Centrifugal dedusting equipment for mine stones

A technology for centrifugal dust removal and stone removal, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems affecting the health of operators, affecting the quality of buildings, polluting the surrounding environment, etc., achieving good dust removal effects and improving Economic and social benefits, less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

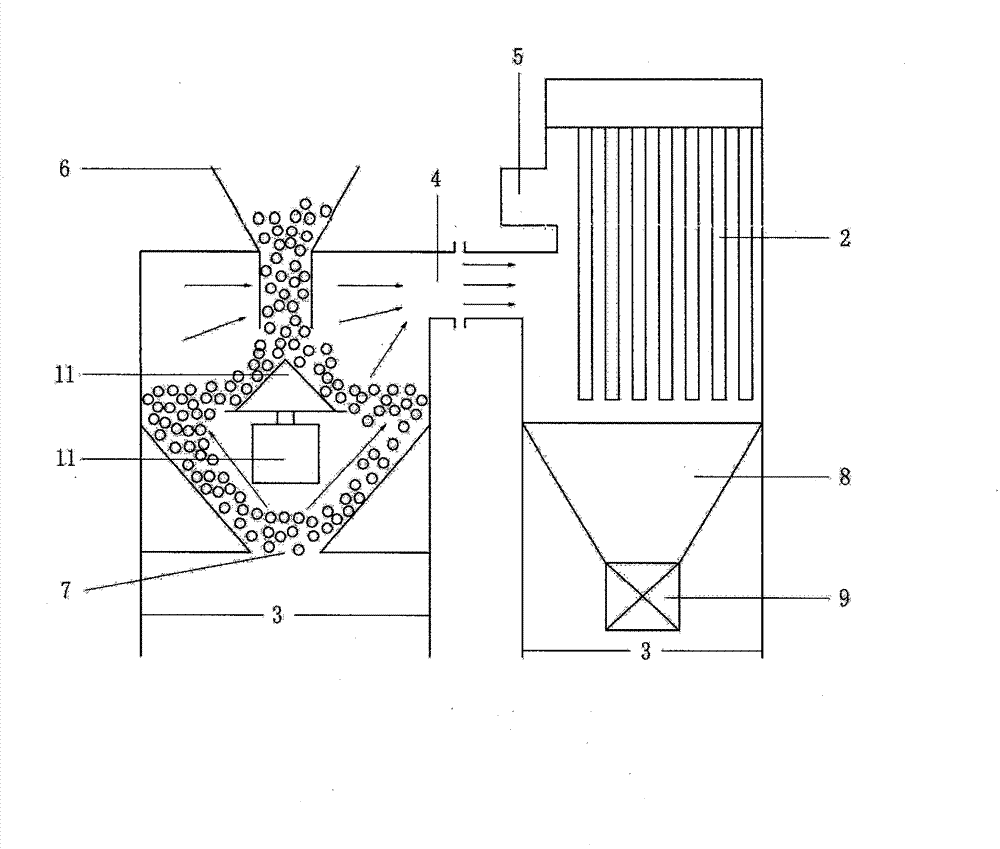

[0019] The mine stone centrifugal dedusting equipment of the present invention mainly includes two parts, a centrifuge and a pulse bag filter, and their respective advantages can be fully exerted through the synergistic effect.

[0020] The centrifuge and the pulse bag filter 2 are installed side by side on the support 3, and the centrifuge and the pulse bag filter are connected through the pipe 4, and the upper part of the pulse bag filter is provided with an induced draft fan 5. Below the feeding port 6 of the centrifuge, a centrifugal disc 10 is arranged, and the centrifugal disc has a conical structure. The centrifugal disc is driven by a motor 11. The liner of the centrifuge is made of high toughness wear-resistant material (such as high wear-resistant composite rubber). The bottom of the centrifuge has a discharge port 7. There is a dust collection bucket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com