Ceramic dust-removing device

A dust removal device and ceramic technology, which is applied in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of low dust removal efficiency and inability to realize continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

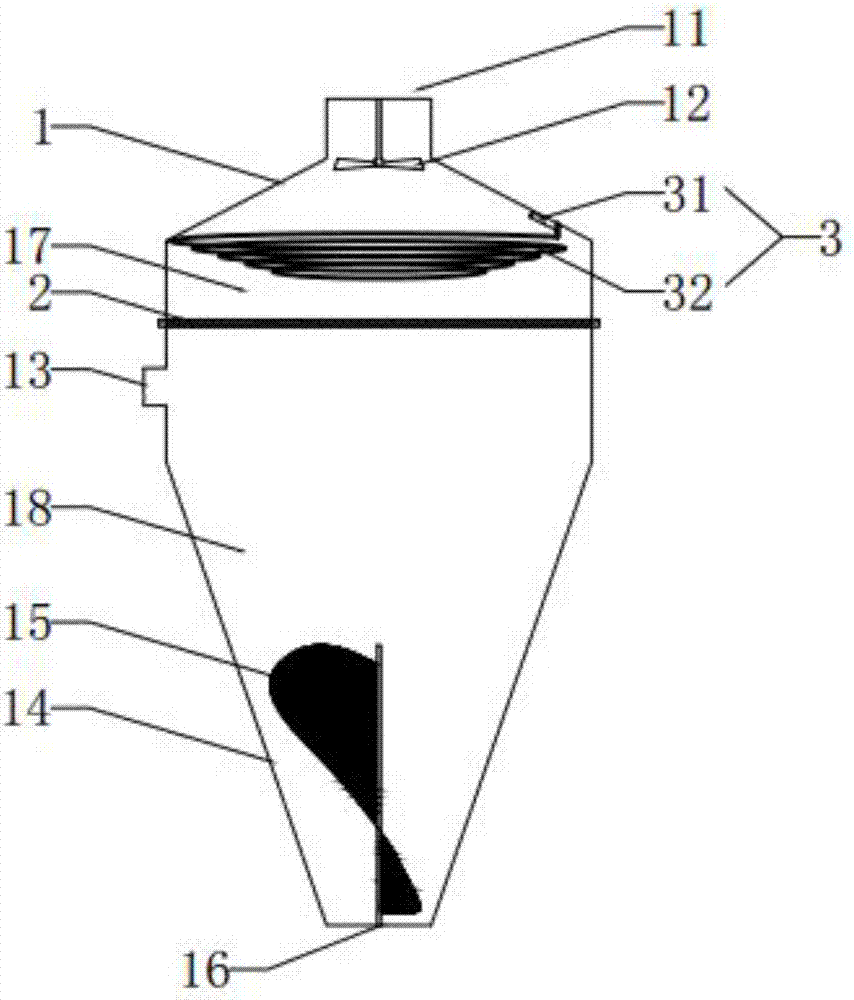

[0044] This embodiment provides a ceramic dust removal device, such as figure 1 As shown, it includes a tank body 1, a filter mechanism 2, and a pneumatic spray mechanism 3.

[0045] Wherein, the tank body 1 includes a first shell and a second shell; the second shell is detachably fastened with the first shell to enclose an inner cavity. An air outlet 11 is provided on the upper end of the first housing, and an exhaust fan 12 is provided at the air outlet 11 to provide power for the dusty gas to pass through the filter mechanism 2 . The second housing includes a vertical part and an inclined part arranged up and down, and the side wall of the vertical part is provided with a feed inlet 13, and the inclined part is an inverted cone-shaped dust bucket 14, which is beneficial to dust or glaze under the action of gravity. Flow to the bottom of the second chamber. A spiral scraper 15 is arranged inside the dust collecting hopper 14, and a discharge port 16 is opened at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com