Flexible production device for directly charging high-temperature casting blanks in sequence

A flexible production and slab casting technology, applied in metal rolling and other directions, can solve problems such as the mismatch of work system and production rhythm, and achieve the effects of improving market competitiveness, increasing production, and reducing production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

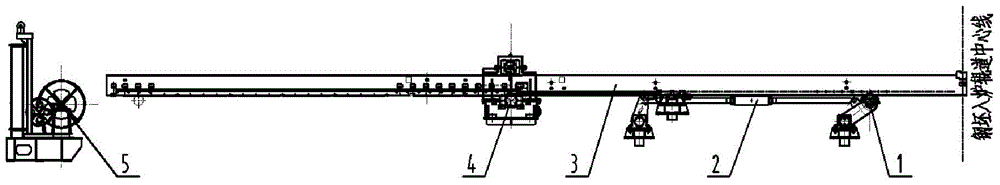

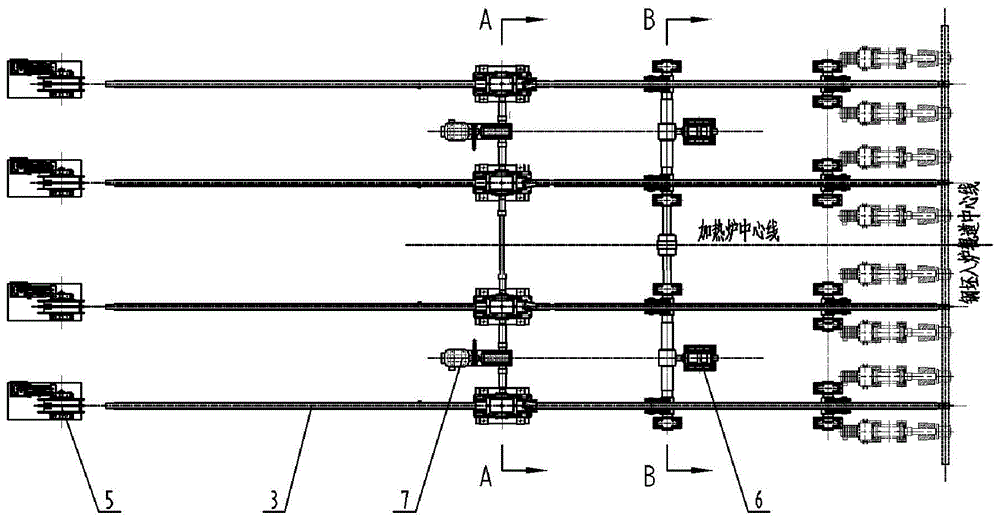

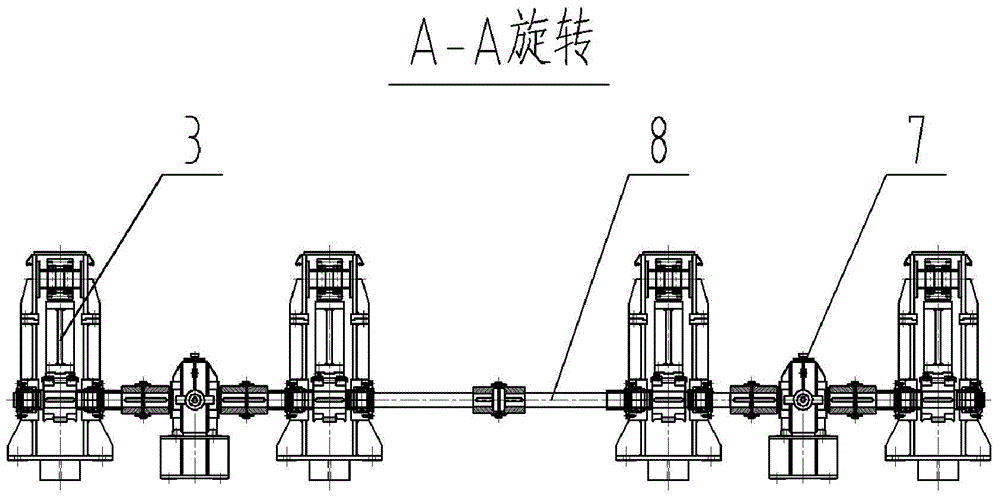

[0022] Figure 1-Figure 6 It is a specific embodiment of the present invention.

[0023] The present invention includes a lifting roller device 1, a parallel linkage mechanism 2, a supporting steel arm 3, a gear box 4, a cooling water pipe curling device 5, a lifting drive device 6, a translation drive device 7, a translation drive synchronous shaft 8, a lift drive crank 9, Lifting synchronous shaft 10, lifting follow-up crank 11; The lifting synchronous shaft 10 rotates at a certain angle; the lifting follower crank 11 and the lifting roller device 1 are connected through a parallel linkage mechanism 2, and the lifting roller device 1 rotates with the lifting drive crank 9, and supports the supporting steel arm 2 at the same time. up or down. The translation driving device 7 drives the rotation of the gear installed on the translation drive synchronous shaft 8, and the gear meshes with the rack installed on the supporting steel arm 3 to realize the advancement or retreat of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com