Intelligent dust removal device for workshop

A technology for dust removal devices and workshops, which is used in combination devices, atomized substances, transportation and packaging, etc., can solve the problems of reducing the use effect of the device, troublesome spraying direction, inconvenience, etc., to reduce labor intensity, improve functionality, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

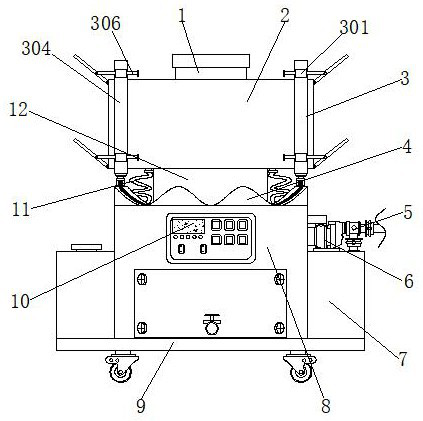

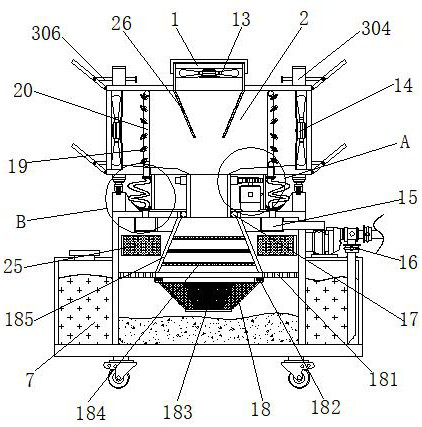

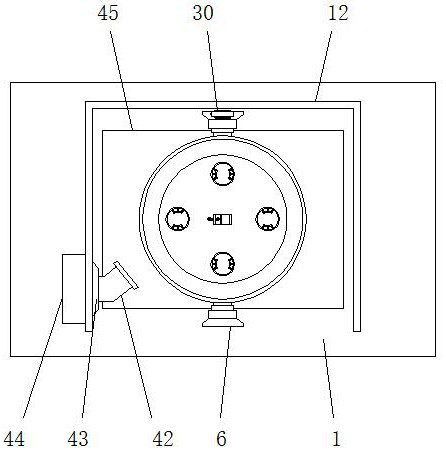

[0033] Example 1, such as figure 1 , 2 , 3 and 6, when starting to remove dust, first open the control valve 16 connected to the external water pipe, and then control the two groups of fans A14 to rotate clockwise through the control panel 10, blowing the air inside the workshop into the inside of the spray chamber 2, And turn on the fan B13 to blow the blown air to the inside of the connecting pipe 21. In the process, the water pump 6 is turned on, and the clean water passes through the arc-shaped warehouse 15 and the connecting pipe 11 and then enters the inside of the annular water pipe 20, and then passes through the spray head 19 to The form of water mist is sprayed into the interior of the spray chamber 2. The water mist enters the interior of the installation chamber 185 from the connecting pipe 21 along with the flowing air. During the process, the water mist gradually absorbs the dust in the air. After passing through the multi-layer screen Part of the water mist con...

Embodiment 2

[0034] Example 2, such as Figure 1-8 As shown, when it is necessary to spray the disinfectant mist to various positions in the workshop, firstly, the control panel 10 controls the drive motor 24 to drive the gear A23 and the gear B22 for continuous forward and reverse rotation, so that the connecting pipe 21 and the spray chamber 2 are all in the same position. After turning 180° clockwise, turn it counterclockwise back to the original position, so that the two ends of the spray chamber 2 can suck the air from different directions of the workshop into the interior of the processing chamber 8 for dust removal, while the spray chamber 2 rotates back and forth During the process, since the roller 308 rolls on the ring-shaped wave slideway 4, the movable frame 304 is continuously moved up and down, the slider 302 slides inside the chute 307, and the spring 303 is continuously shortened and then elongated, so that the guide plate 305 moves with its The hinge is constantly swinging...

Embodiment 3

[0035] Example 3, such as figure 1 , 2 As shown in and 6, when the collected dust needs to be cleaned up, the dirt after the sedimentation inside the processing chamber 8 is discharged through the drain valve on the door outside the processing chamber 8, then the door on the outside of the processing chamber 8 is opened, and the Open the fixing screw on the ring slot 182, take out the cone-shaped filter screen 183 from the inside of the ring slot 182, clean up the dust collected at the bottom of the cone-shaped filter screen 183, and then settle the sewage at the bottom of the treatment chamber 8 residues to clean up.

[0036] Working principle: connect the device to the power supply before use, then move the device to the position designated by the workshop through the universal wheel and brake, then connect a set of control valves 16 to the external water pipe, and then inject into the liquid storage tank 7 Disinfectant, and manually remove the top cover on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com