Electrostatic precipitator

A technology of electrostatic precipitator and cyclone dust collector, which is applied in the field of electrostatic precipitator, and can solve problems such as large pressure loss and easy clogging of filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be described below with reference to the drawings.

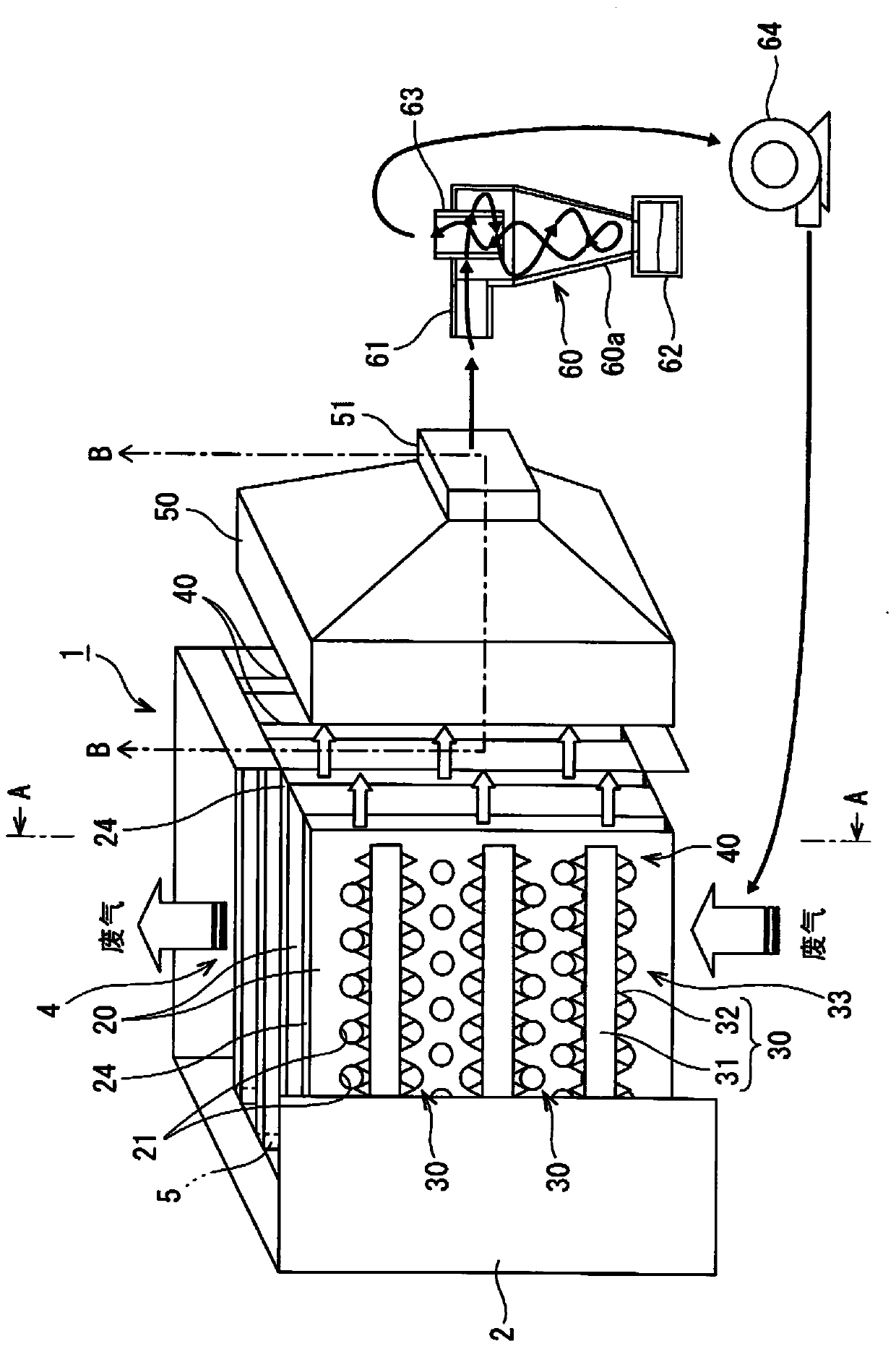

[0063] figure 1 It is a perspective view showing a part of the housing showing the first embodiment of the present invention cut away.

[0064] In the figure, 1 is an electrostatic precipitator, which can capture, for example, particulate matter (PM: Particulate Matter) whose main component is carbon and whose particle size is less than 100 μm, especially the particle size Suspended particulate matter (SPM: Suspended Particulate Matter) below 10 μm.

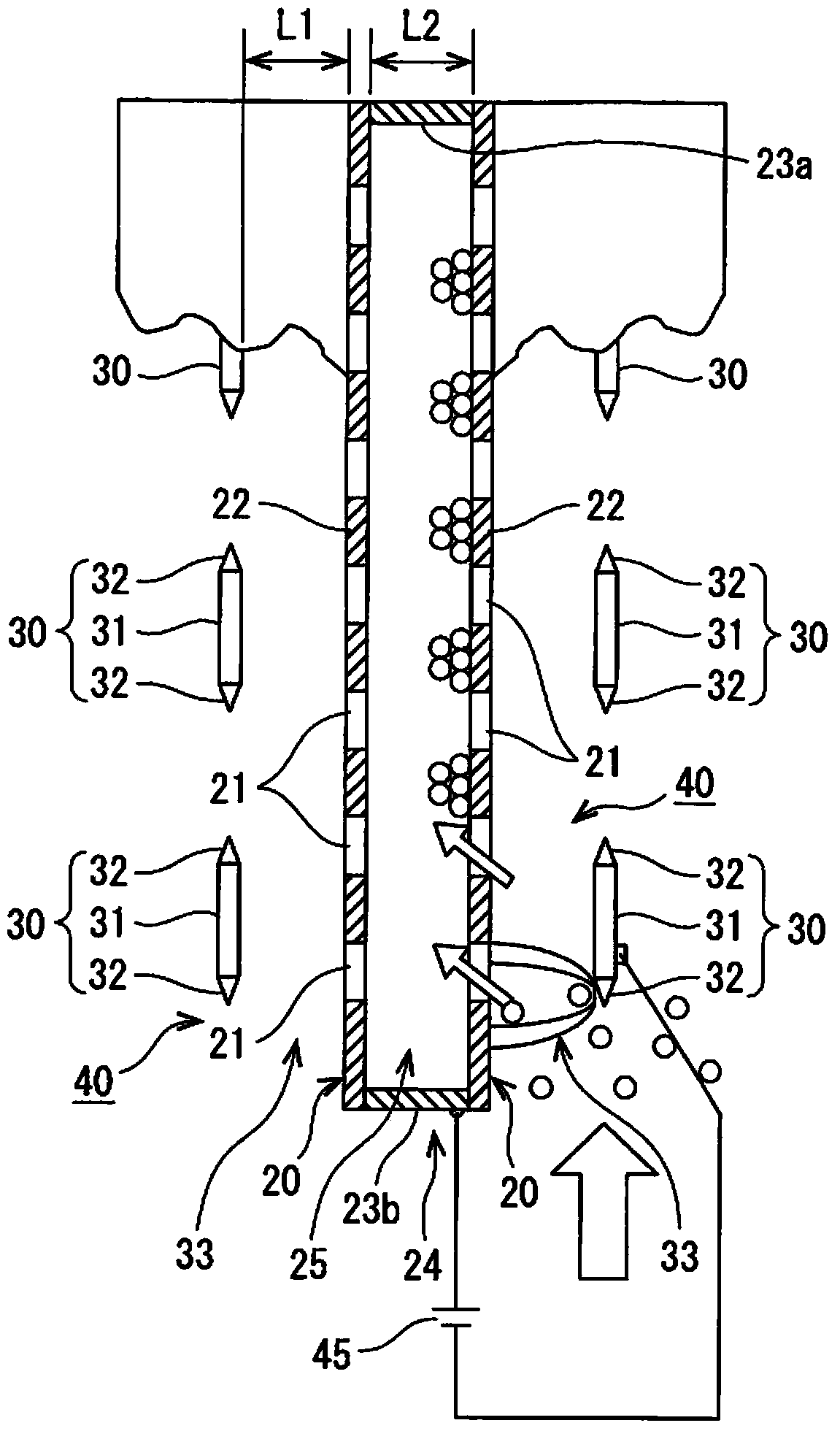

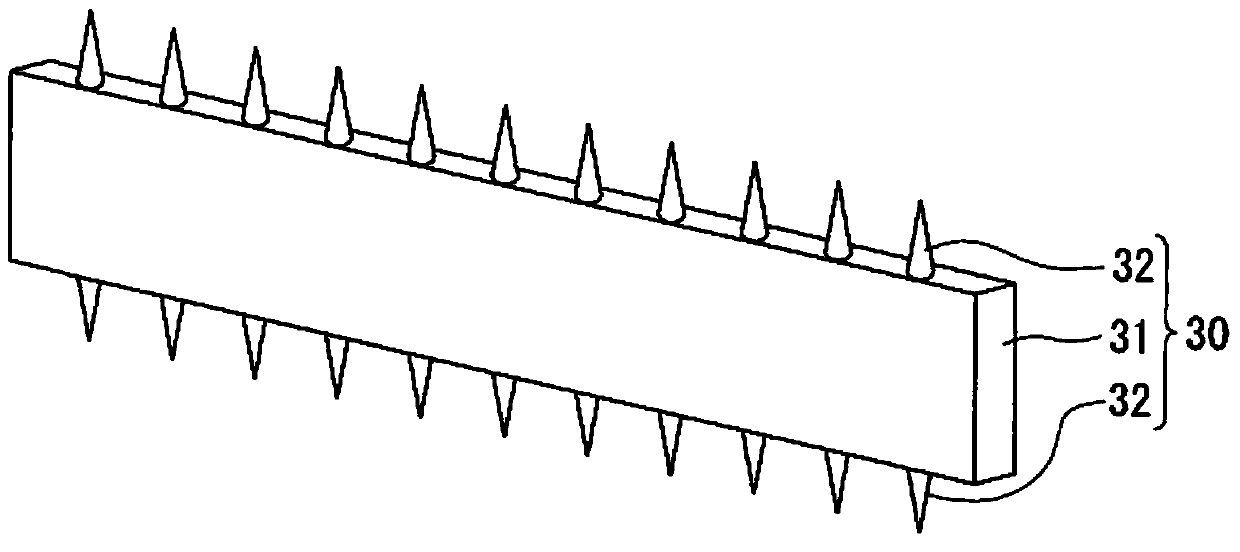

[0065] The electrostatic precipitator 1 has, for example, a cube-shaped frame body 2, and a plurality of groups of dust-collecting electrodes 40 are arranged in the frame body 2, and the dust-collecting electrodes 40 are composed of, for example, square plate electrodes 20 and discharge electrodes 30. Among them, such as figure 2 As shown, the discharge electrode 30 is opposed to one surface of the plate-shaped electrode 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com