Electric precipitator for removing ash through isolated vibration and striking and isolated vibration-striking time schedule control method

An electrostatic precipitator and timing control technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of back-corona after electric field, clean anode plate, clean anode plate fine dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

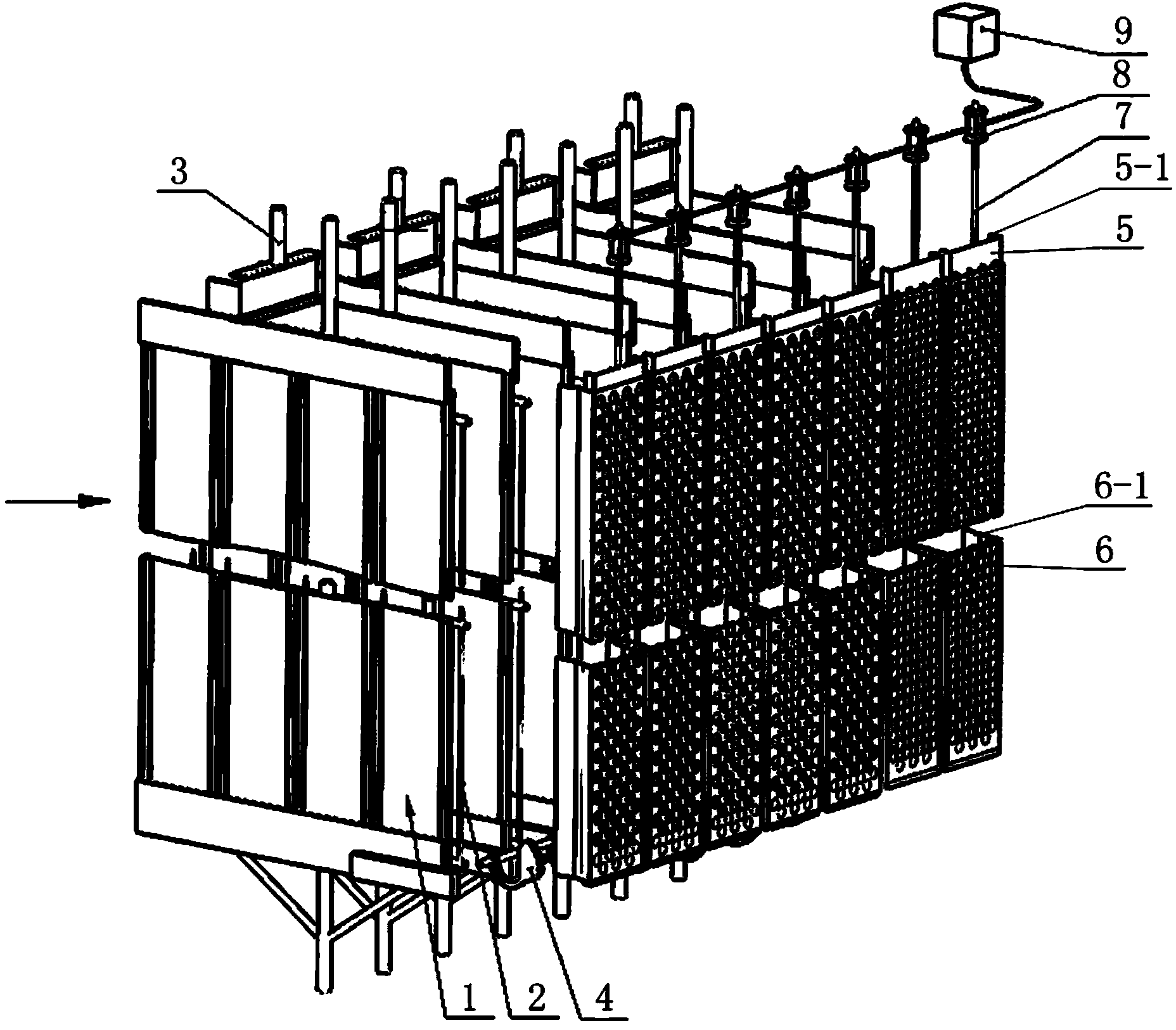

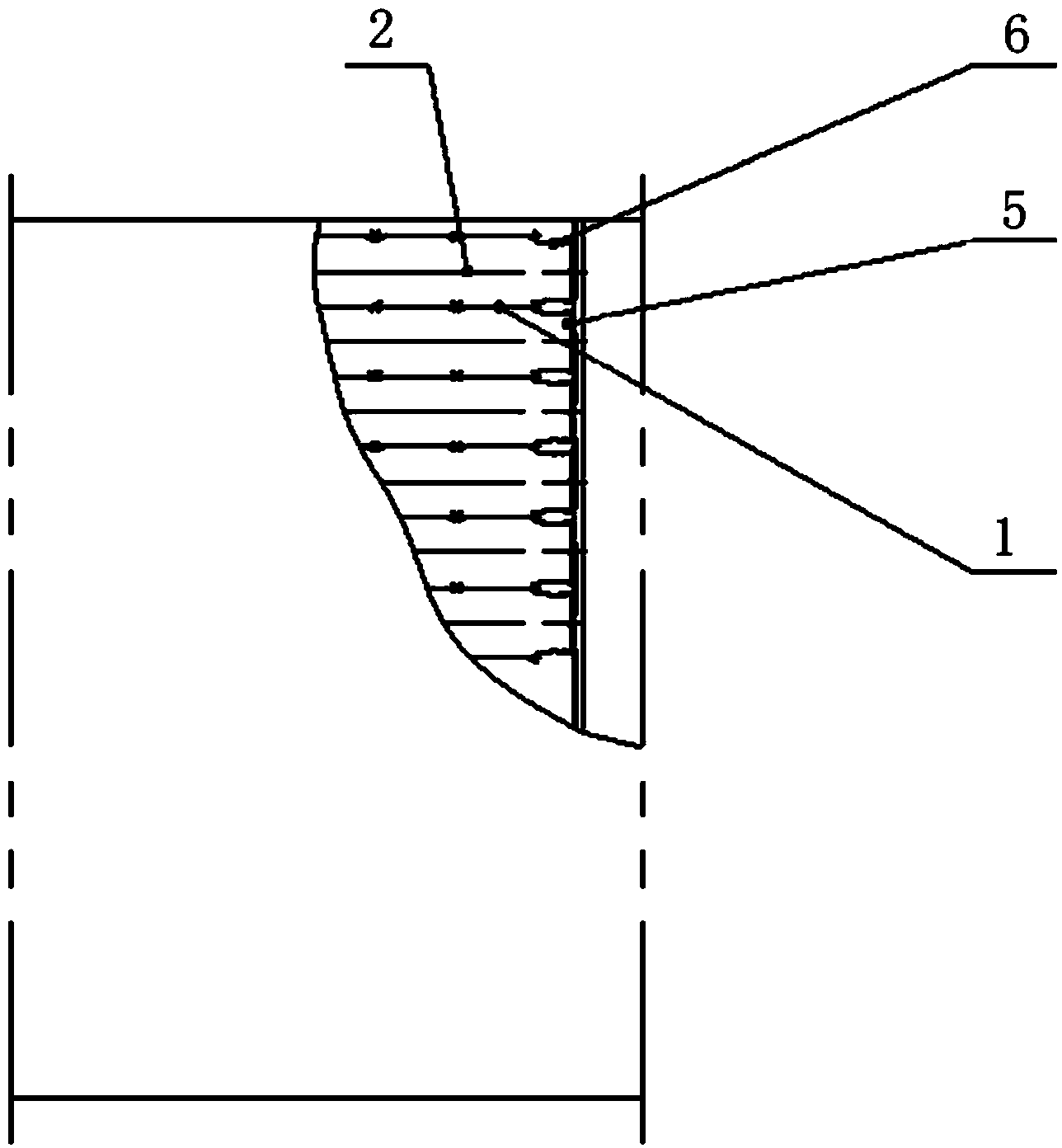

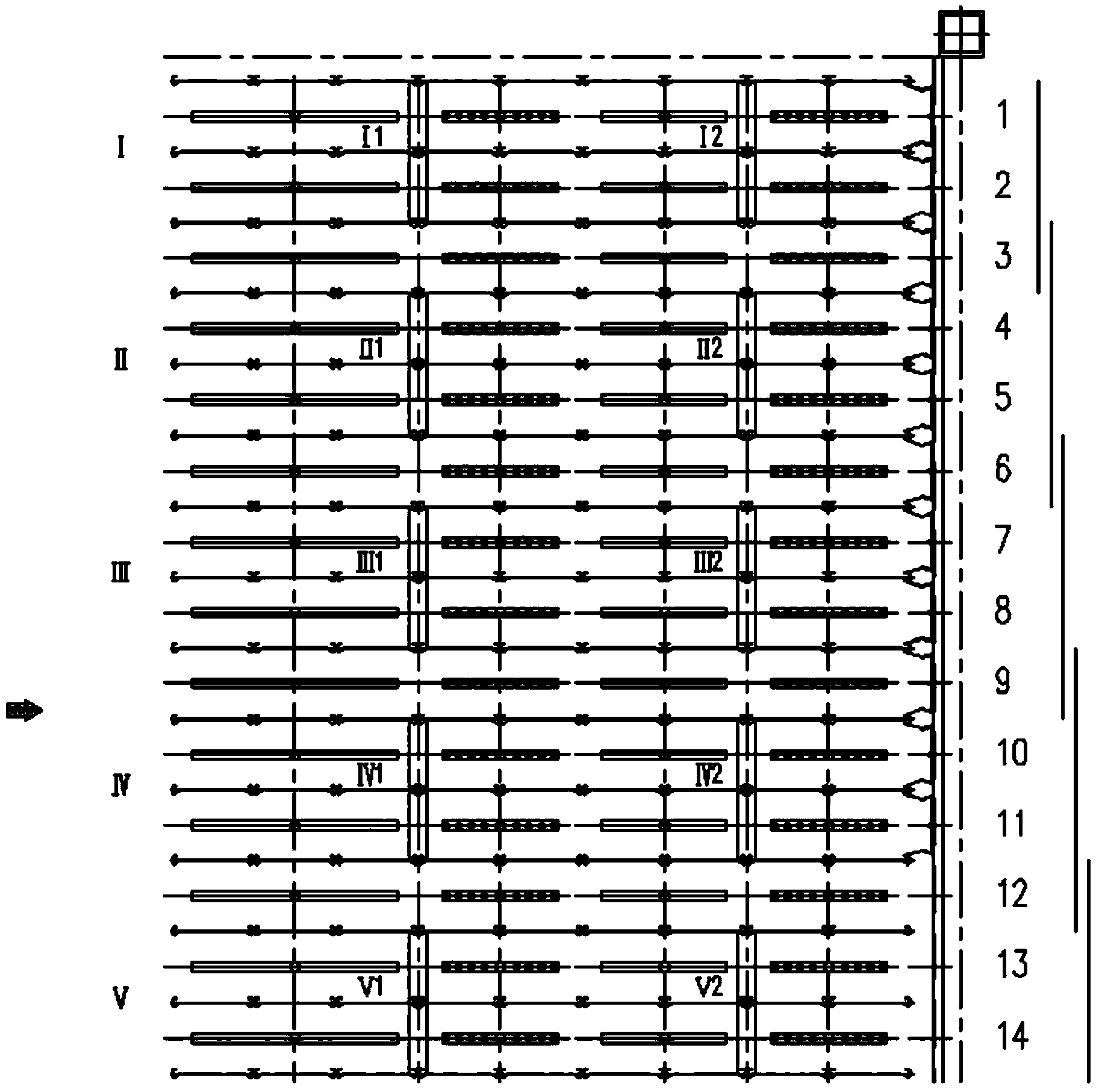

[0036] Please refer to figure 1 , figure 2 , figure 1 It is a structural schematic diagram of a specific embodiment of the isolated rapping dust-cleaning electrostatic precipitator provided by the present invention; figure 2 It is a schematic diagram of the positional relationship between the isolation orifice plate, the anode plate and the airflow channel.

[0037] In a specific embodiment, the electrostatic precipitator provided by the present invention is mainly composed of a plurality of anode plates 1, a plurality of cathode wires 2, a plurality of anode plate top rapping devices 3, a plurality of anode plate side rapping devices 4, A plurality of movable orifice plates 5, a plurality of fixed orifice plates 6 and other co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com