Storage type static dedusting device

A dust-removing device and storage-type technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of inability to prevent the floating of dust, the proportion of industrial waste gas dust removal is not high, and the cost of dust removal is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

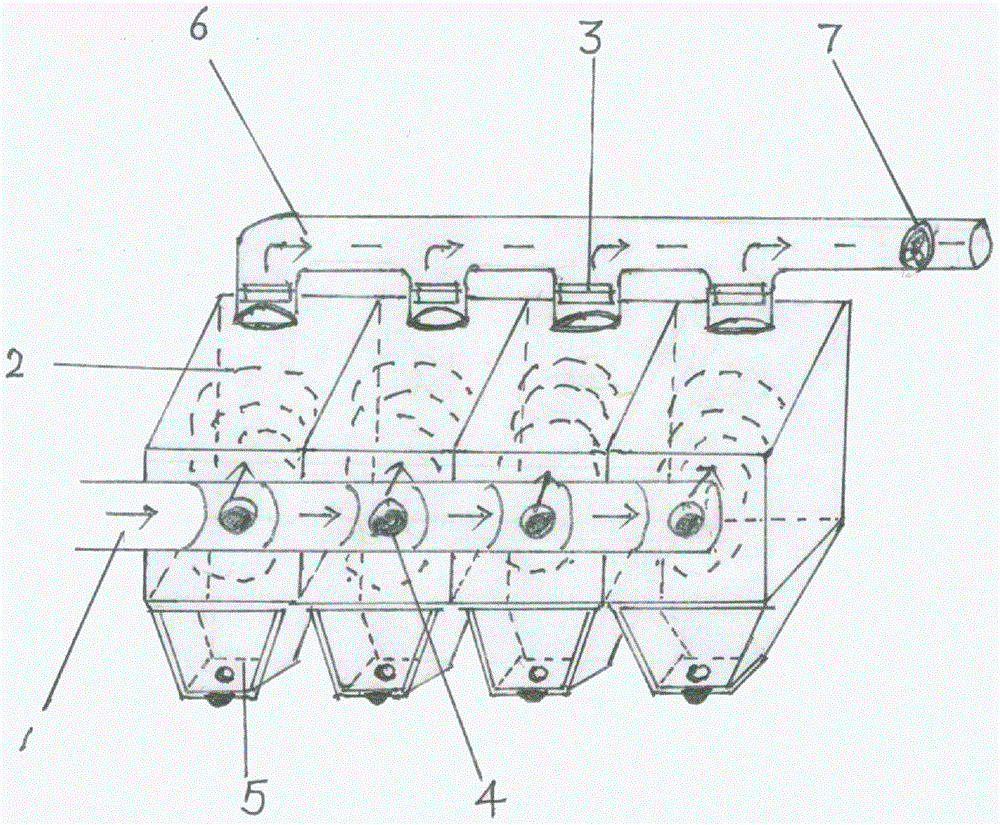

[0007] A warehouse-type static dust removal device, such as figure 1 As shown, it includes a dust-laden air inlet pipe 1, an exhaust fan 7 and an exhaust pipe 6; it also includes an inlet solenoid valve 4, a dust removal box and an outflow solenoid valve 3; when the exhaust fan 7 is working, a N static gravity dust-suppression chambers 2 composed of the first static gravity dust-suppression chamber, the second static gravity dust-suppression chamber ... to the N-1st static gravity dust-suppression chamber, and the N-th static gravity dust-suppression chamber are respectively located in each A bucket-shaped dust-collecting chamber 5 directly below the static gravity-type dust-suppression chamber 2 and connected to each static gravity-type dust-suppression chamber 2, the bottom of the bottom of the bucket-shaped dust-collection chamber 5 is provided with a dust leak port, and the gravity makes the The dust falling down into the bucket-shaped dust collecting chamber 5 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com