Surface slot blasting sealing method of dewaxed powder metallurgy green ware body

A technology of powder metallurgy and treatment method, which is applied in the field of high-temperature forging of powder metallurgy green bodies, can solve the problems of undamaged oxides and affecting pore structure, etc., and achieve the effects of weakening sensitivity, improving quality, and reducing oxidation and decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

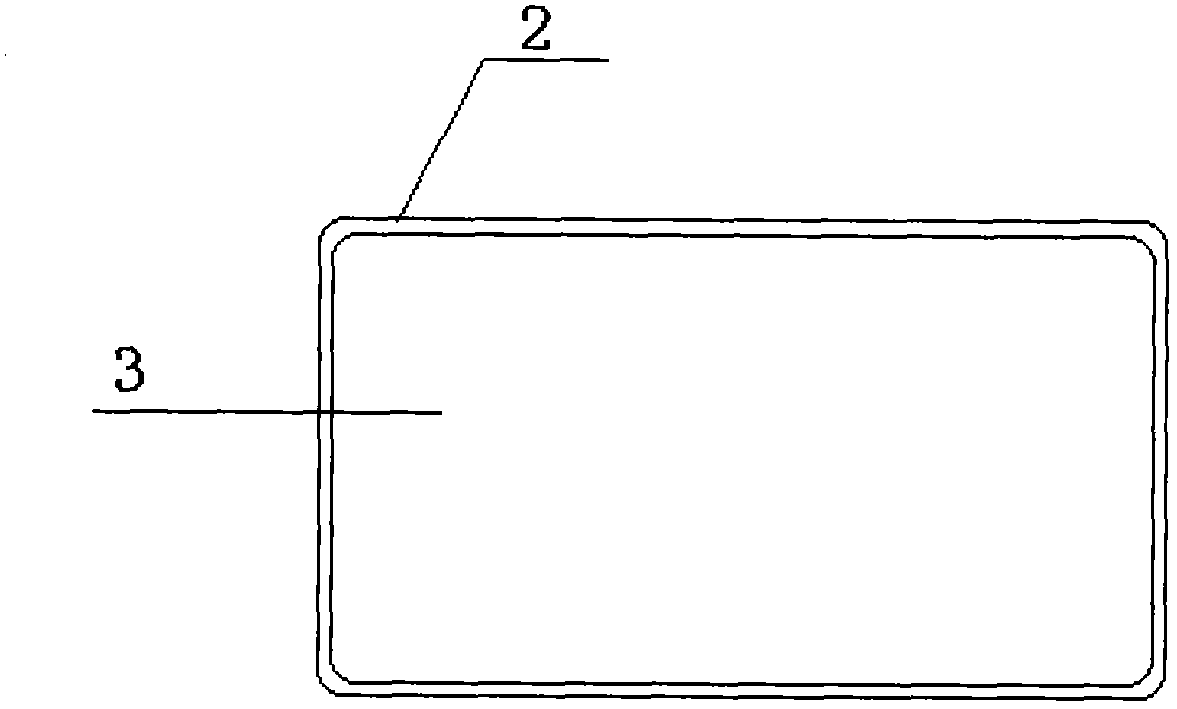

[0026] Combine below image 3 , the present invention is further described:

[0027] A high-density layer 2 is formed on the surface of the powder metallurgy green body 3 after dewaxing and before sintering, and the thickness of 0.1mm≤high-density layer≤0.5mm. Specifically, the high-density layer 2 is formed on the surface layer of the powder metallurgy green body after dewaxing and before sintering by shot peening and sealing with a shot peening machine.

[0028] The shot peening sealing treatment technology of the shot blasting machine can seal the surface of the powder metallurgy workpiece, that is, close the pores on the surface and near the surface as channels for oxide penetration and decarburization. This technology reduces the oxidation depth by more than 50% and the decarburization thickness by more than 70%. In addition, the hot forged product treated by the shot peening sealing treatment technology of the shot blasting machine eradicates the pores on the surface a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com