Special dust remover for tail dust removal of drying machine

A dust collector and dryer technology, applied in chemical instruments and methods, dispersed particle filtration, combined devices, etc., can solve problems such as pollution and harmful gases are not effectively removed, save energy, reduce the use of water resources, The effect of saving dust removal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

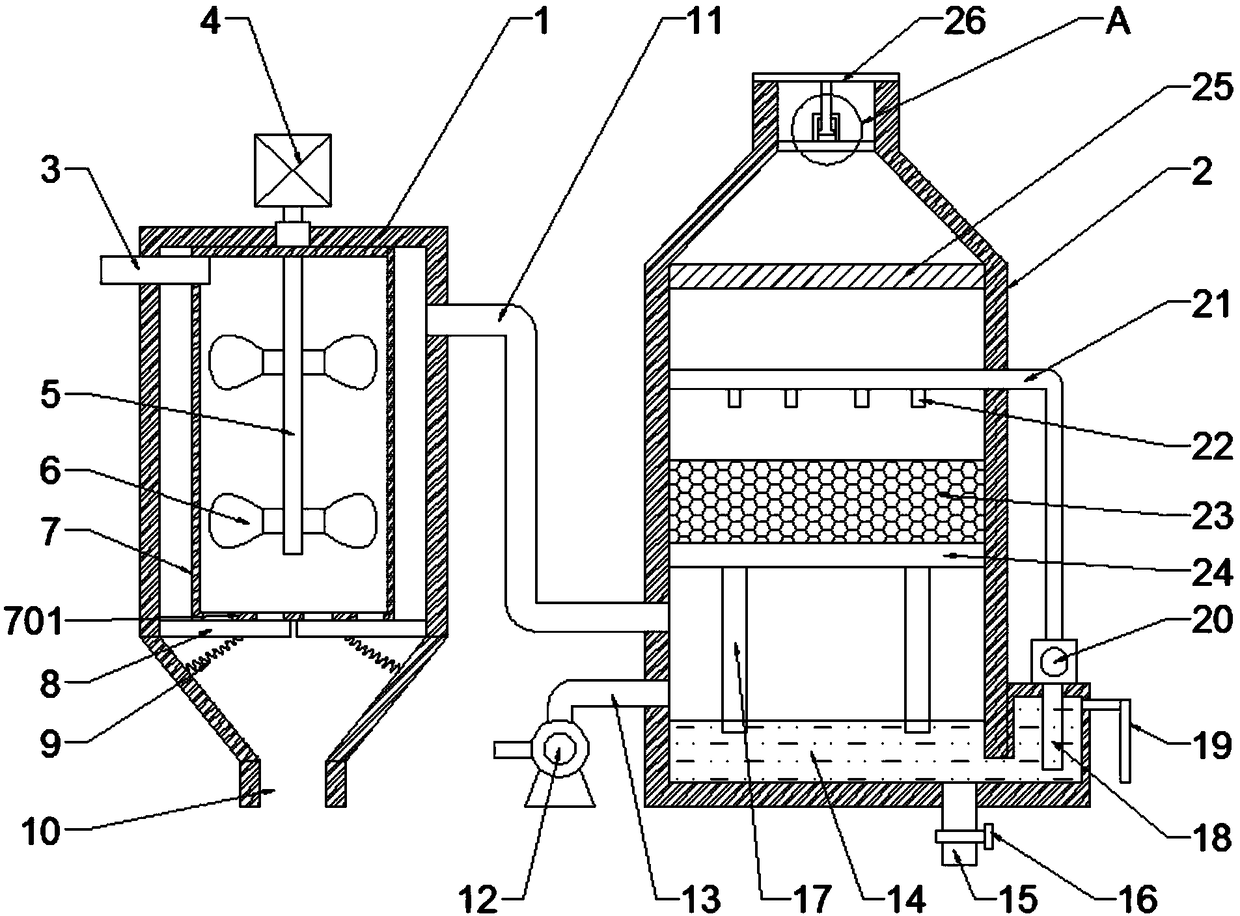

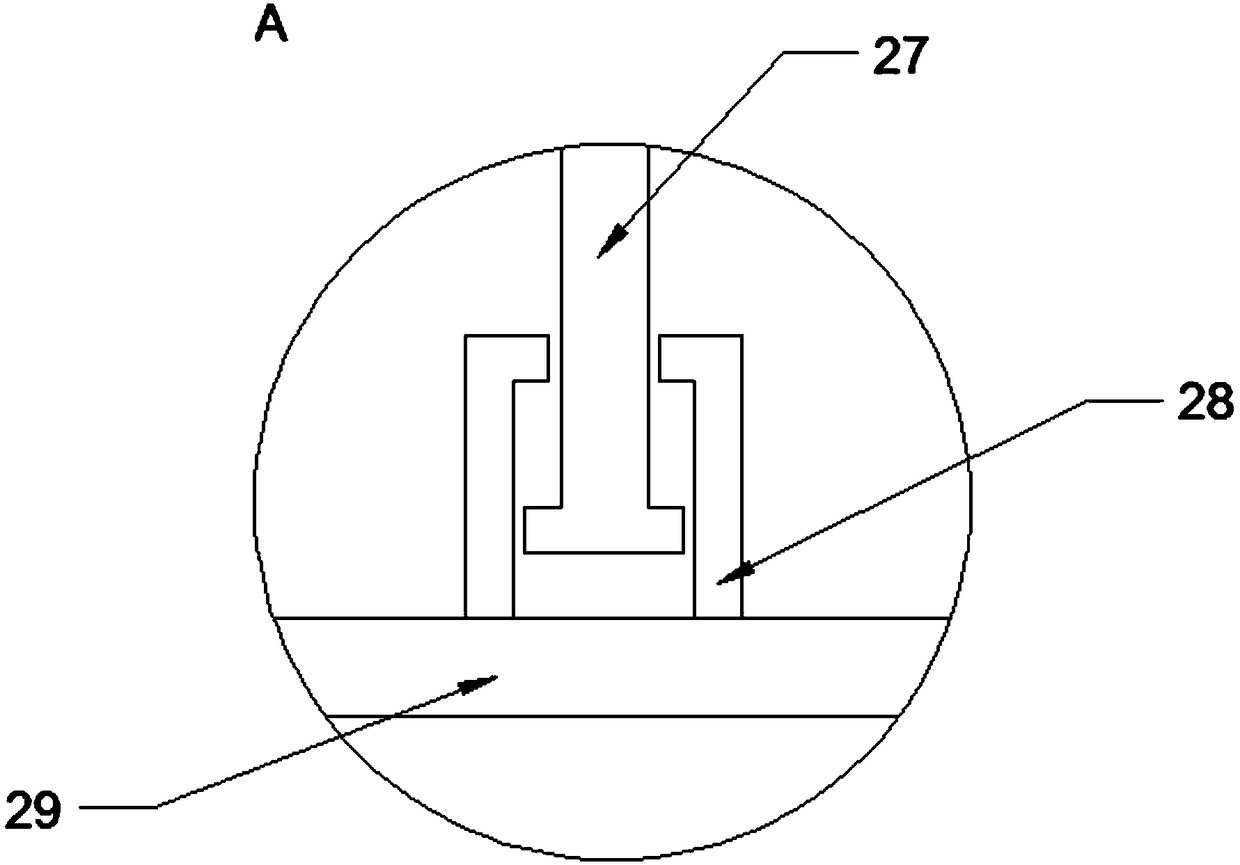

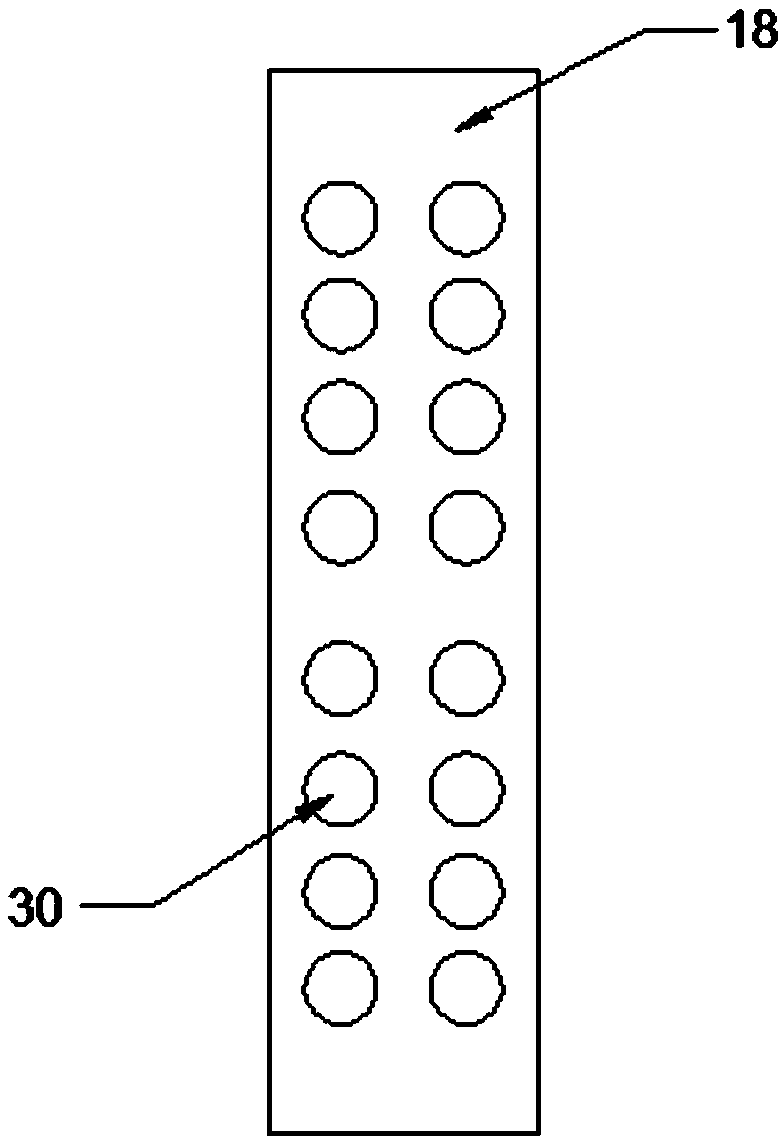

[0019] like Figure 1-Figure 3 As shown, the present invention proposes a special dust collector for dust removal at the tail of a dryer, including a dust removal chamber 1, a deodorization chamber 2 and a servo motor 4, the upper end of the dust removal chamber 1 is provided with a servo motor 4, and the servo motor 4 is connected to a transmission shaft 5, The transmission shaft 5 is provided with a plurality of fan blades 6, and the outer side of the fan blades 6 is provided with a filter bag 7, the upper end of the left side of the filter bag 7 is provided with an air inlet 3, and the lower end of the filter bag 7 is symmetrically provided with a dust shield 8, and the dust shield 8 The lower end is provided with a spring 9, and the lower end of the spring 9 is connected to the inner wall of the dust removal chamber 3, and the lower end of the dust removal chamber 3 is provided with a dust outlet 10, and the dust removal chamber 1 is connected to the deodorization chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com