Enrichment and pre-separation system for VOCs in atmosphere

A pre-separation and enrichment technology, which is applied in the field of VOCs enrichment and pre-separation systems in the atmosphere, can solve the problems of low multi-concentration, complex characteristics, high test range and precision requirements of chromatographs, and achieves simple operation and high adsorption efficiency. , to achieve the effect of self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

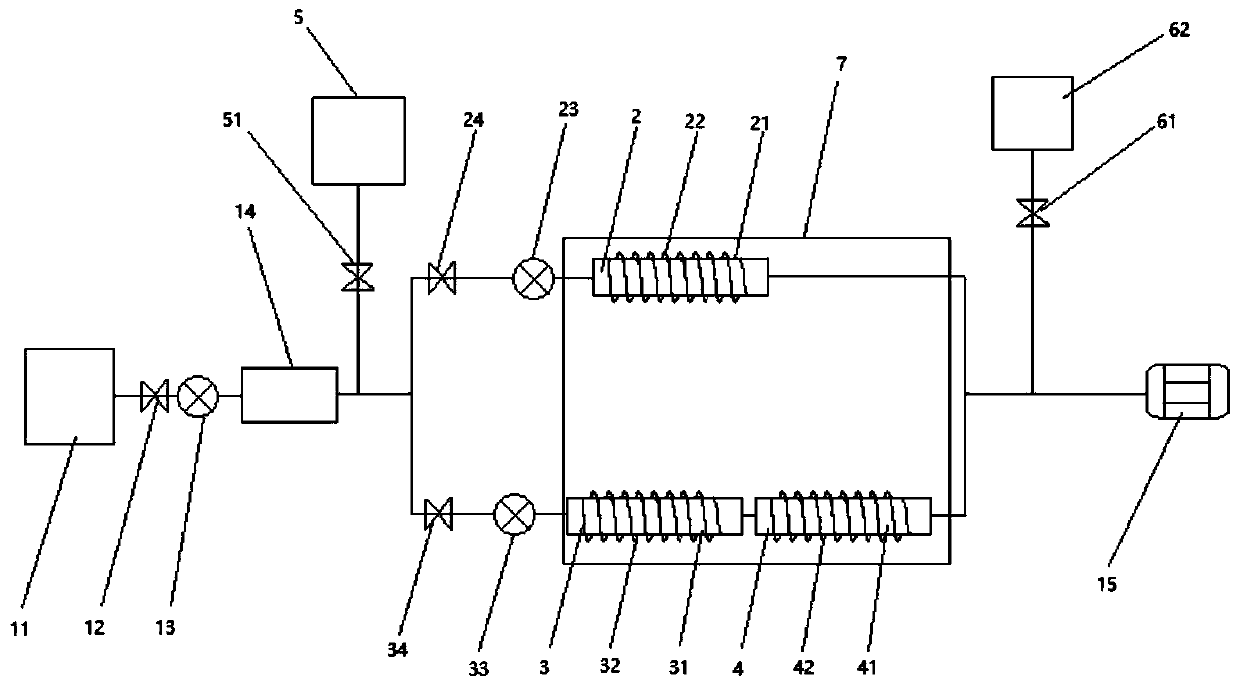

[0048] This embodiment provides an enrichment and pre-separation system for VOCs in the atmosphere, including a sampling device, a water removal device, an enrichment and pre-separation device, and a sampling device. Such as figure 1 As shown, the sampling device includes an atmospheric sampler 11, a first control valve 12, and a first gas flow controller 13, the atmospheric sampler 11 is connected to the first gas flow controller 13, and the atmospheric sampler 11 is connected to the first gas flow controller 13. A first control valve 12 is provided between the first gas flow controllers 12 . The water removal device includes a first cold trap 14 , and the first cold trap 14 is connected with the first gas flow controller 12 .

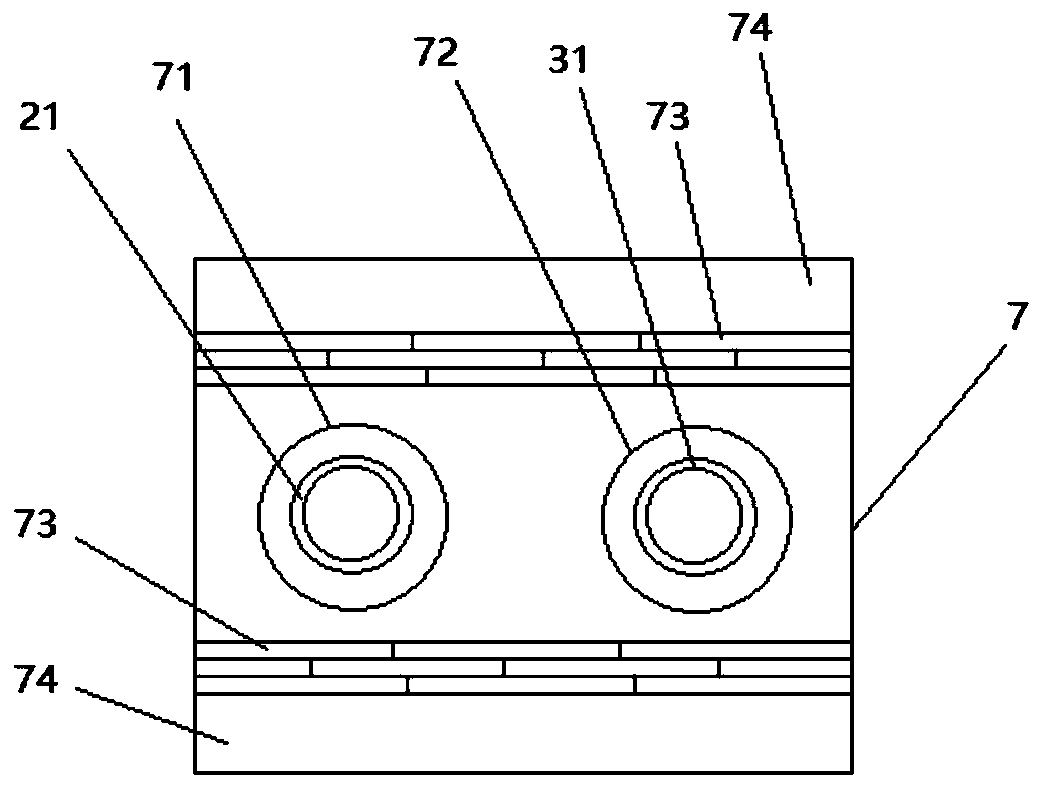

[0049] Such as figure 1 As shown, the enrichment and pre-separation device includes a second cold trap 2, a third cold trap 3, a fourth cold trap 4, a second gas flow controller 23, a third gas flow controller 33, a second control Valve 24, the thi...

Embodiment 2

[0058] This embodiment provides a system for enriching and pre-separating VOCs in the atmosphere, and its working method includes three processes: adsorption concentration, classified capture, and equipment self-cleaning.

[0059] (1) Adsorption and concentration:

[0060] Such as figure 1 As shown, close the fourth control valve 61 and the fifth control valve 51; open the first control valve 12, the second control valve 24, the third control valve 34, and the air pump 15, and open the low temperature state of the low temperature environment box 7 The sample gas in the atmospheric sampler 1 enters the first cold trap 14 through the first control valve 12 and the first gas flow controller 13, and the water vapor in the sample gas condenses on the stainless steel pipe of the first cold trap, thereby realizing for the purpose of removing water vapor. The sample gas after water vapor removal is divided into two paths, one path passes through the second control valve 24, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com