Reciprocated flowing type marine diesel engine continuous catalyzing regenerating diesel oil particle filter

A technology for marine diesel engines and particle filters, which is applied in engine components, combustion engines, machines/engines, etc., can solve the problems of catalyst sulfur ash deposition blocking failure, no breakthrough progress has been achieved, etc., to improve the ability of sulfur poisoning failure, The effect of strong anti-catalyst sulfur poisoning ability and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

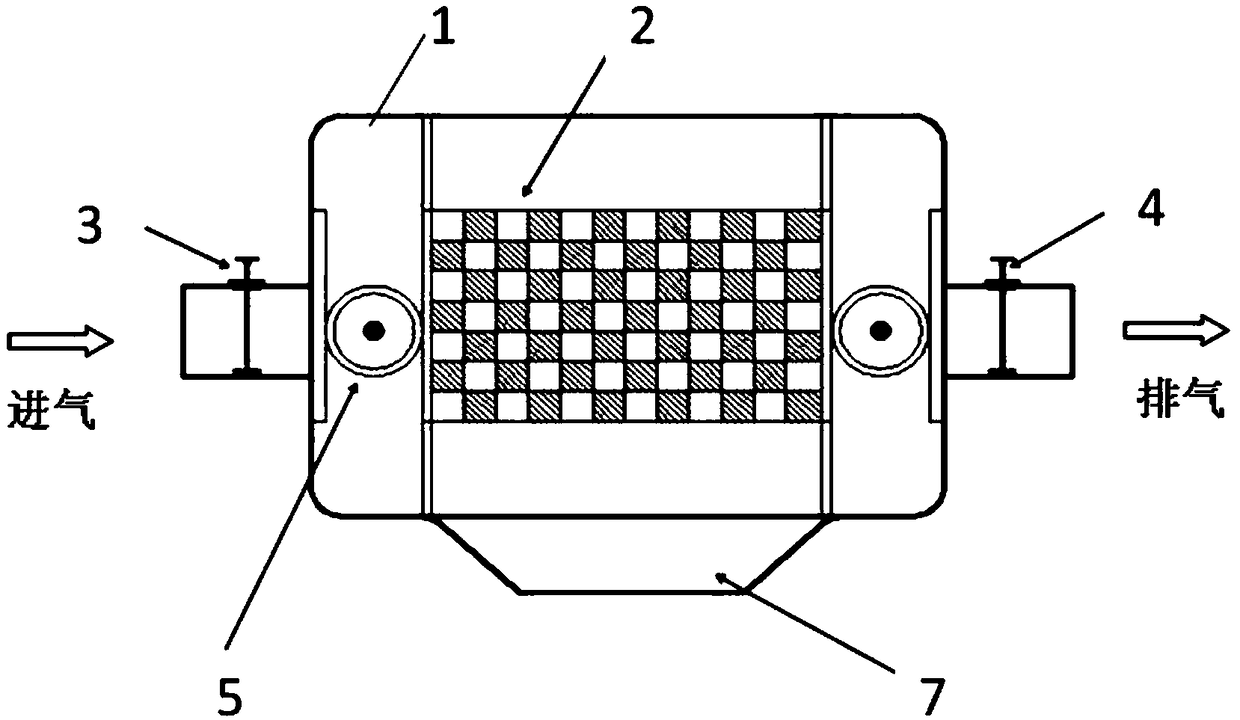

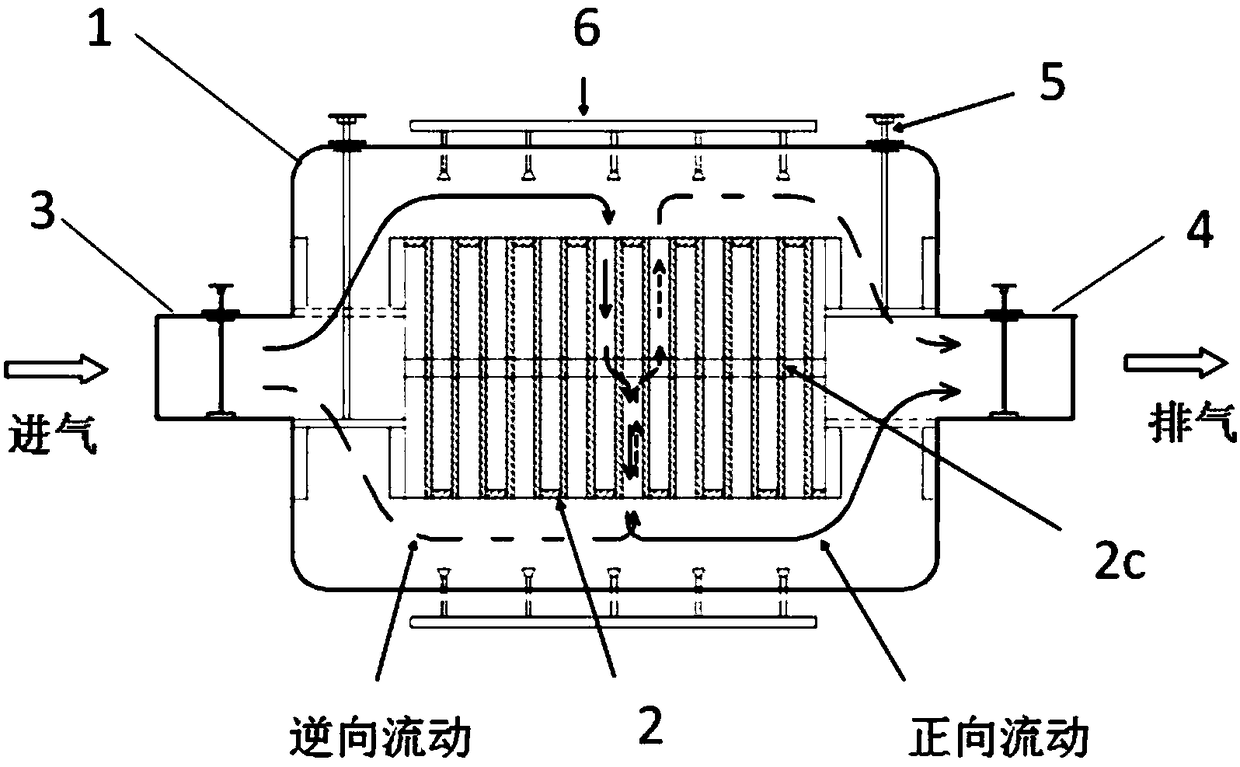

[0033] Such as figure 1 and figure 2 As shown, the reciprocating flow marine diesel engine continuously catalytically regenerates the diesel particulate filter, which includes a housing 1 and a filter body 2. The filter body 2 is fixedly installed in the housing 1, and the opposite ends of the housing 1 are provided with an air inlet 3 and an exhaust gas. Inlet 4, air inlet 3 and exhaust port 4 are respectively provided with an intake valve and an exhaust valve. The microcomputer controls the synchronous opening and closing and controls the flow direction of the airflow, so as to realize the periodic reciprocating flow of the airflow in the filter body 2; the ash hopper 7 is arranged at the bottom of the shell 1 and communicated with the shell 1 to collect the dust deposited by blowback.

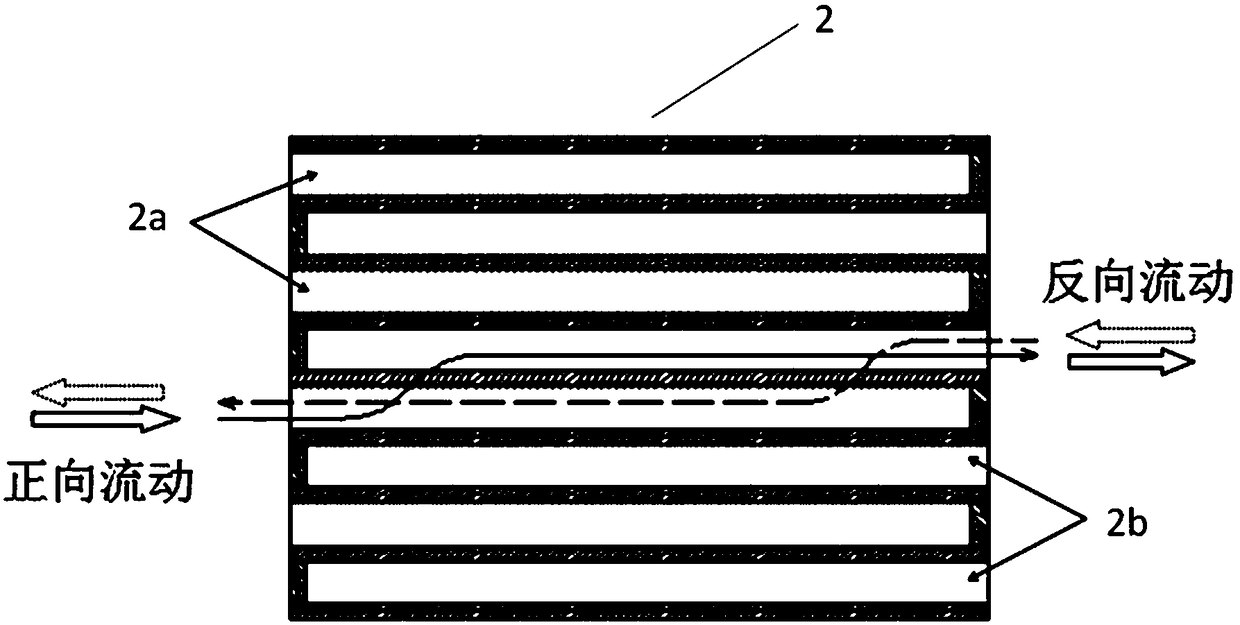

[0034] Such as figure 2 As shown, the filter body 2 adopts a wall-flow structure, and two adjacent channels are separated by a solid wall 2c with a penetrating microporous structure. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com