Sewage treatment tank sludge discharge device based on environmental protection

A technology of sewage treatment tank and sludge discharge device, which is applied to the feed/discharge device of the settlement tank, the settlement tank, chemical instruments and methods, etc., which can solve the problems of wasting time, inability to ensure the cleanliness of the treatment tank, and insufficient sludge cleaning and other problems to achieve a thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

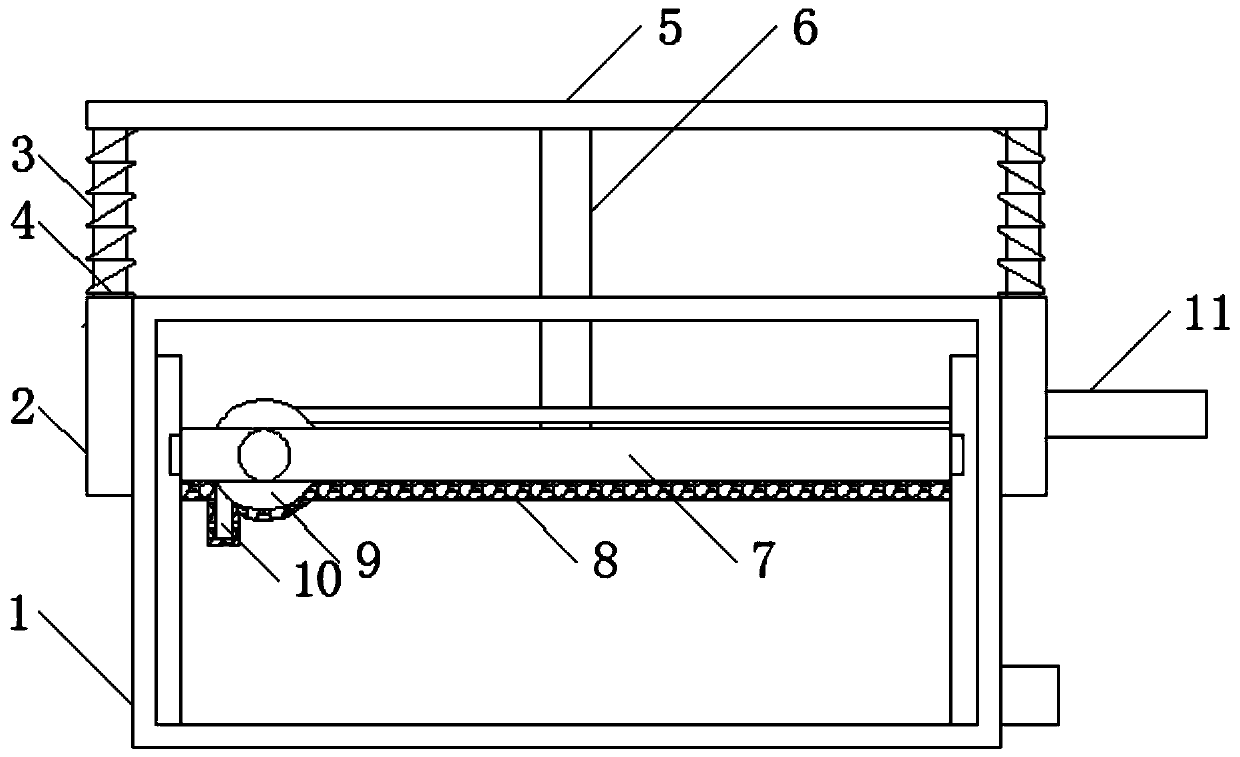

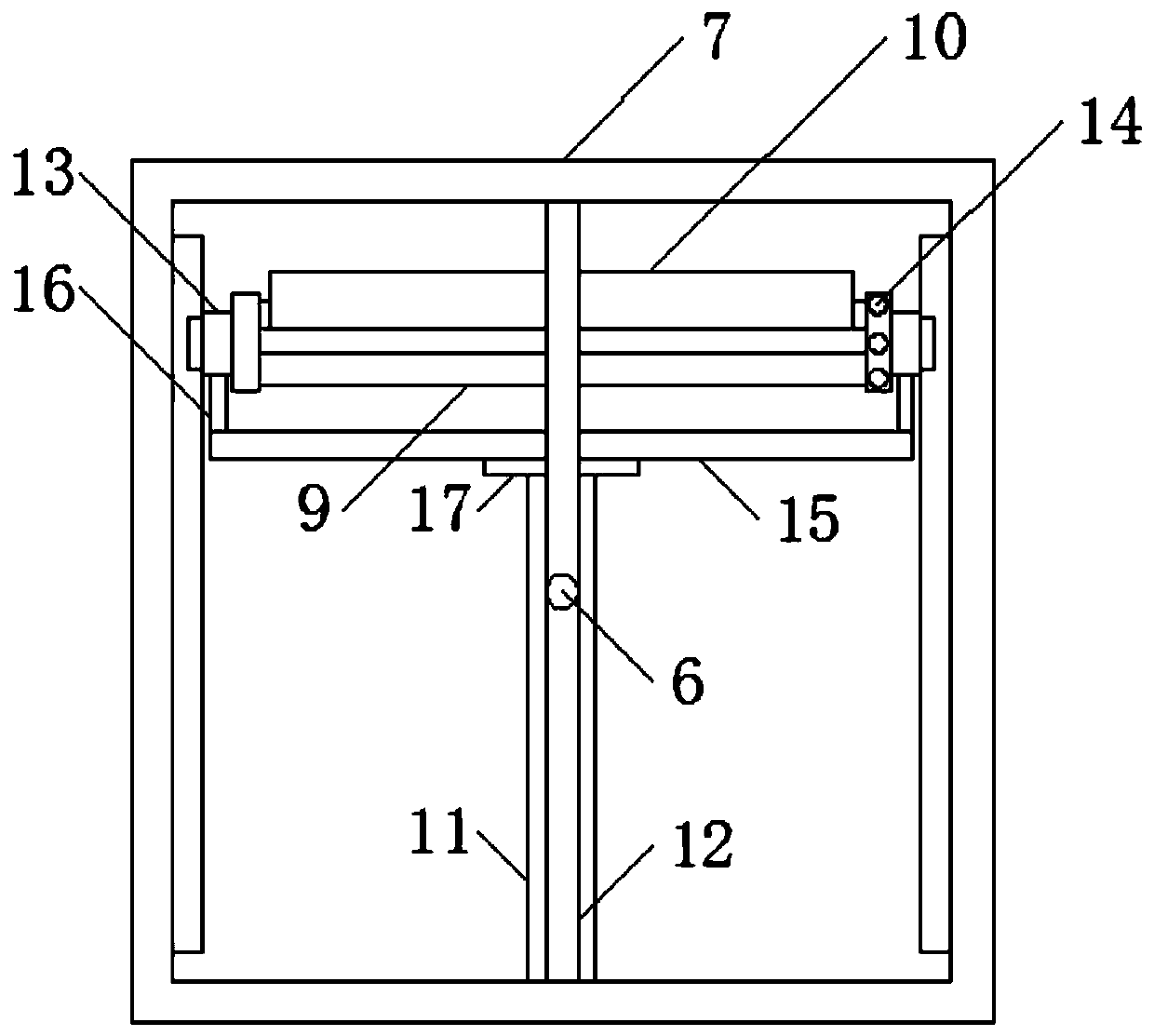

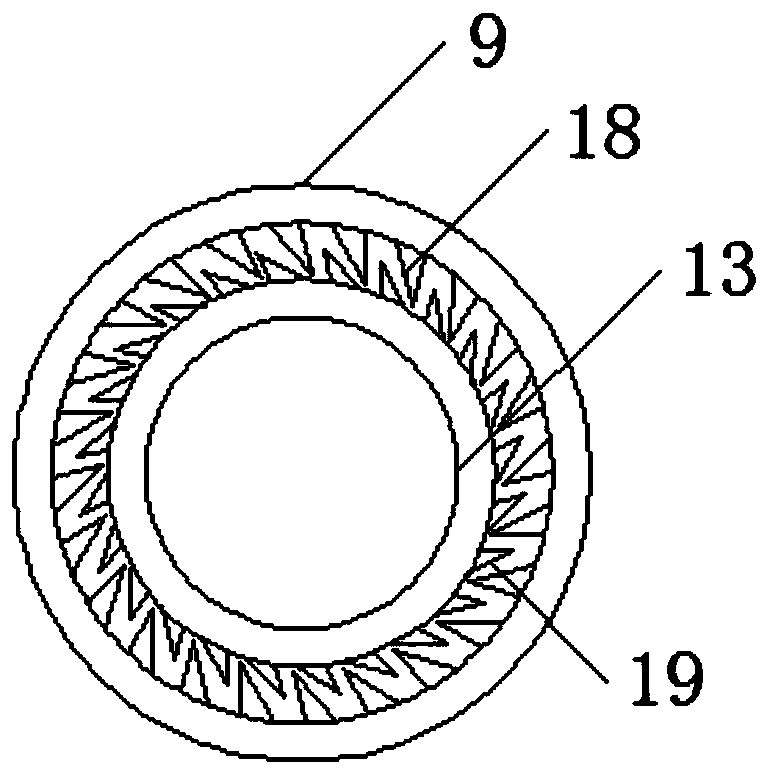

[0022] Embodiment: After the sludge in the treatment tank 1 is settled, the fixed plate 5 is pushed downward to move downward, and the fixed plate 5 slides in the limit tube 2 through the limit rod 3 during the downward movement to ensure the stability of the movement , turn the rotating rod 16 to rotate the rotating roller 9 to turn over on the connecting shaft 13, and rotate in one direction through the conical teeth 18 in the tooth groove 19, so that the rotating roller 9 drives the scraper 10 to rotate downward, and at the same time pushes the support plate through the connecting rod 6 7. Move downwards so that the scraper 10 can be inserted into the sludge, and then run the hydraulic push rod 11 to drive the connecting shaft 13 to move to the right side of the treatment tank 1, so that the scraper 10 can remove the sludge from the right side of the treatment tank 1 The mud outlet is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com