Industrial waste gas emission method

A technology for industrial waste gas and waste gas discharge, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of high cost of dust removal, and achieve the effect of low cost of dust removal, good effect and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

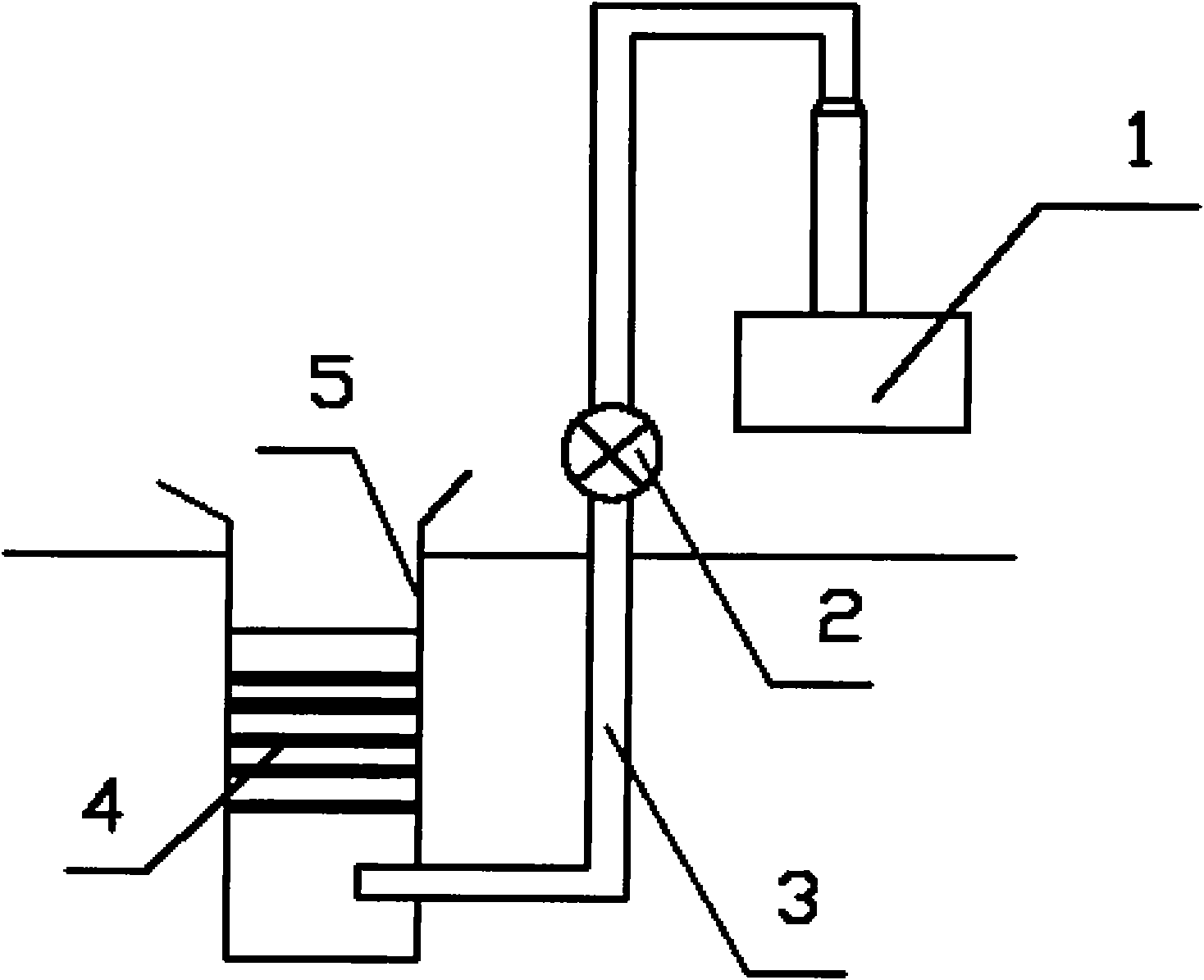

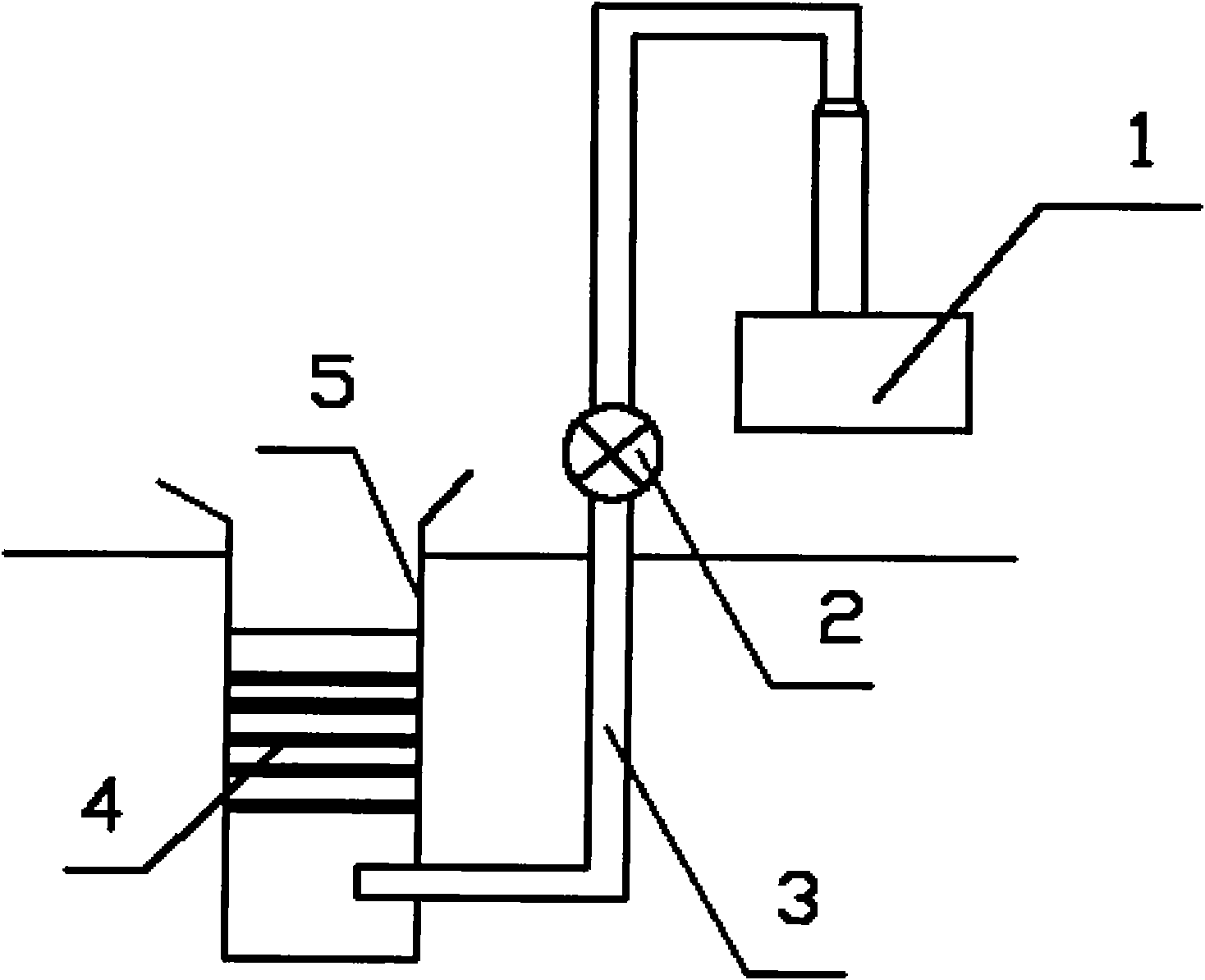

[0009] Below by accompanying drawing and embodiment this industrial waste gas discharge method is further explained:

[0010] In the embodiment shown in the accompanying drawings, the equipment used in the method includes: an air pump 2, an exhaust gas pipeline 3, a mesh plate 4, and a well. The method is implemented as follows: dig a well 5 near the exhaust gas discharge source 1, accumulate water in the well, and put Lime water is poured into the well to maintain a suitable CaOH concentration, and a multi-layer stencil 4 is installed in the well. The mesh of each stencil 4 is small enough, and the exhaust gas generated by the exhaust gas discharge source is introduced into the bottom of the well by the air pump 2 through the exhaust gas pipeline 3 , so that the carbon dioxide in the exhaust gas is absorbed by the lime water in the well, and the large air bubbles are divided at the 4 meshes of the mesh plate, so that the dust in the gas is dissolved into the water when the air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com