Process for treating iron vanadium slag by virtue of dry-process rotary kiln

A dry rotary kiln and waste heat treatment technology, applied in the direction of improving process efficiency, can solve problems such as weakening of the bonding ability between grains and grains, unfavorable separation of gas and solids, unfavorable recovery, etc. Economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

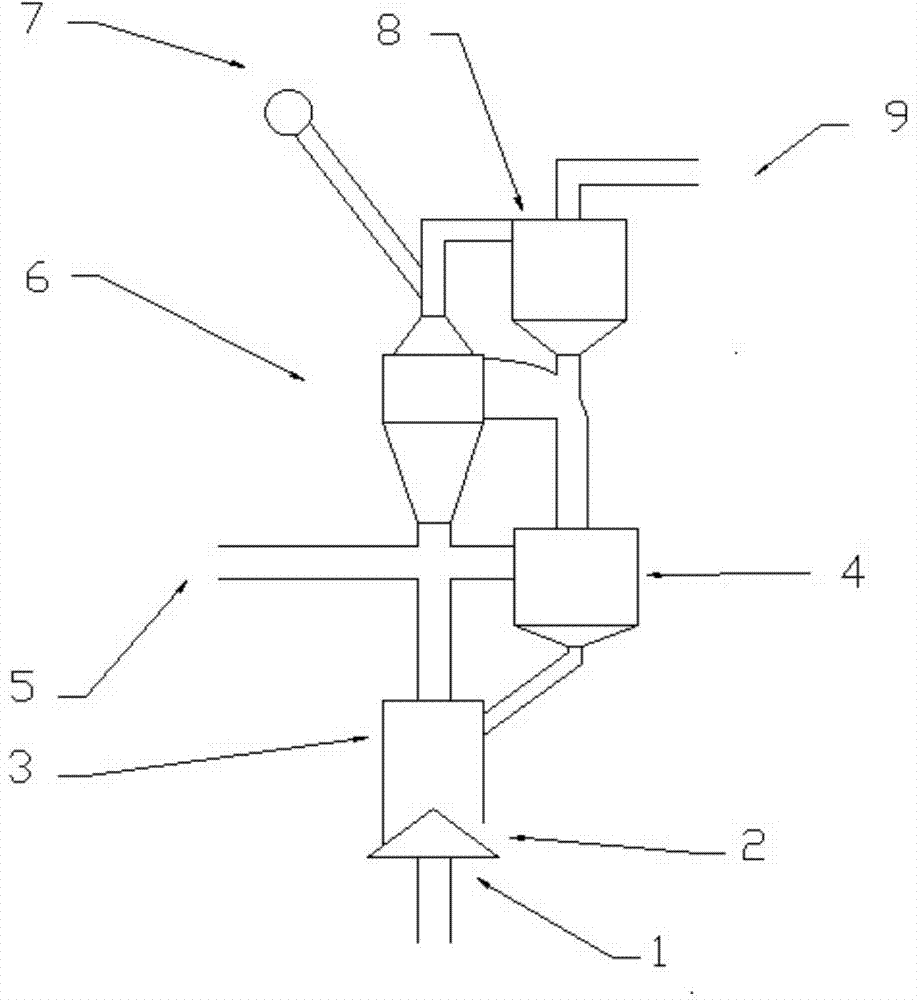

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] A kind of technology utilizing the residual heat of dry method rotary kiln to treat alum slag, comprises the following steps:

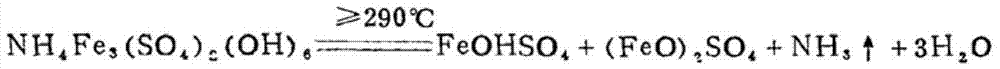

[0028] (1) Deammonization treatment of alum slag

[0029] After crushing the alum slag, send it to the rotary dryer for drying. The hot air used for drying is the hot air at the tail of the dry rotary kiln. The temperature of the hot air is controlled at 300°C to obtain tail gas containing ammonium carbonate; after the gas and ammonium carbonate are separated, The ammonium carbonate obtained is sent to the zinc smelter for recycling, and the gas is discharged up to standard.

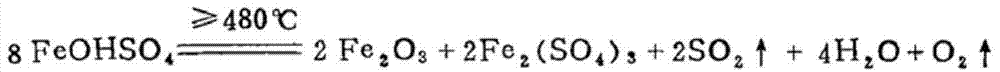

[0030] (2) Desulfurization treatment of alum slag

[0031] Pulverize the deaminized jarosite slag, add binder and water (refer to Table 1 for the formula), mix well, prepare pellets with a particle size of 1 mm, add to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com