Patents

Literature

93results about How to "Reduce dust removal costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

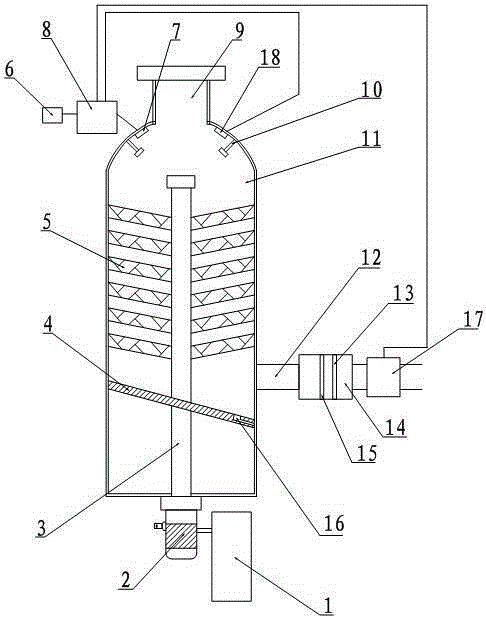

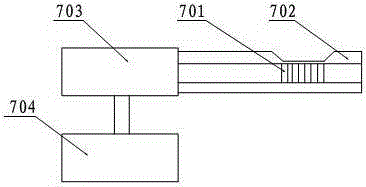

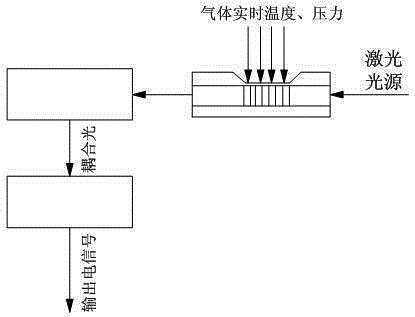

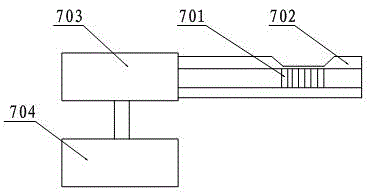

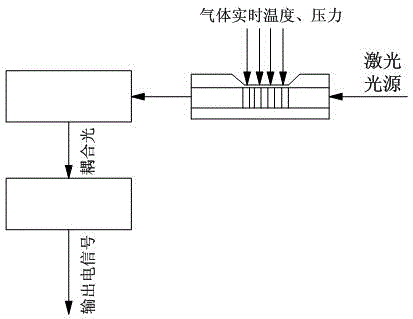

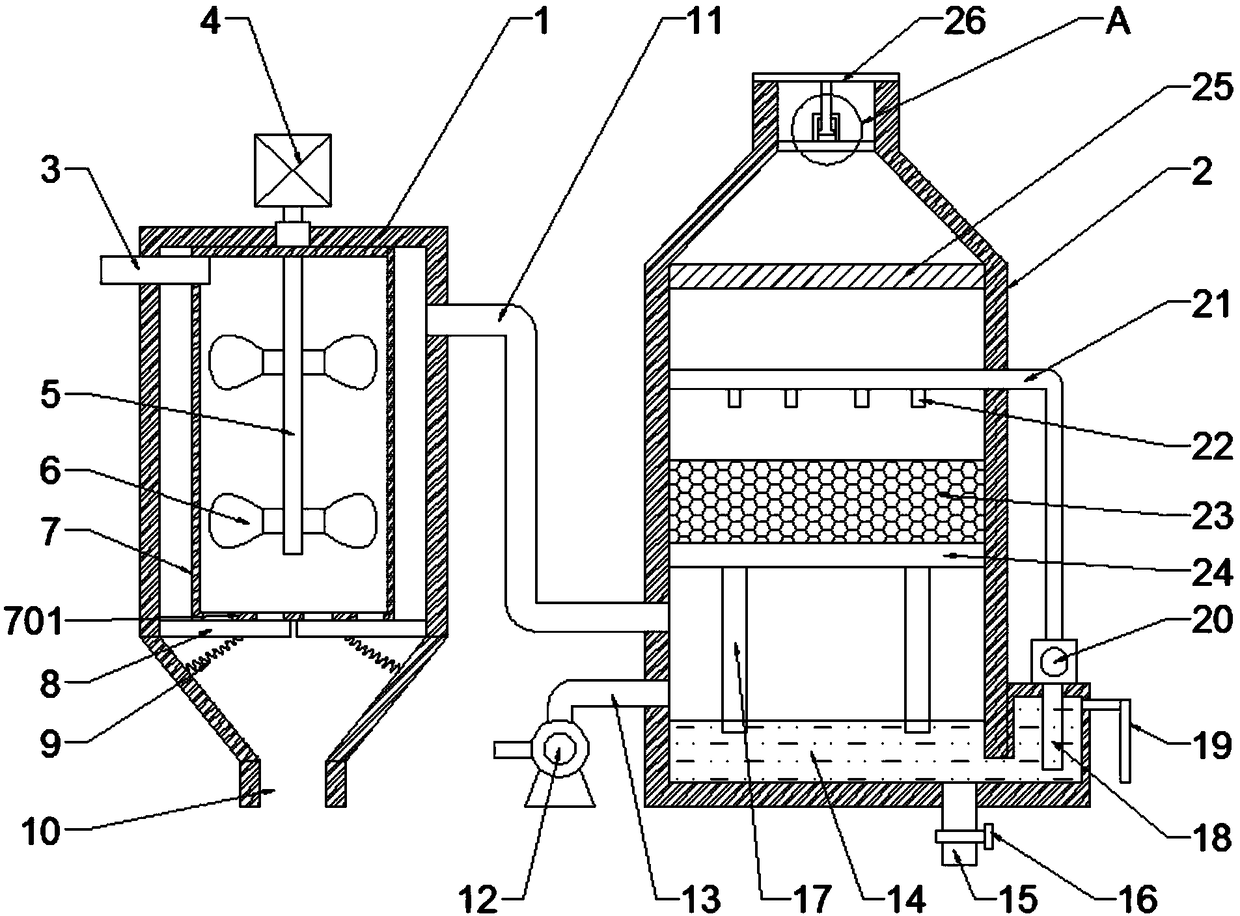

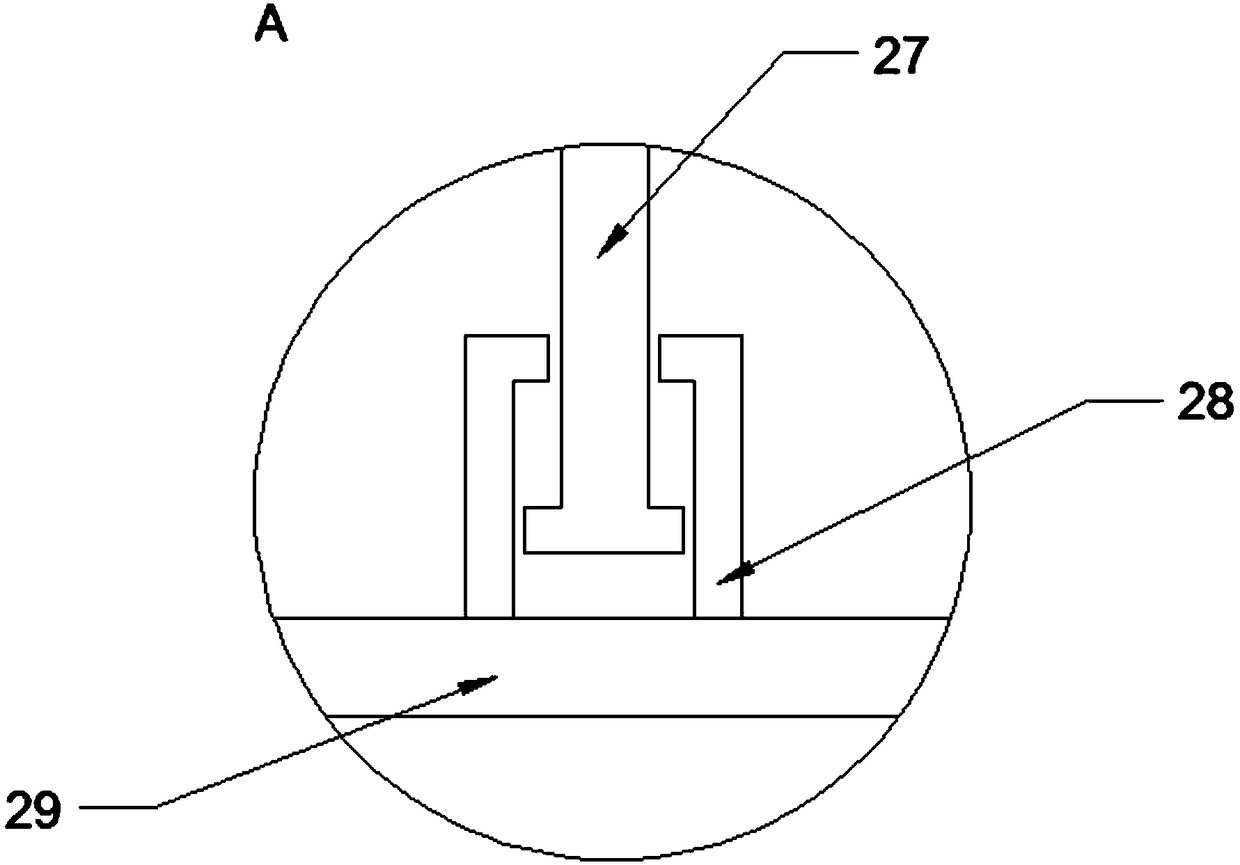

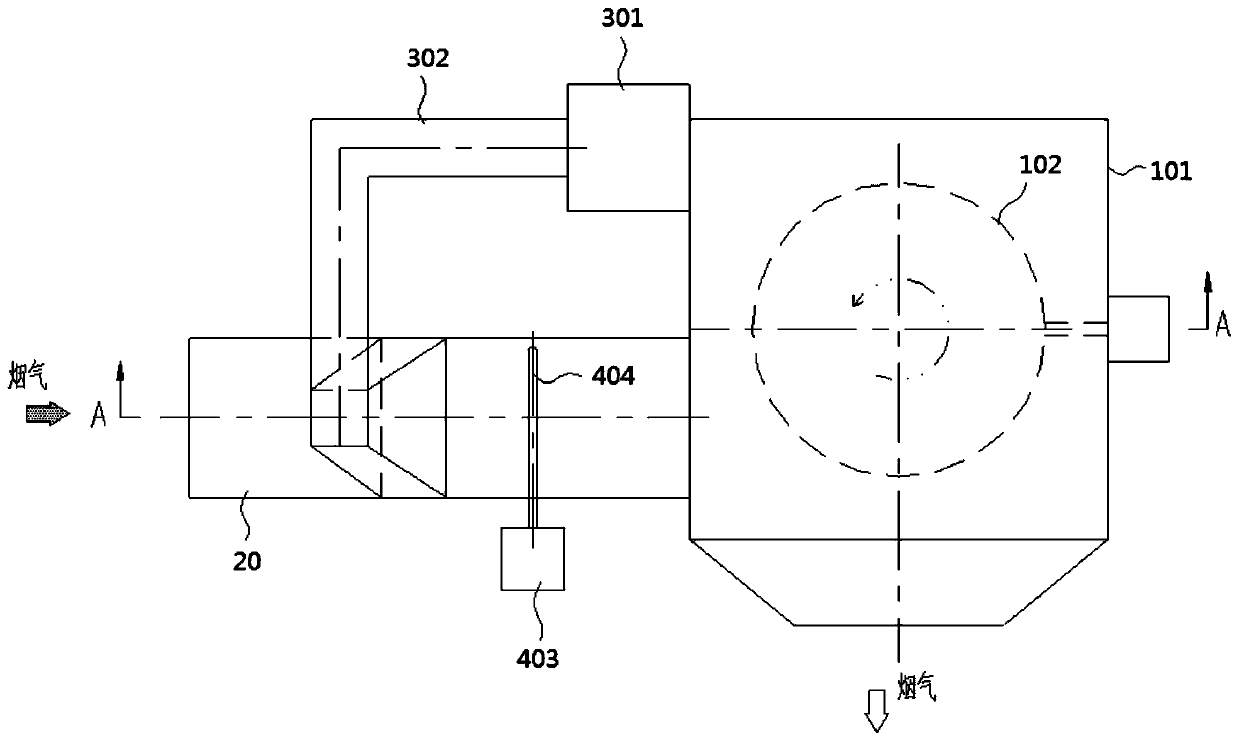

Water spray purifying system applied to industrial flue gas dedusting

InactiveCN105396404AReasonable designSimple structureHuman health protectionCombination devicesLaser transmitterSprayer

The invention discloses a water spray purifying system applied to industrial flue gas dedusting. The water spray purifying system applied to industrial flue gas dedusting comprises a machine body, a sprayer, a filtering screen, a flue gas charge pipeline, a drive mechanism, a temperature and pressure data acquiring device, a gas pressure regulating valve, an alarm, a laser transmitter 1, a laser transmitter 2, a sewage diversion baffle and a primary filtering device, wherein the top of the machine body is provided with a clean air discharge pipeline; the sprayer and the filtering screen are both arranged in the machine body; the flue gas charge pipeline is communicated with the side wall of the machine body; the drive mechanism is connected with the machine body and is used for controlling the filtering screen to drive; the temperature and pressure data acquiring device stretches into the machine body and is connected with a PLC; the gas pressure regulating valve, the alarm and the laser transmitter 1 are all connected with the PLC; the laser transmitter 2 is connected with the temperature and pressure data acquiring device and the PLC; the sewage diversion baffle is arranged in the machine body and is positioned below the filtering screen; the sprayer is positioned above the filtering screen; the sewage diversion baffle is of a slope structure, and the bottom of the slope is provided with a water drainage channel; light sources of the laser transmitters are directed to the temperature and pressure data acquiring device. The water spray purifying system applied to industrial flue gas dedusting is reasonable in design, is simple in structure, effectively enhances the flue gas purifying effect, and enhances the dedusting efficiency.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

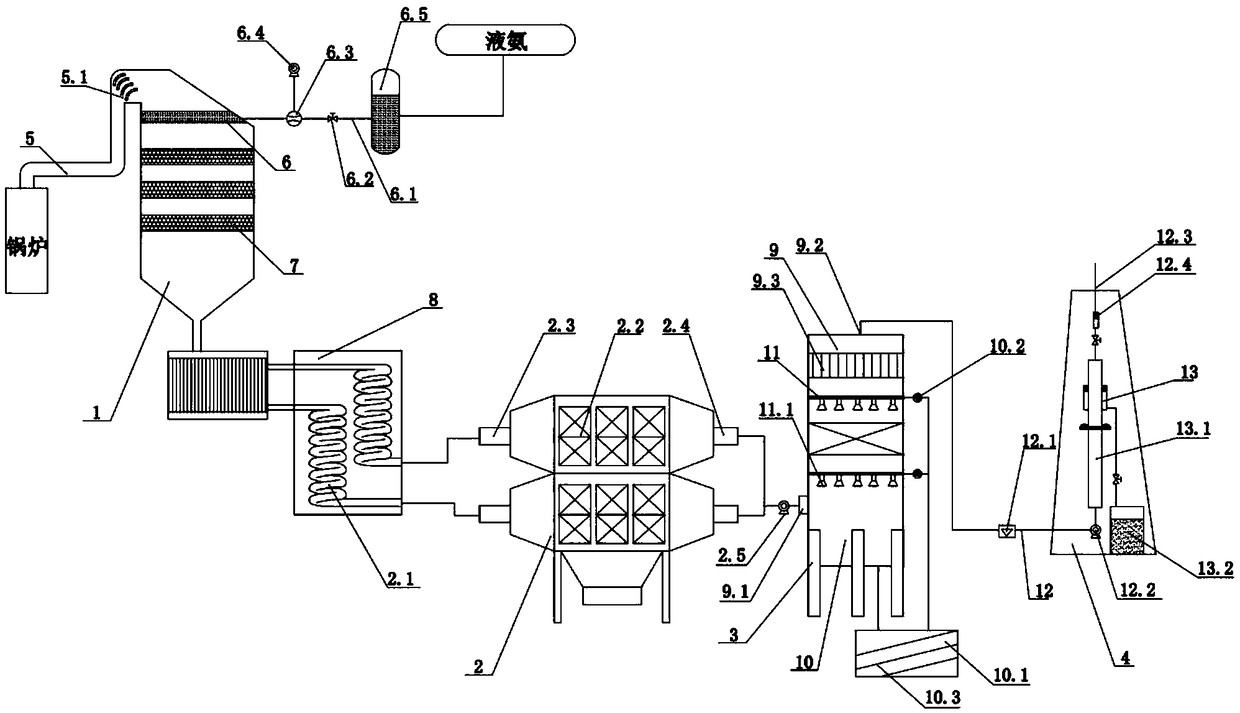

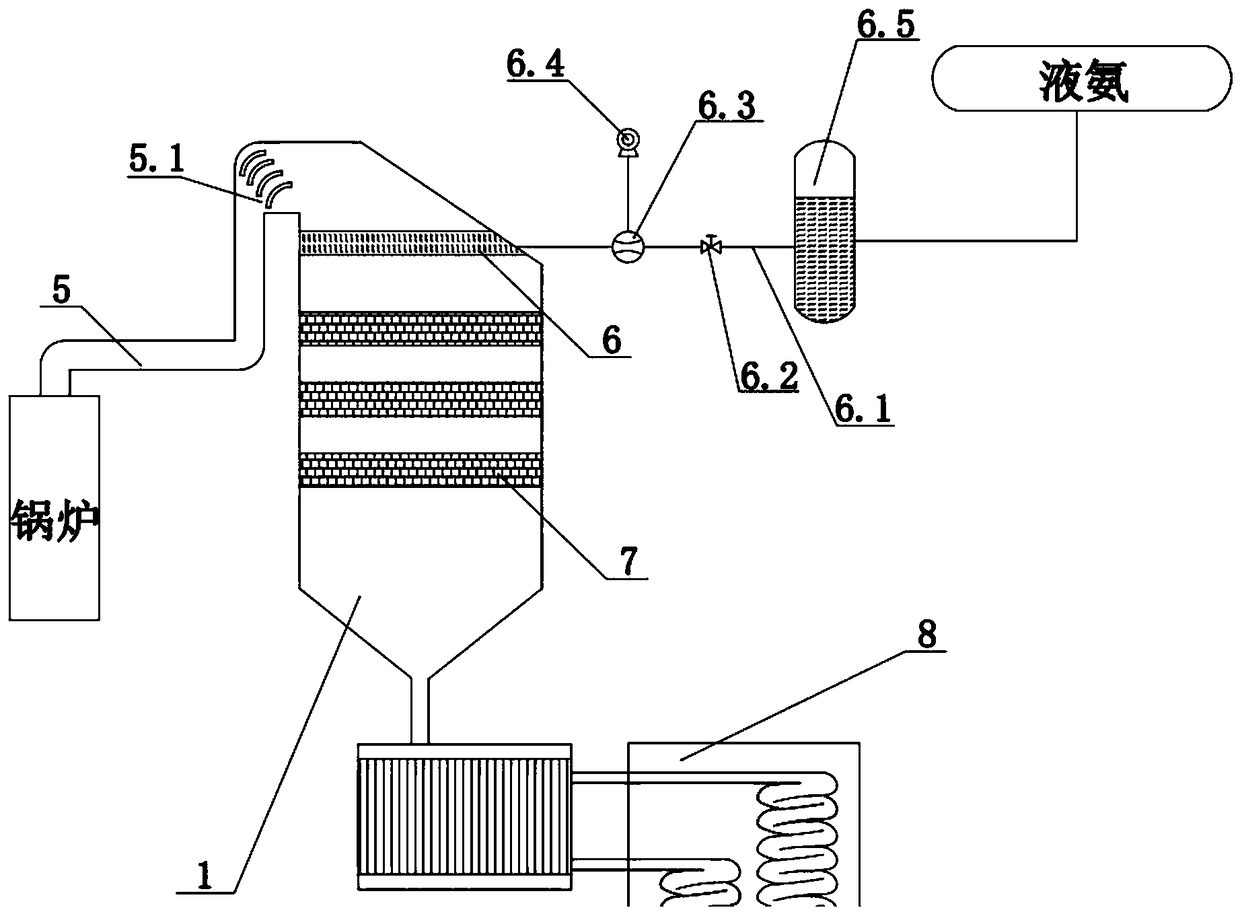

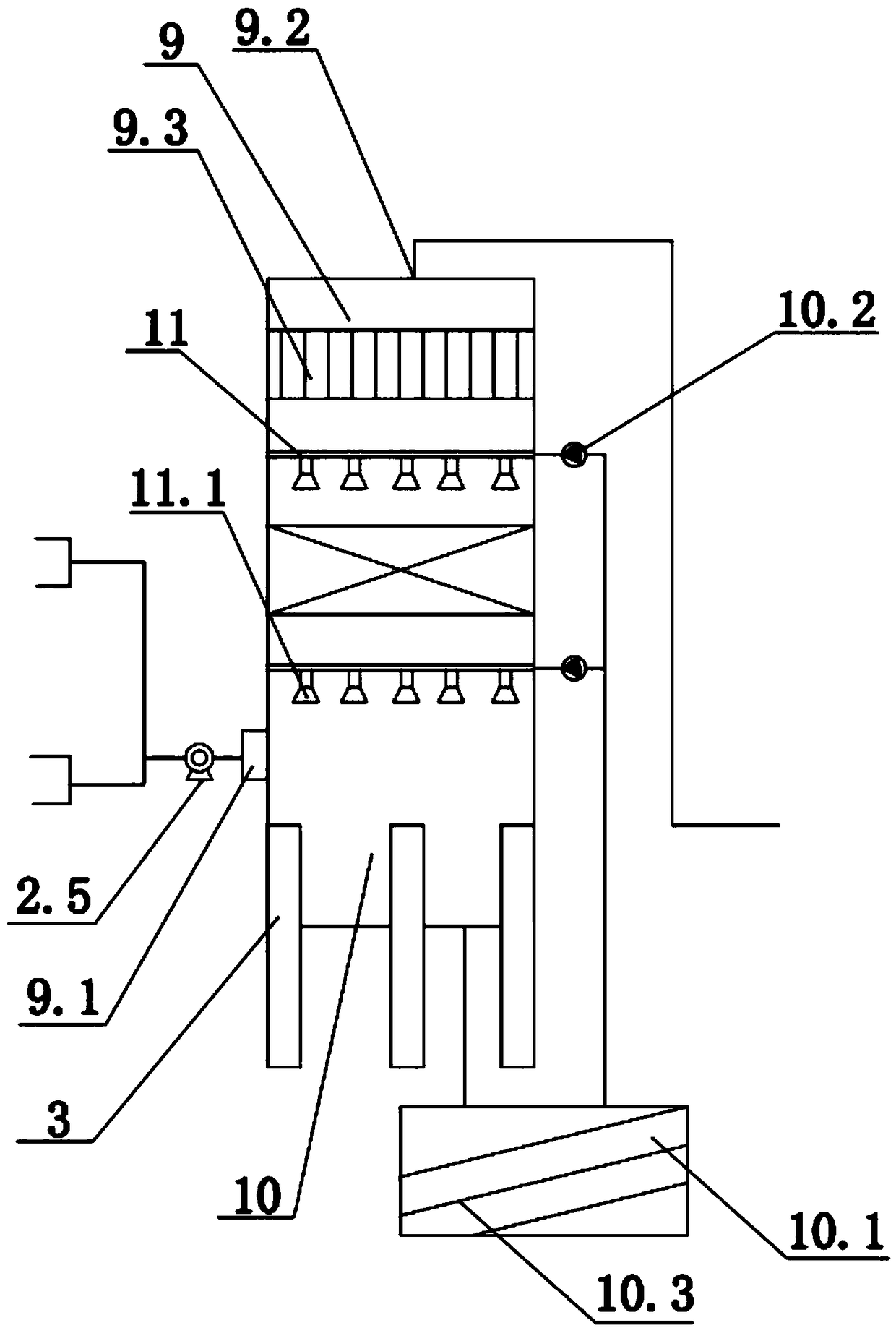

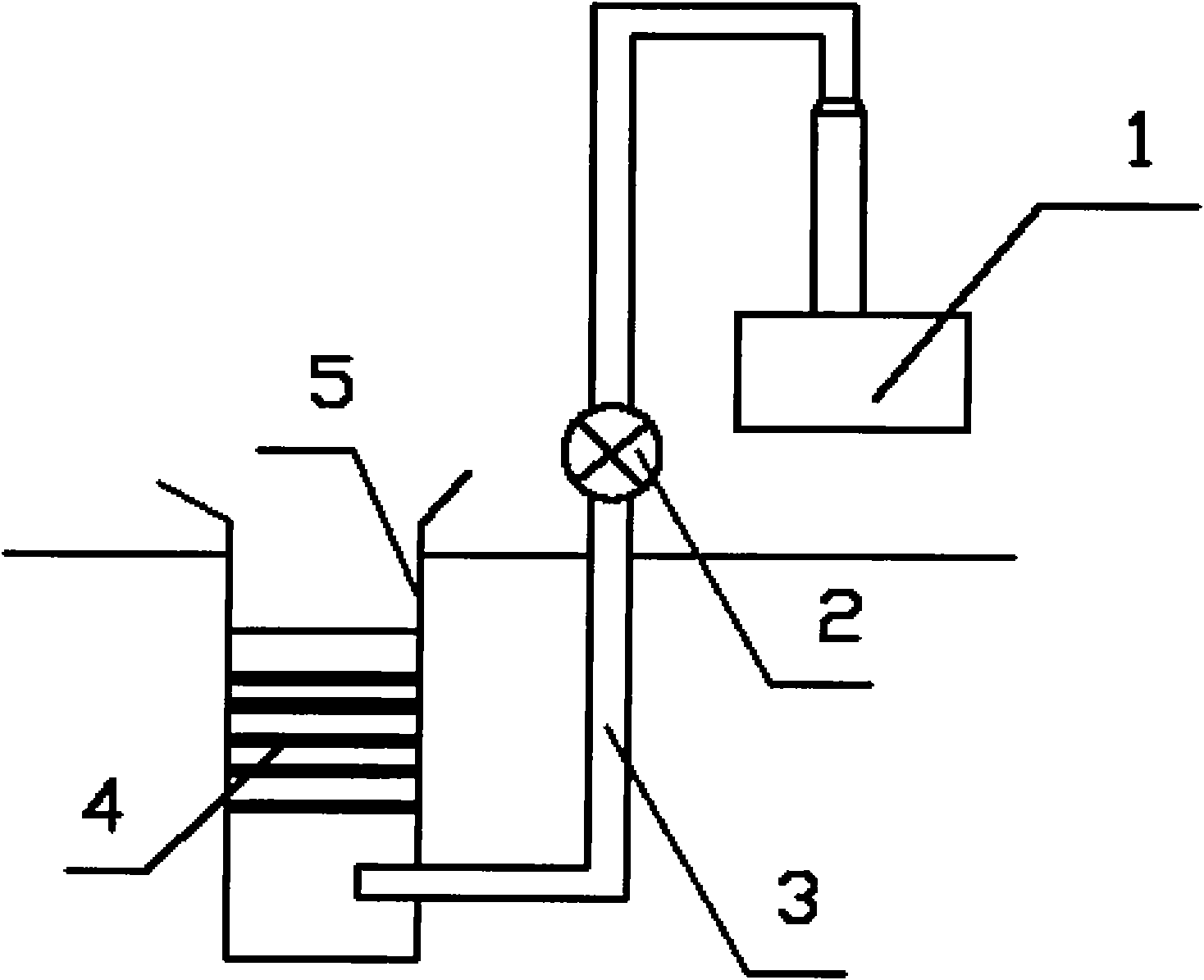

Flue gas purification system for power plant

InactiveCN109289516AEvenly distributedAvoid accumulationCombination devicesGas treatmentEngineeringExhaust pipe

The invention discloses a flue gas purification system for a power plant. The flue gas purification system comprises a conveying pipeline which is sequentially communicated with a denitration reactiondevice, a dust removal device, a desulfurization system and a chimney. An inlet flue is arranged on the denitration reaction device, the dust removal device comprises a dust removal pipe and an electrostatic precipitator and bag filter, the desulfurization system comprises a desulfurization tower, a flue gas inlet and a flue gas outlet, the bottom of the chimney is connected with the flue gas outlet through an exhaust pipe, and an exhaust port is formed in the top of the chimney. Flue gas is more uniformly distributed by the aid of guide vanes and rectified by a rectifier grille; waste heat in the flue gas is recovered by a heat exchanger; the electrostatic and bag composite dust removal device combines the advantages of electric dust removal and bag dust removal and is high in dust removal efficiency and low in dust removal cost; used alkaline liquid is low in cost, easy to obtain and wide in applicable range, and the sprayed alkaline liquid contacting with the flue gas returns intoan alkaline liquid treatment tank and is subjected to reduction regeneration treatment, preliminarily filtered by a filter plate, sprayed out by a spray pipe and recycled.

Owner:刘鹏

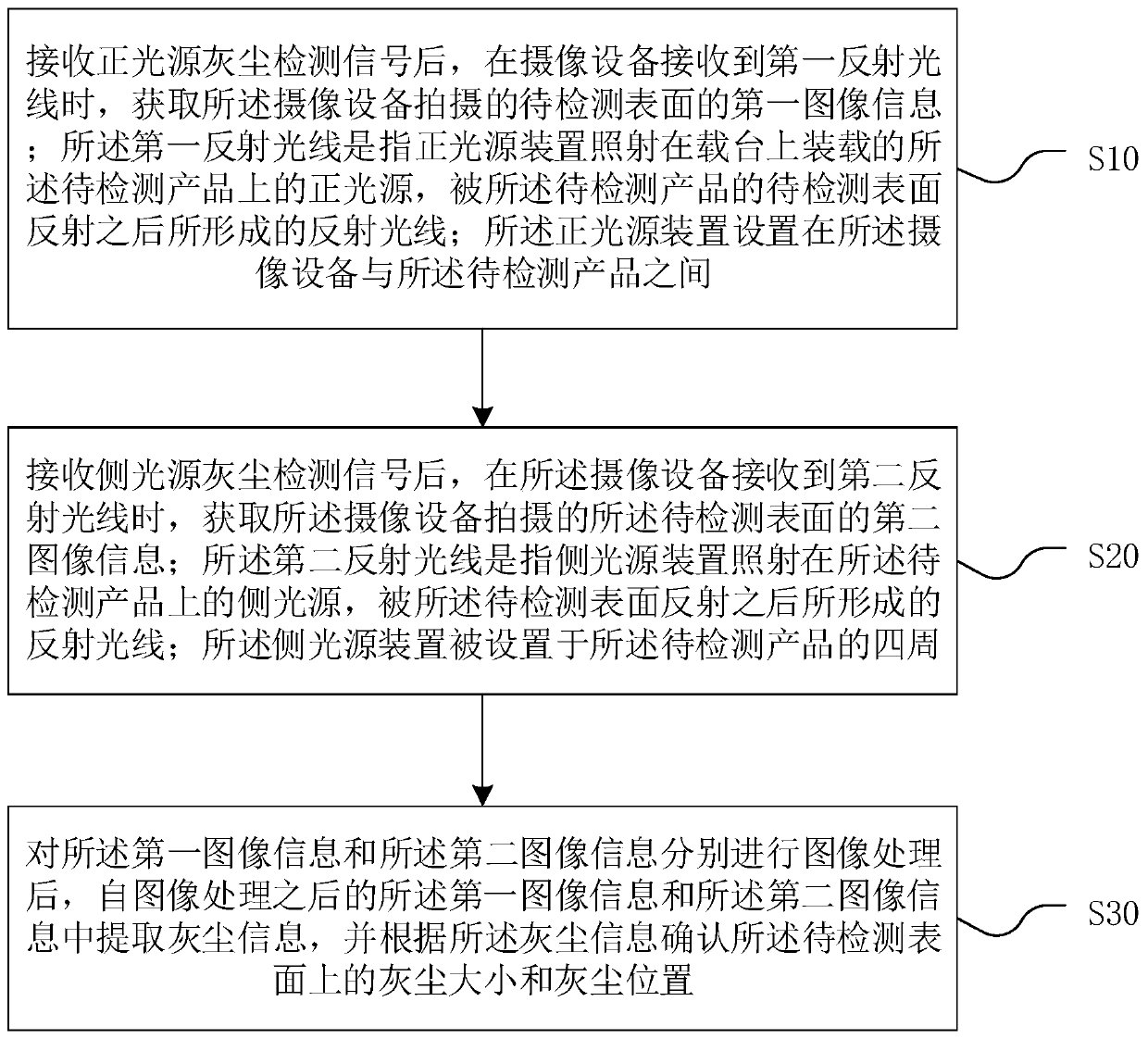

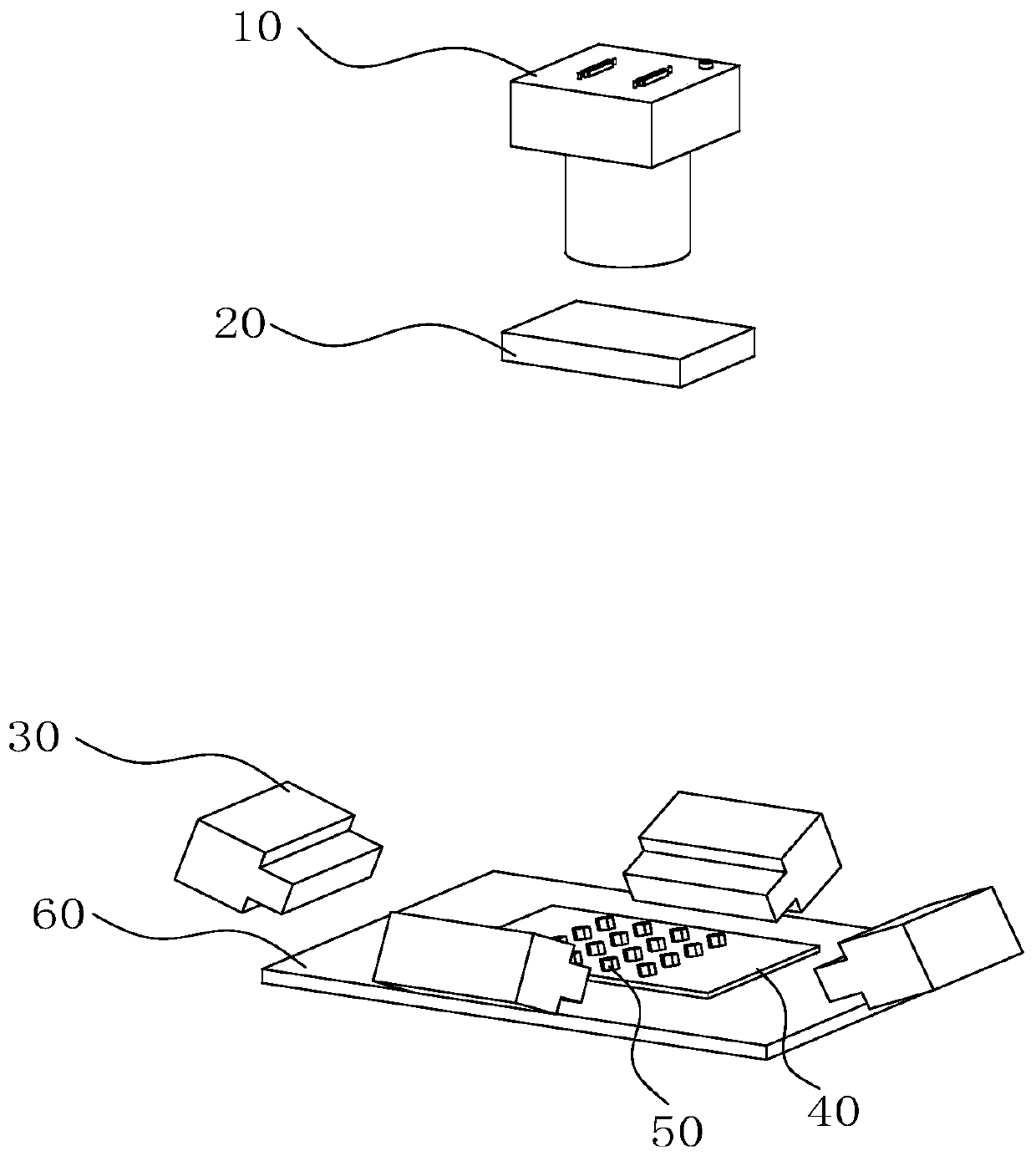

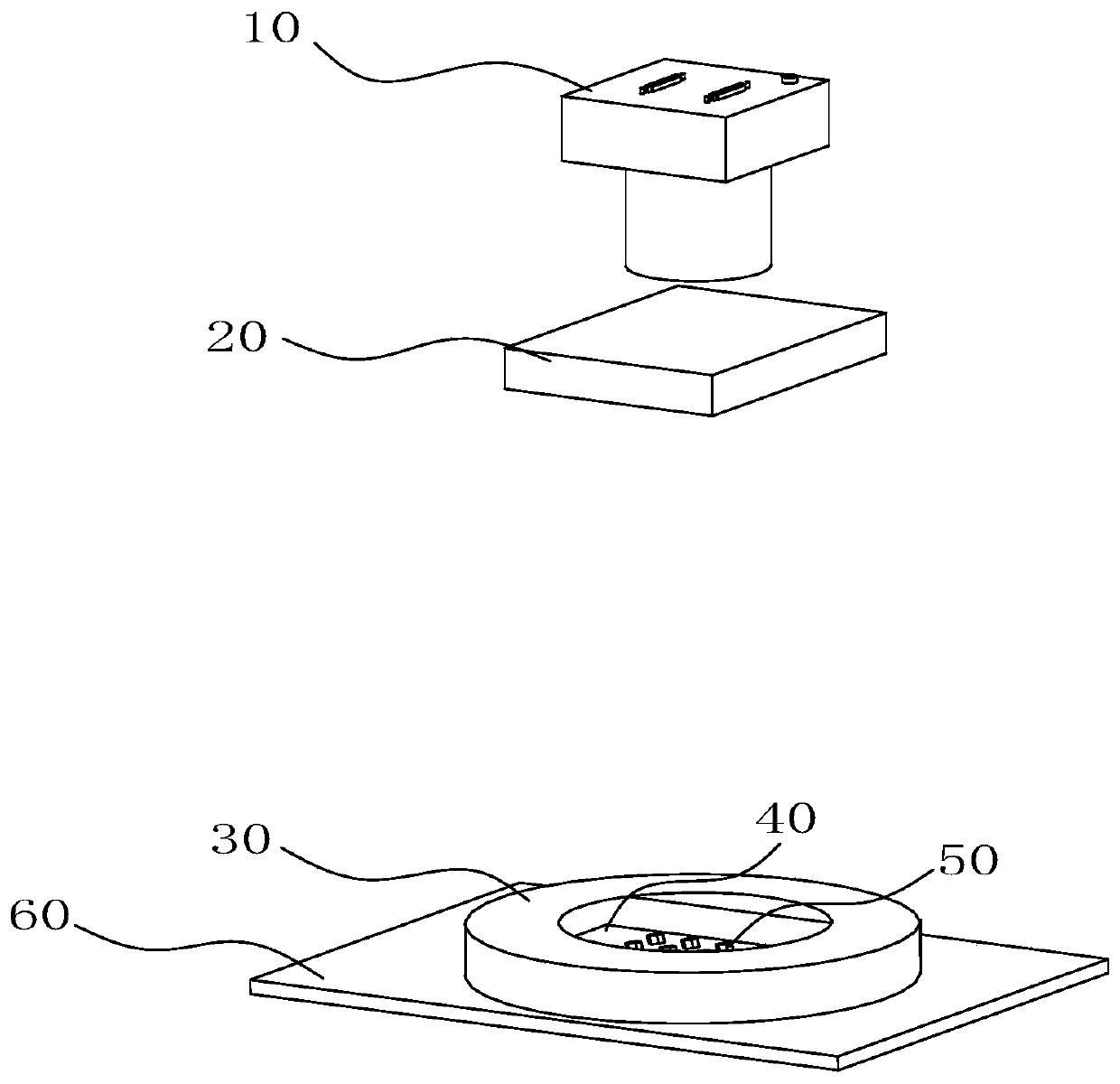

Product surface lighting method and system

ActiveCN110441323AAvoid damageImprove dust removal efficiencyOptically investigating flaws/contaminationImaging processingDust detection

The invention discloses a product surface lighting method and system. The method comprises the steps that after a front light source dust detection signal is received, when camera equipment receives first reflected light, first image information, shot by the camera equipment, of a to-be-detected surface is acquired; after a side light source dust detection signal is received, when the camera equipment receives second reflected light, second image information, shot by the camera equipment, of the to-be-detected surface is acquired; and after the first image information and the second image information are subject to image processing respectively, dust information is extracted from the first image information and the second image information which are obtained after image processing, and thesize and position of dust on the to-be-detected surface are confirmed according to the dust information. Through the product surface lighting method, the position of transparent and non-transparent dust on the to-be-detected surface of a transparent or non-transparent to-be-detected product can be precisely positioned, the size of the dust also can be confirmed, and therefore dust removal efficiency can be improved.

Owner:深圳市大族半导体装备科技有限公司

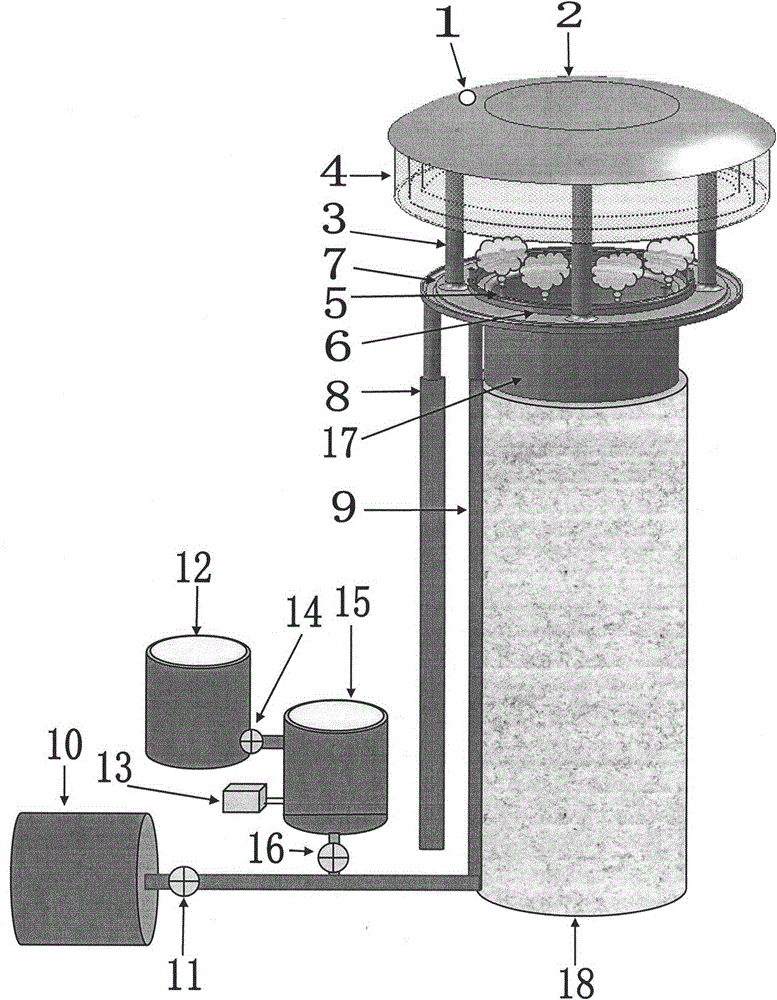

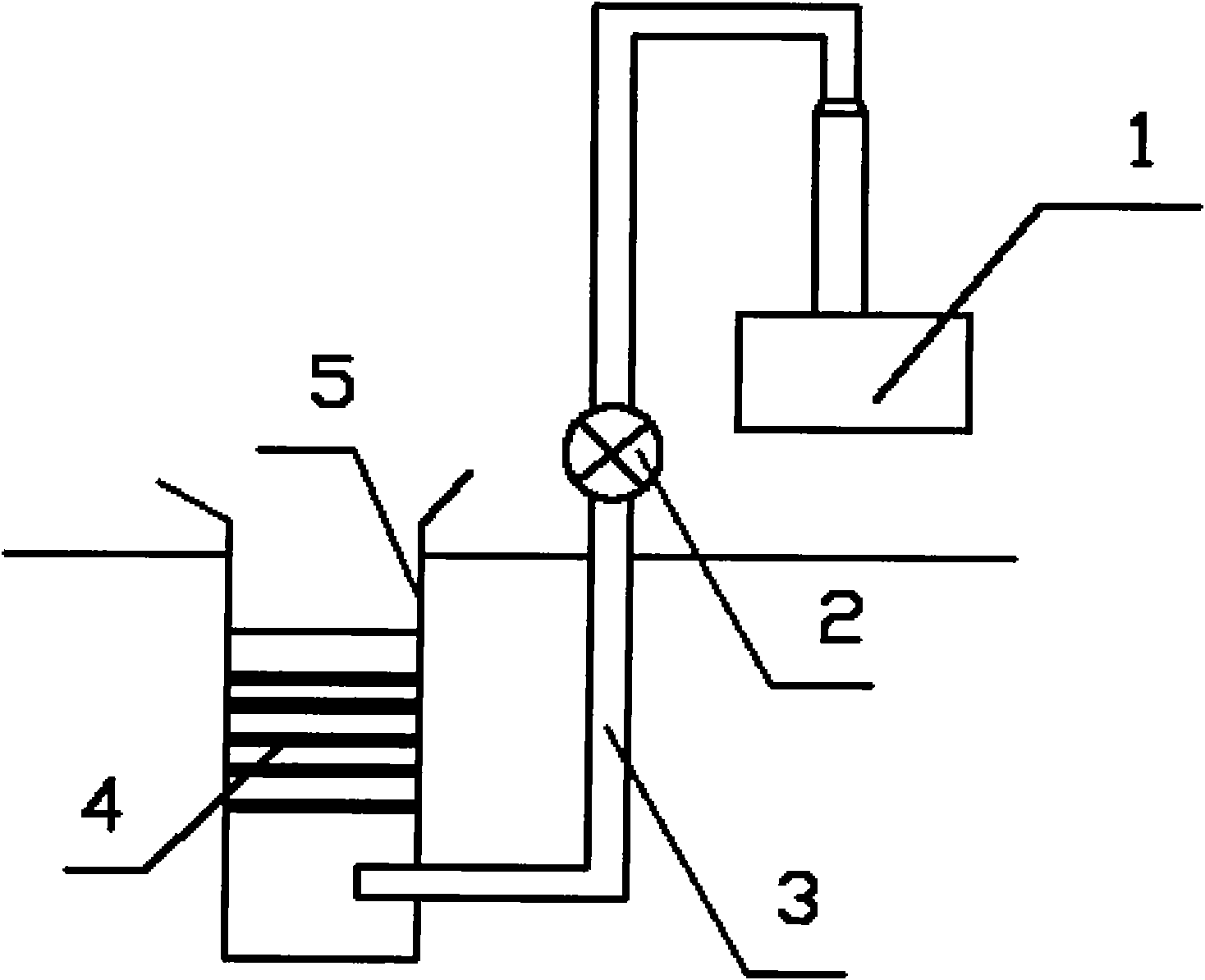

Dust eliminating and fog and haze controlling method for chimney smoke

InactiveCN104689667AEasy to processAchieve the goal of eradicating the main causes of smogCombination devicesLife qualityWater vapor

The present invention discloses a dust eliminating and fog and haze controlling method for chimney smoke, avoids pervading and retention of chimney smoke and dust diffusion in the air to form fog and haze and pollute air, and belongs to the environmental protection field. The dust eliminating and fog and haze controlling method takes advantage of the characteristics that the dry and floating smoke and dust are extremely easy to adsorb and integrate water vapor, uses a top cover to block, multi-layered acidproof filters to block and detain, and chemical substance vapor flow with enhanced absorption effect to absorb and fuse chimney smoke and dust, condenses the chimney smoke and dust into raindrops to fall to the ground, and reaches the purpose of removing the main causes of chimney smoke and dust smoke and eradicating the main causes of fog and haze. The dust eliminating and fog and haze controlling method of the present invention creatively and firstly uses water vapor and fog to absorb and clear chimney smoke and dust in the world, has low investment and high efficiency, radically treat the main causes of fog and haze, completely solves the worldwide problem of industrial and mineral chimney smoke, and air pollution and environmental degradation caused by fog and haze, and can maintain national health, reduce disease occurrence, improve the quality of national life, avoid relocations, reduced production and suspended projects of factories, and have a significant effect in avoiding immeasurable economic losses for countries. The dust eliminating and fog and haze controlling method belongs to a major and important environmental protective and innovative invention of clearing chimney smoke and dust, and radically treating fog and haze.

Owner:肖意坚

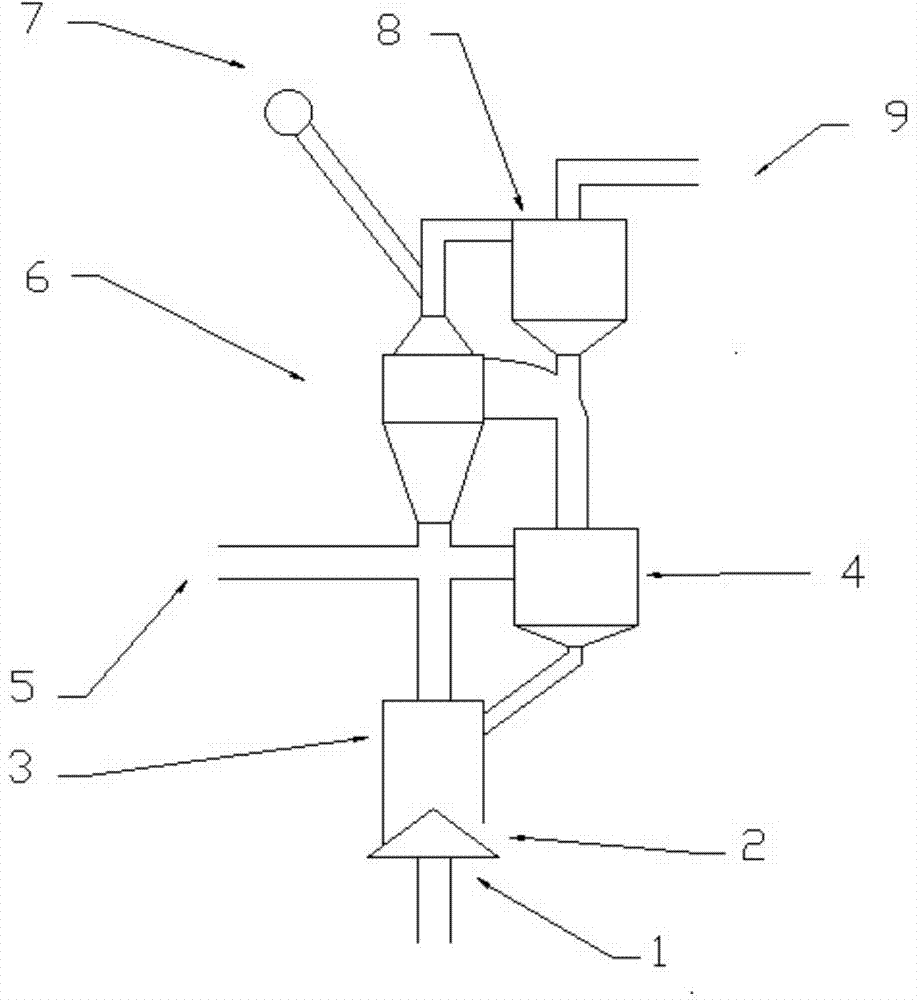

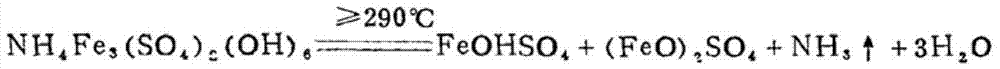

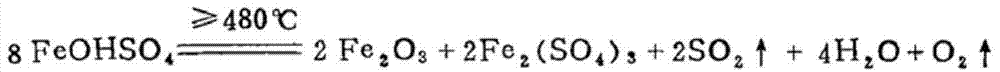

Process for treating iron vanadium slag by virtue of dry-process rotary kiln

InactiveCN103789533AReduce dust removal costsEasy to recycleProcess efficiency improvementSteelmakingAmmonium carbonate

The invention discloses a process for treating iron vanadium slag by virtue of a dry-process rotary kiln. The process comprises the following steps: breaking the iron vanadium slag, and feeding into a rotary dryer for drying to obtain tail gas with ammonium carbonate, wherein drying hot air is hot air at the tail of the dry-process rotary kiln; grinding deaminized iron vanadium slag, adding a bonder and water, feeding into a multistage cyclone treatment device, and desulfurizing to obtain iron oxide and tail gas; feeding the tail gas generated by the desulfurization of the iron vanadium slag into a sulfuric acid workshop to produce sulfuric acid; washing the iron oxide, recovering valuable metals, and taking the washed iron oxide as a steelmaking material. According to the process, all heat sources are residual heat of the dry-process rotary kiln, so that the economic and environment-friendly benefits are remarkable.

Owner:SHAANXI UNIV OF TECH

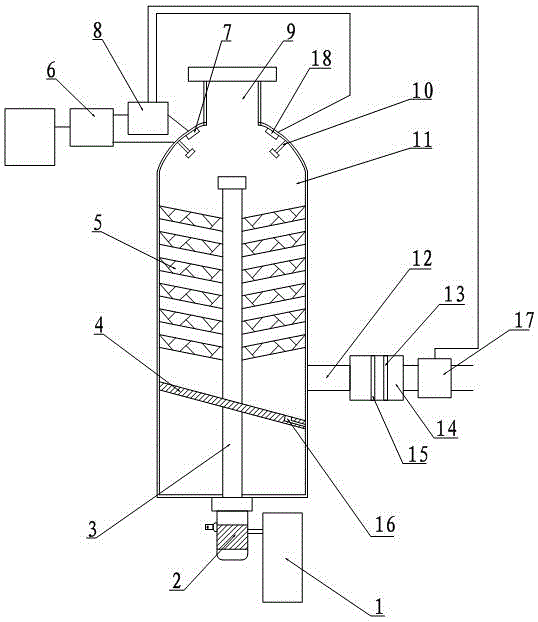

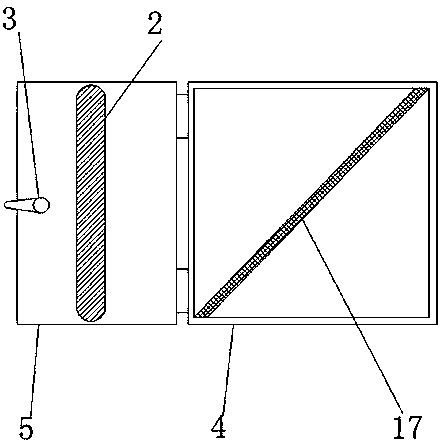

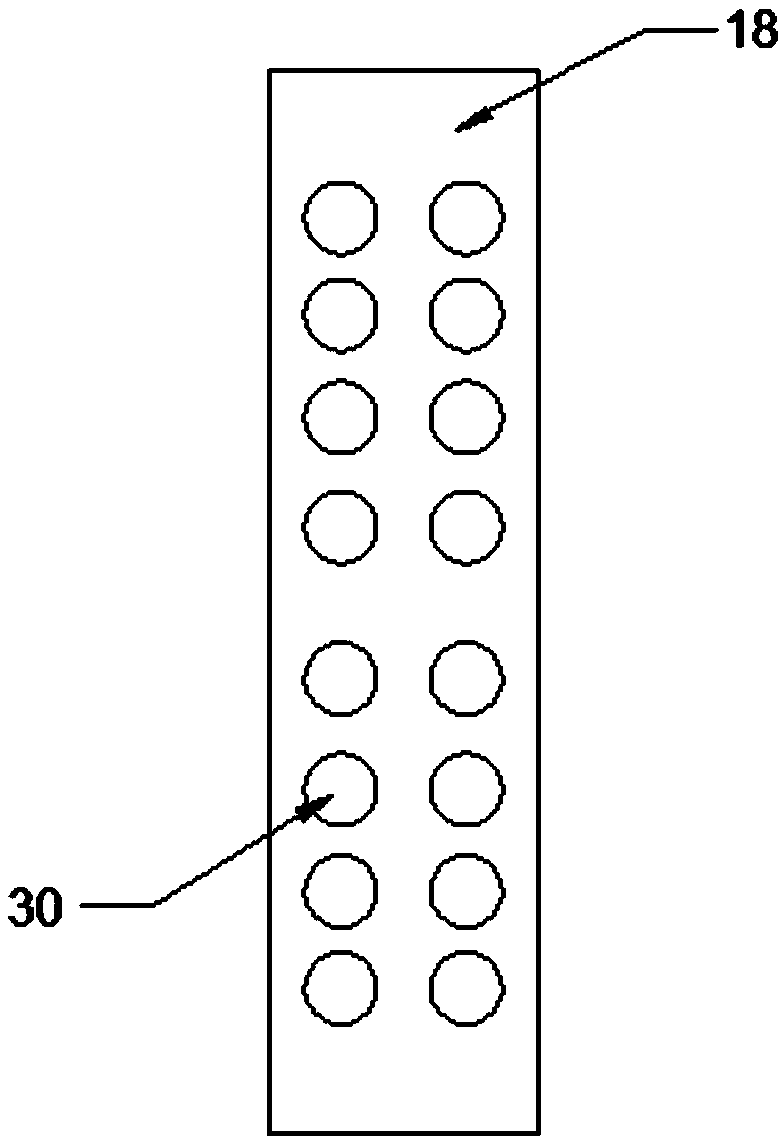

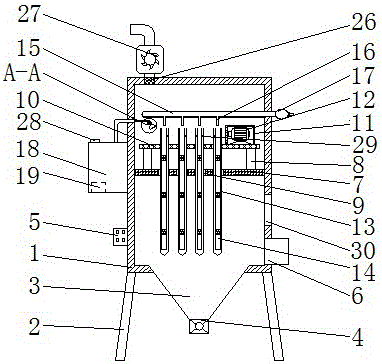

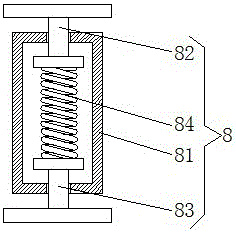

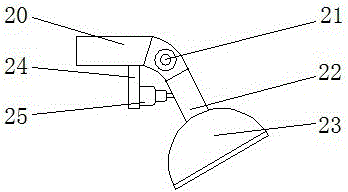

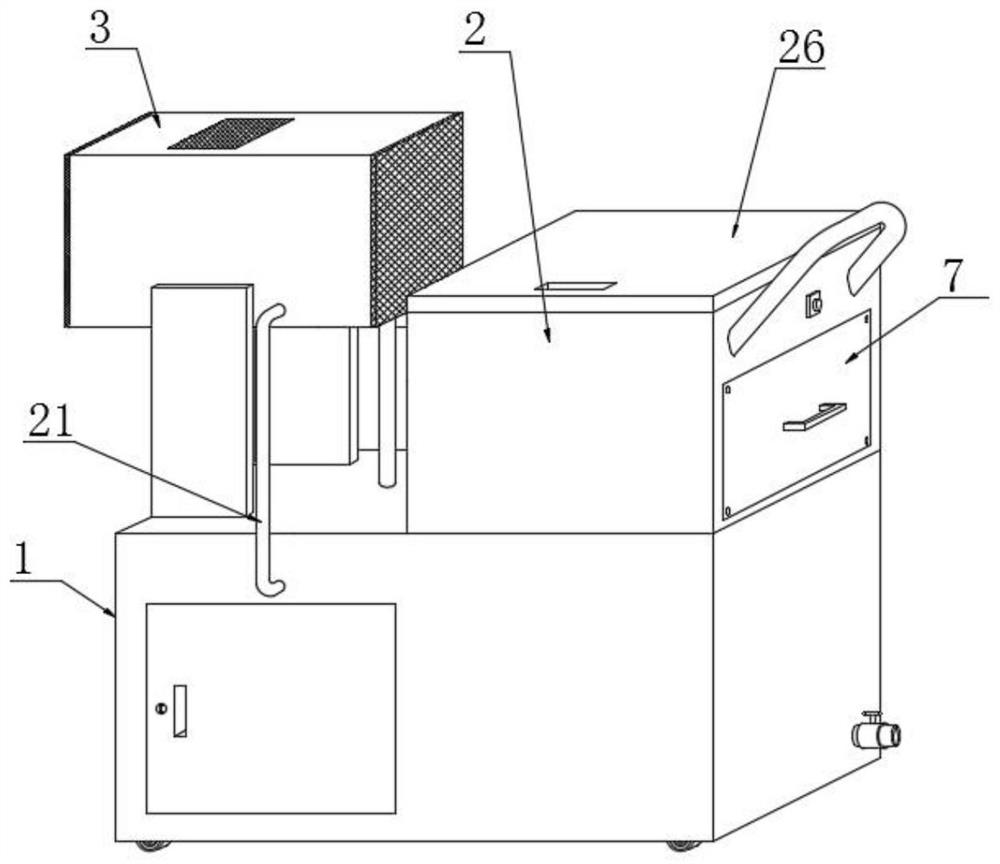

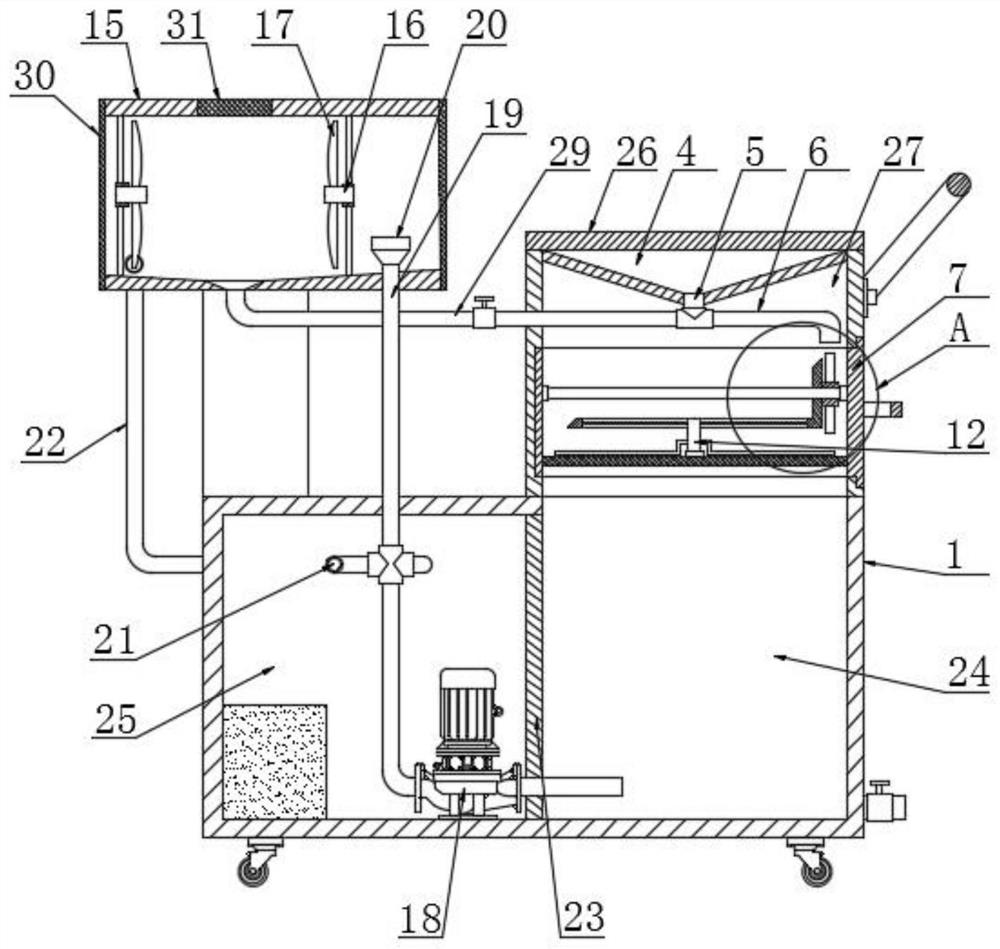

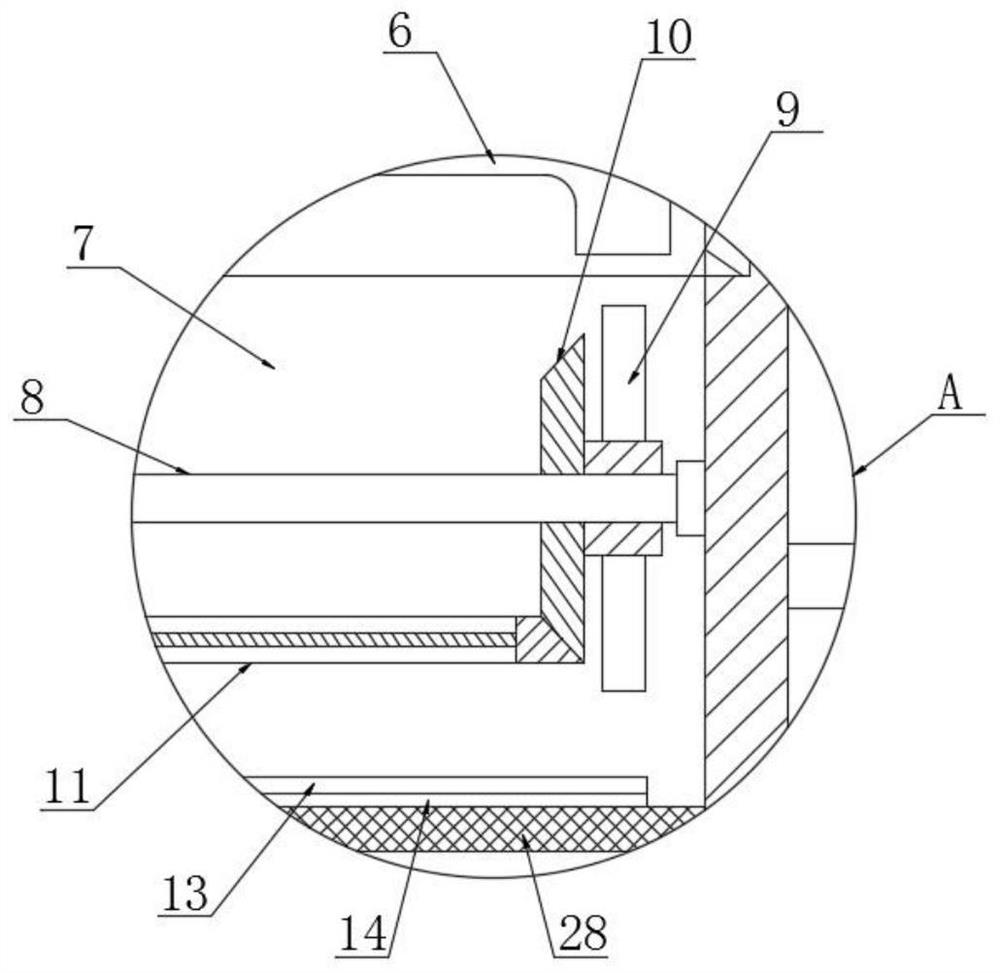

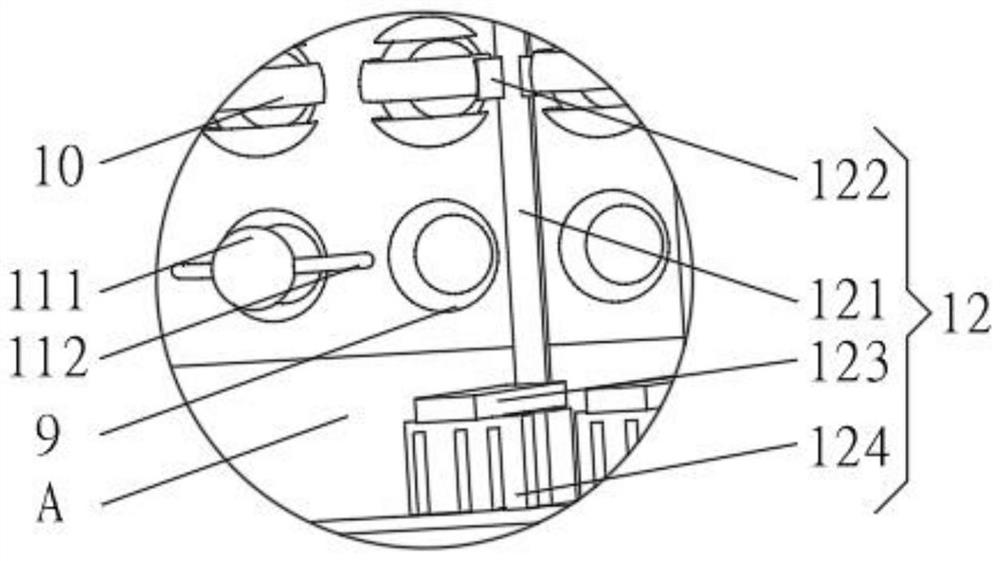

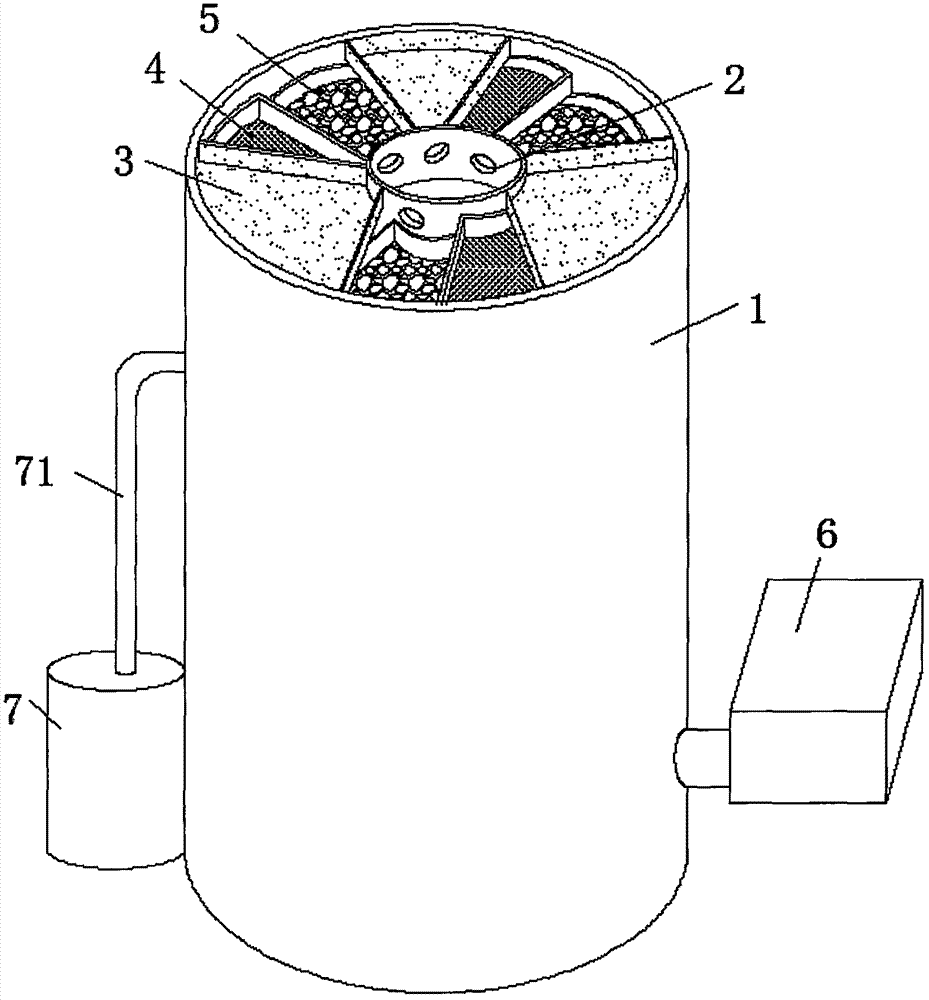

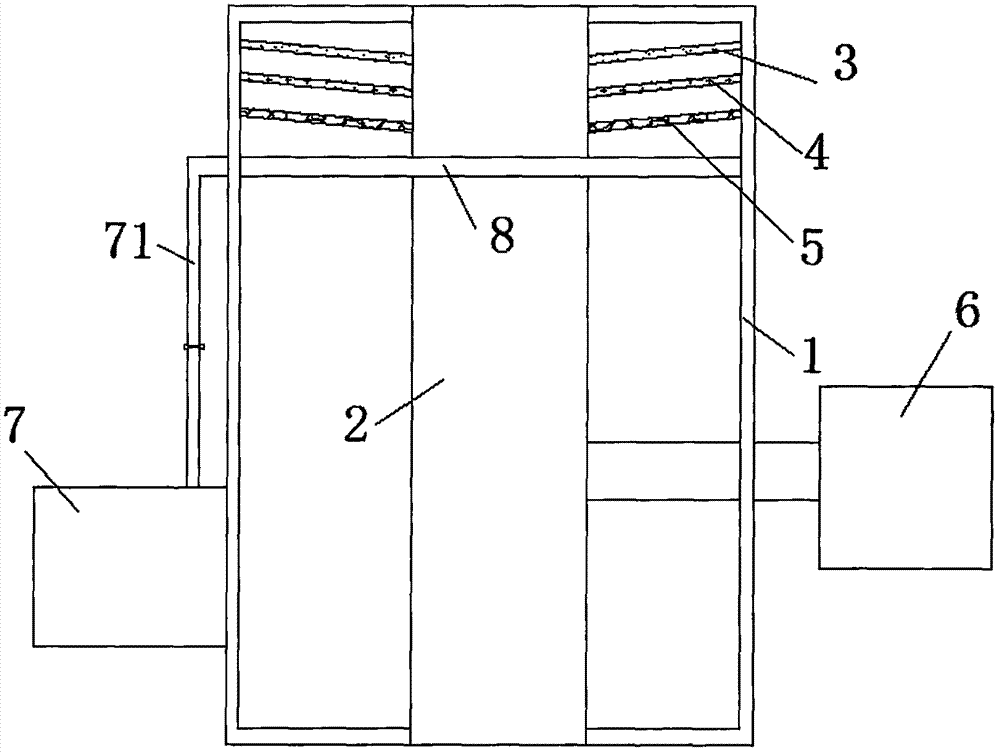

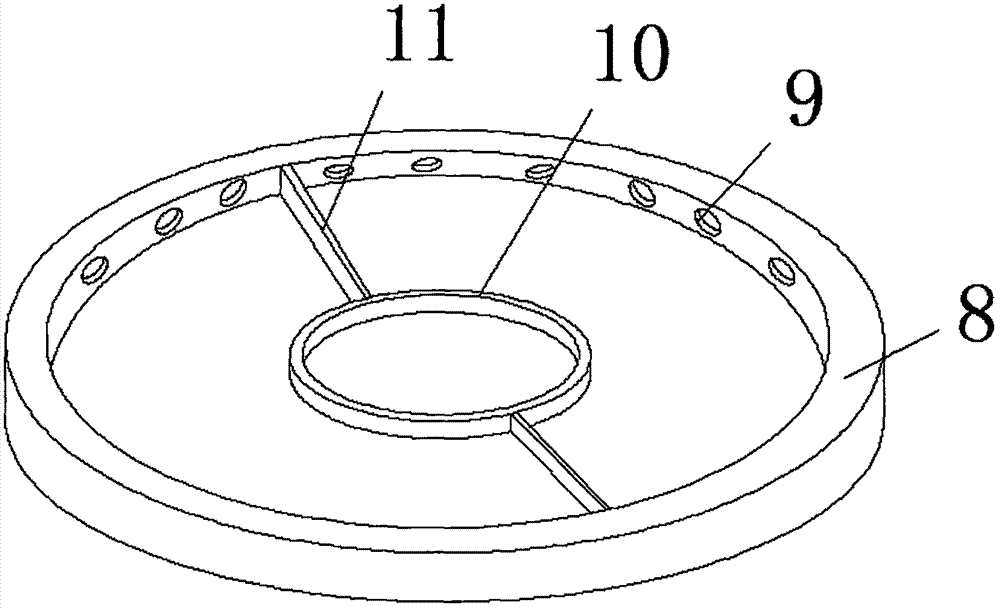

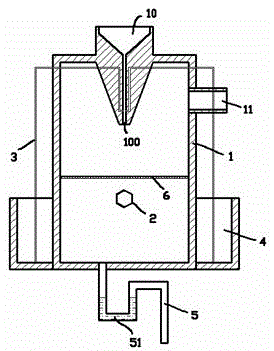

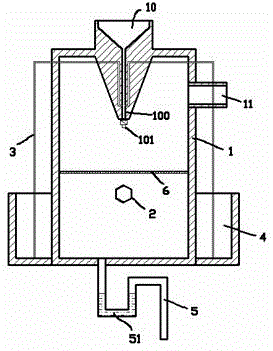

Automatic industrial flue gas purifying system

InactiveCN105344194AReasonable designSimple structureHuman health protectionCombination devicesLaser transmitterControl system

The invention discloses an automatic industrial flue gas purifying system. The automatic industrial flue gas purifying system comprises a body, and the top of the body is equipped with clean air discharging pipe. The automatic industrial flue gas purifying system comprises a spray thrower and a filtering screen, and the spray thrower and the filtering screen are arranged in the body. The automatic industrial flue gas purifying system comprises a flue gas input pipe communicated with the side wall of the body, a transmission mechanism connected with the body and used for controlling rotation of the filtering screen, a temperature and pressure data collection device extending into the body and connected with a PLC controller, a gas pressure regulating valve, a liquid flow control system and a laser emitter. The gas pressure regulating valve, the liquid flow control system and the laser emitter are connected with the PLC controller. The automatic industrial flue gas purifying system also comprises a spray water box connected with the liquid flow control system, a laser emitter connected with the temperature and pressure data collection device and the PLC controller, a sewage drainage separation plate arranged inside the body and located under the filtering screen and a primary filtering device. The automatic industrial flue gas purifying system is reasonable in design, is simple in structure, improves flue gas purifying effects effectively and raises the dedusting efficiency.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

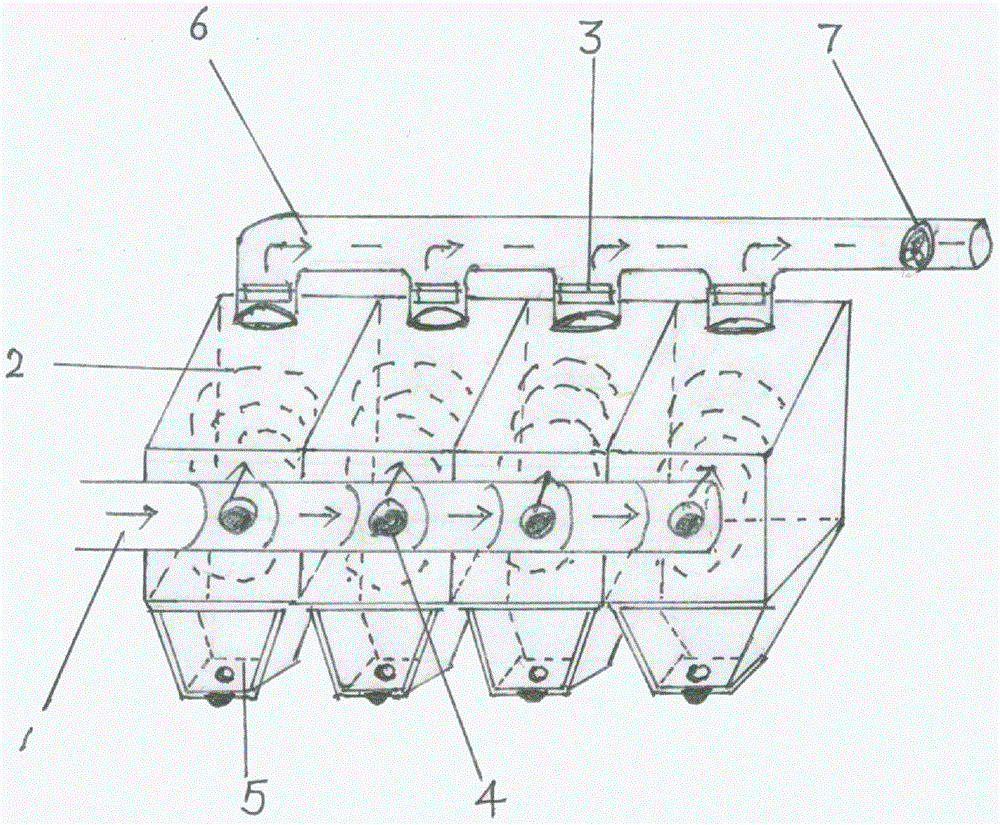

Storage type static dedusting device

InactiveCN104353286AIncrease the ratio of filtrationReasonable structureDispersed particle separationSolenoid valveAtmospheric air

The invention discloses a storage type static dedusting device. The storage type static dedusting device comprises a dusty air inflowing pipe, an exhaust fan, an exhaust pipe, inflowing solenoid valves, a dedusting box and outflowing solenoid valves; when the exhaust fan works, N static gravity type dust-settling compartments and bucket type dust collection chambers positioned right below the static gravity type dust-settling compartments and communicated with the static gravity type dust-settling compartments respectively are arranged in the dedusting box, a dust leakage hole is formed in the bottom end of the lowest part of each bucket type dust collection chamber, N is more than or equal to 2, the outflowing pipe orifice in one end of the dusty air inflowing pipe stretches into the Nth static gravity type dust-settling compartment, and one section, close to the outflowing pipe orifice, namely a dusty air outflowing pipe section, of the dusty air inflowing pipe sequentially passes through the (N-1)th static gravity type dust-settling compartments; inflowing holes are formed in dusty air inflowing pipe bodies positioned in all the static gravity type dust-settling compartments respectively, the inflowing solenoid valve is arranged on each inflowing hole, an outflowing hole corresponding to each static gravity type dust-settling compartment is formed in the top side wall of the uppermost part of the dedusting box, and the outflowing solenoid valve is arranged on each outflowing hole. The storage type static dedusting device can greatly improve the filtering ratio of dust in industrial waste gas before the industrial waste gas is exhausted to the atmosphere.

Owner:XINJIANG JIAHUI XINYUAN ENVIRONMENT PROTECTION TECH CO LTD

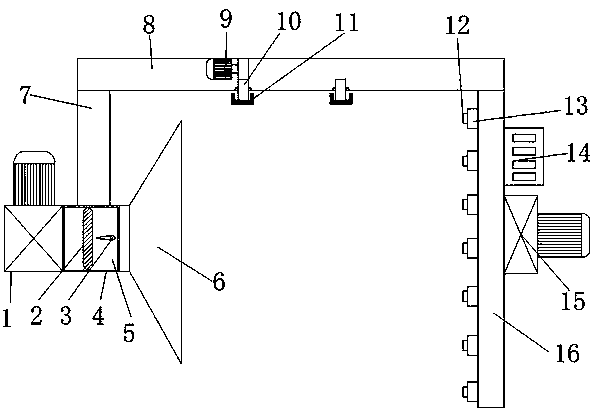

Dust removing device for textile workshop

PendingCN108554927AReduce in quantityReduce manufacturing costDispersed particle filtrationDirt cleaningArchitectural engineeringIdler-wheel

The invention discloses a dust removing device for a textile workshop. The dust removing device comprises guide rails and a supporting frame. An opening is formed in the outer wall of the bottom end of the supporting frame, and idler wheels are fixed to the inner wall of the opening through bolts; a servo motor is fixed to the inner wall of the top end of the supporting frame through a bolt, and an output shaft of the servo motor and the idler wheels form rolling fit through a belt; and a first supporting arm is welded to one end of the outer wall of the bottom end of the supporting frame, a filter box is fixed to the outer wall of the bottom end of the first supporting arm through a bolt, and a suction fan is fixed to the outer wall of the side, away from the supporting frame, of the filter box through a bolt. According to the dust removing device for the textile workshop, by additionally arranging sliding rails and the idler wheels, the whole dust removing device can remove dust backand forth in the workshop; rotatable air nozzles can blow nearby attachments and floating objects, the blown attachments and floating objects can be adsorbed by a dust collection cover, and a filternet conducts centralized treatment on the attachments; and the dust removing device for the workshop can conduct large-area circuit dust removing, the dust removing efficiency is high, and the dust removing cost is reduced.

Owner:盐城融凡纺织制衣有限公司

Waterless pump blowing bench

InactiveCN102949908AImprove dust removal effectTo achieve the purpose of dust removal and filtrationCombination devicesDispersed particle filtrationEngineeringWater tanks

Owner:JIANGSU CHANGJING ENVIRONMENTAL PROTECTION TECH

Industrial waste gas emission method

InactiveCN102008877AThe legal process is simpleReduce dust removal costsUsing liquid separation agentExhaust gas emissionsEnvironmental engineering

The invention provides an industrial waste gas emission method, which is characterized in that a well with water accumulated is dug up near a waste gas emission source and then added with lime water, proper CaOH concentration is maintained, multiple layers of meshed plates are arranged in the well with meshes of each being small enough, the waste gas from the waste gas emission source is guided to the bottom of the well by a gas pump through a waste gas pipeline so that carbon dioxide in the waste gas is absorbed by the lime water in the well and large bubbles are divided at the meshes of the meshed plates, thus dusts and impurities in the gas are dissolved in the water when the bubbles break up. The industrial waste gas emission method has simple flow and equipment adopted, low dust removal cost and good effect.

Owner:褚礼政

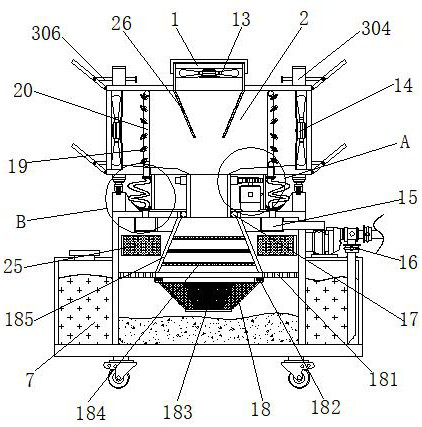

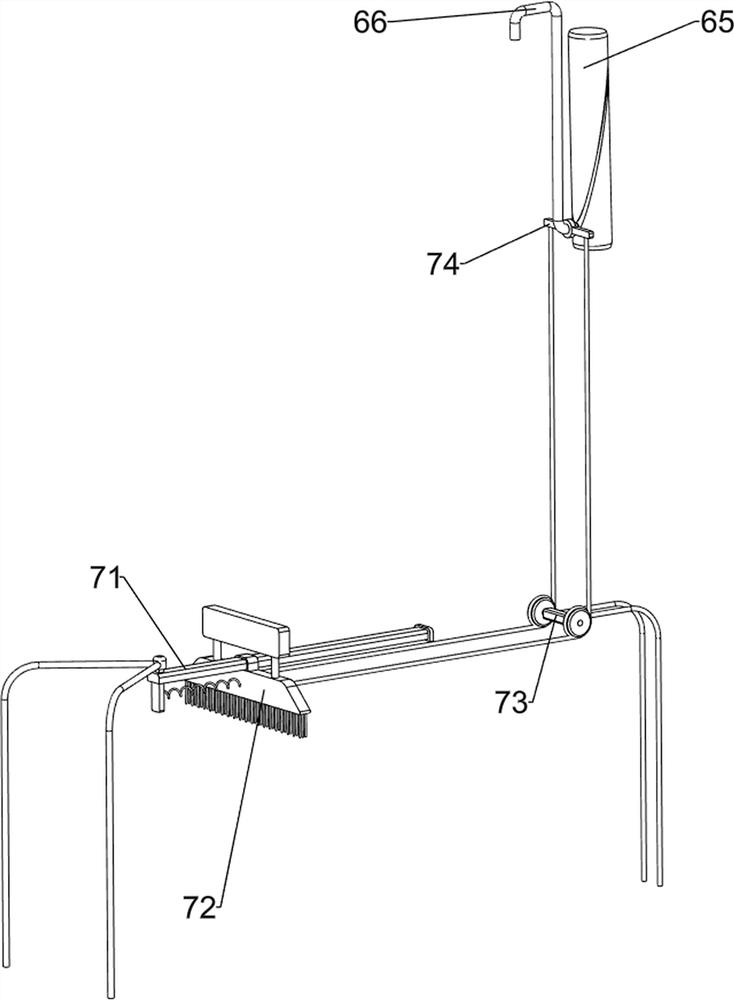

Intelligent dust removal device for workshop

InactiveCN111939701AReduce dust removal costsAvoid cleaningCombination devicesDispersed particle filtrationGear wheelDust control

The invention discloses an intelligent dust removal device for a workshop. The device comprises a bottom plate, wherein a treatment bin is arranged at the middle portion of the top of the bottom plate, an annular wavy slide way is arranged at the edge of the top of the treatment bin, a bearing is arranged at the center of the top of the treatment bin, a connecting pipe is arranged on the inner side of the bearing, a spraying bin is arranged at the top of the connecting pipe, fans A are symmetrically arranged at the two inner ends of the spraying bin, and annular water pipes are symmetrically arranged at the two ends of the inner side wall of the spraying bin. Through the cooperative use of the spraying bin, the annular wavy slide way, the treatment bin, a protection bin, the bearing, the connecting pipe, a gear B, a gear A and a driving motor, when the device is used for dust removal, the driving motor is used for driving the gear A and the gear B to continuously rotate forwards and backwards so as to allow the two ends of the spraying bin to suck air in different directions in the workshop into the treatment bin for dust removal treatment, so the labor intensity of operators is greatly reduced, and the device is very convenient to use.

Owner:杨明清

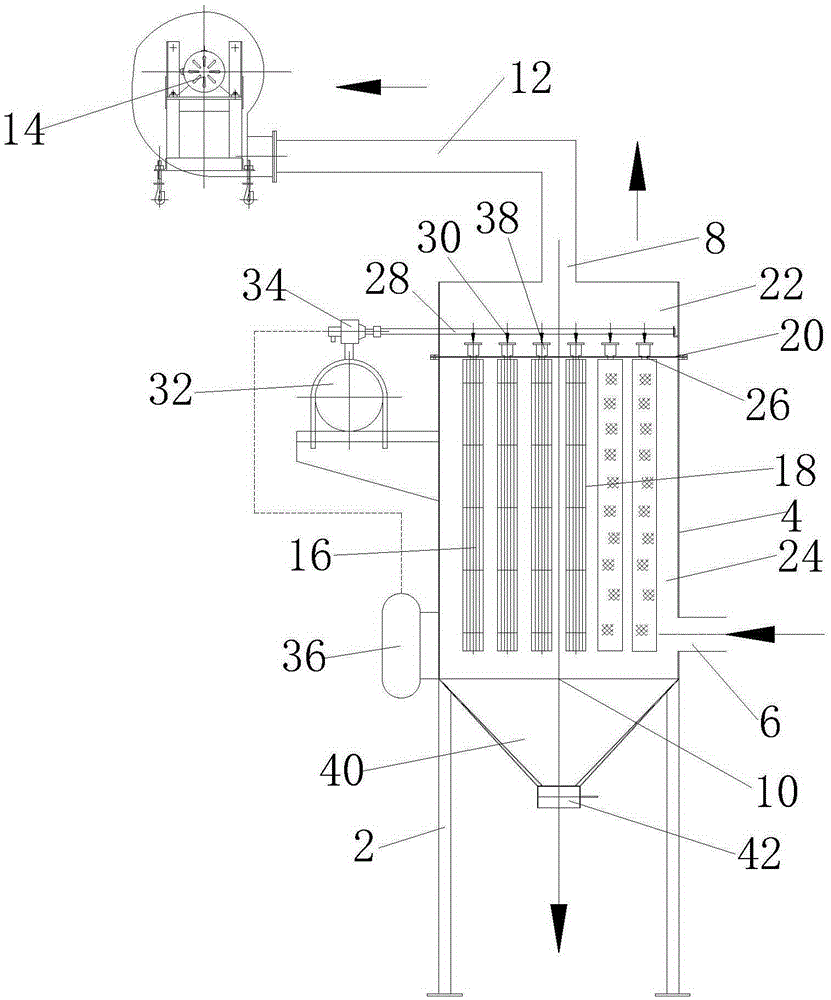

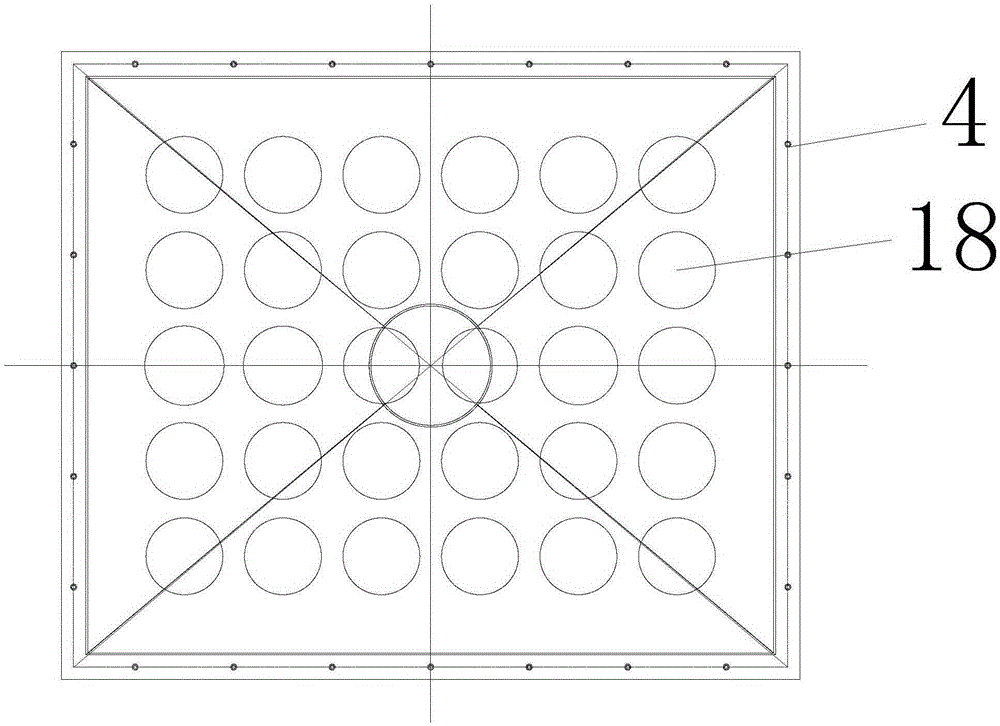

Dust removing system for wood-plastic pelletizer

InactiveCN105289138AExtended service lifeImprove dust removal effectDispersed particle filtrationSuction forceKeel

The invention provides a dust removing system for a wood-plastic pelletizer. The dust removing system comprises a rack and a dust removing box body fixed to the rack. The dust removing system is characterized in that a dust gas inlet is formed in the position, located on the lower half part of the side face, of the dust removing box body; a clean gas outlet and a dust outlet are formed in the top and the bottom of the dust removing box body respectively; an air suction pipe is arranged at one end of the box body in the way of being in butt joint with the clean gas outlet, and the other end of the air suction pipe is connected with an air suction device; a plurality of keel frames arrayed in parallel are arranged in the dust removing box body, and each keel frame is sleeved with a dust removing filter bag. By means of optimized structure design, dust gas enters the interior of the dust removing box body from the dust gas inlet under the suction force action of the air suction device, the dust removing filter bags arranged inside the box removing box body conduct dust and gas separation on the dust gas, clean gas after separation is exhausted from the clean gas outlet, dust is discharged from the dust outlet, and by controlling the mesh number of the dust removing filter bags, the gas exhausted from the clean gas outlet can meet the emission standard stipulation of the nation with respect to gases which are harmless to human bodies and the atmosphere.

Owner:ZHANGJIAGANG XINTIAN MACHINERY

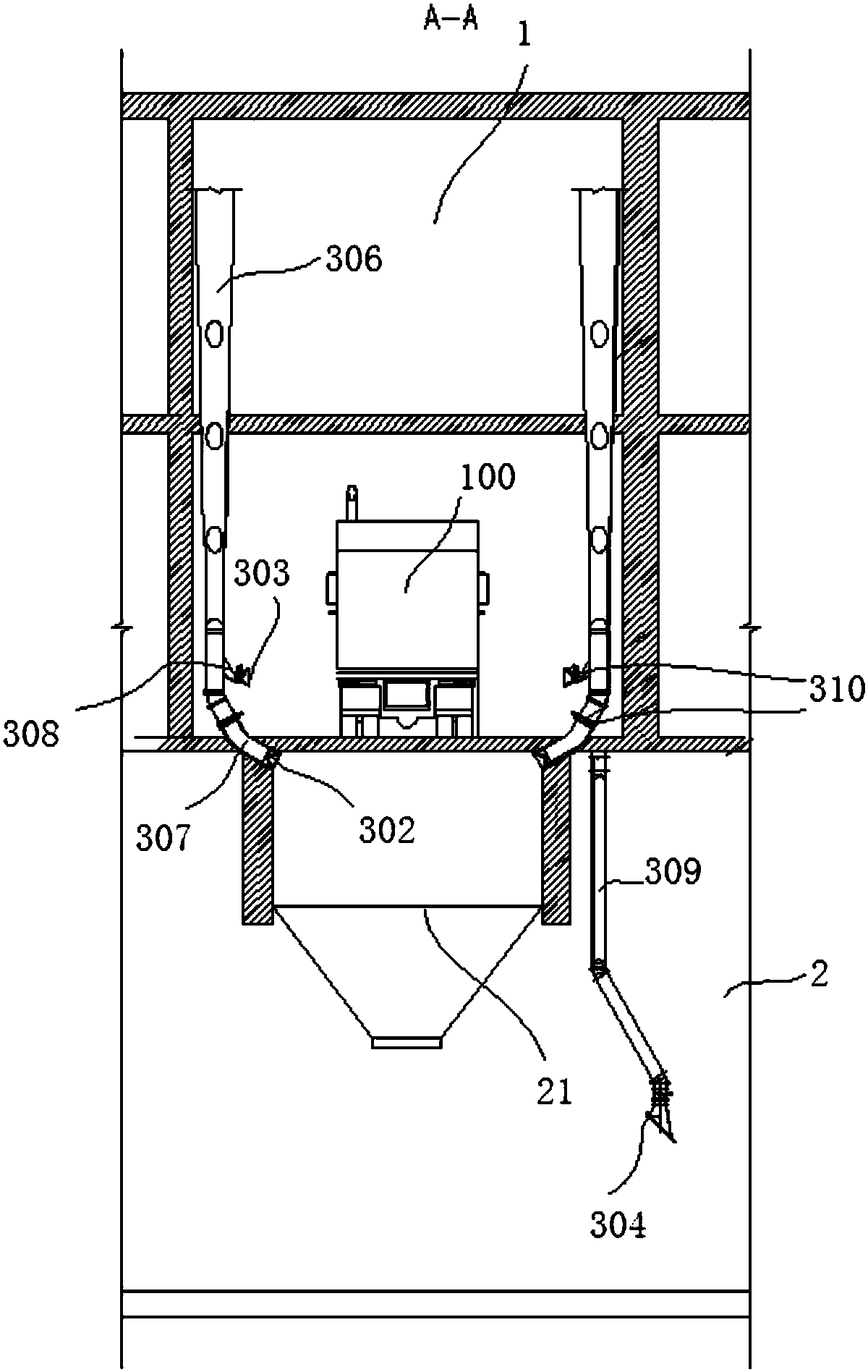

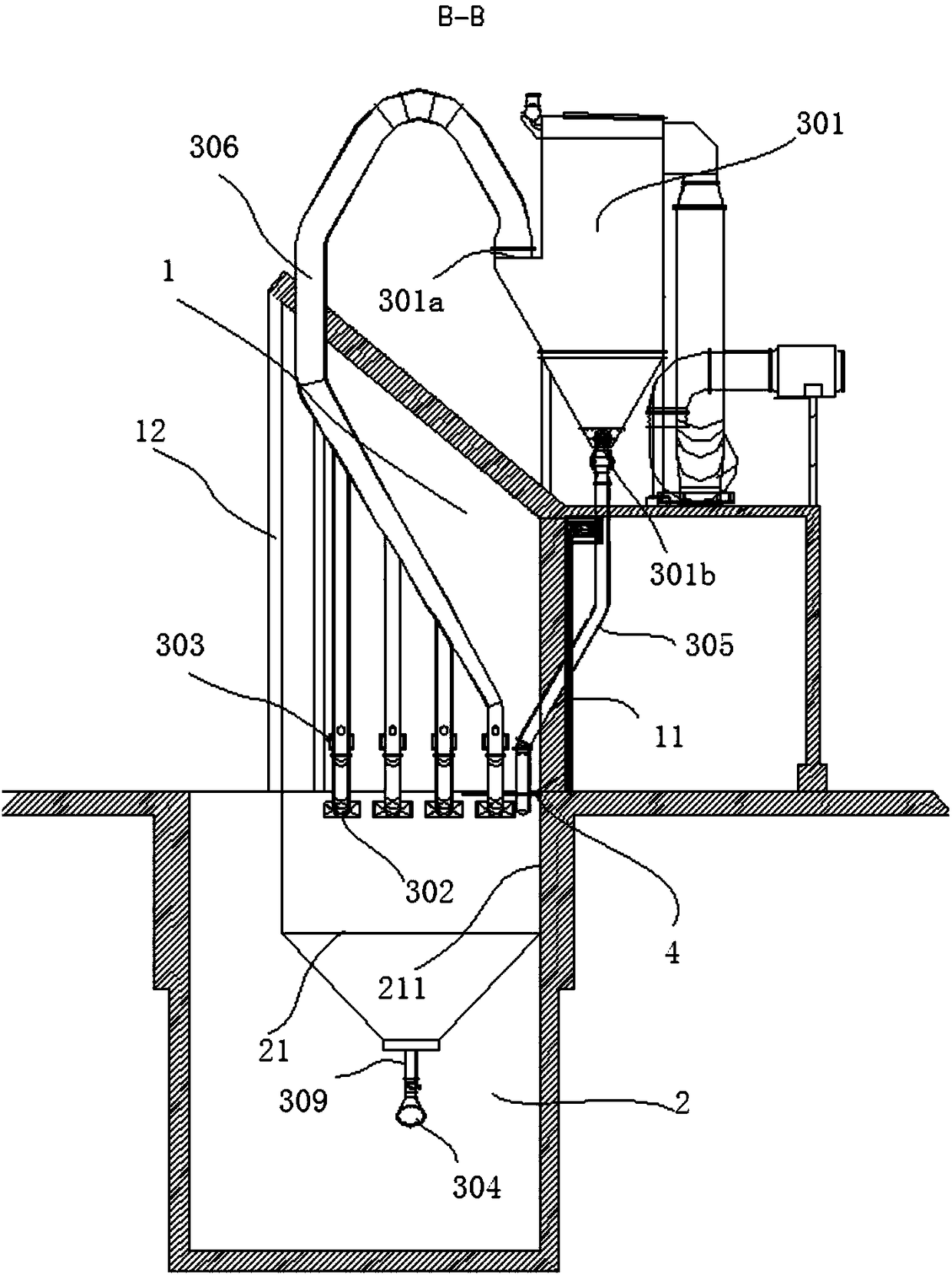

Warehousing system used for truck unloading

The invention provides a warehousing system used for truck unloading. The system comprises a warehouse, an underground stock bin, a dust removal device and a dust restraining baffle, wherein the underground stock bin, the dust removal device and the dust restraining baffle are arranged in the warehouse. The warehouse is provided with an entry and an exit, the underground stock bin receives materials, required to be unloaded, of a truck through an opening in the top of the underground stock bin, the dust removal device comprises a dust remover and a bin interior dust collection cover which is connected with the dust remover and arranged in the underground stock bin, the dust restraining baffle is arranged in the top opening of the underground stock bin and is connected with a reserved sidebin wall of the underground stock bin, the reserved side bin wall is the side bin wall which is arranged on the underground stock bin and allows the truck to run along the reserved path the earliest,the dust restraining baffle allows the truck to run through above the baffle and then carries out unloading on the interior of the underground stock bin, in the truck unloading process, generated raised dust can be restrained, and the raised dust can be collected conveniently through a dust collecting cover in the bin. The system can be widely suitable for various materials, good dust removal effect is ensured, and meanwhile the dust removal cost is reduced.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

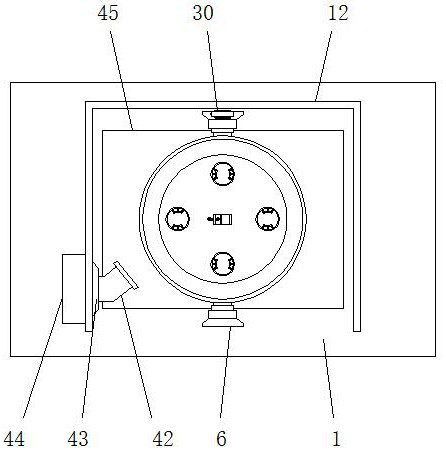

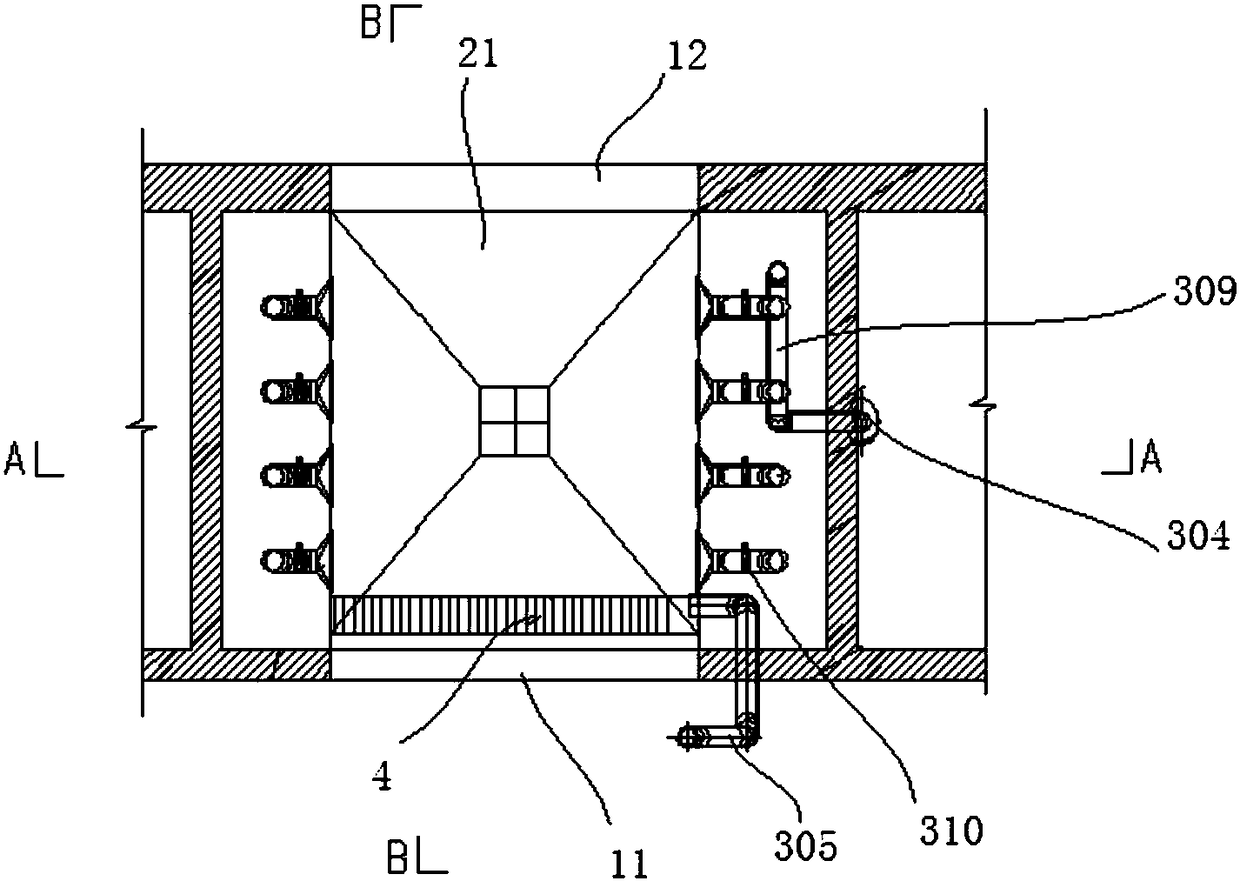

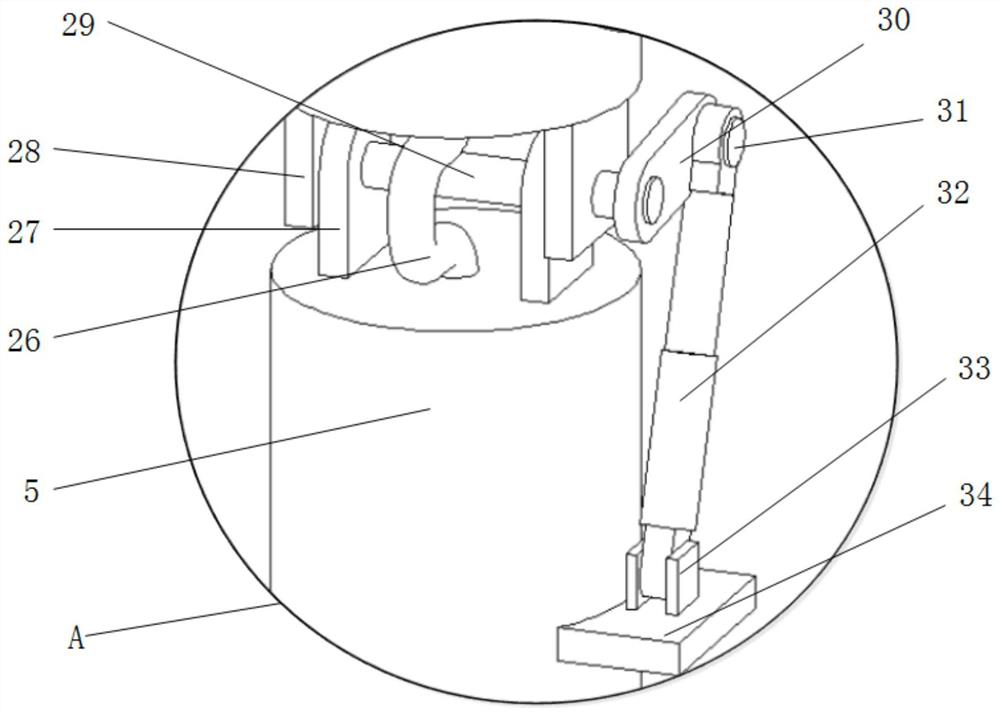

Special dust remover for tail dust removal of drying machine

InactiveCN109224657AAvoid pollutionReduce dust removal costsCombination devicesGas treatmentDrive shaftWater resources

The invention discloses a special dust remover for tail dust removal of a drying machine. The special dust remover comprises a dust removal chamber, a deodorization chamber and a servo motor, whereinthe servo motor is arranged at the upper end of the dust removal chamber and is connected with a transmission shaft, a plurality of fan blades are arranged on the transmission shaft, a filter bag is arranged outside the fan blades, an air inlet is formed in the upper end of the left side of the filter bag, and dust baffles are symmetrically arranged at the lower end of the filter bag. When the special dust remover is used, gas exhausted from the tail of the drying machine enters the dust removal chamber from the air inlet, and the dust is removed through gravity, so that the dust removal costis lowered; the dust is accumulated to be cleaned, so that the environmental pollution caused due to the scattering of the dust is avoided; the scattering of dust is avoided, and the environmental pollution is avoided; the filtered gas enters the deodorization chamber from the air outlet and is cleaned through a filtering plate and a filling layer, and sulfide in the gas is removed, so that the environmental pollution caused due to the emission of the gas is avoided; by utilizing the design, the situation that the dust in air enters the deodorization chamber through an exposed exhausting holeof the deodorization chamber is prevented; and a circulating system is adopted in the deodorization chamber, so that the use of water resource is reduced, and the energy source is saved.

Owner:安徽粮友机械科技有限公司

Automatic cleaning dust remover

InactiveCN106390624AExtended service lifeAvoid easy cloggingDispersed particle filtrationEngineeringNozzle

The invention discloses an automatic cleaning dust remover. The automatic cleaning dust remover comprises a shell, two sides of the bottom of the shell are fixedly connected with supporting legs, the bottom of the shell between the supporting legs is provided with a dust outlet, the bottom of the dust outlet is fixedly connected with a dust discharging valve, the bottom of the left side of the shell is fixedly connected with a controller, the bottom of the right side of the shell is provided with a dust gas inlet, the inner cavity of the shell is fixedly connected with a fixed plate, and two sides of the top of the fixed plate are fixedly connected with dampers. A vibration machine is used to make dusts aggregated in a filter bag fall after being vibrated by the vibration machine, so the filter bag is difficult to obstruct, and the dust removal efficiency is improved; a nozzle is used to keep the dust removal effect of the dust remover in a good state, the working efficiency is improved, and the service life of the dust remover is prolonged; and the automatic cleaning dust remover also has the advantages of reasonable structure, simplicity in operation, and high practicality.

Owner:林志城

Environment-friendly dust removal equipment for constructional engineering construction

InactiveCN111921310AIncrease flow rateSave waterCombination devicesUsing liquid separation agentWater useArchitectural engineering

The invention discloses environment-friendly dust removal equipment for constructional engineering construction, and particularly relates to the technical field of building dust removal, the environment-friendly dust removal equipment comprises a box body, a recycling mechanism and a dust removal mechanism are fixedly arranged at the top end of the box body, the recycling mechanism comprises a recycling box, a conical hopper is fixedly arranged on the inner wall of the recycling box, a first pipeline is fixedly arranged at the bottom end of the conical hopper, a second pipeline is arranged atone end of the first pipeline, a rectangular frame is arranged at the bottom of the second pipeline, a first filter screen is fixedly arranged on the inner wall of the rectangular frame, the dust removal mechanism comprises a dust removal box, two second rotating shafts are arranged in the dust removal box, and a plurality of fan blades are fixedly arranged at the outer ends of the two second rotating shafts. Used domestic water is filtered and stored for dust removal, meanwhile, a mixture of dust and water is filtered during dust removal, so that the water can be recycled, water resources areeffectively saved, the dust removal cost is effectively reduced, and more energy is saved and more environment is protected.

Owner:湖北汇宜建设工程有限公司

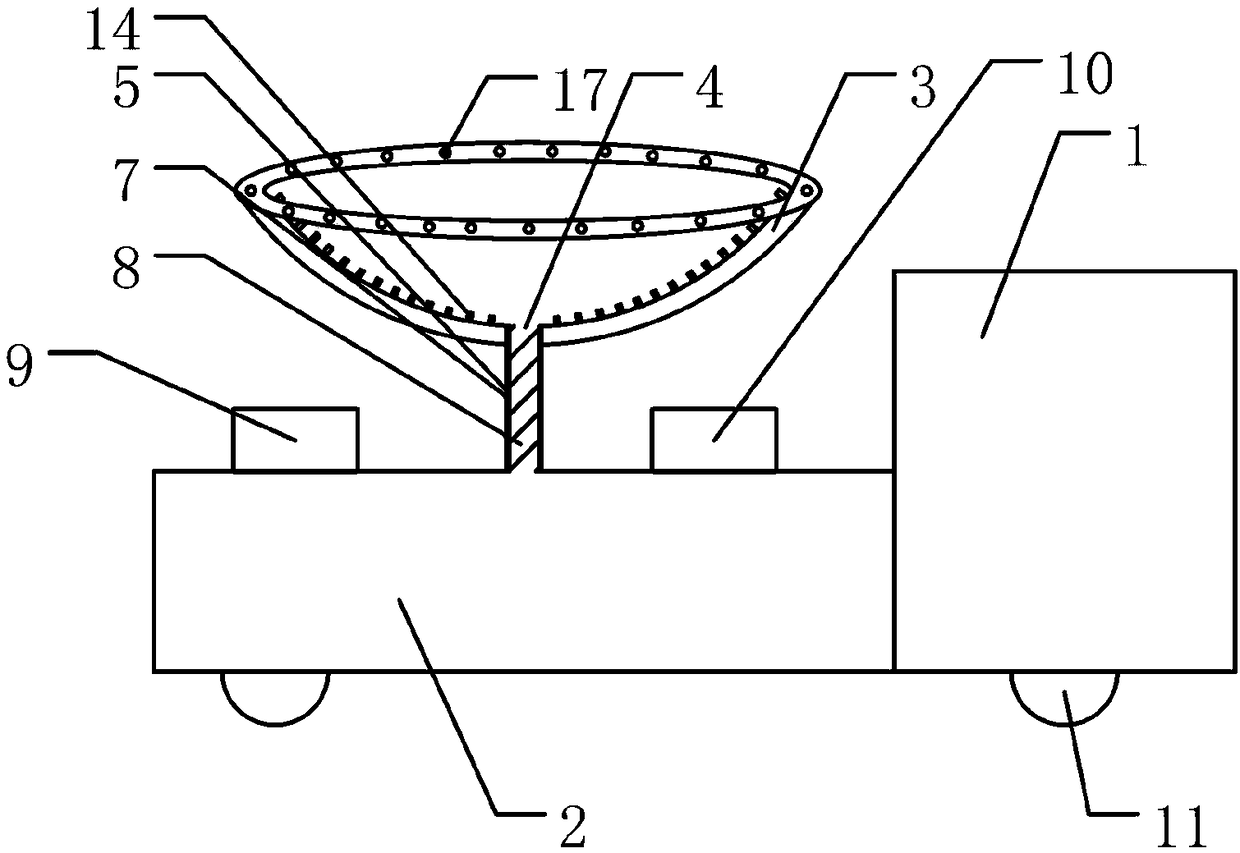

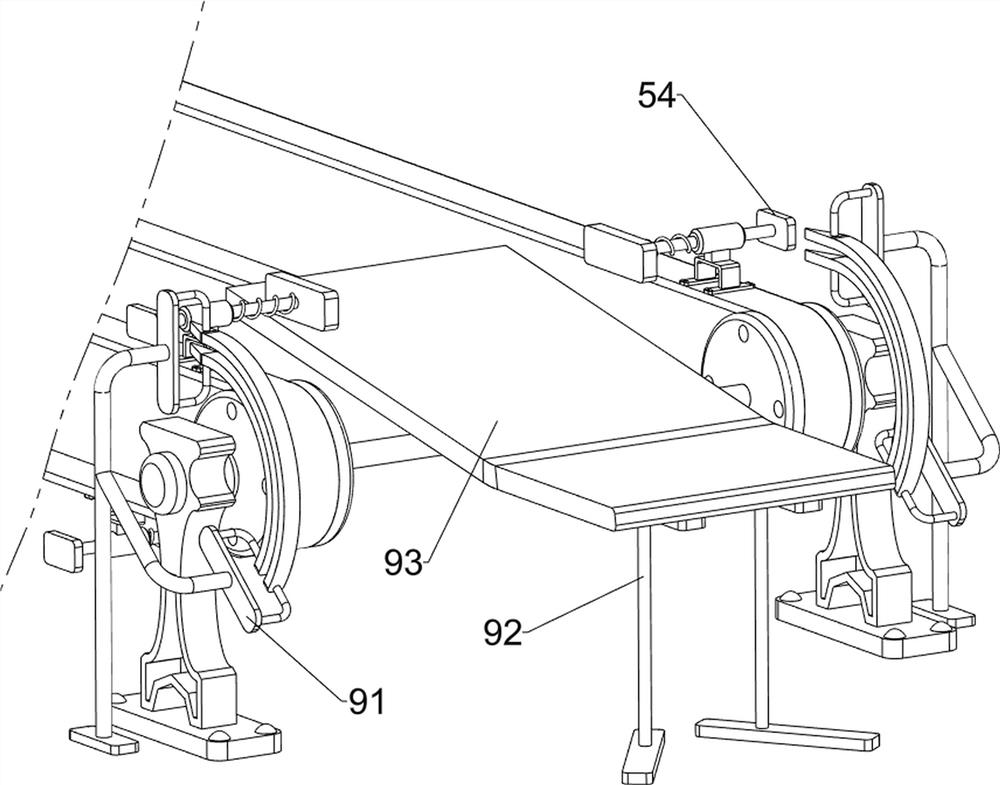

Green dustfall environmental protection construction structure of highway and construction method thereof

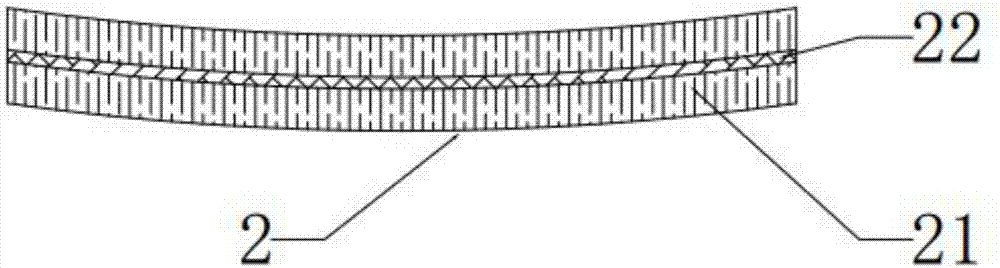

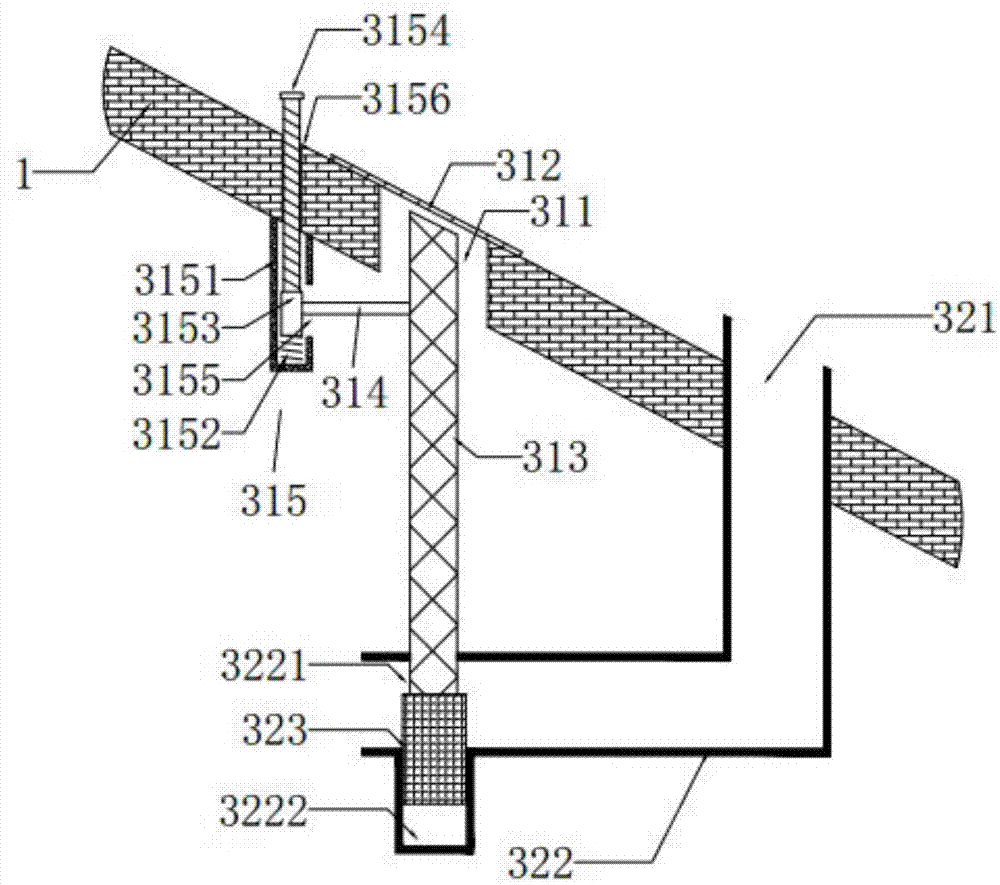

ActiveCN109083075AWide coverage of dust collectionImprove dust removal effectGeneral water supply conservationRoad cleaningDrive wheelControl system

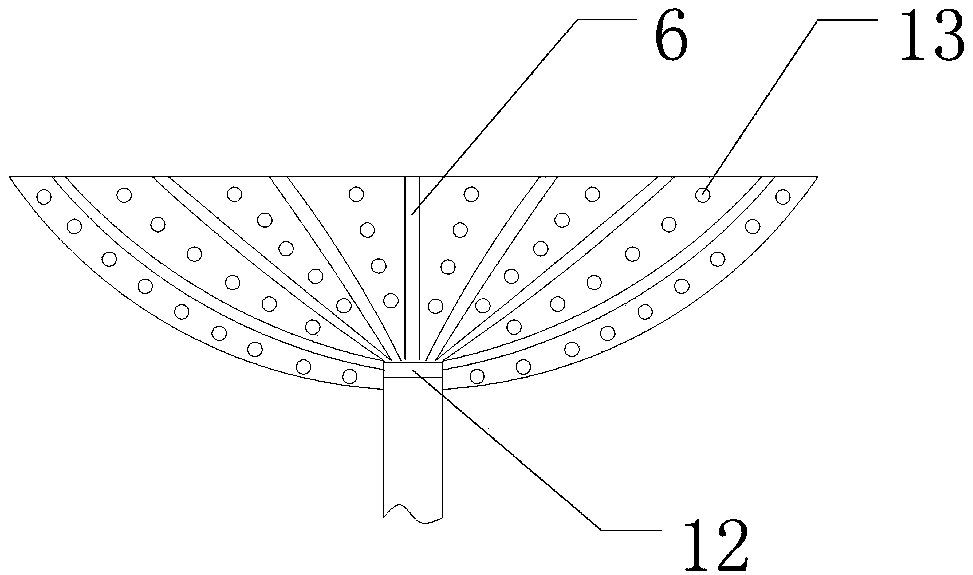

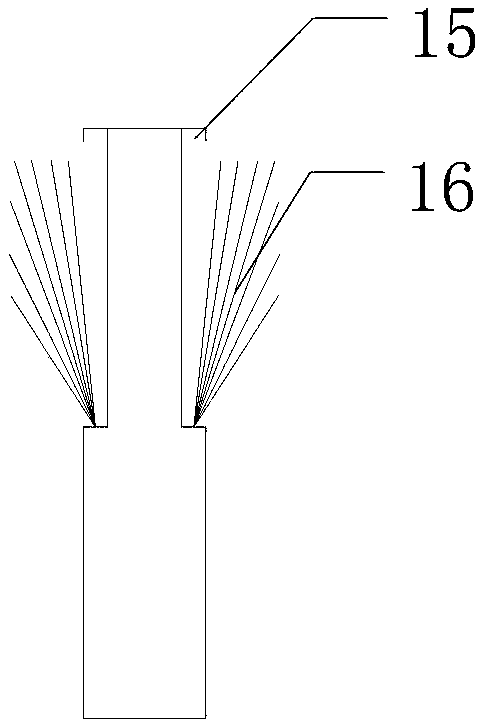

The invention discloses a highway green dustfall environmental protection construction structure and a construction method thereof, wherein the structure is as follows: a cab with a control system arranged therein; A body composed of a water storage tank, a filtering mechanism and a water spray disc; The water spray disc is of a semicircular bowl-shaped structure with an upper opening; The bottomsurface of the water spray disc is provided with a water collecting port; The wwater spray dis is connected to the water storage tank in a rotatable manner with respect to the water storage tank through a rotating shaft; The water spray disc is a double-layer structure with an interlayer in the middle. A plurality of water delivery pipes are evenly arranged in the interlayer; The rotating shaft ishollow; The filter mechanism comprises a sleeve pipe and a filter layer; The sleeve is arranged inside the rotating shaft; The filter layer is arranged inside the sleeve pipe; A drive mechanism connected to a control system; The control system controls the rotation of the rotating shaft and the spraying of water from the water supply pipe. A drive wheel disposed below the cab and the vehicle bodyto drive the cab and the vehicle body to move. The invention enlarges the spraying range in the air and realizes high-efficiency dust removal.

Owner:山西省交通环境保护中心站(有限公司)

Chemical dust removal device

PendingCN112933809ASmall footprintLow costTransportation and packagingUsing liquid separation agentDust controlProcess engineering

A disclosed chemical dust removal device comprises a storage frame, an extension plate is fixedly connected to one side of the storage frame, an electric control telescopic rod is installed at the end, away from the storage frame, of the extension plate, the output end of the electric control telescopic rod penetrates through the extension plate and is fixedly connected with an extrusion plate, a spraying hole is formed in the side, close to the extension plate, of the storage frame, and a liquid storage bag is installed in the storage frame. According to the chemical dust removal device, the purposes of reducing the equipment cost and the occupied space are achieved, a cleaning agent with a purification function does not need to be prepared in advance, the problem that the dust removal and purification effect cannot be guaranteed due to volatilization of effective components after the cleaning agent is stored for a long time can be solved, the purification component preparation time is shortened, the dust removal efficiency is improved, waste caused by sinking of purification components in the blending process can be reduced, and the cost required by dust removal and purification is reduced.

Owner:于文静

Bag dedusting collection device

ActiveCN109381937AEasy to dropGuaranteed cleanlinessDispersed particle filtrationTransportation and packagingEngineeringBellows

The invention provides a bag dedusting collection device. The bag dedusting collection device comprises a dust outlet channel, wherein a horizontal dust outlet cavity is designed in the dust outlet channel, an elastic filter screen is designed on the front side in the dust outlet channel, a bellows plate capable of sliding forwards and backwards is assembled at the rear part of the dust outlet cavity, a dust inlet channel is formed in the upper part of the dust outlet channel, a dust inlet cavity vertically intersecting with the dust outlet cavity is designed in the dust inlet channel, and theintersection of the dust inlet cavity and the dust outlet cavity is located between the filter screen and the bellows plate; a push plate block for pushing a push rod and the bellows plate to move forwards and backwards is assembled at the rear part of the bellows plate, a control valve for controlling on-off is designed on the dust inlet channel, and a dust storage box is assembled at the lowerpart of the dust outlet channel. When the device is in use, dust attached to the filter screen can be shaken off automatically by designing the bellows plate and the elastic filter screen, so that cleanliness of the filter screen can be kept.

Owner:山东蓝清环境工程有限公司

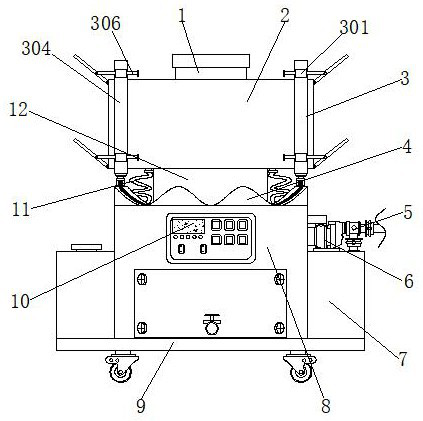

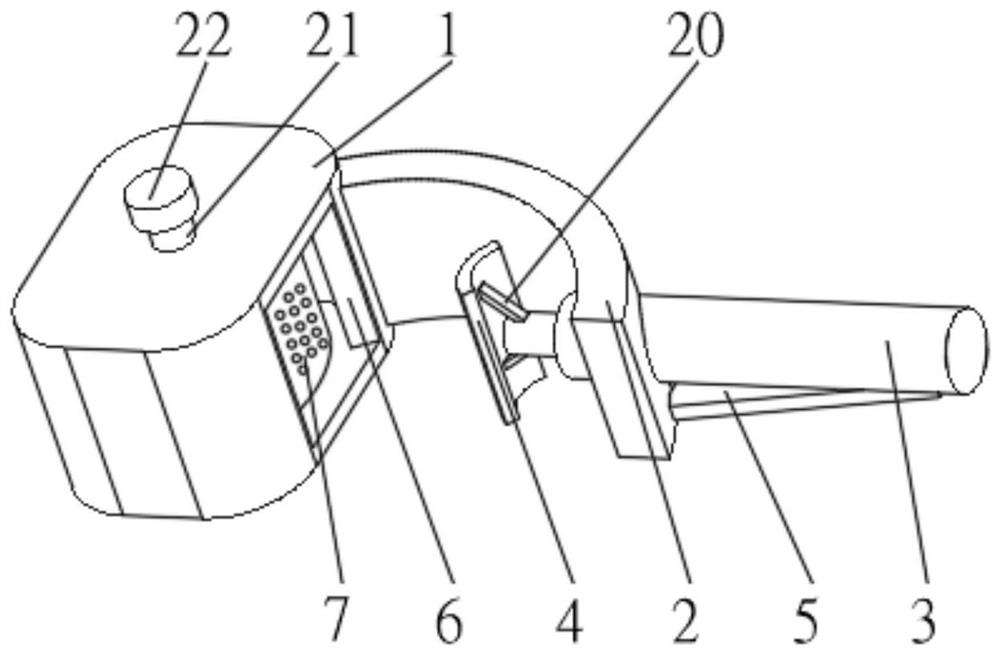

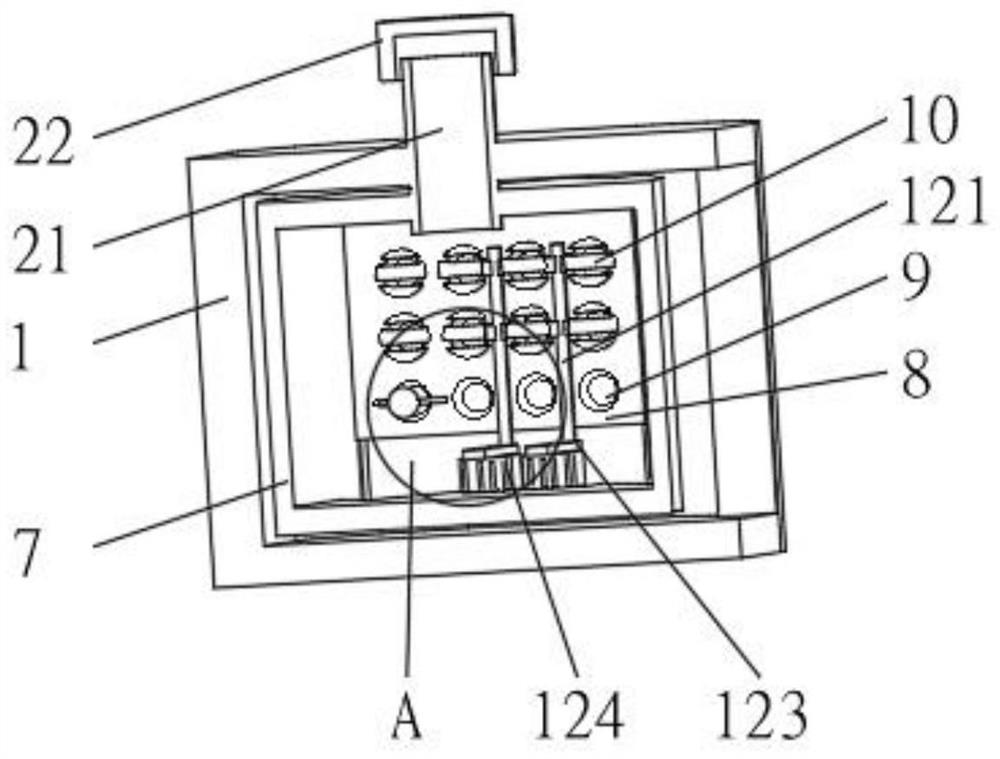

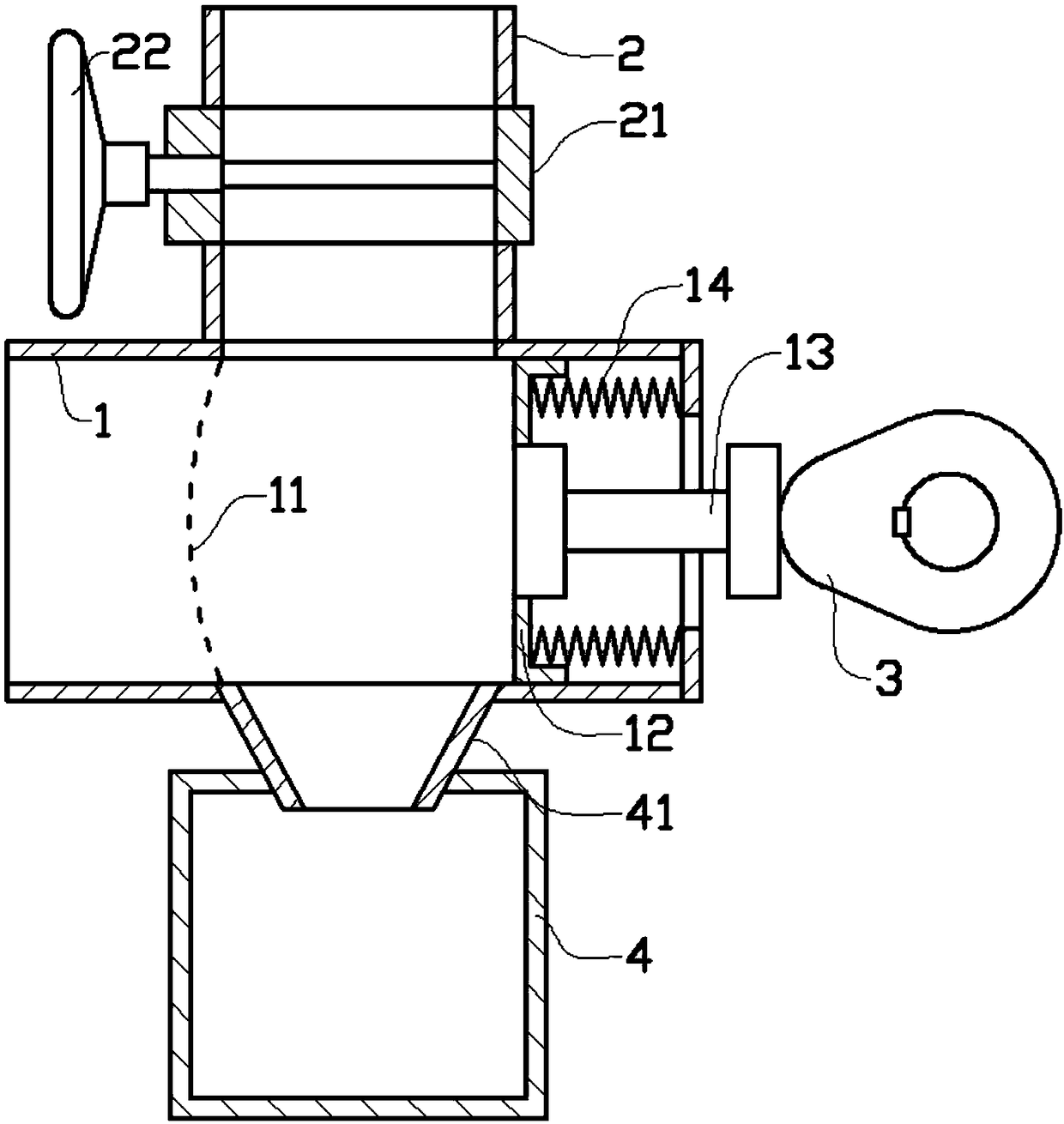

Dust catching system and method for gas drainage drilling

The invention provides a dust catching system and method for gas drainage drilling. The dust catching system comprises a drill rod, a drilling machine, a drill rod clamp, a gas pipe and a gas valve and further comprises a dust catching device for gas drainage drilling. The dust catching device for gas drainage drilling comprises a dust fall spray chamber, a positioning sleeve, a spray nozzle, a water pipe, a water valve and a slag discharging guide device. The front end of the dust fall spray chamber is fixedly connected with the positioning sleeve; the top end of the dust fall spray chamber is fixedly connected with the spray nozzle, the spray nozzle penetrates into the dust fall spray chamber, the spray nozzle is connected with the water pipe, and the water valve is installed on the water pipe; the lower end of the dust fall spray chamber is connected with the slag discharging guide device; the front end of the dust fall spray chamber and the rear end of the dust fall spray chamber are provided with a first sleeve hole an a second sleeve hole respectively, and the first sleeve hole and the second sleeve hole are coaxial with the positioning sleeve, and the diameter of the first sleeve hole is equal to the inner diameter of the positioning sleeve. The dust catching system and method are good in dust removal effect, low in water consumption and simple and convenient to operate.

Owner:CCTEG CHINA COAL RES INST

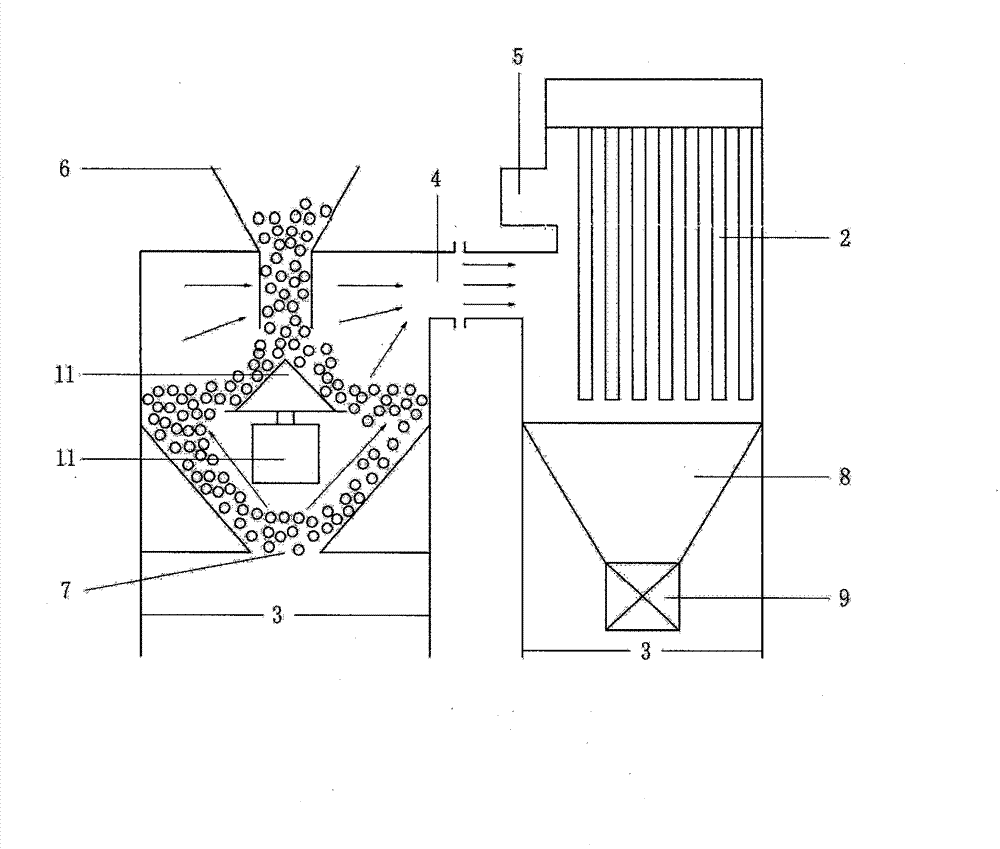

Centrifugal dedusting equipment for mine stones

InactiveCN102772970AEfficient purificationImprove build qualityCombination devicesBaghouseEngineering

The invention provides centrifugal dedusting equipment for mine stones, comprising a support, a centrifugal machine and a pulsed bag filter, wherein the centrifugal machine and the pulsed bag filter are arranged on the support side by side and are communicated with each other by a pipeline, and the upper part of the pulsed bag filter is provided with a draught fan. According to the centrifugal dedusting equipment, in the crushing and producing process of the mine stones, the centrifugal dedusting equipment is added between a crusher and a screening device, so that due to the synergistic effect of the mechanical centrifugal force and the reversed air charging, the stones in the process of producing can be further purified, the dust pollution of the mine production site can be thoroughly eliminated, the quality of the building stones can be effectively improved, and the quality of a building can be guaranteed. The product has the advantages that the dedusting effect is good, the dead angle of a dedusting device in the crushing and producing process of the mine stones can be eliminated, the equipment is safe and reliable to use and is beneficial for the environment protection of the mine production, etc.

Owner:哈尔滨市阿城区昌利矿山除尘设备厂

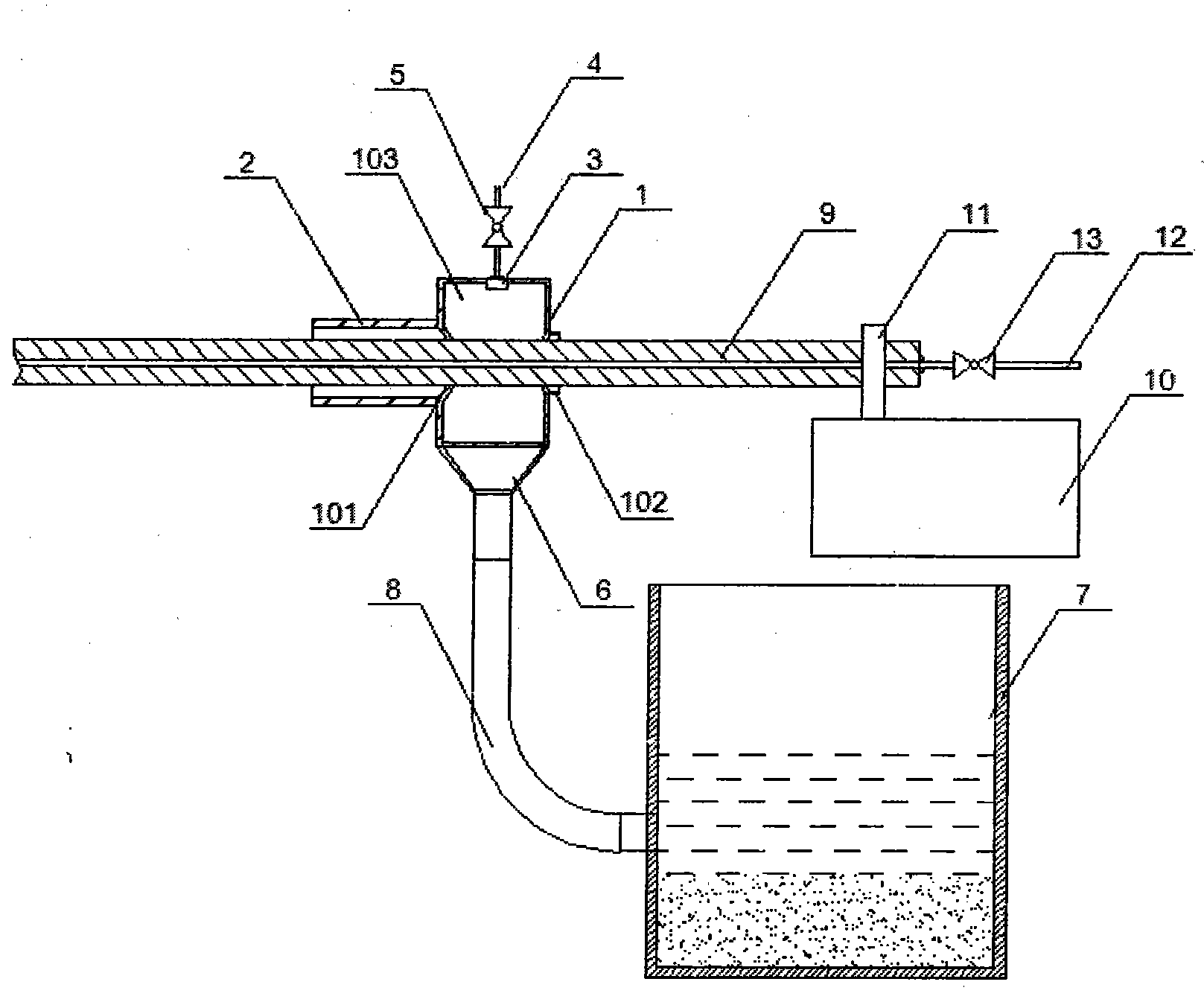

Device and method capable of recovering soot particulate matters

The invention discloses a device and a method capable of recovering soot particulate matters. The device comprises a flue body, a blow-off pipeline, a first dustpan, a second dustpan and a third dustpan, wherein the blow-off pipeline is arranged in the middle of an inner cavity of the flue body; the first dustpan is arranged on the side surface of the top end of the blow-off pipeline; the second dustpan is arranged at the lower end of the first dustpan; a third dustpan is arranged at the lower end of the second dustpan; a connector is arranged between a spray ring pipe and a fixing ring; a spray head is arranged on the inner surface of the spray ring pipe; a connection pipe penetrates through the outer side of the flue body to be connected with a water tank; a foam generator is arranged on the side surface of the flue body and an inlet of the foam generator penetrates through the flue body through a pipeline and is communicated with the blow-off pipeline. Dustpan-type dust collection is carried out through a physical method, the emission amount of pollutants is reduced, the process is simple, the production is convenient, the cost is low, staged treatment, level-to-level quantification and real-time adjustment are achieved, and the efficiency is improved.

Owner:张久明

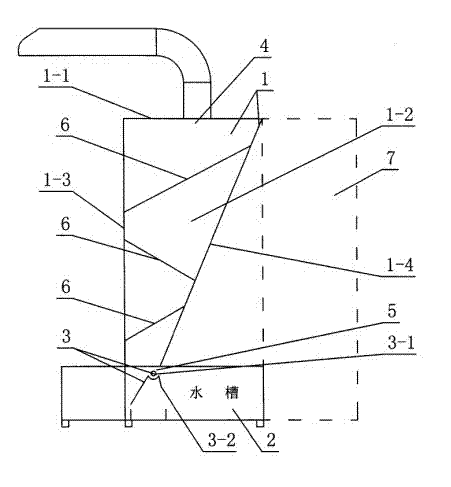

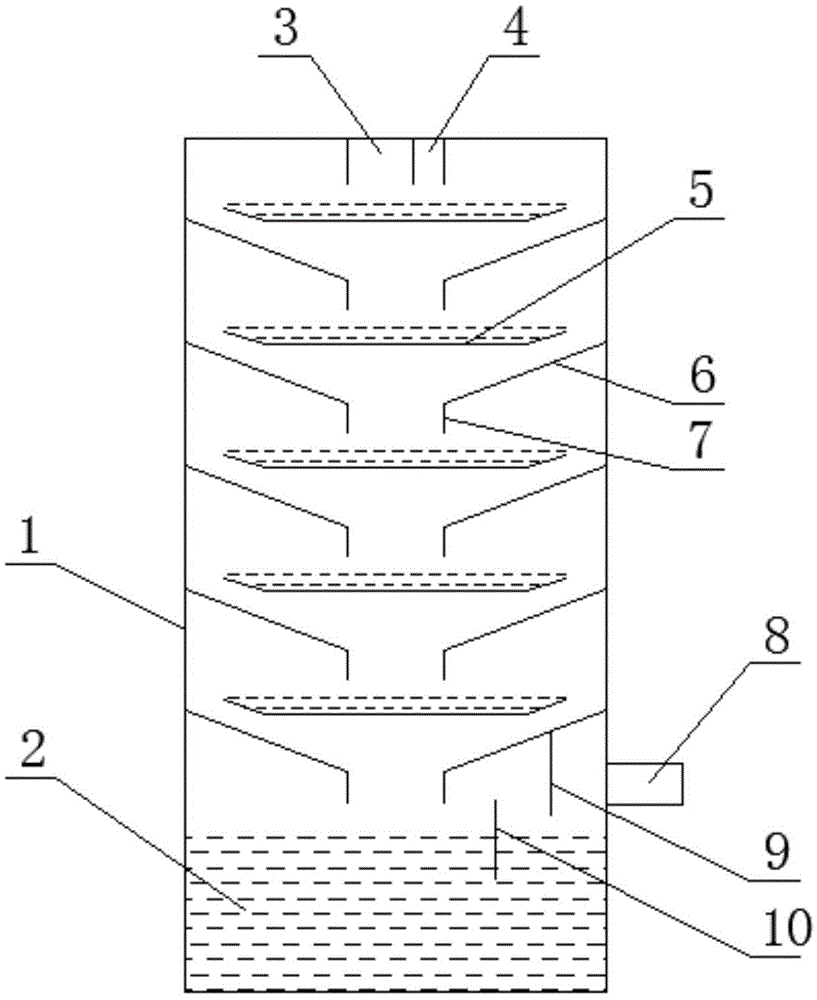

Impact-type water film desulfurization dust remover

InactiveCN104083967AShock fullImprove dust removal effectUsing liquid separation agentWater storage tankEngineering

The invention discloses an impact type water film desulfurization dust remover. The impact type water film desulfurization dust remover comprises a tower body, a plurality of trays and a plurality of flow guide funnels, wherein a water storage tank is formed on the lower end of an inner cavity of the tower body; a water level regulating chamber is formed at the water storage tank; a water inlet pipe and an air inlet pipe are arranged at the upper end of the inner cavity of the tower body; an air outlet pipe is arranged at the bottom of the tower body; the air outlet pipe is higher than the water surface of the water storage tank; the plurality of trays are arranged in the tower body at equal spaces from top to bottom; gaps are formed between the left ends of the trays and the inner wall of the tower body and between the right ends of the trays and the inner wall of the tower body; a flow guide funnel is correspondingly arranged under each tray; the upper ends of the flow guide funnels are large ends, and the upper ends of the flow guide funnels are connected with the inner wall of the tower body in a sealing manner; the lower ends of the flow guide funnels are connected with the upper end of a direct flow pipe. By virtue of the impact type water film desulfurization dust remover, the impact of smoke and water can be enhanced, so that a relatively large amount of dust in the smoke can be absorbed, and the dust removal effect is improved.

Owner:GUANGXI NANNING ZHONGJIA ENVIRONMENTAL PROTECTIONVALVE MFG

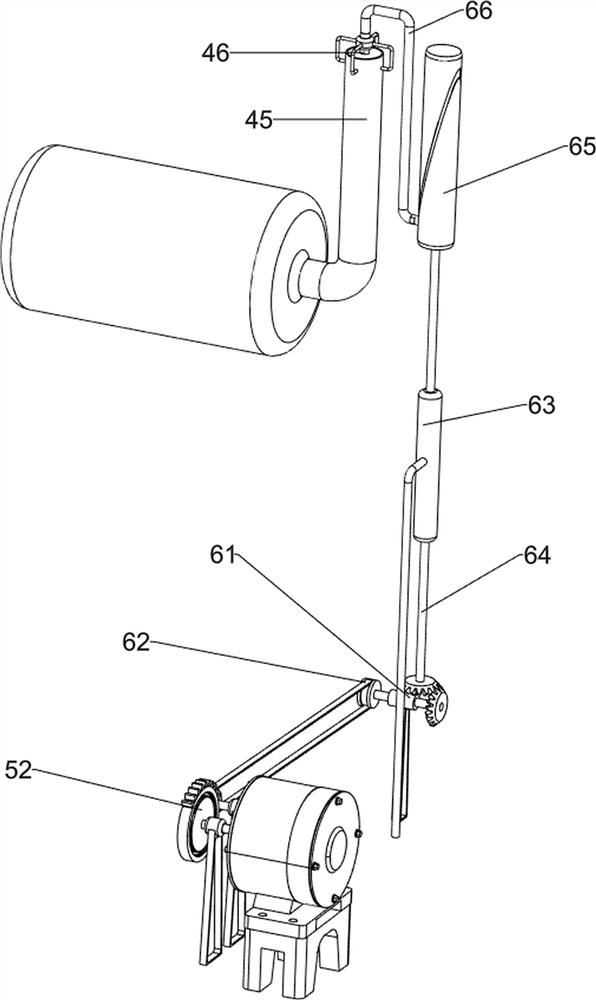

Efficient PCB dust removal device for LED production

ActiveCN112691974AImprove dust removal efficiencyReduce usageCleaning using liquidsDust controlElectric machinery

The invention relates to a dust removal device, in particular to an efficient PCB dust removal device for LED production. The efficient PCB dust removal device for the LED production is high in dust removal work efficiency, low in cost and capable of achieving automatic discharging. The efficient PCB dust removal device for the LED production comprises a bottom plate, a support, a motor, a pressurizing spraying mechanism, and a transmission clamping mechanism, and the support is arranged on the bottom plate. The motor is mounted on the support. The pressurizing spraying mechanism is arranged on the bottom plate. The transmission clamping mechanism is arranged on the bottom plate and is connected with an output shaft of the motor. According to the efficient PCB dust removal device for the LED production, the effect of conducting PCB dust removal work with high efficiency is achieved, through cooperation of the pressurizing spraying mechanism, the transmission clamping mechanism, a telescopic mechanism and a cleaning mechanism, dust on a PCB is cleaned up while the PCB is transported, the PCB dust removal efficiency is improved, and meanwhile through cooperation of a switch mechanism and the pressurizing spraying mechanism, and the use amount of alcohol can be reduced.

Owner:广州市翔哲自动化设备有限公司

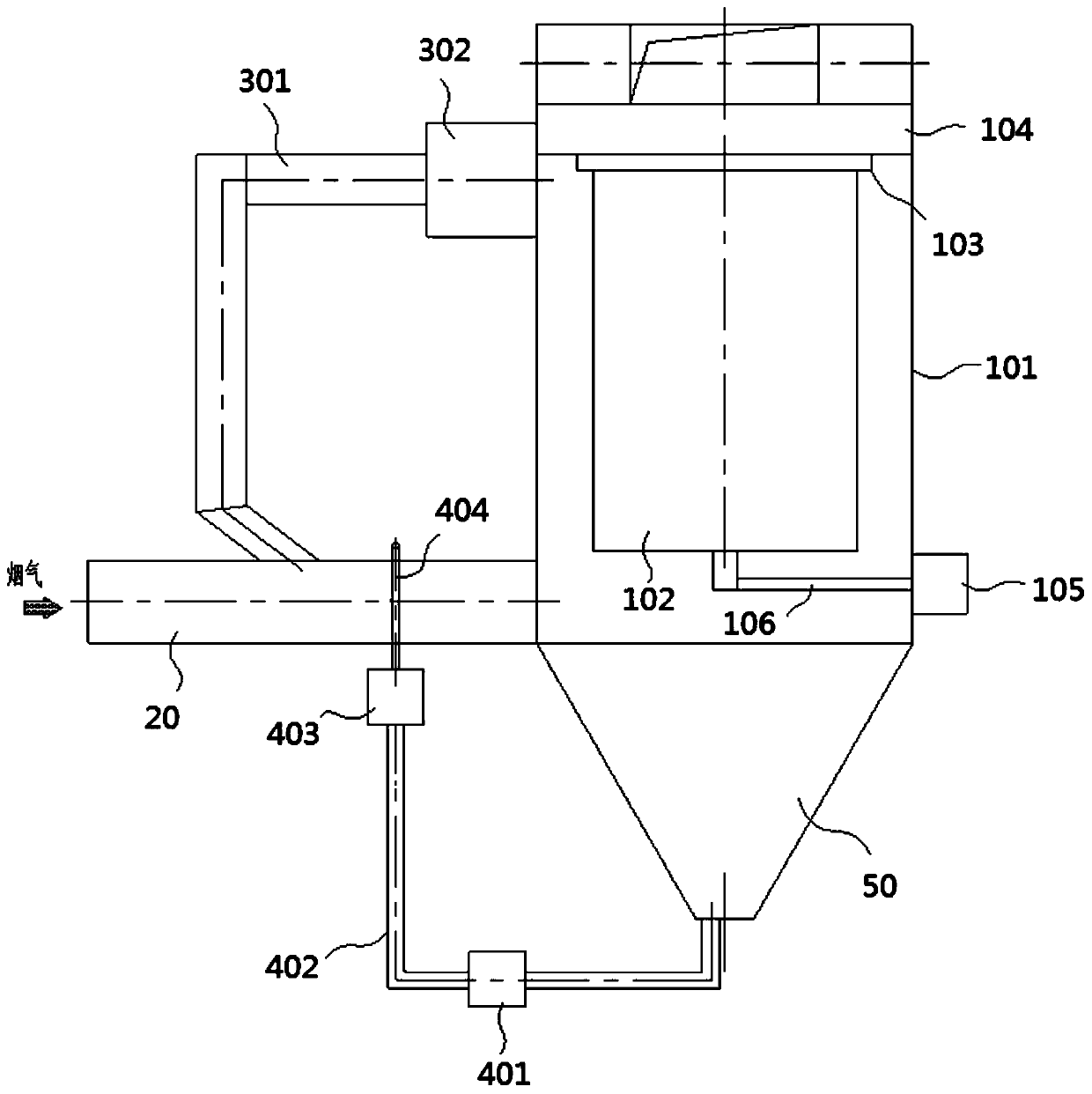

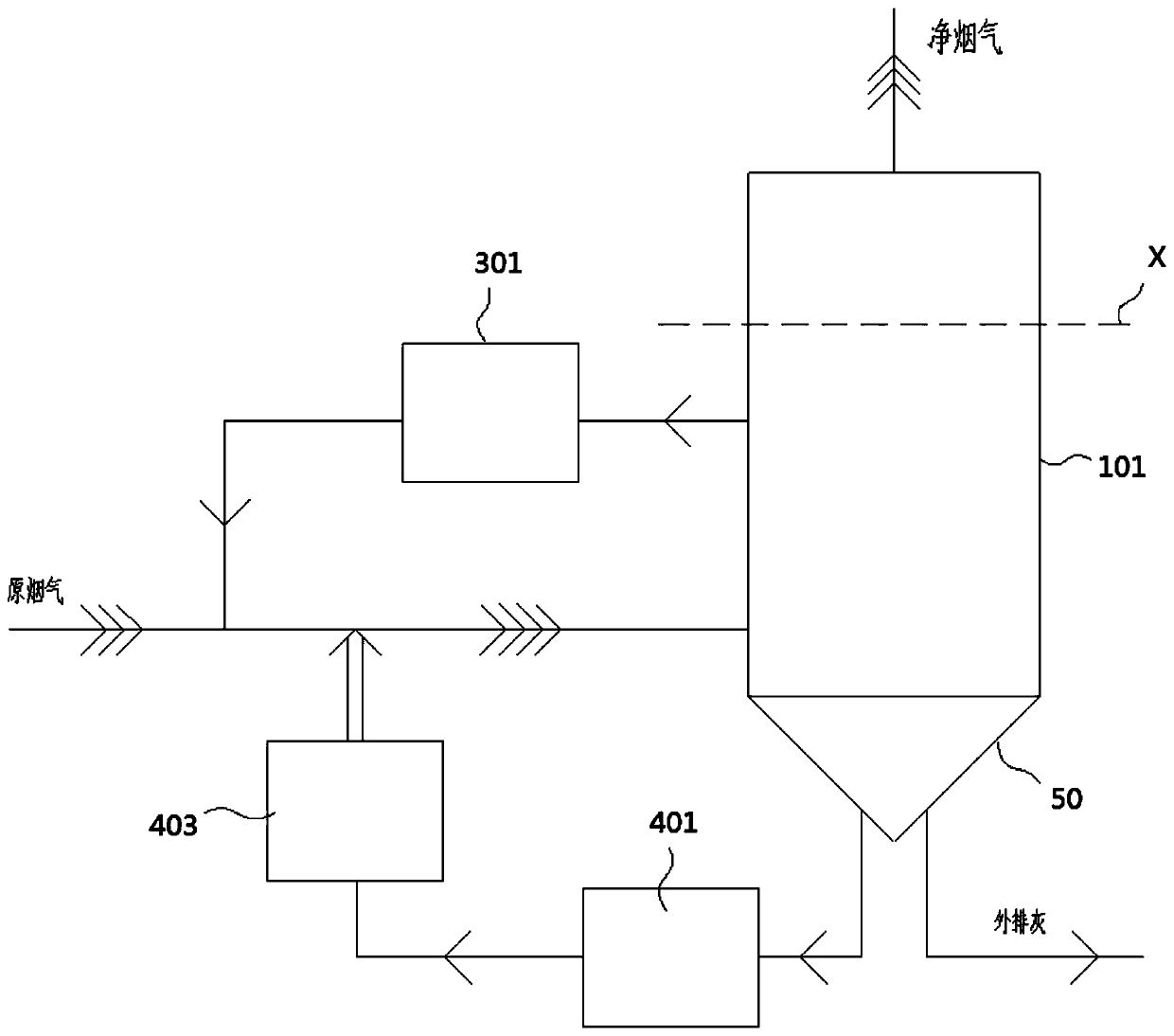

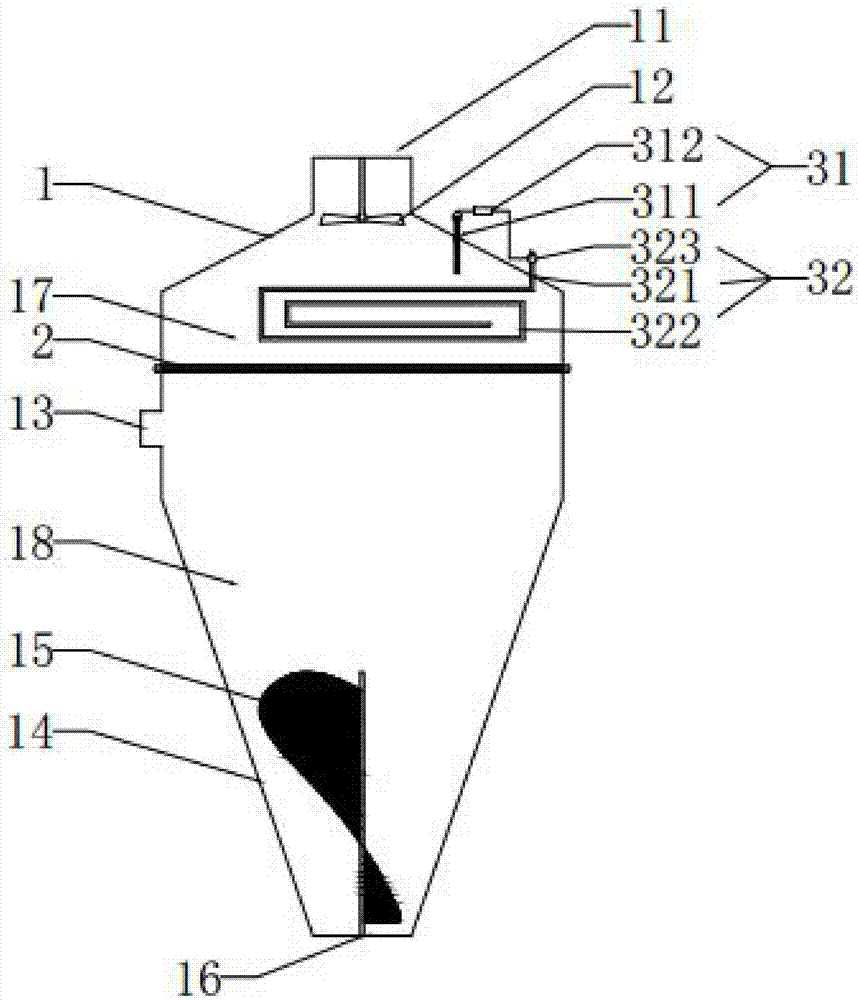

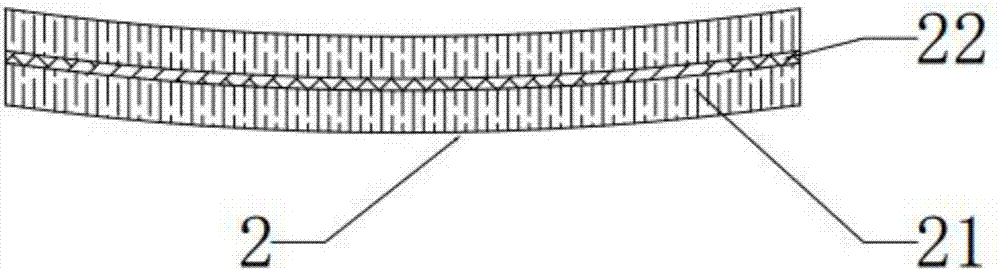

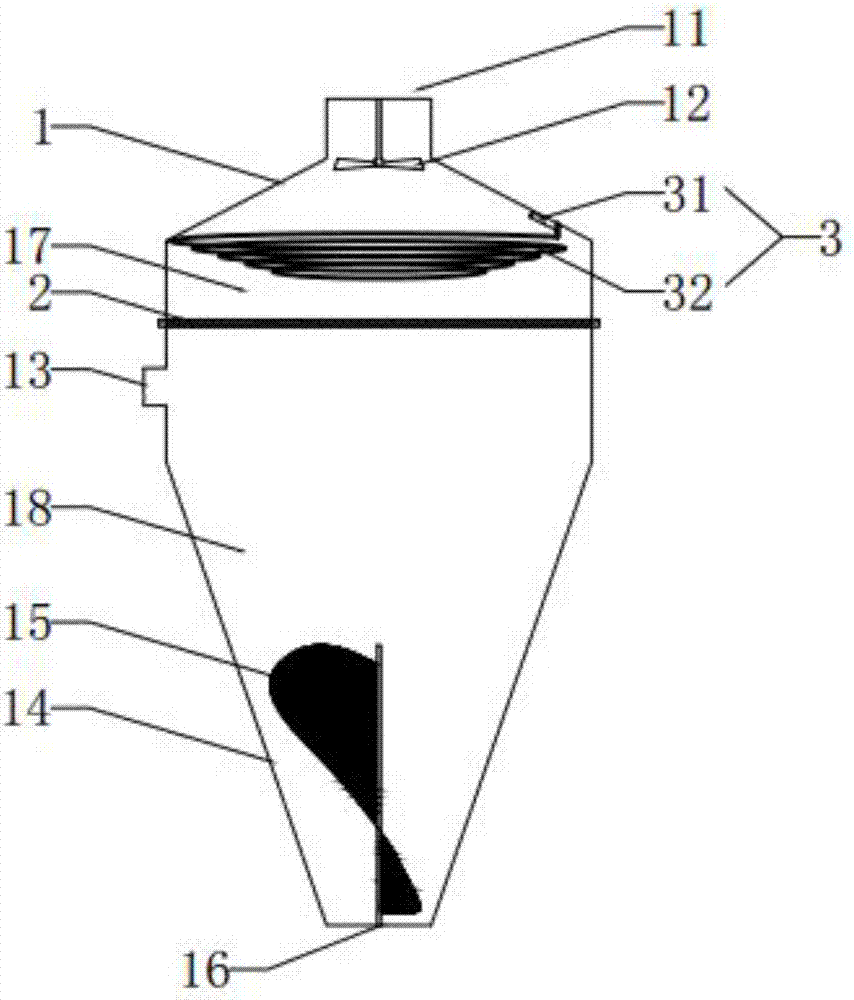

Flue gas purification device

InactiveCN111408207ASimple structureSmall footprintGas treatmentDispersed particle filtrationParticulatesFlue gas

The invention discloses a flue gas purification device which comprises a rotary filter bag dust remover, and the rotary filter bag dust remover comprises a filter bag capable of rotating, an inlet flue communicated with the rotary filter bag dust remover and an adsorbent supply device, and the adsorbent supply device can spray an adsorbent used for removing acidic harmful substances into the inletflue. Based on the flue gas purification device, the filter bag can rotate to drive flue gas to spirally ascend, and the flue gas slowly ascend after entering the rotary filter bag dust remover, thus, the flue gas and the adsorbent have contact reaction time in the rotary filter bag dust remover, the rotary filter bag dust remover provides a place for the removal reaction, and a reactor for the removal reaction does not need to be specially arranged, so that the structure of the flue gas purification device is simplified, the occupied area is saved, and the dust removal cost is controlled. Moreover, particles floating to the surface of the filter bag along with the flue gas can be thrown away from the filter bag, freely fall down under the influence of gravity, fall into an ash bucket below the rotary filter bag dust remover and are collected.

Owner:FUJIAN LONGKING

Industrial ceramic dust removing device

ActiveCN107051046AReduce dust removal costsAdjust the degree of opening and closingCombination devicesDispersed particle filtrationContinuous operationProduct gas

The invention discloses an industrial ceramic dust removing device, which comprises a tank body, a filtering mechanism and a pneumatic spraying mechanism. The filtering mechanism is arranged in an inner chamber of the tank body, and divides the inner chamber of the tank body into a first cavity and a second cavity. The pneumatic spraying device comprises a pneumatic component and a spraying component. Specifically, the pneumatic component comprises a pressure gauge and a controller; the spraying component comprises a water inlet, a spray pipe and a quick shut-off valve. According to the industrial ceramic dust removing device provided by the invention, the filtering mechanism an tank body inner wall surface are in seal connection, no gap exists, and the dust removing efficiency is high. Through linkage of the pneumatic component and the spraying component, dust or glaze on the filtering mechanism can be cleared automatically to realize continuous operation, the equipment utilization rate is high, and the production capacity is large. The opening degree of the quick shut-off valve is controlled in real time according to the deposition degree of dust or glaze on the filtering mechanism, thus saving spraying liquid and reducing the dust removing cost. The industrial ceramic dust removing device is especially suitable for the circumstance of uneven concentration of dust or glaze in dusty gas of different periods.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Energy-saving wet type dust collector

InactiveCN105561701AReduce wasteGood energy saving effectCombination devicesUsing liquid separation agentWater levelDust particles

The invention provides an energy-saving wet type dust collector. The energy-saving wet type dust collector comprises a dust chamber, the upper end of the dust chamber is provided with an air inlet, a narrow air passage which is vertically and downwardly communicated with the dust chamber is formed in the air inlet and downwardly faces a rhombic block fixed in the dust chamber, and the narrow air passage is laterally and vertically communicated with capillary tubes which are communicated to a water tank with a water level lower than a port of the narrow air passage. The upper portion of the dust chamber is laterally provided with an air outlet, the lower end of the dust chamber is connected with a water drain pipe which forms a water-sealed joint below the dust chamber, and water seal can be formed in the water-sealed joint. The energy-saving wet type dust collector has the advantages that small dust particles in dusty air can be removed by a small amount of water, excellent energy saving effect is achieved, and dedusting cost can be remarkably reduced.

Owner:朱虹斐

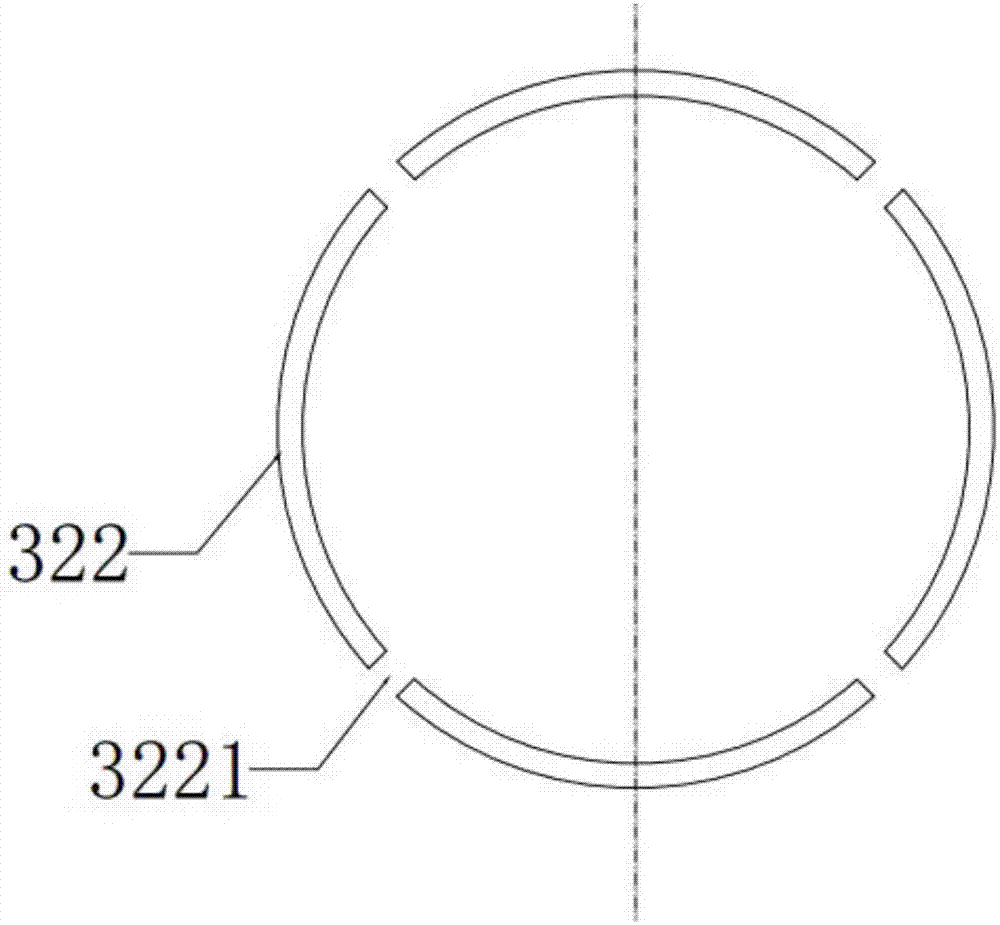

Ceramic dust-removing device

ActiveCN107088338AAvoid cloggingSpray evenlyDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

The invention discloses a ceramic dust-removing device, which comprises a tank body, a filtering mechanism and a pneumatic spraying mechanism, wherein the filtering mechanism is arranged in an inner cavity of the tank body, and divides the inner cavity of the tank body into a first cavity body and a second cavity body; the pneumatic spraying mechanism comprises a pneumatic component and a spraying component; the pneumatic component comprises a pneumatic opening, an elastic film, an elastic element and a conducting rod; the spraying component comprises a water inlet, a spraying pipe and a quick switching valve. According to the ceramic dust-removing device with the structure, the filtering mechanism is hermetically connected with the inner wall surface of the tank body, no gap exists and the dust removal efficiency is high; the spraying component is linked through the pneumatic component; dust or a glaze on the filtering mechanism is automatically purged; the continuous operation is realized; the utilization rate of equipment is high; the production capacity is high; the opening size of the quick switching valve and a spraying occasion are controlled in real time according to the deposition extent of the dust or the glaze on the filtering mechanism and the adsorption extent of the filtering mechanism to the dust or the glaze; spray liquid is saved; the dust removal cost is reduced.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Multifunctional building concrete

The invention relates to the technical field of buildings and in particular relates to multifunctional building concrete which comprises the following components in parts by weight: 10-12 parts of phosphorus slag, 5-7 parts of coal ash, 3-5 parts of cement, 3-5 parts of PDMS (Polydimethylsiloxane), 1-2 parts of straw ash, 3-5 parts of nickel powder, 1-2 parts of chromium powder, 2-5 parts of aluminum oxide powder, 1-2 parts of silicon carbide powder, 3-5 parts of lime powder, 1-2 parts of asbestos, 1-2 parts of glass fibers, 1-2 parts of silicon micro powder and 0.2-0.5 part of octadecanethiol. The multifunctional building concrete has the advantages of relatively good energy storage collection function, good lyophobic self-cleaning function, relatively good strength, waste resource reuseand relatively good popularization and use value.

Owner:CHENGDU ZHIA TECH CO LTD

Dust removal spraying device for safety engineering management

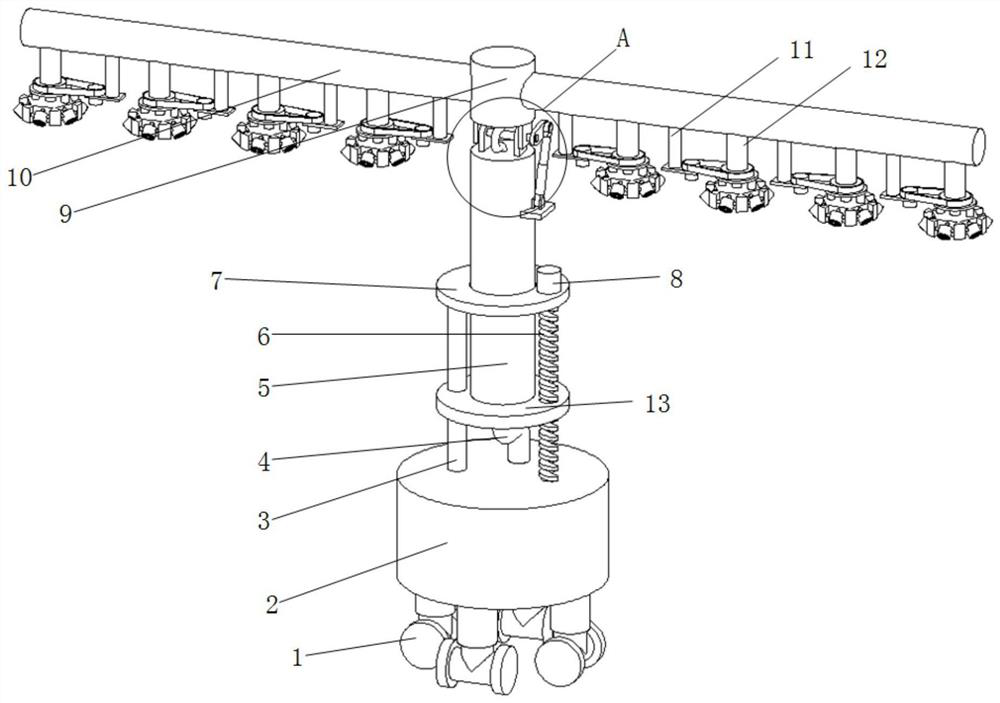

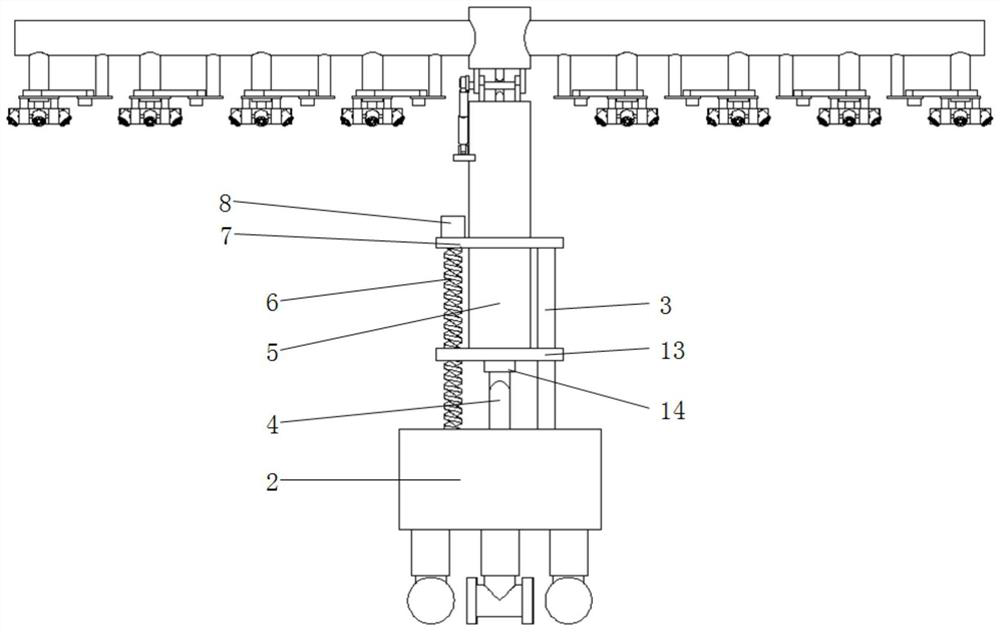

InactiveCN112973341AExpand the spraying areaIncrease the effective spray rangeUsing liquid separation agentRotational axisDust control

The invention provides a dust removal spraying device for safety engineering management. The dust removal spraying device comprises a rotating pipe, a supporting pipe and two groups of spraying structures symmetrically arranged on the two sides of the rotating pipe, wherein the rotating pipe is erected at the top of the supporting pipe through a swinging device, the swinging device comprises a rotating shaft and a connecting rod, a supporting table is fixedly arranged on the side face of the supporting pipe, an air cylinder is rotationally arranged at the top of the supporting table, a joint bearing is fixedly arranged at the end of an air cylinder push rod, the inner ring of the joint bearing is matched with a short shaft, the rotating shaft drives the rotating pipe to rotate, two ends of the connecting rod are rotationally connected with the ends of the rotating shaft and the short shaft respectively, the rotating pipe is communicated with the supporting pipe, the spraying structure comprises a conveying pipe, a plurality of rotating devices erected at the bottom of the conveying pipe, and a plurality of spraying heads communicated with the conveying pipe, one end of the conveying pipe is closed, the other end of the conveying pipe is communicated with the supporting pipe, and each spraying head is driven to rotate by a rotating device. According to the device, through the multi-angle rotating spraying structure, large-area spraying dust falling is achieved, the water consumption is small, and the dust falling cost is saved.

Owner:SHANGQIU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com