Water spray purifying system applied to industrial flue gas dedusting

A technology for purification system and industrial flue gas, applied in the field of purification system, can solve the problems of poor purification effect and low dust removal efficiency of flue gas purification equipment, and achieve the effects of low dust removal cost, high dust removal efficiency, and enhanced film forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

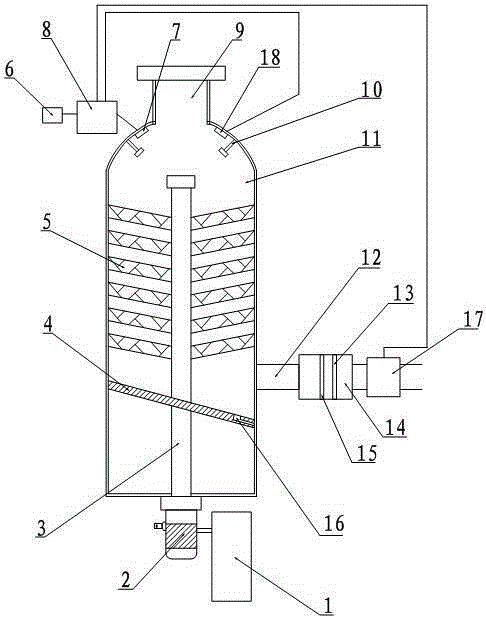

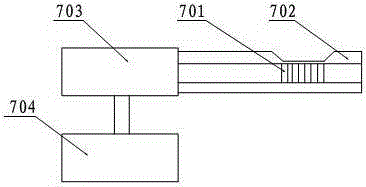

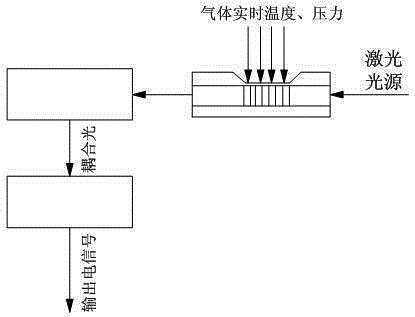

[0031] Such as figure 1 As shown, the present invention includes a body 11, a sprayer 10, a filter screen 5, a clean air exhaust pipe 9, a flue gas intake pipe 12, a sewage drainage partition 4, a temperature and pressure data acquisition device 7, a PLC controller 8, Laser emitter 18, primary filter device and transmission mechanism. Both the shower 10 and the filter screen 5 are arranged inside the machine body 11 , and the shower 10 is located above the filter screen 5 . The clean air exhaust duct 9 and the flue gas intake duct 13 are all in communication with the body 11, wherein the flue gas intake duct 12 is used to feed in the flue gas that needs dust removal and purification, and the clean air exhaust duct 9 is used to The clean air after flue gas purification is discharged.

[0032] The laser transmitter 18 is connected to the PLC controller 8 for emitting laser light under the control of the PLC controller 8; and the temperature and pressure data collection device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com