System and method for directly mineralizing carbon dioxide in flue gas by using gypsum

A technology of carbon dioxide and gypsum, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of large-scale application and high cost, achieve flue gas decarbonization and low utilization cost, improve utilization rate, and reasonable design Effect

Pending Publication Date: 2021-07-30

XIAN THERMAL POWER RES INST CO LTD

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Aiming at the problems of high cost and incapable of large-scale application in the prior art of mineralization and decarburization, the present invention provides a system and method for directly mineralizing flue gas carbon dioxide by using gypsum

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

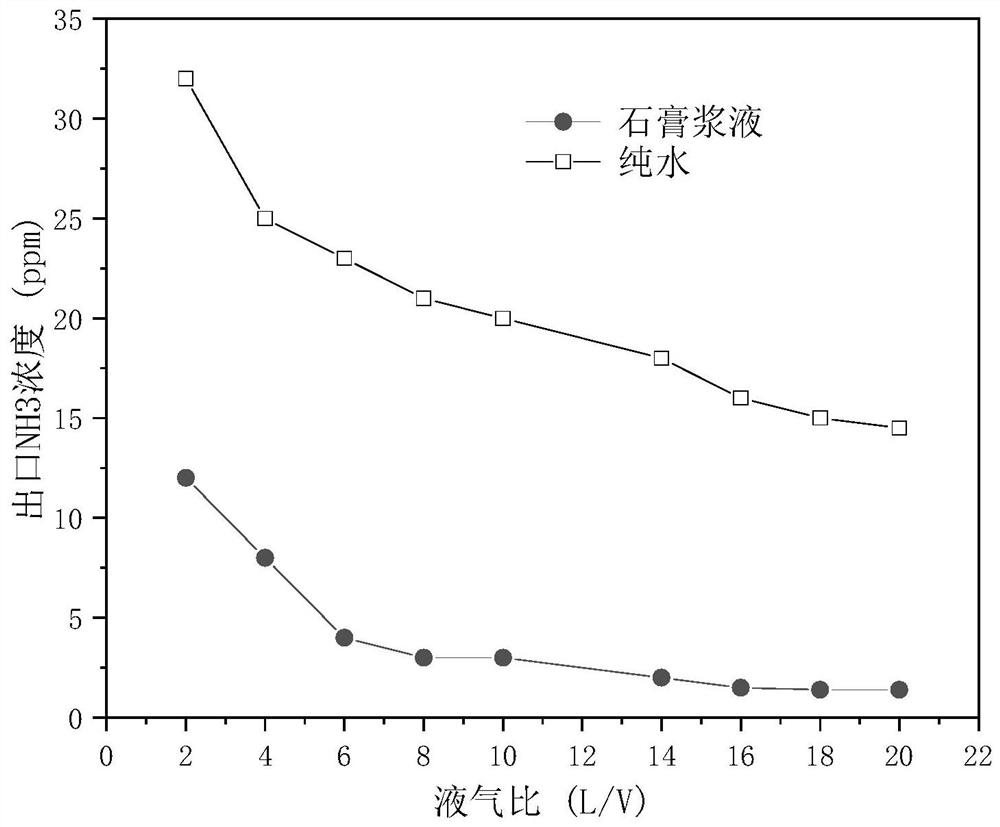

[0061] The present invention provides a specific embodiment to test the absorption effect of gypsum slurry on ammonia escape under laboratory simulated flue gas conditions:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

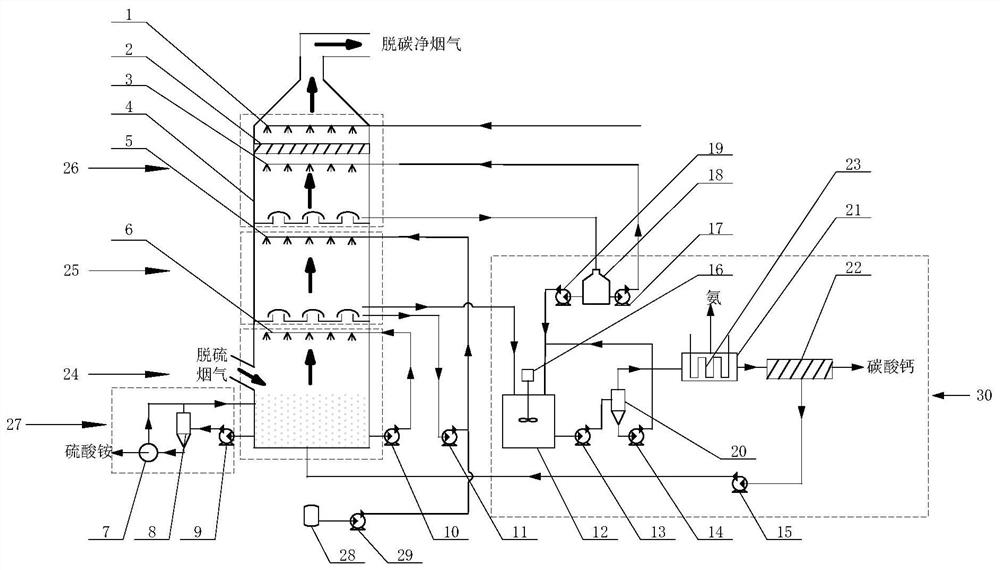

The invention relates to a system and a method for directly mineralizing carbon dioxide in flue gas by using gypsum. An absorption tower can sequentially realize cooling, decarburization and escape ammonia trapping processes of desulfurized flue gas; the bottom of a lower cooling section is provided with a slurry area and is circularly connected with an upper ammonium bicarbonate spraying layer, so that the trapping of the waste heat of the desulfurized flue gas can be realized, and heat is provided for the low-temperature concentration and crystallization of ammonium sulfate slurry; the bottom of a middle decarburization section is provided with an ammonium bicarbonate liquid holding layer, and the ammonium bicarbonate liquid holding layer and the ammonium bicarbonate spraying layer form circulation; ammonia is supplemented through an ammonium bicarbonate spraying layer pipeline, so that continuous decarburization reaction can be carried out on cooled flue gas; and meanwhile, the lower cooling section and the middle decarburization section are separated, and a gypsum spraying layer, a demister, a process water spraying layer, a gypsum liquid holding layer and a gypsum spraying layer which are sequentially arranged on the upper deamination section in the height direction form circulating spraying, and the continuous trapping process of escaping ammonia is achieved. The system is simple in structure, reasonable in design and low in smoke decarburization and utilization cost, and meanwhile, continuous online treatment of a large amount of smoke can be achieved.

Description

technical field [0001] The invention belongs to the field of purification of air pollutants, and relates to a system and a method for directly mineralizing carbon dioxide in flue gas by using gypsum. Background technique [0002] The problem of climate warming is a problem that affects the development of the whole human being, CO 2 is the main cause of climate warming, and large coal-fired power generation equipment is the main cause of CO 2 largest source of emissions, and anyone who wants to control CO on a large scale 2 emissions, and to deal with climate warming, efforts must be made to reduce CO emissions from large-scale combustion equipment. 2 capture. [0003] At present, the decarbonization of flue gas from coal-fired units is mainly based on carbon capture, utilization and storage (CCUS) technology, which uses organic amines as absorbents to combine with CO in flue gas. 2 The reaction generates a water-soluble salt, and then heats the absorption liquid to reali...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/75B01D53/62B01D53/58B01D53/78B01D53/96C01F11/18C01C1/24

CPCB01D53/58B01D53/62B01D53/75B01D53/78B01D53/96B01D2251/2062B01D2251/404B01D2251/608B01D2257/504B01D2258/0283C01C1/24C01F11/18Y02P20/129

Inventor 杨成龙程广文姚明宇蔡铭李阳赵瀚辰付康丽杨嵩郭中旭

Owner XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com