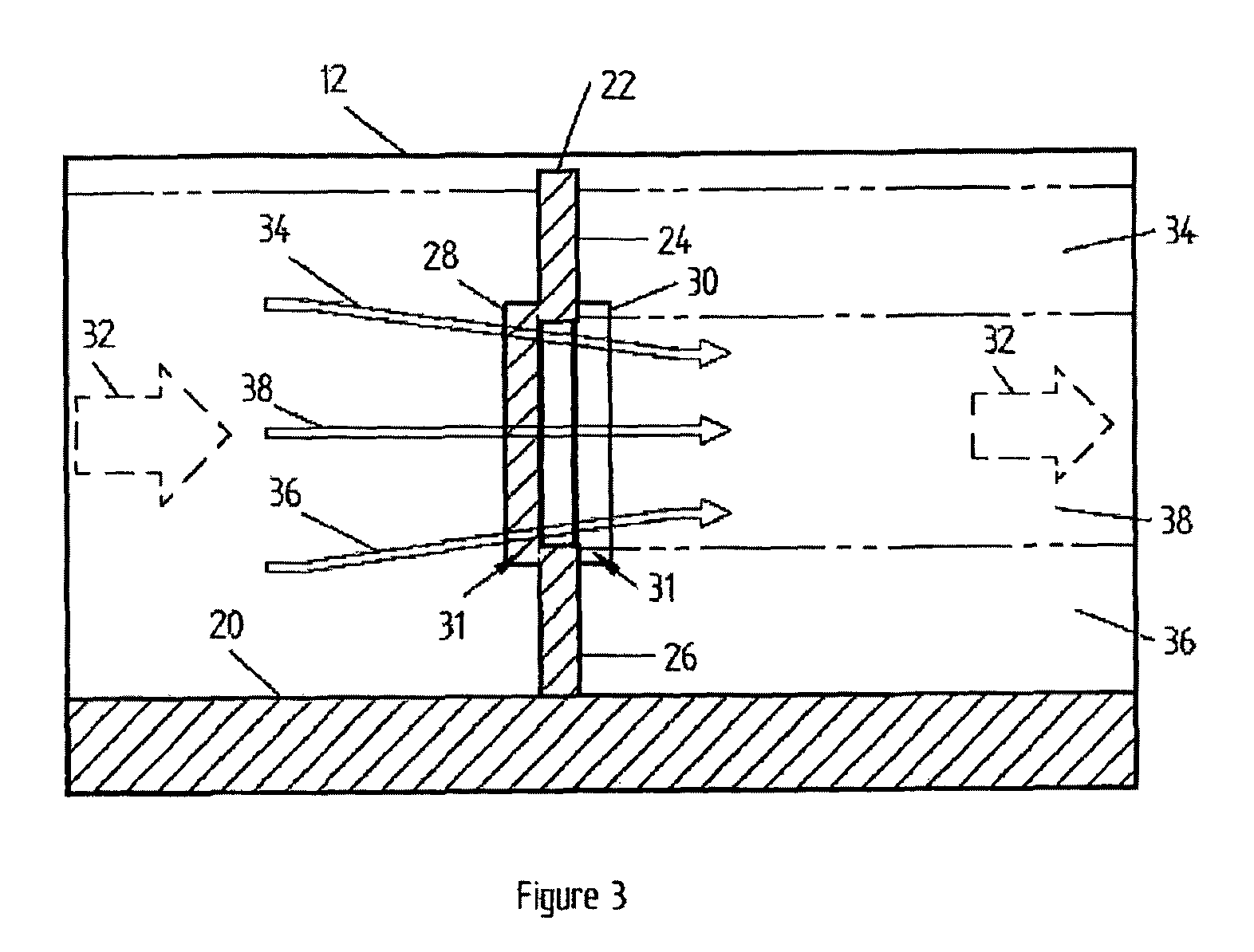

Re-entrainment is a physical phenomenon of two-phase stratified fluid flow.The onset of re-entrainment occurs at the boundary of the stratified wavy andannular mist two-phase flow regimes at relatively high gas/liquid velocities,as Fig. 1 2 shows. Re-entrainment is caused by rapid momentumtransfer from gas to liquid.

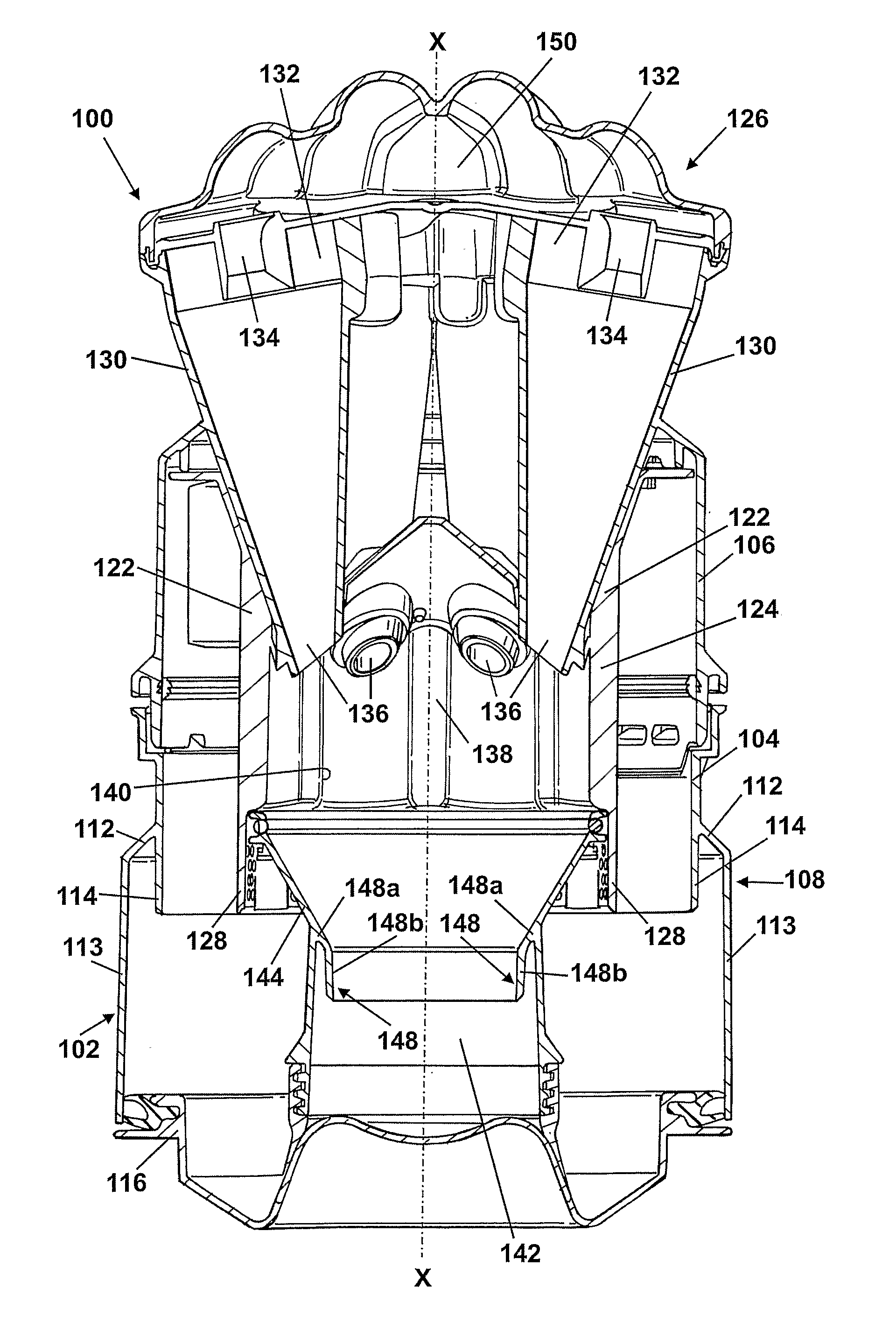

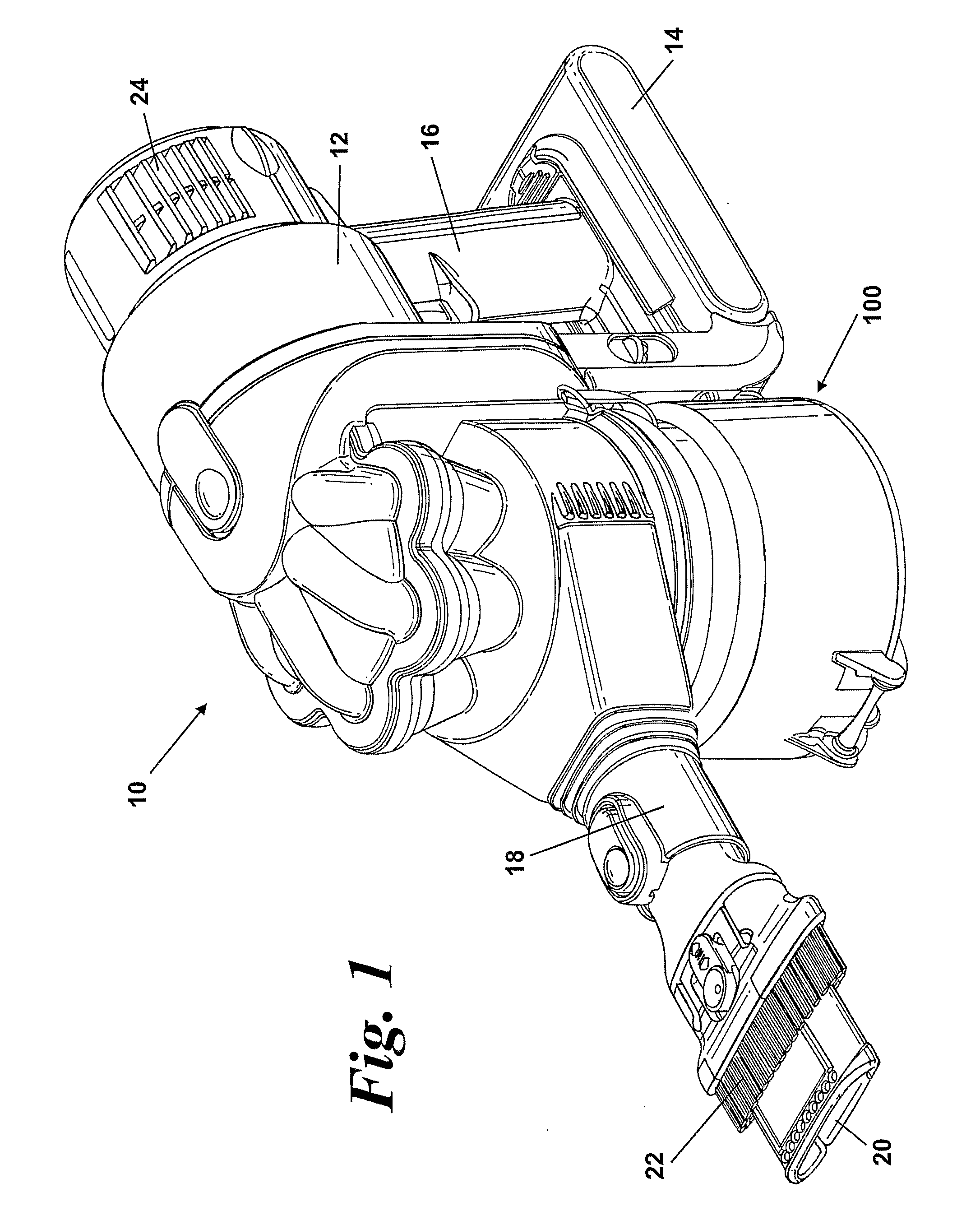

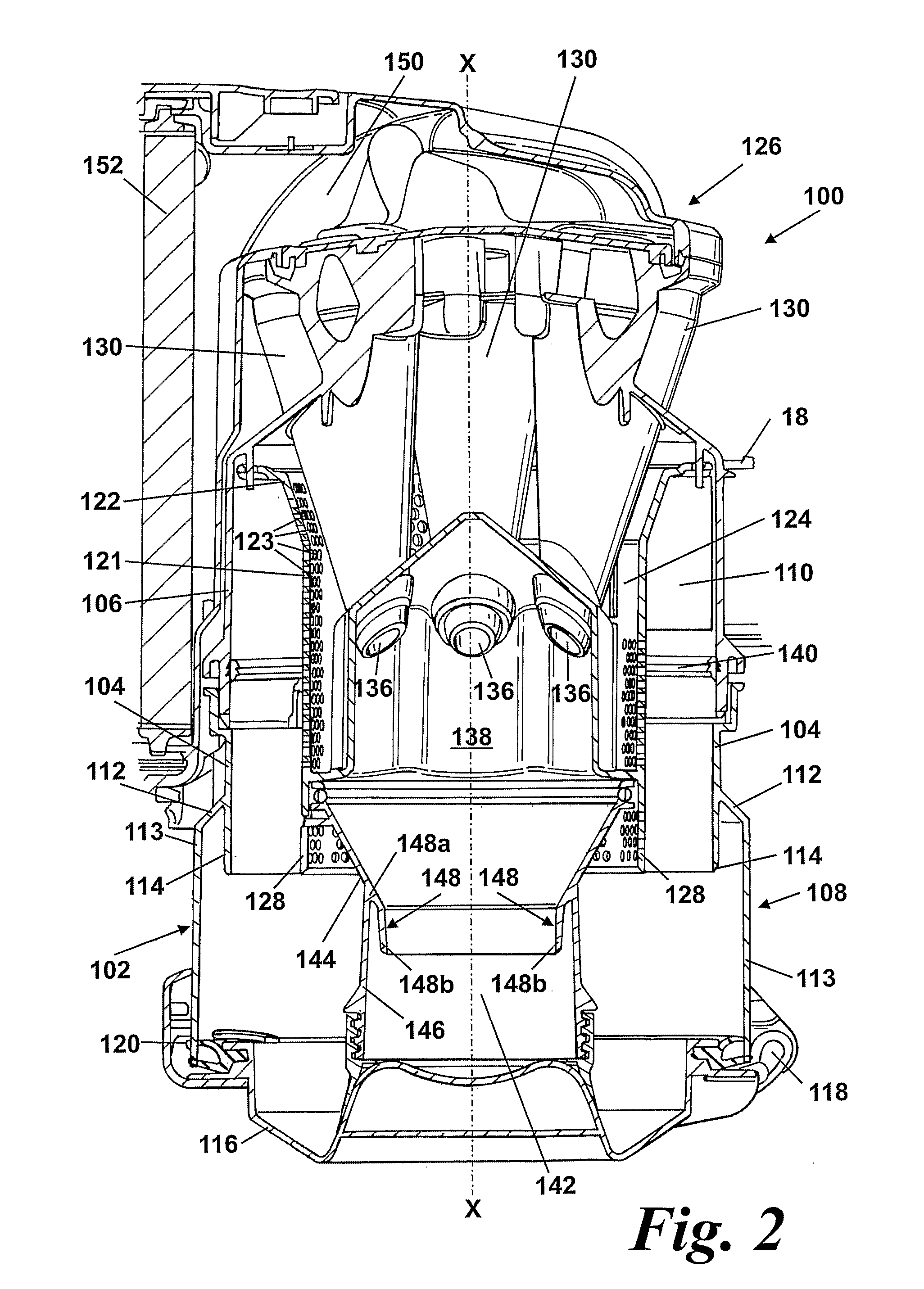

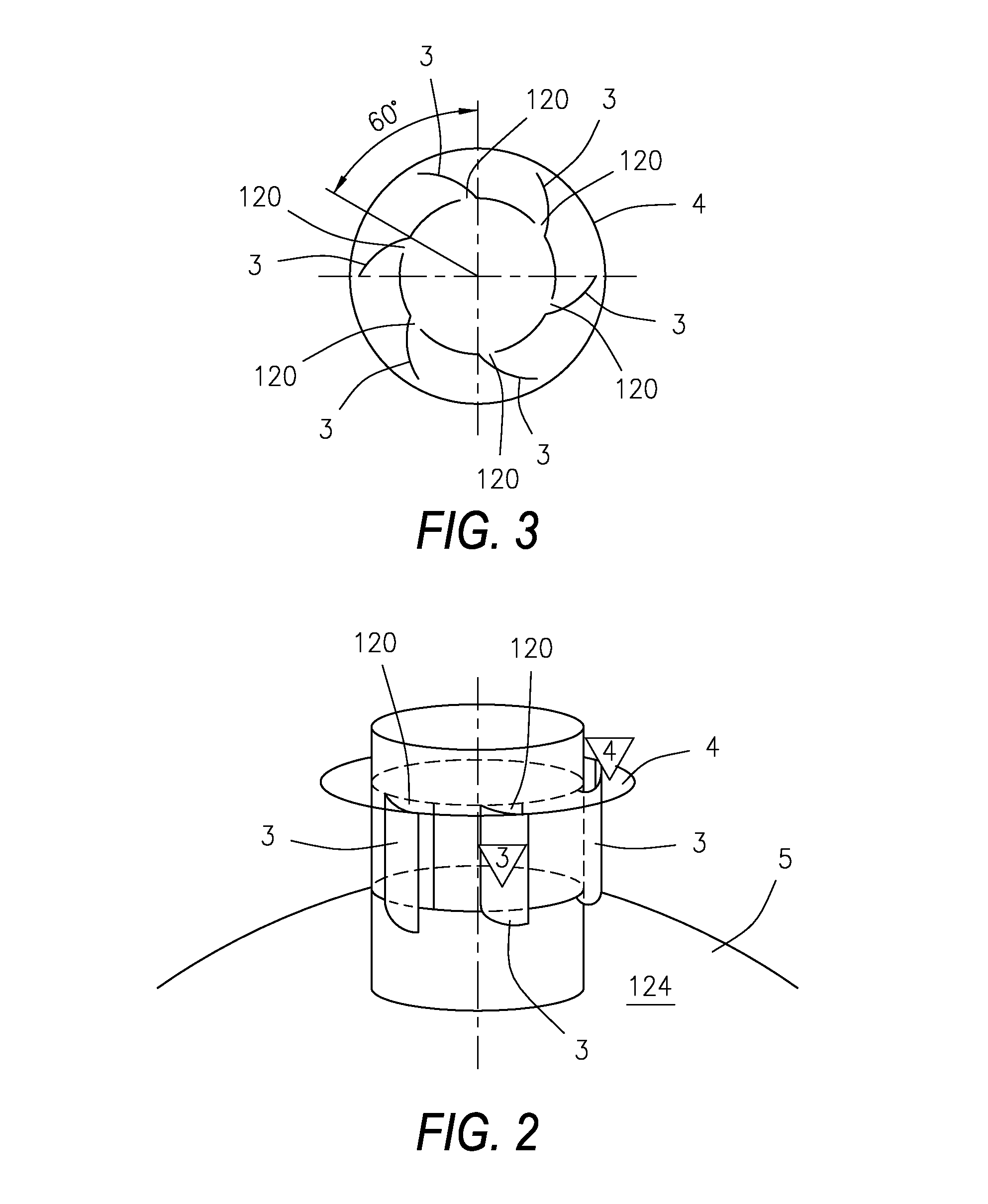

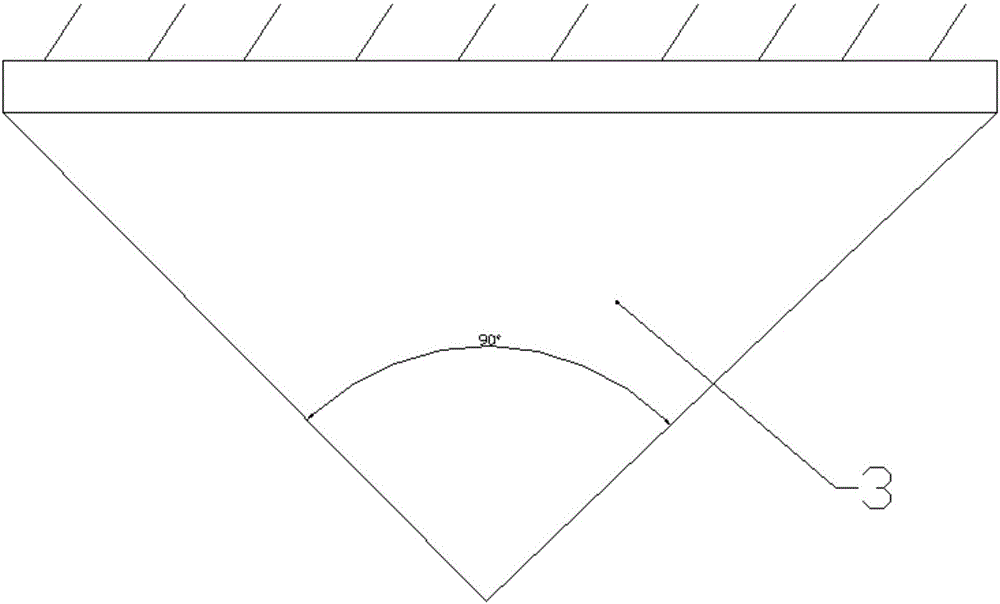

Cyclonic separating apparatus

InactiveUS20090313958A1Reduces risk of re-entrainmentMinimize impactCombination devicesSuction filtersCycloneCyclonic separation

A cyclonic separating apparatus for separating particles from a dirt-laden airflow includes a cyclone for separating and collecting dirt and dust from the dirt-laden airflow. The cyclone has an air inlet, an air outlet, a longitudinal axis and a wall. The wall includes a first portion and a second portion spaced farther from the longitudinal axis than the first portion, the first and second portions being spaced along the longitudinal axis. The cyclone also includes at least one lip extending from the first portion of the wall into a portion of the cyclone surrounded by the second portion of the wall. By providing a cyclone with a wall having two portions of different sizes and a lip extending from the portion with the smaller size into the portion with the larger size, the risk of blockages due to re-entrainment and movement of dirt and dust within the cyclonic separating apparatus is reduced.

Owner:DYSON TECH LTD

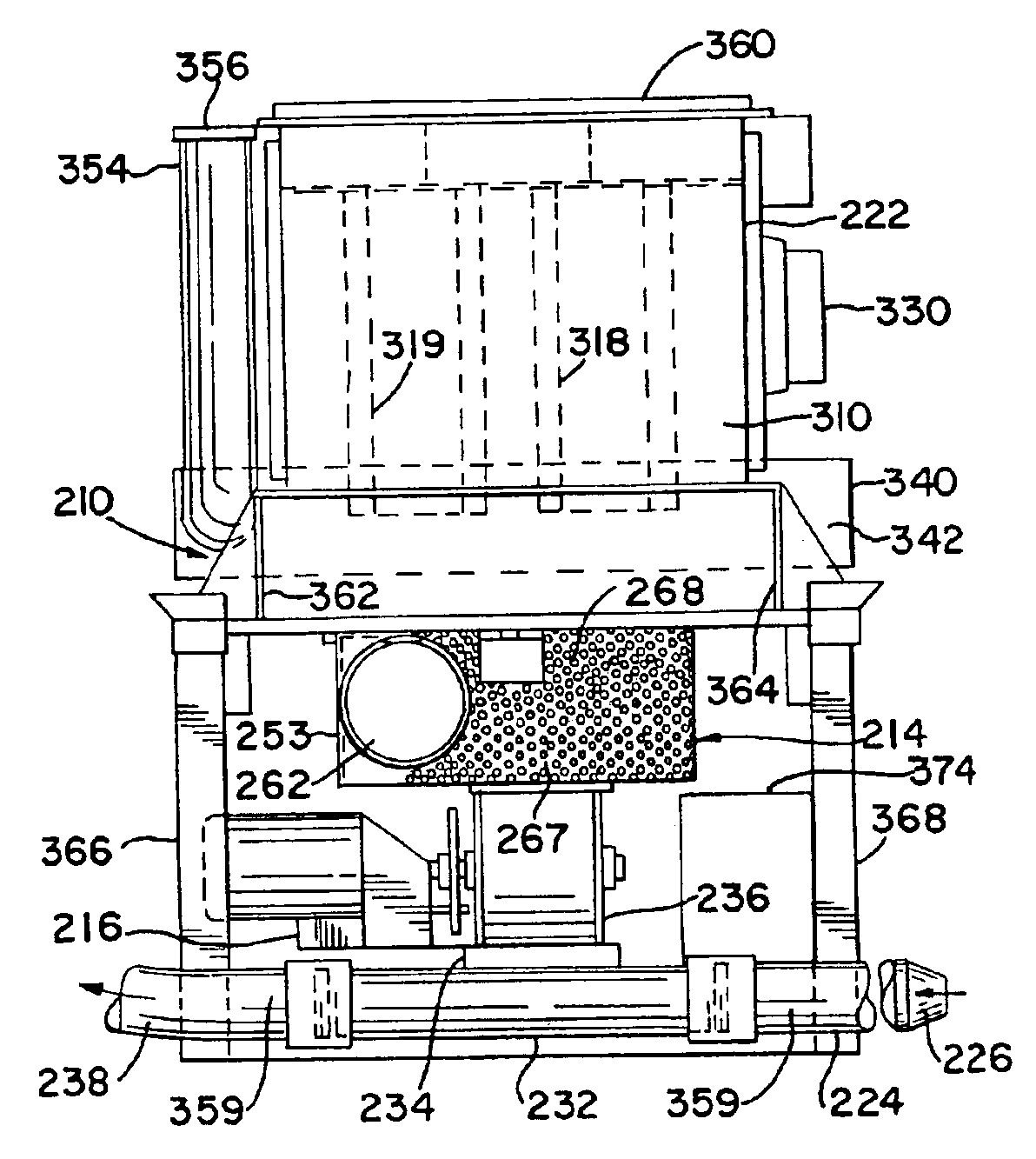

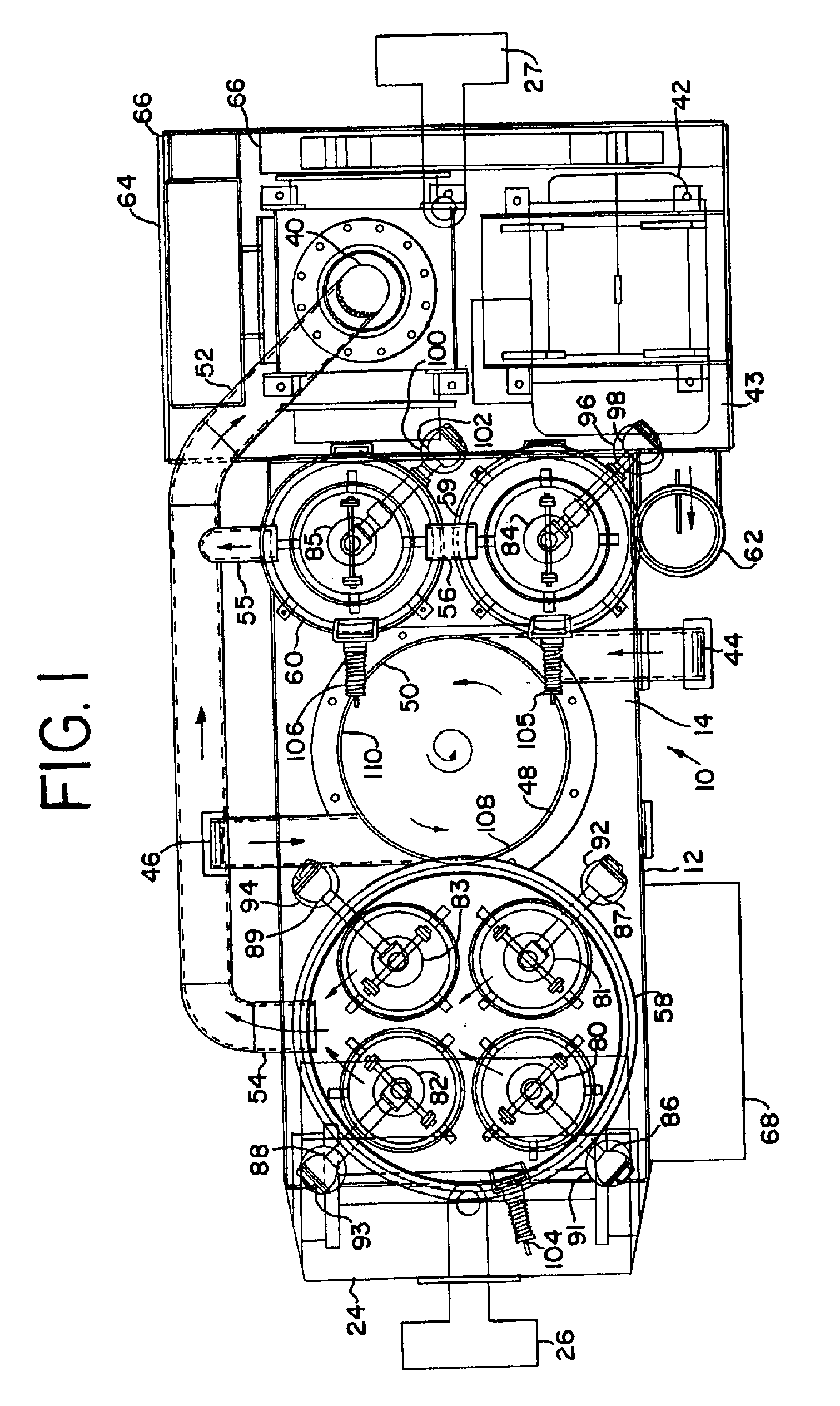

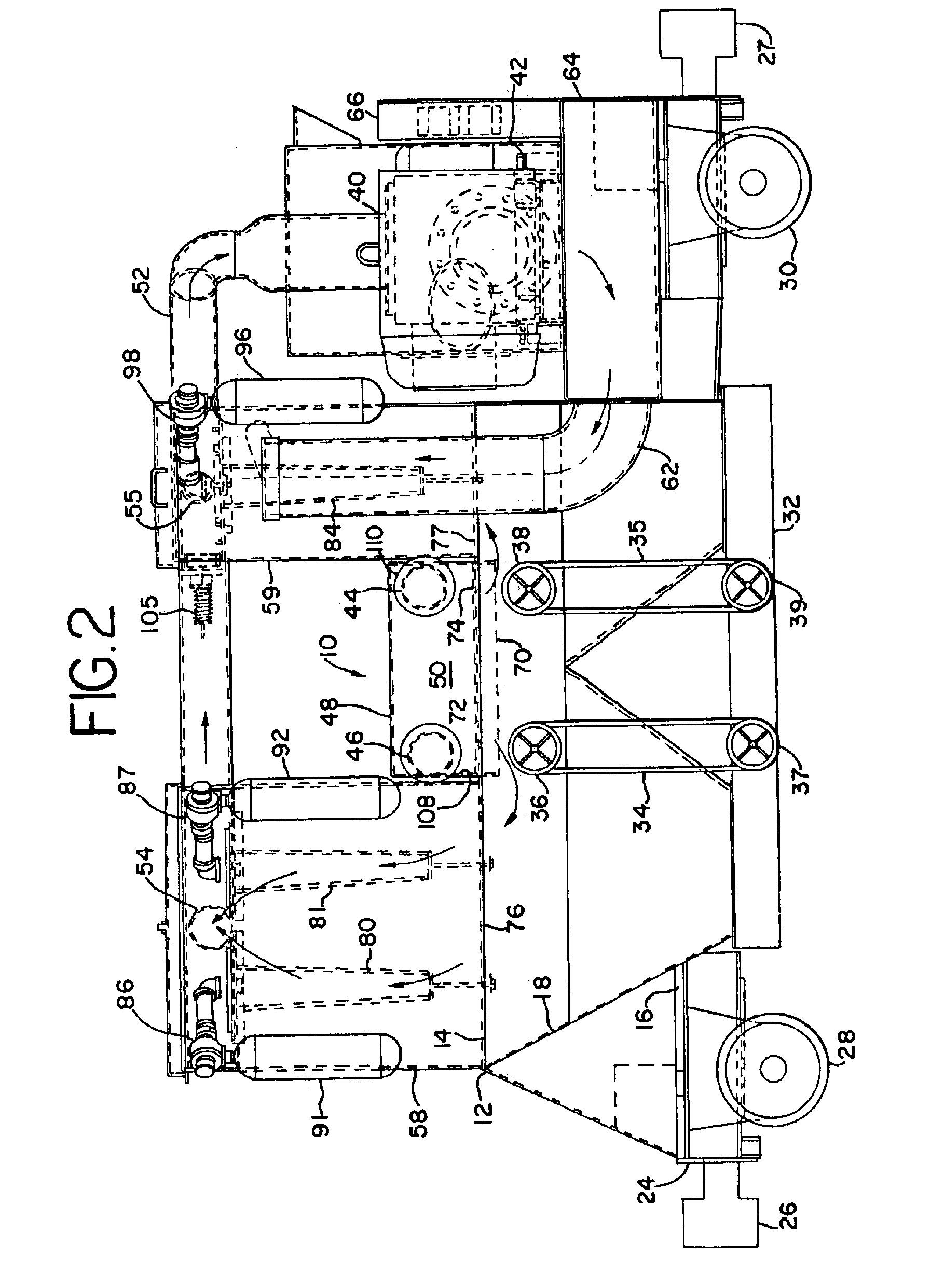

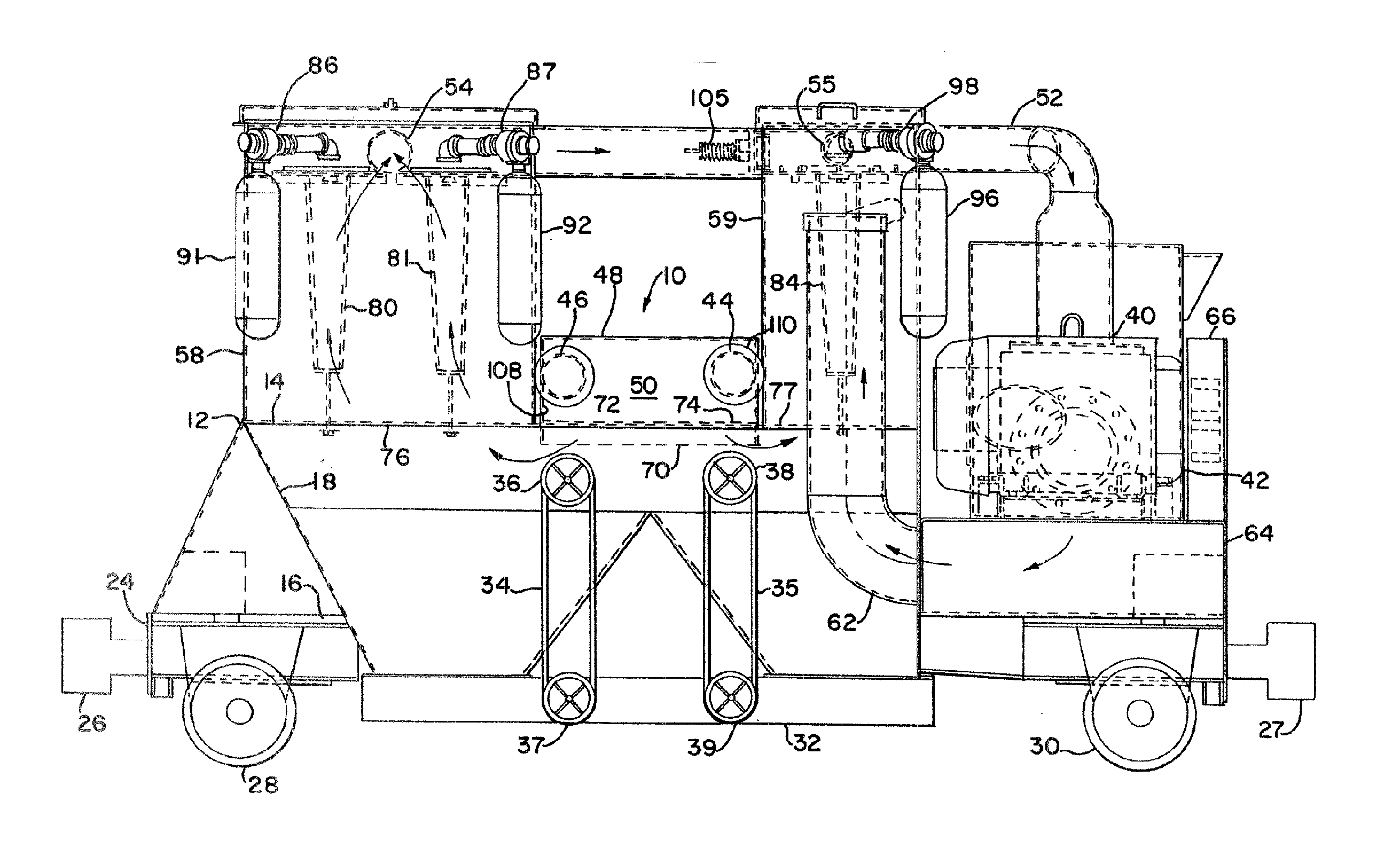

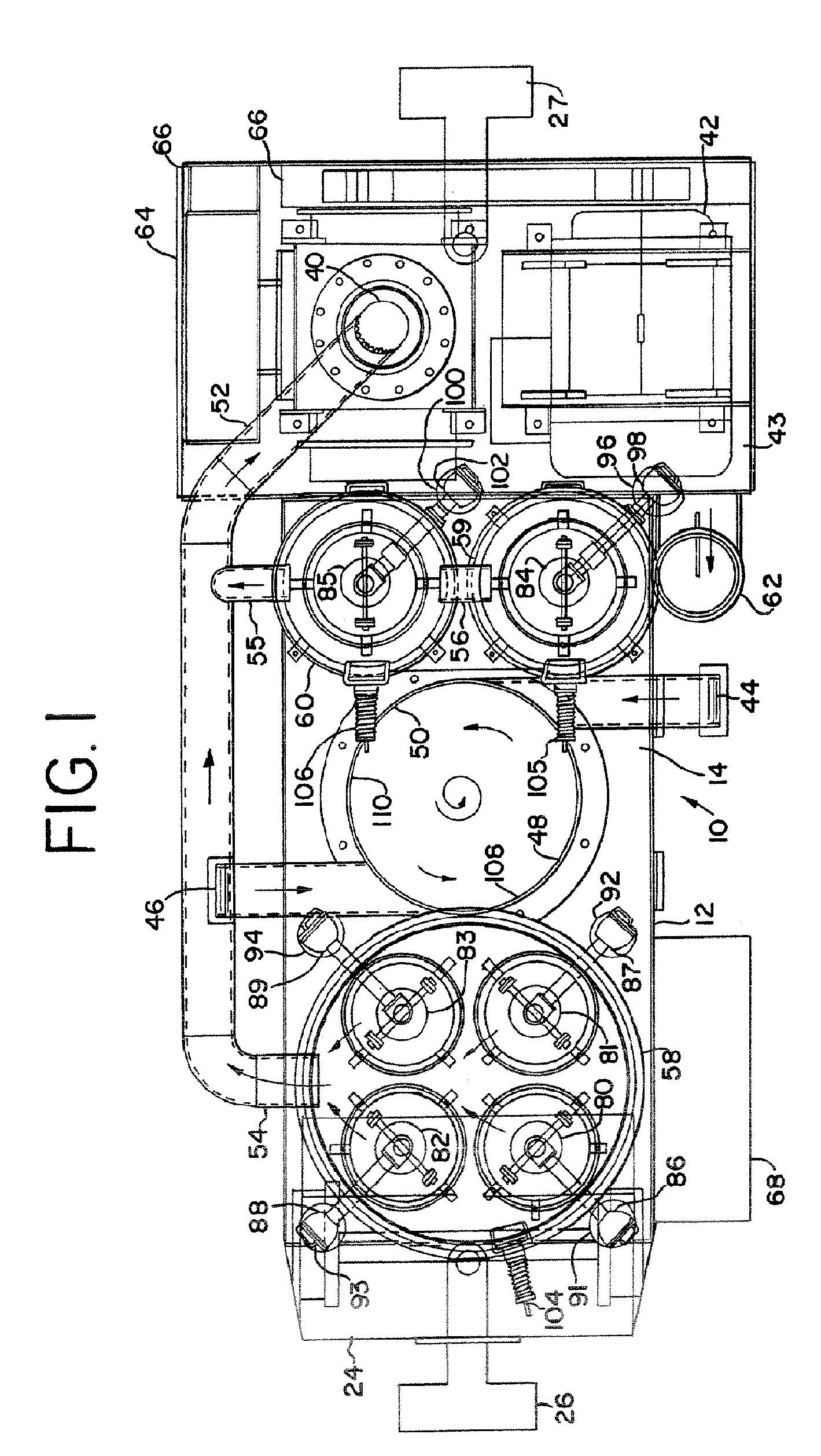

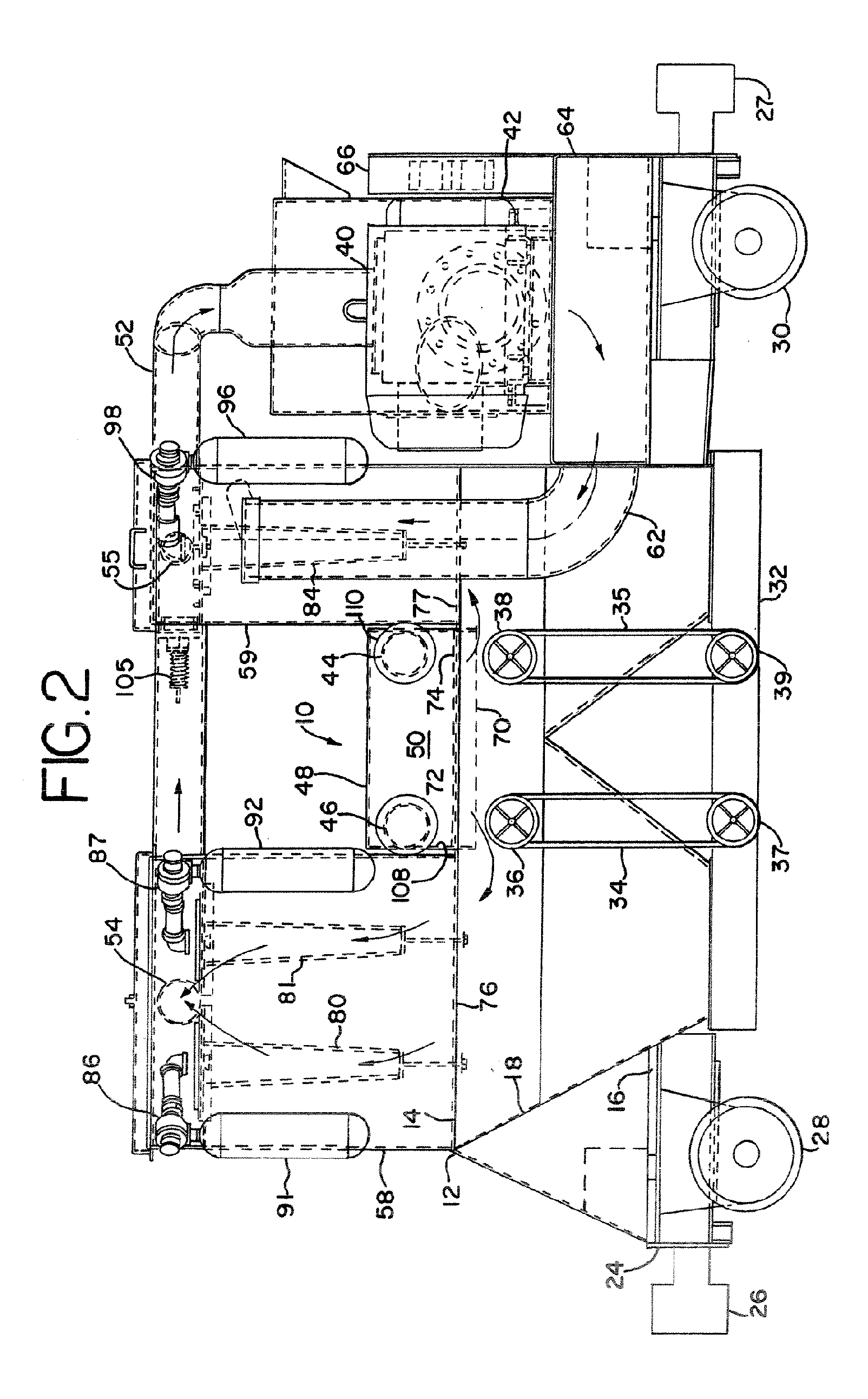

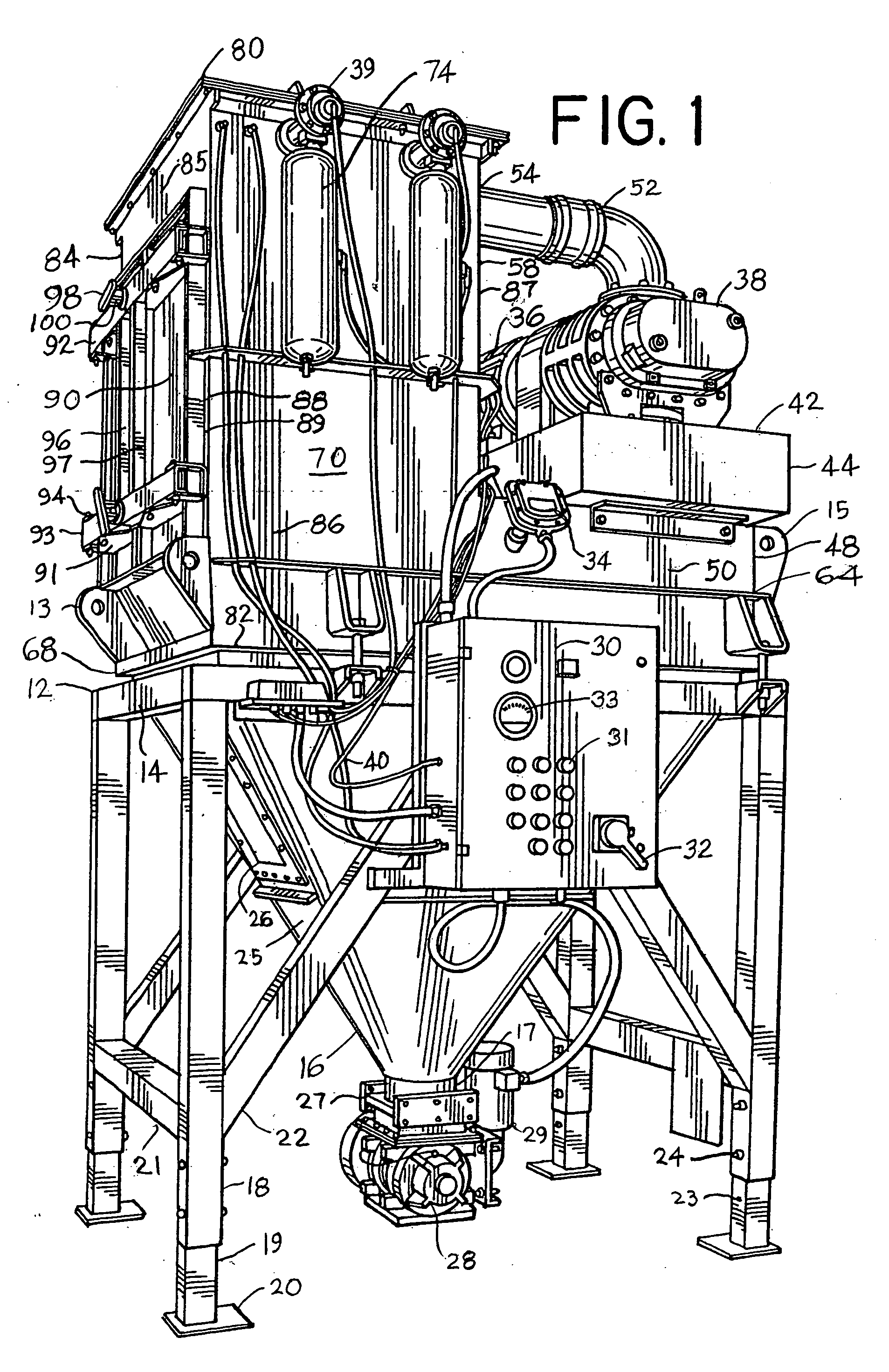

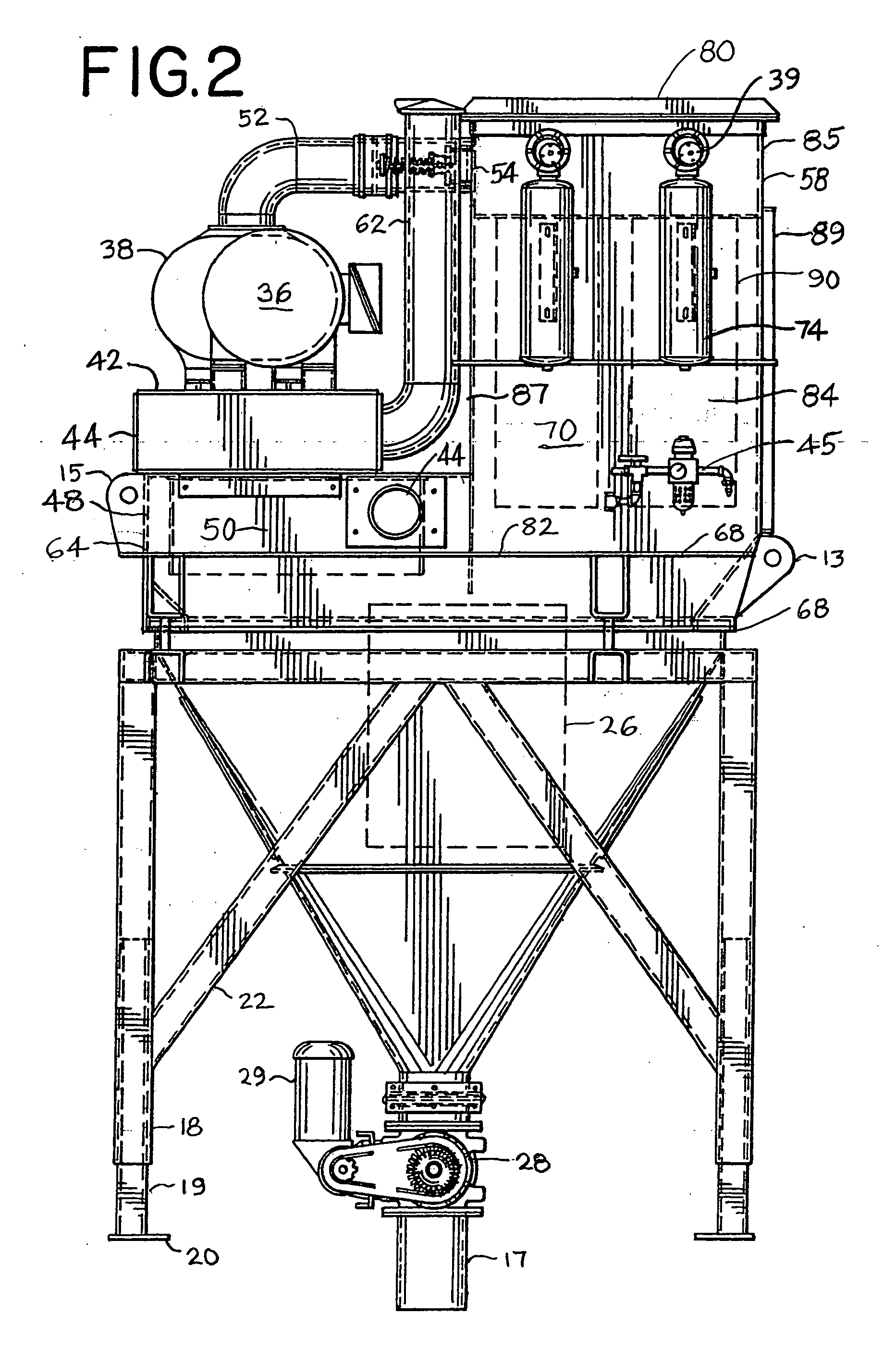

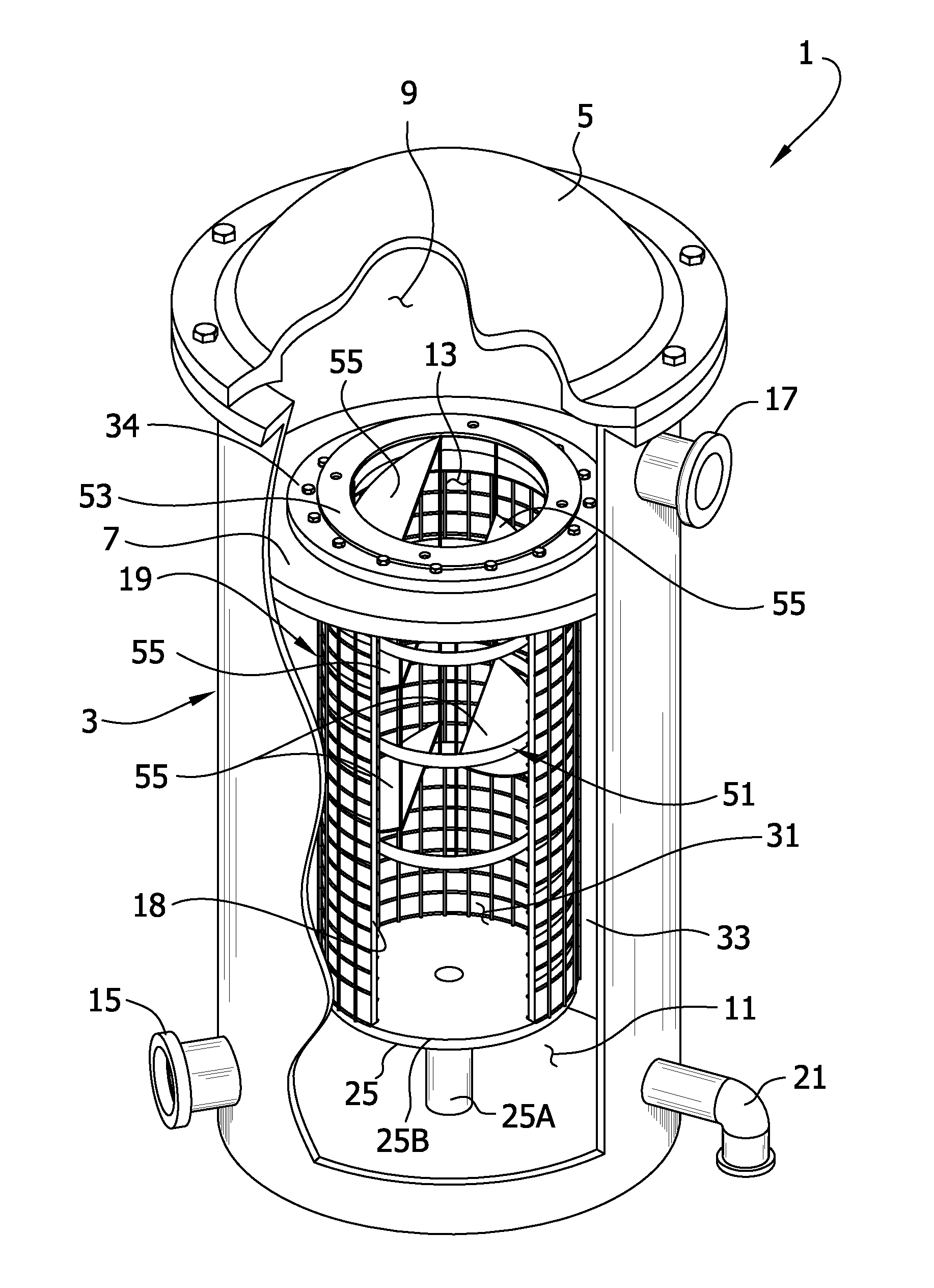

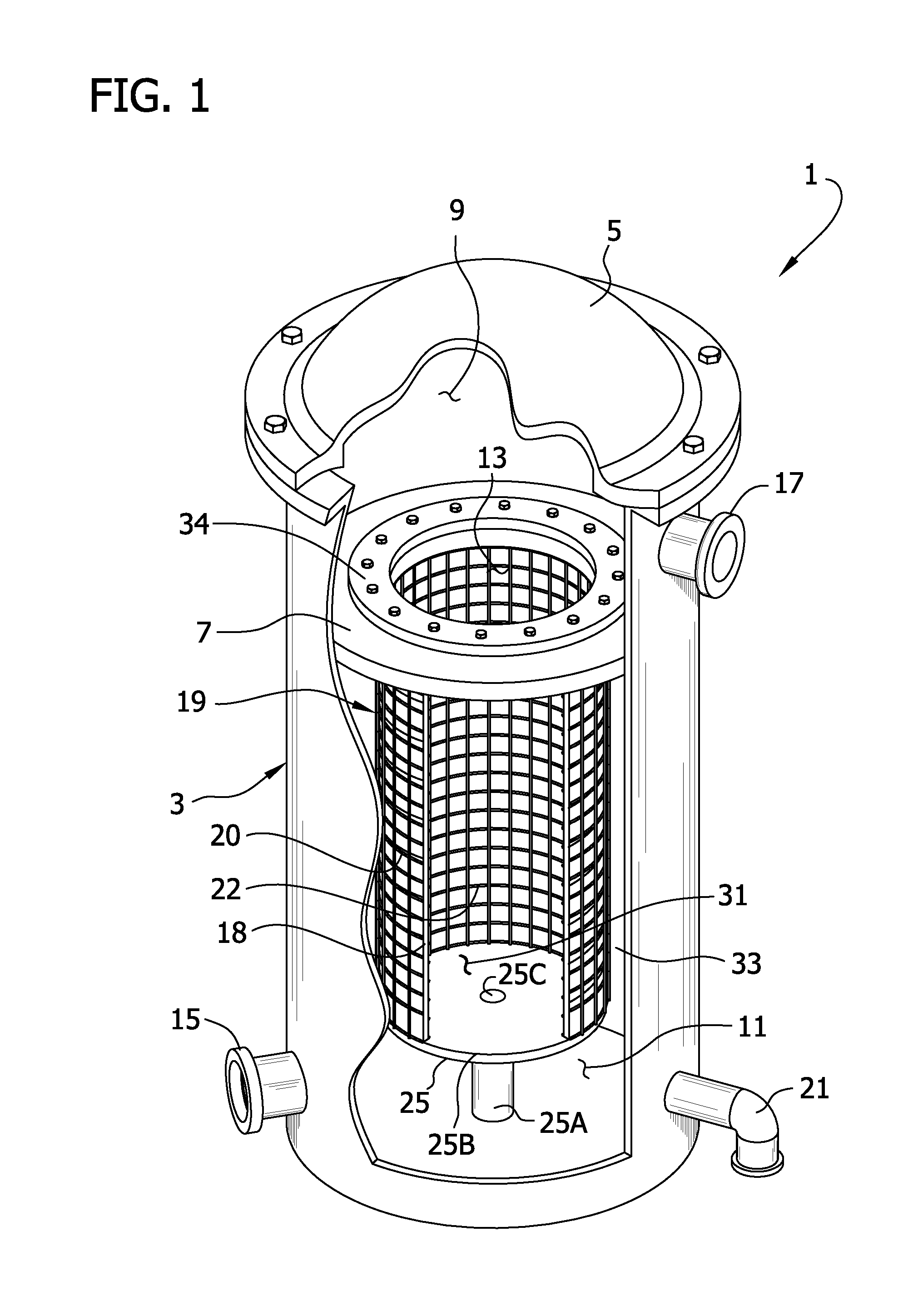

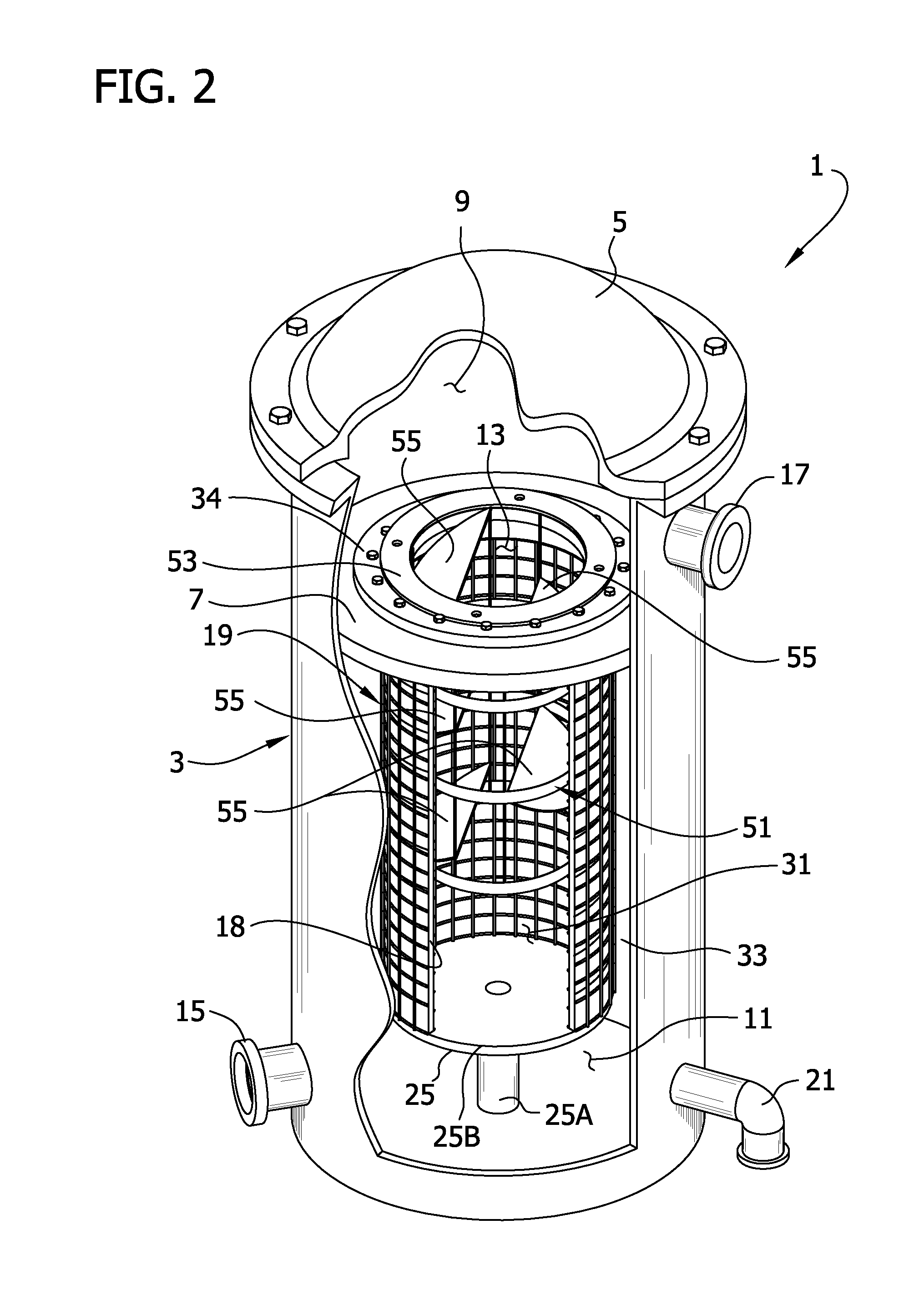

Vacuum loader

InactiveUS6936085B2Efficient and effective and safeCombination devicesAuxillary pretreatmentCycloneFiber

A specially arranged vacuum loader and industrial dust collector with a perforated plate tangential cyclone separator is provided to efficiently remove, readily collect, effectively separate and safely dispose of wet, dry and fibrous materials, including liquids and slurries. The special vacuum loader and industrial dust collector has a solids-gas separation compartment comprising a tangential cyclone separator, preferably a perforated plate tangential separator, which is positioned generally alongside and laterally offset from one or more filtering compartments to minimize turbulence and re-entrainment of the collected particulate material.

Owner:DEMARCO VACUUM CORP

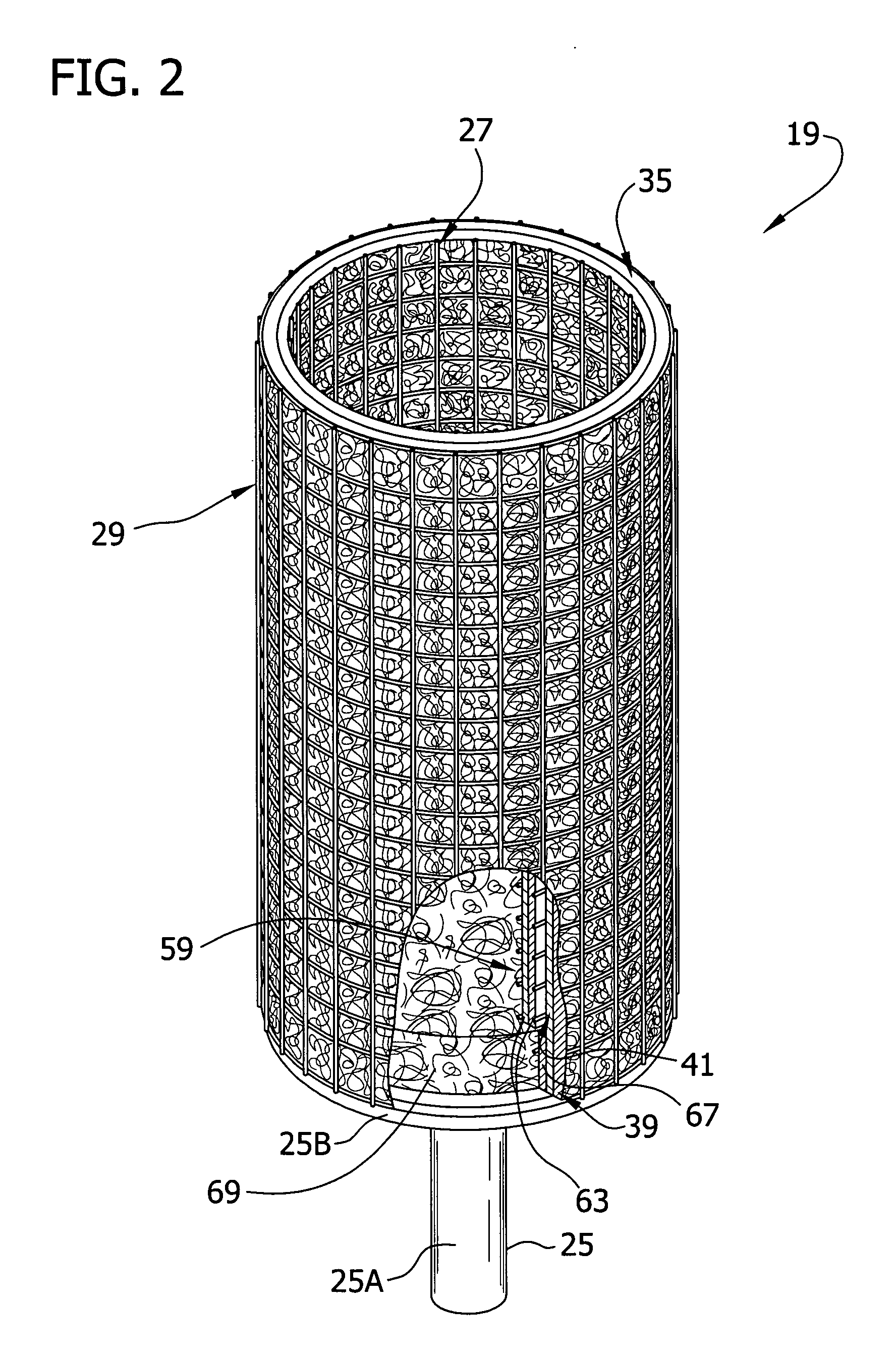

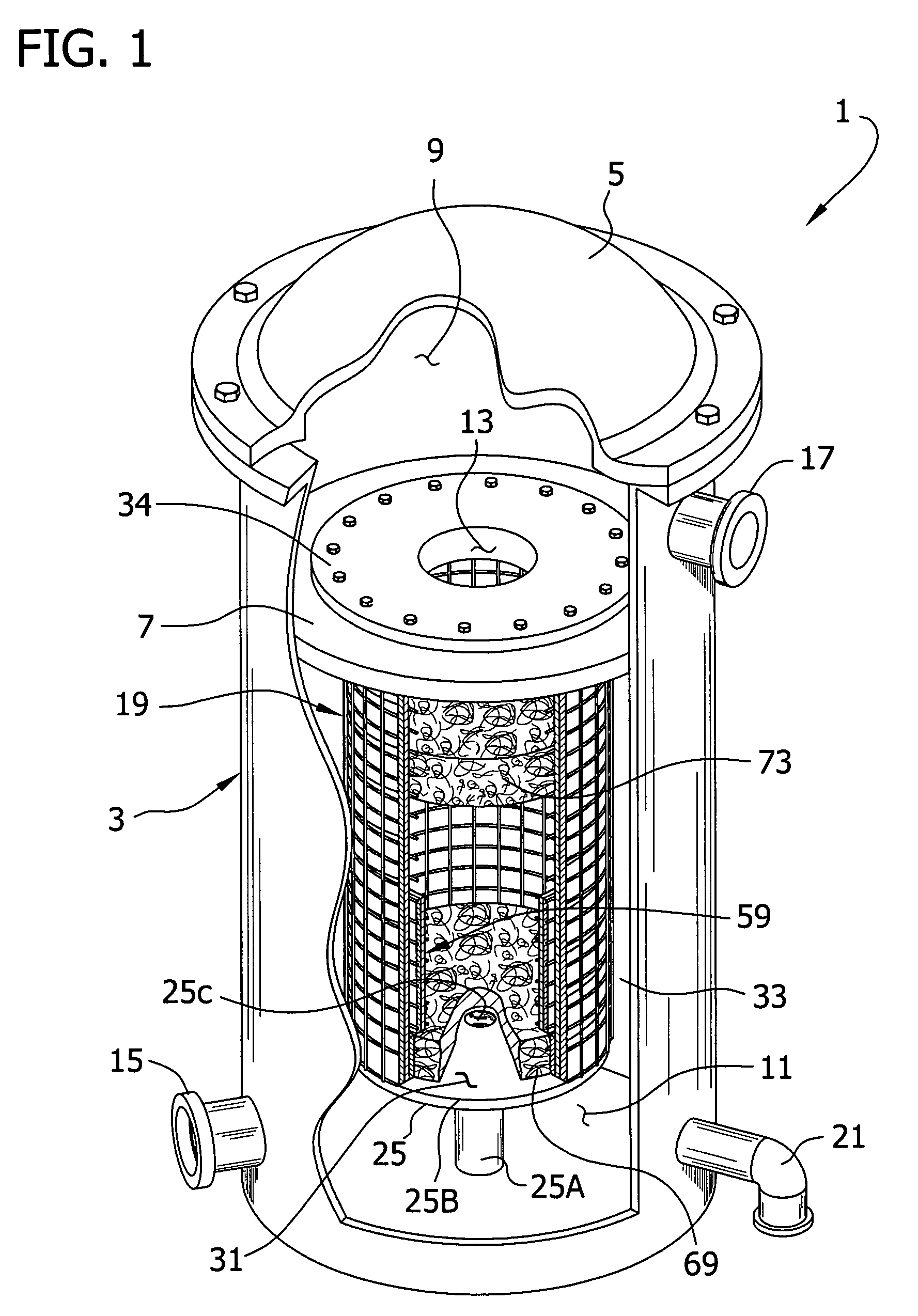

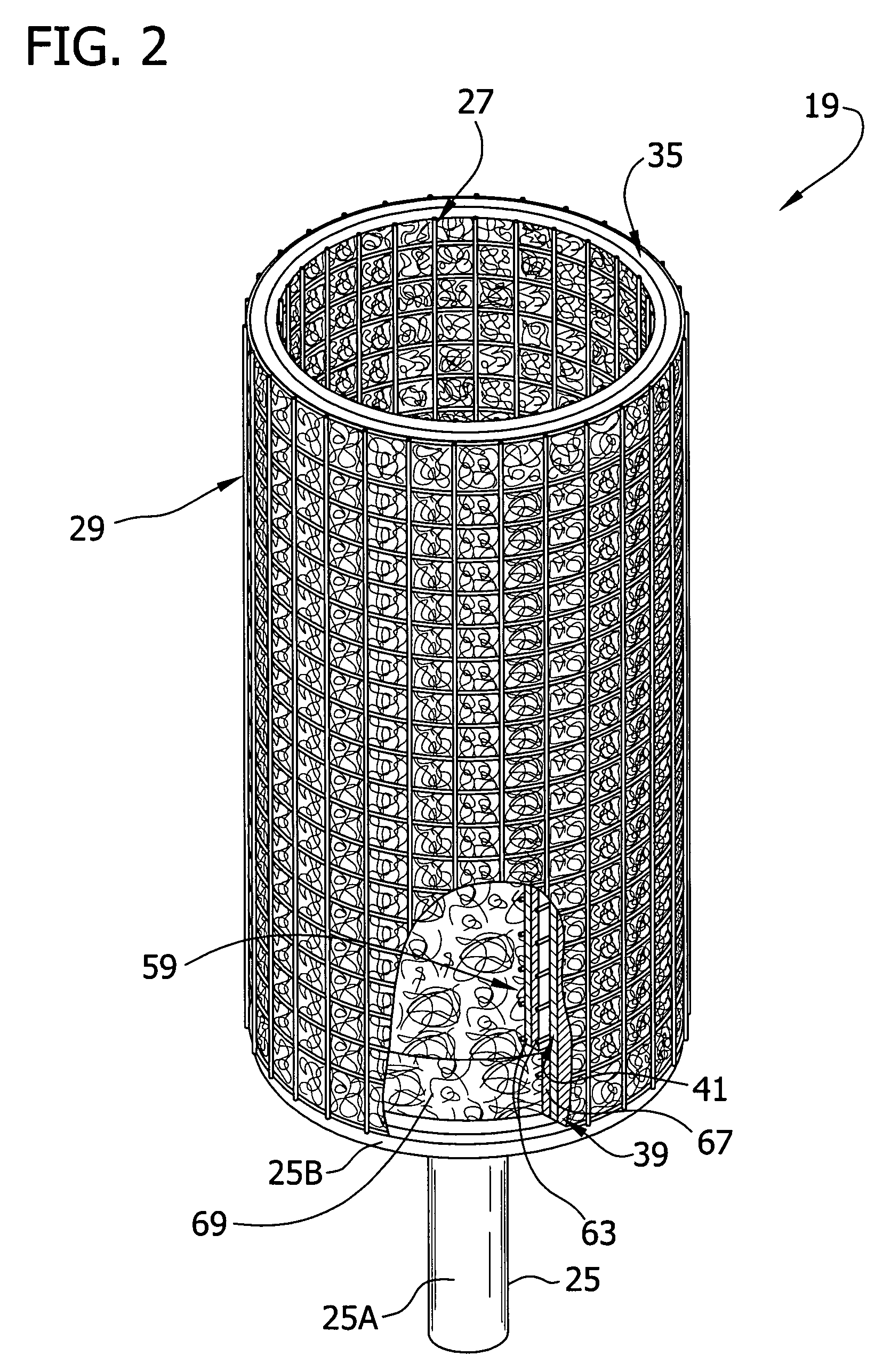

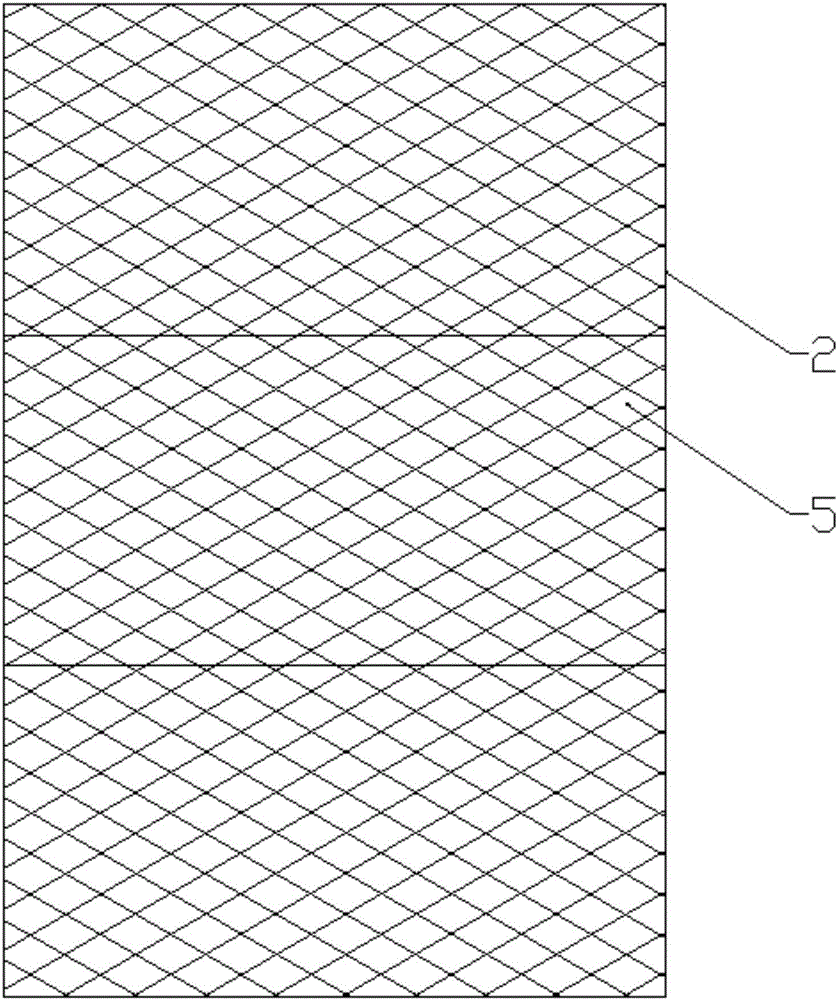

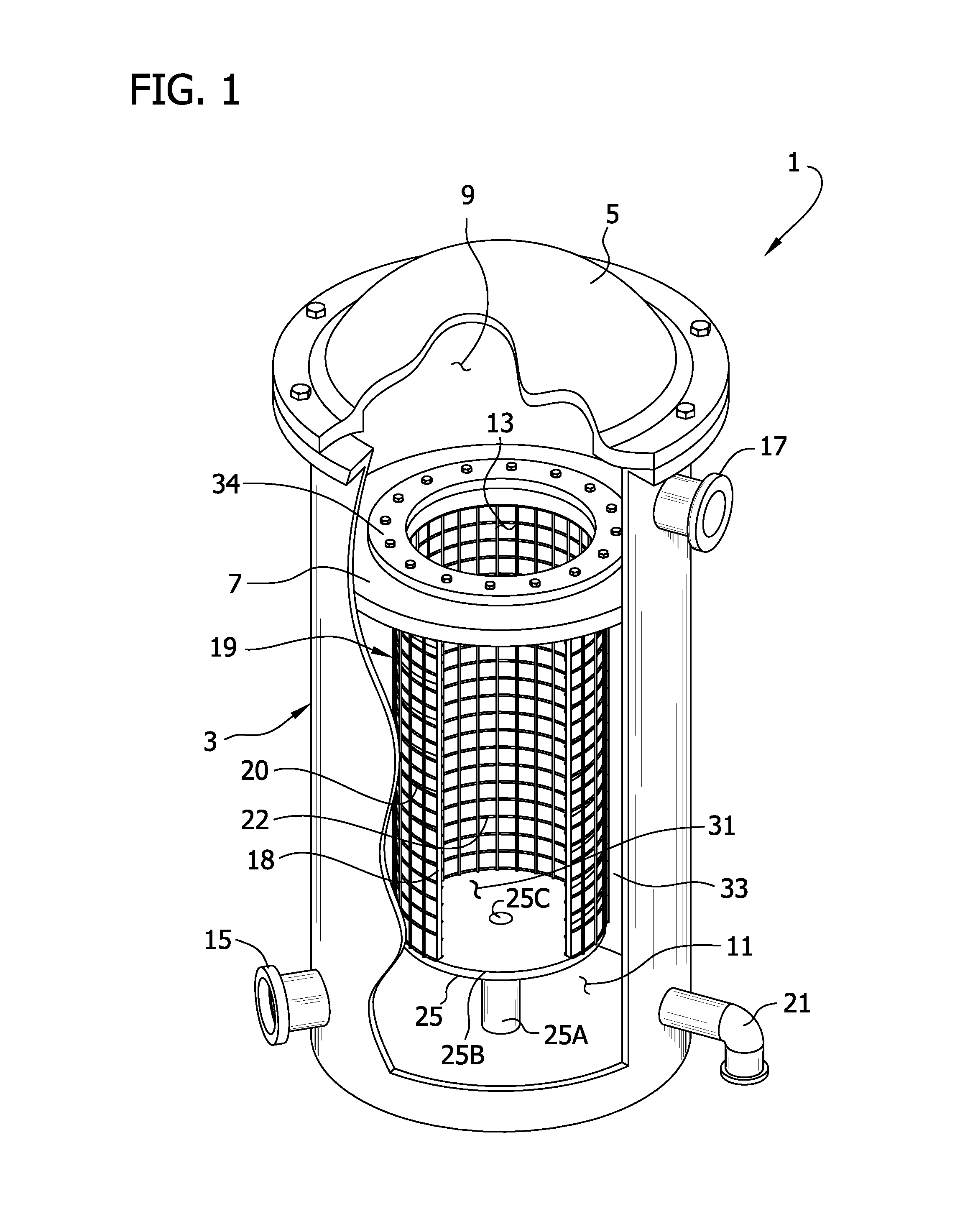

Fiber Bed assembly and fiber bed therefor

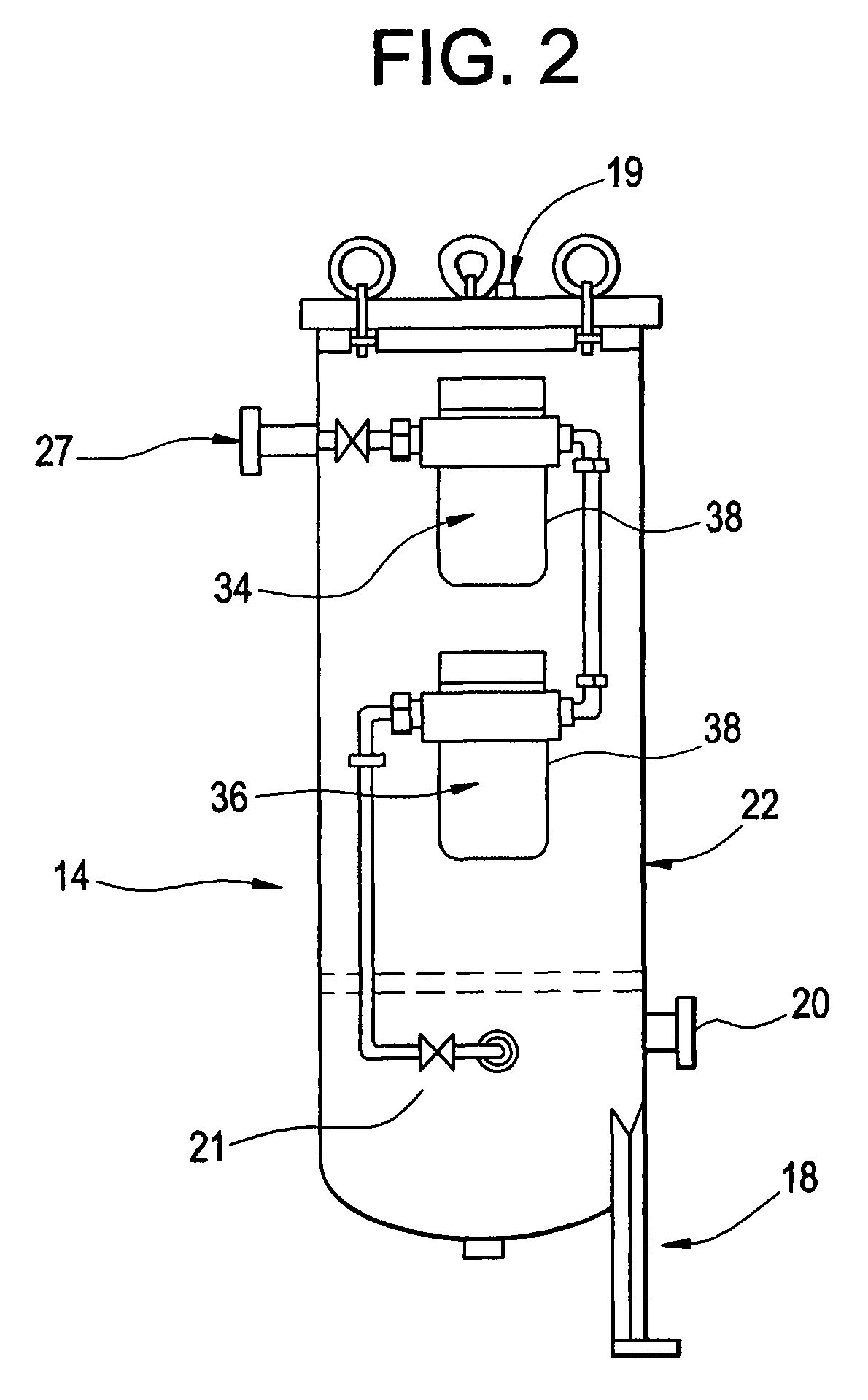

A fiber bed assembly for a mist eliminator that operates at high efficiency and inhibits re-entrained liquid from leaving the mist eliminator. The fiber bed assembly has a construction that facilitates rapid drainage of liquid collected by the fiber bed. A pre-filter media can be employed upstream of the primary collection media to remove larger liquid drops. The pre-filter media can be used in unique combination with other features to reduce liquid re-entrainment, and / or allow increased flow capacity.

Owner:MECS

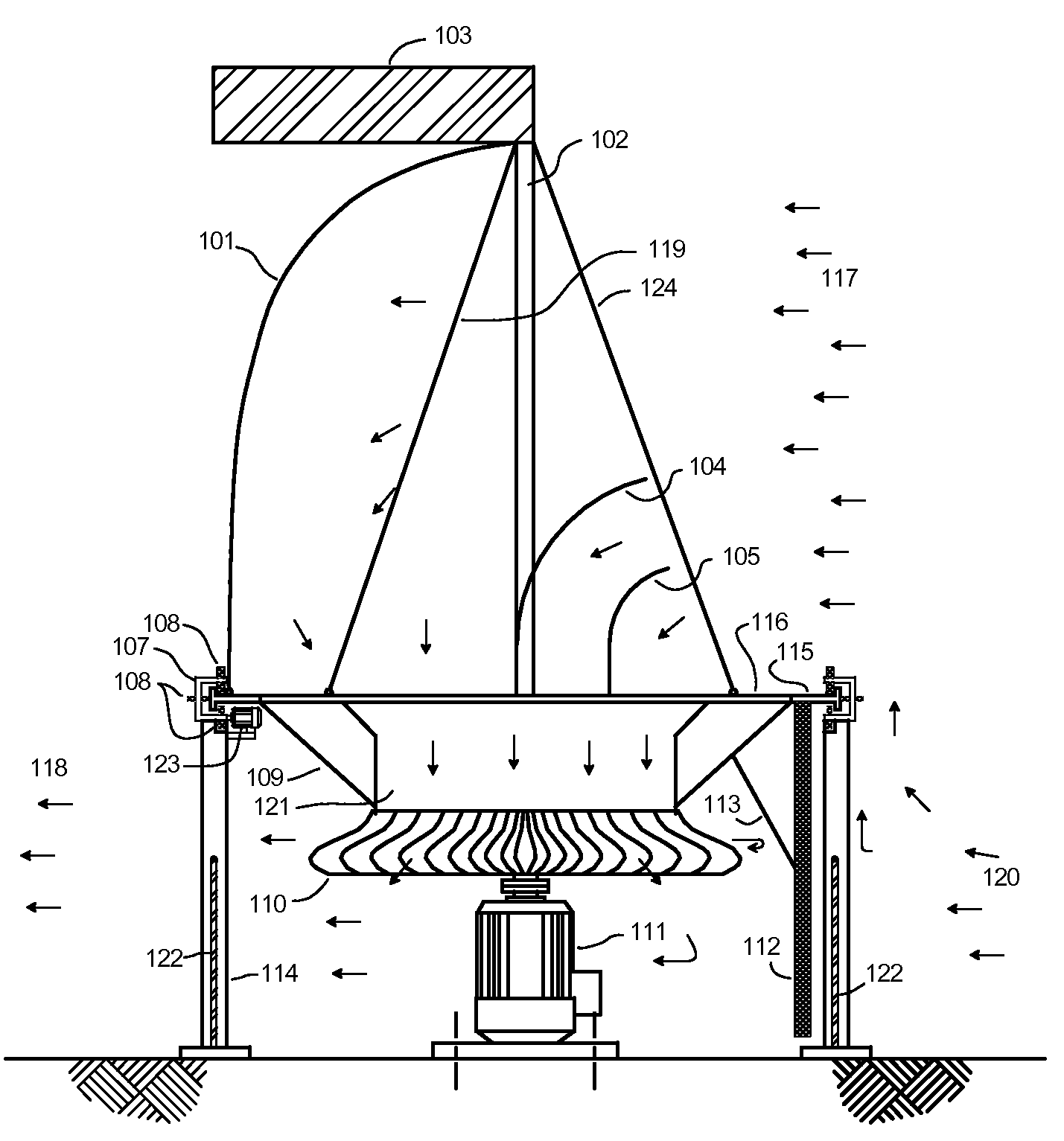

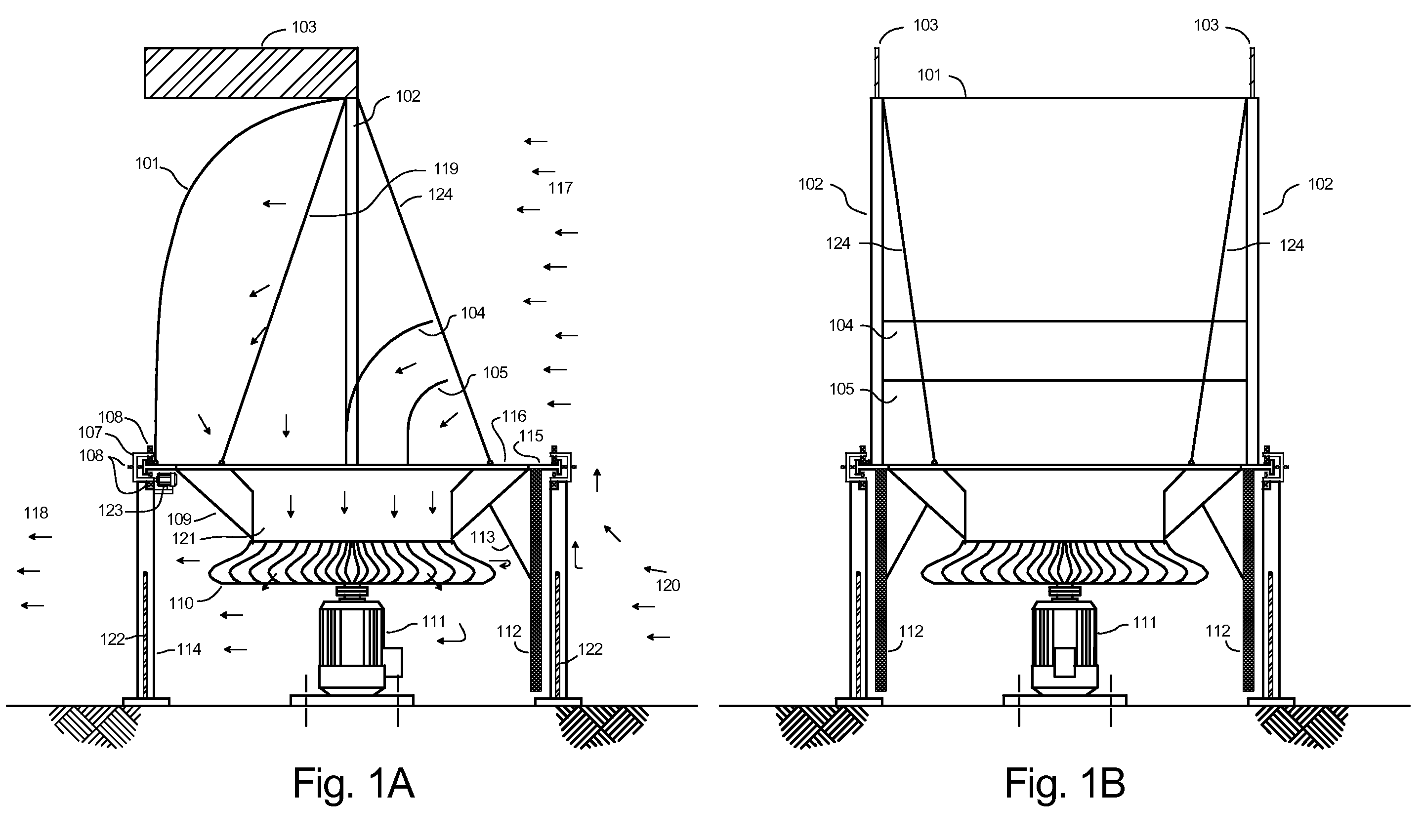

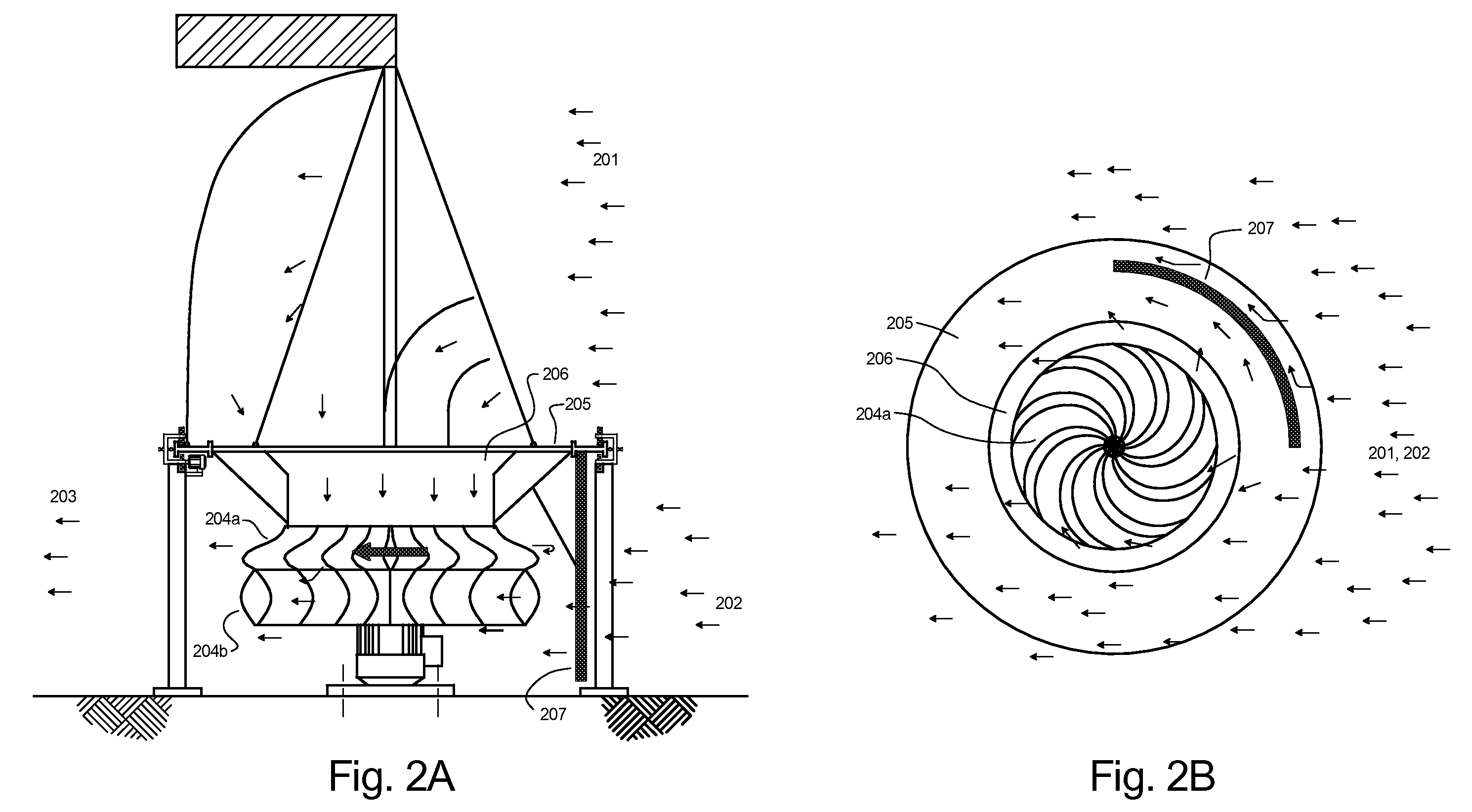

Vertical wind turbine system with adjustable inlet air scoop and exit drag curtain

Owner:AEROMINE TECH

Vacuum loader

InactiveUS20050274094A1Reliable and safe and effectiveEfficient removalCombination devicesAuxillary pretreatmentCycloneFiber

A specially arranged vacuum loader and industrial dust collector with a perforated plate tangential cyclone separator with angular perforations is provided to efficiently remove, readily collect, effectively separate and safely dispose of wet, dry and fibrous materials, including liquids and slurries. The special vacuum loader and industrial dust collector has a solids-gas separation compartment comprising a tangential cyclone separator, preferably a perforated plate tangential separator with angular perforations, which is positioned generally alongside and laterally offset from one or more filtering compartments to minimize turbulence and re-entrainment of the collected particulate material.

Owner:DEMARCO VACUUM CORP

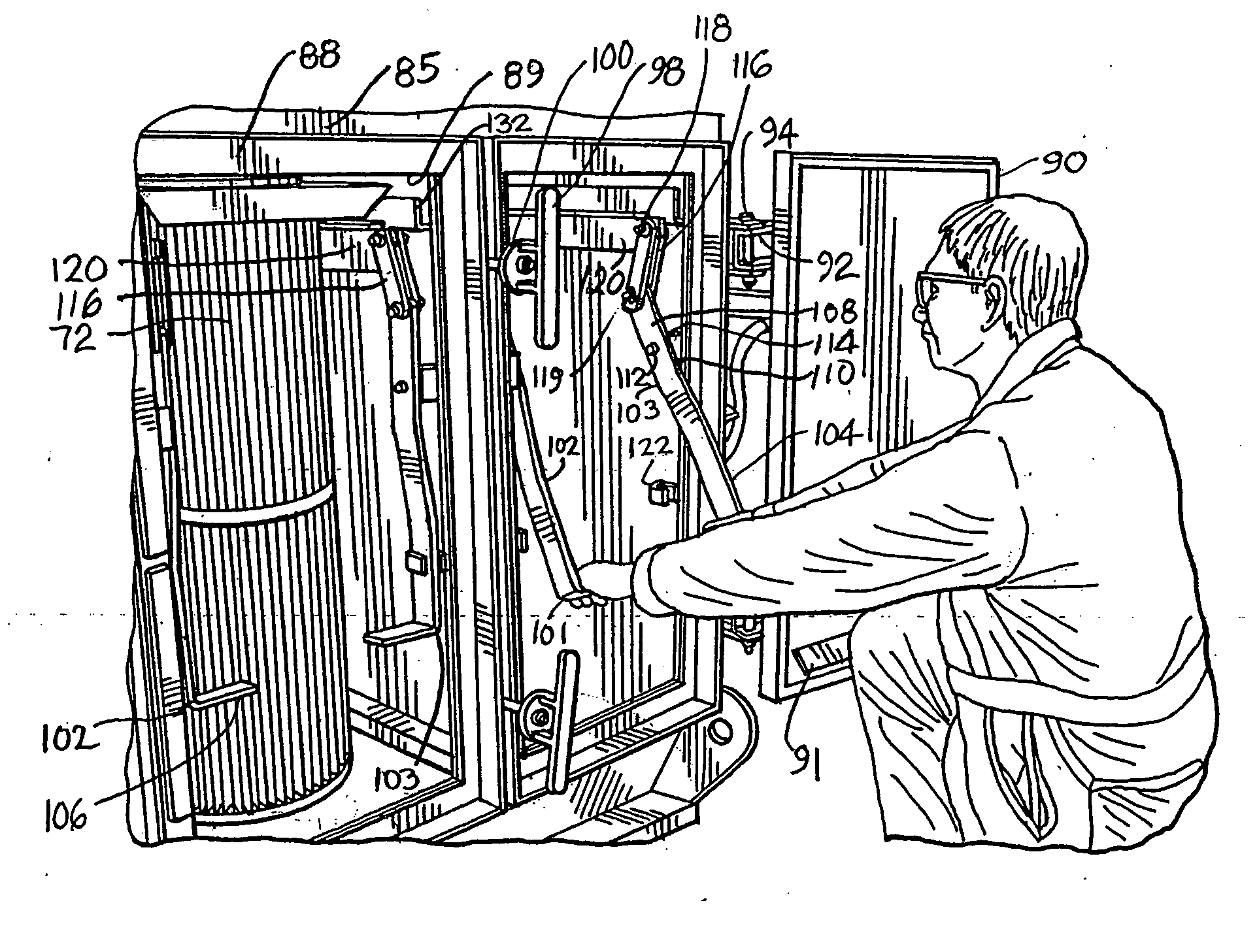

Vacuum loader with filter doors

InactiveUS20060207230A1Efficient removalIncrease kinetic separation and removalCombination devicesDispersed particle filtrationEngineeringProcess engineering

An improved industrial vacuum loader is equipped with a special filter door system to permit insertion, removal, inspection, and maintenance of filters during maintenance and to safely close and lock the filters during operation of the industrial vacuum loader. The industrial vacuum loader can have a solids-gas separation compartment with a tangential cyclone separator which is preferably positioned generally alongside and laterally offset from one or more filtering compartments to minimize turbulence and re-entrainment of the collected particulate material.

Owner:DEMARCO VACUUM CORP

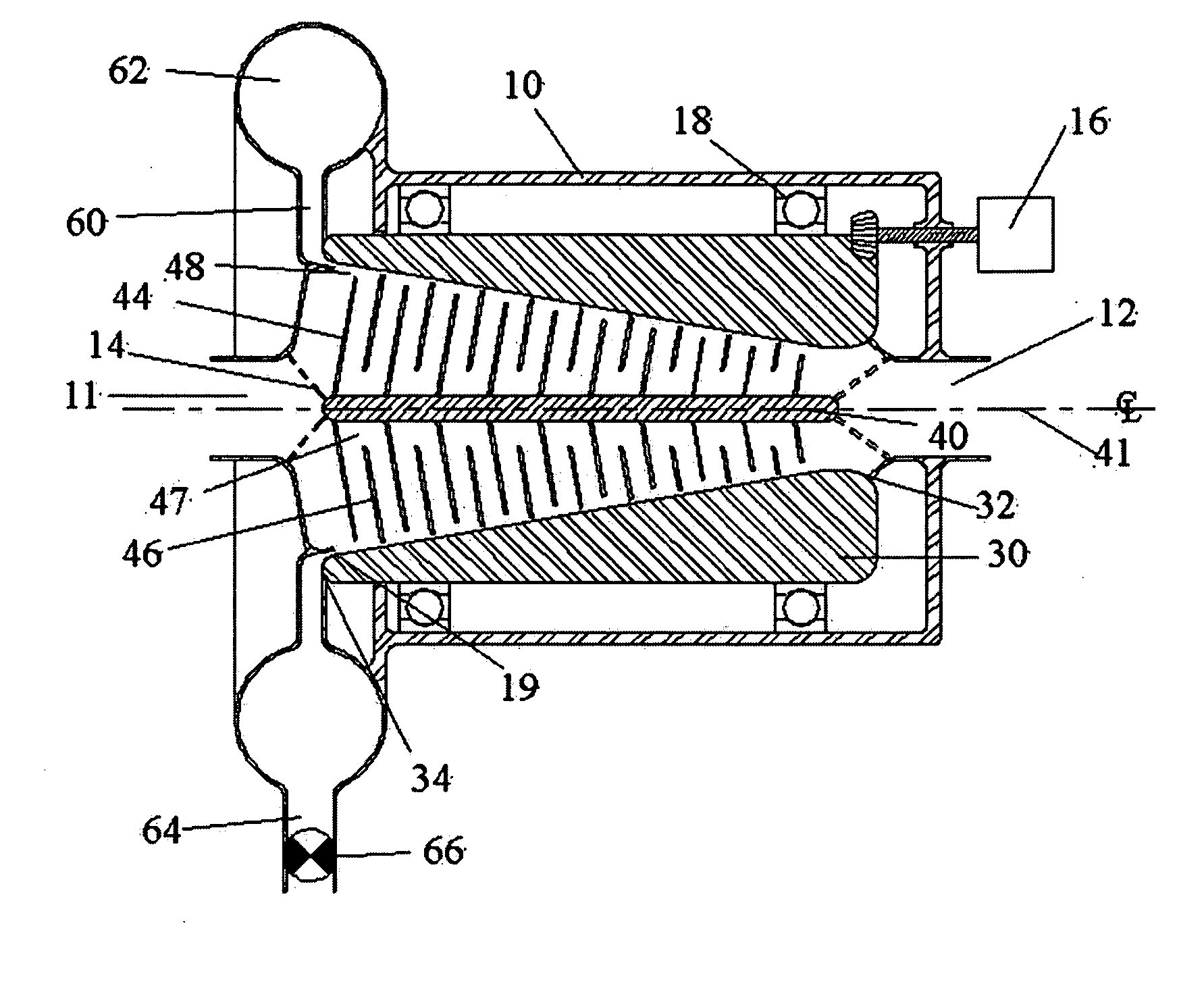

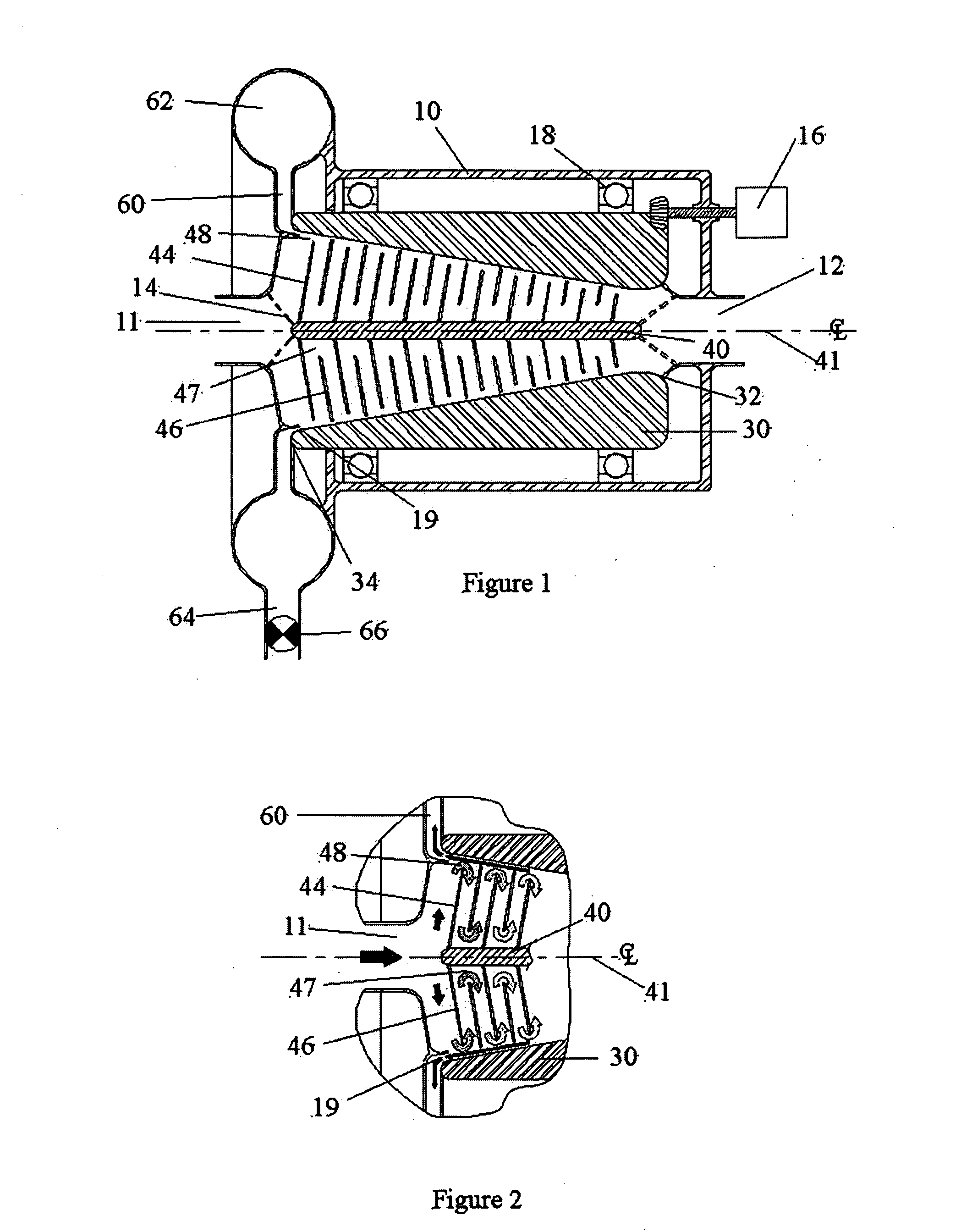

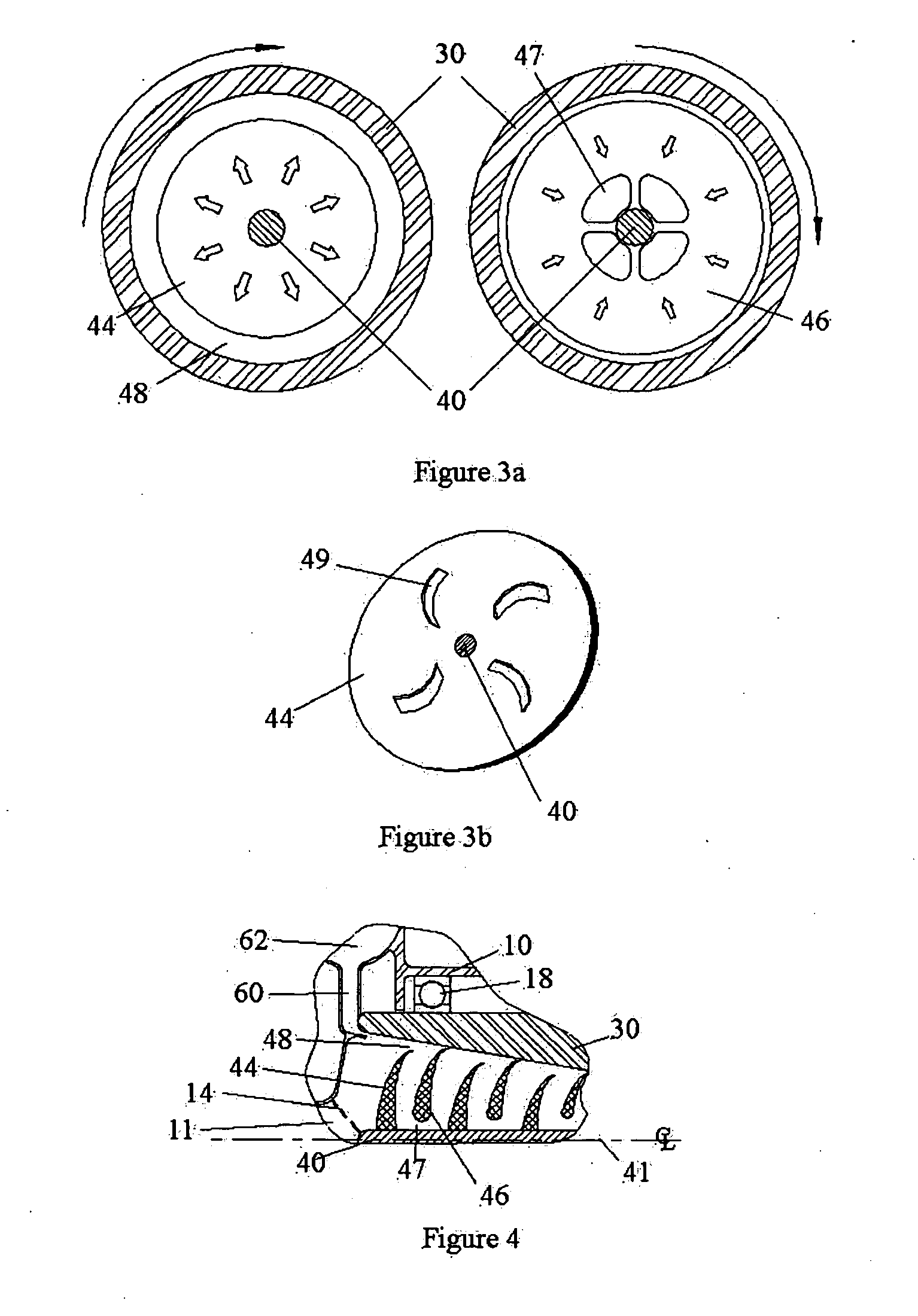

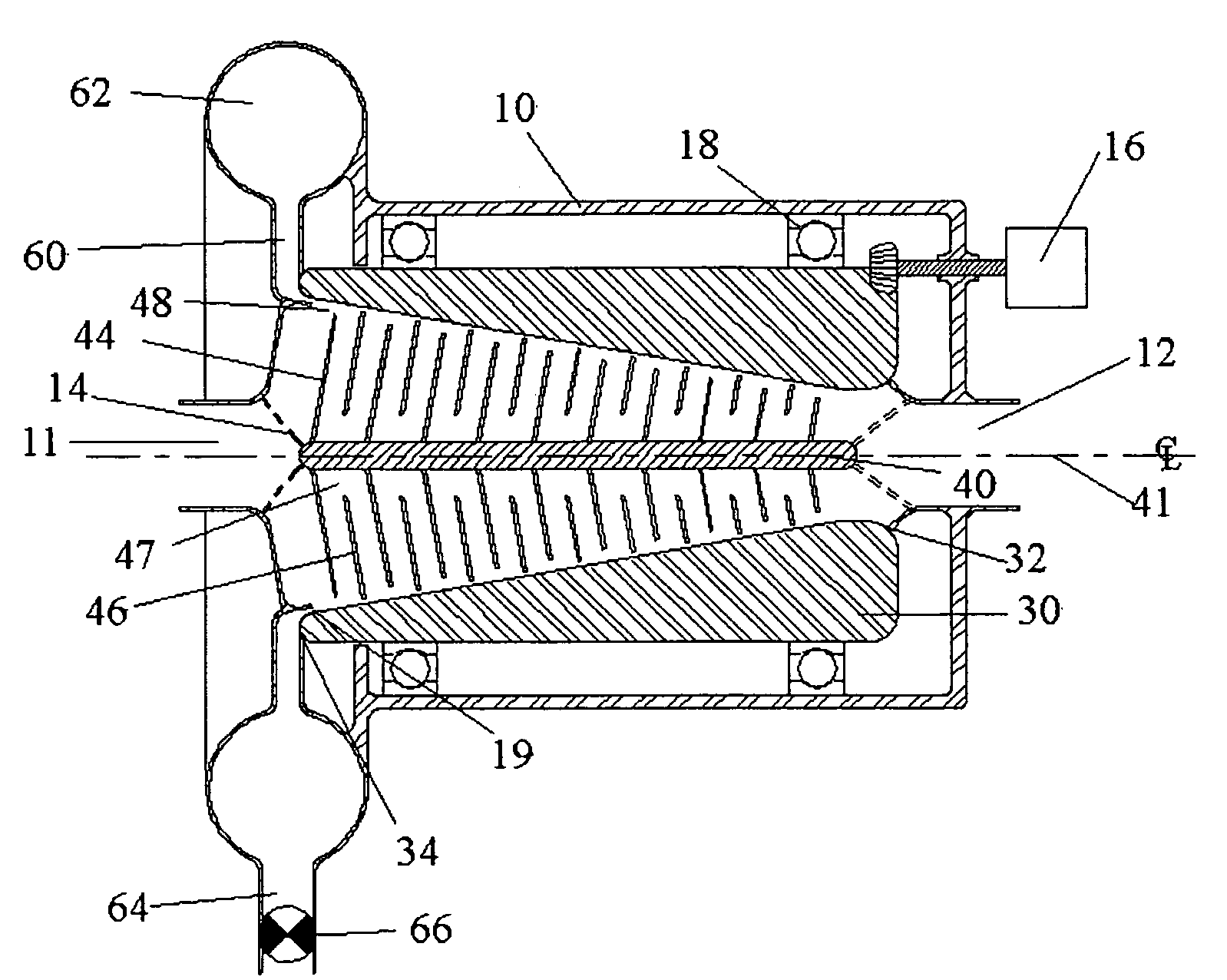

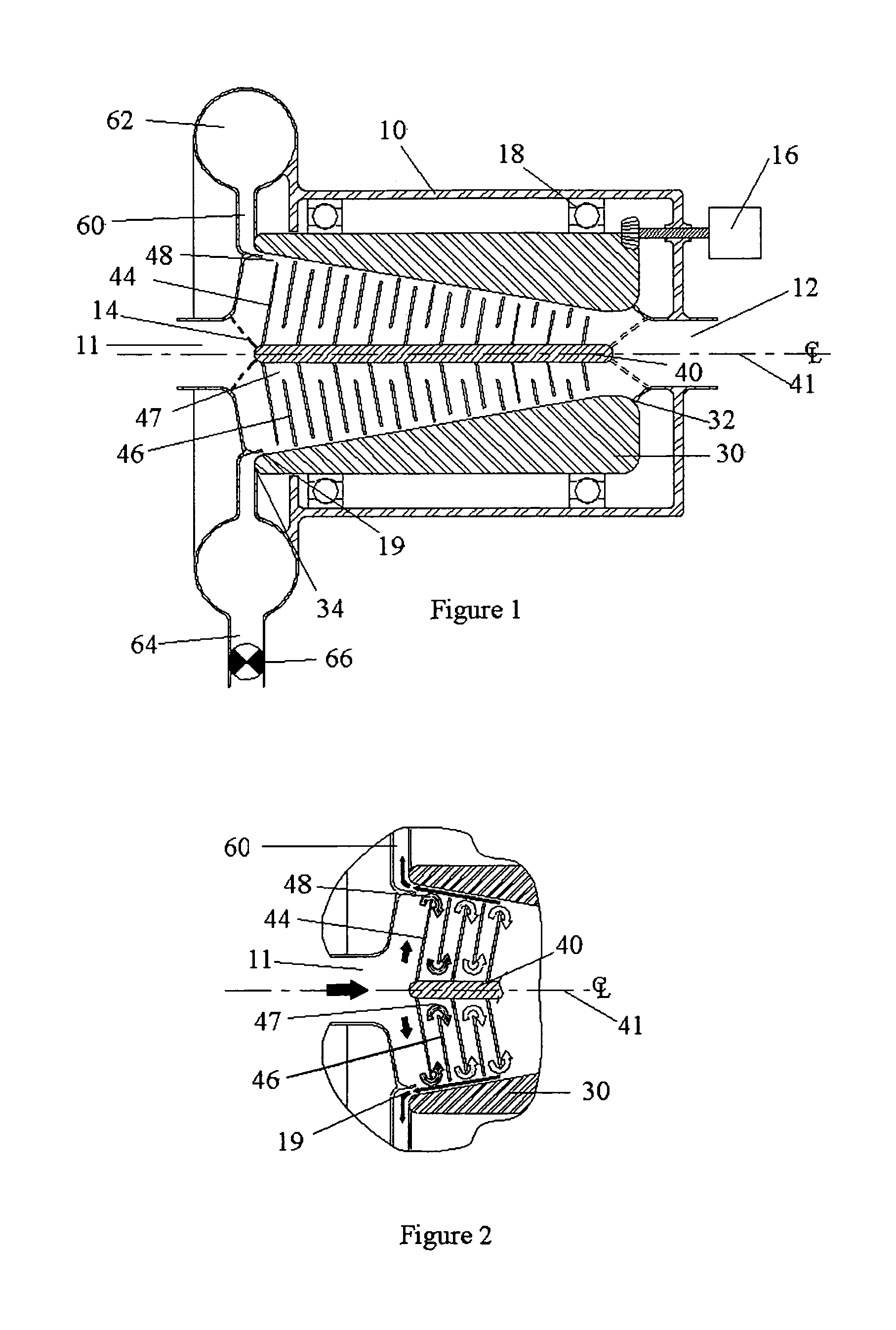

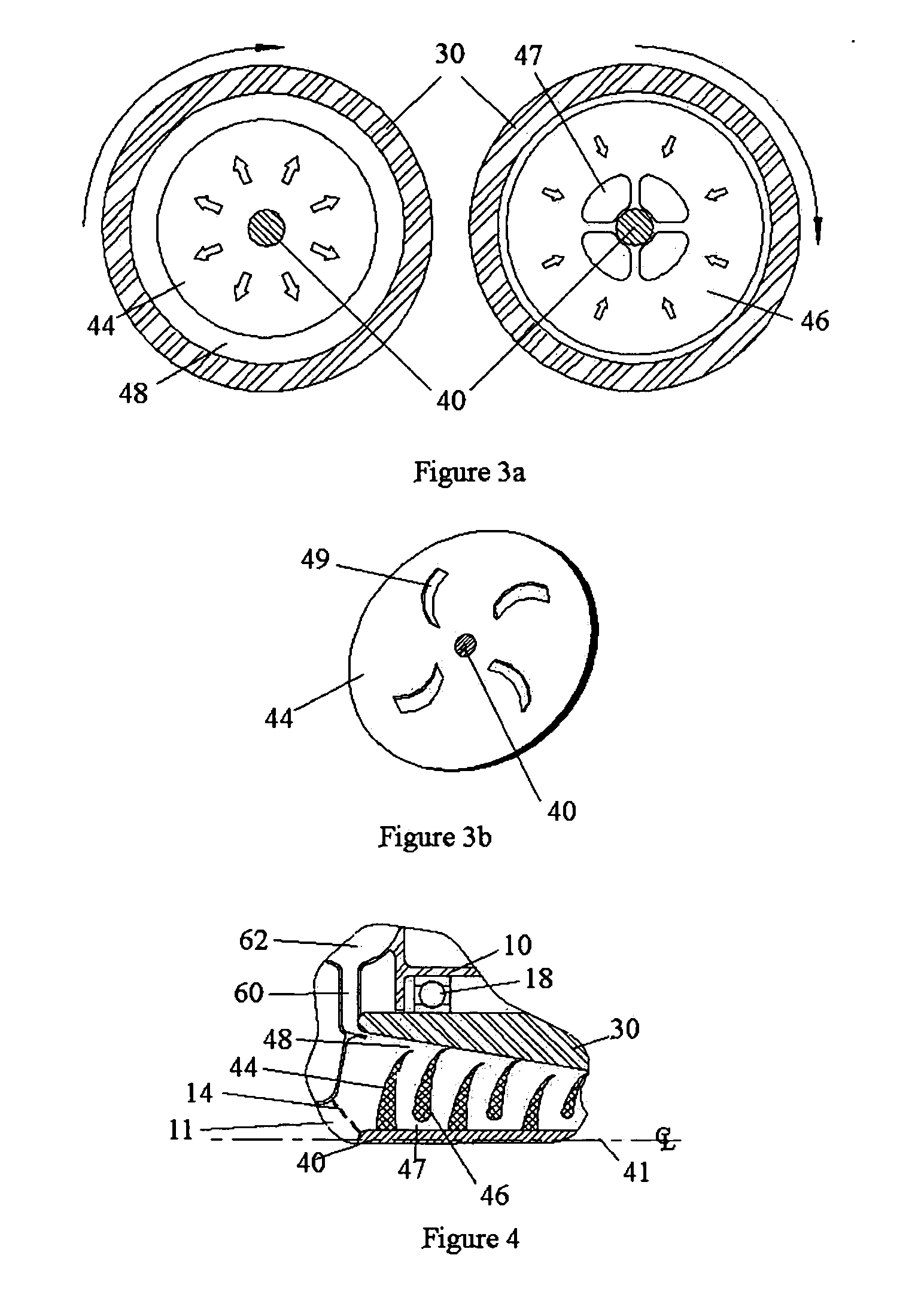

Method and apparatus for separating particles

InactiveUS20080009402A1Meet cutting requirementsSmall sizeCombination devicesDispersed particle filtrationEnergy transferParticle physics

A method and apparatus for separating particles preferentially accelerates particles to a rotating collector, which then reliably conveys collected particles to a discharge with minimal re-entrainment of the particles in the fluid stream. The collector minimizes energy transfer to the fluid and maximizes separation under conditions of high particle loading, fine particle content, or both. The separator may be operated in any vertical, horizontal or oblique orientation, or within devices whose orientation varies over time.

Owner:WELLS PRODS GROUP

Method and apparatus for separating particles

InactiveUS7569094B2Meet cutting requirementsSmall sizeCombination devicesDispersed particle filtrationEnergy transferParticle physics

A method and apparatus for separating particles preferentially accelerates particles to a rotating collector, which then reliably conveys collected particles to a discharge with minimal re-entrainment of the particles in the fluid stream. The collector minimizes energy transfer to the fluid and maximizes separation under conditions of high particle loading, fine particle content, or both. The separator may be operated in any vertical, horizontal or oblique orientation, or within devices whose orientation varies over time.

Owner:WELLS PRODS GROUP

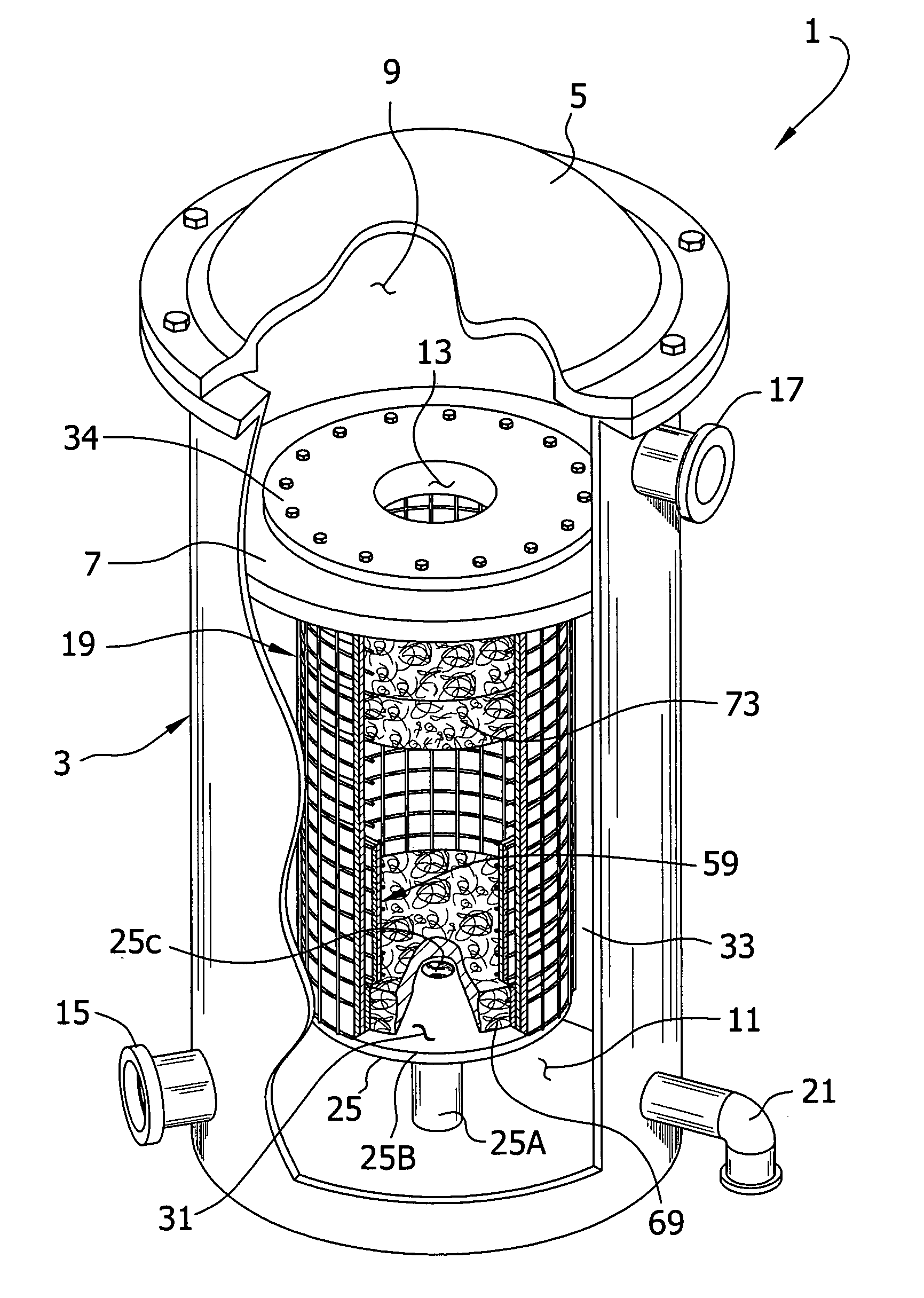

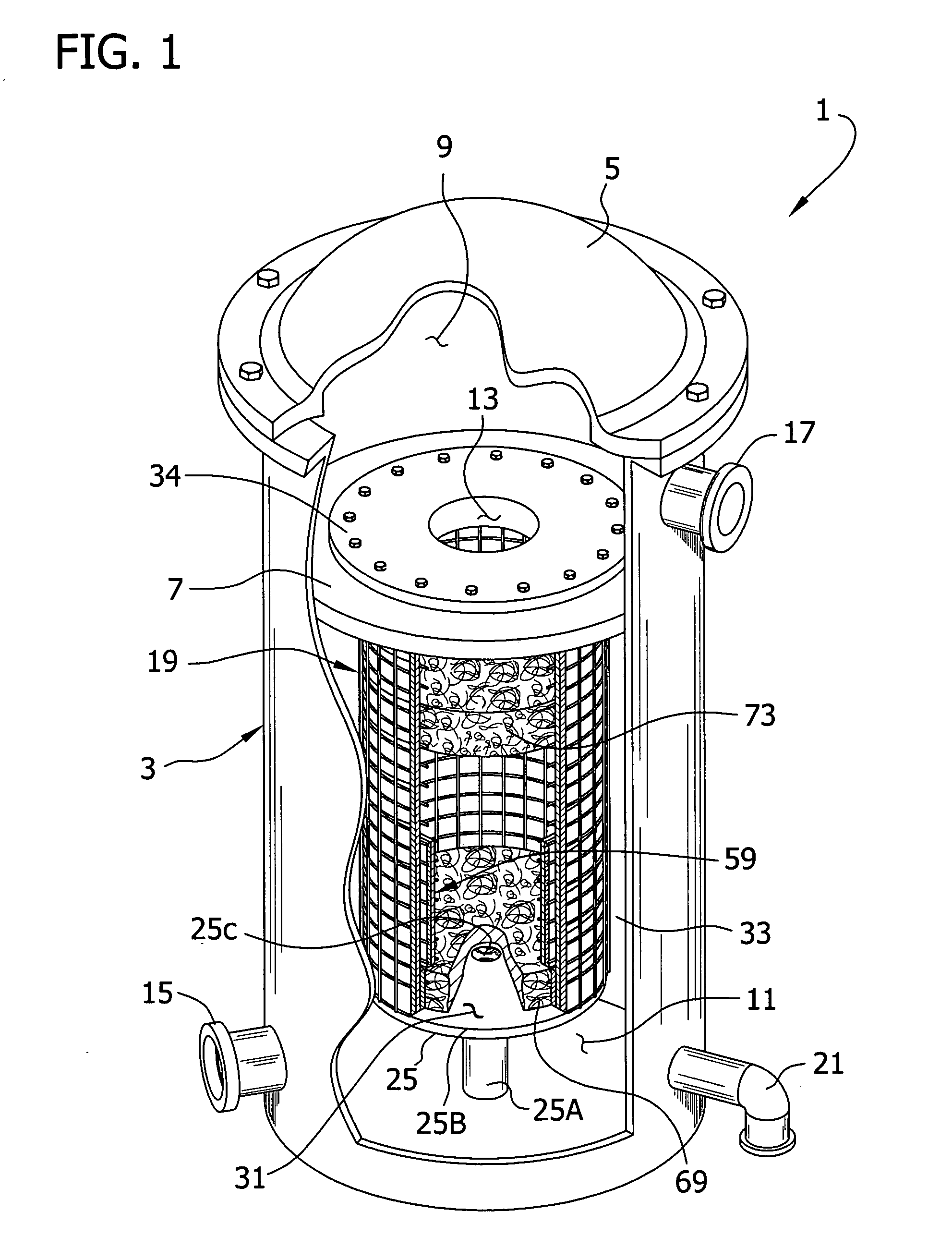

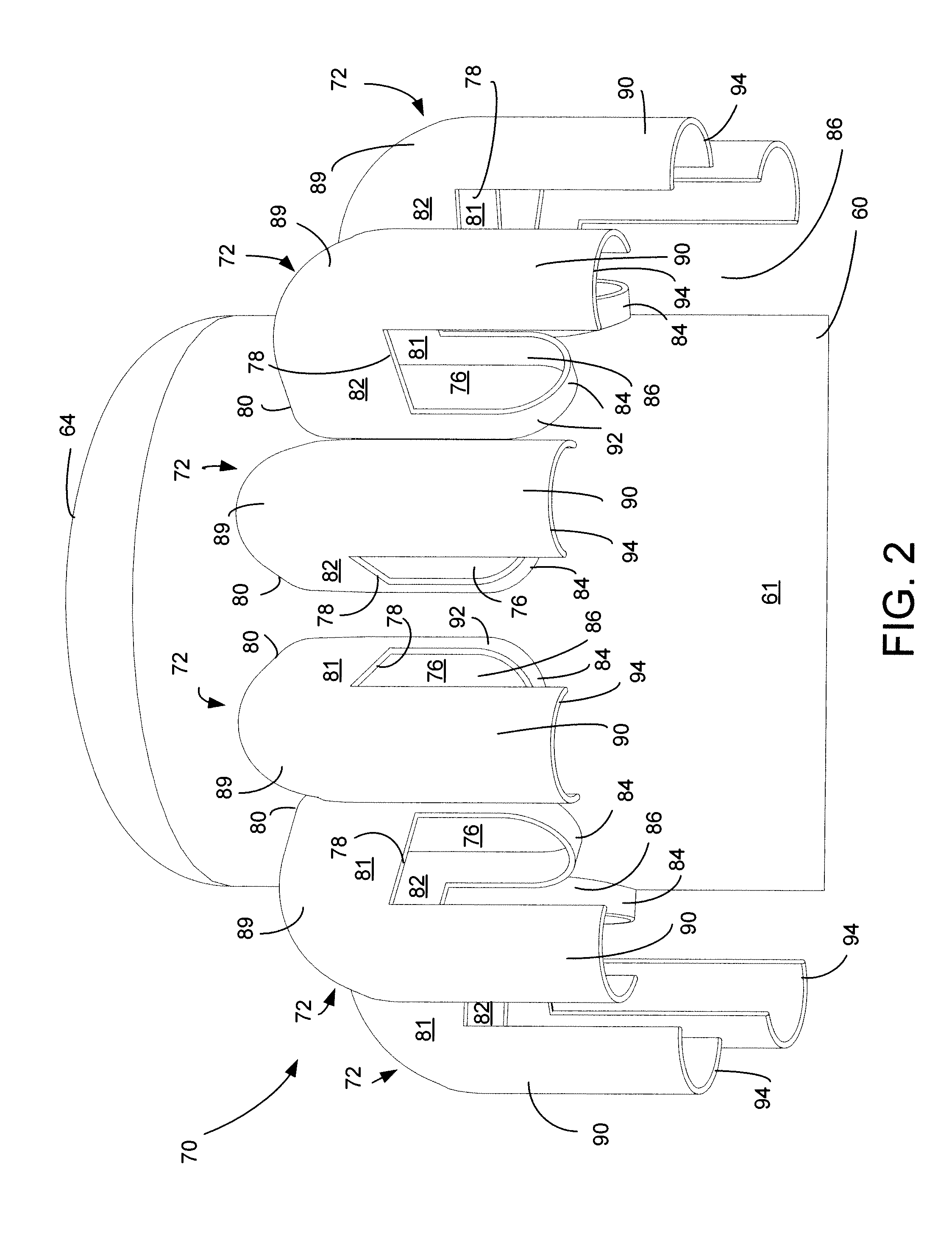

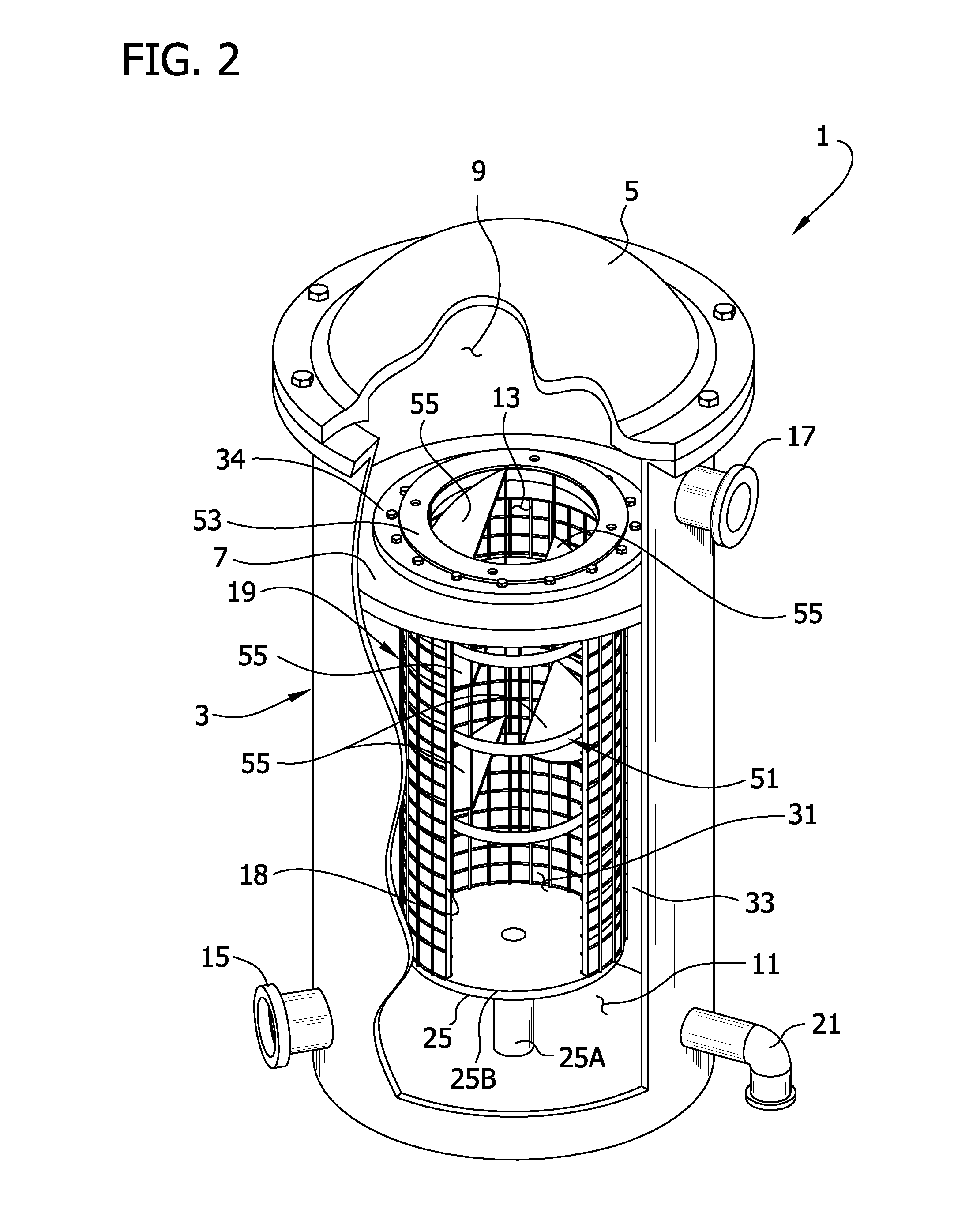

Fiber bed assembly including a re-entrainment control device for a fiber bed mist eliminator

A fiber bed assembly used to remove aerosols and / or wetted soluble solids from a moving gas stream includes a fiber bed support and a fiber bed supported by the fiber bed support so that the gas stream passes through the fiber bed moving from an upstream space to a downstream space with respect to the fiber bed. A re-entrainment control device is located within a downstream space defined by the fiber bed so that at least a portion of the gas stream passes through the re-entrainment control device. The re-entrainment control device is shaped to change the direction of the average flow path of the gas stream as the gas stream passes through the re-entrainment control device so as to cause aerosols and / or wettable solids contained therein to be separated from the gas stream by inertial force. A re-entrainment control device and method of use are also disclosed.

Owner:MECS

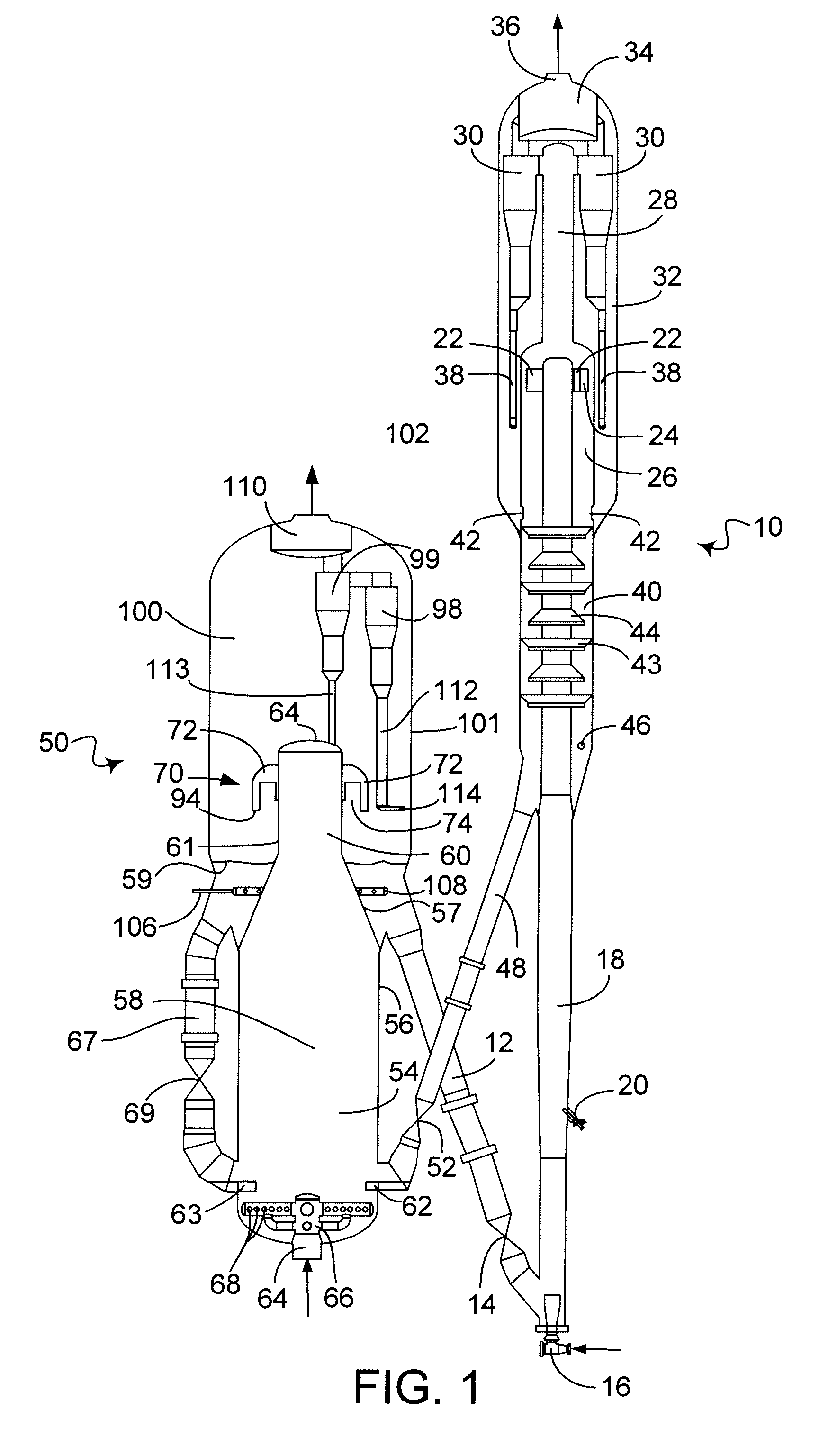

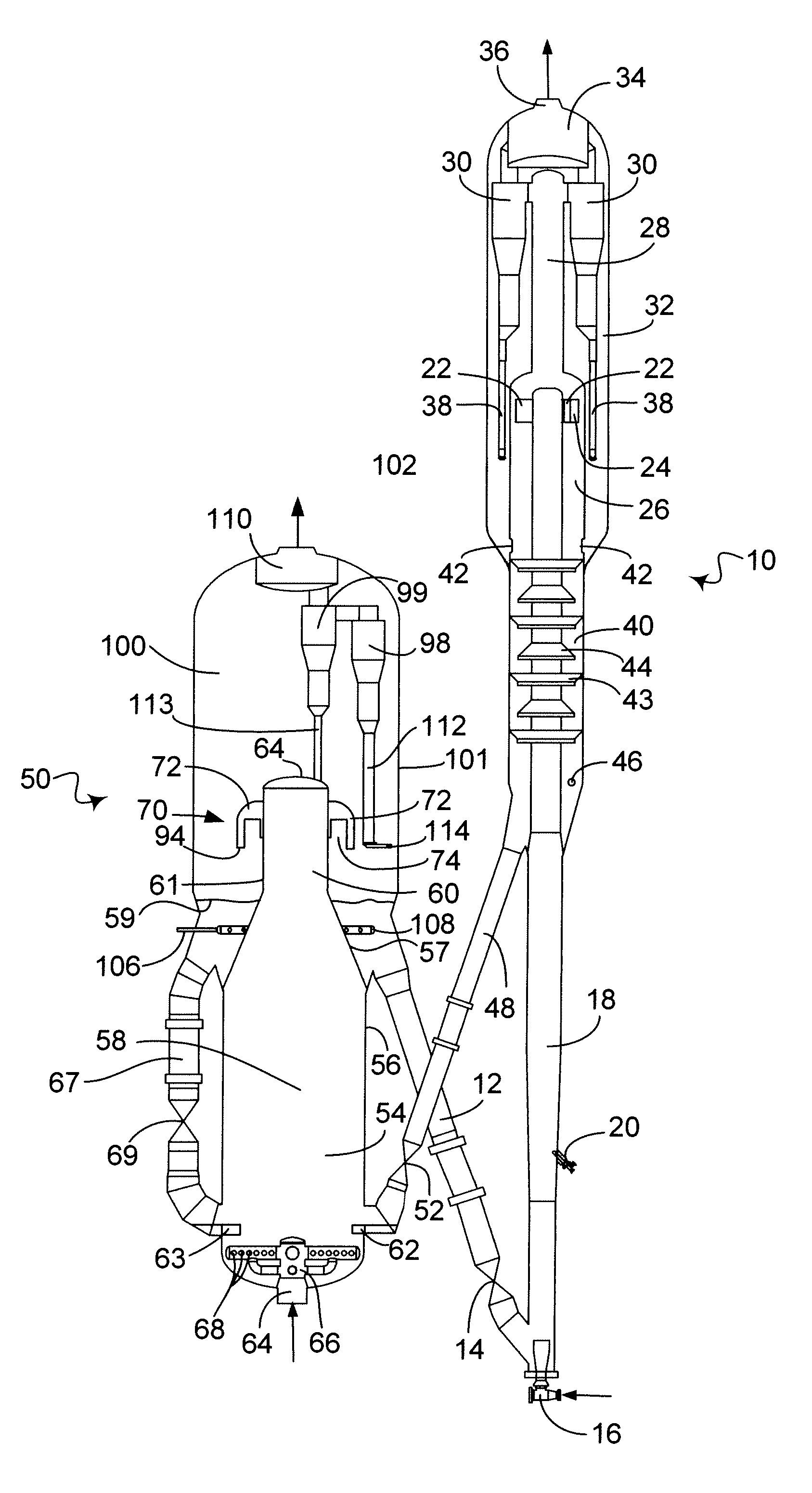

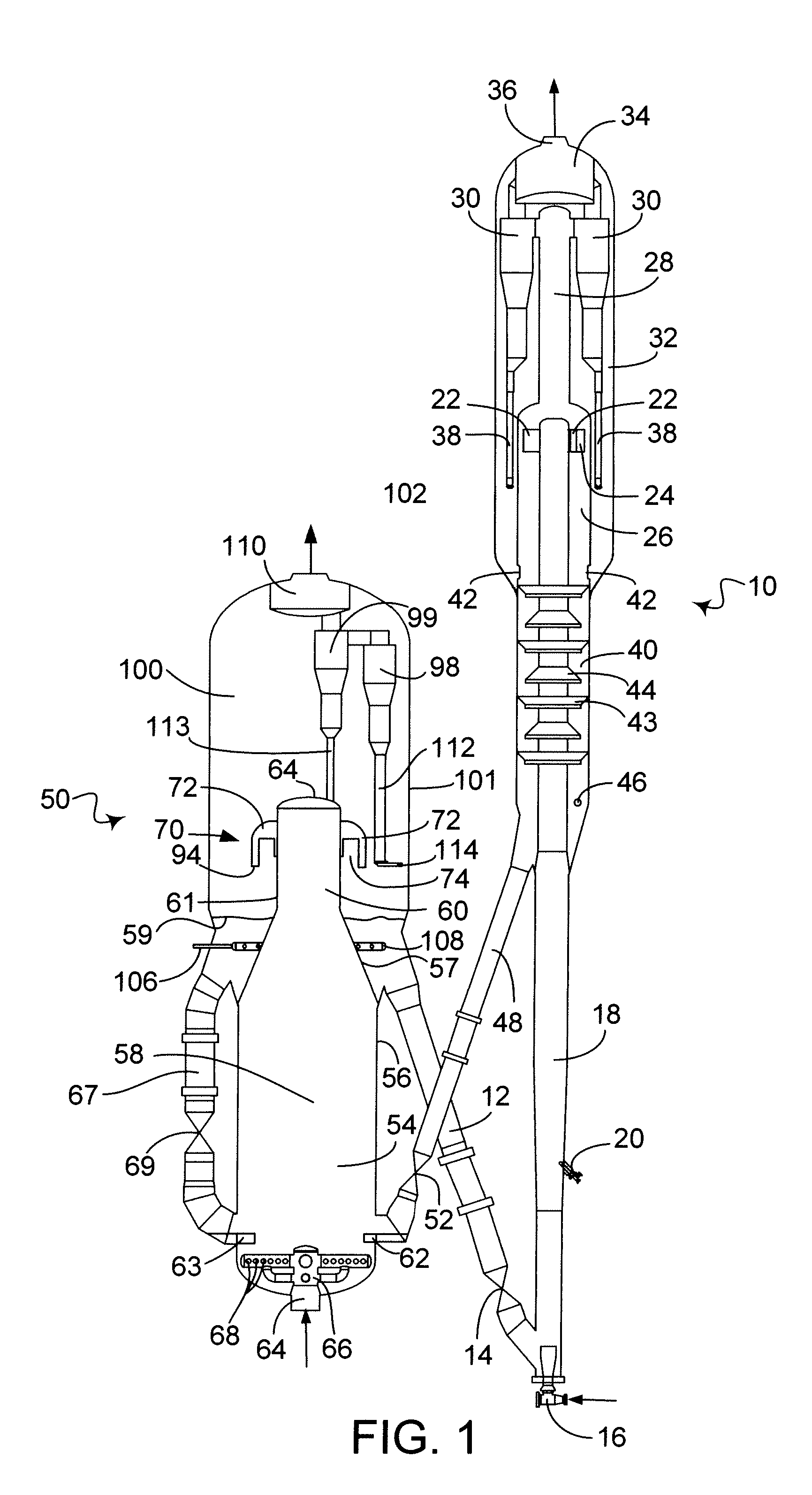

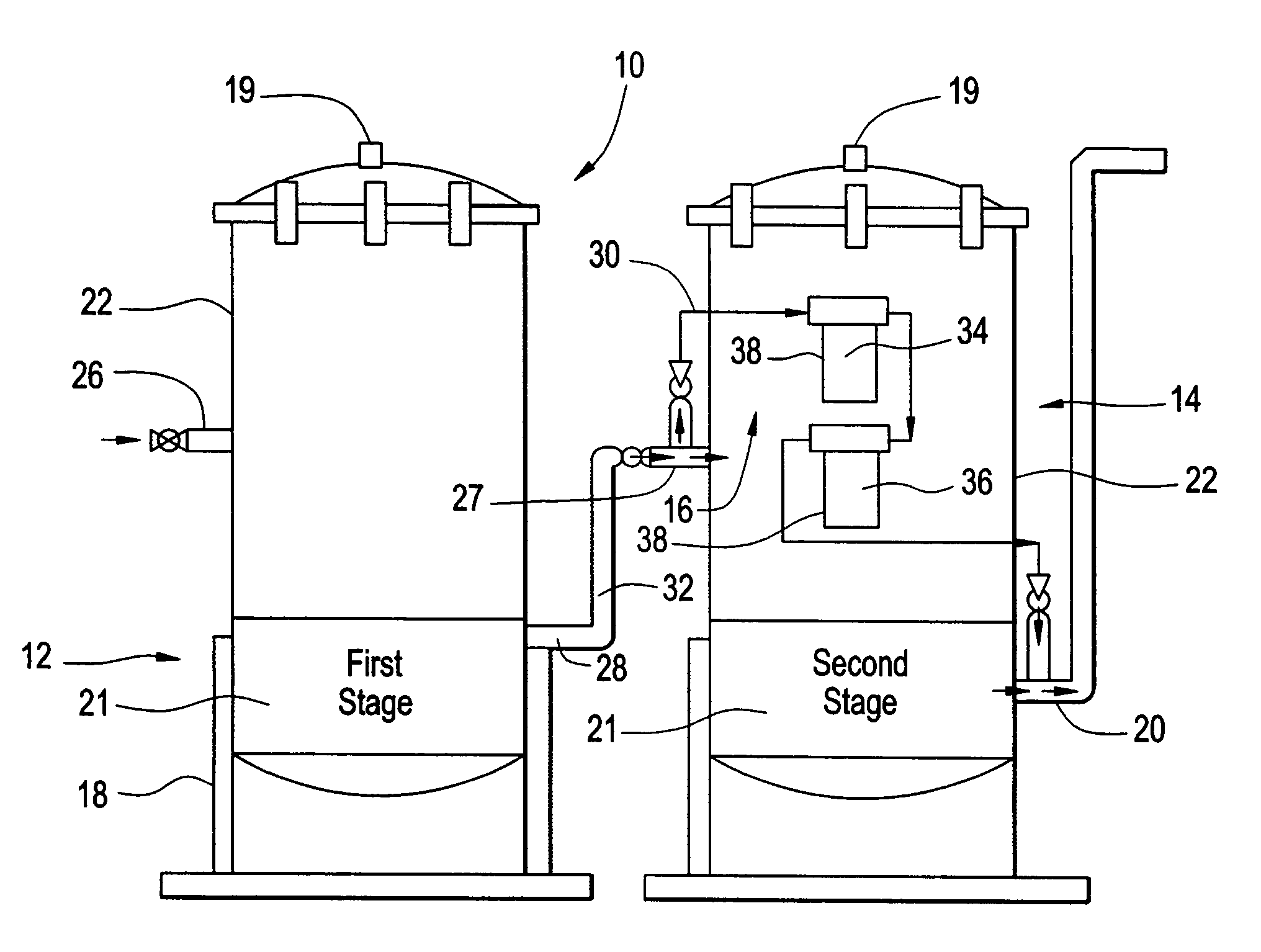

Apparatus and process for regenerating catalyst

ActiveUS7799287B2Increased disengager discharge velocityMinimizing any tendencyCatalytic crackingOther chemical processesFlue gasSurface velocity

Owner:UOP LLC

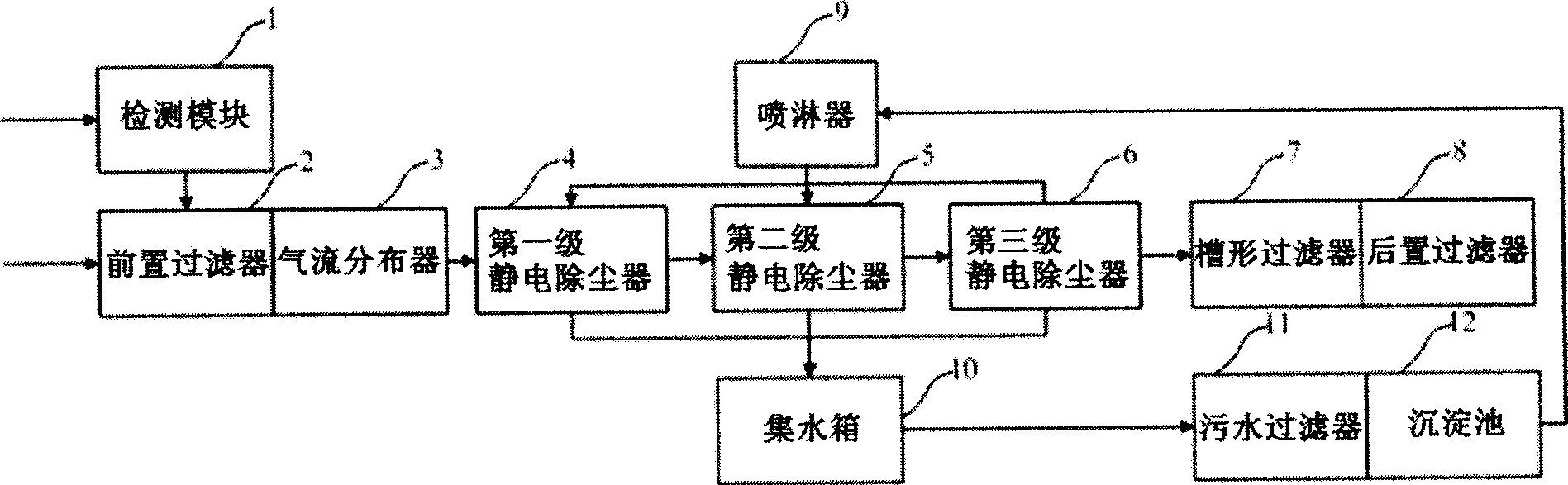

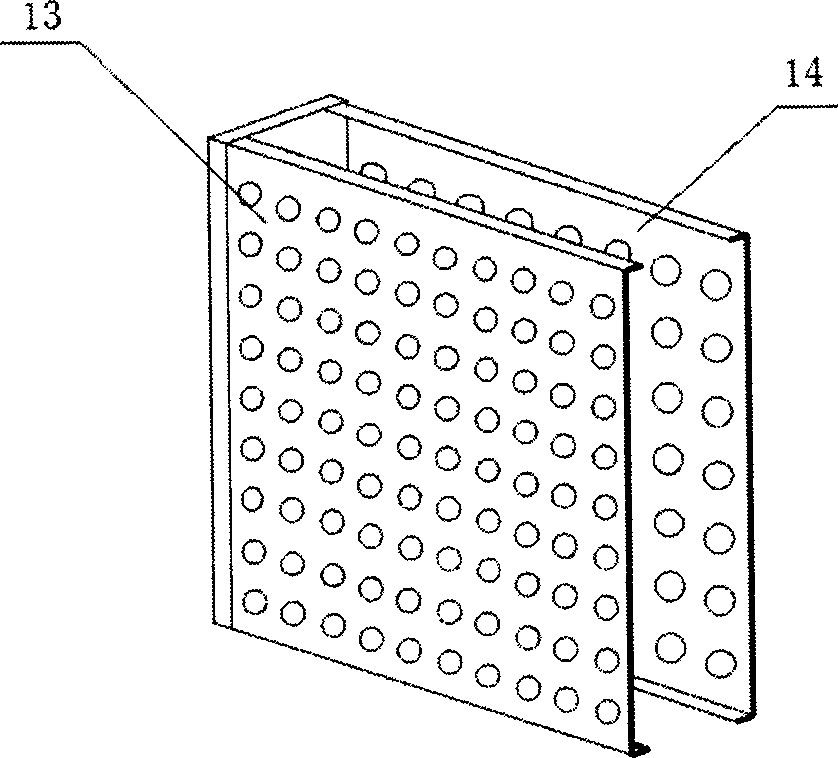

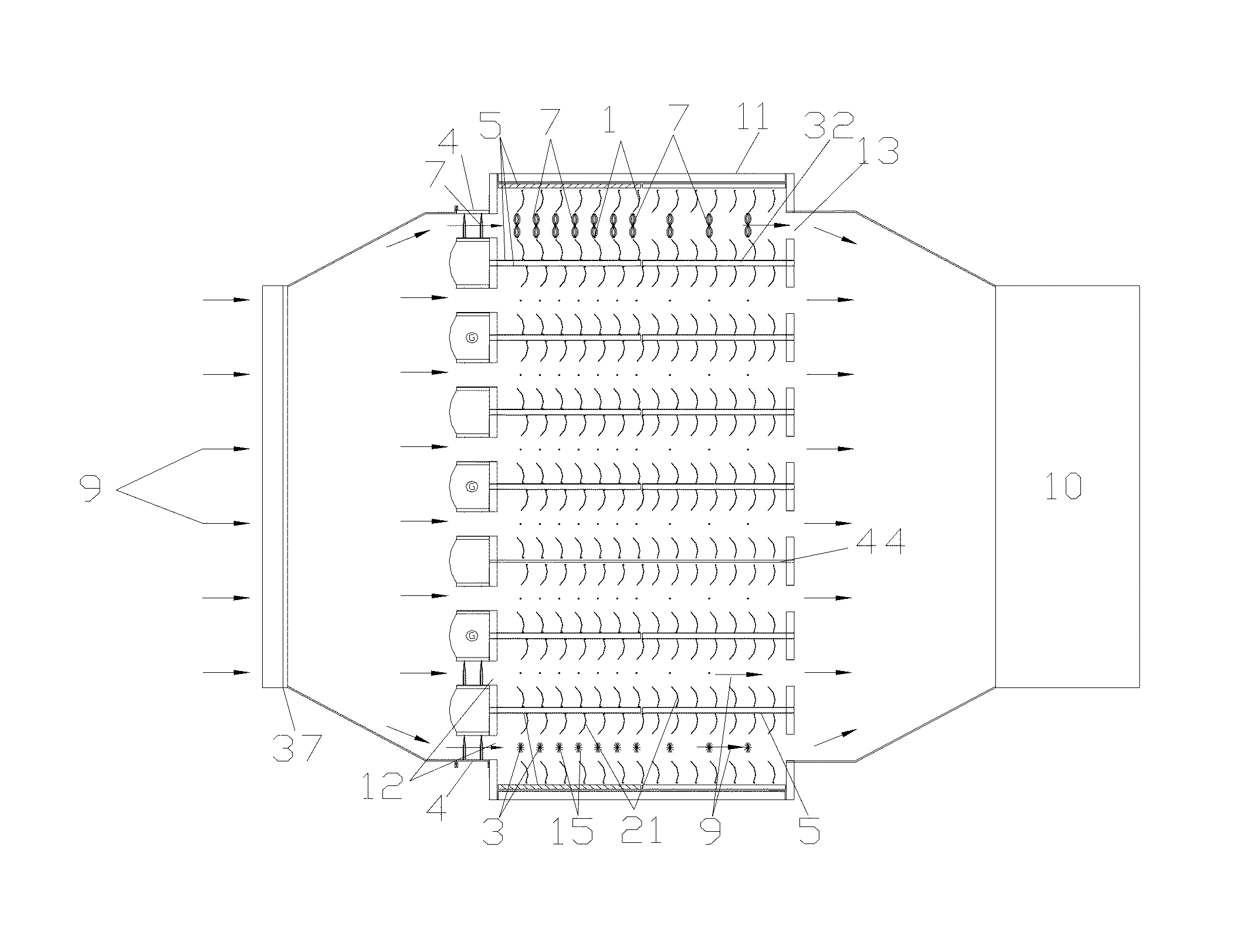

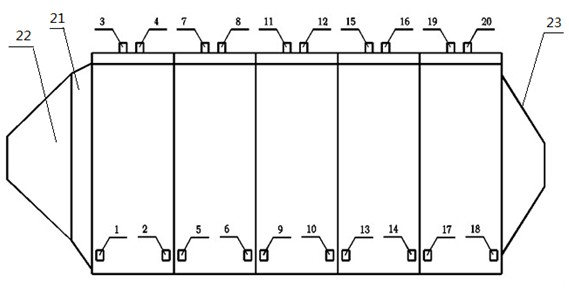

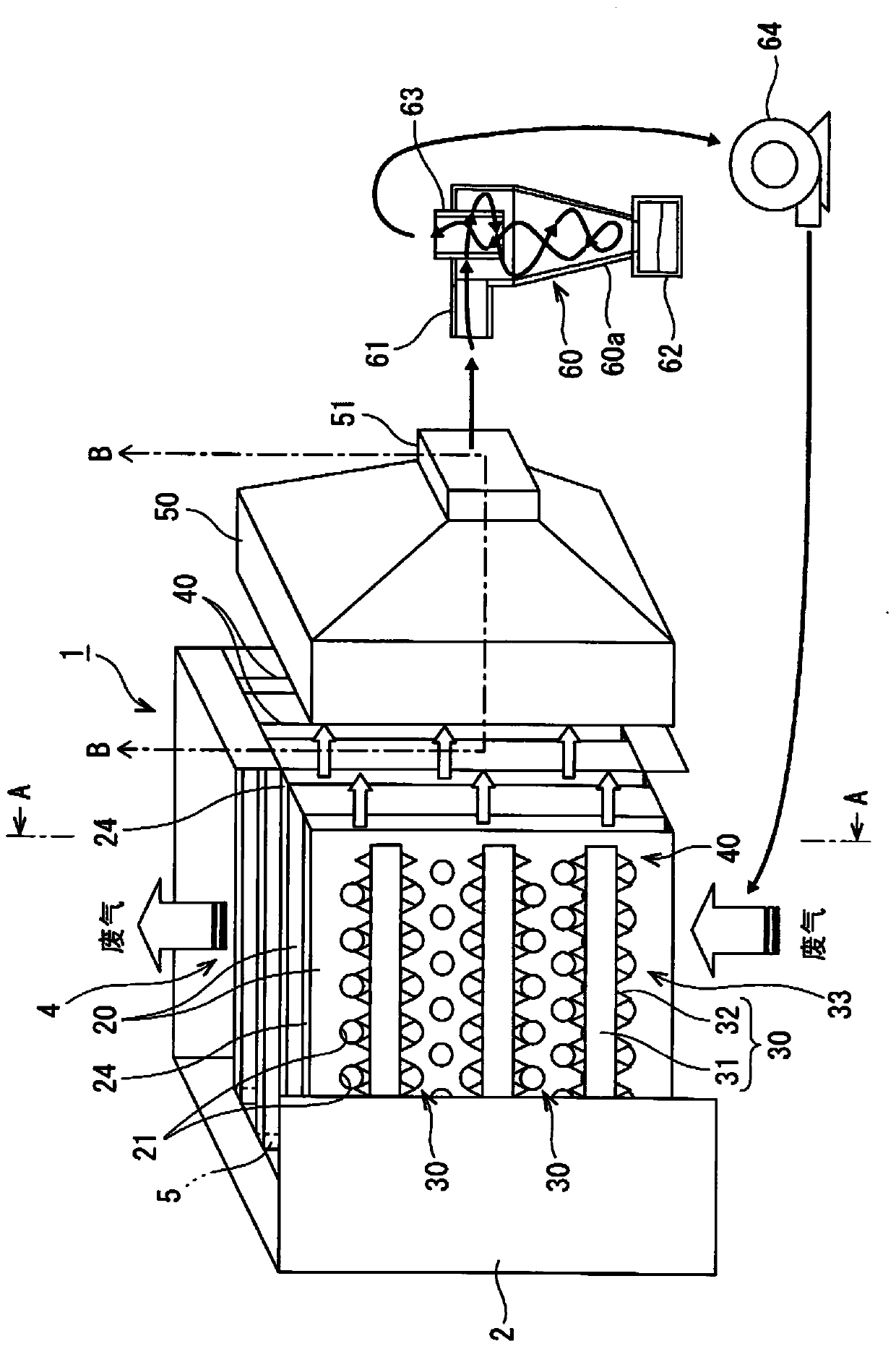

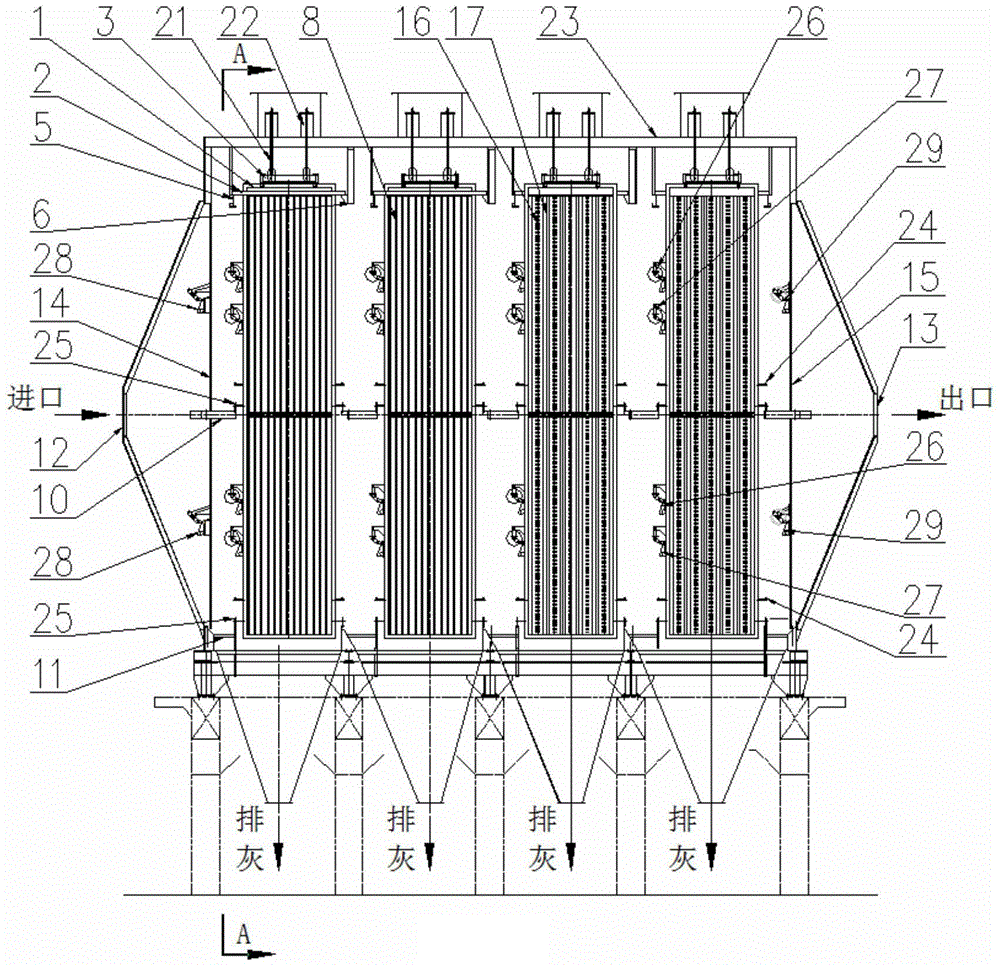

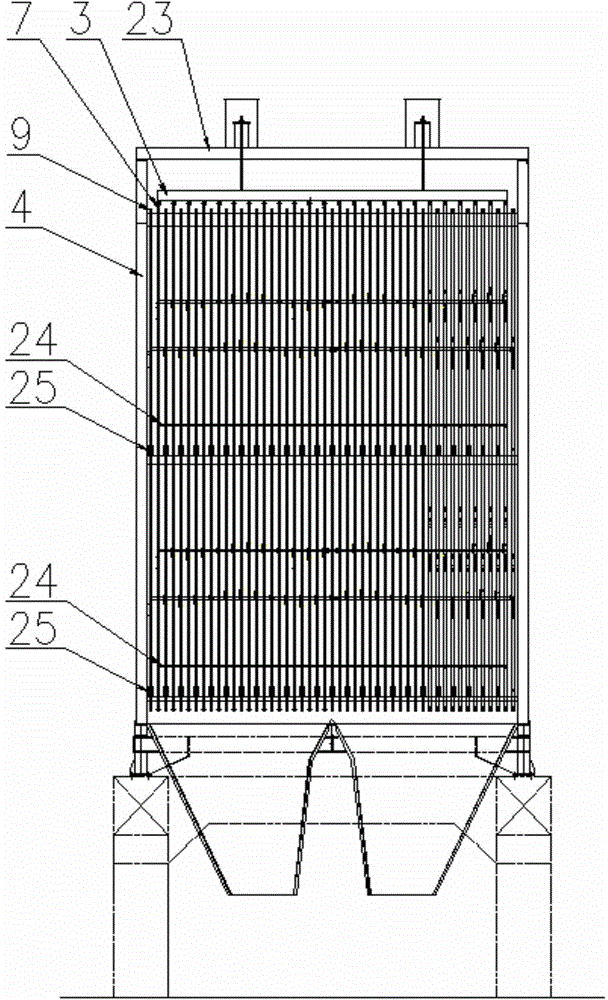

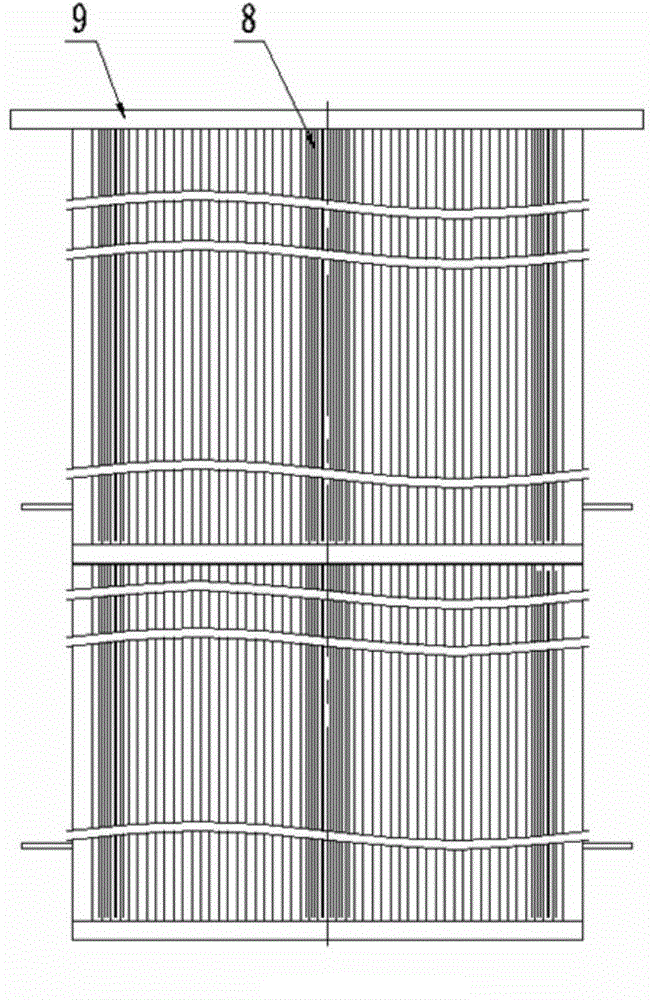

High wind-speed tunnel air electric dust-collection system

InactiveCN101455929ASuppress secondary dustEasy to installCombination devicesProcess moduleEngineering

The invention provides an electrostatic precipitation system for air in a high wind-speed tunnel, which belongs to the technical field of air purification. The system comprises a purification module, a detection module and a cleaning process module, wherein the input ends of the purification module and the detection module both receive tunnel air; the cleaning process module is connected with the purification module; and the purification module comprises a pre-filter, an air flow distributor, an electrostatic precipitator, a slot-formed filter and a post-filter. Under the conditions of wind speed of 4 to 9m / s and dust content of 0.2 to 10mg / m<3>, the dust collection coefficient reaches 90 to 98 percent, and the dust re-entrainment can be effectively restrained; and all parts are designed and manufactured according to modular requirement, so that the system is assembled and disassembled conveniently.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Roof greening structure and construction method

InactiveCN103982009AWith retentionDelay structural agingRoof improvementClimate change adaptationVegetationEngineering

The invention discloses a roof greening structure and a construction method. The roof greening structure comprises a waterproof polyurethane layer, a mortar protection layer, a waterproof leakproof two-cloth one-film layer, a plastic roof plant support module, a permeable filter layer, a filter layer, a matrix layer, a permeable filter layer, a plant layer and a vegetation layer which are overlapped or paved on the roof in sequence from the bottom to top. The roof greening structure is simple in structure, easy to implement and obvious in effect. The roof greening structure has advantages of heat insulation, rainwater interception, dust re-entrainment reducing, building structure aging delaying and building life span prolonging.

Owner:ANHUI GREEN BUILDING TECH

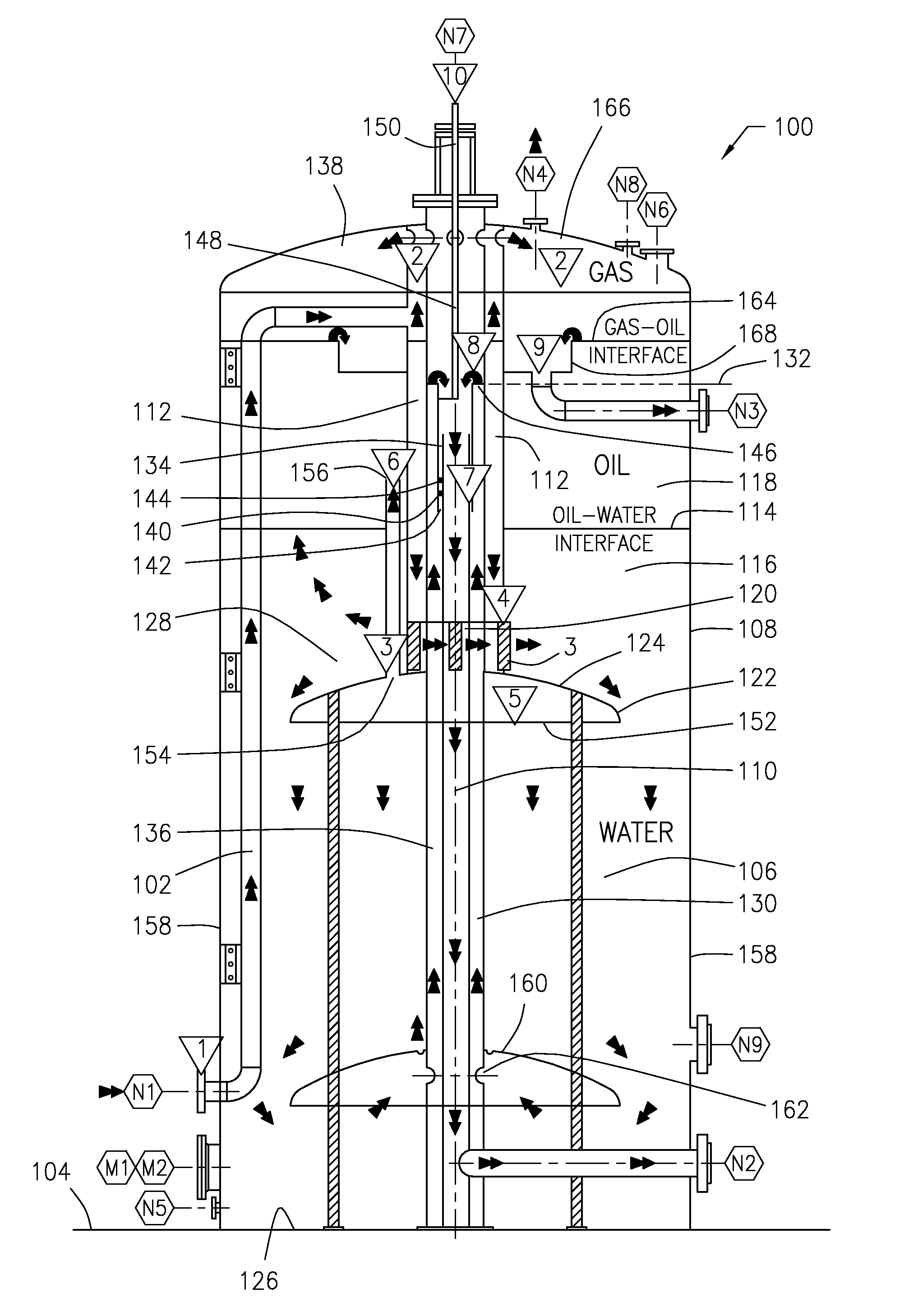

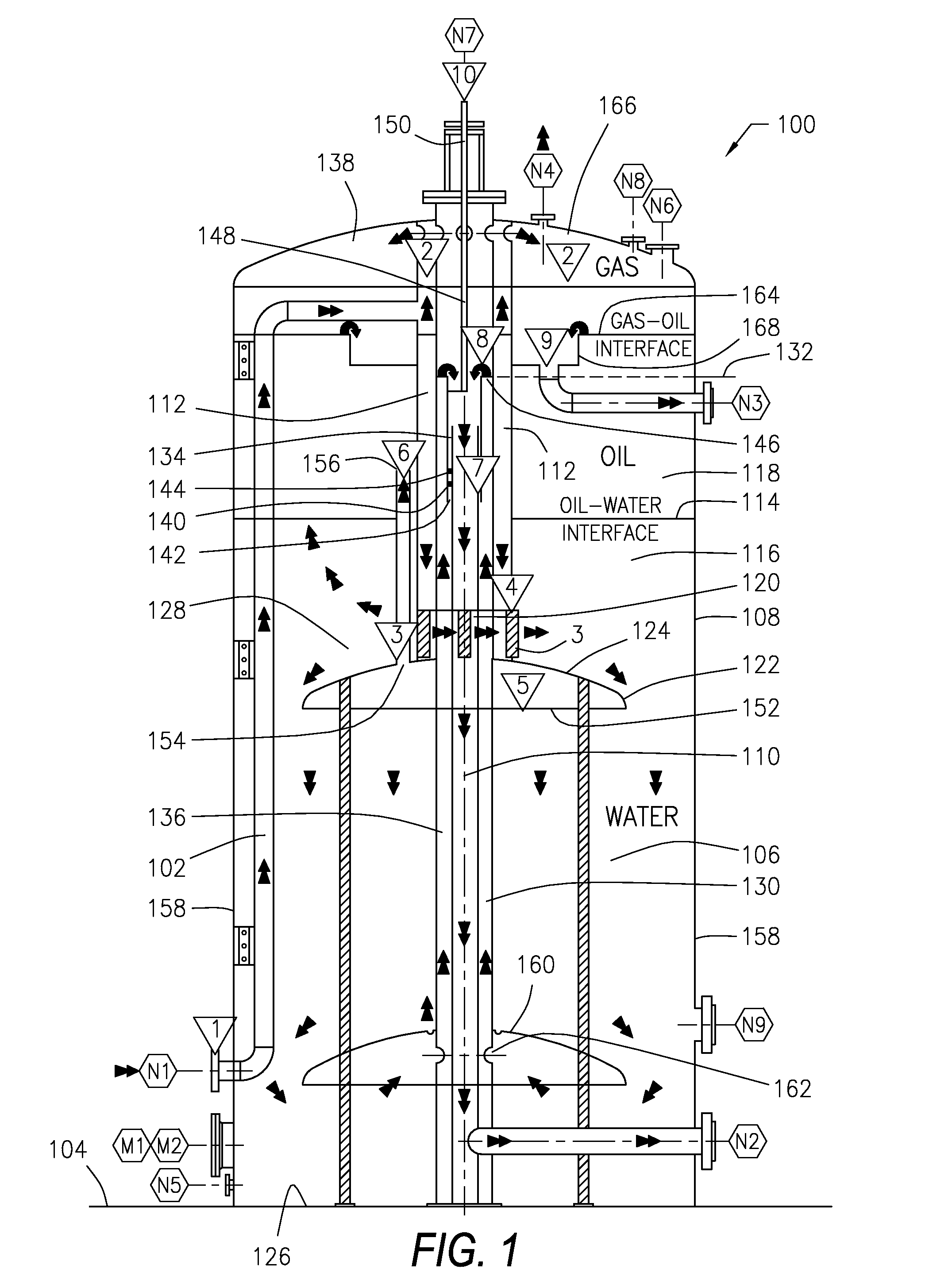

Apparatus for separating oil well products

ActiveUS8496740B1Prevents re-entrainmentPrevents separation upsetLiquid degasificationFluid removalOil waterResidence time

An atmospheric oil, water and gas separator designed for oilfield applications having ground level inlet, internal water leg, internal piping, a degassing chamber, a horizontal inlet fluid swirl wing distributor that creates centrifugal spiraling of inlet fluids to slow and increase flow residence time, a horizontal swirl wing baffle above the inlet that minimizes oil re-entrainment by preventing turbulence at the oil-water interface, an inverted upper spreader that prevents solids plugging and performance deterioration, an oil conduit extending from the lower surface of the inverted upper spreader to the oil layer to prevent re-entrainment of separated oil in the inlet water turbulent zone, an externally adjustable slide tube for the water leg spillover weir tube, engineered water and oil spillover weirs that prevent separator upsets and overflows, and a water leg adjuster providing fine tuning of the height of the water leg from outside the vessel without shutdown.

Owner:KBK IND

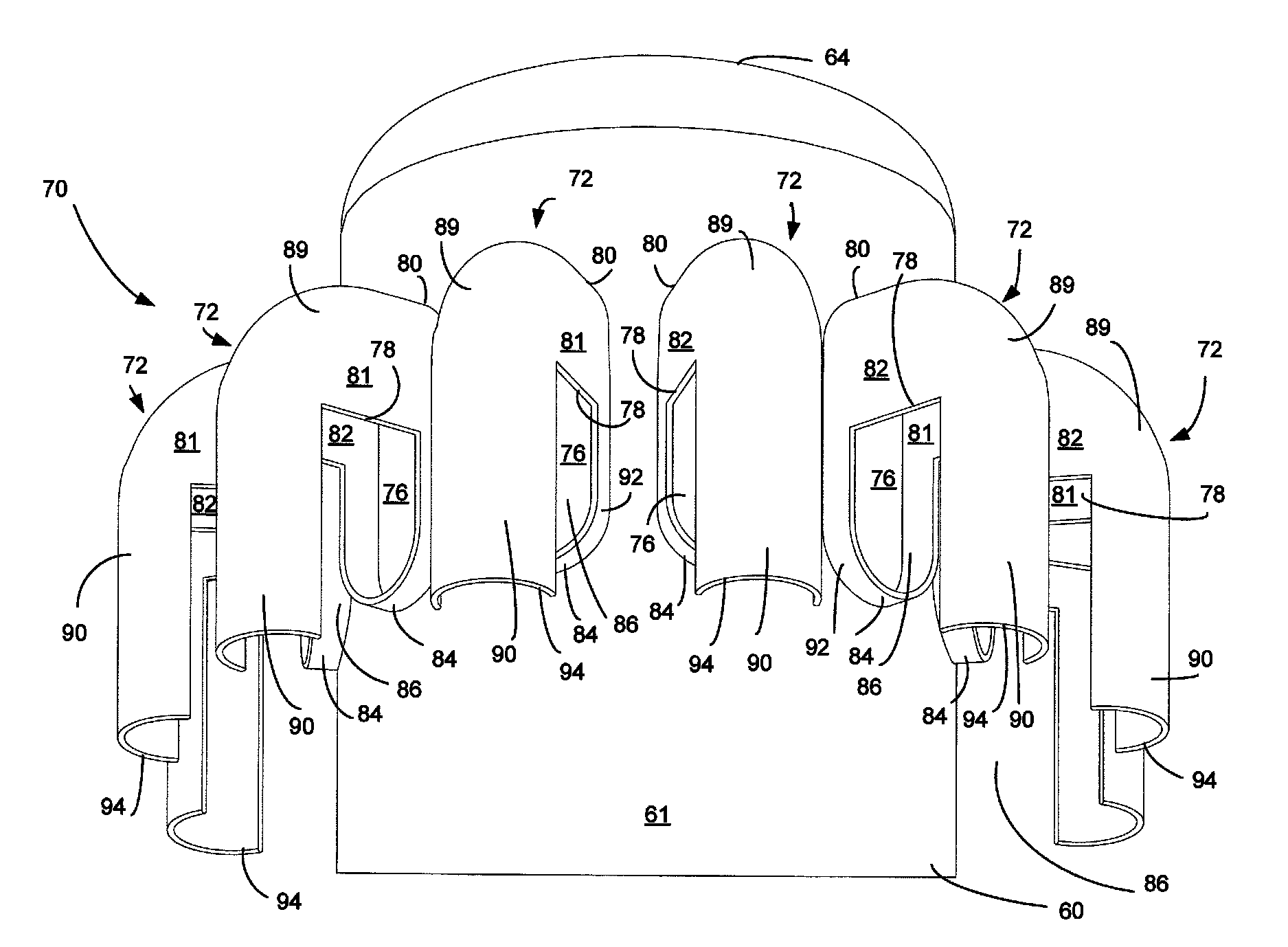

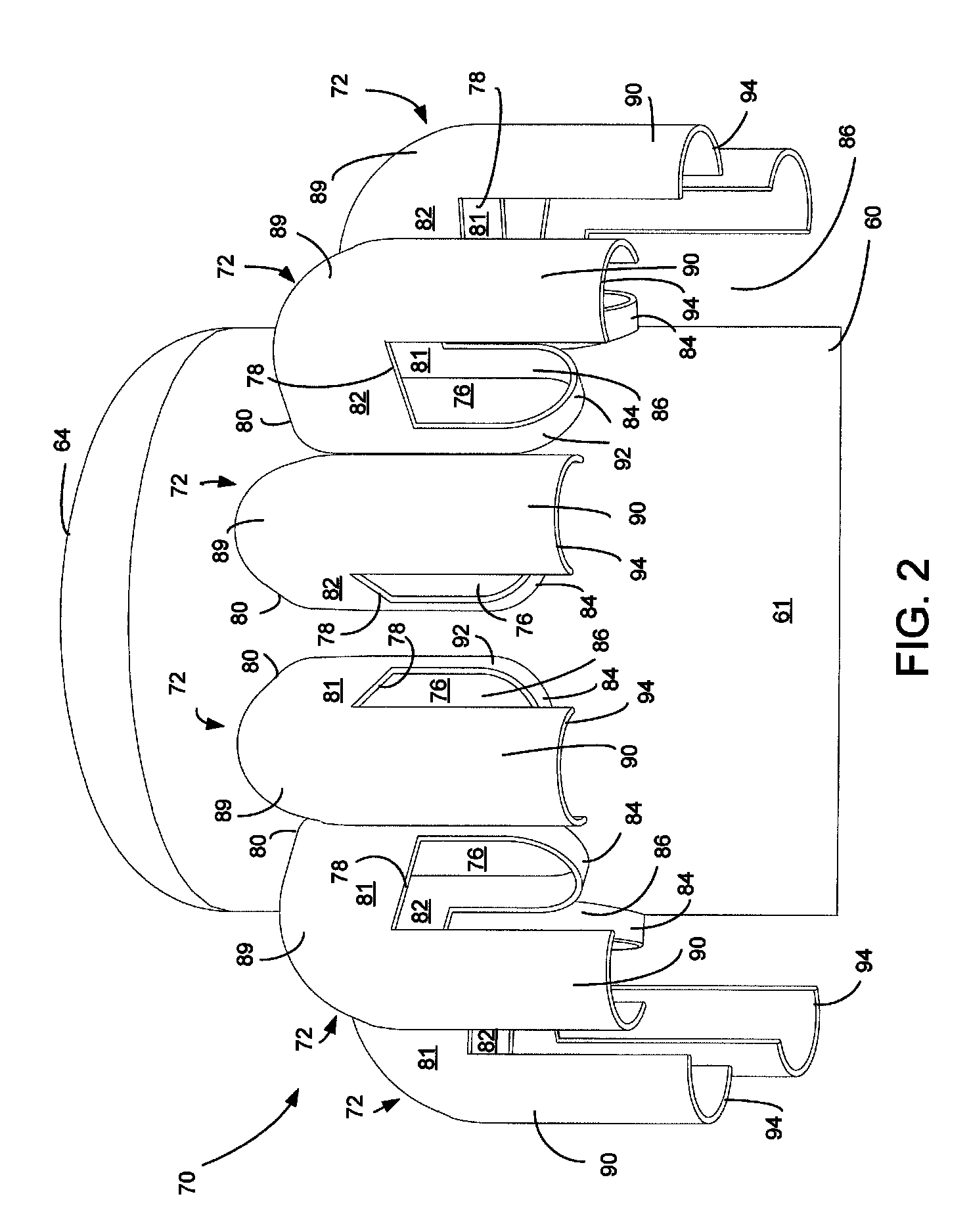

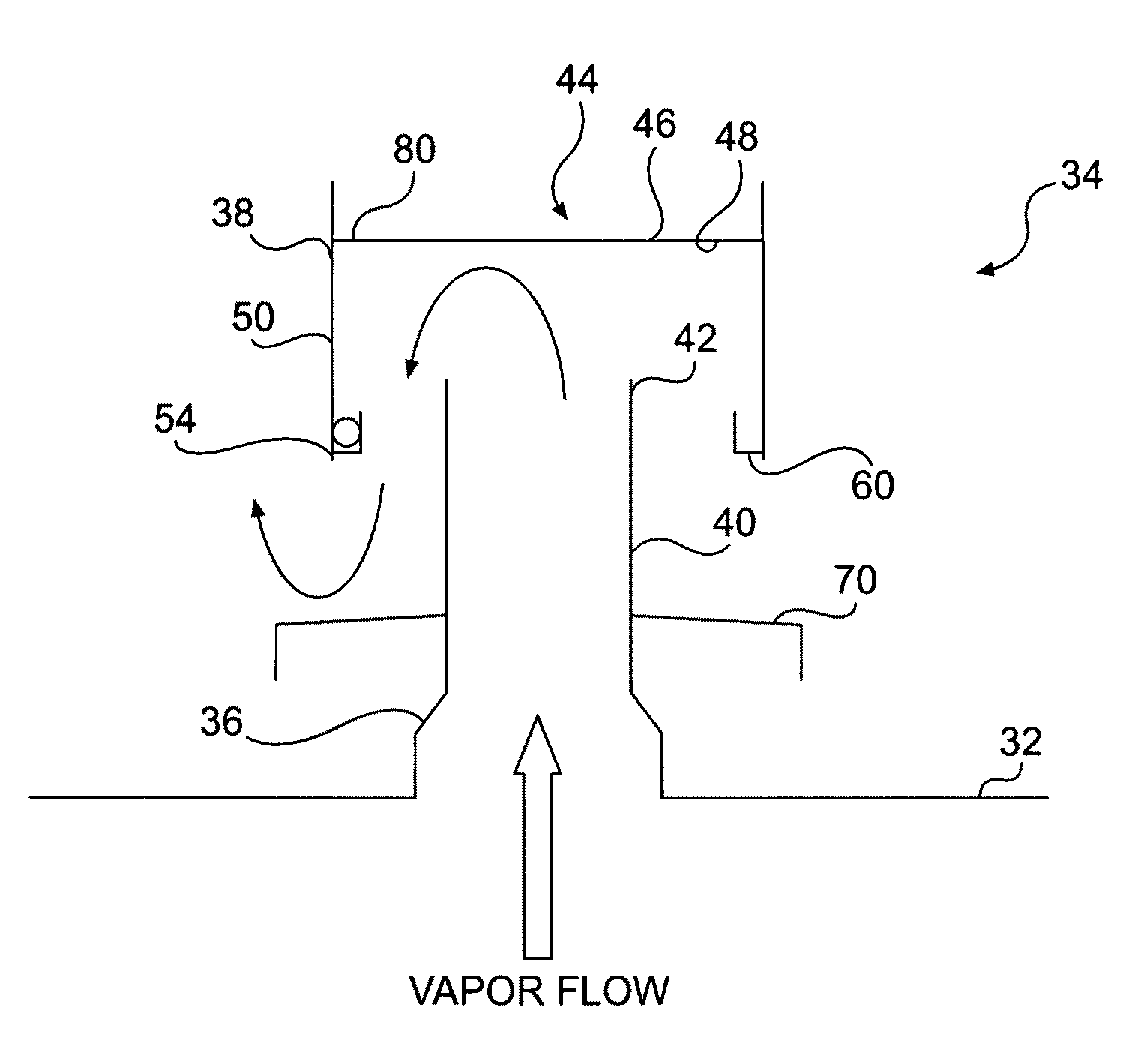

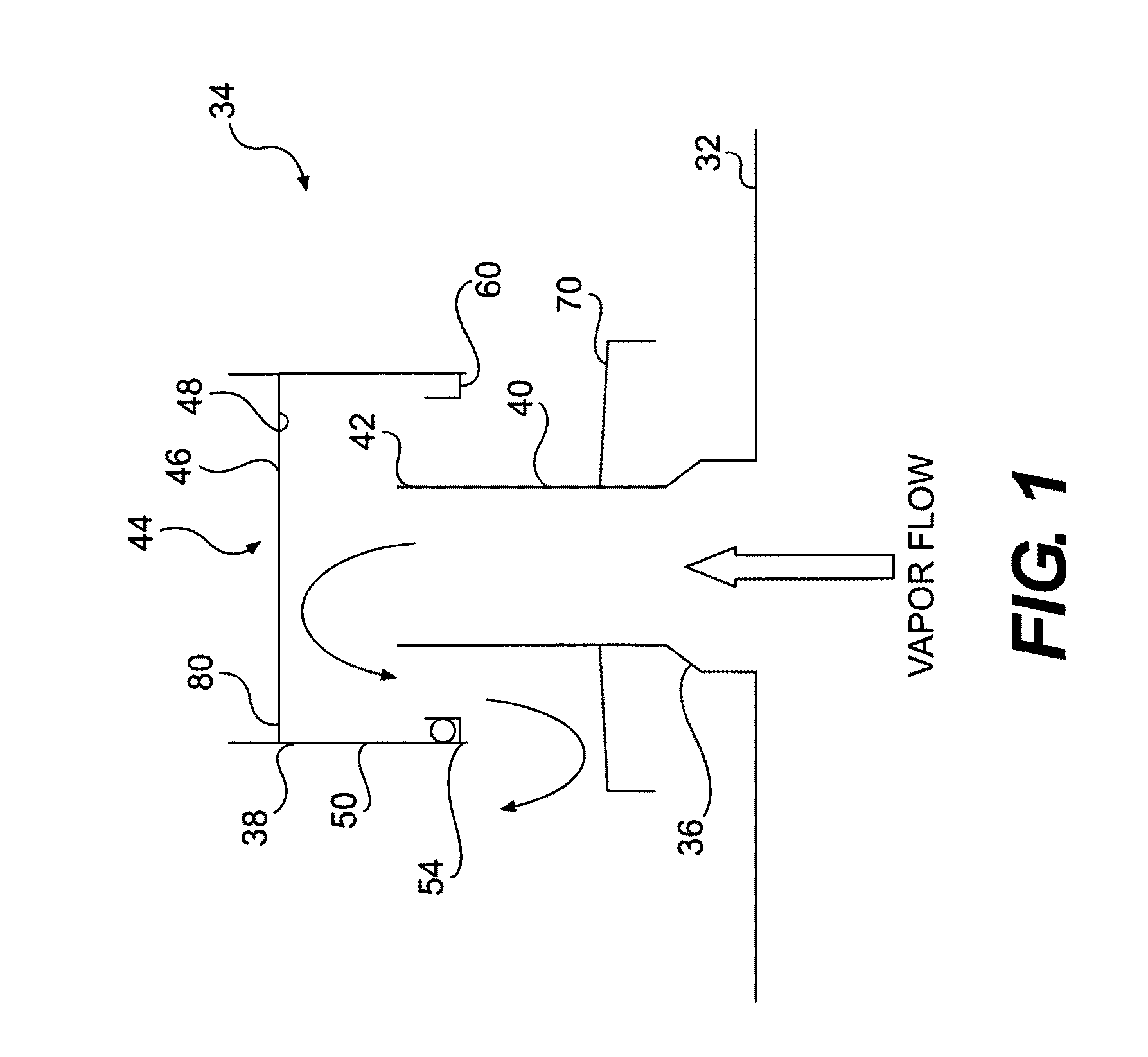

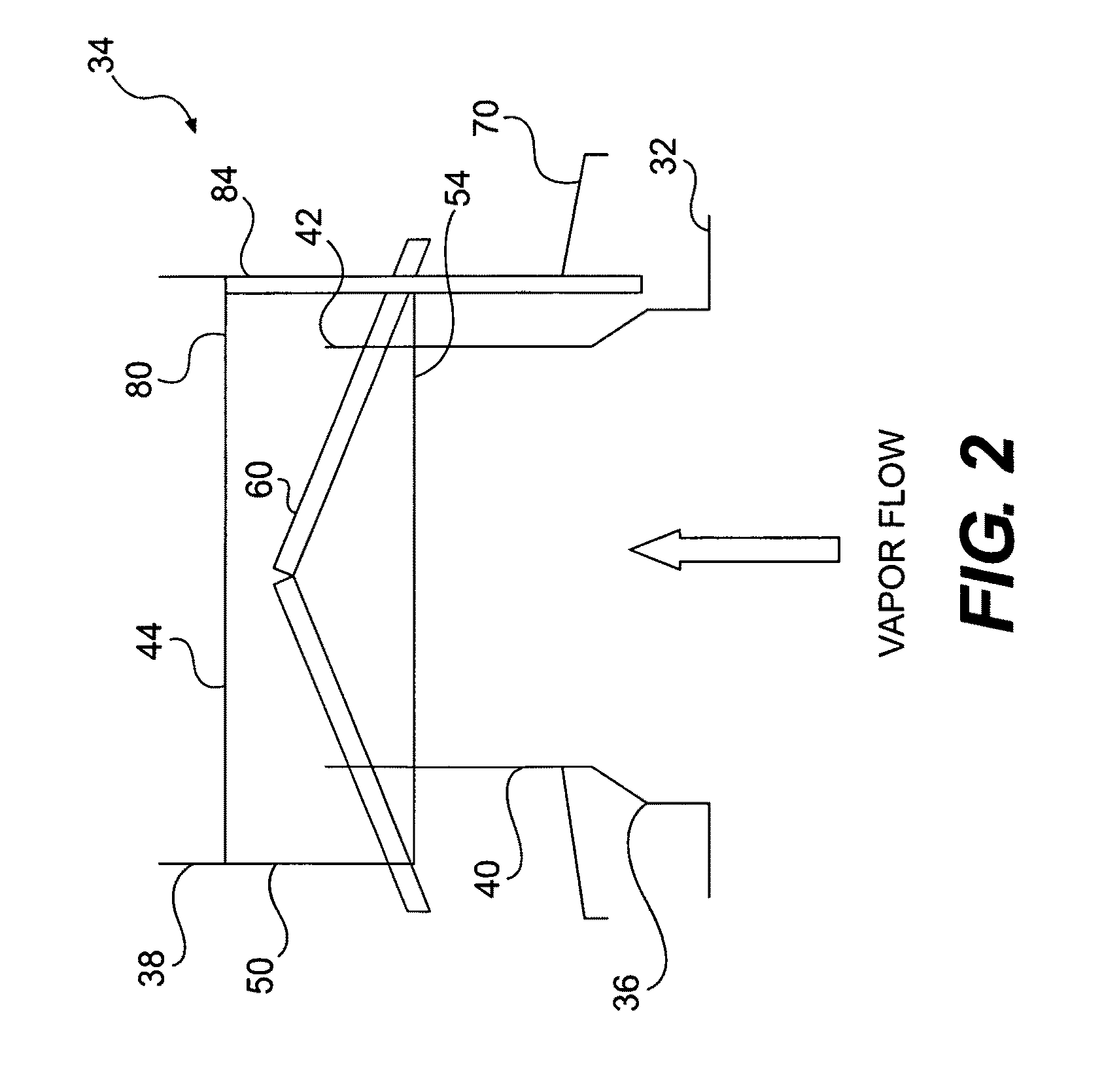

De-entrainment tray for high capacity operation

ActiveUS8083901B2Efficient separationLiquid degasificationUsing liquid separation agentVertical tubeDistillation

A de-entrainment device separates entrained liquid from vapor in a fluid stream that flows through a chimney tray in a distillation tower. The separated liquid is collected and shielded from the fluid stream to prevent re-entrainment of the liquid in the vapor flowing upward into the tower. The chimney tray includes risers with hats that have gutters to guide liquid toward the tray deck, channels to collect and drain liquid from the top of the hats to the tray deck, and baffles extending from the risers to shield the liquid collected on the tray deck from the vapor flow.

Owner:EXXON RES & ENG CO

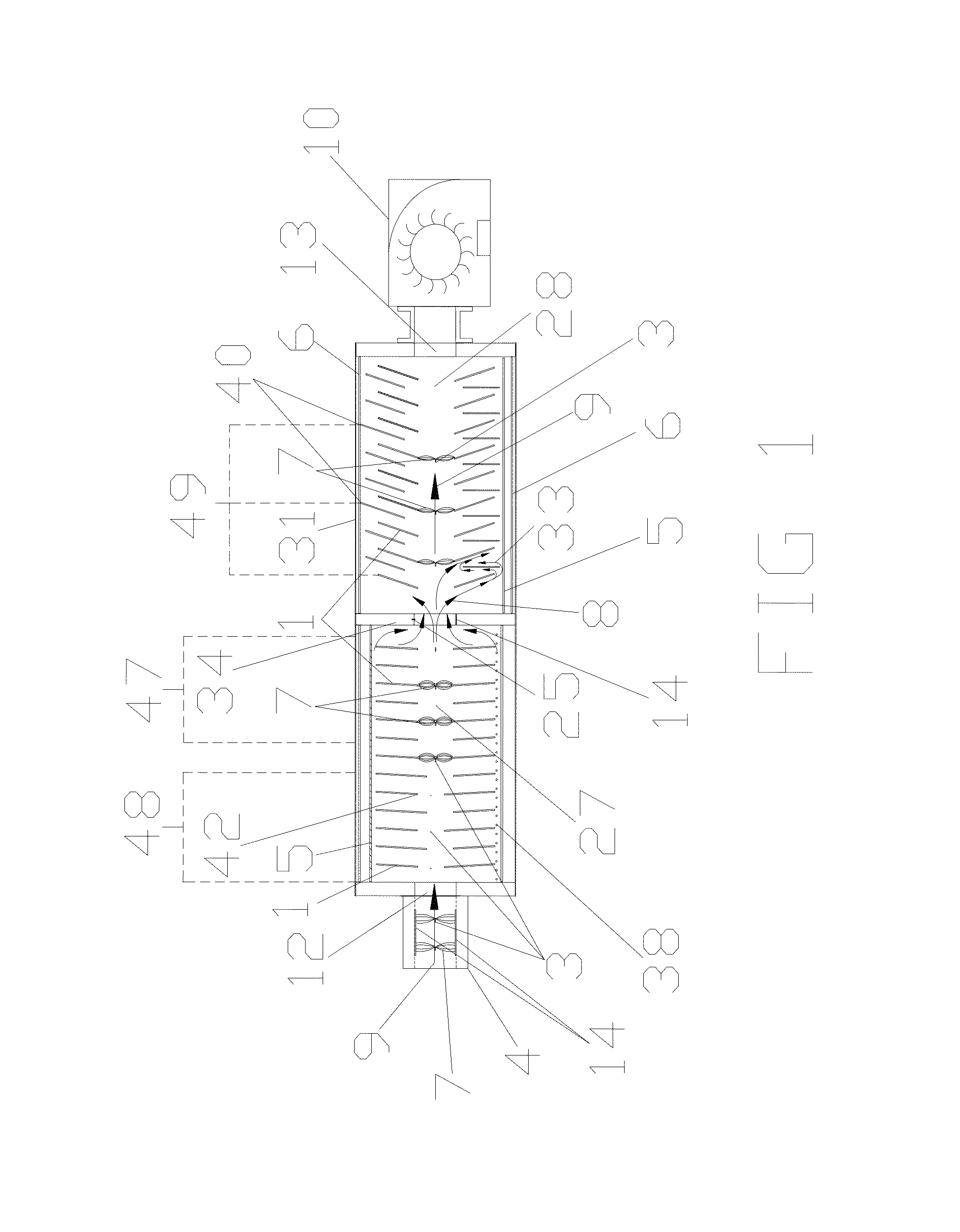

Wire mesh gas-liquid separator capable of preventing liquid drop re-entrainment and application of wire mesh gas-liquid separator

InactiveCN104922982AImprove separation efficiencyCarry controlDispersed particle separationChemical industryVapor–liquid separator

The invention discloses a wire mesh gas-liquid separator capable of preventing liquid drop re-entrainment and application of the wire mesh gas-liquid separator. The gas-liquid separator comprises a shell body and a drawer-type super-lyophobic wire mesh plate, wherein the drawer-type super-lyophobic wire mesh plate is inserted into the shell body and divides the shell body into a gas cavity and a gas-liquid cavity; a gas vent is formed in the top of the gas cavity; a gas-liquid inlet is formed in a side surface of the gas-liquid cavity; a liquid storage cavity is isolated by a baffle in the upper part of the gas-liquid cavity; a liquid storage tank is arranged at the bottom of the liquid storage cavity. Through the design combining wire mesh super-lyophobic treatment, buffering of the liquid drop impact of lyophilic metal foam, isolation of the liquid storage cavity, and timely guiding of a storage liquid, liquid drop re-entrainment caused by tearing of liquid films on the wire mesh and the surface of the liquid storage tank as well as splashing of the liquid drop impact can be prevented from the source, the separation efficiency of the gas-liquid separator can be greatly improved, the entrainment of outlet gas droplets can be effectively controlled, and a reliable guarantee is provided for efficient and safe production of the energy and chemical industry.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

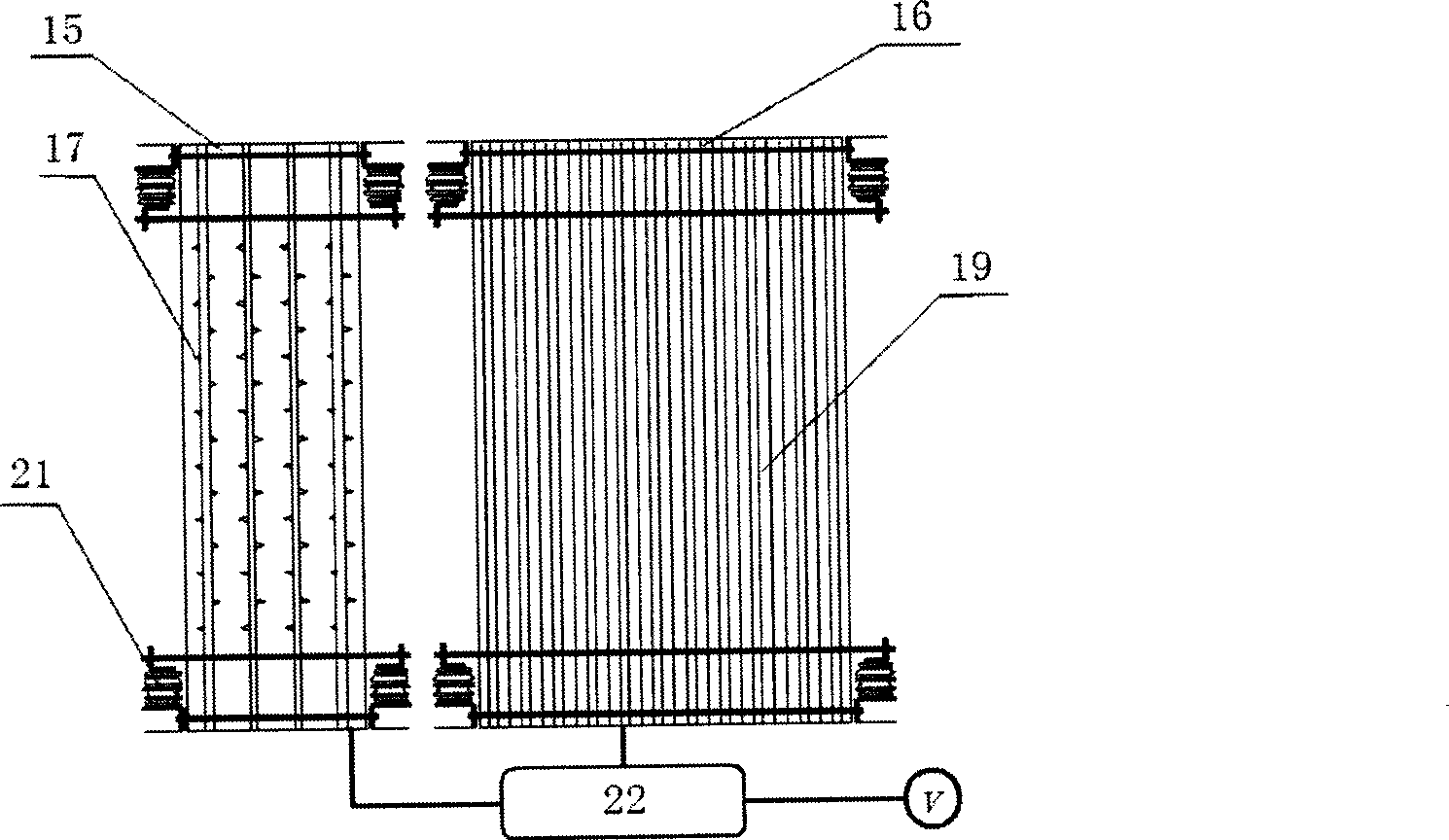

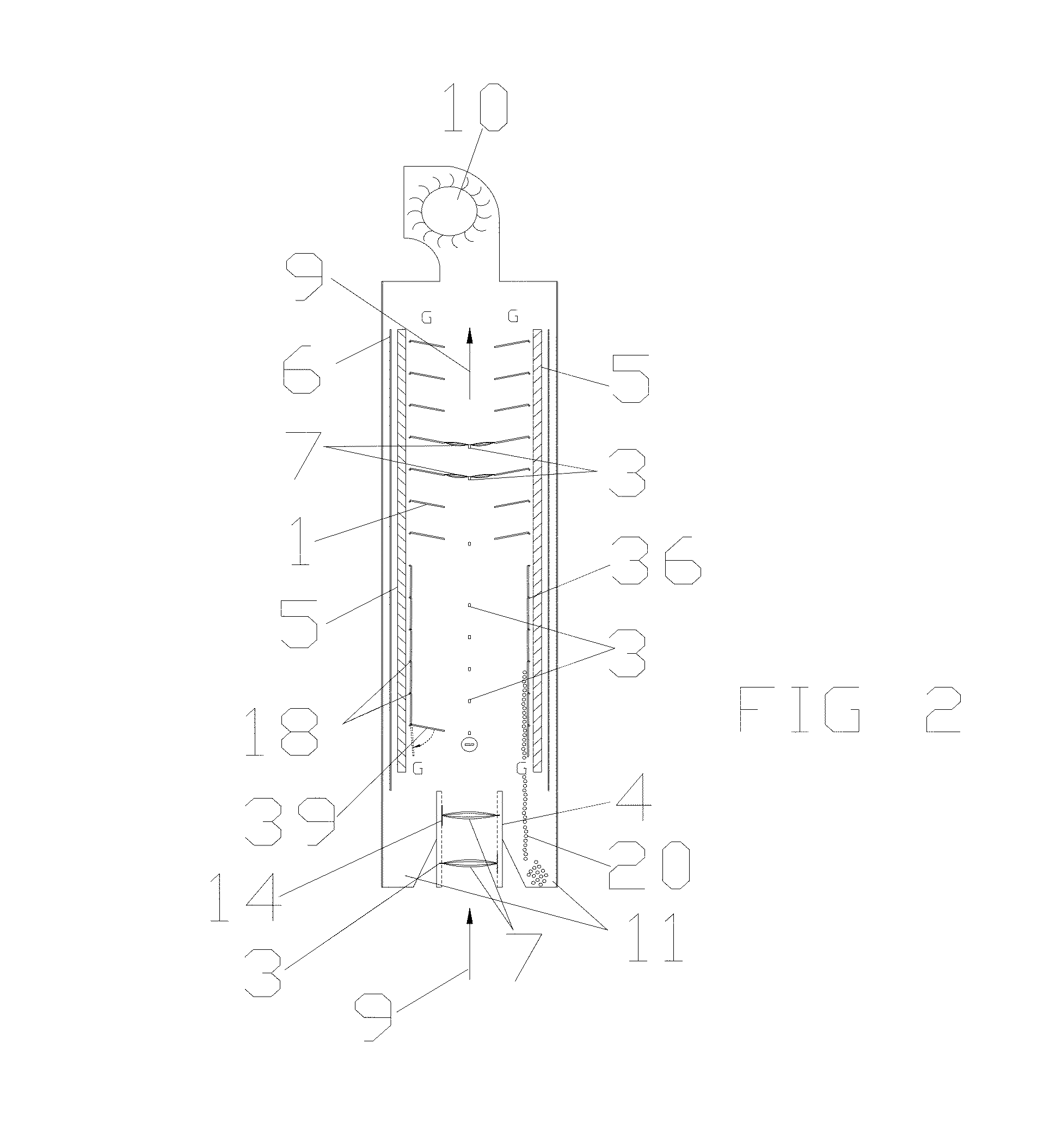

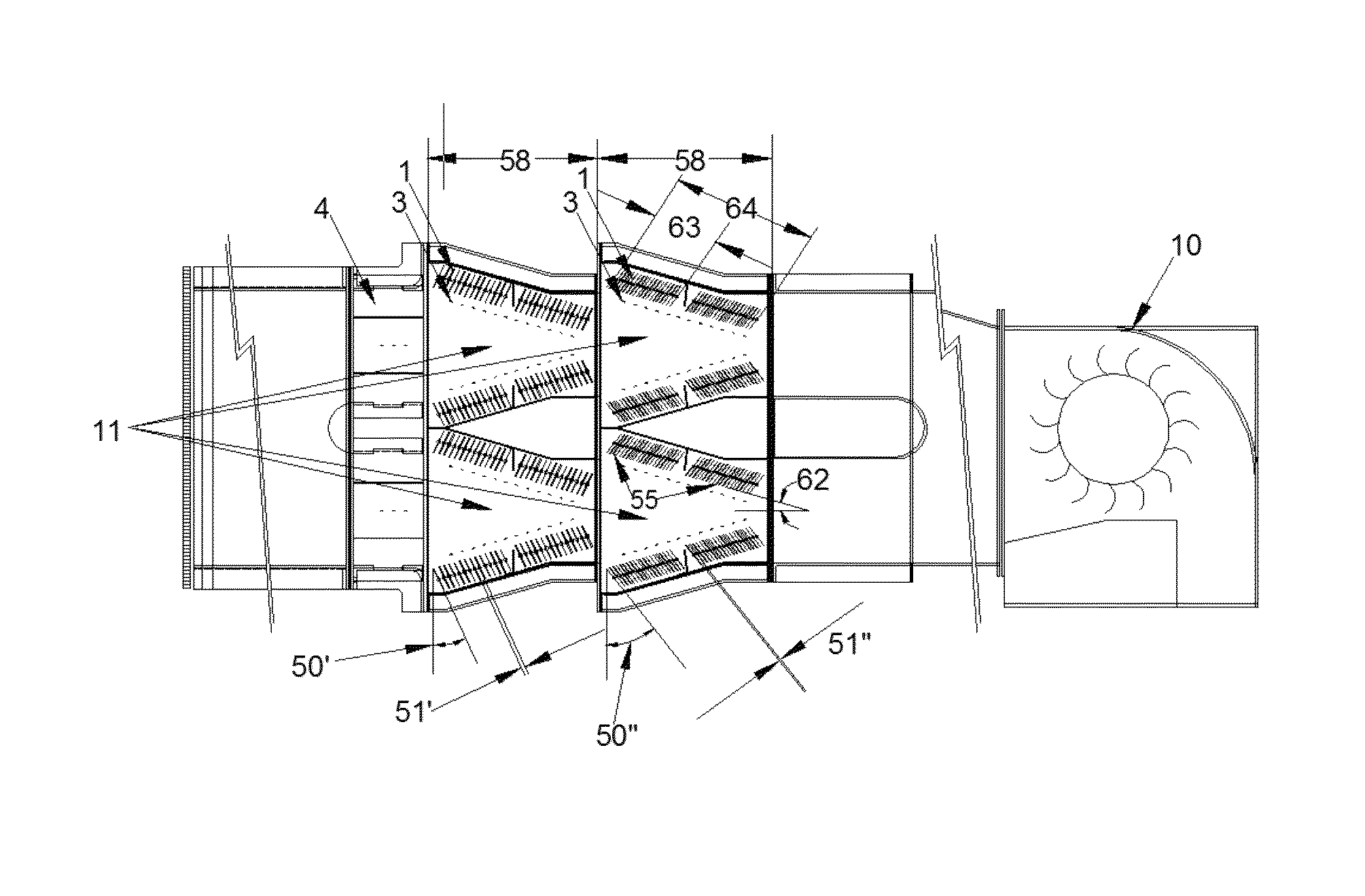

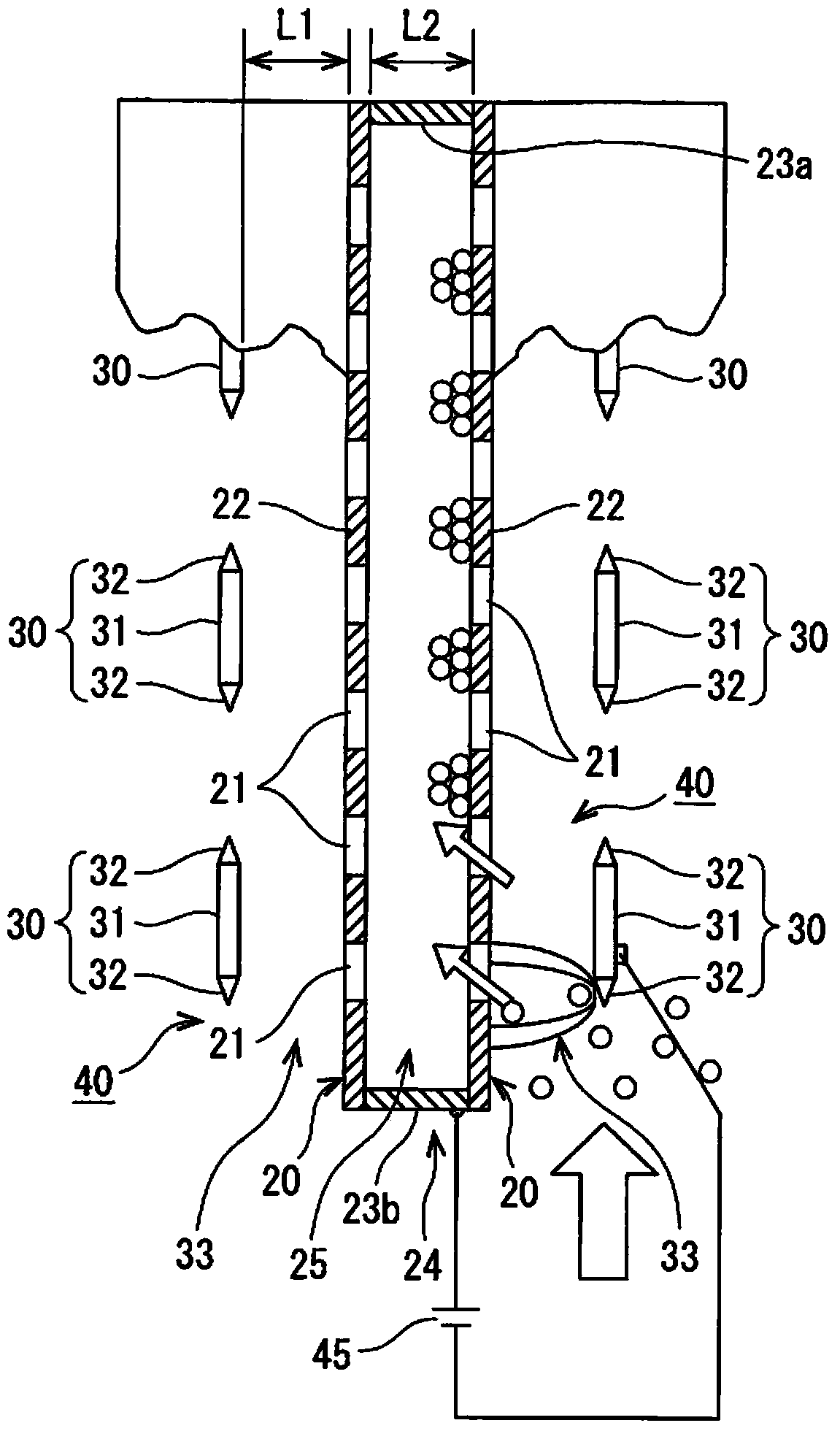

Vane Electrostatic Precipitator

InactiveUS20140283686A1Efficient processingEfficiently collecting particulatesExternal electric electrostatic seperatorVapor flow controlEngineeringStreamflow

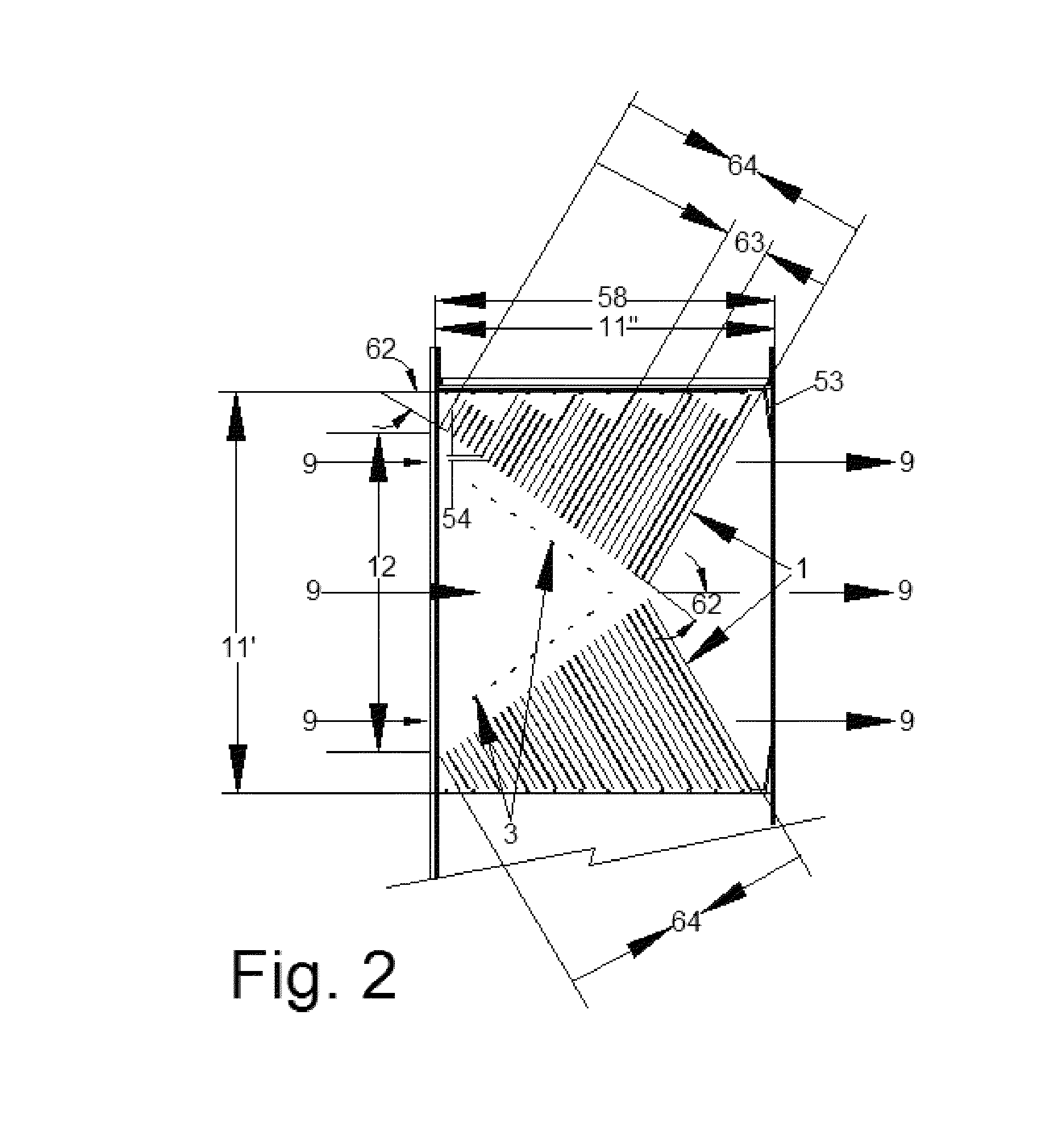

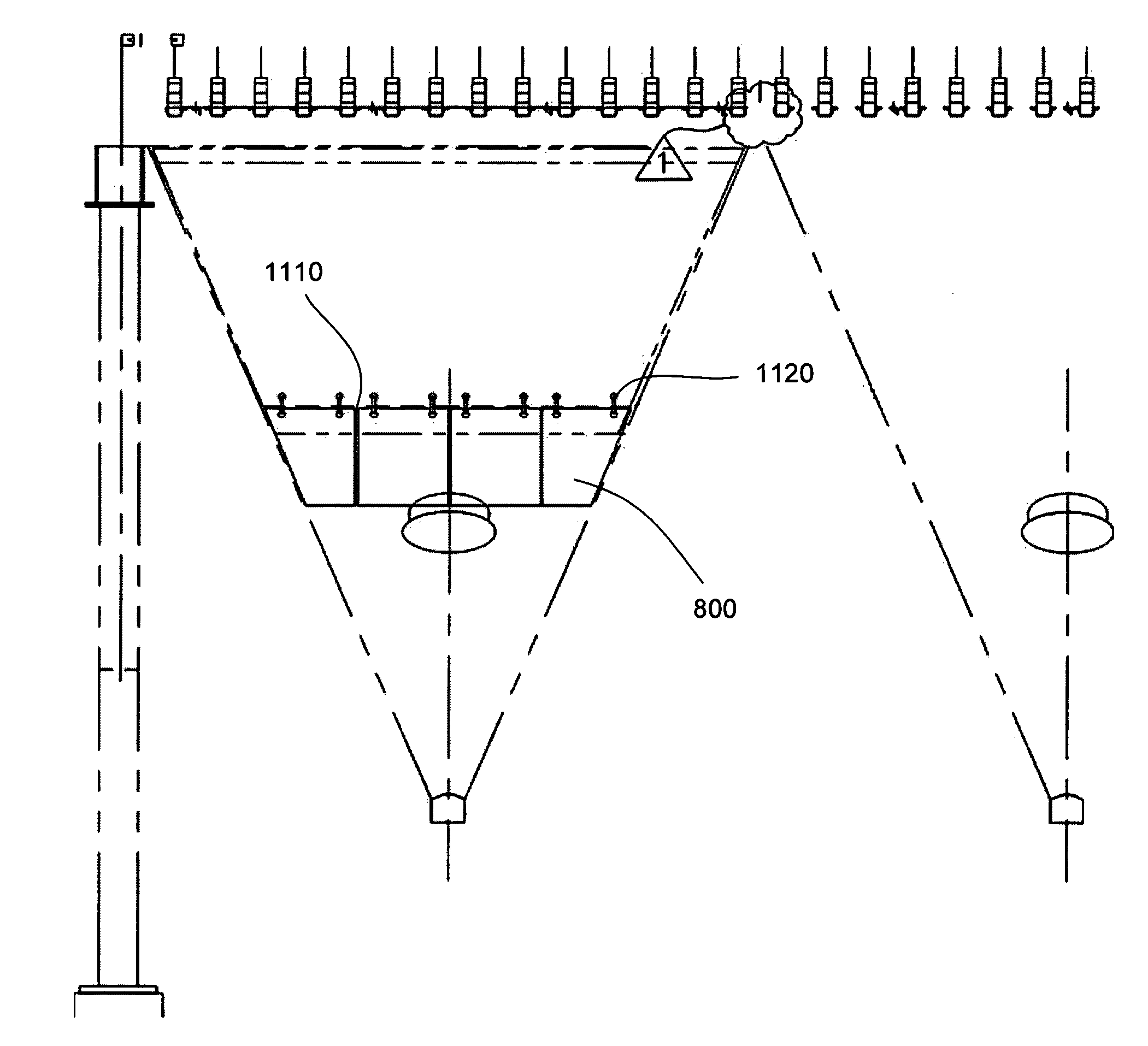

Methods using vane electrostatic precipitators collect charged and uncharged particles with vane assemblies that are physically arranged to reduce the air flow rate to at or below 1.0 ft / sec (0.305 m / sec). In preferred embodiments, the main entrained air is divided into smaller proportions by using a plurality of vane assemblies in a vane electrostatic precipitator operating at a specific angle that have discharge electrodes in front of the vanes. This results in both the particles being charged and the flow rate of the air and articles being reduced as they traverse between vanes and over the vane surface. The vane width, operating angle, vane length and vane offset are designed to reduce the air flow rate. As a result, at the ends of the vanes, a high percentage of the air flow is less than 1 ft / s. This allows the particles that are discharged from the vanes during operation to fall by gravity and in the direction of lower air flow, resulting in extremely low re-entrainment and efficient particle collection.

Owner:DUNN JOHN P

Vane electrostatic precipitator

InactiveUS9073062B2Efficiently collecting particulatesEfficient processingExternal electric electrostatic seperatorVapor flow controlAir entrainmentEngineering

Methods using vane electrostatic precipitators collect charged and uncharged particles with vane assemblies that are physically arranged to reduce the air flow rate to at or below 1.0 ft / sec (0.305 m / sec). In preferred embodiments, the main entrained air is divided into smaller proportions by using a plurality of vane assemblies in a vane electrostatic precipitator operating at a specific angle that have discharge electrodes in front of the vanes. This results in both the particles being charged and the flow rate of the air and articles being reduced as they traverse between vanes and over the vane surface. The vane width, operating angle, vane length and vane offset are designed to reduce the air flow rate. As a result, at the ends of the vanes, a high percentage of the air flow is less than 1 ft / s. This allows the particles that are discharged from the vanes during operation to fall by gravity and in the direction of lower air flow, resulting in extremely low re-entrainment and efficient particle collection.

Owner:DUNN JOHN P

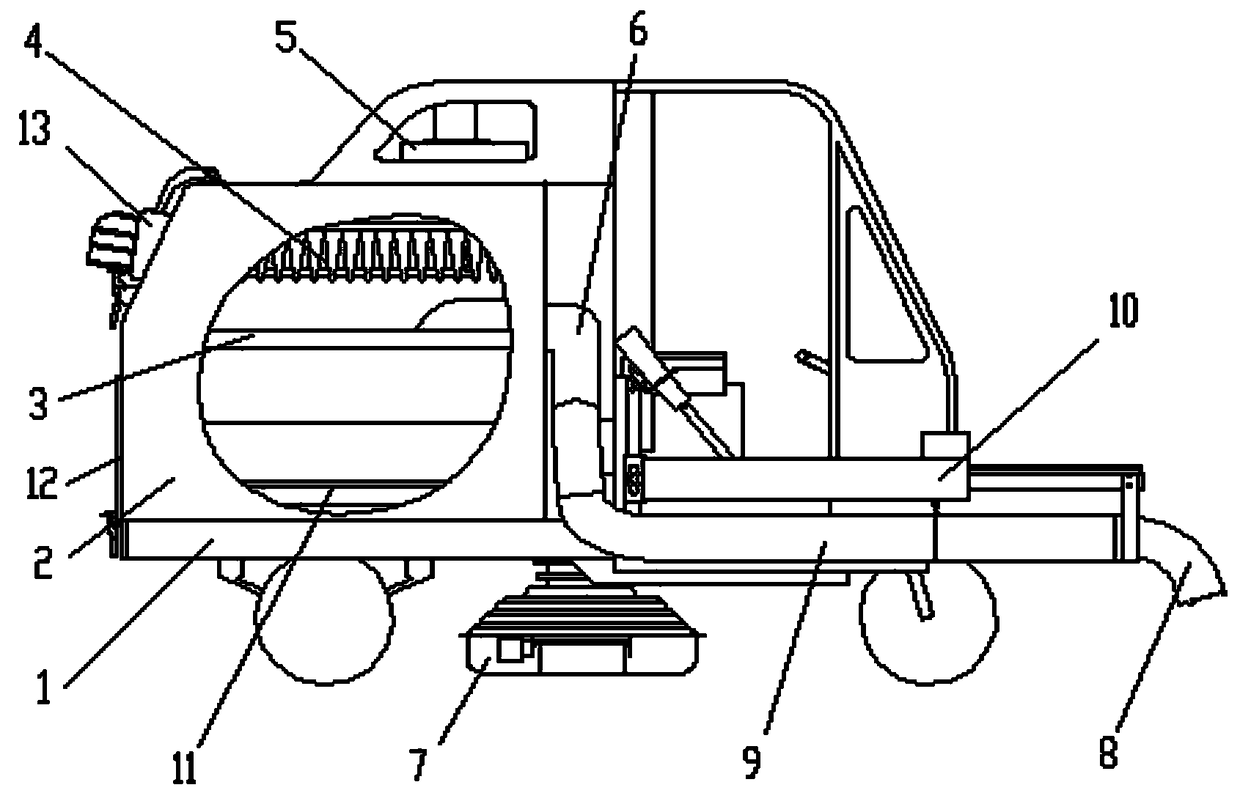

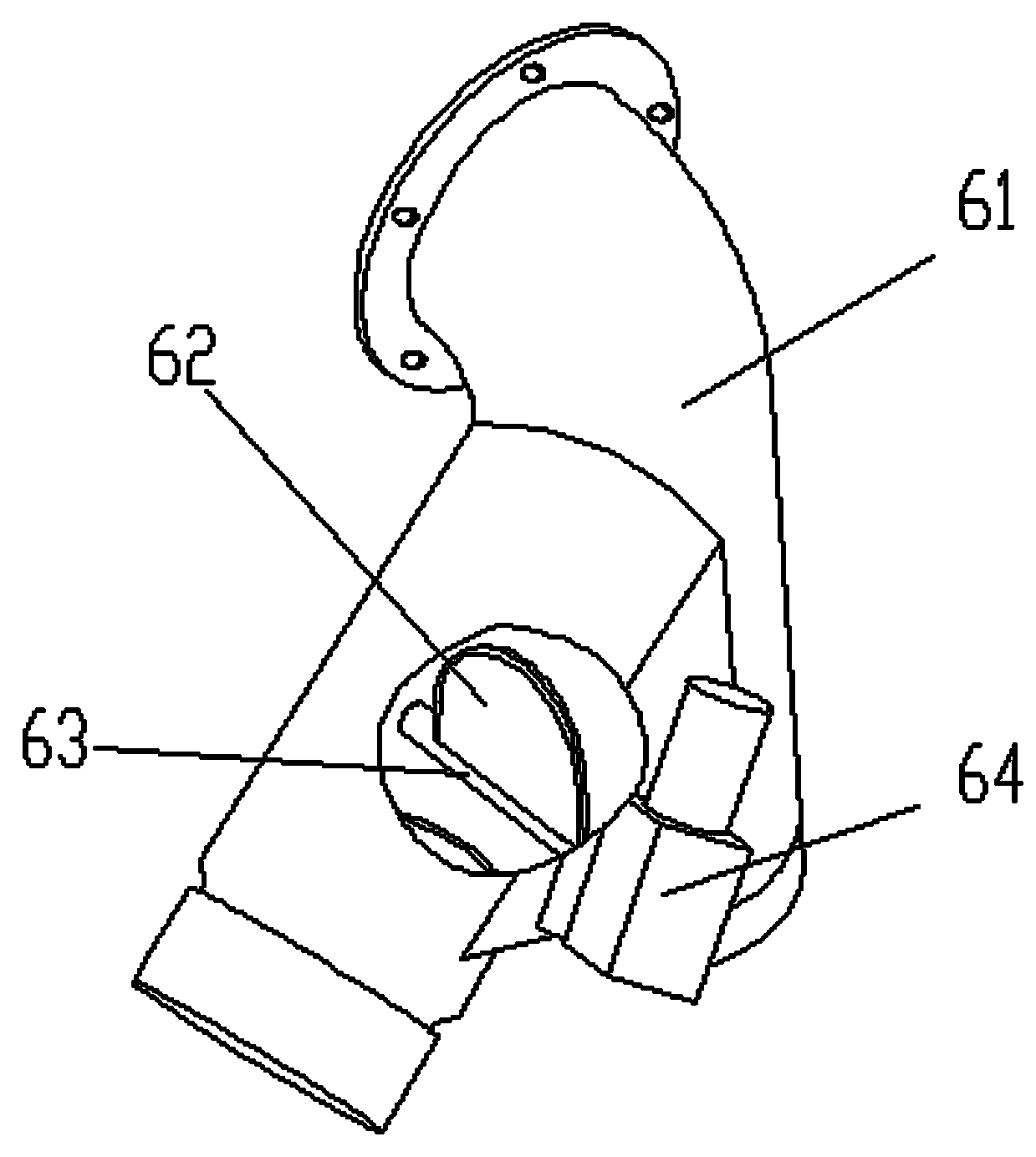

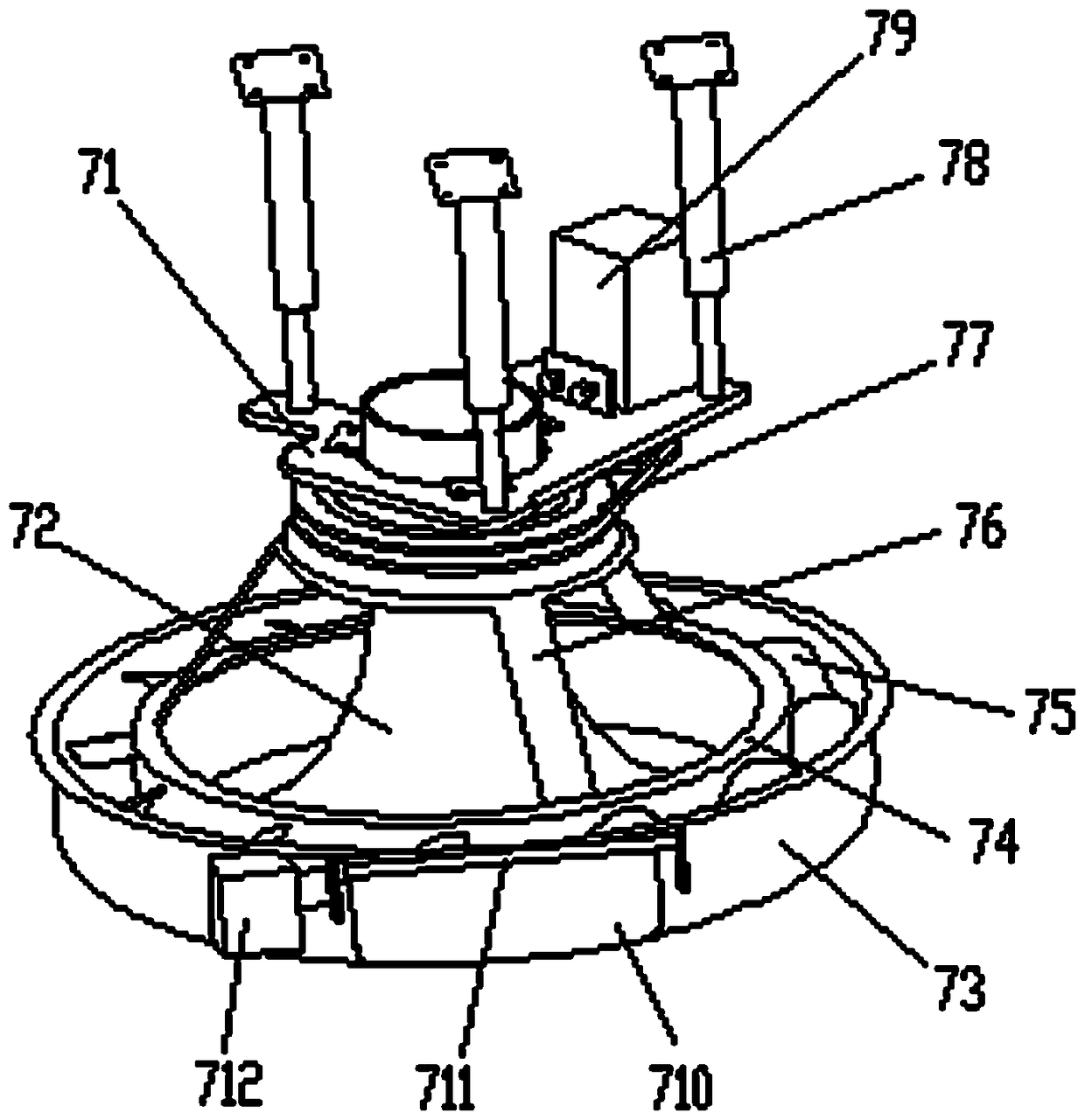

Blowing-suction street cleaner

A blowing-suction street cleaner comprises an electric vehicle chassis. A built-in filter is arranged on the electric vehicle chassis, a garbage can of an exhaust fan is assembled on the electric vehicle chassis, a bottom suction dust collection device comprising a flared dust collection nozzle and a fan wheel placed on the periphery of the lower end of the dust collection nozzle is arranged on the lower surface of the electric vehicle chassis, a side suction dust collection device comprising a side suction telescopic pipe and a dust collection elbow is arranged on the right side of the electric vehicle chassis, the dust collection nozzle and the side suction telescopic pipe are communicated with the inside of the garbage can through a reversing tee joint, a bottom suction dust collectiondevice lifting electric push rod and a fan motor are assembled on the bottom suction dust collection device, and the dust collection elbow is provided with a dust collection elbow position adjusting mechanism. All street cleaning operations are finished by airflow, the blowing-suction street cleaner has the advantages of large blowing cover area, strong suction force, high working efficiency, no dust re-entrainment, simple equipment structure, no cleaning wear-out parts and convenience in use and maintenance, and garbage on two sides of a street can be cleaned.

Owner:秦皇岛握石环保科技有限公司

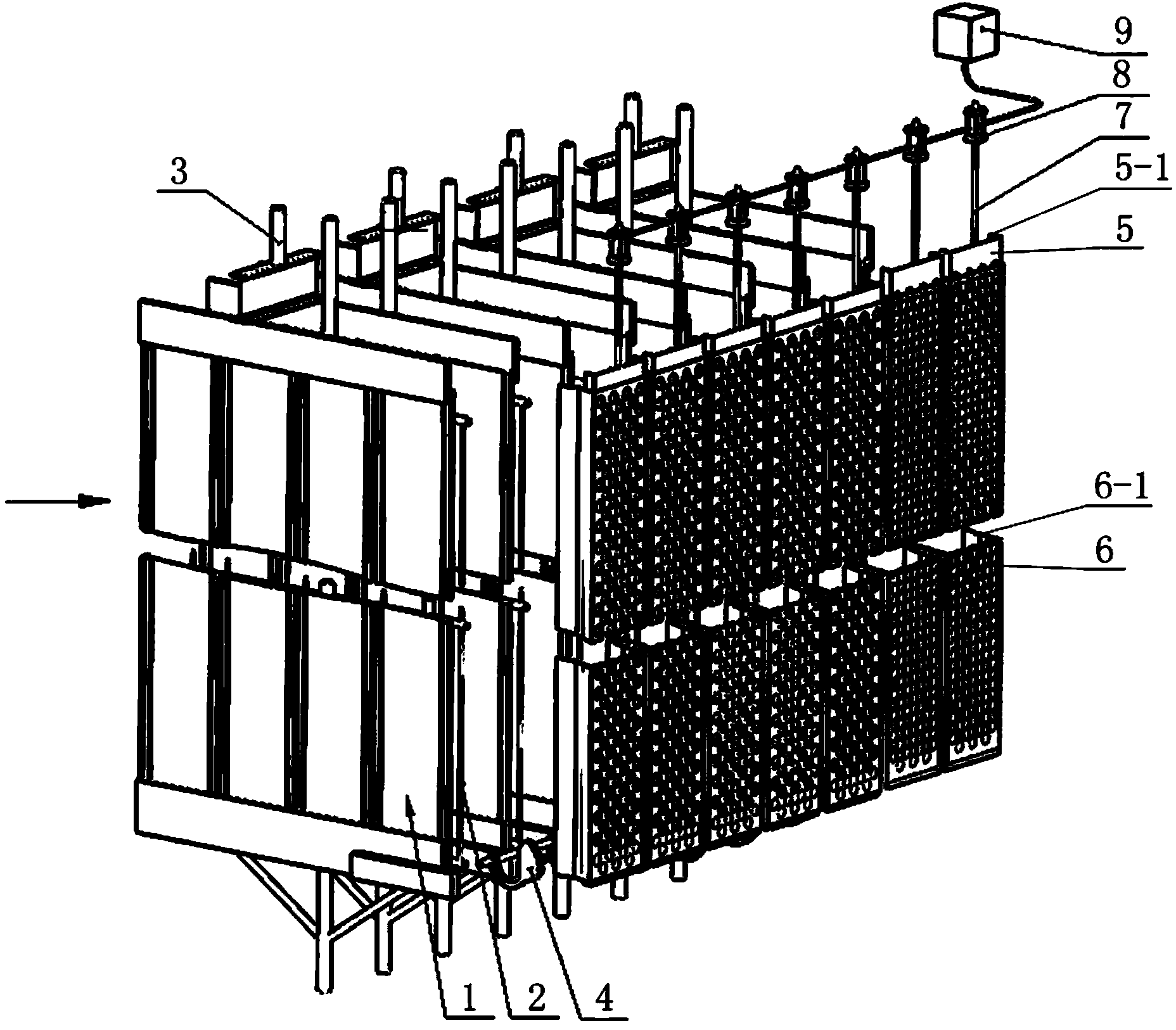

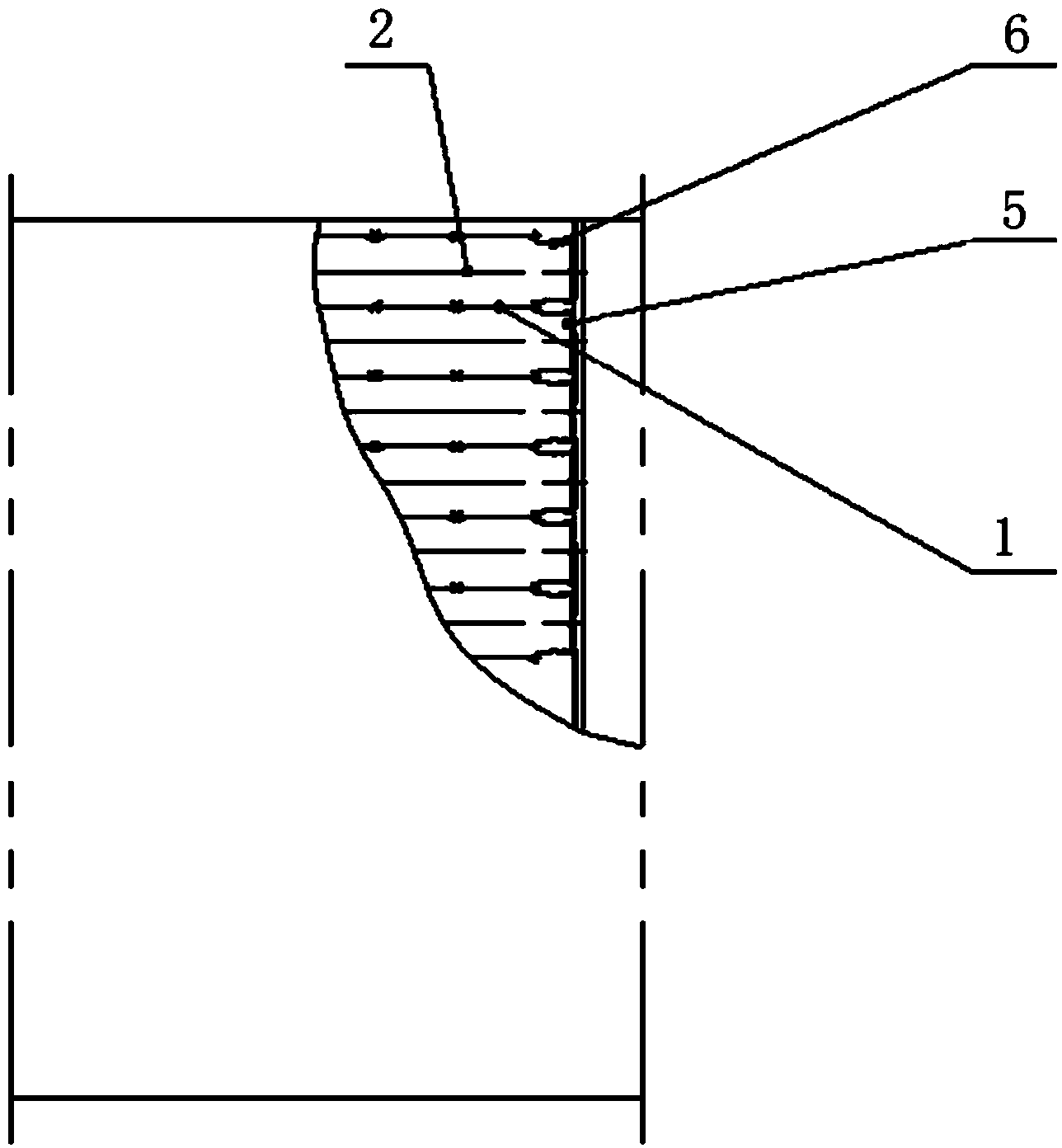

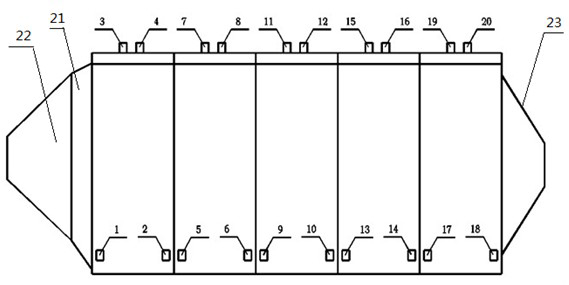

Electric precipitator for removing ash through isolated vibration and striking and isolated vibration-striking time schedule control method

ActiveCN103537373AEasy to controlHigh degree of automationExternal electric electrostatic seperatorElectrodes cleaningTime scheduleElectricity

The invention discloses an electric precipitator for removing ash through isolated vibration and striking. The electric precipitator comprises anode plates (1), cathode wires (2), anode plate vibration-striking devices and isolation pore plates, wherein the isolation pore plates are arranged at the rear parts of the anode plates (1) and respectively correspond to airflow channels between two adjacent pore plates (1), and through holes are formed in the isolation pore plates; the through holes are in an opening state and a closed state and are used for guiding through the corresponding airflow channels in the opening state and blocking the corresponding airflow channels in the closed state. According to the electric precipitator, the back corona and re-entrainment of a rear electric field can be effectively prevented, so that the dust removing efficiency is effectively increased; the electric precipitator can stably work in a low emission manner for a long time. The invention further discloses an isolcated vibration-striking time schedule control method applied to the electric precipitator.

Owner:FUJIAN LONGKING

Static deduster and step-by-step rapping deashing method thereof

ActiveCN102553721AReduce the total amount of secondary dustElectrodes cleaningEngineeringElectric field

The invention which discloses a static deduster and a step-by-step rapping deashing method thereof belongs to the technical field of static dedusting. The static deduster of the invention comprises a casing, two ends of the casing are provided with an air inlet and an air outlet respectively, at least one electric field comprising a cathode wire and an anode plate which cooperate with each other is arranged in the casing, and at least two cathode wire rapping deashing devices and at least two anode plate rapping deashing devices are arranged in each electric field. According to the step-by-step rapping deashing method of the static deduster of the invention, all the cathode wire rapping deashing devices and all the anode plate rapping deashing devices run in different periods of time. According to the invention, the total amount of re-entrainment generated during rapping deashing is reduced, and the concentration of dust on the outlet of the static deduster is reduced.

Owner:CHINA POWER INVESTMENT CORPORATION +1

Process for regenerating catalyst

ActiveUS20090149315A1Easy to separateMinimizing any tendencyInorganic chemistryCatalytic crackingFlue gasSurface velocity

Disclosed is a process for disengaging regenerated catalyst from flue gas in a catalyst regenerator so as to avoid re-entrainment of catalyst that has settled into a bed in the catalyst regenerator using a disengaging device. A disengaging arm of the disengaging device has an outer shell that encloses the arm, an inner shell with a slot for allowing catalyst and flue gas to exit the arm and an outer baffle having a lower edge located below the opening in the outer wall. The baffle directs the catalyst and flue gas downwardly and limits radial flow. Catalyst and flue gas enter the disengaging arm through an opening in an outer wall of a riser section at a first superficial velocity and exits through a slot in a bottom of the disengaging arm at no more than 1.33 the first superficial velocity.

Owner:UOP LLC

Vane electrostatic precipitator

InactiveUS9238230B2Low re-entrainmentEfficient collectionElectrode constructionsParticulatesAir velocity

The embodiments described herein improve on the present electrostatic precipitator method of using parallel plates to collect particulates by using multiple parallel vanes set at operating parameters described below. By using vanes, the main entrained air is subdivided and directed to flow between vanes that induce resistance to flow allowing charged particles to collect on the vanes. The width of the vane is designed to be wide enough so the air flow rate at the ends of the vanes is less than 1 ft / s, allowing particles discharged from the plates to fall by gravity and in the direction of very low air flow, resulting in extremely low re-entrainment and efficient particle collection. Using vanes also allows for higher operating air velocities resulting in a smaller equipment foot print.

Owner:DUNN JOHN P

Systems and methods for organic particulate filtration

ActiveUS20080257148A1Reduce the amount requiredCombination devicesAuxillary pretreatmentParticulatesCombustion system

The present invention provides systems and methods for organic particulate filtration. An organic particulate filtration system is implemented within a fossil fuel power plant combustion system. The filtration system comprises a gas flow, in which gas are entrained particulates. The filtration system has a collection hopper located proximate a precipitator collection area. Within the collection hopper, a particulate baffle is provided in a downward-angled orientation. The particulate baffle is enabled to trap particulate, such as organic particulate, in the collection hopper, thereby preventing particulate re-entrainment in the gas flow.

Owner:THE SOUTHERN CO

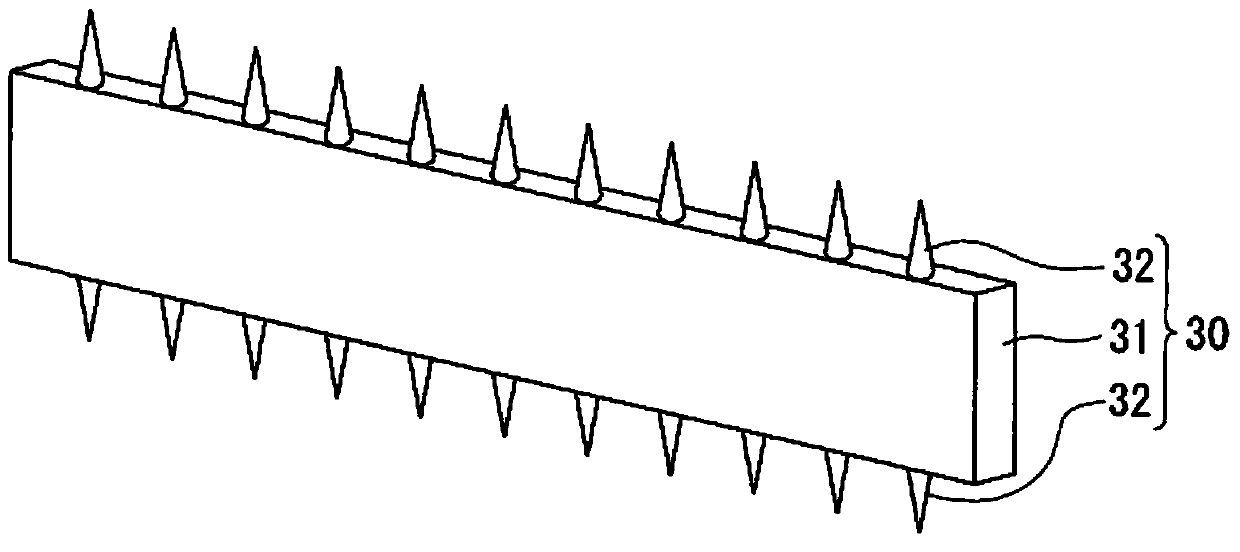

Demister blade unit for demister, efficient demister and application

ActiveCN105999862AReduce washoutLarger than the areaDispersed particle separationFlue gasEngineering

The invention relates to a demister blade unit for a demister. The demister blade unit comprises a plurality of blades arranged in parallel at intervals, wherein each blade comprises a blade body, a net-shaped structural layer and cones, the cones are arranged on the outer surface of the blade body at intervals along the blade body, the vertexes of the cones are arranged in the gravity settling direction of liquid drops, and the net-shaped structural layer is arranged tightly on the outer surface of the blade body outside the cones. The demister blade unit is provided with the cones and the net-shaped structural layers, the blade structure of a plate type demister is improved, the problem of re-entrainment of flue gas by the demister can be solved effectively, the demisting efficiency of the plate type demister is improved, efficient demisting can be realized, and the demister has small resistance and low system investment cost, so that the demister blade unit for the demister can be applied to separation of the flue gas and the liquid drops in a wet flue gas desulfurization system.

Owner:AEROSPACE ENVIRONMENTAL ENG

Visual bilgewater quality indicator

A visual bilgewater quality indicator for use in a bilgewater filtration system which includes a filtration stage for removing oily contaminants. The quality indicator utilizes one or more filtration status chambers which are provided with a fluorescent or phosphorescent dye or pigment treated filtration media. The status chamber has a transparent outer wall. Flow through the status chamber is from the outer lateral wall toward its central axis, whereby oily contaminants in the flow collect selectively at the outer portions of the filtration media which are highly visible to an observer. Oil droplets as small as one micron, are captured and immobilized by the primary filter and are instantly visible against the background of the exemplary dye. If two status chambers are used in series, due to the ability of the infused media to permanently capture oil without re-entrainment, the second chamber is always kept transparent until complete loading and supersaturating breakthrough at the primary chamber. Oily droplet visibility can be further enhanced with ultraviolet illumination.

Owner:MYCELX TECH CORP

Electrostatic precipitator

ActiveCN104271248AWon't mix in againNot easy to flyMagnetic separationExternal electric electrostatic seperatorParticulatesElectricity

Provided is an electrostatic precipitator that, when collecting particulate matter (PM), does not require a large-volume air purging unit, tends not to clog, exhibits minimal re-entrainment even in high-speed air flows, demonstrates excellent collection performance, and tends not to fail. The present invention is provided with: a plate electrode (20) in which are formed a plurality of holes through which PM passes; a discharging electrode (30) disposed so as to face one surface of the plate electrode; a discharge generation unit for applying a voltage between the plate electrode and the discharging electrode to generate a discharge for providing a Coulomb force to the particulate matter; a PM-collecting collection region formed on the side opposite the side on which the discharge electrode faces the plate electrode; a gas circulation region (33) in which a PM-containing gas is caused to circulate, the gas circulation region (33) formed between the plate electrode and the discharging electrode; and a PM recovery unit (50) that separatingly recovers PM collected by circulating a recovery gas in a direction intersecting the PM-gas circulation direction in the collection region.

Owner:FUJI ELECTRIC CO LTD

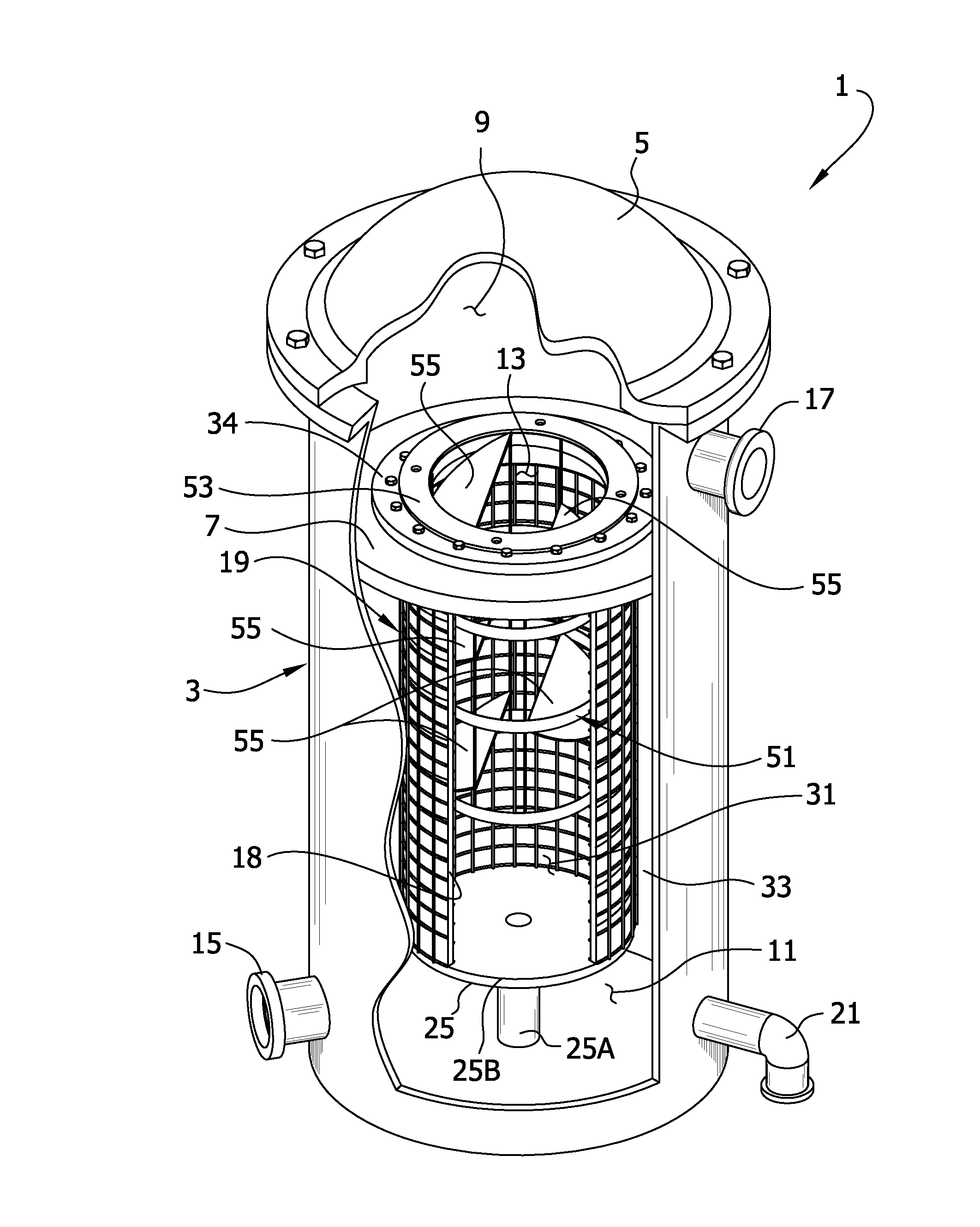

Fiber bed assembly including a re-entrainment control device for a fiber bed mist eliminator

A fiber bed assembly used to remove aerosols and / or wetted soluble solids from a moving gas stream includes a fiber bed support and a fiber bed supported by the fiber bed support so that the gas stream passes through the fiber bed moving from an upstream space to a downstream space with respect to the fiber bed. A re-entrainment control device is located within a downstream space defined by the fiber bed so that at least a portion of the gas stream passes through the re-entrainment control device. The re-entrainment control device is shaped to change the direction of the average flow path of the gas stream as the gas stream passes through the re-entrainment control device so as to cause aerosols and / or wettable solids contained therein to be separated from the gas stream by inertial force. A re-entrainment control device and method of use are also disclosed.

Owner:MECS

High-temperature electric dust-removing system for flue gas of industrial kilns

InactiveCN104984826AHigh temperature resistantImprove dust removal efficiencyExternal electric electrostatic seperatorElectrode constructionsArray data structureEngineering

The invention discloses a high-temperature electric dust-removing system for flue gas of industrial kilns. The high-temperature electric dust-removing system comprises a shell, wherein the shell is internally provided with a plurality of groups of high-voltage electric fields, wherein each group of high-voltage electric fields comprises a plurality of dust collecting electrodes, discharging electrodes and auxiliary electrodes which are vertically distributed; the electric field is divided into a plurality of parallel channels by the dust collecting electrodes; the discharging electrodes and the auxiliary electrodes are positioned at the middle parts of the channels to form staggered distribution; the discharging electrodes and the auxiliary electrodes are arranged in a discharging electrode frame; the dust collecting electrodes are vertically arranged in a dust collecting electrode frame; the dust collecting electrode frame and the discharging electrode frame are connected with clamping grooves on a cross beam at the top part of the shell in a clamping manner and are hung on a lifting beam; and the lifting beam is suspended on a top beam of the shell by a supporting insulator. The high-temperature electric dust-removing system disclosed by the invention has the characteristics of high-temperature resistance, high dust removing efficiency, long service life, less dust re-entrainment and long-term and stable operation and the like and can be applicable to dust removal of high-temperature flue gas of the industrial kilns below 500 DEG C.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

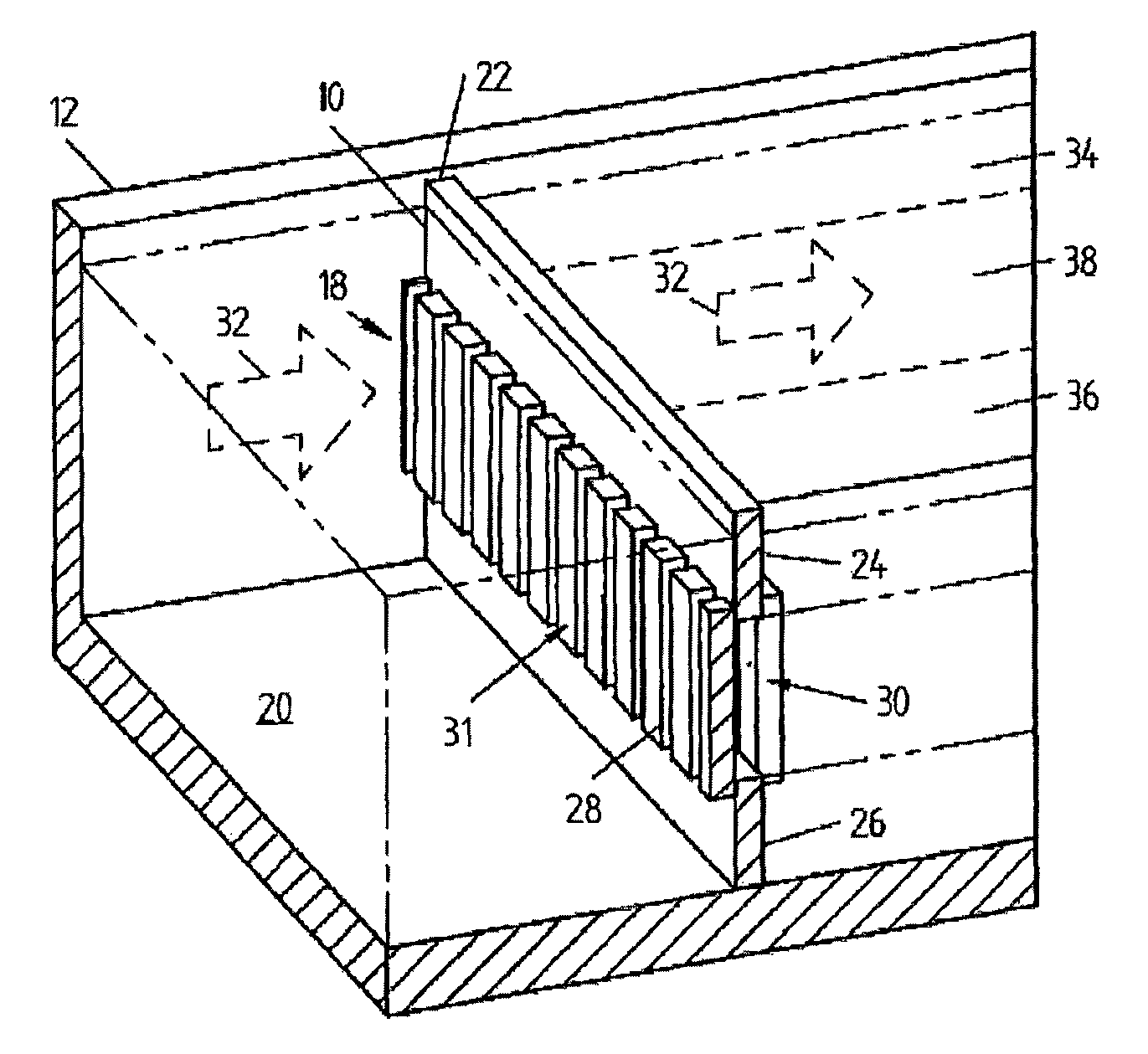

Re-entrainment prevention apparatus

ActiveUS9308471B2Preventing and limiting vertical componentSettling tanks feed/dischargeRecovering materialsEngineeringMixer-settler

Owner:HATCH PTY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com