Dust removing device for textile workshop

A technology for dust removal devices and workshops, applied in the directions of removing smoke and dust, cleaning methods and utensils, and cleaning methods using gas flow, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

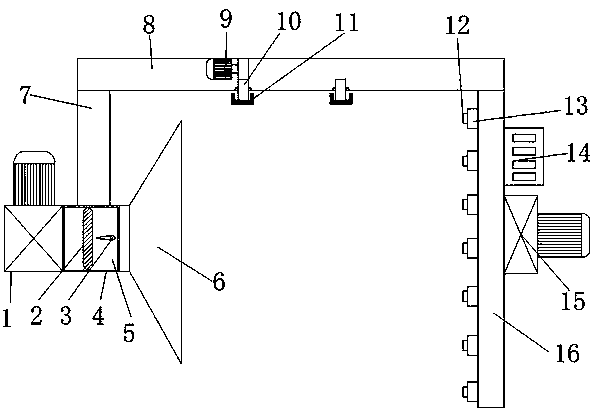

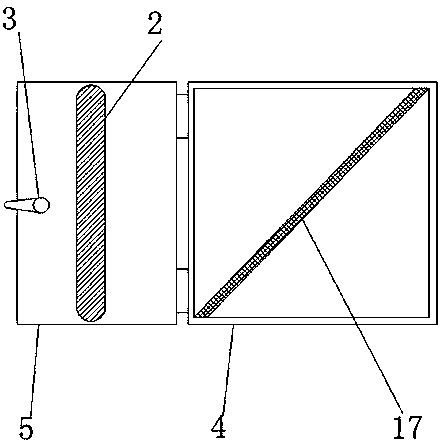

[0021] refer to Figure 1-2 , a dust removal device for a textile workshop, comprising a guide rail 11 and a support frame 8, the bottom outer wall of the support frame 8 is provided with an opening, and the inner wall of the opening is fixed with a roller 10 by bolts, and the top inner wall of the support frame 8 is fixed with a servo motor by bolts 9, and the output shaft of the servo motor 9 forms a rolling fit with the roller 10 through the belt, and one end of the outer wall of the bottom end of the support frame 8 is welded with the first support arm 7, and the bottom outer wall of the first support arm 7 is fixed with a filter box by bolts 4, and the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com