Patents

Literature

55results about How to "Purify the production environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

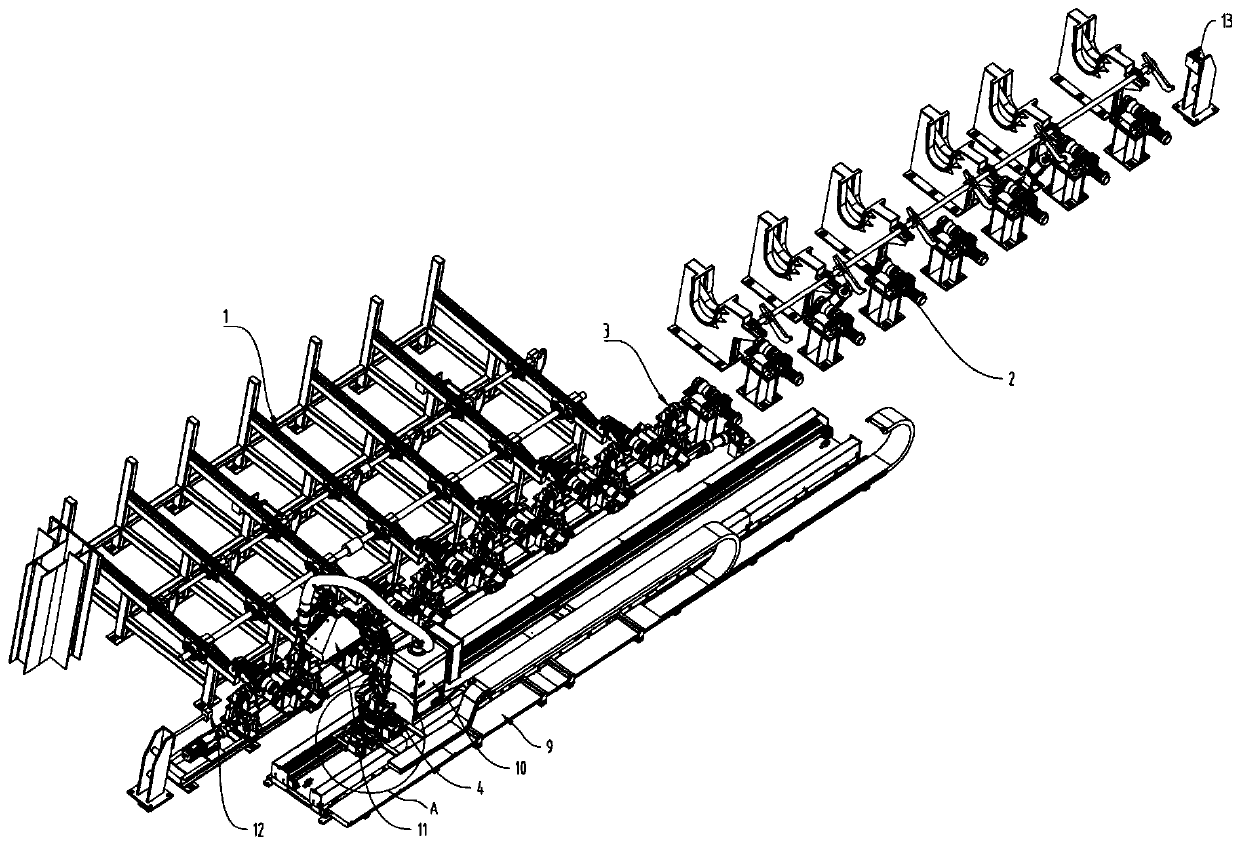

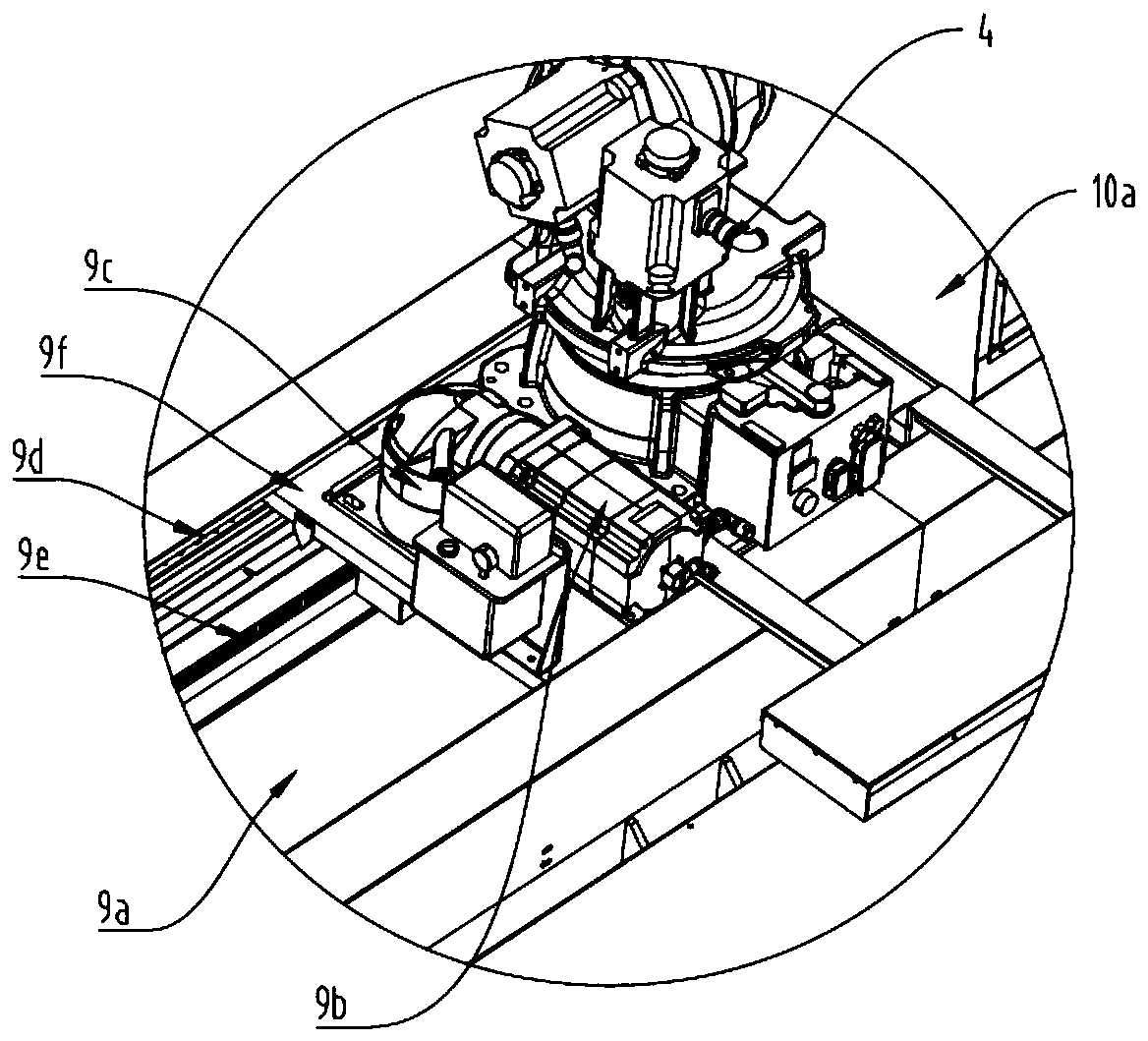

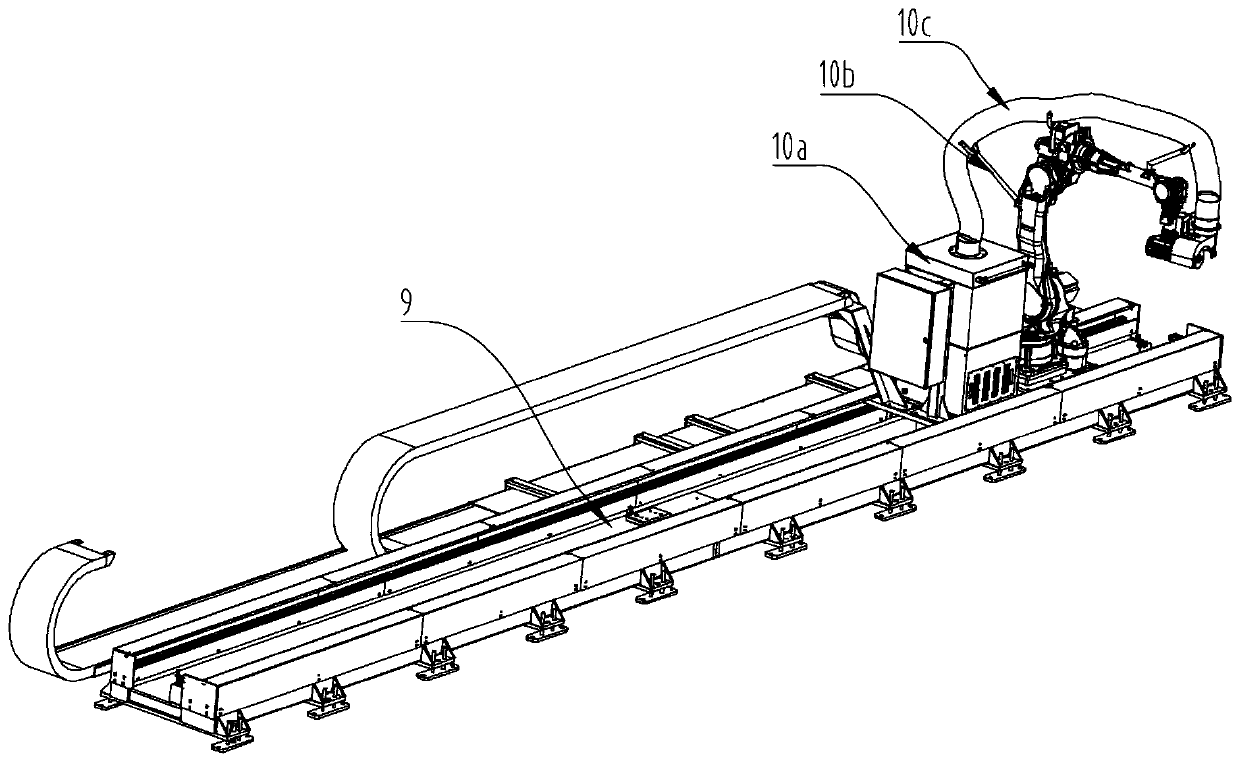

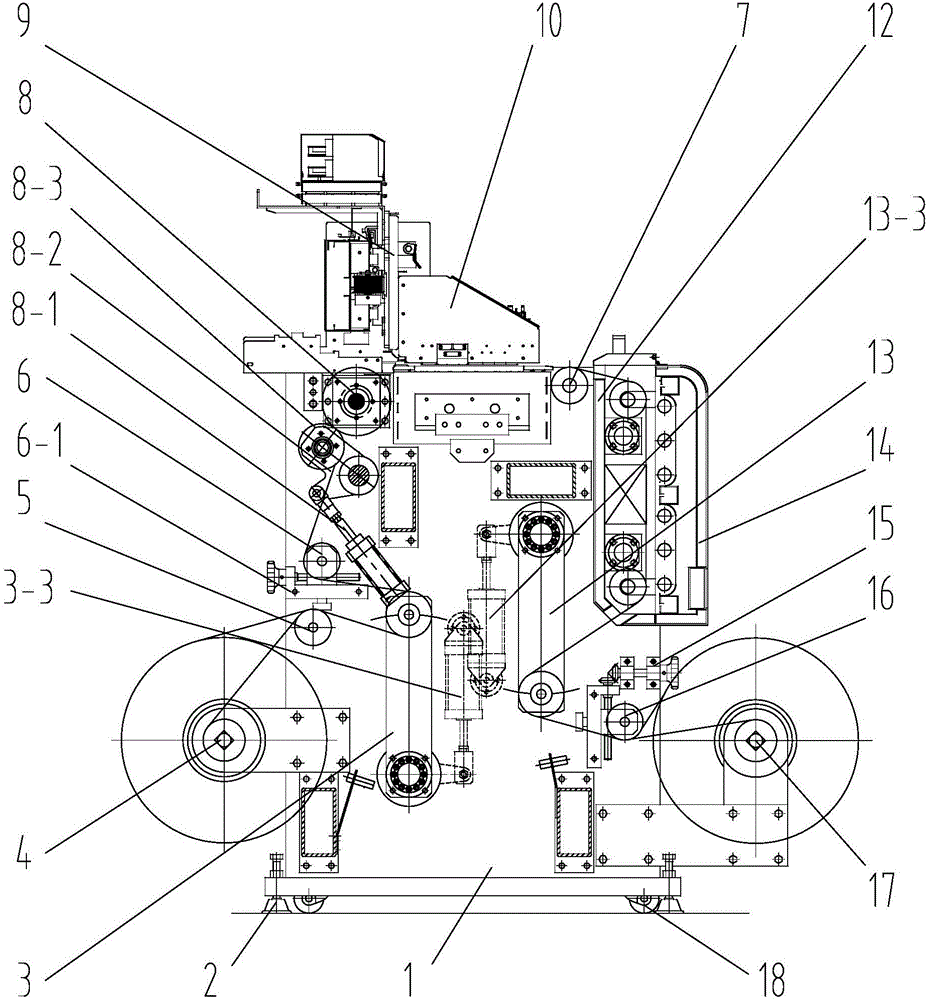

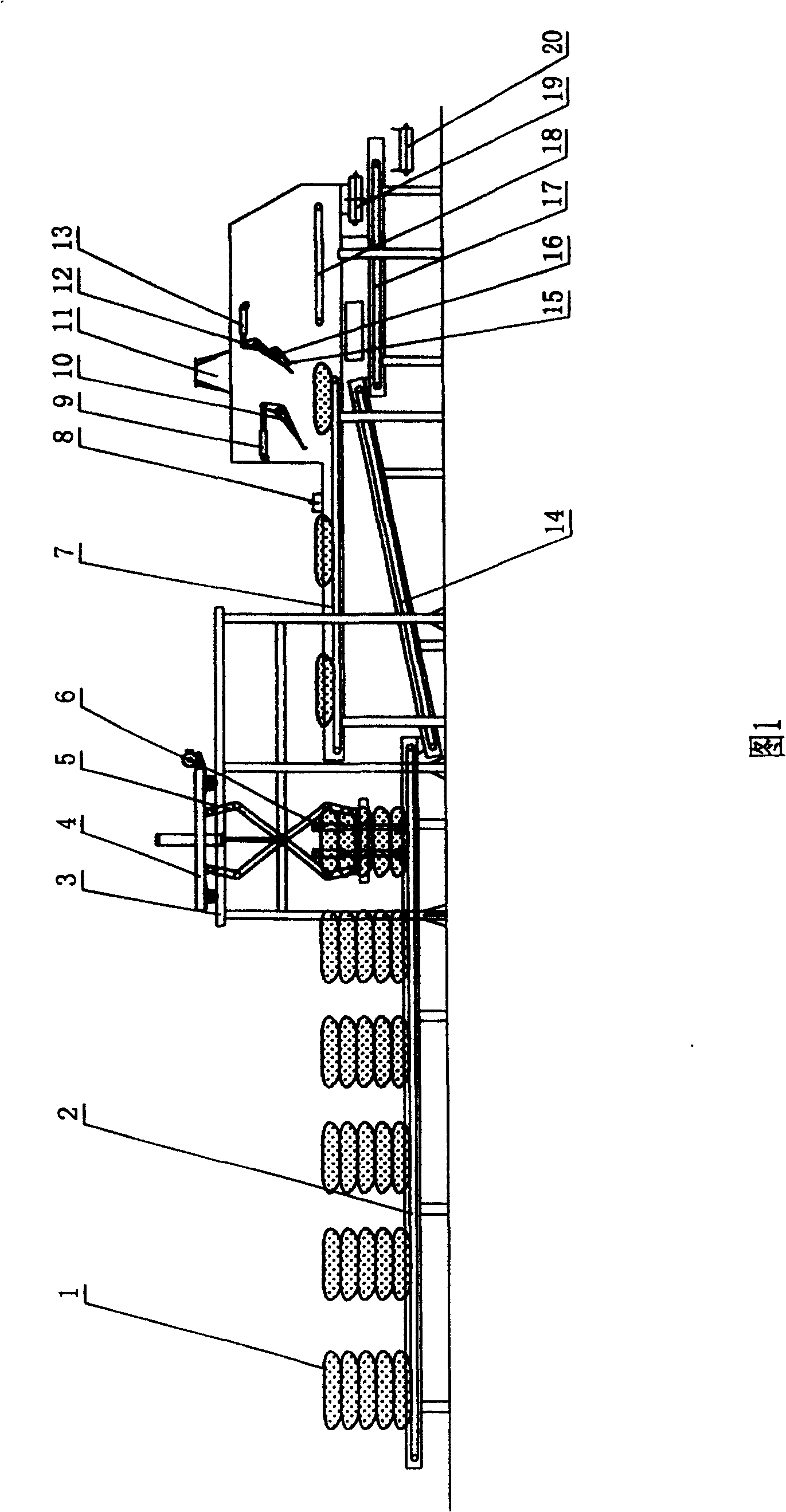

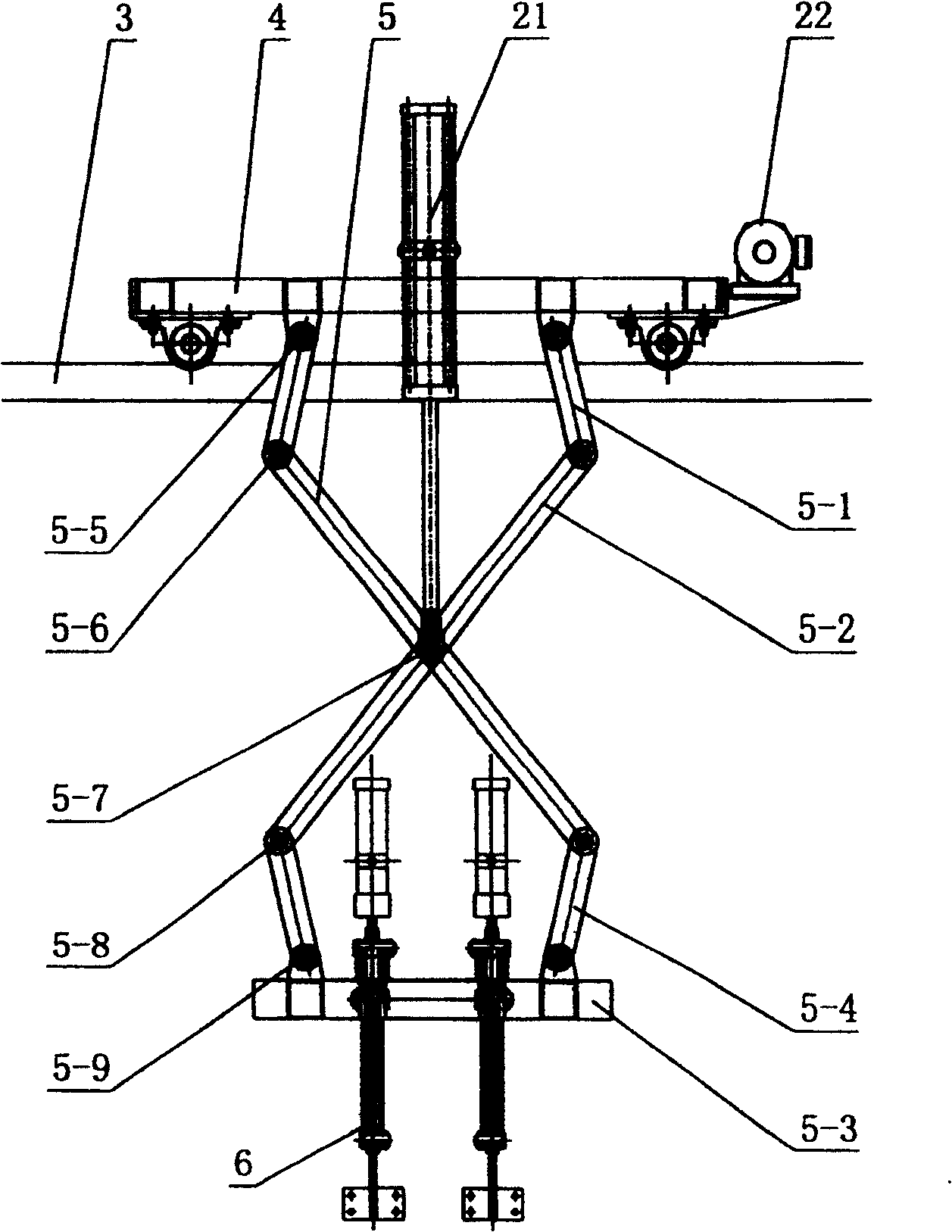

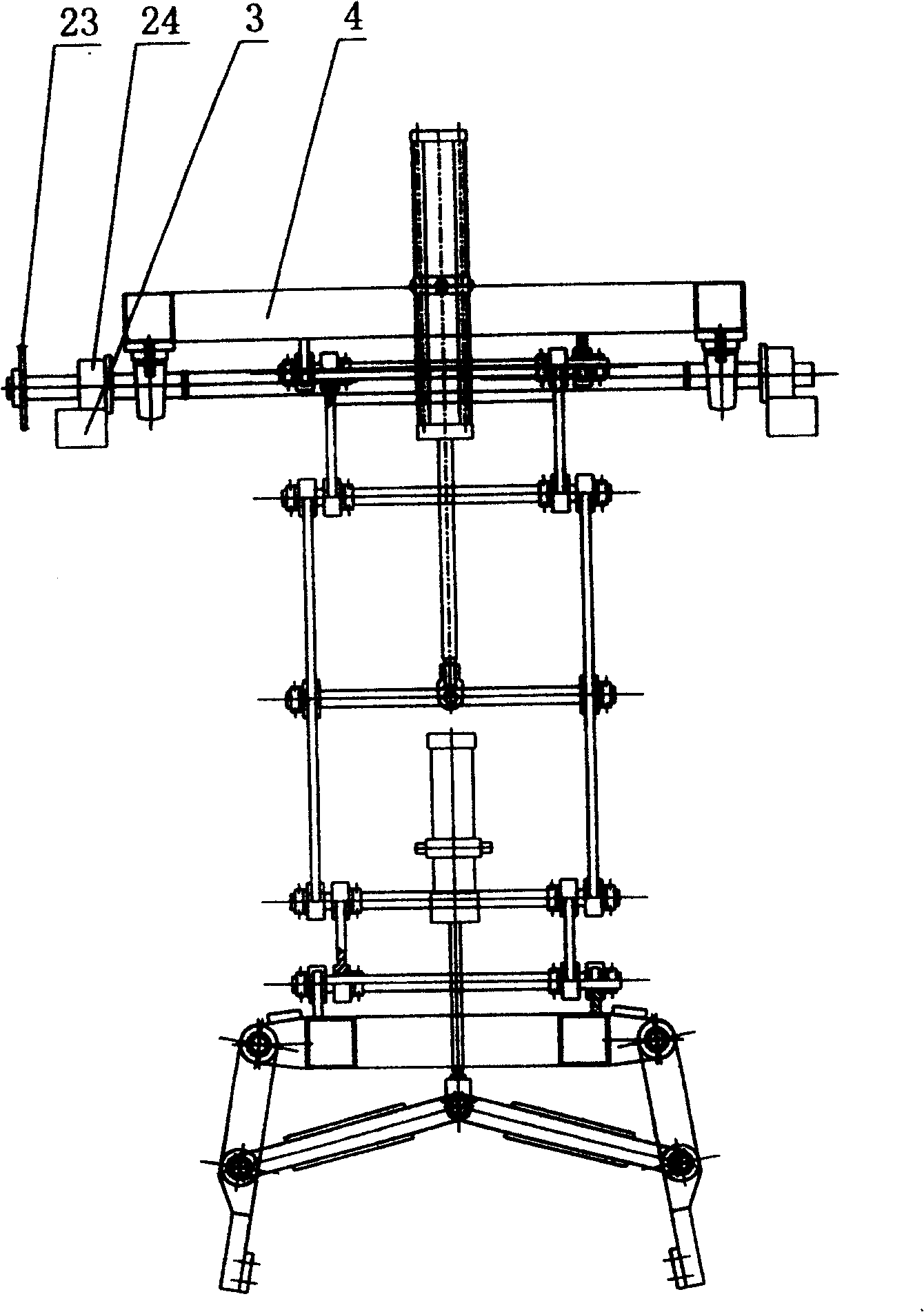

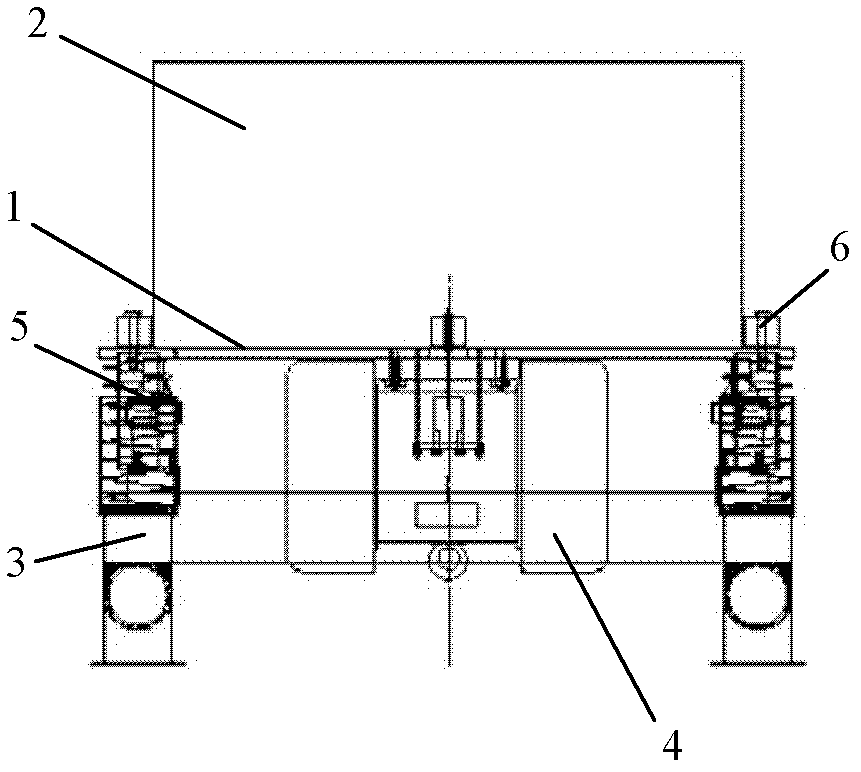

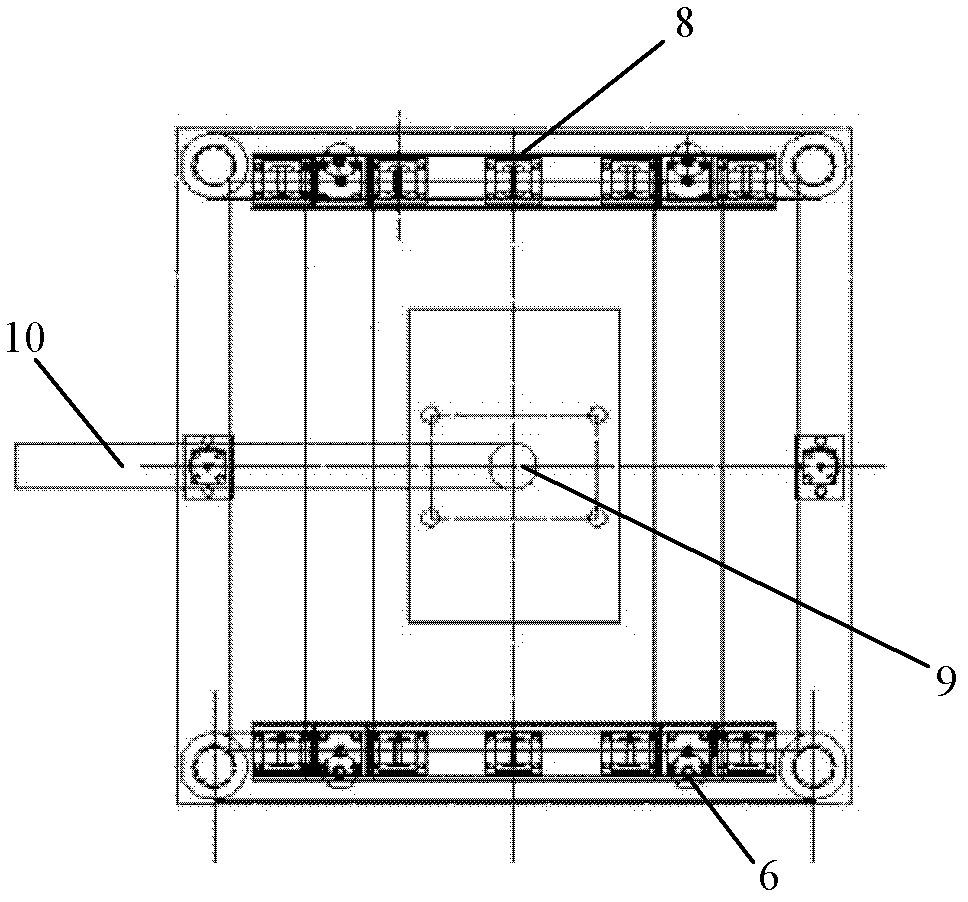

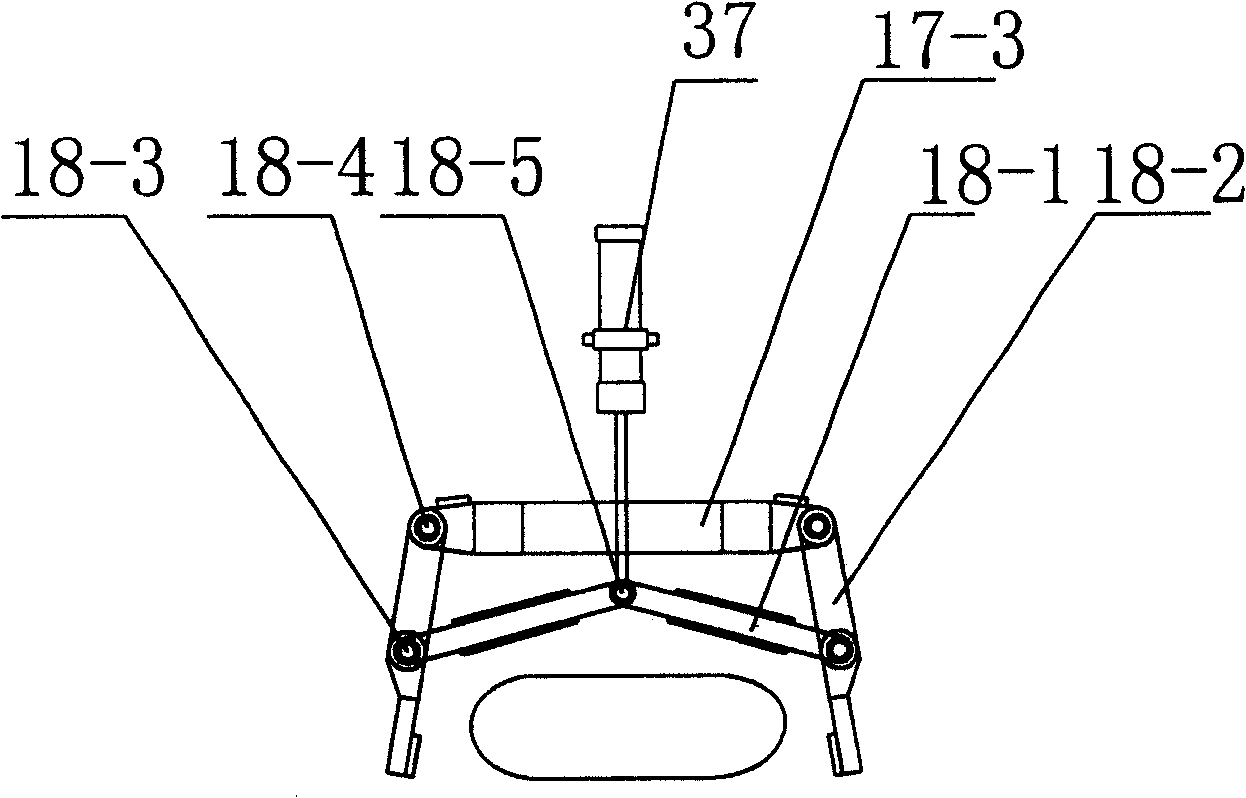

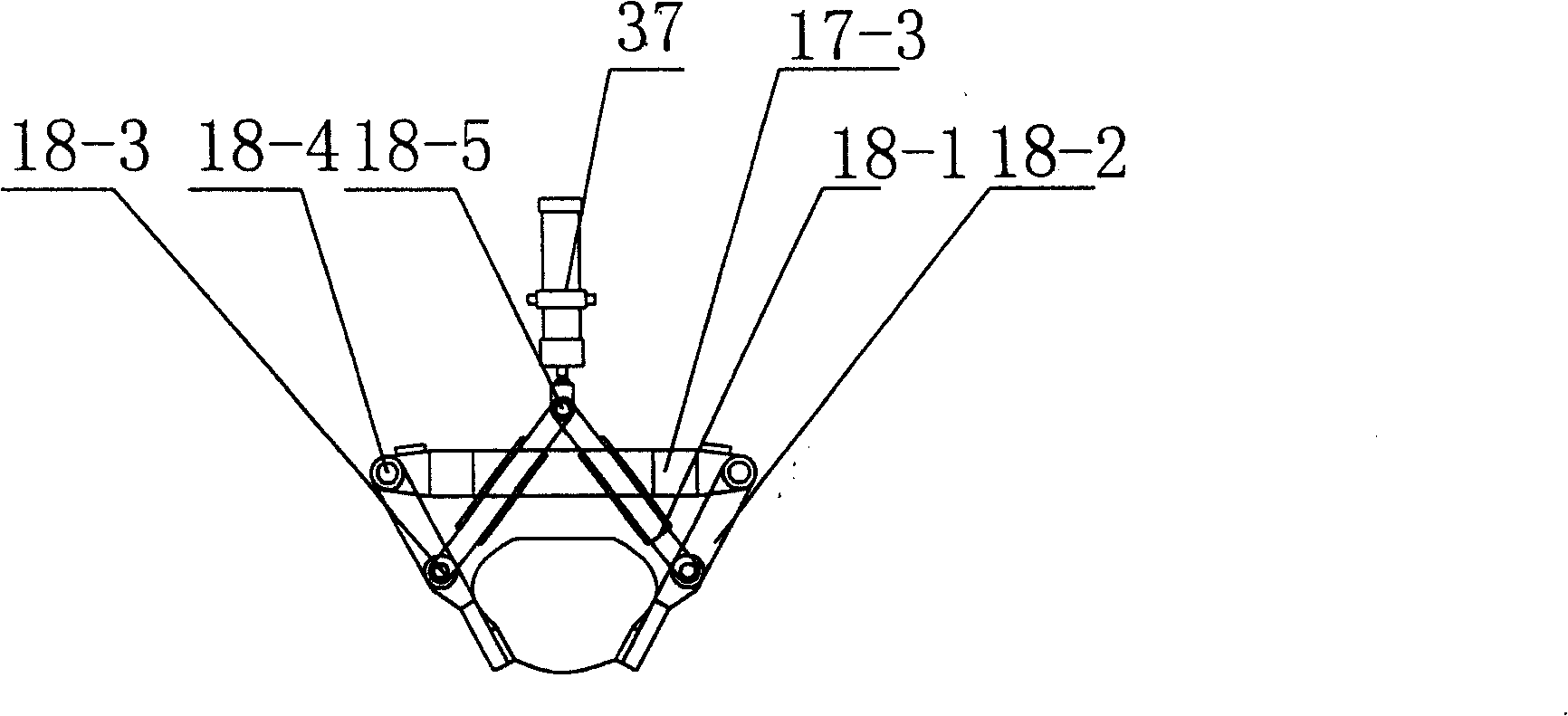

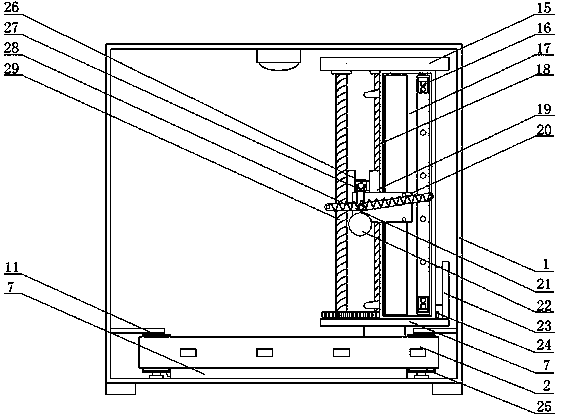

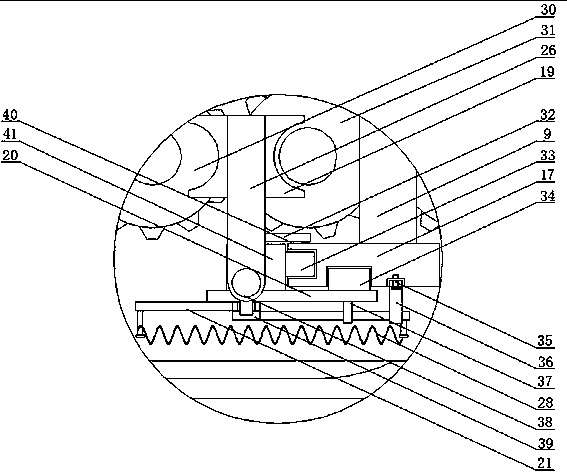

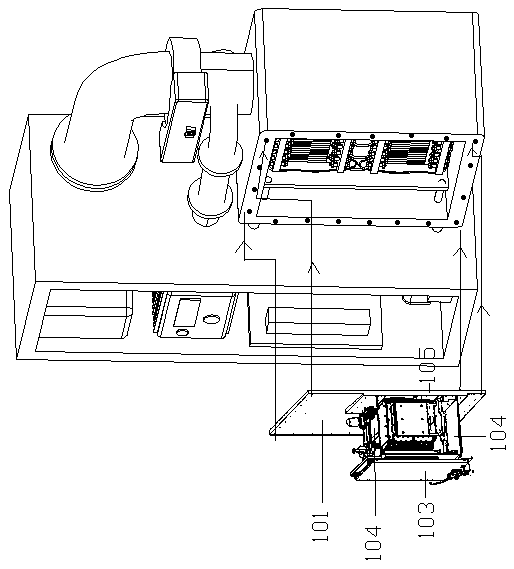

Full-automatic bar flaw grinding system based on industrial robot

PendingCN111152082AImprove grinding accuracyAutomate defect locationRevolution surface grinding machinesGrinding drivesControl engineeringProcess engineering

The invention discloses a full-automatic bar flaw grinding system based on an industrial robot. The full-automatic bar flaw grinding system comprises a feeding device, a discharging device, an opposite rotation roller way, a robot body, an installation flange, a force position actuator, a floating grinding head and a first servo motor. The upper end of the force position actuator is connected withthe movable end of the robot body through the installation flange, the lower end of the force position actuator is connected with the first servo motor, the floating grinding head is fixed to an output shaft of the first servo motor, the opposite rotation roller way comprises driving rollers, driven rollers, a second servo motor and a transmission mechanism, the driving rollers and the driven rollers are longitudinally arranged at intervals and transversely arranged in multiple groups, and the output end of the second servo motor is connected with each driving roller through the transmissionmechanism. The full-automatic bar flaw grinding system has the advantages that automatic flaw location, automatic feeding and discharging and automatic feeding of bars are integrated, the intelligencedegree is high, and production efficiency is improved.

Owner:JIANGSU JINHENG INFORMATION TECH CO LTD

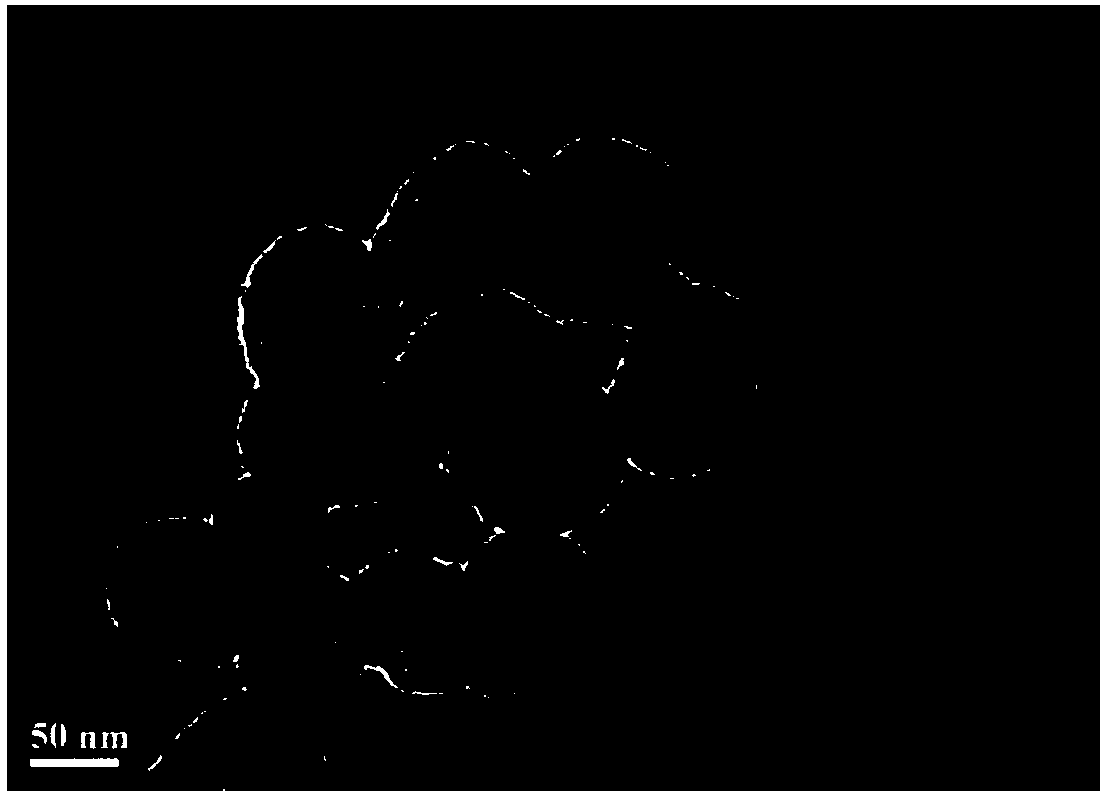

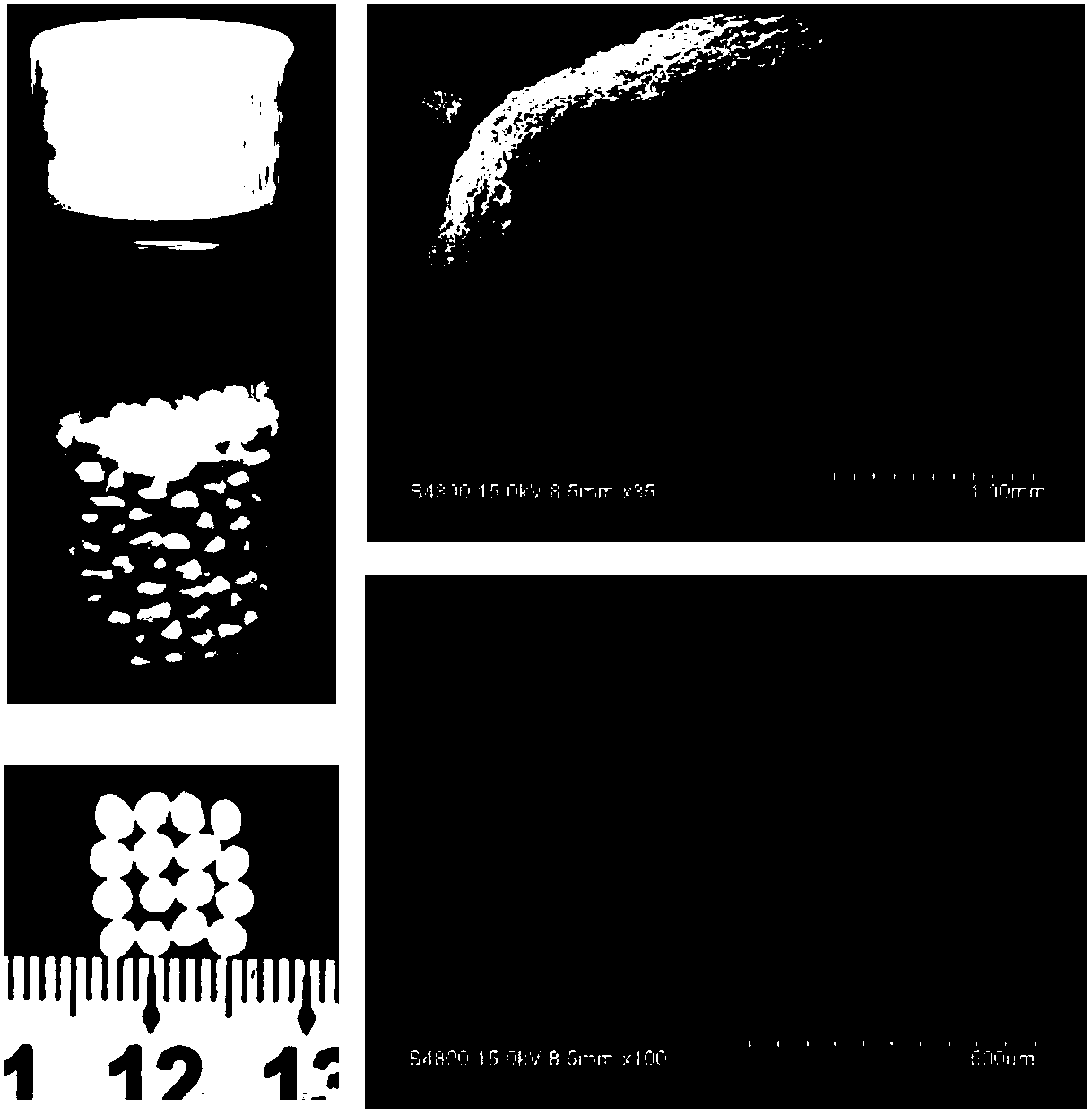

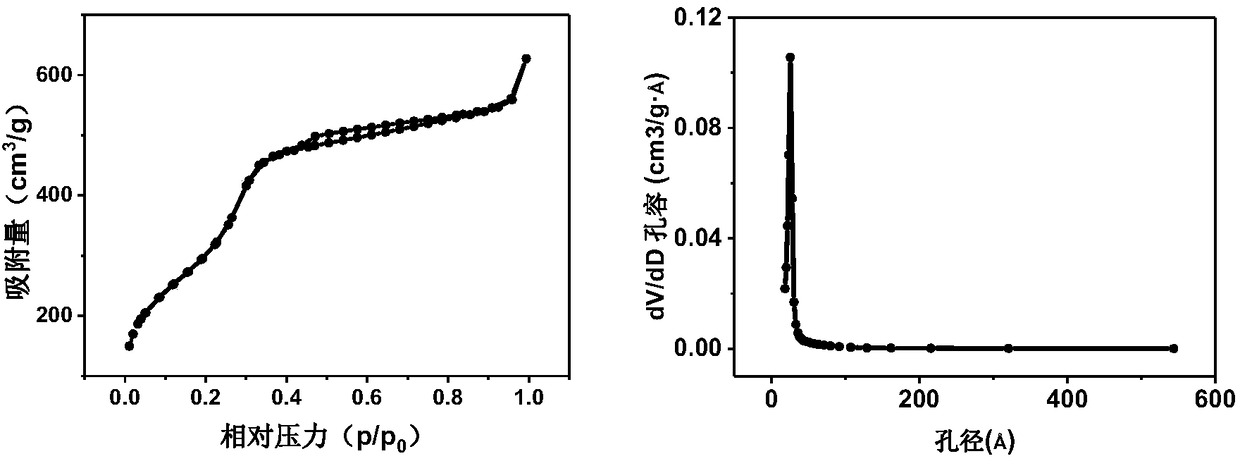

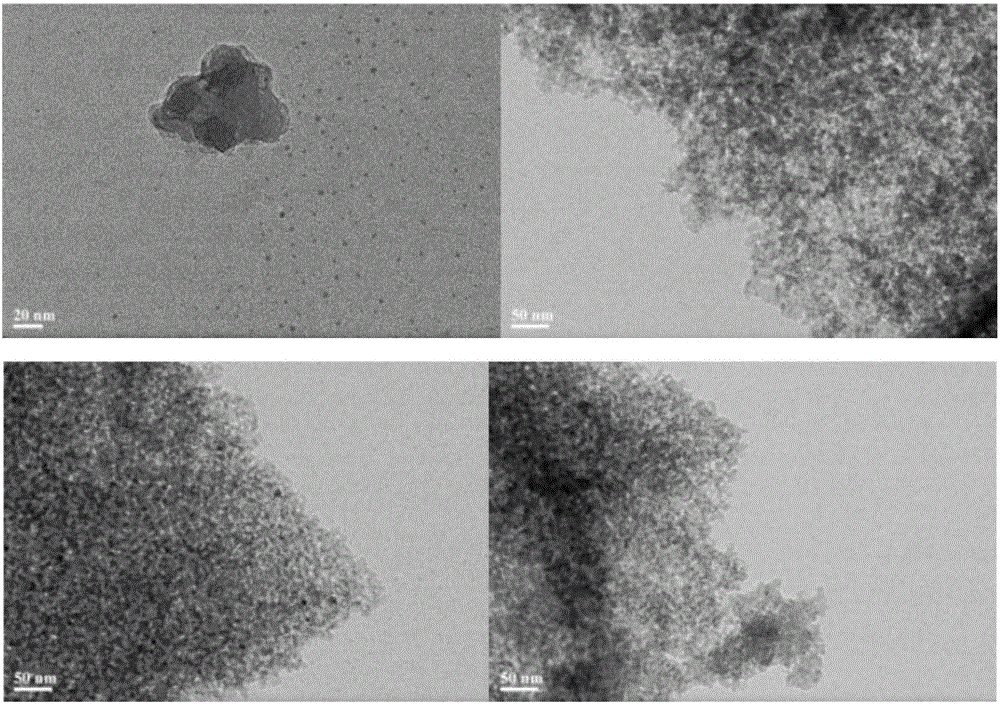

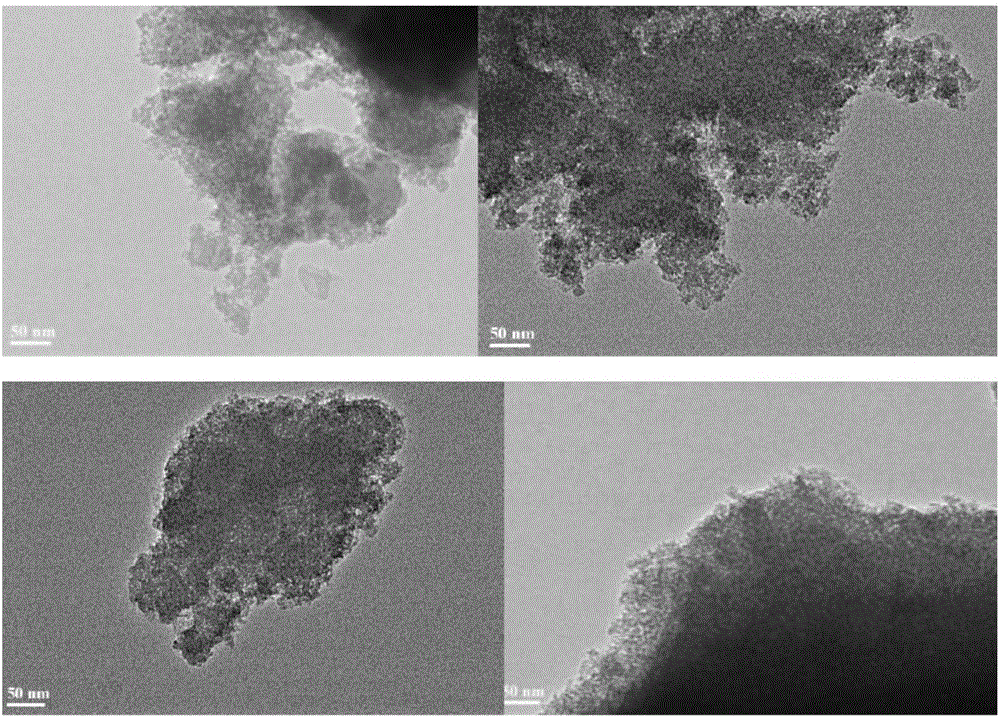

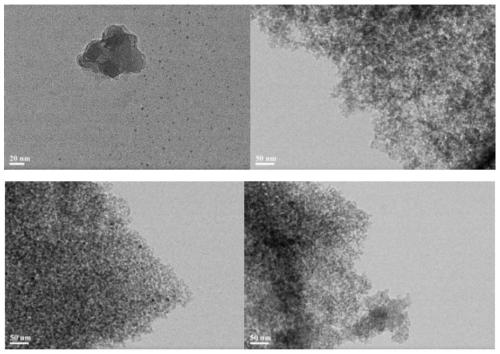

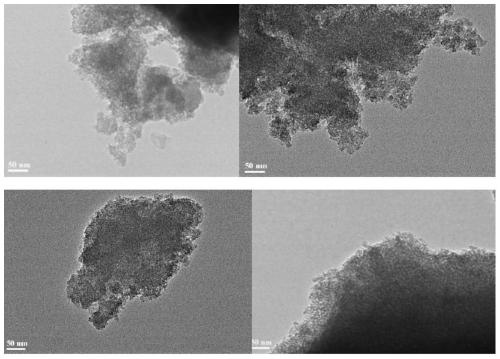

Mesoporous silica matrix composite microsphere with efficient coagulation function and preparation method thereof

InactiveCN108339148ASealing Adhesive WoundsReduce bleedingPharmaceutical delivery mechanismProsthesisTissue engineeringNoise pollution

The invention discloses a mesoporous silica matrix composite microsphere with an efficient coagulation function and a preparation method thereof. The mesoporous silica matrix composite microsphere comprises mesoporous silica and natural polysaccharide, and the diameter of the mesoporous silica matrix composite microsphere is 0.2-5 millimeters. A granulation solution containing the weight ratio of100:800-3000:5-200:5-50 of mesoporous silica, water, natural polysaccharide and foaming pore forming agent is dropped into a consolidation liquid to obtain the mesoporous silica matrix composite microsphere. The preparation process is simple and efficient, granulation forming and secondary pore-forming are carried out to eliminate the problems of dust, noise pollution and high energy consumption in secondary calcining during former granulation, the preparation period of products is shortened, and the utilization of equipment is improved. The composite microsphere has functions of quick coagulation, sealing and sticking wounds, reducing bleeding amount and the like, can be applied to the fields of tissue engineering, skin regeneration and the like, and has great clinical application value.

Owner:EAST CHINA UNIV OF SCI & TECH +1

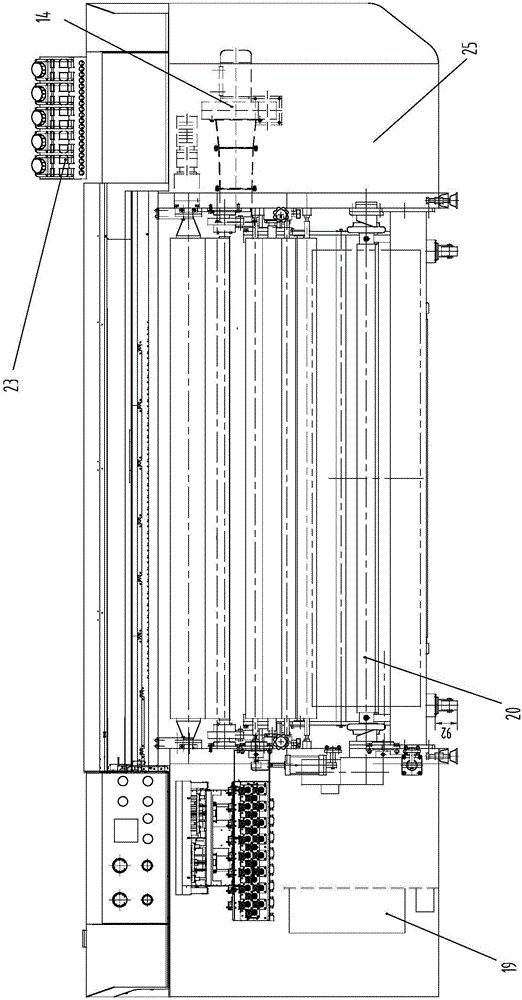

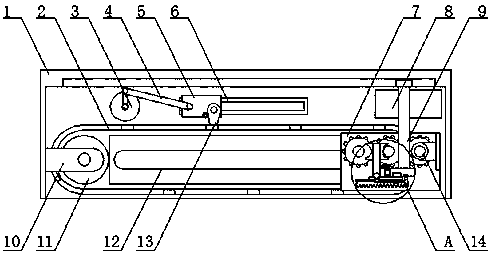

Scanning digital high-speed ink jet printing machine

ActiveCN106494086ASolving Intermittent InertiaAddress material and labor wastageOther printing apparatusWebs handlingDigital inkEngineering

The invention relates to a scanning digital high-speed ink jet printing machine, and aims to provide a digital reciprocating ink jet printing machine which has the characteristics of improving the quality of a printed product and the production efficiency and reducing the production cost. According to the technical scheme, the digital reciprocating ink jet printing machine comprises a feeding part, a pulling part, a digital ink jet part, a drying part and a winding part. The feeding part is equipped with a feeding tension stabilizing mechanism which comprises two first tension swing arms, a first tension swing arm guide roller and two first swing arm tension cylinders. The two ends of the first tension swing arm guide roller are separately hinged to the swing ends of the two first tension swing arms. The winding part is equipped with a winding tension stabilizing mechanism used for maintaining the constant tension of a printed object. The winding tension stabilizing mechanism comprises two tension swing arms, a second tension swing arm guide roller and two second swing arm tension cylinders. The two ends of the second tension swing arm guide roller are separately hinged to the swing ends of the two second tension swing arms. The two second swing arm tension cylinders separately drive the two second tension swing arms to rotate.

Owner:ZHEJIANG MEIGE MACHINERY

Waterborne polyurethane based quick-drying wood coating with superhigh solid content

InactiveCN104861846ASimple processSource Simple ConventionalPolyurea/polyurethane coatingsViscous liquidFilm-forming agent

The invention specifically relates to a waterborne polyurethane based quick-drying wood coating with superhigh solid content. The coating comprises polyurethane, polyacrylic acid, a dispersing agent, a thickener, ethanol water, DNS (3,5-dinitrosalicylic acid), a film forming agent and pigment, and the prepared coating is a flowable viscous liquid. According to the waterborne polyurethane based quick-drying wood coating with the superhigh solid content, the process is simple, the equipment investment is small, resources of raw materials are simple and conventional, and the raw materials are easy to obtain.

Owner:GUANGDONG VALSPAR CHEM IND

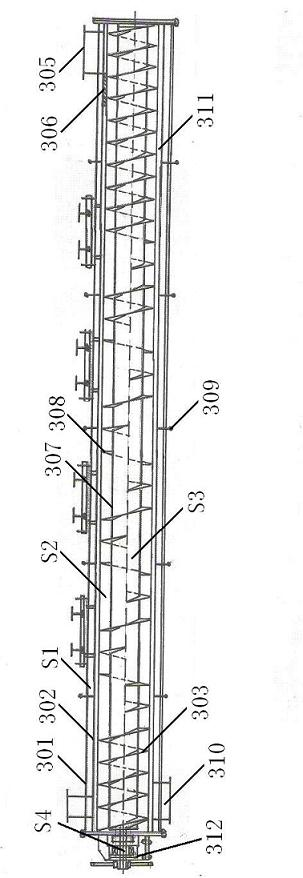

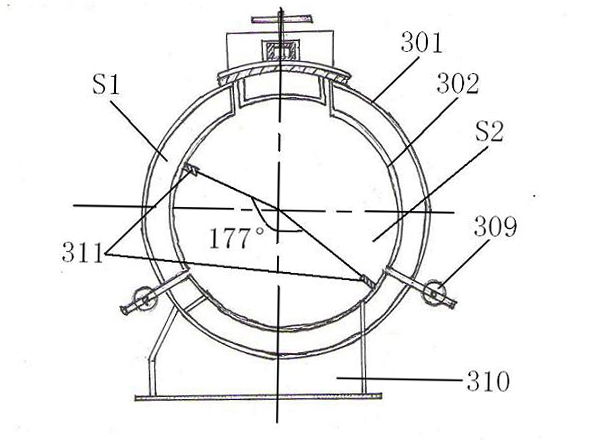

Multi-level flipping type proteopexy cooking machine and fishmeal machine

InactiveCN101926424AImprove processing outputNo raw meal phenomenonFood preparationElectricitySpiral blade

The invention discloses a multi-level flipping type proteopexy cooking machine and a fishmeal machine. The cooking machine comprises a cylindrical outer shell, a cylindrical inner shell, a heave dragon shaft, a feeding hole and a discharging hole, wherein the outer shell and the inner shell are coaxially sleeved; a confined space S1 is formed between the inner shell and the outer shell and is used for heating gases; both ends of the heave dragon shaft are respectively connected with a shaft head; the feeding hole is arranged on one end of the outer shell, and is communicated with an inner cavity S2; the discharging hole is arranged on the other end of the outer shell, and is communicated with the inner cavity S2; and a plurality of half-leaf spiral blades are arranged on the heave dragon shaft. The fishmeal machine comprises a multi-level flipping type proteopexy heating cooking machine, a heating type forced fat separation squeezing machine, a fishmeal drying chamber and a fishmeal sifting machine, which are sequentially connected. The invention has the advantages of stable mechanical property, simple and convenient operation, high security, electricity saving, no noise, large output, product purity, and simple and convenient maintenance, repair, installation and debugging.

Owner:孙仁和

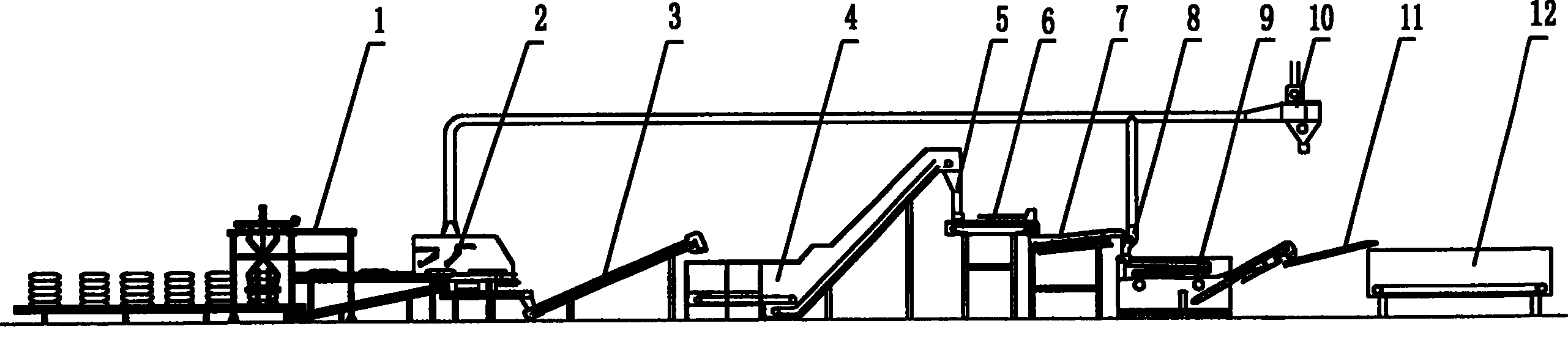

Green tea mechanized processing method capable of lowering tea hair

InactiveCN102578309APurify the production environmentProtect your healthPre-extraction tea treatmentWater contentEpigallo-catechin gallate

The invention relates to a green tea mechanized processing method capable of lowering tea hair. The method comprises the following working procedures of picking up fresh leaves, spreading the fresh leaves, removing green, tidying tea strip, reshaping and drying, wherein the working procedures of removing green, tidying tea strip, reshaping and drying are respectively carried out in a removing green machine, a tea strip tidying machine and a reshaping and drying multipurpose machine. The green tea mechanized processing method is characterized in that an air sucking and venting hole connected with a bag-type dust remover and an induced draft fan is arranged above the working face of the reshaping and drying multipurpose machine; and when the water content of the tea is 40%, the induced draft fan is started to suck and separate the tea hair separated from the tea. In the green tea mechanized processing method, the optimal time is selected in the traditional mechanized tea manufacture technology process, the tea hair is effectively separated by the induced draft fan, the production environment is purified, the body health of a producer is guaranteed, and the tea quality is improved.

Owner:镇江市丹徒区上党墅农茶叶专业合作社

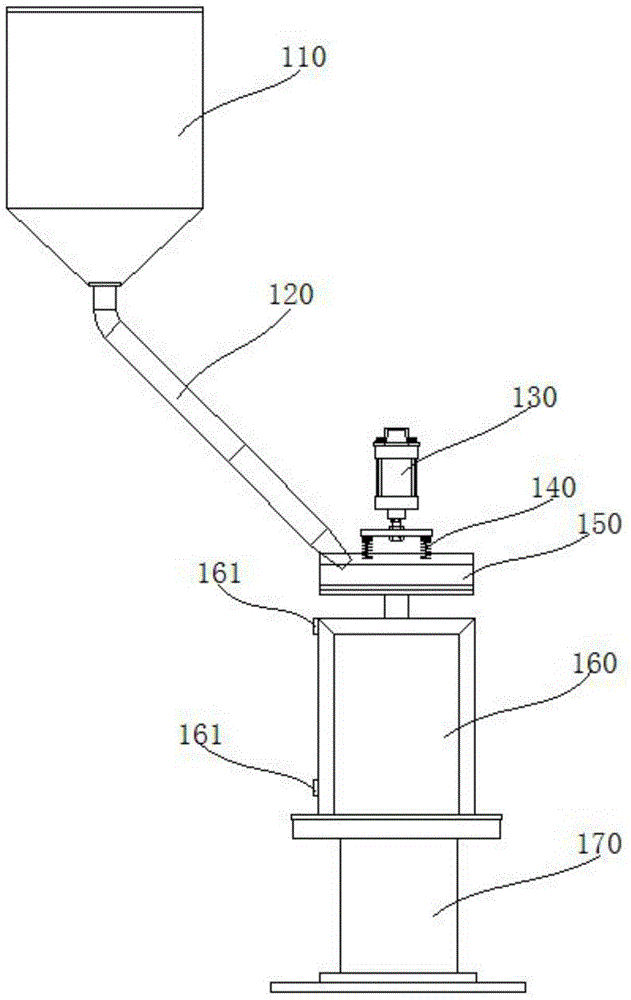

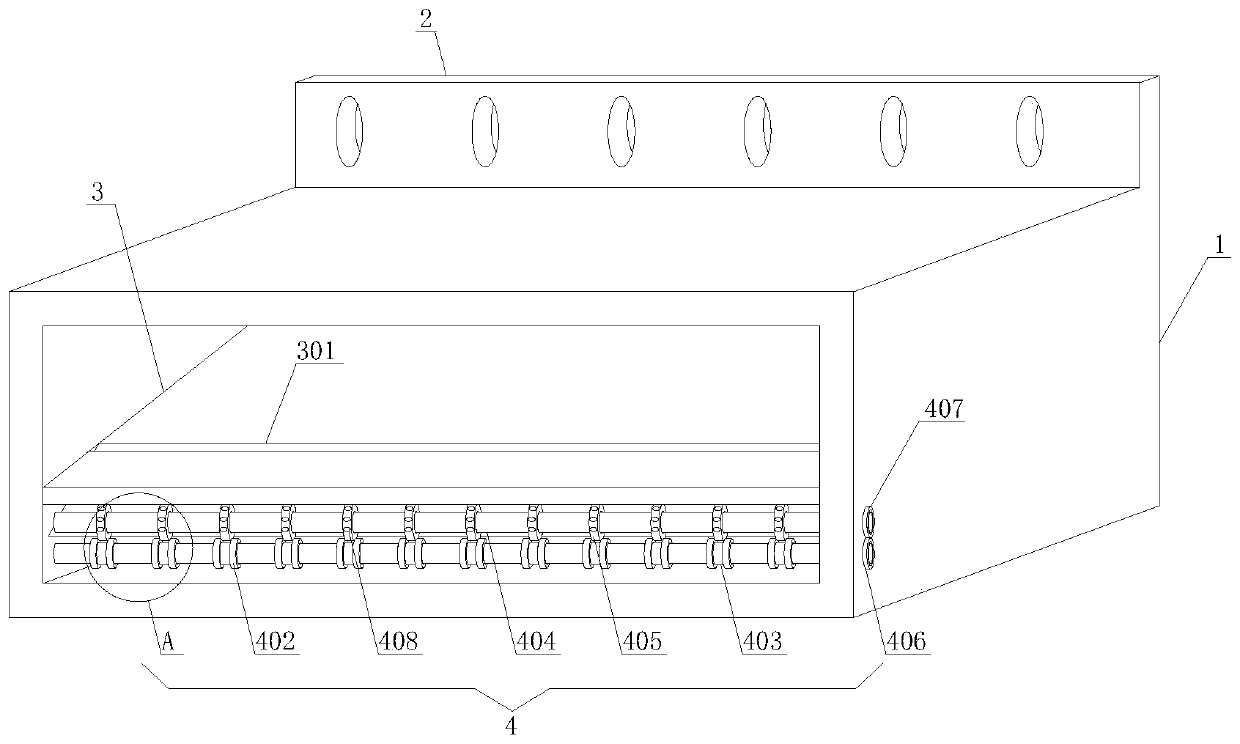

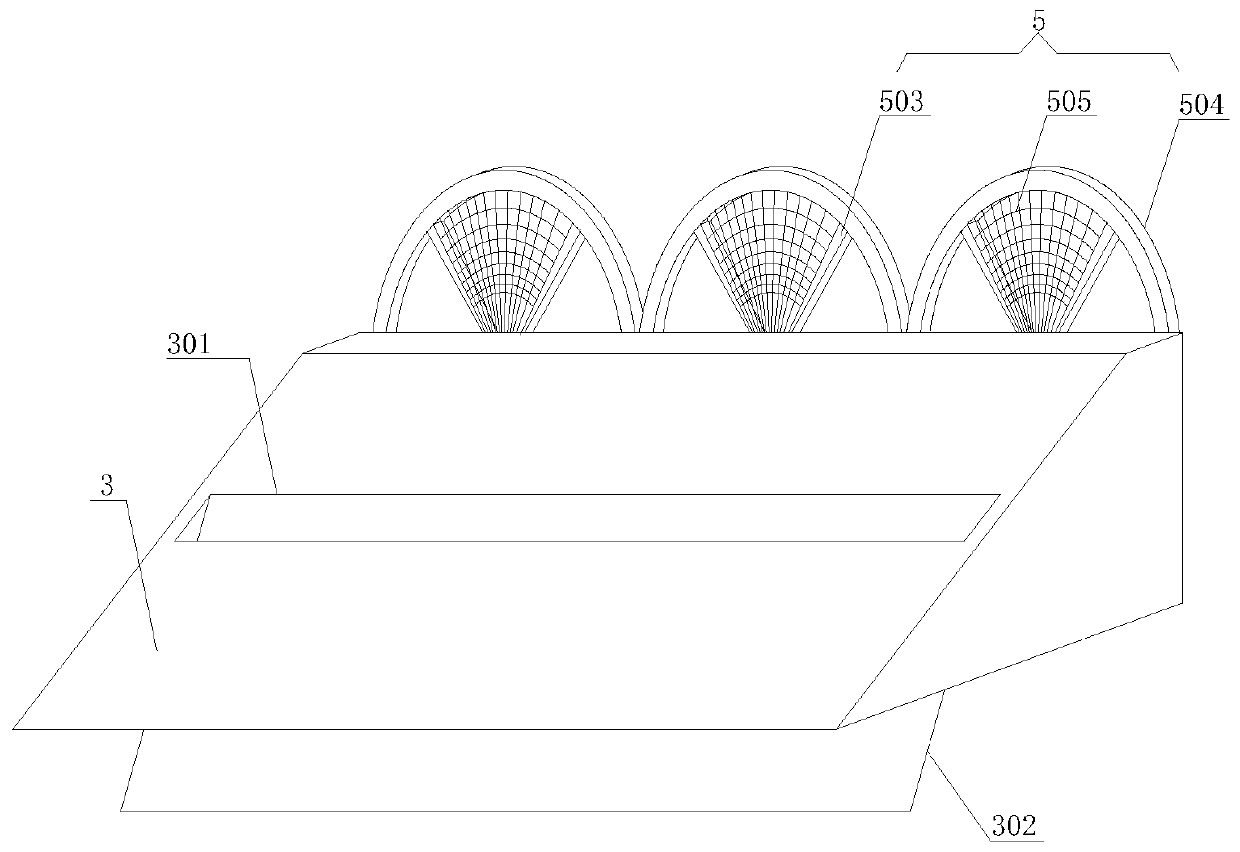

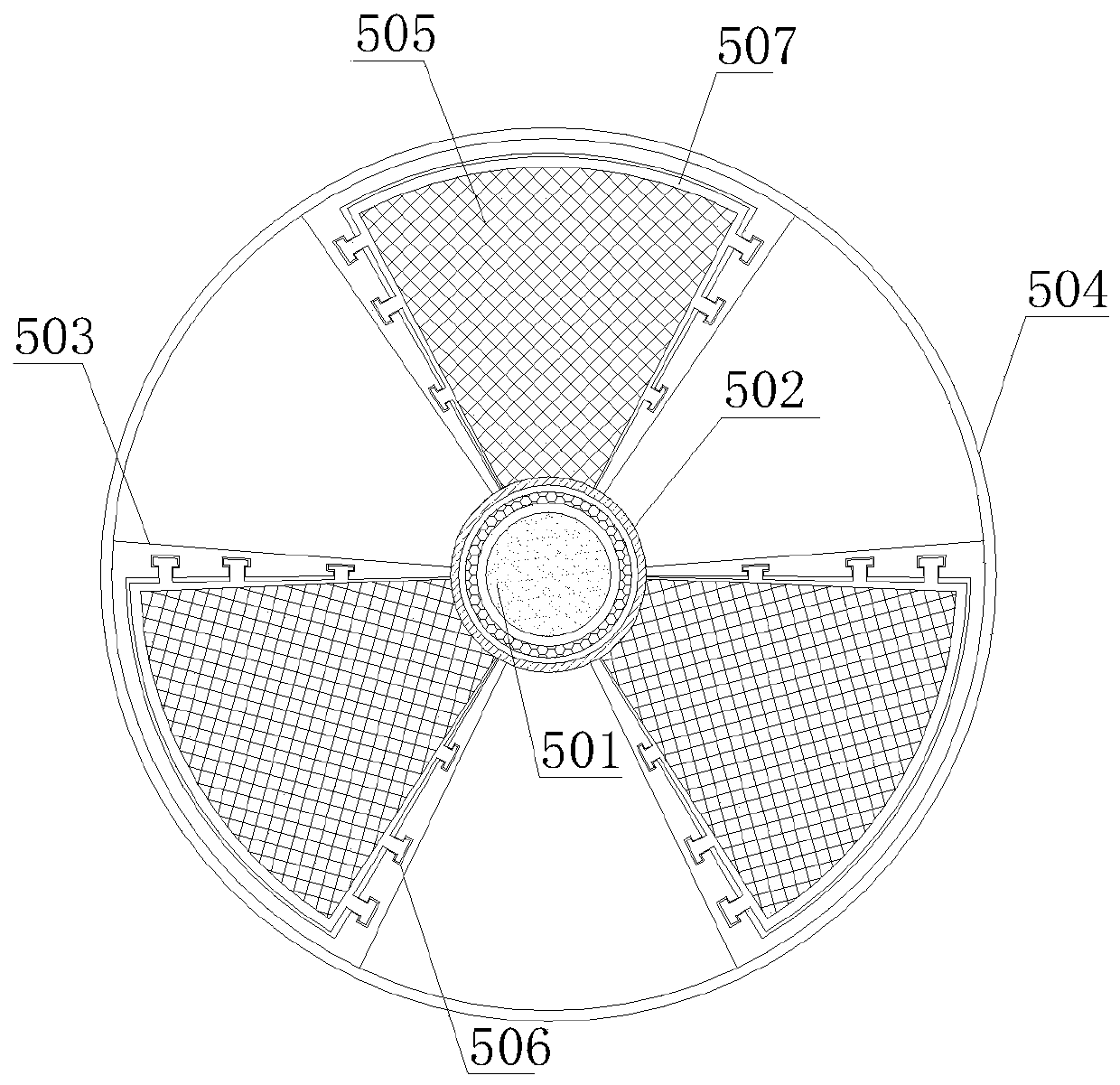

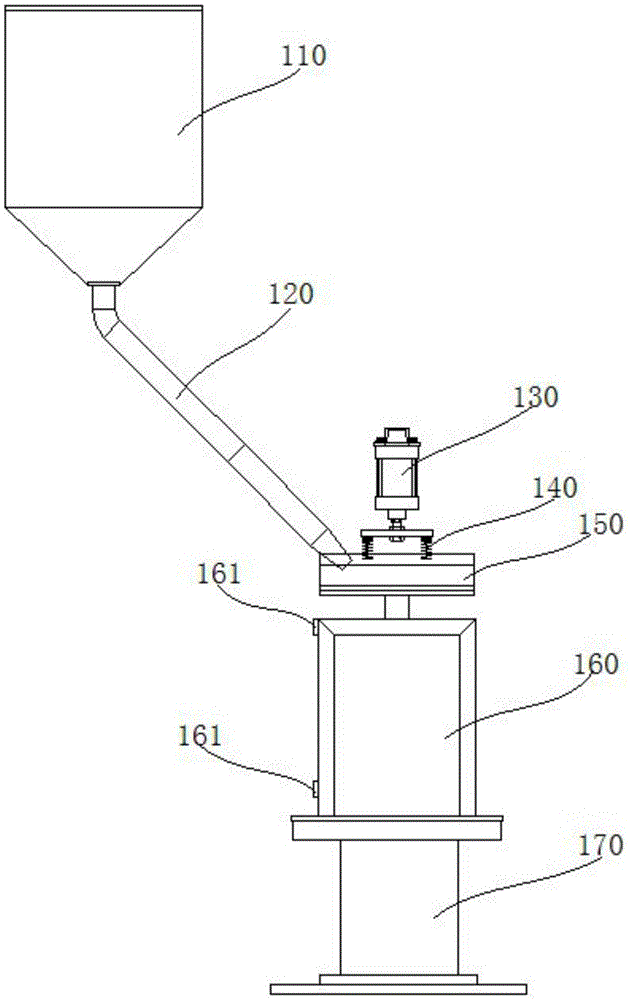

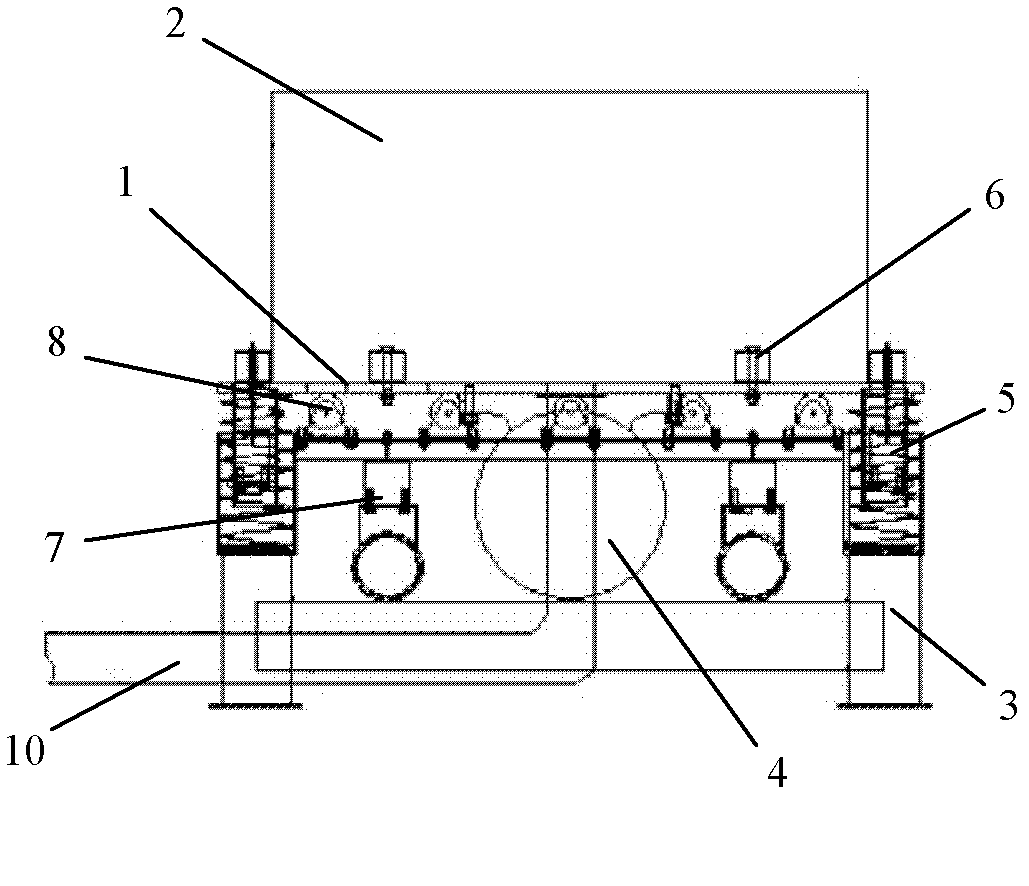

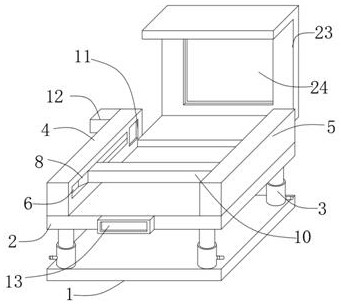

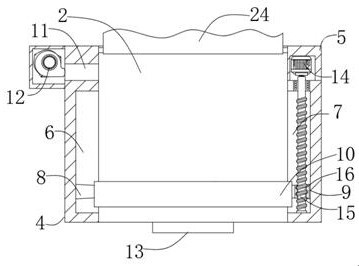

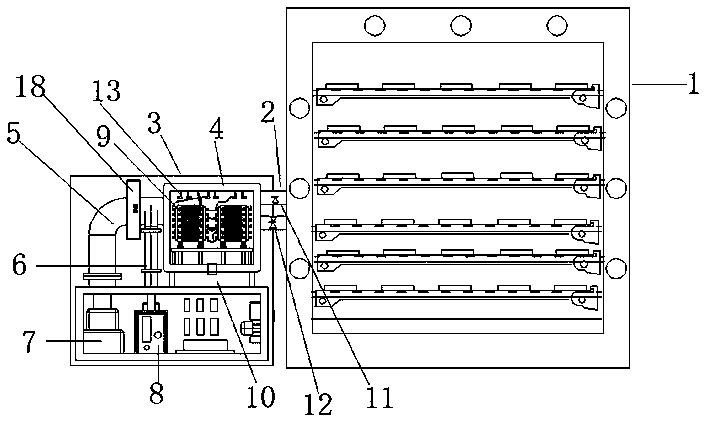

Filling device for activated carbon plate in filtering and absorption device

ActiveCN104147894AUniform dense fillingIncrease productivityDispersed particle separationActivated carbonEngineering

The invention relates to civil defense equipment, and particularly relates to a filling device for an activated carbon plate in a filtering and absorption device. The filling device for the activated carbon plate in the filtering and absorption device comprises a material storage tank (110), a hopper (150), a support frame (160) and a vibration table (170), wherein a feeding pipeline (120) is arranged between the material storage tank (110) and the hopper (150); the hopper (150) is arranged on the support frame (160) in a height adjustable manner; the support frame (160) is arranged on the vibration table (170), and is provided with clamping mechanisms (161); a to-be-filled activated carbon plate is arranged between the vibration table (170) and the hopper (150) and can be clamped by the clamping mechanisms (161). According to the filling device, activated carbon particles and dust are reduced, and the to-be-filled activated carbon plate can be filled with the activated carbon particles in a compact and uniform distribution manner.

Owner:ZHEJIANG SANYI TECH CO LTD

Efficient preparation method of mesoporous silica particles with efficient blood coagulation function

The invention discloses an efficient preparation method of mesoporous silica particles with an efficient blood coagulation function. The method comprises the following steps of (1) dissolving tetraethylortho silicate into a hydrochloric acid water solution or an ammonia-water solution and carrying out solating and gelation on the solution to form wet gel; (b) adding the wet gel and a forming agent to a granulator to obtain blank particles; and (c) drying the blank particles to obtain the mesoporous silica particles. According to the method, the raw material cost is greatly reduced, the polluting dust is eliminated, a gel drying stage is not needed, the preparation cycle of a product is obviously shortened, and the time cost is reduced while the utilization rate of equipment is improved.

Owner:苏州佰济生物科技有限公司

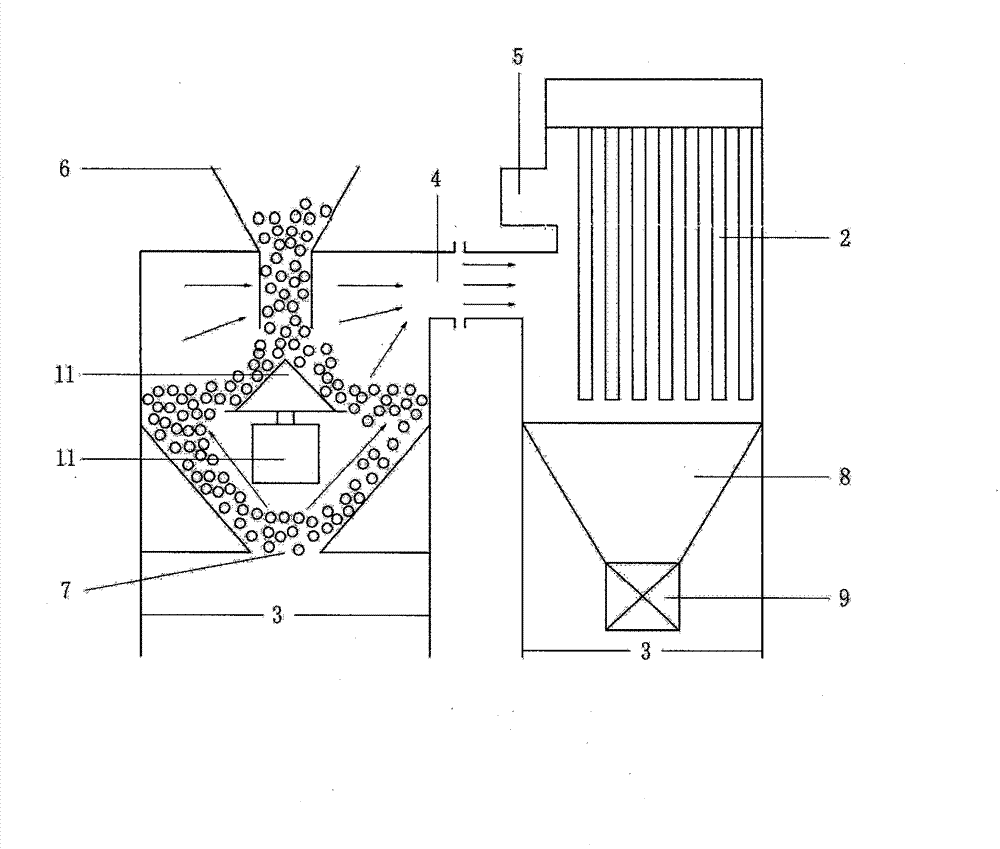

Centrifugal dedusting equipment for mine stones

InactiveCN102772970AEfficient purificationImprove build qualityCombination devicesBaghouseEngineering

The invention provides centrifugal dedusting equipment for mine stones, comprising a support, a centrifugal machine and a pulsed bag filter, wherein the centrifugal machine and the pulsed bag filter are arranged on the support side by side and are communicated with each other by a pipeline, and the upper part of the pulsed bag filter is provided with a draught fan. According to the centrifugal dedusting equipment, in the crushing and producing process of the mine stones, the centrifugal dedusting equipment is added between a crusher and a screening device, so that due to the synergistic effect of the mechanical centrifugal force and the reversed air charging, the stones in the process of producing can be further purified, the dust pollution of the mine production site can be thoroughly eliminated, the quality of the building stones can be effectively improved, and the quality of a building can be guaranteed. The product has the advantages that the dedusting effect is good, the dead angle of a dedusting device in the crushing and producing process of the mine stones can be eliminated, the equipment is safe and reliable to use and is beneficial for the environment protection of the mine production, etc.

Owner:哈尔滨市阿城区昌利矿山除尘设备厂

Efficient energy-saving type paint mixing device

InactiveCN108261948AAvoid security risksFully heatedRotary stirring mixersTransportation and packagingCombustionEfficient energy use

The invention discloses an efficient energy-saving type paint mixing device. A feeding opening and an air outlet are formed in the top surface of a kettle body; a discharging opening is formed in thebottom surface of the kettle body; a valve is arranged in a position of the discharging opening; a stirring mechanism comprises an anti-explosion motor positioned on the top surface of the kettle body; the anti-explosion motor is connected with a rotating shaft; a stirring rotating shaft and an additional rod are respectively welded on the surface of the rotating shaft; one end of the additional rod is fixedly connected with an outer rotating rod; a round groove is fixedly formed in the surface of the outer rotating rod; a turntable is sleeved and connected onto the surface of the outer rotating rod; the inner wall of the turntable is sleeved and connected onto the surface of the round groove; disc teeth are fixedly arranged on the surface of the turntable; grinding teeth are fixedly arranged on the inside of the stirring mechanism and are engaged with the disc teeth; a stirring blade is connected onto the stirring rotating shaft; a spiral heating pipe is also arranged in the kettle body; the heating pipe is connected with a combustion machine through a blast blower to heat a heat conduction oil boiler; an oil outlet pipe of the boiler is connected with an inlet of the spiral heating pipe; an oil return pipe of the boiler is connected with an outlet of the spiral heating pipe. The efficient energy-saving type paint mixing device has the advantages that the efficiency is high; the energy is saved; the paint can be sufficiently stirred.

Owner:百世杉集团有限公司

Process method for digesting plant oil by using carbon dioxide

The invention relates to a process method for digesting plant oil by using carbon dioxide, and aims at solving a conventional plant grease processing method and achieving the purpose that plant powder grains are separated from grease by soaking plant powder grains in carbon dioxide to rapidly separate the grease from the plant grain powder. By adopting the process method for digesting the plant oil by using the carbon dioxide, a production process of the grease is greatly simplified, residues which can affect human bodies because of chemical components are eliminated, the original juice and the original taste of the plant oil are maintained, and the product quality of the plant oil is improved. The method is safe and reliable in production, free of explosion, free of combustion and free of toxicity, the method is simple, and convenient to operate, the degreasing is rapid and thorough, the oil yield is high, the production cost is low, the production efficiency is high and pollution on grease is free, and the processing quality of the plant oil is improved.

Owner:孙梅 +1

Aluminum alloy sodium removal agent and preparation method thereof

The invention discloses an aluminum alloy sodium removal agent and a preparation method thereof. The aluminum alloy sodium removal agent comprises the following raw materials in parts by weight: potassium chloride, potassium fluoroaluminate, magnesium chloride, hexachloroethane, water and impurities, wherein the impurities are a mixture of ammonium chloride, ammonium carbonate and ammonium bicarbonate. The preparation method of the aluminum alloy sodium removal agent comprises the following steps: weighing all the raw materials according to the weight parts, sequentially adding the potassium chloride, magnesium chloride, hexachloroethane and potassium fluoroaluminate into a ball mill for ball milling, evenly mixing and screening, detecting and packaging. Residues can be removed by adsorbing and dissolving oxides and entrainments in a melt through a solvent, so that the aluminum slag burning phenomena can be effectively reduced, metal loss can be decreased, and further the production cost is lowered; the usage amount of the product is less, only 1-1.5kg sodium removal agent is need for removing 1kg of sodium, more than 80% of sodium in aluminum water can be removed, the potassium fluoroaluminate used is non-hydroscopic and non-toxic, the production environment is purified, smoke emission is reduced, and the aluminum alloy sodium removal agent is stable in performances.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

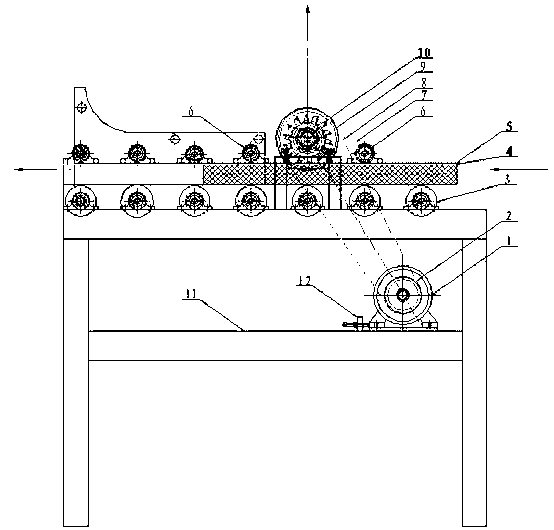

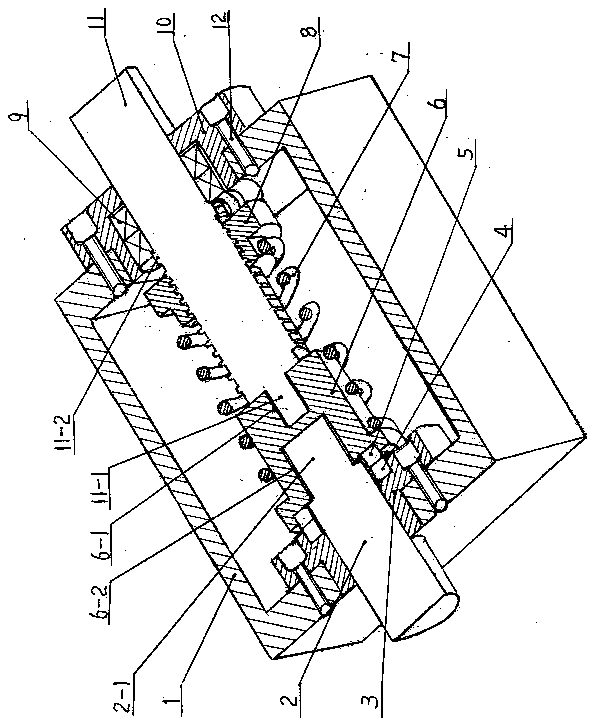

Rock wool board thickness size milling device

ActiveCN103213202AImprove cleanlinessReach sizeWorking accessoriesStone-like material working toolsMilling cutterEngineering

The invention relates to a rock wool board machining device, and particularly discloses a rock wool board thickness size milling device. The rock wool board thickness size milling device comprises a large frame and a plurality of guide rollers which are installed on the large frame in parallel. The rock wool board thickness size milling device is characterized in that pinch rollers located above the guiding rollers are arranged on the large frame, rock wool milling lines used for conveying rock wool boards are formed between the pinch rollers and the guiding rollers, a milling cutter shaft parallel to the guiding rollers is installed on the large frame through bearing blocks, milling cutters are fixed on the milling cutter shaft, a large triangle belt wheel is arranged on the outer side of each bearing block, motors for installing small triangle belt wheels are arranged on the large frame, and each large triangle belt wheel is connected with each small triangle belt wheel through a triangle belt. The rock wool board machining device is ingenious in design, accumulated error is eliminated during wool distribution after a milled rock wool board is turned over at the angle of 180 degrees in a splitting mode, product quality and production efficiency are improved, the beneficial effects are remarkable, and convenience is brought to wide popularization and application.

Owner:万事达建筑钢品(江苏)股份有限公司

Textile dust collecting equipment for textile machine

InactiveCN110420903APurify the production environmentImprove qualityFilament handlingDirt cleaningYarnEngineering

The invention discloses textile dust collecting equipment for a textile machine. The textile dust collecting equipment comprises a butting box, a dismounting and mounting plate, an air draft table, ayarn guide mechanism and a fluff collecting mechanism, wherein the bottom of the dismounting and mounting plate is fixedly welded to the back side of the top of the butting box, the two sides of the air draft table are fixedly welded to the inner wall of the butting box, the yarn guide mechanism is arranged at the bottom of the front side of an inner cavity of the butting box, and the fluff collecting mechanism is arranged on the back side of the air draft table. According to the textile dust collecting equipment for the textile machine, collecting and cutting-off of fluff adhered to yarn or not broken is carried out from a yarn inlet, so that on one hand, the amount of the fluff floating in the air can be reduced, the production environment is purified, on the other hand, the quality of the woven products can be improved, and the economic benefits of textile production can be improved; and the rotating speed of the fluff collecting mechanism can be accelerated continuously along withthe increase of the collection amount of the fluff, certain attraction force can be increased to better suck the floating fluff, and on the other hand, the generated wind power can be used for blowingand cooling the textile equipment.

Owner:宁波市鄞州智伴信息科技有限公司

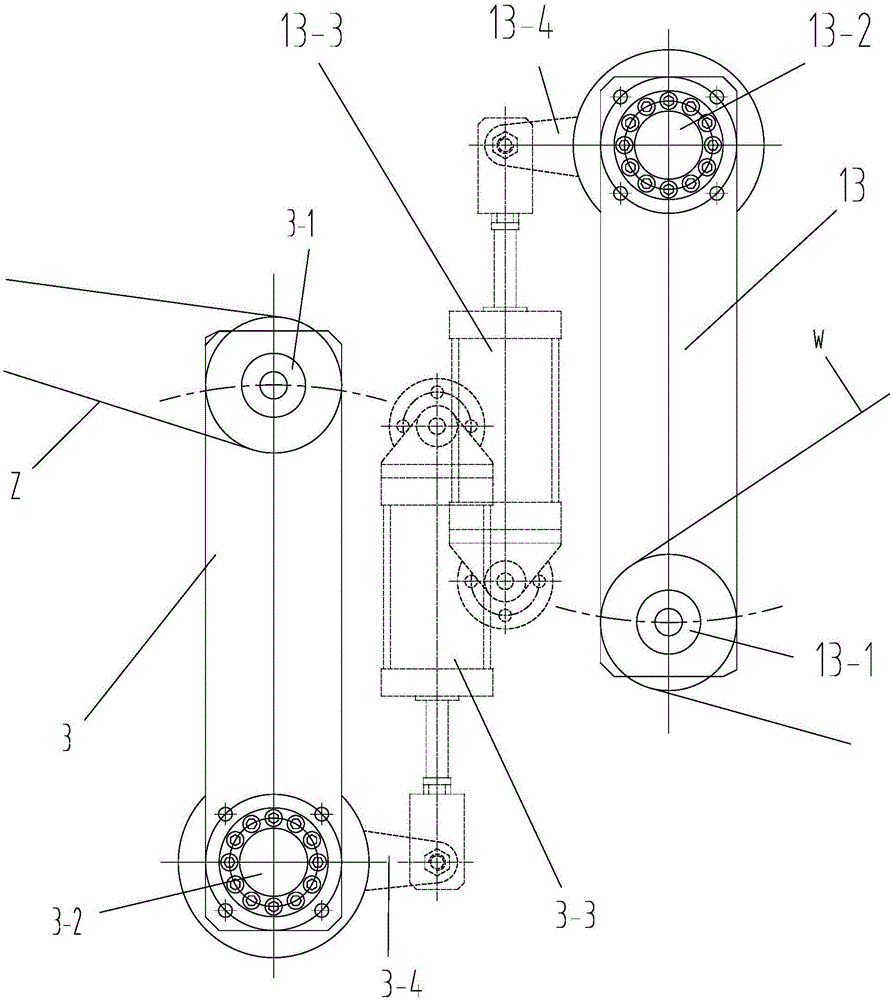

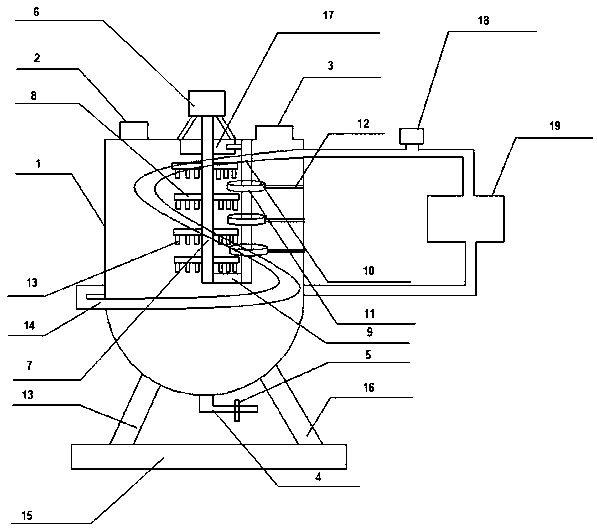

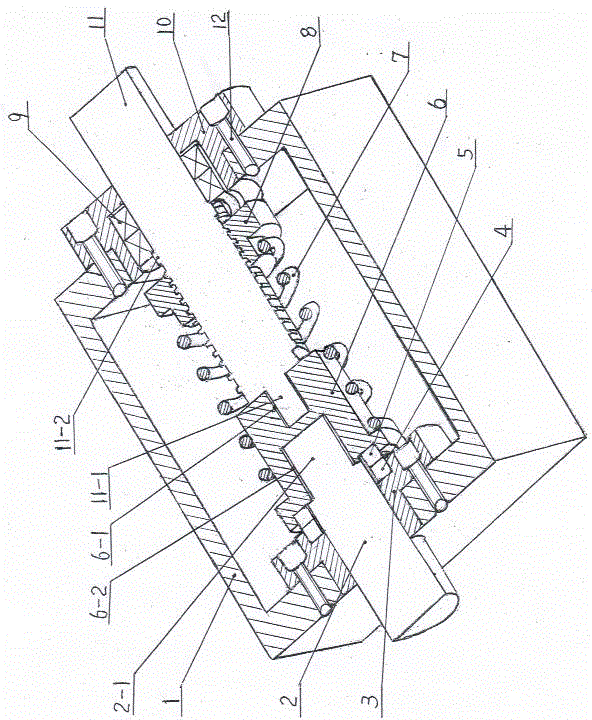

Oldham Sealed Couplings

ActiveCN104235210BSimple structureGuaranteed pressureEngine sealsYielding couplingCouplingEngineering

The invention belongs to the mechanical sealing devices, and in particular relates to a crosshead shoe sealing shaft coupler, wherein a static sealing flange (3) is fixedly arranged in the center hole in the left end of a shell (1) through a connecting bolt (12); an overturning shaft (2) is movably arranged in the static sealing flange (3) in a penetration manner; a flange bearing seat (10) is fixedly arranged in the center hole in the right end of the shell (1) through a connecting bolt (12); a swing rod connecting shaft (11) is arranged in the flange bearing seat (10) and a bearing (9) in the penetration manner; the overturning shaft (2) is connected with the swing rod connecting shaft (11) through a crosshead shaft coupling slider (6); the crosshead shaft coupling slider (6) is a stepped cylinder in shape; a static sealing ring (4) is arranged in the circular groove in the right end surface of the static sealing flange (3); a moving sealing ring (5) is arranged in the circular groove in the left end surface of the crosshead shaft coupling slider (6); the static sealing ring (4) and the moving sealing ring (5) both sleeve the overturning shaft (2). The crosshead shoe sealing shaft coupler has the advantages of simple structure and capabilities of purifying the production environment and prolonging the service life of equipment.

Owner:柔金(辽宁)电力科技发展有限公司

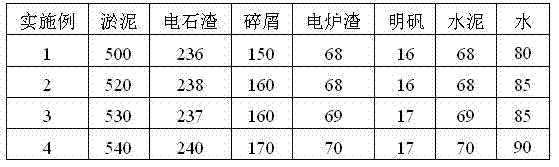

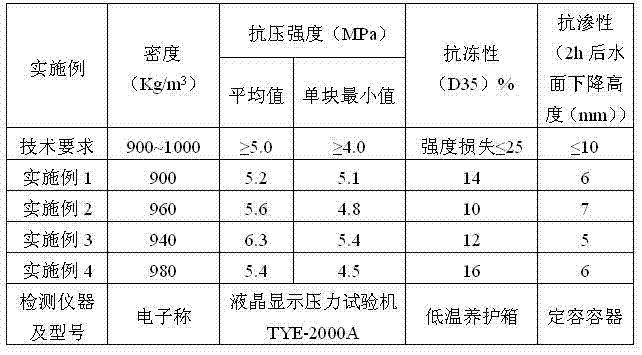

Slit burning-free bricks and production method thereof

ActiveCN102206073BHigh activityImprove cementing performanceSludge treatmentSolid waste managementSocial benefitsBrick

The invention discloses slit burning-free bricks and a production method thereof. The slit burning-free bricks are produced by using the following raw materials in part by weight: 500 to 540 parts of dried slit, 236 to 240 parts of carbide slag, 150 to 170 parts of scrap, 68 to 70 parts of electric furnace slag, 16 to 17 parts of alumen, 68 to 7 parts of cement and 80 to 90 parts of water. The slit burning-free bricks are produced by the following steps: dewatering, drying slit, adding the carbide slag into the dried slit, uniformly mixing, piling, turning, deodorizing and sterilizing; adding other raw materials, slit and carbide slag into a mixer in turn and uniformly mixing; and forming by extruding the mixture, and curing to obtain the finished slit burning-free bricks. In the invention, the carbide slag is used to sterilize and disinfect the slit; the slit is deodorized by piling and turning; the quality of the product slit burning-free bricks reaches a standard, and the cost is low; and the social benefit of saving energy, protecting farm land and optimizing water environment is created.

Owner:无锡市康顺节能材料科技有限公司

Crosshead shoe sealing shaft coupler

ActiveCN104235210ASimple structurePurify the production environmentEngine sealsYielding couplingEngineeringCrosshead

The invention belongs to the mechanical sealing devices, and in particular relates to a crosshead shoe sealing shaft coupler, wherein a static sealing flange (3) is fixedly arranged in the center hole in the left end of a shell (1) through a connecting bolt (12); an overturning shaft (2) is movably arranged in the static sealing flange (3) in a penetration manner; a flange bearing seat (10) is fixedly arranged in the center hole in the right end of the shell (1) through a connecting bolt (12); a swing rod connecting shaft (11) is arranged in the flange bearing seat (10) and a bearing (9) in the penetration manner; the overturning shaft (2) is connected with the swing rod connecting shaft (11) through a crosshead shaft coupling slider (6); the crosshead shaft coupling slider (6) is a stepped cylinder in shape; a static sealing ring (4) is arranged in the circular groove in the right end surface of the static sealing flange (3); a moving sealing ring (5) is arranged in the circular groove in the left end surface of the crosshead shaft coupling slider (6); the static sealing ring (4) and the moving sealing ring (5) both sleeve the overturning shaft (2). The crosshead shoe sealing shaft coupler has the advantages of simple structure and capabilities of purifying the production environment and prolonging the service life of equipment.

Owner:柔金(辽宁)电力科技发展有限公司

Hard alloy mixing material vibration drying method and device

InactiveCN101104251ASolve the problem of easy oxygenationAvoid contactDrying using combination processesDrying solid materials with heatProduct gasAlloy

The invention relates to a drying method and a device for cemented carbide mixture. The method adopts a steam jacket to heat the cemented carbide mixture so as to make the temperature of the cemented carbide mixture rise, and to make the liquid grinding medium change into gaseous state so that the liquid grinding medium can be separated from cemented carbide powder; when the cemented carbide mixture is heated inside a sealed system in the sated of vacuum, the gaseous grinding medium is condensed into liquid in the state of vacuum. The equipment is composed of a steam vibrating drying device, a vacuum pipe, a condensing plant, a vacuum pump and a recovery drum. The gas outlet of the steam vibrating drying device is connected with the condensing plant, the recovery drum and the vacuum pump in order by the vacuum pipe, which forms a sealed vacuum system. The gasified grinding medium can be separated from the powder fast and completely by vacuum drawing without adopting spraying method to discharge exhaust gas and no powder sprays out. Thus, the invention saves precious resources and purifies the production environment, can also avoid the powder contacting the air and solves the problem that the oxygen of the material is easy to be increased.

Owner:ZHUZHOU JINGGONG CEMENTED CARBIDE

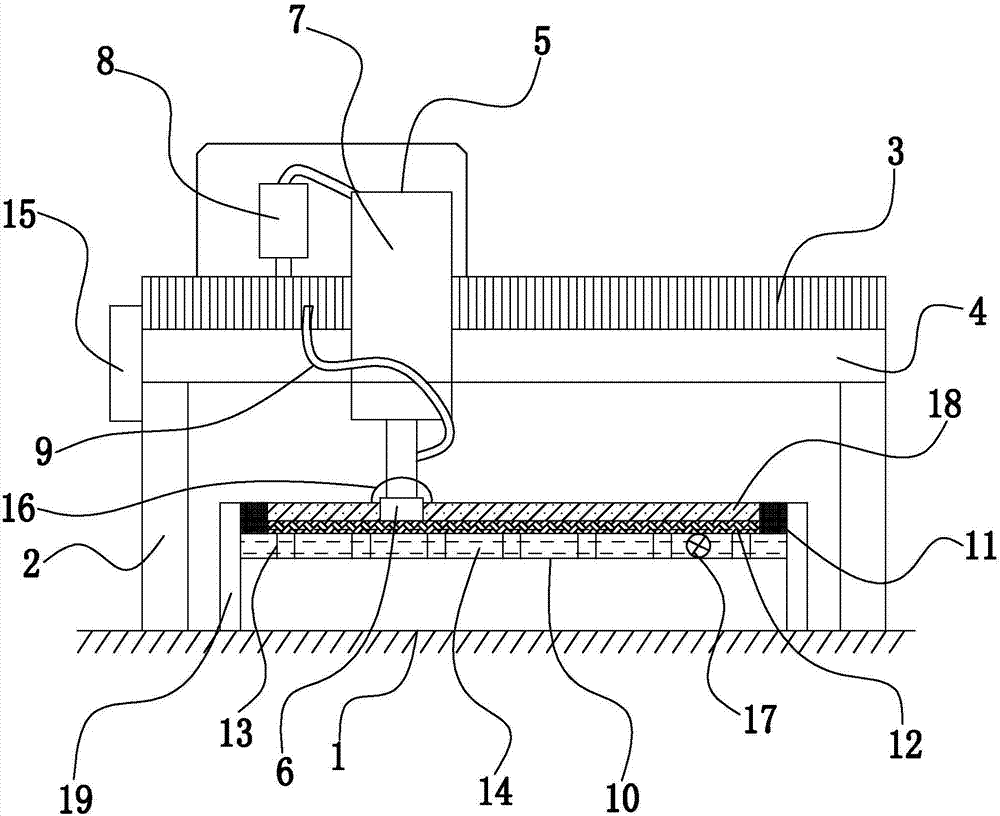

A high-pressure cutting and punching device for glass

ActiveCN106003434BFast feedingAvoid corrosionWorking accessoriesStone-like material working toolsEngineeringHigh pressure

The invention relates to a high pressure cutting and perforating device for glass. The device comprises two supporting columns arranged at two ends of a horizontal base, wherein a cross beam is connected to the upper ends of the two supporting columns; a slideway and a cutting device are arranged on the cross beam; the cutting device slides along the length direction of the slideway and is controlled by a controller through a circuit; a liquid tank is formed in the middle of the bottom end of the cross beam and is fixedly connected through supporting rods; the cutting device comprises a drill, a pressurizing device and a drill lifting air cylinder for driving the drill to feed; the pressurizing device is connected to the drill through a pressure pipeline, so that the drill is quickly fed; the moving trajectory of the drill corresponds to the length of the liquid tank. The device provided by the invention is simple in structure and convenient and rapid to use; during mounting, the drill is quickly fed by matching the drill lifting air cylinder and the pressurizing device in operation, so that the device is high in degree of automation and the production efficiency is improved.

Owner:浙江飞越汉禾坊新材料有限公司

Filling device for activated carbon plates in filter absorbers

ActiveCN104147894BUniform dense fillingIncrease productivityDispersed particle separationActivated carbonEngineering

The invention relates to civil defense equipment, and particularly relates to a filling device for an activated carbon plate in a filtering and absorption device. The filling device for the activated carbon plate in the filtering and absorption device comprises a material storage tank (110), a hopper (150), a support frame (160) and a vibration table (170), wherein a feeding pipeline (120) is arranged between the material storage tank (110) and the hopper (150); the hopper (150) is arranged on the support frame (160) in a height adjustable manner; the support frame (160) is arranged on the vibration table (170), and is provided with clamping mechanisms (161); a to-be-filled activated carbon plate is arranged between the vibration table (170) and the hopper (150) and can be clamped by the clamping mechanisms (161). According to the filling device, activated carbon particles and dust are reduced, and the to-be-filled activated carbon plate can be filled with the activated carbon particles in a compact and uniform distribution manner.

Owner:ZHEJIANG SANYI TECH CO LTD

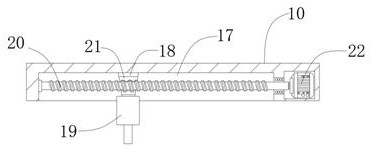

Automatic offal untie method and device

ActiveCN100443380CReduce manufacturing costAutomated program highCigarette manufactureArticle unpackingMechanical engineeringCleaner production

The invention discloses a method and equipment for automatically unpacking tobacco stems. It uses the sack conveyor belt to send the whole stack of sacks to the bottom of the clamping lifting mechanism, and the clamping mechanism puts them one by one on another sack conveyor belt. The front end of the sack is cut open by an automatic cutting device. When the cut of the sack exceeds the front end of the sack conveyor belt, the cut of the sack hangs down, and the tobacco stems begin to pour out gradually from the cut of the sack. When there are only half or 1 / 3 of the tobacco stems in the sack, use the hook bag lifting device to hook the sack, and after the remaining tobacco stems in the sack are poured out, the empty sack clamping mechanism located near the hook bag lifting device will After the empty bale is clamped, move it to the conveyor belt to send it out. When the present invention is applied to the process of re-curing tobacco stems, it can improve the automatic program, reduce the labor intensity, purify the production environment, effectively reduce the production cost of cigarettes, and improve the economic benefits of cigarette production enterprises.

Owner:许敬敏

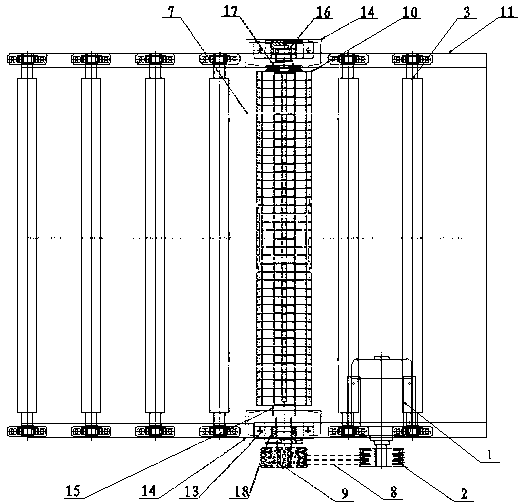

Active carbon filling vibration bed of iodine adsorber

The invention relates to a mechanical device used for compacting active carbon, in particular to an active carbon filling vibration bed of an iodine adsorber. The active carbon filling vibration bed of the iodine adsorber structurally comprises a vibration bed surface used for the arrangement of a shell of the iodine adsorber, the vibration bed surface is arranged on a support, a vibration motor is arranged below the vibration bed surface, a damper spring is arranged between the vibration bed surface and the support, a lifting air cylinder is arranged below the vibration bed surface, two parallel rolling wheel devices are arranged above the lifting air cylinder, and after rising, the rolling wheel devices can upbear the shell of the iodine adsorber and move horizontally. The active carbon filling vibration bed of the iodine adsorber is low in energy consumption, small in amplitude and high in frequency, lifting rolling wheels can displace the iodine adsorber and ensure that the lifting rolling wheels can be placed into a vibration platform in vibration, meanwhile, fine carbon dust generated in a filling process can be sucked, and filling requirements of the iodine adsorber are met.

Owner:CHINA INST FOR RADIATION PROTECTION

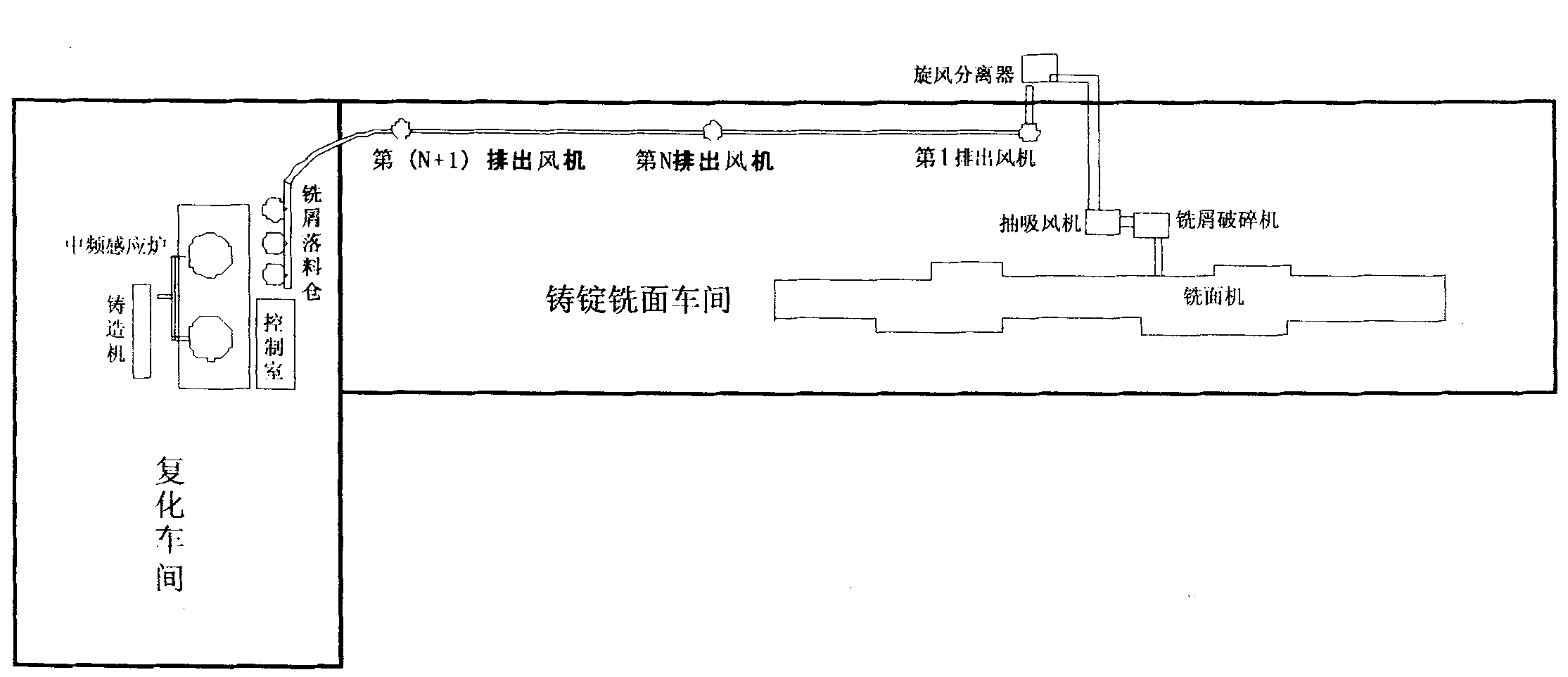

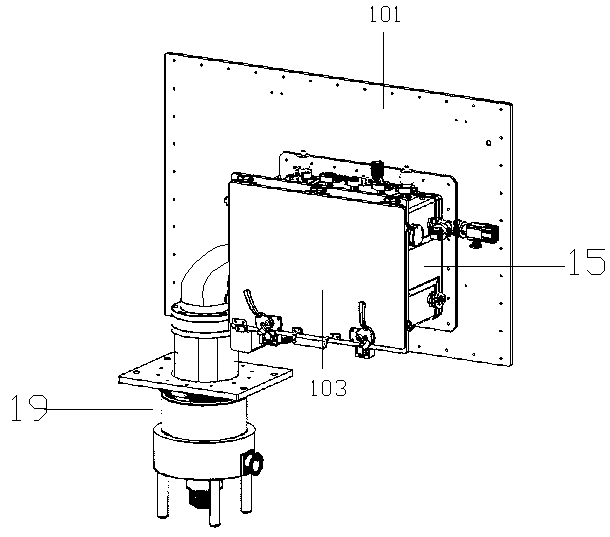

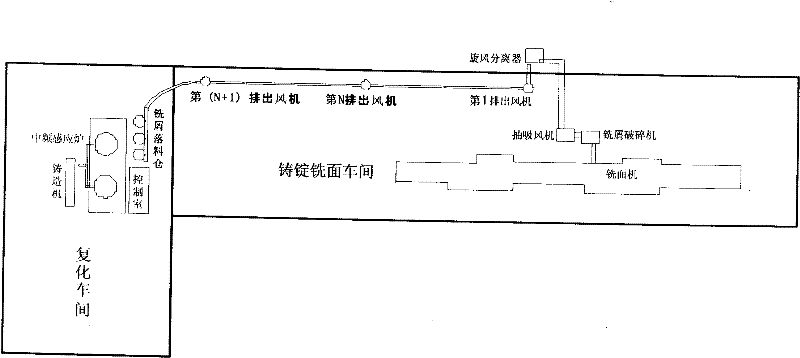

Method for transporting aluminum milling scraps to complexification workshop through pipelines

ActiveCN101934935AReduce usageSave on repeated transportationBulk conveyorsPulp and paper industryCrusher

The invention relates to a method for transporting aluminum milling scraps to a complexification workshop through pipelines, which comprises a surface milling machine, a suction fan, a milling scrap crusher, a cyclone separator and a milling scrap charging bin, wherein the pipelines are erected on the plant top of an ingoting and surface milling workshop and the complexification workshop and led into the workshop; the pipelines led into the ingoting and surface milling workshop are linked with the milling scrap crusher after being linked with the suction fan; the cyclone separator is erected on the plant top of the ingoting and surface milling workshop; a section of the pipelines linked from the suction fan is linked with the inlet end of the cyclone separator, and the outlet end of the cyclone separator is linked with a first exhaust fan and N exhaust fans; the space between the adjacent exhaust fans is controlled between 100 to 120m; and finally, the (N+1)th exhaust fan is directly communicted with the milling scrap charging bin of the complexification workshop. The invention can ensure that the aluminum milling scraps are sucked into the pipelines by the suction fan after being crushed and then transmitted to the milling scrap charging bin of the complexification workshop through the cyclone separator and the exhaust fans with the functions of pressurization and air exhaust so as to carrying out resmelting.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Plane cutter of plane armoring mechanism

PendingCN112192050AProtect your healthPurify the production environmentLaser beam welding apparatusStructural engineeringMechanical engineering

The invention discloses a plane cutter of a plane armoring mechanism. The cutter comprises a fixed base and a cutting table, the four corners of the top face of the fixed base are fixedly connected with the bottoms of horizontal adjusting assemblies, the tops of the horizontal adjusting assemblies are fixedly connected with the cutting table, the two sides of the top face of the cutting table arefixedly connected with a left support and a right support correspondingly, and a left sliding groove is formed in the left support; a left sliding block is connected into the left sliding groove in asliding manner, a right sliding groove is formed in the right support, and a right sliding block is connected into the right sliding groove in a sliding manner; and the cutter is provided with a dustoutlet and a draught fan, smoke dust generated in the cutting process can be discharged, the production environment is purified, and the body health of an operator is protected. The angle of the cutting table can be adjusted through the horizontal adjusting assemblies, whether the cutting table is located at the horizontal position or not is judged through a horizontal liquid level instrument, thesituation that a cut workpiece cannot be used due to inclination of the cutting table is avoided, the yield is guaranteed, and economic losses are avoided.

Owner:ANHUI AOYU CNC TECH +1

A tobacco stalk pretreatment equipment

ActiveCN1994158BReduce manufacturing costReduce labor intensityTobacco treatmentArticle unpackingForeign matterEngineering

The invention relates to a cigarette stem pretreatment device, which comprises that: enveloping and opening device, clamping lifter, flux stabilizer, washing regain device, wind selector and stem storage device; the flux stabilizer is formed by chamber feeder, meter tube, and meter weighting machine; it uses wind to remove dust, etc; then feeding stem into washing regain device, to control the water content; feeding into storage device, to balance the inner water content. The invention can shorten production time and reduce cost.

Owner:许敬敏

A kind of aluminum alloy sodium removing agent and preparation method thereof

The invention discloses an aluminum alloy sodium removal agent and a preparation method thereof. The aluminum alloy sodium removal agent comprises the following raw materials in parts by weight: potassium chloride, potassium fluoroaluminate, magnesium chloride, hexachloroethane, water and impurities, wherein the impurities are a mixture of ammonium chloride, ammonium carbonate and ammonium bicarbonate. The preparation method of the aluminum alloy sodium removal agent comprises the following steps: weighing all the raw materials according to the weight parts, sequentially adding the potassium chloride, magnesium chloride, hexachloroethane and potassium fluoroaluminate into a ball mill for ball milling, evenly mixing and screening, detecting and packaging. Residues can be removed by adsorbing and dissolving oxides and entrainments in a melt through a solvent, so that the aluminum slag burning phenomena can be effectively reduced, metal loss can be decreased, and further the production cost is lowered; the usage amount of the product is less, only 1-1.5kg sodium removal agent is need for removing 1kg of sodium, more than 80% of sodium in aluminum water can be removed, the potassium fluoroaluminate used is non-hydroscopic and non-toxic, the production environment is purified, smoke emission is reduced, and the aluminum alloy sodium removal agent is stable in performances.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

A high-efficiency preparation method of mesoporous silica particles with high-efficiency blood coagulation function

The invention discloses an efficient preparation method of mesoporous silica particles with an efficient blood coagulation function. The method comprises the following steps of (1) dissolving tetraethylortho silicate into a hydrochloric acid water solution or an ammonia-water solution and carrying out solating and gelation on the solution to form wet gel; (b) adding the wet gel and a forming agent to a granulator to obtain blank particles; and (c) drying the blank particles to obtain the mesoporous silica particles. According to the method, the raw material cost is greatly reduced, the polluting dust is eliminated, a gel drying stage is not needed, the preparation cycle of a product is obviously shortened, and the time cost is reduced while the utilization rate of equipment is improved.

Owner:苏州佰济生物科技有限公司

Protective device for textile machinery

InactiveCN108246756ALow densityProtect your healthLighting applicationsMechanical apparatusFiberPhysical well being

The invention discloses a protective device for textile machinery. The protective device comprises a mounting block, wherein a mounting slot is formed in one side of the mounting block; the bottom inthe mounting slot is fixedly equipped with a first drive device; the tail end of the output shaft of the first drive device is fixedly equipped with a first polish rod; one end of the first polish rodis rotatably connected with a first connecting rod; and one end of the first connecting rod is rotatably connected with a first movable block. The protective device realizes recycling fibers in a production space, reduces density of the fibers in the space, reduces production accidents which possibly occur, purifies the production environment, protects body health of a worker, solves production accidents which are possibly brought by accumulating the fibers in the space and the harmful effect which is possibly caused on the body of the worker, creates a better production environment, is beneficial for increasing a profit rate of the enterprises, is simple in structure, is convenient to operate, and is suitable for being popularized.

Owner:郑州星联新创信息科技有限公司

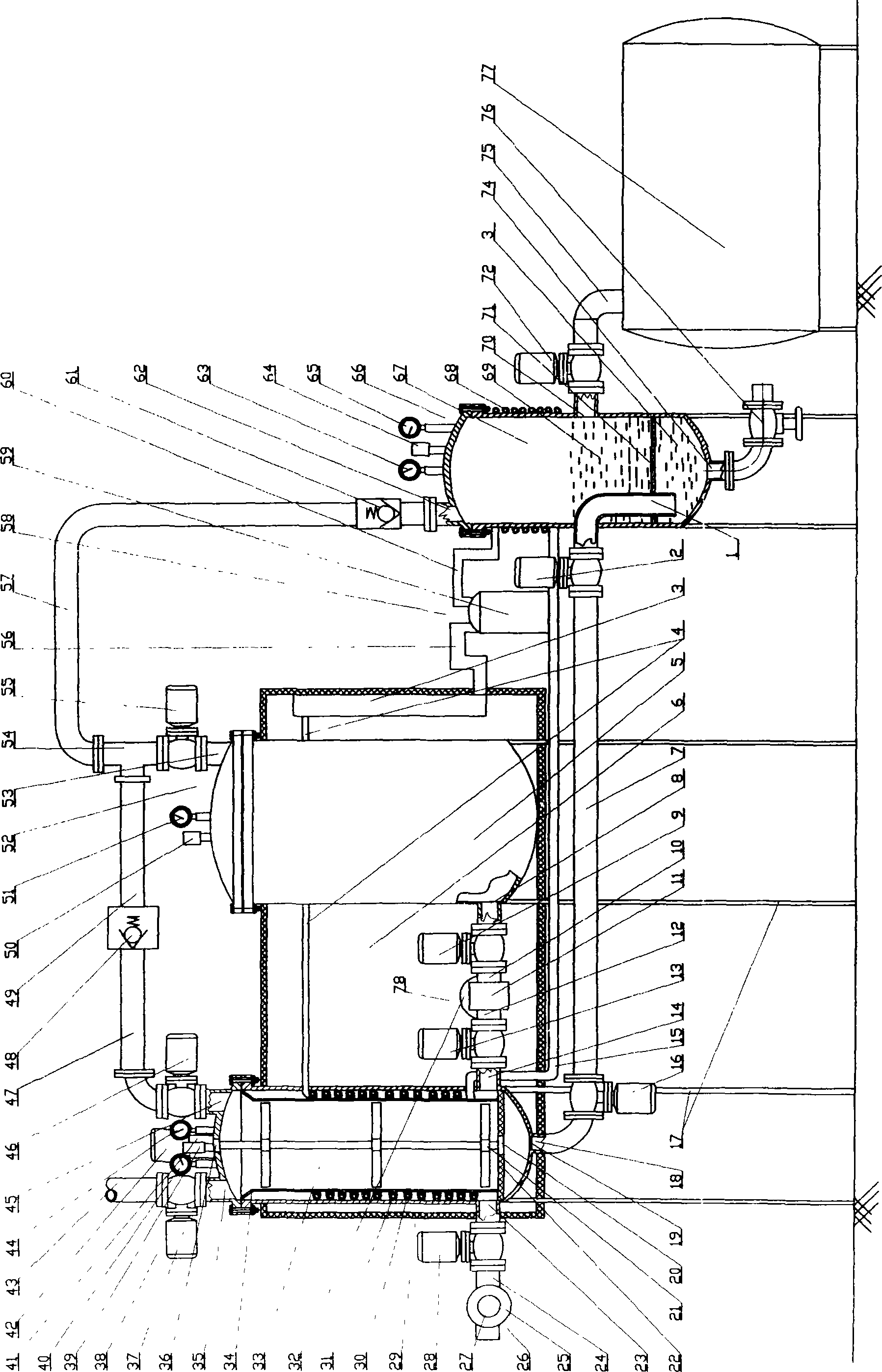

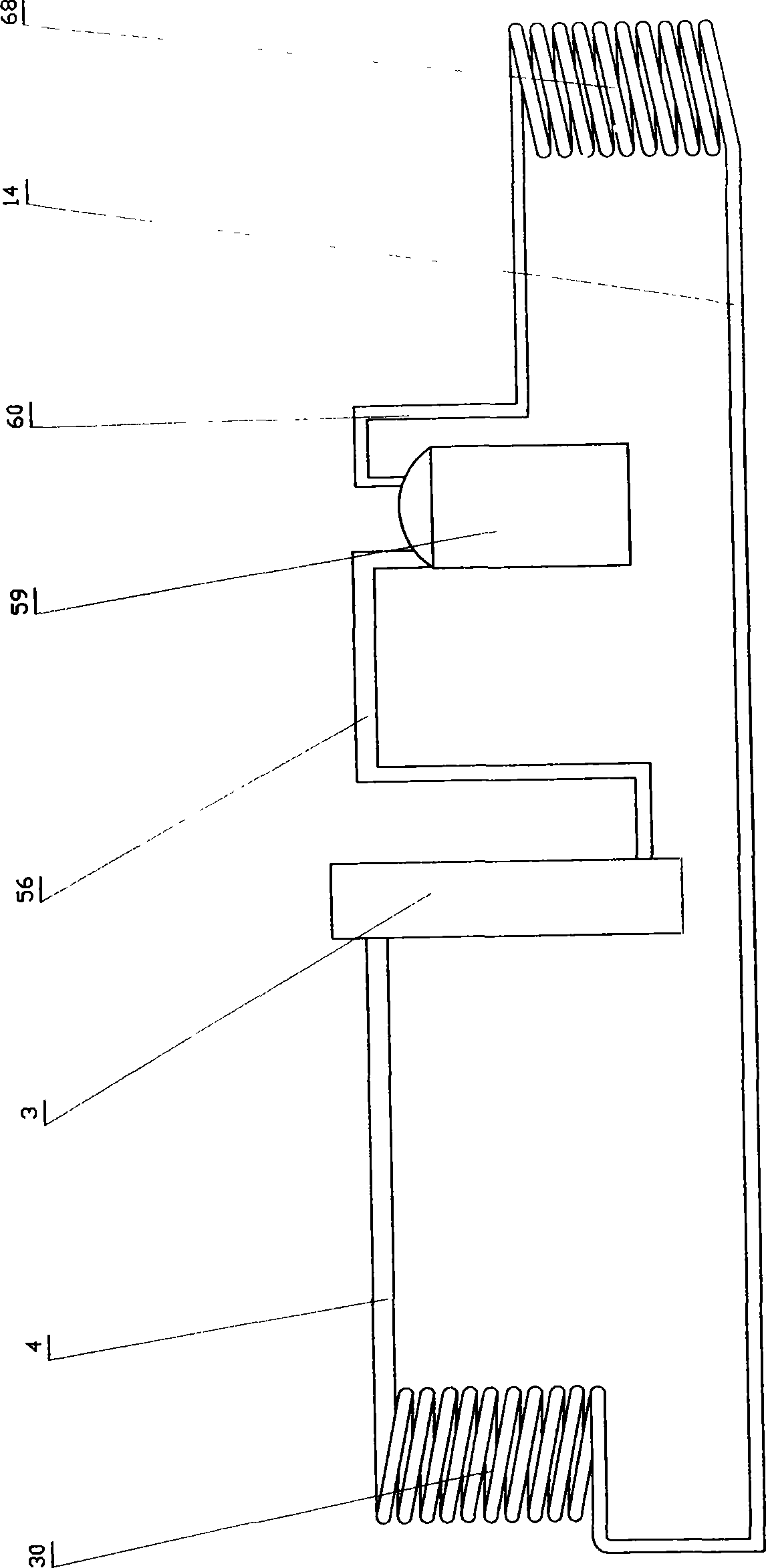

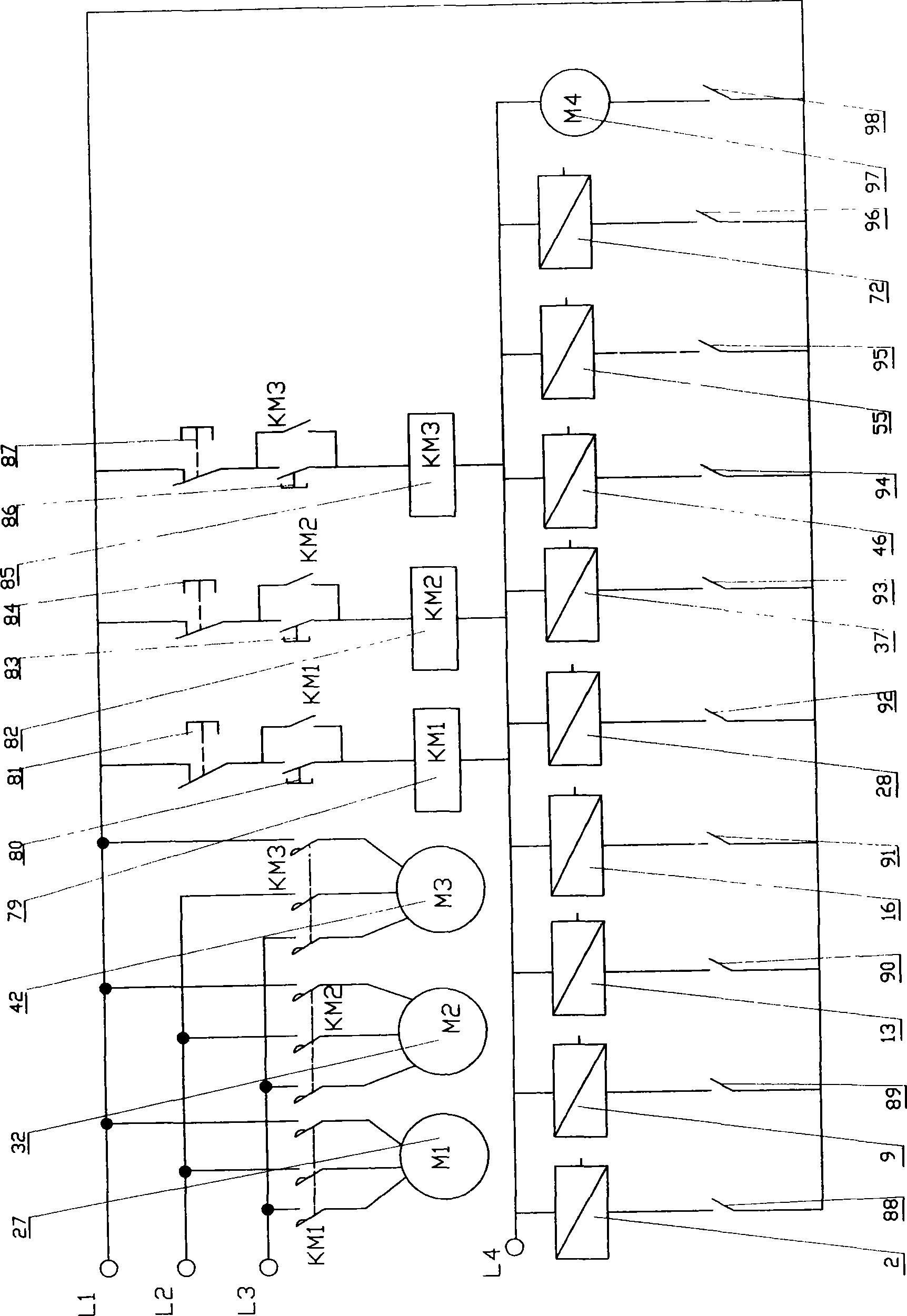

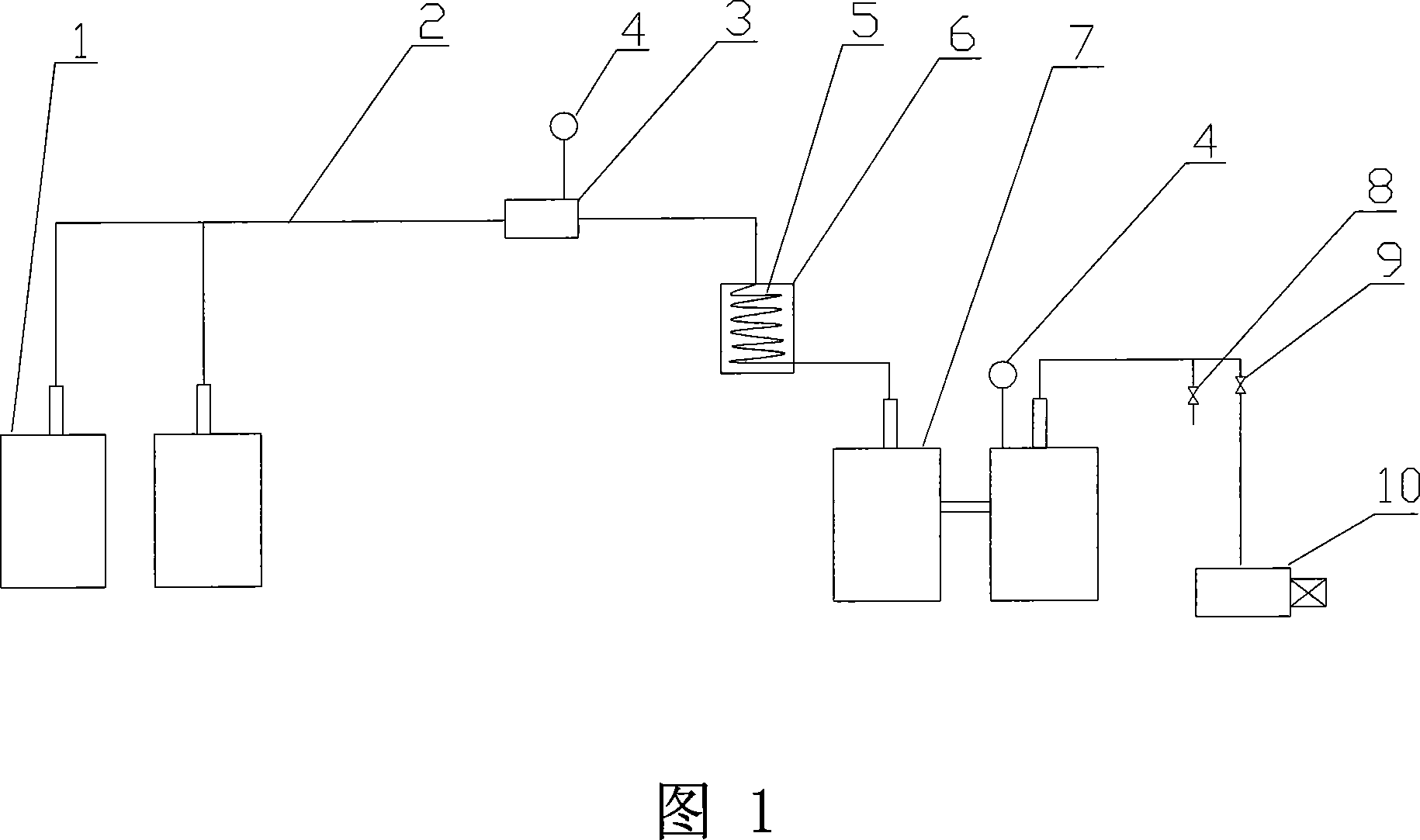

Temperature-compensating and temperature-adjusting annealing furnace system

ActiveCN110218854AImprove comfortTemperature will not affectFurnace typesHeat treatment process controlSheet pileVacuum pump

The invention relates to the field of electronic circuit crystal parts, in particular to a temperature-compensating and temperature-adjusting annealing furnace system. The temperature-supplementing and temperature-adjusting annealing furnace system comprises a furnace main body and a complementary temperature regulator, wherein the complementary temperature regulator is connected with the furnacemain body through a compensation vent pipe; the complementary temperature regulator comprises a temperature adjusting bin, a condensation vacuumizing pipe, a mechanical air exhaust vacuum pipe, a condensation vacuumizing pump and a mechanical air exhaust vacuum pump, wherein the temperature adjusting bin is connected with the furnace main body through the compensation vent pipe at the head end, anelectric heating sheet pile is arranged in the temperature adjusting bin, the tail end of the temperature adjusting bin communicates with the condensation vacuumizing pipe, the tail end of the condensation vacuumizing pipe is downwards connected with the condensation vacuumizing pump, and the mechanical air exhaust vacuum pipe is connected with the mechanical air exhaust vacuum pump; an inlet ofthe mechanical air exhaust vacuum pipe is connected with the condensation vacuumizing pipe, and a vacuumizing passage is formed by connecting the compensation vent pipe through the temperature adjusting bin to the condensation vacuumizing pipe and connected with the condensation vacuumizing pump; and a cooling bin is welded or hinged to the front bin wall of the temperature adjusting bin.

Owner:ZHEJIANG TIANQI CUP

Method for transporting aluminum milling scraps to complexification workshop through pipelines

ActiveCN101934935BReduce usageSave on repeated transportationBulk conveyorsPulp and paper industryCrusher

The invention relates to a method for transporting aluminum milling scraps to a complexification workshop through pipelines, which comprises a surface milling machine, a suction fan, a milling scrap crusher, a cyclone separator and a milling scrap charging bin, wherein the pipelines are erected on the plant top of an ingoting and surface milling workshop and the complexification workshop and led into the workshop; the pipelines led into the ingoting and surface milling workshop are linked with the milling scrap crusher after being linked with the suction fan; the cyclone separator is erected on the plant top of the ingoting and surface milling workshop; a section of the pipelines linked from the suction fan is linked with the inlet end of the cyclone separator, and the outlet end of the cyclone separator is linked with a first exhaust fan and N exhaust fans; the space between the adjacent exhaust fans is controlled between 100 to 120m; and finally, the (N+1)th exhaust fan is directly communicted with the milling scrap charging bin of the complexification workshop. The invention can ensure that the aluminum milling scraps are sucked into the pipelines by the suction fan after beingcrushed and then transmitted to the milling scrap charging bin of the complexification workshop through the cyclone separator and the exhaust fans with the functions of pressurization and air exhaustso as to carrying out resmelting.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com