Dust removal spraying device for safety engineering management

A sprinkler device and safety engineering technology, which is applied in the field of safety engineering, can solve the problems of small spraying range, waste of water resources, and increased dust suppression costs, and achieve the effects of low dust removal cost, small water consumption, and increased spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

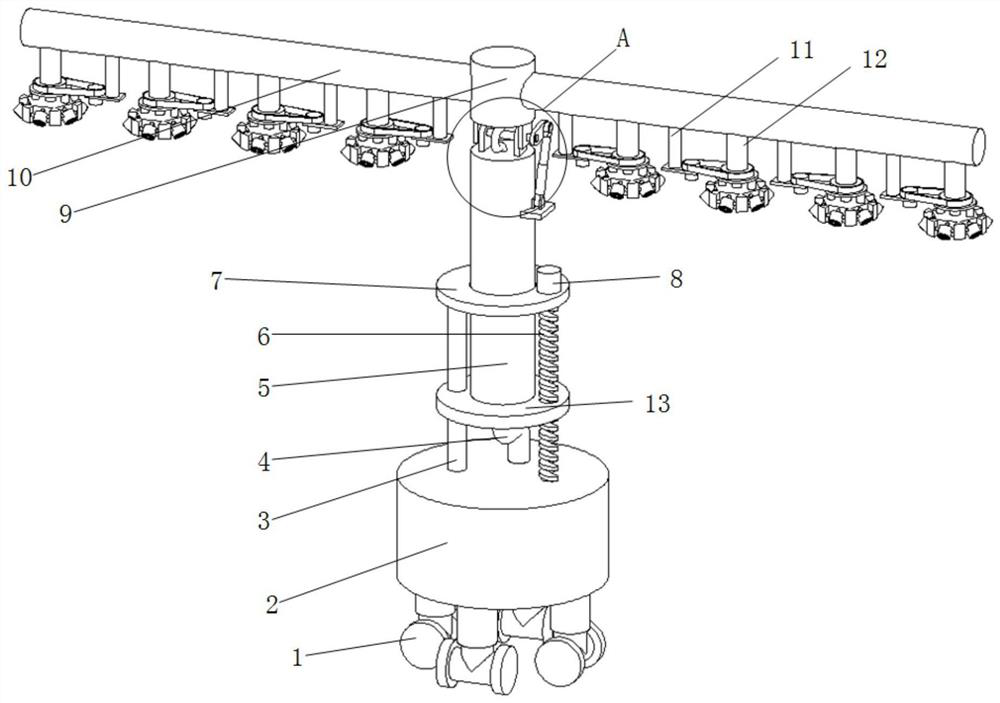

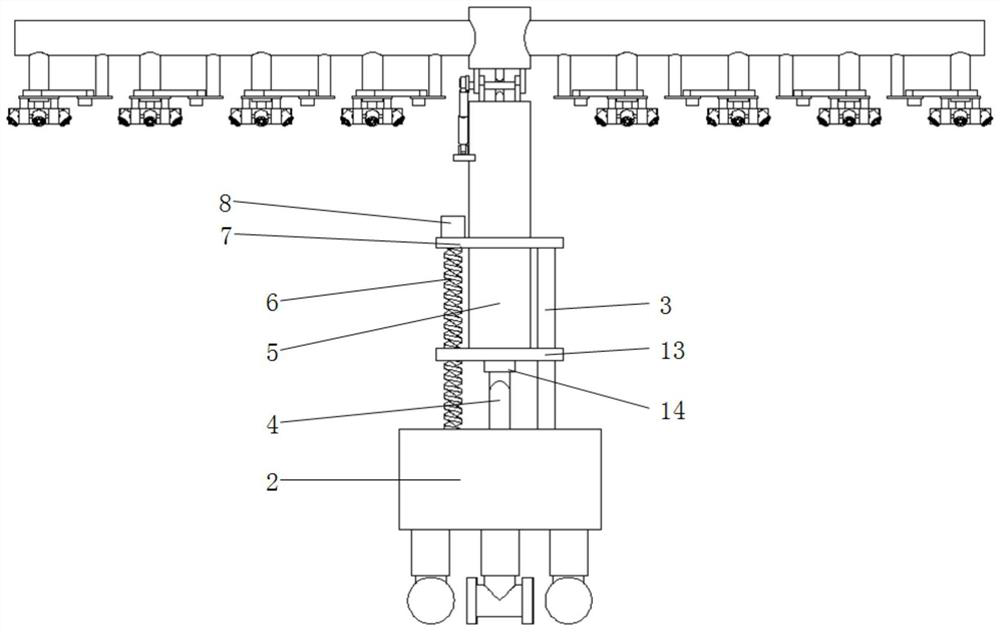

[0025] A kind of dust removal spray device for safety engineering management, such as Figure 1-4 As shown, it includes a rotating tube 9, a support tube 5 and two groups of spray structures symmetrically arranged on both sides of the rotating tube 9;

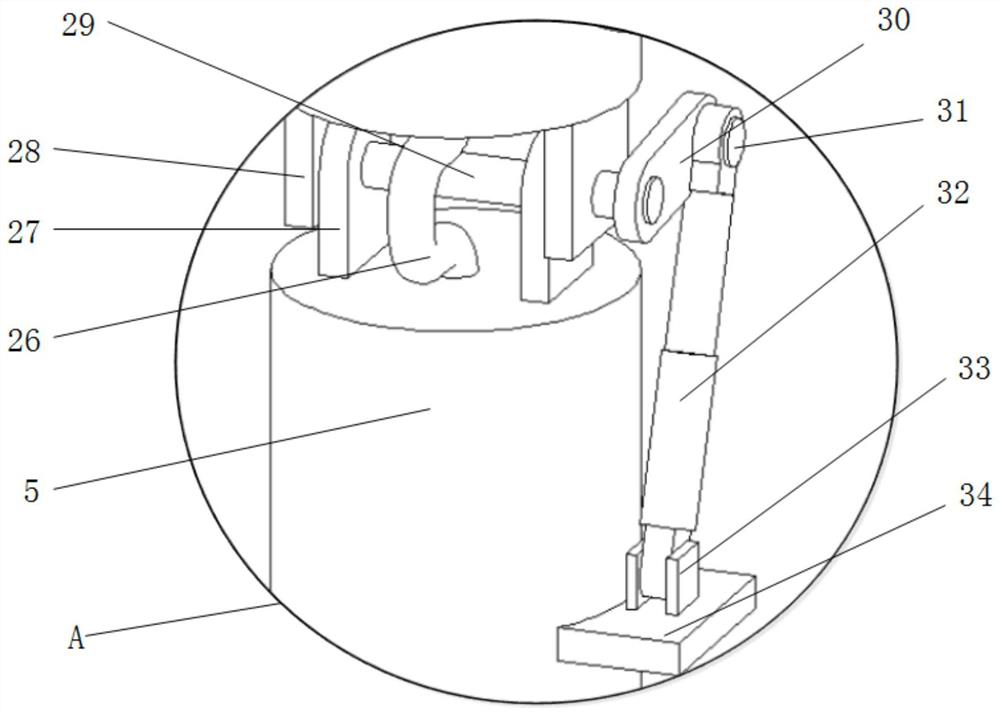

[0026] The rotating tube 9 is erected on the top of the support tube 5 by a swinging device, such as image 3 As shown in the partial enlarged view; the swing device includes a rotating shaft 29 and a connecting rod 30; a support platform 34 is fixedly installed on the side of the support tube 5, and a cylinder 32 is installed on the top of the support platform 34 to rotate, and a joint bearing is fixedly installed at the end of the push rod of the cylinder 32 , the inner ring of the joint bearing is equipped with a short shaft 31; the top of the support tube 5 and the bottom of the rotating tube 9 are respectively fixed with a first frame plate 27 and a second frame plate 28, and the rotating shaft 29 passes through the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com