Static deduster and step-by-step rapping deashing method thereof

An electrostatic precipitator and ash cleaning technology, applied in electrostatic separation, electrode cleaning and other directions, can solve the problems of increasing dust concentration at the outlet of electrostatic precipitator, inaccurate setting of ash cleaning and rapping plan, and large amount of secondary dust. Achieve the effect of reducing the total amount of secondary dust, reducing the total amount of secondary dust, and reducing the concentration of outlet dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

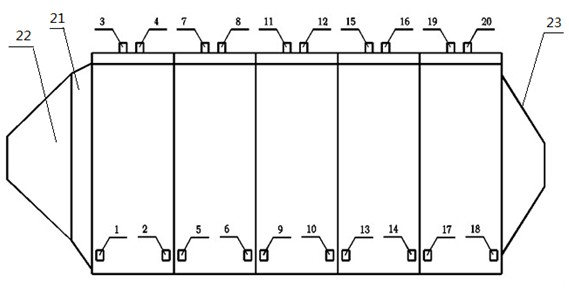

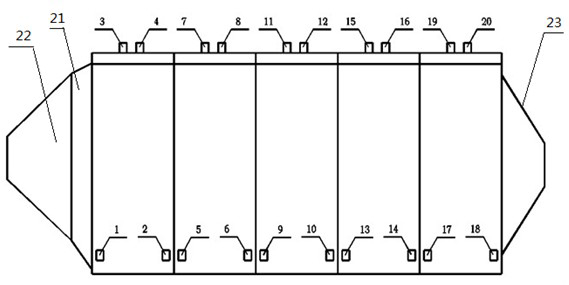

[0016] figure 1 It is a structural schematic diagram of the electrostatic precipitator of the present invention. As shown in the figure, the electrostatic precipitator of the present invention includes a casing 21, and the two ends of the casing 21 are respectively provided with an air inlet 22 and an exhaust port 23. There are five electric fields composed of cathode wires and anode plates in the casing 21 (from left to right in the figure are the first, second, third, fourth, and fifth electric fields), and two cathodes are arranged in each electric field Line vibration cleaning device and two anode plate vibration cleaning devices.

[0017] In this embodiment, the cathode line rapping and cleaning devices in each electric field are respectively located on the left and right sides of the cathode line (in the figure, 3, 7, 11, 15, 19 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com