Energy-saving wet type dust collector

A wet dust collector and energy-saving technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve the problems of wasting water, waste, and high overall cost, achieve less waste, reduce dust removal costs, The effect of high energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

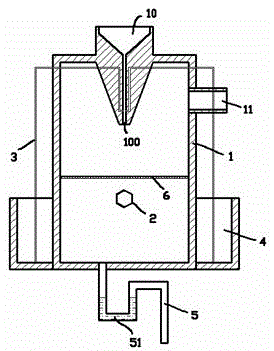

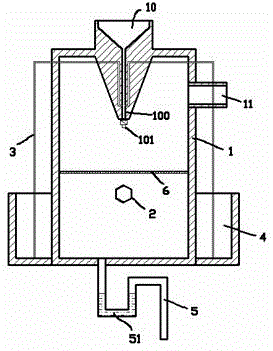

[0012] exist figure 1 In the shown first embodiment, the energy-saving wet dust collector includes a dust removal chamber 1, and the upper end of the dust removal chamber 1 has an air inlet 10, and a narrow air inlet 10 is formed inside the air inlet 10 to communicate with the dust removal chamber 1 vertically downward. Channel 100, the narrow air channel 100 faces downwards to the edge block 2 fixed in the dust removal chamber 1; and the narrow air channel 100 is vertically connected to the capillary 3 laterally; in the first embodiment, the capillary 3 has two The roots are symmetrically connected to both sides of the narrow air passage 100, and the capillary 3 is connected to the water tank 4 whose liquid level is lower than the port of the narrow air passage; the upper side of the dust removal chamber 1 is provided with an air outlet 11; the lower end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com